36IBAC,N,S,M,R,L,J

Installation Instructions

Induction Beams

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . 1

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Storage and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Installation Precaution . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

PREINSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Prepare Jobsite for Unit Installation . . . . . . . . . . . . . . 1

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30, 31

Step 1 — Install Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

• 36IBAC

• 36IBAN

• 36IBAS,M,R,L,J

Step 2 — Connect Induction Beams

to the Piping System . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Step 3 — Connect Induction Beams

to the Condensate Drainage System. . . . . . . . . . . 31

Step 4 — Connect Induction Beams

to the Primary Air Ducting System. . . . . . . . . . . . 31

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Airflow Balancing Procedure . . . . . . . . . . . . . . . . . . . . 31

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Condensate Float Switch Wiring. . . . . . . . . . . . . . . . . 31

SAFETY CONSIDERATIONS

SAFETY NOTE

Air-handling equipment will provide safe and reliable

service when operated within design specifications. The

equipment should be operated and serviced only by authorized personnel who have a thorough knowledge of system operation, safety devices and emergency procedures.

Good judgement should be used in applying any

manufacturer’s instructions to avoid injury to personnel

or damage to equipment and property.

time of delivery. Store in a clean, dry, and covered location. Do

not stack cartons. When unpacking units, care should be taken

that the inlet collars and water connections do not become

damaged.

CAUTION

Do not lift the unit by the drain pipes, water piping, or

metal duct. Units should be lifted using the mounting

brackets.

The 36IBAC unit packaging includes a base tray and an inverted box cover. Remove the box cover to fully expose the

unit.

The 36IBAN and 36IBAR units are packaged in cardboard

cartons. Open the carton top and fold the flaps back to gain access to the unit. Two people are required to lift the unit out of

the carton. These units are shipped with the grille attached, and

when setting the unit down, care must be taken to put it on a

clean, soft surface so as not to scratch the grille face.

The 36IBAS, M, L, and J units are packaged in cardboard

cartons. Open the carton top and cut the carton vertically on the

side where the duct collar is located. The grille is attached to

the unit and should not be removed. After cutting the side of

the carton, remove the unit from the box and set it on a clean

surface being careful not to scratch the grille.

Initial Inspection — Once items have been removed

from the carton, check carefully for damage to duct connections, coils, or controls. File damage claim immediately with

transportation agency and notify Carrier.

Installation Precaution — Check that construction de-

bris does not enter unit or ductwork. Accumulated dust and

construction debris distributed through the ductwork can adversely affect unit operation.

Codes — Install units in compliance with all applicable

code requirements.

PREINSTALLATION

GENERAL

The overhead induction beam distribution unit has been designed to give the customer many years of trouble free service.

Each unit contains a row or number of rows of aerodynamic

airflow nozzles located within the 20-gage heavy duty housing

assembly. These airflow nozzles deliver the proper ventilation

air from the main outdoor ventilation unit and produce an airflow profile across the coil. This aerodynamic airflow causes a

venturi effect across the coil face, which induces air from the

room across the coil surface. When cool water or hot water is

pumped through the coil, the induced airflow across the coil is

heated or cooled, then mixed with the primary airflow from the

nozzles to deliver conditioned airflow to the space.

Storage and Handling — Inspect for damage upon re-

ceipt. Shipping damage claims should be filed with shipper at

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53360006-01 Printed in U.S.A. Form 36IB-3SI Pg 1 3-14 Replaces: 36IB-2SI

Prepare Jobsite for Unit Installation —

time and to reduce the possibility of costly errors, set up a complete sample installation in a typical room at jobsite. Check all

critical dimensions such as pipe, wire, and duct connection requirements. Refer to job drawings and product dimension

drawings as required (see Fig. 1-28). Instruct all trades in their

part of the installation.

Refer to Tables 1-6 and Fig. 1-28 for unit data.

To save

CAUTION

Prior to hanging the unit, remove the two cotter pins holding the supply/return section to the grille frame. Failure to

remove these pins will prevent access to coils and internal

workings of the units.

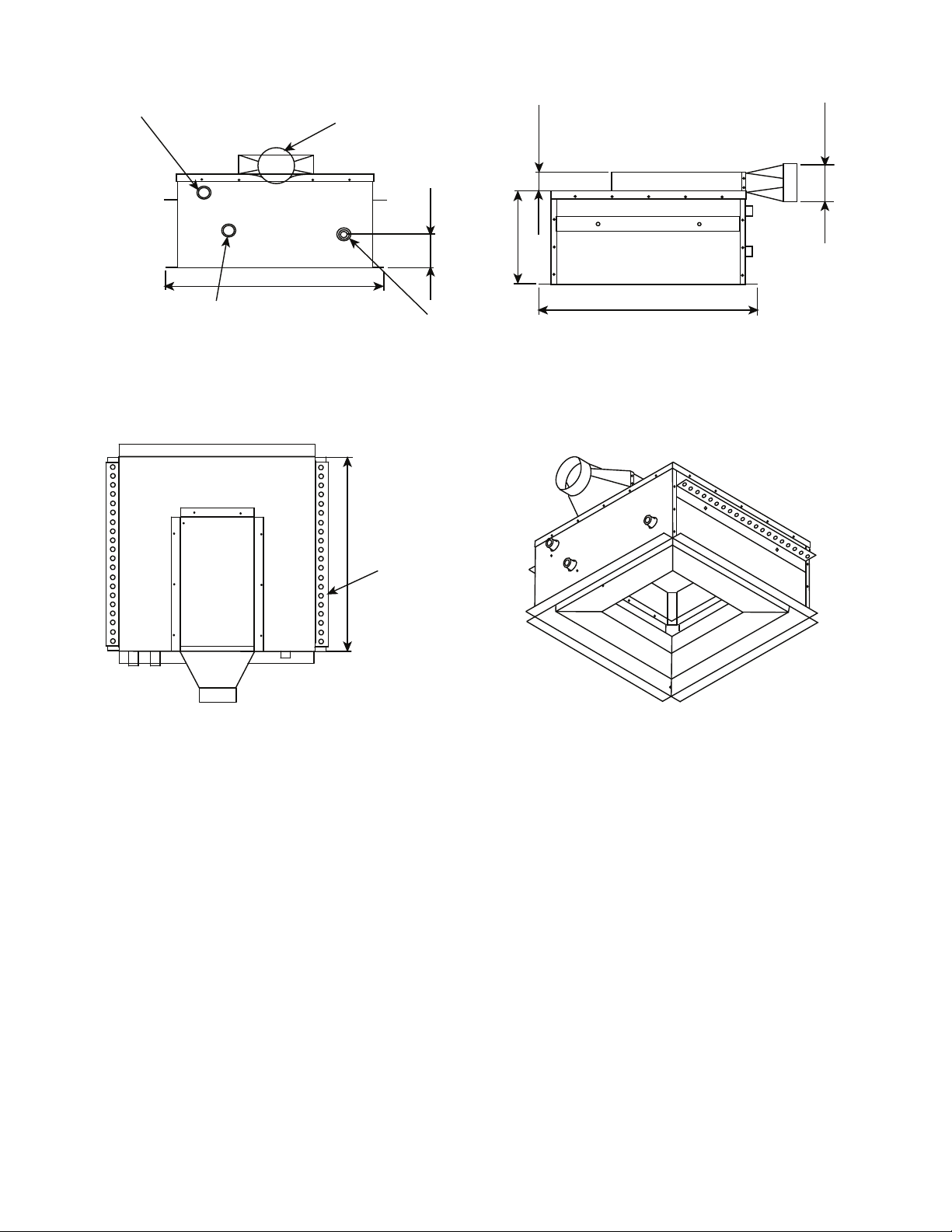

Fig. 1 — 36IBAC 2 x 2, All-Way Blow, 2-Pipe Unit Dimensions

3/4" FPT CWR/HWR

a36-579

LEGEND NOTES:

1. Dimensions shown in inches.

2. Drawing shows 2-pipe arrangement.

CWR — Chilled Water Return

CWS — Chilled Water Supply

FPT — Female Pipe Thread

HWR — Hot Water Return

HWS — Hot Water Supply

3/4" FPT CWS/HWS

TOP VIEW

FRONT VIEW

23.70

4" Ø

3.59

3/4" CONDENSATE

DRAIN

2.04

10.05

RIGHT SIDE VIEW

4.00

23.76

HANGING BAR

21.15

DIFFUSER PLATE

(SUPPLY/RETURN

GRILLE NOT SHOWN)

2

Fig. 2 — 36IBAC 2 x 2, All-Way Blow, 4-Pipe Unit Dimensions

23.76

HANGING BAR

4.00

10.05

23.76

23.70

3.59

4" Ø PRIMARY AIR

CONNECTION

3/4" FPT CWR

3/4" FPT CWS

3/4" CONDENSATE

DRAIN

12.09

1/2" FPT HWR

1/2" FPT HWS

FRONT VIEW

RIGHT SIDE VIEW

TOP VIEW

DIFFUSER PLATE

(SUPPLY/RETURN

GRILLE NOT SHOWN)

a36-580

LEGEND NOTES:

1. Dimensions shown in inches.

2. Drawing shows 4-pipe arrangement.

CWR — Chilled Water Return

CWS — Chilled Water Supply

FPT — Female Pipe Thread

HWR — Hot Water Return

HWS — Hot Water Supply

3

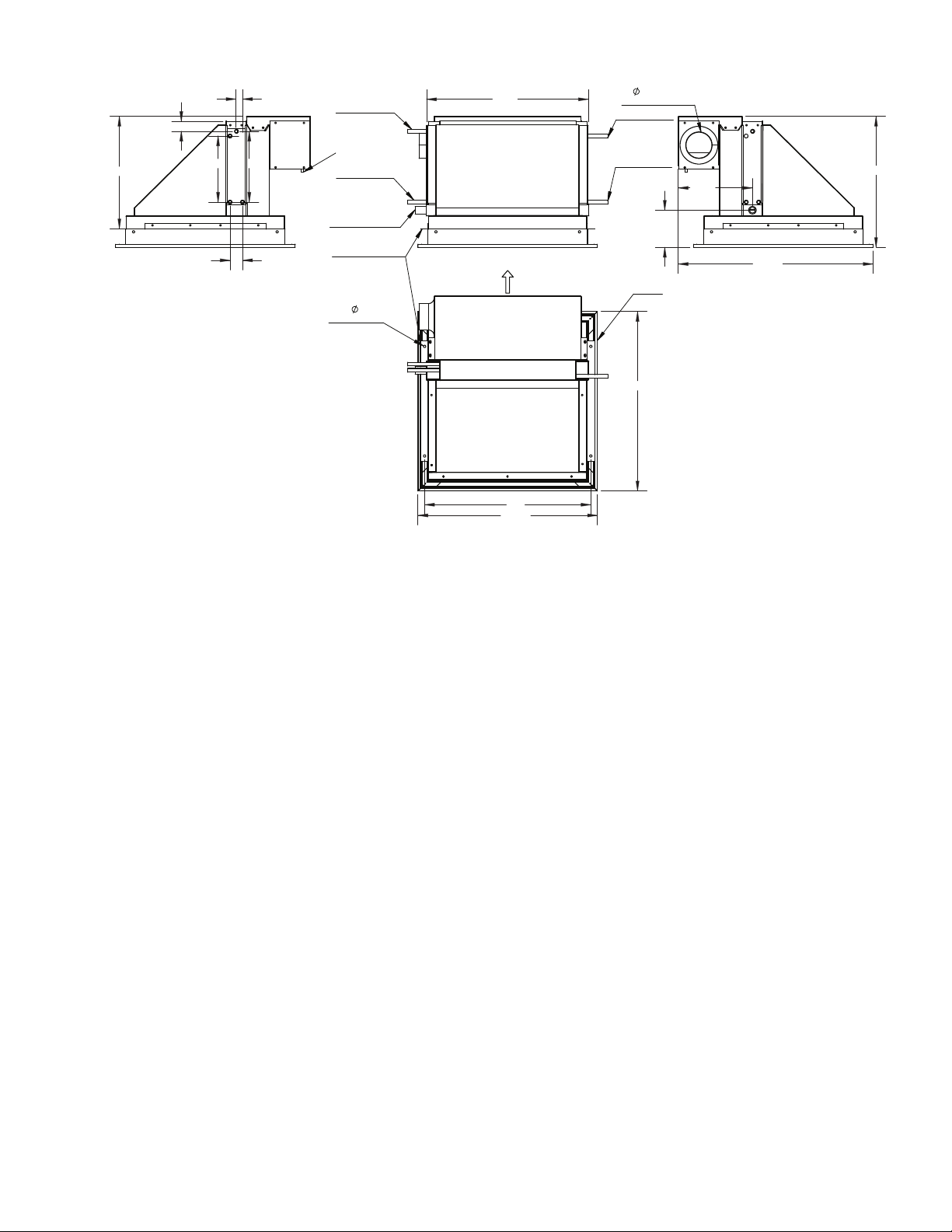

Fig. 3 — 36IBAC 4 x 4, All-Way Blow, 2-Pipe Unit Dimensions

3.20

4.11

17.89

3/4" Ø FPT WR

8" Ø SUPPLY AIR

3/4" PVC DRAIN

HANGING BRACKET

37.55

37.57

HANGING BRACKET

HANGING BRACKET

3/4" Ø FPT WS

FRONT VIEW

LEFT SIDE VIEW

TOP VIEW

a36-578

LEGEND NOTES:

1. Dimensions shown in inches.

2. Drawing shows 2-pipe arrangement.

FPT — Female Pipe Thread

WR — Water Return

WS — Water Supply

4

Fig. 4 — 36IBAC 4 x 4, All-Way Blow, 4-Pipe Unit Dimensions

3.20

4.11

17.89

3/4" Ø FPT CWR

1/2" Ø FPT HWR

8" Ø SUPPLY AIR

3/4" PVC DRAIN

HANGING BRACKET

35.95

36.14

HANGING BRACKET

HANGING BRACKET

1/2" Ø FPT HWS

3/4" Ø FPT CWS

FRONT VIEW

LEFT SIDE VIEW

TOP VIEW

a36-575

LEGEND NOTES:

1. Dimensions shown in inches.

2. Drawing shows 4-pipe arrangement.

CWR — Chilled Water Return

CWS — Chilled Water Supply

FPT — Female Pipe Thread

HWR — Hot Water Return

HWS — Hot Water Supply

5

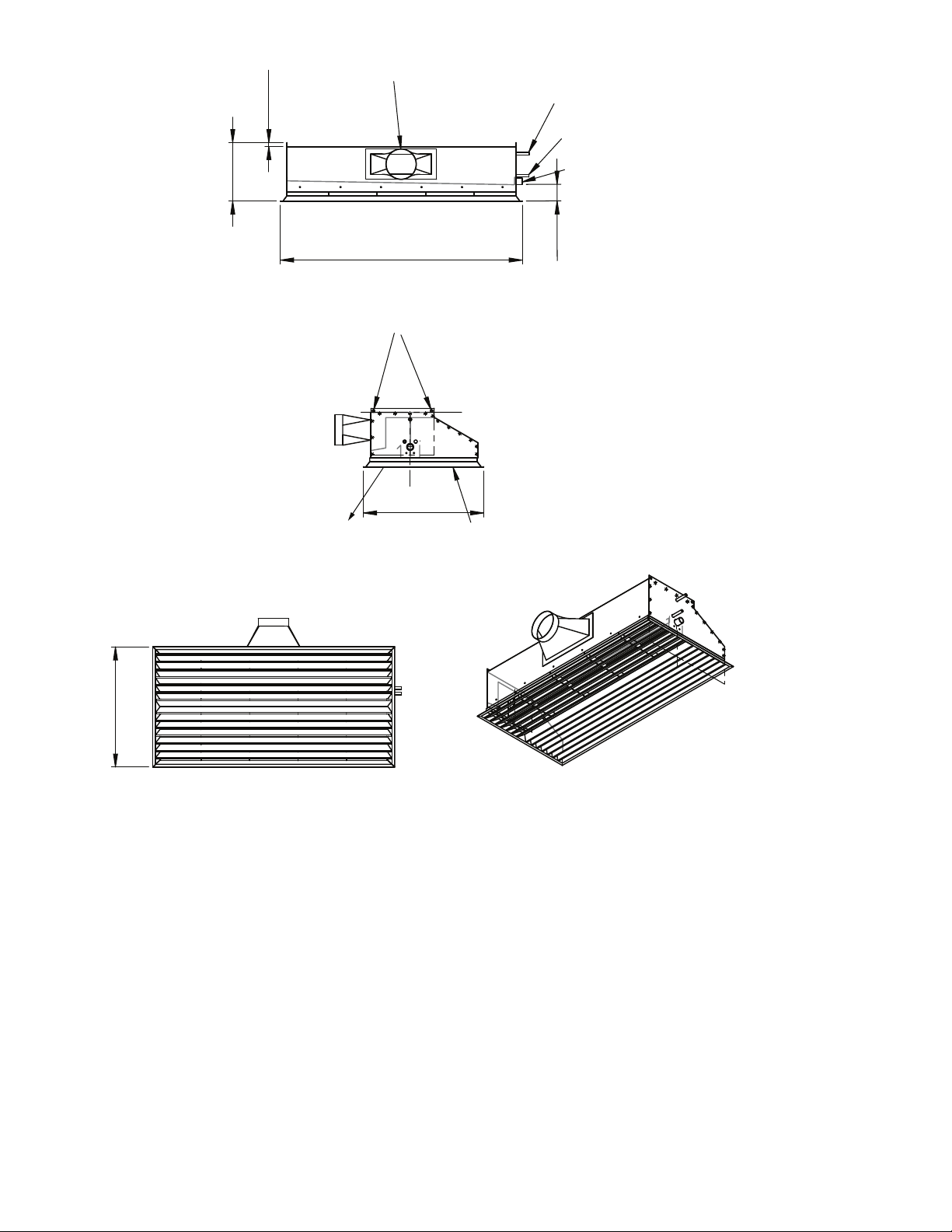

21.4

1/2" O.D. HWS/CWS

1/2" O.D. HWR/CWR

3/4" CPVC DRAIN

CONNECTION

AIR BLOW DIRECTION

23.75

23.75

22.0

GRILLE

0.31"

HOLE

TYP OF 4

H

25.78

D

9.82

4"

PRIMARY AIR

CONNECTION

8.75

.88

1.7

9.37

1.31

14.9

PRESSURE TAP

HANGER BRACKET

REAR VIEW

LEFT SIDE VIEW

RIGHT SIDE VIEW

TOP VIEW

Fig. 5 — 36IBAS 2 x 2, 1-Way Blow, 2-Pipe LH Unit Dimensions

a36-592

LEGEND NOTES:

1. Dimensions shown in inches.

2. Drawing shows 2-pipe arrangement, left-hand piping connection; right hand connection would be opposite.

3. Hand is determined by standing on the front side of the unit

with the supply air blowing against the back of your head.

4. Front face of the unit is determined by the nozzle side (supply

air) side of the unit.

CWR — Chilled Water Return

CWS — Chilled Water Supply

HWR — Hot Water Return

HWS — Hot Water Supply

6

21.4

1/2" O.D. CWS

1/2" O.D. CWR

1/2" O.D. HWS

1/2" O.D. HWR

3/4" CPVC DRAIN

CONNECTION

AIR BLOW DIRECTION

23.75

23.75

22

GRILLE

0.31"

HOLE

TYP OF 4

H

25.78

D

9.82

4"

PRIMARY AIR

CONNECTION

8.75

.88

1.7

9.37

1.31

14.9

PRESSURE TAP

HANGER BRACKET

RIGHT SIDE VIEW LEFT SIDE VIEW

REAR VIEW

TOP VIEW

a36-593

Fig. 6 — 36IBAS 2 x 2, 1-Way Blow, 4-Pipe LH Unit Dimensions

LEGEND NOTES:

1. Dimensions shown in inches.

2. Drawing shows 4-pipe arrangement, left-hand piping connection; right hand connection would be opposite.

3. CW piping connection determines the hand of the unit.

4. Hand is determined by standing on the front side of the unit

with the supply air blowing against the back of your head.

5. Front face of the unit is determined by the nozzle side (supply

air) side of the unit.

CWR — Chilled Water Return

CWS — Chilled Water Supply

HWR — Hot Water Return

HWS — Hot Water Supply

7

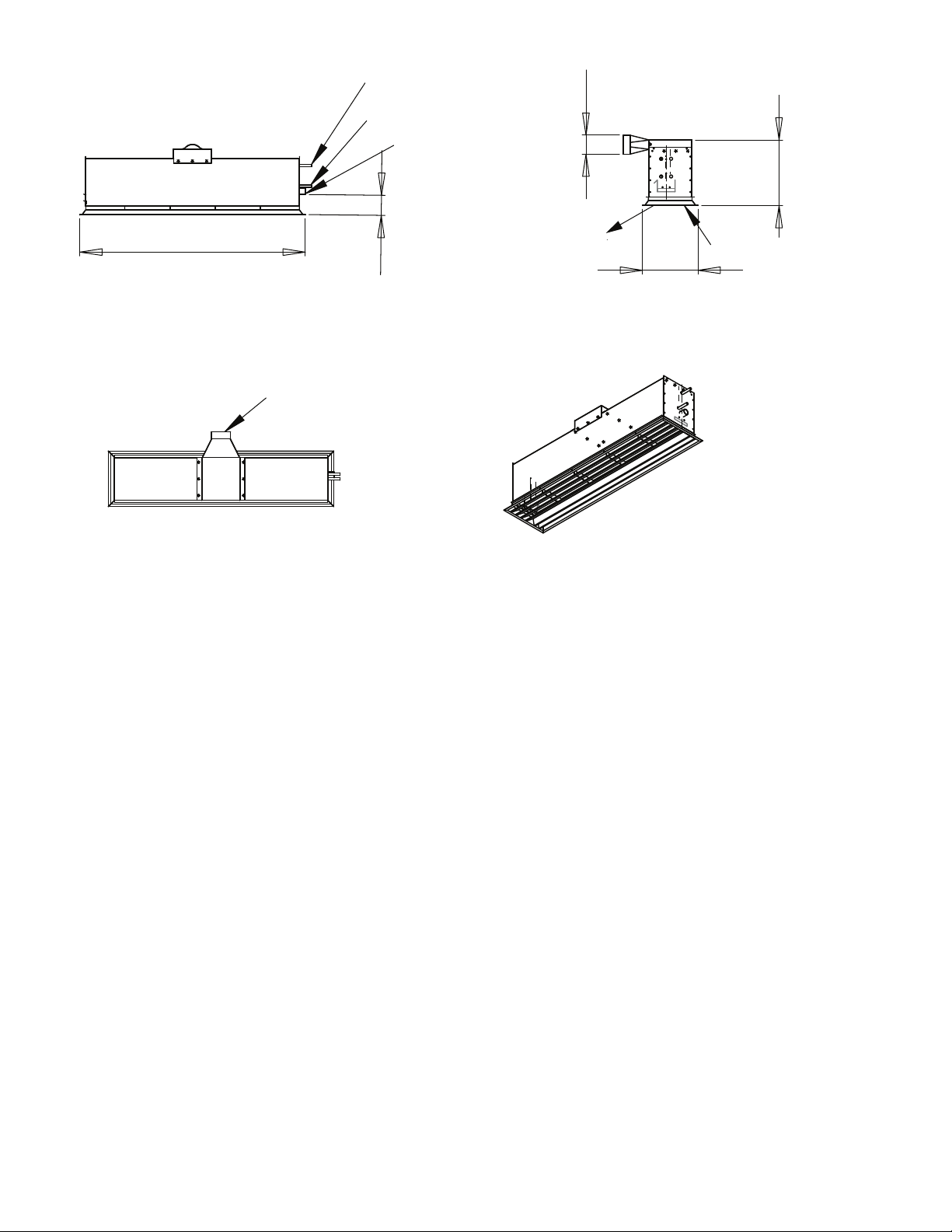

Fig. 7 — 36IBAN 2 x 4, 1-Way Blow, 2-Pipe LH Unit Dimensions

11.52

a36-571

LEGEND NOTES:

1. Dimensions shown in inches.

2. Drawing shows 2-pipe arrangement, left-hand piping connection; right hand connection would be opposite.

3. CW piping connection determines the hand of the unit.

4. Hand is determined by standing on the front side of the unit

with the supply air blowing against the back of your head.

5. Front face of the unit is determined by the nozzle side (supply

air) side of the unit.

CWR — Chilled Water Return

CWS — Chilled Water Supply

FPT — Female Pipe Thread

HWR — Hot Water Return

HWS — Hot Water Supply

6" Ø PRIMARY AIR CONNECTION

1/2" Ø FPT CWR/HWR

0.75

1/2" Ø FPT CWS/HWS

3/4" PVC DRAIN

92.3

47.75

FRONT VIEW

HANGING BRACKET

Ø 0.50

Ø 0.50

23.75

23.75

SUPPLY AIR

BOTTOM VIEW

LEFT SIDE VIEW

RETURN AIR

SUPPLY/RETURN GRILLE

WITH OPTIONAL LOUVERED

SUPPLY AND RETURN

FACE SHOWN

8

Fig. 8 — 36IBAN 2 x 4, 1-Way Blow, 4-Pipe LH Unit Dimensions

1/2" FPT HWR

a36-574

LEGEND NOTES:

1. Dimensions shown in inches.

2. Drawing shows 4-pipe arrangement, left-hand piping connection; right hand connection would be opposite.

3. CW piping connection determines the hand of the unit.

4. Hand is determined by standing on the front side of the unit

with the supply air blowing against the back of your head.

5. Front face of the unit is determined by the nozzle side (supply

air) side of the unit.

CWR — Chilled Water Return

CWS — Chilled Water Supply

FPT — Female Pipe Thread

HWR — Hot Water Return

HWS — Hot Water Supply

11.52

1/2" FPT HWS

1/2" Ø HANGING HOLES

TYPICAL OF 4

1/2" FPT CWR

1/2" FPT CWS

12.00

3/4" PVC DRAIN

93.

FRONT VIEW

3

12.50

57.9

00.9

7.75

6" Ø

RETURN AIR

RIGHT SIDE VIEW

23.75

6" Ø PRIMARY AIR

CONNECTION

TOP VIEW

23.75

47.75

SUPPLY AIR

9

Fig. 9 — 36IBAN 1 x 4, 1-Way Blow, 2-Pipe RH Unit Dimensions

47.75

62.4

1/2" FPT WR

1/2" FPT WS

3/4" PVC DRAIN

CONNECTION

4" Ø DUCT CONNECTION

4.00

11.75

13.89

SUPPLY AIR

RETURN AIR

REAR VIEW

LEFT SIDE VIEW

TOP VIEW

SUPPLY/RETURN GRILLE

WITH OPTIONAL LOUVERED

SUPPLY AND RETURN

FACE SHOWN

a36-573

LEGEND NOTES:

1. Dimensions shown in inches.

2. Drawing shows 2-pipe arrangement, right-hand piping connection; left hand connection would be opposite.

3. Hand is determined by standing on the front side of the unit

with the supply air blowing against the back of your head.

4. Front face of the unit is determined by the nozzle side (supply

air) side of the unit.

FPT — Female Pipe Thread

WR — Water Return

WS — Water Supply

10

Loading...

Loading...