Page 1

Carrier

ctíons

^ (p 7^h - jr /Q-yc^

Bypass Weathermaster® Air Terminals

INTRODUCTION

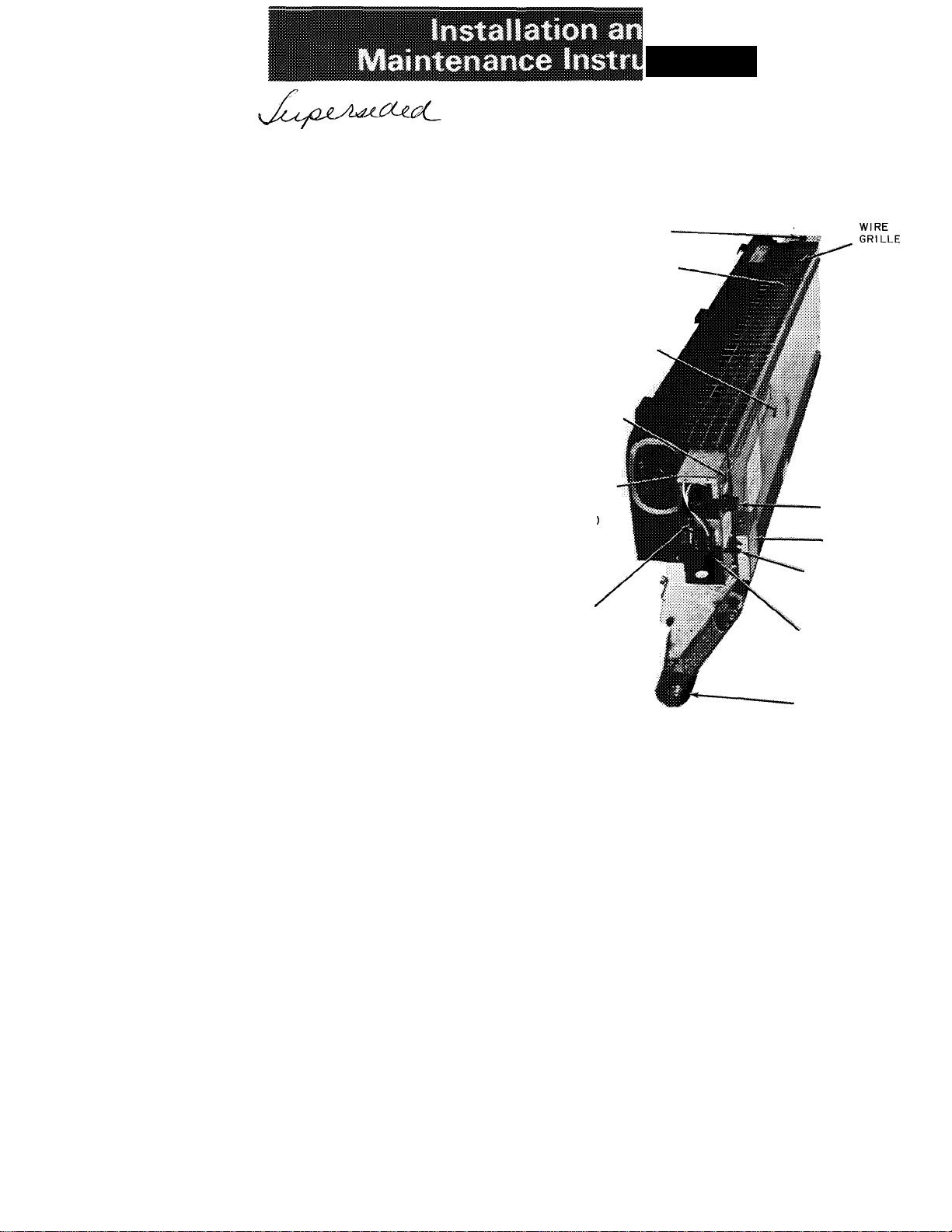

The 36TE unit (see Fig. 1) is a nonchangeover

version of the 36RV Bypass WEATHERMASTER

Air Terminal with an electriciresistance heater. It

consists of an air inlet, sound absorbing plenum,

balancing damper, primary air nozzles, bypass damp

er assembly, secondary coil, and condensate pan.

Controls for this unit are either self-contained

or wall mounted: the thermostat can be mounted

on the right-hand side of the unit or on the wall;

the electrical controls are mounted on the left-

hand side of the unit. Electrical controls include an

On-Off toggle switch, fuse holder, fuse, micro

switch, terminal block, automatic high-temperature

Umit switch, and a manual reset temperature limit

switch.

When the unit thermostat senses a cold room

temperature, it causes the bypass damper to close.

Induced room air is then directed around the

secondary coil. When the damper reaches its full

bypass position, it contacts the microswitch which

activates the heater.

This publication is designed as a supplement to

the 36R Installation Instructions. Since the 36RV

and 36TE units are similar, installation of the

36TE unit is the same as that described for the

36RV unit with the changes noted in this pubhcation. Refer also to the 36R literature for unit and

enclosure dimensional data.

When unpacking unit, should any in-transit

damage be observed, file claim with transportation

agency.

INSTALLATION

Unit Installation

1. Follow procedures outlined for installation of

the 36RV air terminals. Refer to 36R Installa

tion Instructions for details.

2. Do not remove protective cover from unit

discharge unless discharge grille is being in

stalled. If construction debris is still present in

area, keep discharge covered to prevent debris

from getting into unit heater.

Wiring

1. Observe national and local codes.

2. Check to ensure that unit nameplate voltage

corresponds with the line voltage available at

the job site. Do not exceed the allowable

voltage variation of ± 10 percent.

3. Make line voltage connections to terminal block

in control box on unit. Make ground connec

tion to green screw above terminal block. (See

Fig. 1 and Fig. 2.)

THERMOSTAT

ELECTRIC RESISTANCE

HEATER

DAMPER ADJUSTMENT

SCREW (SEE FIG 3)

MANUAL RESET

TEMPERATURE

LIMIT SWITCH

ELECTRICAL

CONTROL BOX

{COVER

REMOVED

GROUND

(CONNECTION)

Fig. 1 -36TE Bypass WEATHERMASTER

Air Terminal

FUSE

MICROSWITCH

ON-OFF

TOGGLE SWITCH

TERMINAL BLOCK

CONDENSATE PAN

4. Refer to Table 1 for electrical data and usage.

NOTE: Whenever the fan in the central station

air handling apparatus is shut down, make sure

that the electric resistance heater located in the

36TE unit discharge is inoperative To ensure

this, the heater circuit should be interlocked

with the apparatus fan.

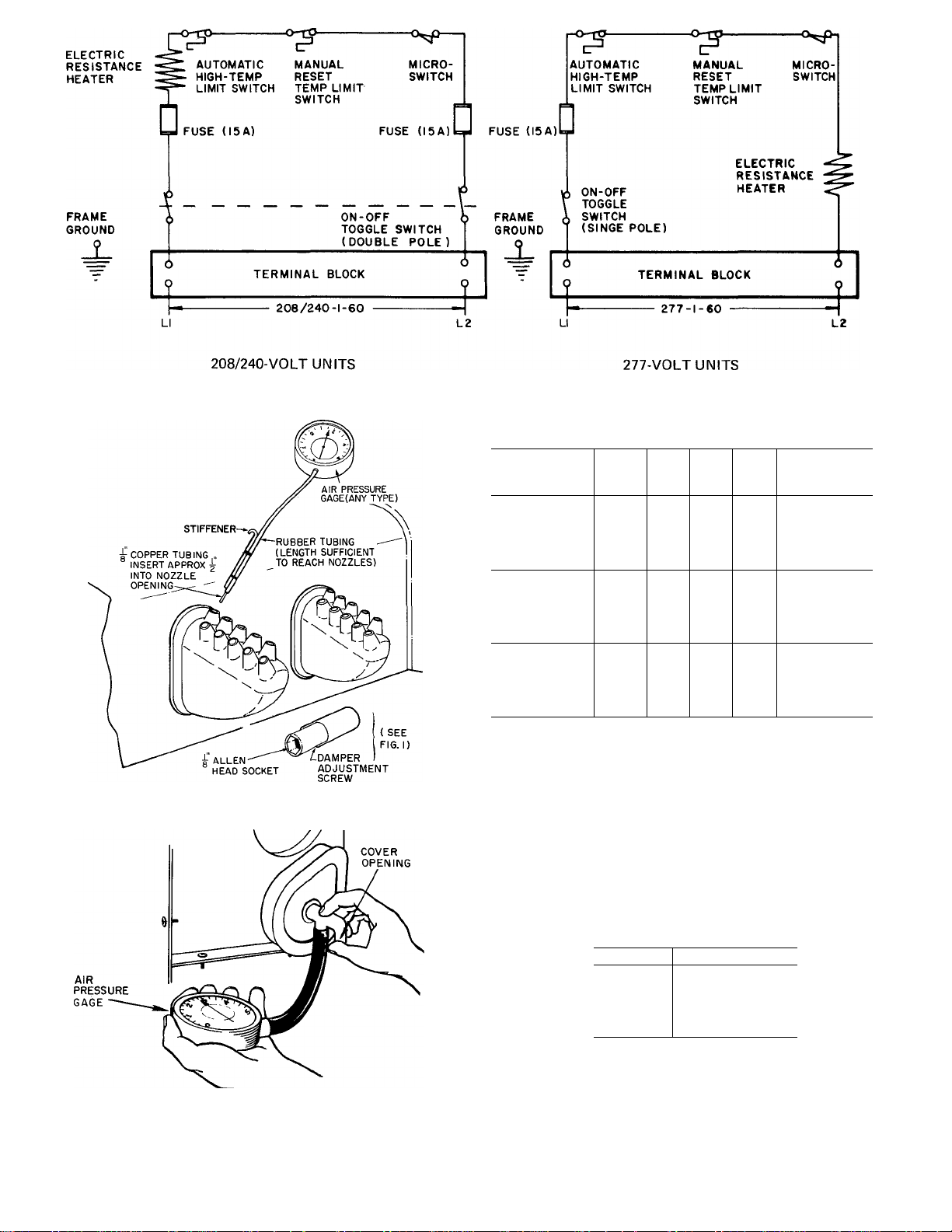

Unit Balancing

1. Remove construction debris from unit and

make sure that protective plastic has been

removed from thermostat cover.

2. Units are shipped with plenum damper wide

open. Turn damper adjustment screw, which is

located in the front of the unit (see Fig. 1 and

Fig. 3), clockwise to close damper and decrease

nozzle pressure to design value. (Minimum

allowable nozzle pressure is 1.0 in. wg.) Two or

three runs may be necessary to obtain proper

balance. (See Fig. 3.)

NOTE: 36TE unit requires minimum 1.5 in. wg

plenum pressure for control operation; maxi

mum allowable plenum pressure is 5 in. wg.

©Carrier Corporation 1972

Form 36TE-1SI

Page 2

Fig. 2 — 36TE Bypass Weathermaster® Air Terminal Wiring Schematics

MEASURING NOZZLE PRESSURE

Table 1 - Electrical Data and Usage

WIRE

VOLTAGE/HZ

208-1-60

240-1-60

277-1-60

FLA — Full Load Amps

*Copper wire sizes based upon 60 C Use latest National Electric

Code (NEC) for wire lengths (allow 3% voltage drop) and fuse

sizes Follow all local codes required. To obtain maximum wire

length, divide allowable amp—feet by FLA

WATTS FLA

1000

1500

2000

2500

3000

1000

1500

2000

2500

3000

1000

1500

2000

2500

3000 10.85 6

FUSE

AMPS

4.81

7 22

9.63 : 15 0

12.10 8

14.41 6

4.17

6.25 12 609

8.33

10.40 8

12.50

3.62

5.42 12

7 23 15 0

9.03 8

p.

15.0

SIZE

(AWG)

14

12

10

10

6

14

10

ALLOWABLE

AMP-FT*

332

527

834

1328

2061

383

962

1533

2378

442

702

nil

1769

2745

MEASURING PLENUM PRESSURE

NOTE Unit must not be operated below a 1-in. wg nozzle pres.-

sure and a 1 5-in. wg plenum pressure

Fig. 3 — Measuring Nozzle and Plenum Pressures

3. Total primary air flow to a series of units fed

by a common runout should not exceed 220

cfm.

iMK>RTANTt Unit ttoi be operated

With iese ptxxm^y thsm sbowjr below:

__

ja

IbCC

2&X!

fif

6;

33

JOOO

Enclosure Selection

Standard 36RV enclosures with stamped steel

discharge grilles can be used with the 36TE units.

Plastic grilles must never be used. The steel grille

should be locked in place after installation. On

furred-in units, a discharge grille frame may be

used with the discharge grille.

Page 3

MAINTENANCE

CAimON: Wbm Oii^T tisggis swileh {see

Fig> l> i$ m tB«? posliimj liower h siEl

su|5ii!iesd to lower ierraimi of switch. 80.4 to

ierooiw! bloii:. To ptwtni electrical shodc

whcoe^r imloteoaoce is l>eiog petforoted oo

omt, disooxioeet mam power supply to ooit.

Observe basic troubleshooting procedures as

outlined for the 36RV units. Refer to 36R

Operating and Maintenance Instructions. Check

and follow up until malfunction is isolated.

If electric heater malfunctions, observe the

procedures in Table 2; if bypass damper mal

functions, refer to procedures outlined for the

36RV units.

Table 2 — 36TE Electric Resistance Heater

Troubleshooting

PROBLEM POSSIBLE CAUSE REMEDY

Heater

Inoperative-

On-Off toggle switch

in "Off*' position

No power to unit

Fuse{s) blown

Microswitch

deactivated

Back-up manual

reset temperature

! imit switch open

circuited

Turn to "On" position

Check main power supply

Replace as required

Check bypass damper to

make sure it is in the full

bypass position. If not,

move thermostat lever to

red . (See Fig. 1 ) If still

not functioning, follow

procedures outlined for

36RV unit.

Dep ress button (see

Fig. 1) to activate

Page 4

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to change a n y product specifications without n o tic e .

CARRIER AIR CONDITIONING COMPANY • SYRACUSE, NEW YORK

Tab 17

Form 36TE-1SI New

Printed in U.S A. 6-72

Codes C and MD

Catalog No. 533-602

Loading...

Loading...