Page 1

Carrier

ermetic Centrifugal Liquid Chillers

INTRODUCTION

persons concerned with the start-up and

ope^ion of the 19EA machine should understand

thteie instructions and all necessary job data before

initial start-up. Instructions are in proper sequence

for optimum machine performance.

Data and Equipment Required

PRINTS: Machine assembly and

wiring,

piping

Starter diagrams

Special controls and related

wiring (if any)

INSTRUCTIONS:

19EA Installation book

19EA Operating and Main

tenance book

Starter Instructions

MATERIALS:

Mechanics’ tools, electronic or

halide leak detector, clamp-on

ammeter, volt-ohmmeter

INITIAL PREPARATIONS

Machine Tightness — The 19EA is shipped with the

refrigerant charge in the utility vessel and a holding

charge (10 psig) in the unishell. Several levels of

leak testing may be required depending on

condition of machine on arrival and at start-up.

Determine machine condition and follow pro

cedure indicated in Table 1.

For transferring refrigerant and evacuating

vessels, follow the pumpout instructions on pages 3

and 4.

Table 1 — Selection of Leak Test Procedures

MACHINE CONDITION

1. Unishell holding charge

and utility vessel refrig

erant level unchanged.

2 Unishell holding charge

decreased slightly.

3. Utility vessel refrigerant

level decreased slightly.

4. Unishell holding charge

completely gone Opened

valve or other open con

nection suspected.

5 Unishell holding charge

completely gone Vessel

leak assumed

6 Refrigerant charge in

utility vessel completely

gone. Opened valve or

, \ other open connection

suspected.

7 Refrigerant charge in

utility vessel completely

gone. Vessel leak

assumed

PROCEDURE

4

3 and 4 on unishell

Leak test with halide or

electronic leak detector.

1

'2., 3, and 4 on unishell

1 - Use nitrogen with

R-12 tracer in pressur

izing for leak test pro

cedures 2 and 3

2, 3/ and 4 on uti! ity

vessel. Use nitrogen with

R-12 tracer for pressuriz

ing in 2 and 3

Nev«f charge Squid refr^erant into

the unisheii if vessd isressarc is beiow 3S ps^..,

or vtaife water pumps itoi op«ratirig. Cooler tube

freeze-trp and. dam^e may rearlt,

PROCEDURE 1 — Standing Vacuum Test

1. Attach a mercury manometer (absolute

pressure-type) to the refrigerant charging valve,

(6) Fig. 1. A dial-type gage cannot indicate the

small amount of leakage acceptable during a

short period of time.

2. Pull a vacuum on the vessel (see evacuating

procedures on page 3) equal to 25 in. Hg, ref

30-in. bar. (2.5 psia), using the pumpout system

pump.

3. Valve off pump to hold vacuum, and record

manometer reading.

4. If the leakage rate is less than 0.05 in. Hg/24

hours, perform procedure 3, aU steps under

Machine Dehydration and procedure 4.

5. If the leakage rate exceeds 0.05 in. Hg/24

hours, perform procedures 2, 3, all steps under

Machine Dehydration, and procedure 4 in the

order indicated.

6. Remove mercury manometer from refrigerant

charging valve.

PROCEDURE 2 — Follow steps 1 thru 4 of Return

Refrigerant to Normal Operating Conditions, page

3. Raise vessel pressure slowly to 5 psig by cracking

open valve 4. Perform leak test with hahde or

electronic detector and repair any leaks.

PROCEDURE 3 — Following steps 1 thru 5 of

Return Refrigerant to Normal Operating Condi

tions, page 3, raise vessel pressure to 35 psig.

Perform leak test with halide or electronic detector

and repair any leaks.

PROCEDURE 4 — Equalize pressure between

utility vessel and unishell following steps 1 thru 5

of Return Refrigerant to Normal Operating

Conditions, page 3. Vessel pressure will be approxi

mately 70 psig. Perform leak test with halide or

electronic detector and repair any leaks.

If refrigerant charge was lost and nitrogen has

been used for pressurizing in procedures 2 and 3,

evacuate vessel and then charge 400 lb of R-12 for

procedure 4. If vessels are then leak tight, continue

charging refrigerant to the level indicated in

Charging Quantity Table below.

Table 2 — Charging Quantity

MACHINE SIZE

19EA 400, 430, 465

19EA 500, 550

19EA 590, 630

WEIGHT (lb R-12)

2000

2200

2400

Form 1PFA-1.S?;

Page 2

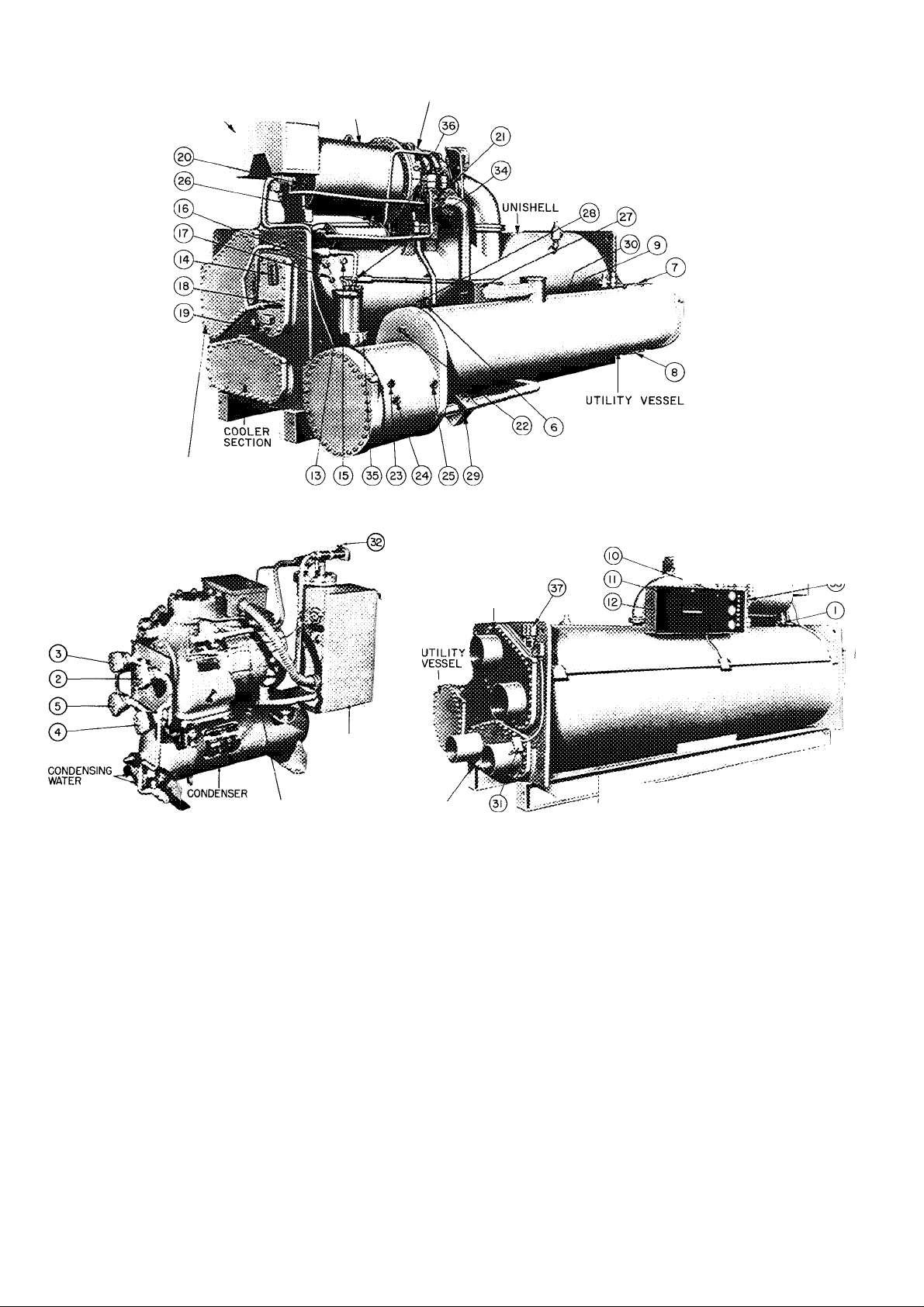

COMPRESSOR MOTOR

TERMINAL BOX

COMPRESSOR

MOTOR DRIVE

e, add

CONDENSER

SECTION

CONTROL BOX

PUMPOUT UNIT

COMPRESSOR

1 Pumpout Service Valve 1

2 Pumpout Service Valve 2

3 Pumpout Service Valve 3

4. Pumpout Service Valve 4

5 Pumpout Service Valve 5

6 Pumpout Service Valve 6 and Refrigerant Charging Valve

7. Pumpout Service Valve 7

8 Pumpout Service Valve 8

9. Service Valve 9 (hidden between unishell and utility vessel)

10 Differential Pressure Gage (oil)

11 Condenser Pressure Gage

12 Cooler Pressure Gage

13. Dehydrator Water Valve

14 Oil Level Sight Glass

15 Oil Temperature Gage

16 Oil Heater (with indicator light)

17. Oil Heater Thermostat

18 Oil Pressure Regulating Valve

19 Oil Reservoir Charging Valve

COOLER

LEGEND

CONDENSER

REAR VIEW

COMPRESSOR

FRONT VIEW

UNISHELL

20.

Sight Glass — Rotation

21.

Sight Glass — Seal Oil

22

Sight Glass — Liquid Level

23

Sight Glass — Liquid Level

24. Sight Glass — Liquid Level

25 Sight Glass — Liquid Level

Refrigerant Drain Valve

26

27. Isolation Valve

Isolation Valve (hidden)

28

29. Isolation Valve

Isolation Valve — ball valve between unishell

30.

and utility vessel (hidden)

31 Chilled Water Control Element

32 Pumpout Vent Valve with Flare Cap

33. Bearing Return Oil Thermometer (hidden)

34 Dehydrator Pressure Gage

35 Dehydrator Discharge Hand Valve

36. Oil Cooler Plug Cock

Chilled Water Lo-Temp Cutout

37

/ MOTOR DRIVE

Fig. 1 — Machine Components

Page 3

ISOLATION VALVE OPERATION

Opening — Compressor must be off and vessel

pressures equalized (see Return Refrigerant to

Normal Operating Condition, steps 1 thru 6).

^. Loosen packing nut 1/2 to 1 turn so valve stem

will rotate and slide smoothly in packing. Do

not let refrigerant trapped in valve body escape.

2. Hold stem in against line pressure and rotate

stem counterclockwise as far as possible.

3. Slide stem out of body.

4i Rotate stem clockwise in the out position, until

snug.

5. Tighten packing nut.

Closing

1. Loosen packing nut 1/2 to 1 turn so valve stem

will rotate and slide smoothly in packing. Do

not let refrigerant trapped in valve body escape.

2. Rotate valve stem counterclockwise as far as

possible.

3. Slide stem into valve until it bottoms.

4. Rotate stem clockwise, holding assembly in,

until it is tight (25 ft-lb).

5. Tighten packing nut.

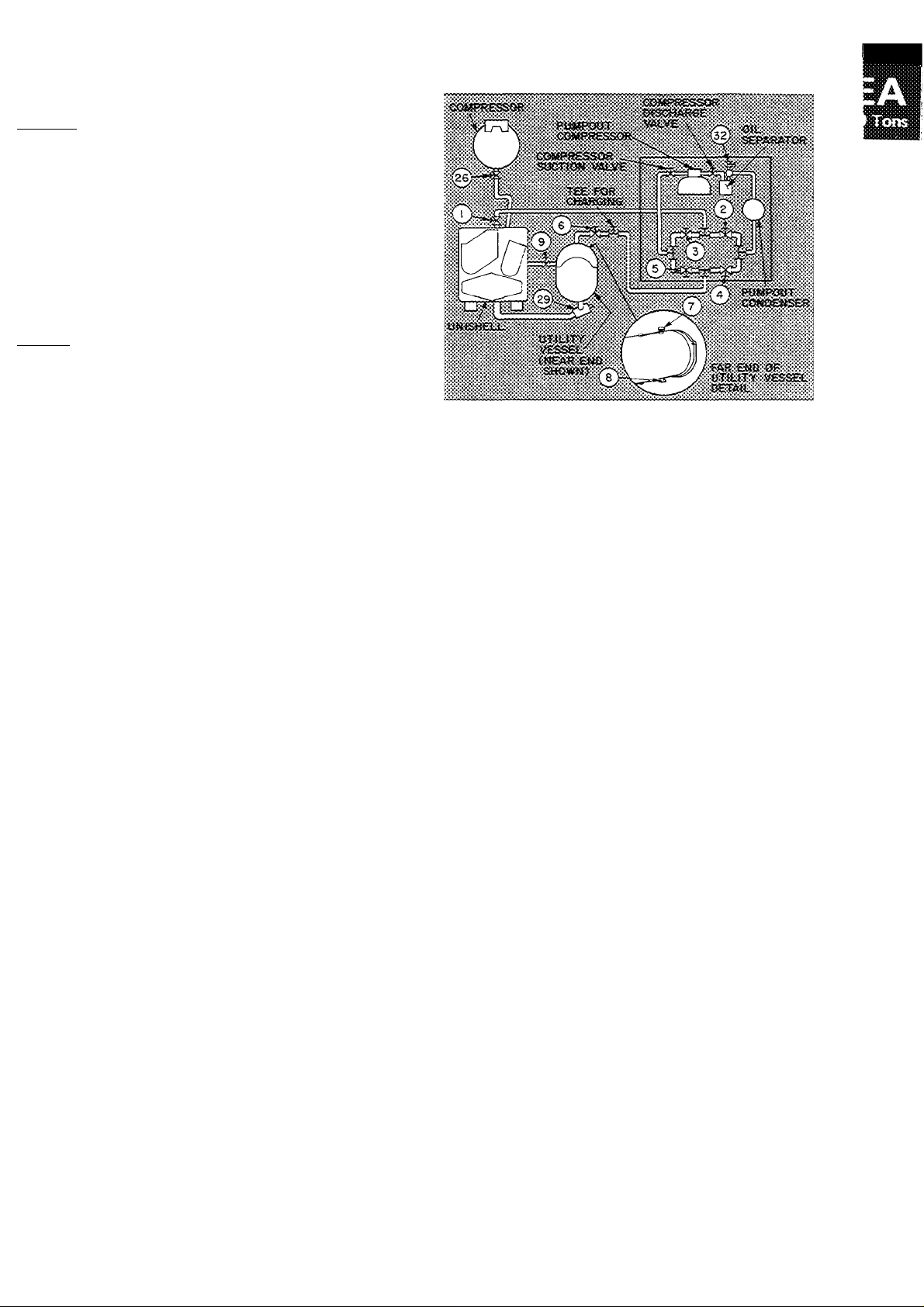

TRANSFER REFRIGERANT FROM UTILITY

VESSEL TO UNI SHELL* from normal operating

condition.

1. Add manometer near charging valve 6.

2. Close isolation valves (27), (28), and (30).

3. Open valves 1, 3, 4, 6, 7 and 8.

4. Close valves 2, 5 and 9.

5. Ensure that pumpout condenser water is off.

6. Turn on pumpout compressor until liquid is

out of utility vessel.

7. Turn off pumpout compressor.

8. Close isolation valve (29).

9. Close valves 3 and 4.

10. Open valves 1,2, 5 and 6.

11. Turn on pumpout condenser water.

12. Run pumpout compressor until utility vessel

pressure reaches 25 in. Hg, ref 30-in. bar. (2.5

psia).

13. Turn off pumpout compressor.

14. Close valves 1, 2, 5 and 6.

15. Turn off pumpout condenser water.

TRANSFER REFRIGERANT FROM UNISHELL

TO UTILITY VESSEL* from normal operating

condition.

1. Open drain valve (26).

2. Wait one hour; close isolation valves (27), (28)

and (30).

3. Open valves 1,2, 5, 6, 7 and 8.

4. Close valves 3 and 4.

5. Ensure that pumpout condenser water is off.

6. Turn on pumpout compressor for 20 minutes.

7. Turn off pumpout compressor.

8. Close isolation valve (29).

Close valves 2 and 5.

10. Open valves 1, 3, 4 and 6.

11. Turn on cooler and condenser pumps and

pumpout condenser water.

*See Fig 1 and 2 for all numbered references.

Fig. 2 — Pumpout System Schematic

(See Fig. 1 Legend for Item Ref)

12. Run pumpout compressor until unishell pres

sure reaches 25 in. Hg, ref 30-in. bar. (2.5

psia). Use dehydrator gage (34) for pressure

reading.

13. Turn off pumpout compressor.

14. Close valves 1, 3, 4 and 6.

15. Turn off pumpout condenser water.

UTILITY VESSEL EVACUATING PROCEDURE*

1. Close valves 1,2, 3, 4 and 9.

2. Open valves 5,6,1 and 8.

3. Open vent valve (32) and remove flare cap.

4. Turn off pumpout condenser water.

5. Operate pumpout compressor until manometer

reads 25 in. Hg, ref 30-in. bar. (2.5 psia).

6. Close valves 5, 6, 7 and 8.

7. Shut off pumpout compressor.

8. Close vent valve (32) and replace flare cap.

UNISHELL EVACUATING PROCEDURE*

1. Close valves 2, 4, 6 and 9.

2. Open valves 1, 3 and 5.

3. Open vent valve (32) and remove flare cap.

4. Turn off pumpout condenser water.

5. Operate pumpout compressor until manometer

reads 25 in. Hg, ref 30-in. bar. (2.5 psia).

6. Close valves 1, 3 and 5.

7. Shut off pumpout compressor.

8. Close vent valve (32) and replace flare cap.

RETURN REFRIGERANT TO NORMAL OPER

ATING CONDITION *

1. Ensure that opened vessel has been evacuated.

2. Close valves 3, 4 and 5.

3. Open valves 1,2, 6, 7 and 8.

4. Run water pumps.

5a. If unishell has been evacuated — Crack open

valve 4, gradually increasing pressure in uni

shell to 35 psig. Feed refrigerant slowly to

prevent tube freeze-up.

Page 4

b. If utility vessel has been evacuated — Crack

open valve 4 to gradually equalize pressure

between unishell and utility vessel. Ensure

that unishell pressure does not drop below 35

psig to prevent tube freeze-up.

6. Open valve 4 fully.

7. Open valve (29) to equalize the liquid refrig

erant levels between vessels.

8. Close valves 1,2, 3, 4, 5, 6, 7 and 8.

9. Open isolation valves (27), (28) and (30) and

service valve 9.

10. Close drain valve (26).

MACHINE DEHYDRATION — It is recommended

that the machine be dehydrated only if it has been

open for a considerable period of time, or if there

has been a complete loss of unishell holding charge

or utility vessel refrigerant charge.

WARNING; Do not staxt compressor ot oil

puH^ even, for a rotation check wliile machine

is under dehydration vacunm.

NOTE: Dehydration is readily accomplished at

normal room temperature. If room temperature is

high, dehydration takes place more quickly. At low

room temperatures, dehydration is extremely

difficult and special techniques must be applied.

Contact your Carrier representative for further

information.

Perform dehydration as follows:

1. Connect a dehydration pump to the refrigerant

charging valve (6) Fig. 1.

2. Connect a mercury manometer (absolute

pressure-type) to the dehydrator discharge hand

valve, (35) Fig. 1, and then open the valve. If

only the utility vessel is to be dehydrated, a tee

for the manometer must be provided between

the refrigerant charging valve and a valve on the

vacuum or dehydration pump.

3. Open the proper pumpout system valves to

evacuate the desired vessel(s).

4. Operate the dehydration pump until the

manometer reads 0.20 in. Hg abs (29.80 in. Hg,

ref 30-in. bar.); continue to operate pump for 2

more hours.

5. Close refrigerant charging valve; stop dehydra

tion pump; record manometer reading.

6. After a 2-hour wait, take another manometer

reading. If reading has not increased, dehydra

tion is complete. If reading has increased,

repeat steps 4 and 5.

7. If reading continues to rise after several dehy

dration attempts, suspect a machine leak. If this

is the case, pressurize the unit to approximately

8 to 10 psi with dry air or nitrogen. Locate and

repair leak. Then repeat dehydration procedure.

Inspect Piping — Refer to piping diagrams in job

data and inspect chilled water, condenser water,

and oil cooler water piping. Ensure that flow direc

tion is correct in all cases and that all specified

piping requirements are met.

CHECK WATER FLOW RATE - Ensure that

cooler and condenser water loop is full, with air

vented from high points. Water flow thru cooler

and condenser must meet job requirements.

Measure water pressure drop across the cooler and

condenser or across the pumps. Check to see that

water flow rates agree with design flow.

Oil cooler water supply should meet the follow

ing specifications:

Clean water

Max water temperature 85 F

Max inlet working pressure 100 psi

Water velocity in tube, ft/sec 10 max ~ 6 min

Water flow, gal./min 7 max -- 4 min

Water press, drop, psi diff 5 max — 2 min

Valves and/or controls Field supplied

Field Wiring — Prior to starting equipment, refer to

wiring diagrams in job data and check power

supply as follows:

1. Connect a voltmeter across power wires to

compressor motor starter and measure voltage.

Compare this reading with voltage rating on

compressor and starter nameplates.

WARNING: Do not attempt to check high

voltage supply without proper equipment.

Serious personal injury can result.

2. Compare ampere rating on starter nameplate

with ampere rating on.inotor nameplate.

3. Check voltage to the following components and

compare to nameplate values: oil pump starter,

pumpout compressor motor starter.

4. Check 120 volt supply to oil heater.

5. Test motor and its power lead insulation

resistance using a 500-volt insulation tester such

as a megohmmeter. Proceed as follows:

a. Open starter main disconnect switch.

b. Test the three phases of compressor motor,

phase to phase, and phase to ground, with

tester connected on the motor side of the

starter contactor in the starter. Take resist

ance readings at 10-second and 60-second

intervals for each phase.

c. Divide the 60-second resistance reading by

the 10-second reading. This gives polariza

tion ratio. The polarization ratio must be

1.15:1 or higher. The 10-second and

60-second resistance readings must be 5.0

megohms or higher.

If the readings are unsatisfactory, repeat the

tests at motor terminals with motor power leads

disconnected. This will indicate whether fault is in

motor or in motor power leads.

Check Starter — Before starting the 19EA, open

the main disconnect and then check starter:

1. Remove contactor arc chutes. Be sure con

tactors move freely, and that shipping string is

removed. Replace arc chutes.

2. If starter has been on jobsite for a considerable

period, check contactors for dirt and rust.

Clean contact magnet surfaces lightly with

sandpaper. Apply a very thin coat of vaseline to ^

magnet surfaces, then wipe it off. If starter haf

been in a dusty atmosphere, vacuum clean

starter cabinet and wipe with a lint-free cloth.

3. Remove fluid cups from magnetic overload

relays. Add dashpot oil to cups per instructions

add

Page 5

on relay nameplate. Oil is shipped in small vials

usually attached to starter frame near relays.

Use only the dashpot oil shipped with starter.

Do not substitute. Overload relays are factory

set for 108 percent of motor full load amper

age. Resetting is not normally required.

4. Check transfer timer for proper time setting.

On Star-Delta starters, timers have adjustable

ranges of 10 seconds to 3 minutes and are

factory set for one minute. On AutoTransformer starters, timers have adjustable

ranges of 0 to 60 seconds and are factory set

for 30 seconds.

5. With main disconnect switch open, manually

open and close main control relay (ICR) to be

sure it operates freely.

Oil Charge is shipped in the oil reservoir. Check

sight glass (14) to be certain oil is visible. If oil

must be added, it must meet Carrier’s oil specifi

cation. Charge oil thru the oil reservoir charging

valve (19). Use a hand pump to charge the oil

against machine pressure.

Oil Heater — Energize the oil heater to minimize

absorption of refrigerant by the oil. A light (16)

indicates when the heater is energized. Set the oil

heater thermostat to maintain a minimum

temperature of 145 F at shutdown.

Refrigerant Charge is shipped in the utility vessel.

If refrigerant must be added, charge it thru the

refrigerant charging valve (6).

WARNING; Never charge liquid refrigerant into

the unjshell if the pressure is helow 35 psig.

Bek>w 35 psig, R-12 will flash to a gas at a

temperature heiow the freezing pomt of water.

With cooler and condenser water fiownng,

charge the refrigerant as a gas tmiil the vessel

pressure is above 35 psig.

Refer to Trimming Refrigerant Charge for full

load adjustment.

Check Operation of Safety Controls — As the

following checks are made, the panel lights

should appear as shown in the diagrams.

CONTROL LIGHTS

STEP

□ -OFF

□ □

□

□ □

□

□ □

■ ■

□

□ □

□ □ □

□

□

2

1

■

□

□ □

3A

l-ON

■

□ □

□ □ □

□

□

■ ■

□ □

□ ■

□

□ □

3B 4 5

ON-STOP

■

START

OIL PUMP

□

POWER

■

SAFETY CIRCUIT

■

LOAD RECYCLE

PROGRAM TIMER

(SEE BELOW)

1. Disconnect main motor leads in starter.

2. Energize the control circuit.

3a. With water pumps off, press oil pump button

for several seconds to determine oil pressure

on differential gage. With pump running,

confirm that circuit between terminals

<Q> and ^ is closed by using an

ohmmeter.

b. Release the oil pump button. Circuit between

terminals ^ and must open.

4. Start the chilled water and condenser water

pumps. Confirm that circuit between terminals

and is closed with pumps run

ning, and opens when pumps stop and flow

switches open.

5. Press ON-STOP button. If safety circuit light is

off, check resets on the condenser highpressure safety, cooler low-pressure safety,

bearing and motor high-temperature circuit

breakers and compressor motor overloads in

starter. Check 3-amp fuse in control center. If

safety circuit light is on but load recycle light

is off, check the automatic resetting chilled

water recycle switch. If both lights are on,

manually trip and then reset bearing and

motor high-temperature circuit breakers and

compressor motor overloads to be sure they

cut off the safety light. Tripping the chilled

water recycle switch will cut off the load

recycle light only.

CONTROL LIGHTS

□ -OFF B-ON

ON-STOP

m

■

■

□

■

□

■

■

■

□

■

□

■

\m

□

START

□

OIL PUMP

□

POWER

■

SAFETY CIRCUIT

■

LOAD RECYCLE

■

PROGRAM TIMER

□

8 {SEE BELOW)

STEP

N

■

□

■

■

■

■

6A 6B 6C

6a. Press machine START button. (Motor leads

disconnected and water pumps running.)

b. Oil pump starts within 30 seconds.

c. Compressor motor start contacts will close 30

seconds later. Starter will transfer to its run

condition 30 to 60 seconds after starter is

energized.

7. Open the oil pump main disconnect. Starter

must de-energize. Close disconnect.

8. In approximately 15 minutes, the program

timer will complete the antirecycle portion of

its cycle and the machine may be started.

9. Open circuit breaker and reconnect main

motor leads.

START-UP

Preliminary Checks

1. Power on to main circuit breaker, control

circuit, water pumps and tower fan.

2. Cooling tower water level.

3. Oil reservoir level and refrigerant level.

4. Oil reservoir temperature 145 F or warmer.

5. All isolation valves open. See (27), (28), (29)

and (30) of Fig. 1. If valves are closed, follow

isolation valve procedure on page 3.

6. Oil cooler plug cock, (36) Fig. 1, cracked open,

and any other valves in oil cooler line fully

open.

Page 6

7. Valves in chilled water and condenser water

circuits open and water circulating properly. Do

not permit water warmer than 100 F to flow

thru cooler.

COMPRESSOR ROTATION — Set capacity control

(item 2, Fig. 3) to “Hold.” Press machine ON-STOP

and START buttons.

As soon as motor starts to turn, press machine

ON-STOP button. Check motor rotation thru sight

glass in motor end bell (Fig. 1). Motor rotation

must be clockwise when viewed from motor end. If

not, reverse any 2 of 3 power leads coming into

motor starter and recheck rotation.

COMPRESSOR OPERATION

Press machine ON-STOP and START buttons and

let compressor come up to speed. Press machine

ON-STOP button and listen for any unusual sounds

coming from the compressor and transmission

housing as compressor coasts to a stop.

Program timer prevents rapid recycling of com

pressor and allows restart-15 minutes after stop.

Checking Safety Control Settings

add

® © 0

LEGEND

1. Motor Current Calibration Adjustment

2. Capacity Control Switch

3. Electrical Demand Adjustment

4. Thermostat (chilled water)

5. Throttle Range Adjustment

6. Condenser High-Pressure Cutout Switch (manual reset)

7. Cooler Low-Pressure Cutout Switch (manual reset)

8. Program Timer

9. Motor High-Temperature Cutout (manual reset)

10. Bearing High-Temperature Cutout (manual reset)

11. Low Oil Pressure Cutout

12. Economizer-Cooler Differential Pressure Switch

© @

Fig. 3 — Control Center

Table 3 — Checking Safety Controls

Open main disconnect (all power off to starter

and controls). Set capacity control to “Hold.”

Place a clamp-on ammeter on one of the 3 starter

leads. Install jumper between [0] •

Close disconnect(s), start compressor and check oil

pressure and temperature (items 10 and 15, Fig. 1).

With compressor running, manually operate the

prewhirl vanes with the capacity control switch.

Do not exceed 100 percent full load amperage.

1. Set control 1 (chilled water low temperature

cutout) as indicated in Table 3.

2. Stop machine, open disconnect(s), remove

jumper and check controls 2 and 3 of Table 3.

3. Controls 4 and 5 do not require alteration of

factory settings. ;

4. Control 6 may require adjustment for operation

of unit at low design suction. Refer to Table 3.

SAFETY OR CONTROL DEVICE

1. Chilled Water Low-Temperature Cutout

and Recycle Switch (Fig. 1)

-TEMPERATURE ADJUSTMENT

2. Oil Heater Thermostat (Fig. 1)

"fcT'- / SCREW

LOCKING

SCREW

RECOMMENDED SETTING

1. Set this switch to break at approximately 5 F below design chilled water

temperature, or at 36 F, whichever is higher

2. Set the differential at 10F±1 F so that whep the machine shuts down

automatically at approximately 5 F below the design chilled water tempera

ture it will restart at approximately 5 F above the design water temperature.

3. This control must break ahead of the cooler low-pressure cutout or the

machine will not recycle automatically

Perform checks 2 and 3 with machine stopped and jumper removed

Set the oil heater thermostat to maintain a minimum oil reservoir temperature of

145 F at shutdown

.adjusting

»

Page 7

Table 3 — Checking Safety Controls (cont)

SAFETY OR CONTROL DEVICE

3. Low Oil Pressure Cutout (Fig. 3)

RANGE

DIAL ADJUSTMEN1?

REMOVE METAL

COVER

DIFFERENTIAL

4. Economizer Cooler Differentia! Pressure

Switch {Fig. 3)

OIL

PRESSURE

RECOMMENDED SETTING

Factory set to cut out at 13 ±1 psi differential Operate oil pump manually

Remove cap and gasket from regulating valve (item 18, Fig 1) Loosen locknut

Turn adjusting screw counterclockwise to lower oil pressure to 12 psi differential

If safety does not trip, turn range dial clockwise until cutout occurs Access to

control is thru knockout at rear of control box

The economizer-cooler differential pressure switch is factory set to energize the

refrigerant feed control at 10 psid

'<7

i. Condenser High-Pressure Cutout (Fig. 3)

Ù.

range

adjustment

SCREW

6. Cooler Low-Pressure Cutout (Fig. 3)

Setting Operating Controls

MOTOR CURRENT CALIBRATION

PROCEDURE

1. Establish a steady motor cun'ent value for this

calibration. Open guide vanes manually

(capacity control to “Inc”) until full load

current is reached. Motor current calibration

adjustment (item 1, Fig. 3) may have to be

turned counterclockwise to permit vanes to

open further. Do not exceed 105 percent of

nameplate full load amps

If building load is sufficient to maintain full

load current for a period of time, calibrate at

this condition. With small loads, pull down to

and maintain (capacity control to “Hold”)

The condenser high pressure switch is factory set to shut machine down when

condenser pressure reaches 161 ±5 psig Field calibration is not required

Cooler low-pressure switch is factory set at 32 ±2 psig If design suction

temperature is below 36 F, field resetting may be necessary With control power

off (power light out), install jumpers between terminals and 0 and

between and . Set switch to cut out at one degree below design

suction temperature Remove jumpers Restore power

design leaving chilled water temperature and

calibrate at this condition.

2. Measure motor current at selected condition.

Determine its percentage of full load motor

current.

3. Use this percentage figure to set the electrical

demand adjustment (item 3, Fig. 3) per the

following table:

Percent of Full

Load Motor Current

105

85 or above

65 to 84

45 to 64

below 45

Electrical Demand

Adjustment Setting

1ÜÜ pêrcêrvF ~

80 percent

60 percent

40 percent

Control cannot be

calibrated

Page 8

4. Turn the motor current calibration adjustment

fully clockwise. This will force the guide vanes

to close part way.

5. Turn the thermostat adjustment (item 4, Fig. 3)

to “Cooler” (fully counterclockwise).

6. Set the capacity control switch (item 2, Fig. 3)

to “Inc” position.

7. Slowly turn the motor current calibration

adjustment counterclockwise, allowing the

guide vanes to open until the motor current

reaches 5 percentage points above the electrical

demand setting.

NOTE: There is a time lag of several seconds

due to feedback capacitance in the motor

current circuit. When motor current calibration

setting is adjusted, this time lag should be

allowed for.

8. Check the foregoing motor current calibrations

with machine under “Auto” control as follows:

a. Close vanes manually (capacity control to

“Dec”).

b. Turn capacity control to “Auto.” Vanes

should stop opening at electrical demand

setting.

9. If control was calibrated at less than 100

percent load, turn electrical demand adjustment

setting to 100 percent. Control is now auto

matically calibrated for 100 percent full load

motor current.

This is a two-step motor current limiting

circuit. At 100 percent full load motor current,

the vanes will stop opening any further. If the

motor current should increase to 105 percent

due to some change in load cpnditions, the

vanes will close until the motor current is

reduced to about 102 percent. If the motor

current is reduced to 98 percent or below, the

control will respond to leaving chilled water

temperature. The electrical demand adjustment

allows the operator to reduce the maximum

current drawn by the motor, minimizing the

electrical demand rate during the off season

operation.

NOTE: If control cannot be calibrated with

above procedure, check voltage signal from

signal resistor in starter. At 100 percent full

load current, voltage between terminals 23 and

24 inside control panel must be 0.5 ± 0.1 volts.

If not in this range, check sizing of resistor in

starter.

CHILLED WATER CALIBRATION PROCEDURE

1. Turn throttle range calibration adjustment

(item 5, Fig. 3) fully clockwise.

2. Turn chilled water thermostat (item 4, Fig. 3)

until design chilled water temperature is main

tained. Mark thermostat at this position. If

capacity control vanes hunt, turn throttle range

calibration adjustment counterclockwise in

small increments until hunting ceases. Chilled

water thermostat may require resetting.

Trimming Refrigerant Charge — After the machine

has been placed in operation, it may be necessary

to adjust the refrigerant charge to obtain optimum

machine performance.

When machine full load is available, add o,

remove refrigerant slowly until the difference

between leaving chilled water temperature and the

cooler temperature reaches design conditions or

becomes a minimum. Shut the machine down and

allow refrigerant level to equalize between vessels.

Mark the level indicator (items 23, 24 or 25, Fig.

1) and maintain that shutdown refrigerant level.

IIMSTRUCTIIMG THE CUSTOMER OPERATOR

Be sure the operator carefully reads the 19EA

Operating and Maintenance Instructions.

Point out the following components; explain

their function and the system in which they are

used.

Compressor

Guide vanes, vane motor and linkage

Refrigerant-cooled motor

Transmission

Unishell

Cooler, condenser

Relief valve, isolation valves

Utility Vessel

Float chambers, sight glasses

Relief valves, charging valve

Dehydrator

Importance of proper operation

Valves and system operation

Sight glasses, gage

Lubrication System

Oil pump, cooler, filter

Solenoid, plug-cock

Heater, thermostat, temperature gage

Oil level and temperature

Pumpout System

Compressor, condenser, oil separator

Valve designation and cycle

Control System

Manual switches, gages and lights

Operating controls, safety controls

AuxiUary and special controls

Auxiliaries

Starter(s), pumps, cooling tower

Describe Refrigeration Cycle

Review Maintenance

Scheduled, extended shutdown

Importance of Log Sheet Record

Importance of water treatment

Check Operator Knowledge

Start-stop procedure

Safety and Operating Controls

Carrier Service

Advise operator of availability, and method of

ordering parts.

Review Operating and Maintenance Instructions.

Manufacturer reserves the right to change any product specifications without notice.

CARRIER AIR CONDITIONING COMPANY • SYRACUSE,

lEW YORK

Tatalnn Nn FS31-929

Loading...

Loading...