Page 1

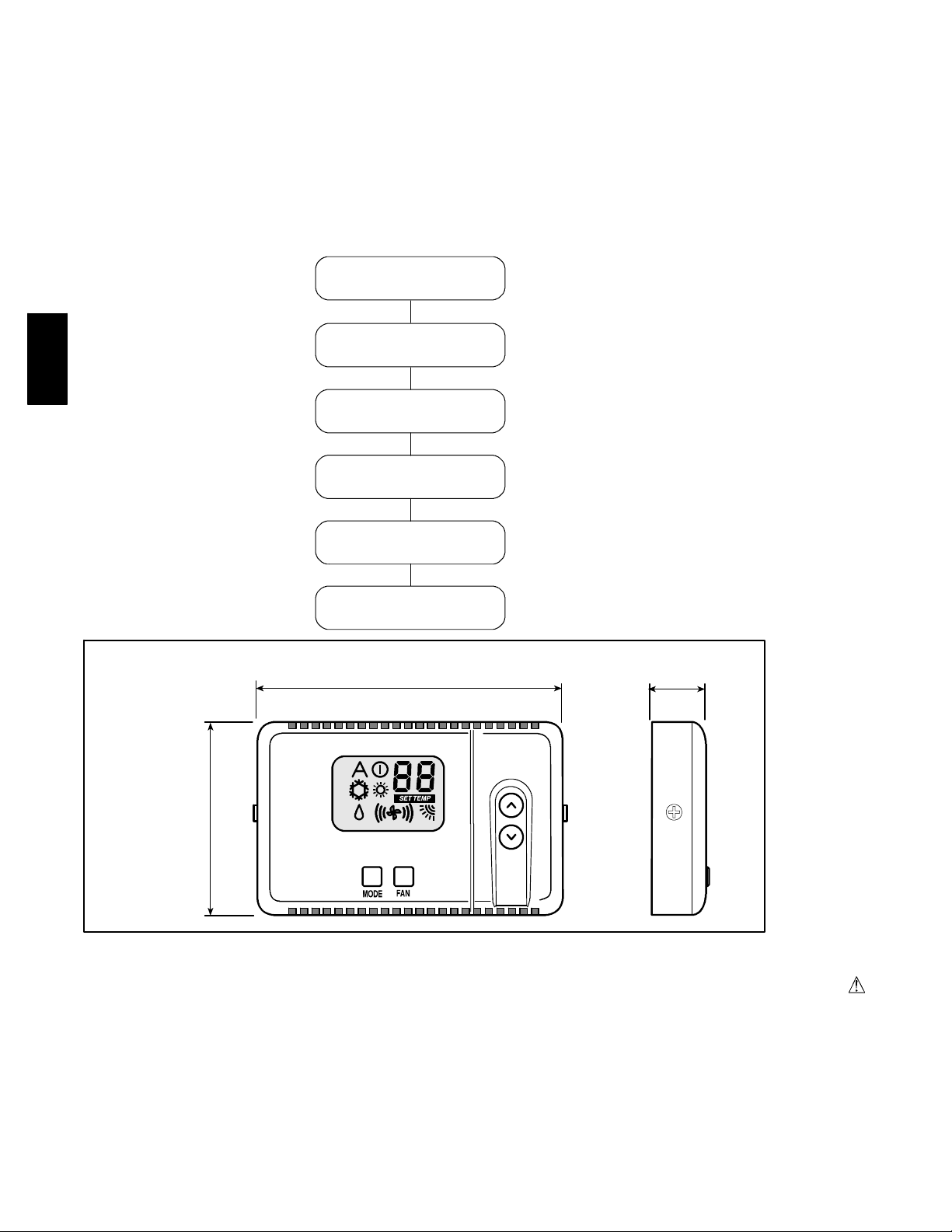

33MC--URC

Room Controller

40KMC

40KMQ

40QNC

40QNQ

INSTALLATION MANUAL

Page 2

This control system only operates with indoor units of the following types:

40KMC, 40KMQ Cassette, 40QNC, 40QNQ High Wall

For insta lla tio n instructions o f th is u n it, refer to the releva n t manuals.

CONTENTS PAGE

General information 2...............................................................................

Characteristics 2.....................................................................................

Choosing the installation site 2........................................................................

“Room Controller” wired control 3....................................................................

Electrical connections to indoor unit 4.................................................................

Unit configuration 4, 6...............................................................................

Troubleshooting 6...................................................................................

INSTALL AT I O N FL O W CHART

Read manual

Install

Room Controller

33MC--URC

Dimensions (mm)

Wire Room Cont roller

and unit networ k

Configure

Room Controller

Test System

Operate

Room Controller

4--1/4”(108)

3/4”(20)

2--3/14”(70)

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury, or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory--authorized kits or accessories

when modifying this product. Refer to the individual instructions

packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions included in

literature and attached to the unit. Consult local building codes and

National Electrical Code (NEC) for special requirements.

Recognize safety information. This is the safety--alert symbol

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury. Understand

these signal words; DANGER, WARNING, and CAUTION. These

words are used with the safety--alert symbol. DANGER identifies

the most serious hazards which will result in severe personal injury

or death. WARNING sign ifies hazard s wh ich co u ld result in

personal injury or death. CAUTION is u sed to identify unsafe

practices which would result in minor personal injury or product

and property damage. NOTE is used to highlight suggestions

which will result in enhanced installation, reliability, or operation.

2

Page 3

G

enera

l

inf

C

h

l

lati

d

I

l

lati

ormation andcharacteristics

IMPORTANT: Read the entire instruction manual before

starting the installation.

S For trouble--free installation, which should be carried out

by a qualified installer, follow the installation chart

sequence.

S Follow all current national safety code requirements. In

particular ensure that a properly sized and connected

ground wire is in place.

S After installation, thoroughly test the system operation

and explain all system functions to the owner.

S Leave this manual with the owner for consultation

during future periodic maintenance.

S Dispose of packaging material in accordance with local

requirements.

S The manufacturer denies any responsibility and warranty

shall be void if these installation instructions are not

observed.

S Inspect equipment. For damage due to improper

transportation or handling, file an immediate claim with

the shipping company. Do not install or use damaged

units.

S In case of any malfunction, turn the unit off, disconnect

the main power supply and contact a qualified service

engineer.

WIRING

The Room Controller will be capable of controlling from 1 to 6

Fan Coil Units.

The total run length of the wire connecting the Room Controller to

the FCUs should be kept to under 500 feet (150 m.).

Only daisy chain wiring will be allowed (See Figure 1).

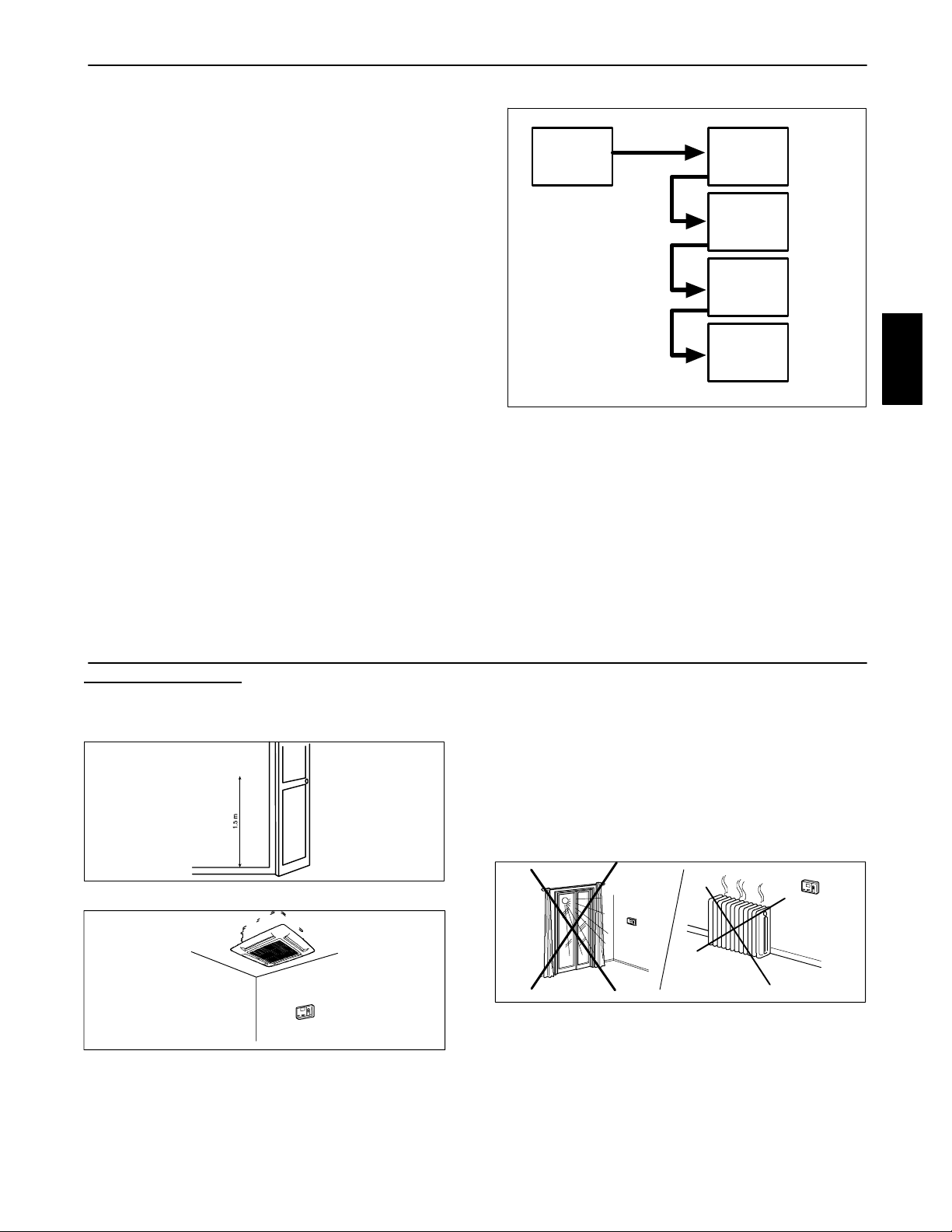

oosing theinsta

on site an

The Room Controller will connect to the receiver board connection

on the electronic board inside the unit.

REMOTE

FCU 1

FCU 2

FCU 3

FCU 6

Fig. 9 – Daisy Chain Wiring (Multidrop)

POWER

The thermostat will be powered by unregulated 12.5 volts DC

nominal (10V min. to 20V max) which is provided by the

electronic board inside the unit.

The power consumption will be 50mA 12.5 volts DC.

For applications where more than one FCU is to be controlled, the

FCU closest to the Room Controller will be the only one that

supplies power to the Room Controller.

The control should be protected from damage if accidental

miswiring of power, ground and signal.

nsta

on

33MC--URC

Room Controller Location

The Room Controller can be located anywhere. However, if the

installation requires the system in the location to use the air sensor

on the Room Controller; then, the controller should be mounted:

S Approximately 5 ft. (1.5 m) from floor.

Fig. 10 – Minimum Clearances

S In the same area where the unit is located, preferably on

an inside partitioning wall.

S On a section of wall without pipes or duct work.

If the air sensor on the Room Controller has been selected, it

should NOT be mounted:

S Close to a window, on an outside wall, or next to a door

leading to the outside.

S Exposed to direct light and heat from a lamp, sun,

fireplace, or other temperature--radiating object which

may cause a false reading.

S Close to or in direct airflow of a heating or cooling

supply.

S In areas with poor air circulation, such as behind a door

or in an alcove.

Maximum of 500 ft. (150 m) of total network wiring.

3

Page 4

G

enera

l

inf

ormation andcharacteristics

MOUNTING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing the Room Controller, turn off all power to

the Unit that will supply power to the Room Controller.

S Turn OFF all power to unit.

33MC--URC

WARNING

P

G

C

S Match and connect equipment wires to proper terminals

in the connector block. Both power and communication

wires must be connected correctly for proper Room

Controller operation.

P

G

C

2

Fig. 13 – Connection Cable

S Push any excess wire into the wall and against mounting

base.

If the air sensor is being used on the Room Controller,

seal hole in wall to prevent air leaks.

Leaks can affect sensor operation.

Fig.11–MountingScrews

S Unscrew the side fixing screw.

S Open the Room Controller rear mounting base to expose

mounting holes. The base can be removed to simplify

mounting (snap apart carefully at hinge to separate

mounting base from remainder of the Room Controller).

S Route the Room Controller wires through the large hole

in the mounting base. Level mounting base against wall

(for aesthetic value only the Room Controller need not

be level for proper operation) and mark the wall through

the 2 mounting holes.

S Drill two 3/16” (5 mm) mounting holes in wall where

marked.

S Secure mounting base correctly (UP↑ ) to wall with 2

screws and anchors provided, (additional anchoring

holes available for more secure mounting if needed)

making sure all wires extend through hole in mounting

base.

S Adjust length and routing of each wire to reach the

proper terminal in the connector block on the mounting

base, with 1/4” (6 mm) of extra wire (strip only 1/4” (6

mm) of insulation from each wire to prevent adjacent

wires from shorting together when connected).

3

4

5

6

3 To indoor Unit

4 Rigid PVC conduit inside ∅ 1 --3/16” (30 mm) min.

5 Plaster approx. 1 --3/16” (30 mm)

6 Room Controller

7 Connector block

Fig. 14 – Mounting location

7

S Push the Room Controller snap hinge to the base.

S Tighten the side fixing screw.

Fig. 12 – Connection Cable

P

G

C

2

4

Page 5

G

enera

l

inf

UnitC

f

i

ormation andcharacteristics

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before connecting any wiring to the Room

Controller, turn off all power to the unit that will supply

power to the Room Controller.

Connection diagram for the following units:

1

emote connector

(J5) 5 pins

A Indoor unit

B Room Controller

1. Main electronic card

2. 4 pins terminal block placed on external control box

3. Wires supplied by the installer

4. Terminal block in the Room Controller

WARNING

Diagram 1:

40KMC and 40KMQ Cassette Family

Red

Black

White

A

2

P

G

C

34

S Loosen the screws of terminals P (DC Power), G

(GROUND) and C (SIGNAL) on the indoor unit and

Room Controller terminal blocks.

S As shown in diagram 1 connect the indoor unit terminal

block to the Room Controller terminal block.

Diagram 2:

Connection diagram for the following units:

40QNC and 40QNQ Highwall Family

1

emote connector

(J5) 5 pins

A Indoor unit

B Room Controller

1. Main electronic card

P

G

C

B

2. 4 pins terminal block placed on external control box

3. Wires supplied by the installer

4. Terminal block in the Room Controller

S Loosen the screws of terminals P (DC Power), G

(GROUND) and C (SIGNAL) on the indoor unit and

Room Controller terminal blocks.

Red

Black

White

A

2

P

G

C

34

P

G

C

B

33MC--URC

S By means of the screw provided with the Room

Controller Kit, secure the auxiliary terminal block (3

poles) to the main terminal box (6 poles).

S As shown in diagram 2.

Cables of auxiliary

terminal block

Red P

Black G

White C

Room Controller

terminal block

S Remove the cables from connector J5 inside the unit on

the electronic card to connect the cables supplied with

the Room Controller. Connect the indoor unit terminal

block to the Room Controller terminal block in the same

way as shown in diagram 2.

Wiring Materials required

(supplied by installer)

on

Room Controller Configuration Setup

To enter installer setup, hold the “MODE“ button down for 5

seconds. After 5 seconds, a “10“ will appear. This indicates that the

user is setting the first software configuration item. To check the

value of configuration item 10, press the “MODE” button. The

value of the Heat/Cool vs Cooling only remote configuration will

be displayed along with the “SET TEMP” icon to indicate that the

number displayed is the configuration data. To change the

Heat/Cool vs Cooling only remote Configuration, use the

“UP“/”DOWN“ buttons. To move to the next setting, press the

“MODE“ button again and the “10“ will be

The BOLD

values are the default values from the factory.

Item Value Description

10

11

12

guration

H Heat/cool remote

C Cooling only remote

On Room Thermistor Override Active.

Control and display room air temperature at the Room Controller control.

OF

C Temperatures displayed in degrees C

F Temperatures displayed in degrees F

Room Thermistor Override Inactive. Do not display room air temperature at the Room Controller and

control to New Modular DFS room air thermistor(s).

• 1 small screwdriver.

• Standard Double insulated wire recommended.

displayed. Press the up button and the display will change to “11”.

The mode button will toggle the display between the software

configuration index (i.e. “10“, “11“, etc.) and the configuration

value. The “UP”/”DOWN“ buttons will change either the index or

the value, which ever is displayed at the time. Press the ”FAN”

SPEED button to exit Configuration Setup Mode. This mode will

exit automatically after 10 seconds of no buttons being depressed.

Once a configuration value is changed, the last value displayed will

be the new configuration value for the Room Controller.

The only way to abort a configuration change is to change the

value back to its original value.

5

Page 6

UnitC

on

f

i

guration

5. Configuration Item 10 — Heat pump Vs Cooling mode

H -- The Room Controller will allow and display the

following modes: Off, Fan, Auto, Cool, Dry, and Heat.

C -- The Room Controller will allow and display the

following modes: Off, Fan, Cool, and Dry.

6. Configuration Item 11 — Room thermistor override

On-- Room Thermistor Override active. Units will be

controlled to the air temperature read in at the Room

Controller.

Keep it pressed for

at least 5 seconds

33MC--URC

Fig. 15 – Unit Configuration Setup

Louver Mode

To enter louver mode selection, make sure the Room Controller is

on and hold the “FAN” SPEED button down for 5 seconds. After 5

seconds, the selected louver setting will be displayed. Depressing

the up and down arrows will allow the user to modify the louver

setting between swing and auto.

The two setting will be displayed in the following way:

“S“ with Swing Louver Icon -- represents Swing Louver.

“A” with Auto Louver Icon -- represents Auto Louver.

Selection

Check the

value

up

down

OF-- Room Thermistor Override not active.

All units will be controlled to the room air thermistors

located on their own respective units.

7. Configuration Item 12 — Celsius Vs Fahrenheit

C -- Indicates that all temperatures will be displayed in

degrees C.

F -- Indicates that all temperatures will be displayed in

degrees F.

Change the

value

up

down

Next

item

A

To check/change

the values of items

11 and 12 go back

to point A

The fan icon shall also be displayed in the louver mode. Press

“FAN” SPEED button to exit LOUVER Mode Selection. This

mode will exit automatically after 10 seconds of no buttons being

depressed.

The only way to abort a louver change, is to change the value back

to its original value.

NOTE:

S If units are grouped to one Room Controller , all units will end

up having the same louver value.

S Louver Mode selection is not available during OFF mode.

Room Controller

ON

8. New DFS Modular Platform D Unit configuration

To enter New DFS Modular Platform D unit configuration, hold

the “UP“ and “DOWN“ buttons down together for 5 seconds while

the Room Controller is in off mode. After 5 seconds, a “20“ will

appear.

This indicates that the user is setting the first software

configuration item. To check the value of configuration item “20“,

press the “MODE” button.

The value for the New DFS Modular Platform D Heat Pump / AC

Only configuration will be displayed. To change the value, use the

“UP“ and “DOWN“ buttons. Once the value that you want is

selected, press the fan button to send that configuration data to the

unit.

Keep it pressed

for 5 seconds

Fig. 16 – Louver Mode Selection

up

down

Only the current value being displayed is transmitted. Once the

“FAN” button is pressed, the Room Controller will switch to

displaying the configuration index.

To move to the next setting, press the “MODE” button again and

the “20“ will be displayed.

Press the “UP“ button and the display will change to “21“. The

”MODE” button will toggle the display between the software

configuration index (i.e. “20“, “21“, etc.) and the configuration

value.

The“UP”/”DOWN” buttons will change either the index or the

value, which ever is displayed at the time.

Unit Configuration items 20 --24 are available at this point.

To change

the value

Automatic

(AUTO)

Or

Continuous

movement

(swing)

6

Page 7

UnitC

on

f

i

T

b

lesh

Item Value Description

1:Heatpump Unit Configuration

20

0:ACOnly(indoor unit with or without electric heaters) Defaults to Heat Pump

21 1--- 199 in increments of 1

22 0 –199 in increments of 1

0:StartinOffMode Auto Restart

24

1 : Start in last mode Defaults to “On”

guration

CCN Address of the unit

Defaults to 1

To display the hundreds, icon ON/OFF is .

Zone number --- Communications zone the system is located in

Defaults to 0

To display the hundreds, icon ON/OFF is .

This mode will exit automatically after 30 seconds of no buttons

being depressed.

NOTE: If units are grouped to one Room Controller, all units will

end up having the same configuration value.

Service test

There is a hidden service test mode that is initiated through a

combination of button presses when the remote is off. The

following combination must be pressed within a 6 seconds period:

mode

DOWN--FAN--UP--FAN--MODE

Once in service test mode, the service test mode message will be

sent, and “Sr“ will be displayed in the temperature icons until the

“DOWN“ bu tton is pressed.

During Service Test mode all the icons are off, the only button that

is active is the “DOWN” button.

To cancel Service Test Mode, press the “DOWN“ button to send a

normal message with “OFF“ mode.

Service Test Mode automatically times out after 30 minutes and the

remote will operate normally.

rou

ooting

S When test mode is selected, the unit will operate as

described below:

⎯ The Unit Status (Green) and Timer (Yellow) LEDS

blink every 2 seconds.

⎯ The indoor fan will operate according to

user--selected speed. If user selected speed is Auto,

the fan will run in High speed.

⎯ If the unit is configured as an A/C Only unit, it will

operate in cool mode with demand.

S The louver will operate according to user--selected

position. If user selected louver is Auto, louver operates

according to cool louver.

⎯ If the unit is configured as a Heat Pump unit, the

louver will operate according to user--selected

position. If user selected louver is Auto, louver

operates according to auto heat or cool louver based

on operating mode.

The unit will run in cool mode for 3 minutes, then it

will run in heat mode for 2 minutes, or until the

indoor coil is greater than 104_F. The unit will run

in cool mode until test mode is exited.

Any of the following will cancel the test Mode:

S When the unit is turned off by the controller.

S If the power is cycled during the Test Mode, the unit will

return to its normal operating mode.

S After 30 minutes of receiving the last valid test request

message.

S Fail Mode

33MC--URC

Symptom Possible Cause Things to check Solution

No LCD display

+12 volts applied to

Room Controller at

the correct terminals

and still does not

operate

1) mis---wiring of the 12 volt power

to Room Controller control.

2) Power not online

3) No 12 volts between P and G of

terminal block.

1) The Room Controller is damaged.

Verify that + 12 V and Ground are connected to

the proper terminals of the Controller.

Reference Installation wiring section for correct

connections

Check that the units main power is connected.

The main control board should be operating

normally

Check the installation of the J6 plug on the

main control board.

7

After disconnecting the

power, correct the wiring

problem and re --- cycle

power.

After verifying the wiring

to the Room Controller,

re--- cycle the unit power.

After disconnecting the

power, correct the wiring

problem and re --- cycle

power.

Change the Room Controller and re-- -cycle power.

Page 8

33MC--URC

Copyright 2006 Carrier Corp. S 7310 W. Mo rris St. S Indianapolis, IN 46231

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

Printed in U.S.A. Edition Date: 07/06

8

C a t a l o g N o . 3 3 M C --- U R C --- 1 S I

Replaces: NEW

Loading...

Loading...