Page 1

AquaEdge® 19DV

Two-Stage Back-to-Back Centrifugal Liquid

Chillers with PIC6 Controls and HFO R-1233zd(E)

50/60 Hz

Start-Up, Operation, and Maintenance

Instructions

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . 2

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ABBREVIATIONS AND EXPLANATIONS . . . . . . . . . . 4

CHILLER FAMILIARIZATION (FIG. 1 AND 2) . . . . . . . 4

Chiller Information Nameplate . . . . . . . . . . . . . . . . . . 4

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Economizer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Motor-Compressor. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Purge Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Variable Frequency Drive (VFD) . . . . . . . . . . . . . . . . . 4

Refrigerant Lubrication System . . . . . . . . . . . . . . . . . 4

Chiller Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Purge Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PIC6 Touch Screen HMI. . . . . . . . . . . . . . . . . . . . . . . . 5

REFRIGERATION CYCLE . . . . . . . . . . . . . . . . . . . . . . 7

REFRIGERANT LUBRICATION CYCLE . . . . . . . . . . . 8

Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Inhibitor Reclaim System . . . . . . . . . . . . . . . . . . . . . . 9

Motor Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . 9

VFD Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . 9

VFD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Purge System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PIC6 System Components . . . . . . . . . . . . . . . . . . . . 12

START-UP/SHUTDOWN/

RECYCLE SEQUENCE. . . . . . . . . . . . . . . . . . . . . . 13

Local Start/Stop Control . . . . . . . . . . . . . . . . . . . . . . 13

Lubrication Control . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

BEFORE INITIAL START-UP . . . . . . . . . . . . . . . . . . . 15

Job Data Required . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . 15

Remove Shipping Packaging . . . . . . . . . . . . . . . . . . 15

Tighten All Gasketed Joints . . . . . . . . . . . . . . . . . . . 15

Check Chiller Tightness . . . . . . . . . . . . . . . . . . . . . . 15

Refrigerant Tracer . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Leak Test Chiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Standing Vacuum Test . . . . . . . . . . . . . . . . . . . . . . . 18

Check the Installation . . . . . . . . . . . . . . . . . . . . . . . . 20

Inspect Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chiller Dehydration . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Inspect Water Piping . . . . . . . . . . . . . . . . . . . . . . . . . 21

Check Safety Valves . . . . . . . . . . . . . . . . . . . . . . . . . .21

Check Purge Compressor Operation . . . . . . . . . . . .21

Ground Fault Troubleshooting . . . . . . . . . . . . . . . . . 22

Carrier Comfort Network® Interface . . . . . . . . . . . . .22

Inhibitor Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Software Configuration . . . . . . . . . . . . . . . . . . . . . . . 23

Charge Unit with Refrigerant . . . . . . . . . . . . . . . . . . . 23

Field Set Up and Verification . . . . . . . . . . . . . . . . . . . 31

Perform a Controls Test

(Quick Calibration/Quick Test) . . . . . . . . . . . . . . .32

INITIAL START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Check Motor Rotation. . . . . . . . . . . . . . . . . . . . . . . . . 33

Check Refrigerant Lube . . . . . . . . . . . . . . . . . . . . . . . 33

To Prevent Accidental Start-Up . . . . . . . . . . . . . . . . . 33

Check Chiller Operating Condition . . . . . . . . . . . . . .33

Instruct the Customer Operator(s) . . . . . . . . . . . . . . 34

OPERATING INSTRUCTIONS. . . . . . . . . . . . . . . . . . .36

Operator Duties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Prepare the Chiller for Start-Up . . . . . . . . . . . . . . . . . 36

To Start the Chiller . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Check the Running System . . . . . . . . . . . . . . . . . . . . 36

To Stop the Chiller . . . . . . . . . . . . . . . . . . . . . . . . . . .36

After Limited Shutdown . . . . . . . . . . . . . . . . . . . . . . . 36

After Extended Shutdown . . . . . . . . . . . . . . . . . . . . . 36

Cold Weather Operation. . . . . . . . . . . . . . . . . . . . . . .37

Manual Guide Vane Operation. . . . . . . . . . . . . . . . . .37

Refrigeration and Service Log. . . . . . . . . . . . . . . . . .37

PUMPOUT AND REFRIGERANT

TRANSFER PROCEDURES . . . . . . . . . . . . . . . . . .39

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

GENERAL MAINTENANCE. . . . . . . . . . . . . . . . . . . . . 42

Refrigerant Properties . . . . . . . . . . . . . . . . . . . . . . . .42

Adding Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Adjusting the Refrigerant Charge . . . . . . . . . . . . . . . 42

Refrigerant Leak Testing . . . . . . . . . . . . . . . . . . . . . .42

Leak Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Test After Service, Repair, or Major Leak. . . . . . . . .42

Repair Leaks, Retest, Standing Vacuum Test . . . . .42

Checking Guide Vanes . . . . . . . . . . . . . . . . . . . . . . . . 42

Trim Refrigerant Charge. . . . . . . . . . . . . . . . . . . . . . . 44

WEEKLY MAINTENANCE . . . . . . . . . . . . . . . . . . . . . .44

Check the Refrigerant Lubrication System . . . . . . . 44

Check for Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

SCHEDULED MAINTENANCE . . . . . . . . . . . . . . . . . .44

Service Ontime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Inspect the Control Panel. . . . . . . . . . . . . . . . . . . . . . 44

Inspect the Purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Catalog No. 04-53190056-01 Printed in U.S.A. Form 19DV-CLT-2SS Pg 1 6-19 Replaces: 19DV-CLT-1SS

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Page 2

Changing Refrigerant Lubrication Filters . . . . . . . . 45

Inspect Refrigerant Float System . . . . . . . . . . . . . . . 45

Inspect Safety Relief Devices and Piping . . . . . . . . 45

Compressor Bearing Maintenance . . . . . . . . . . . . . . 46

Inspect the Heat Exchanger Tubes

and Flow Devices . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Water Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Water Treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Inspect the VFD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Recalibrate Pressure Transducers . . . . . . . . . . . . . . 47

Recalibrate Temperature Thermistors . . . . . . . . . . . 47

Ordering Replacement Chiller Parts . . . . . . . . . . . . . 47

TROUBLESHOOTING GUIDE. . . . . . . . . . . . . . . . . . . 47

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Checking Display Messages . . . . . . . . . . . . . . . . . . . 47

Checking Temperature Sensors . . . . . . . . . . . . . . . . 47

Checking Pressure Transducers . . . . . . . . . . . . . . . 50

High Altitude Locations . . . . . . . . . . . . . . . . . . . . . . . 51

Quick Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Quick Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Pumpdown/Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

APPENDIX A — PIC6 SCREEN AND MENU

STRUCTURE

APPENDIX B — CCN COMMUNICATION WIRING

FOR MULTIPLE CHILLERS (TYPICAL) . . . . . . 75

APPENDIX C — MAINTENANCE SUMMARY AND

LOG SHEETS . . . . . . . . . . . . . . . . . . . . . . . . . . 76

APPENDIX D — REMOTE CONNECTIVITY

COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . 77

INDEX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

INITIAL START-UP CHECKLIST . . . . . . . . . . . . . . CL-1

. . . . . . . . . . . . . . . . . . . . . . . . 72

SAFETY CONSIDERATIONS

Centrifugal liquid chillers are designed to provide safe and reliable service when operated within design specifications. When

operating this equipment, use good judgment and safety precautions to avoid damage to equipment and property or injury

to personnel.

Be sure you understand and follow the procedures and safety

precautions contained in the chiller instructions as well as

those listed in this guide.

DANGER

Failure to follow these procedures will result in severe personal injury or death.

DO NOT VENT refrigerant relief valves within a building.

Outlet from rupture disc or relief valve must be vented outdoors in accordance with the latest edition of ANSI/

ASHRAE 15 (American National Standards Institute/

American Society of Heating, Refrigerating, and AirConditioning Engineers). The accumulation of refrigerant

in an enclosed space can displace oxygen and cause

asphyxiation.

PROVIDE adequate ventilation in accordance with ANSI/

ASHRAE 15, especially for enclosed and low overhead

spaces. Inhalation of high concentrations of vapor is harmful and may cause heart irregularities, unconsciousness, or

death. Misuse can be fatal. Vapor is heavier than air and reduces the amount of oxygen available for breathing. Product causes eye and skin irritation. Decomposition products

are hazardous.

DO NOT USE OXYGEN to purge lines or to pressurize a

chiller for any purpose. Oxygen gas reacts violently with

oil, grease, and other common substances.

NEVER EXCEED specified test pressures; VERIFY the allowable test pressure by checking the instruction literature

and the design pressures on the equipment nameplate.

DO NOT USE air for leak testing. Use only refrigerant or

dry nitrogen.

DO NOT VALVE OFF any safety device.

BE SURE that all pressure relief devices are properly in-

stalled and functioning before operating any chiller.

RISK OF INJURY OR DEATH by electrocution. High

voltage can be present on motor leads even though the motor is not running. Open the power supply disconnect before touching motor leads or terminals.

WARNING

Failure to follow these procedures may result in personal

injury or death.

DO NOT USE TORCH to remove any component. System

contains refrigerant which may be under pressure.

To remove a component, wear protective gloves and goggles and proceed as follows:

a. Shut off electrical power to unit.

b. Recover or isolate refrigerant from system using high-

pressure and low pressure ports as appropriate. Note that

R-1233zd(E) will be less than atmospheric pressure

until a temperature of about 65°F (18.5°C).

c. Traces of vapor should be displaced with nitrogen and

the work area should be well ventilated. Refrigerant in

contact with an open flame produces toxic gases.

d. Cut component connection tubing with tubing cutter

and remove component from unit.

e. Carefully unsweat remaining tubing stubs when necessary.

DO NOT USE eyebolts or eyebolt holes to rig chiller sections or the entire assembly.

DO NOT work on high-voltage equipment unless you are a

qualified electrician.

DO NOT WORK ON electrical components, including

control panels, switches, or starters, until you are sure ALL

POWER IS OFF and no residual voltage can leak from capacitors or solid-state components.

(Warnings continued on next page.)

2

Page 3

WARNING

LOCK OPEN AND TAG electrical circuits during servicing. IF WORK IS INTERRUPTED, confirm that all circuits are de-energized before resuming work.

AVOID SPILLING liquid refrigerant on skin or getting it

into the eyes. USE SAFETY GOGGLES. Wash any spills

from the skin with soap and water. If liquid refrigerant enters the eyes, IMMEDIATELY FLUSH EYES with water

and consult a physician.

NEVER APPLY an open flame or live steam to a refrigerant cylinder. Dangerous overpressure can result. When it is

necessary to heat refrigerant, use only warm (110°F [43°C])

water.

VERIFY that refrigerant storage cylinders are clean with no

residual moisture, oil, or refrigerant that can contaminate

the refrigerant charge.

DO NOT REUSE disposable (nonreturnable) cylinders or

attempt to refill them. It is DANGEROUS AND ILLEGAL. When cylinder is emptied, evacuate remaining gas

pressure, loosen the collar, and unscrew and discard the

valve stem. DO NOT INCINERATE.

CHECK THE REFRIGERANT TYPE before adding refrigerant to the chiller. The introduction of the wrong refrigerant can cause damage or malfunction to this chiller.

Operation of this equipment with refrigerants other than

those cited herein should comply with ANSI/ASHRAE 15

(latest edition). Contact Carrier for further information on

use of this chiller with other refrigerants.

DO NOT ATTEMPT TO REMOVE fittings, covers, etc.,

while chiller is refrigerant charged or at any time while

chiller is running. Be sure pressure is at 0 psig (0 kPa) before breaking any refrigerant connection. Note that chiller

will be in a vacuum condition when temperature is below

normal room temperature.

CAREFULLY INSPECT all rupture discs and other relief

devices AT LEAST ONCE A YEAR. If chiller operates in a

corrosive atmosphere, inspect the devices at more frequent

intervals.

DO NOT ATTEMPT TO REPAIR OR RECONDITION

any relief device when corrosion or build-up of foreign material (rust, dirt, scale, etc.) is found within the valve body

or mechanism. Replace the device.

DO NOT install relief devices in series or backwards.

USE CARE when working near or in line with a com-

pressed spring. Sudden release of the spring can cause it

and objects in its path to act as projectiles.

CAUTION

Failure to follow these procedures may result in personal

injury or damage to equipment.

DO NOT STEP on refrigerant lines. Broken lines can whip

about and release refrigerant, causing personal injury.

DO NOT climb over a chiller. Use platform, catwalk, or

staging. Follow safe practices when using ladders.

USE MECHANICAL EQUIPMENT (crane, hoist, etc.) to

lift or move inspection covers or other heavy components.

Even if components are light, use mechanical equipment

when there is a risk of slipping or losing your balance.

BE AWARE that certain automatic start arrangements CAN

ENGAGE THE STARTER, TOWER FAN, OR PUMPS.

Open the disconnect ahead of the starter, tower fans, or

pumps.

USE only repair or replacement parts that meet the code requirements of the original equipment.

DO NOT VENT OR DRAIN waterboxes containing industrial brines, liquid, gases, or semisolids without the permission of your process control group.

DO NOT LOOSEN waterbox cover bolts until the waterbox has been completely drained.

DO NOT LOOSEN a packing gland nut before checking

that the nut has a positive thread engagement.

PERIODICALLY INSPECT all valves, fittings, and piping

for corrosion, rust, leaks, or damage.

PROVIDE A DRAIN connection in the vent line near each

pressure relief device to prevent a build-up of condensate or

rain water.

DO NOT leave refrigerant system open to air any longer than

the actual time required to service the equipment. Seal circuits

being serviced and charge with dry nitrogen to prevent contamination when timely repairs cannot be completed.

INTRODUCTION

Prior to initial start-up of the 19DV unit, those involved in the

start-up, operation, and maintenance should be thoroughly familiar with these instructions and other necessary job data.

Procedures in this manual are arranged in the sequence required for proper chiller start-up and operation. This book also

outlines the control system for those involved in the start-up,

operation and maintenance of the unit before performing startup procedures. It is intended to be used in combination with the

19DV Semi-Hermetic Centrifugal Liquid Chillers Controls

Operation and Troubleshooting manual that describes the controls in detail.

CAUTION

Do NOT punch holes or drill into the top surface of the control or VFD enclosure for field wiring. Knockouts are provided for field wiring connections. Drilling holes through

the top of the cabinet can result in a loss of warranty on the

starter assembly because of metal particulate falling on and

into electronic components.

CAUTION

PROVIDE MACHINE PROTECTION. Store machine and

starter indoors, protected from construction dirt and moisture. Inspect under shipping tarps, bags, or crates to be sure

water has not collected during transit. Keep protective shipping covers in place until machine is ready for installation.

Follow latest Water-Cooled Chillers Long Term Storage

document located in Chiller Builder Library.

3

Page 4

CAUTION

WHEN FLUSHING THE WATER SYSTEMS isolate the

chiller from the water circuits to prevent damage to the heat

exchanger tubes.

CAUTION

This unit uses a microprocessor control system. Do not

short or jumper between terminations on circuit boards or

modules; control or board failure may result.

Be aware of electrostatic discharge (static electricity) when

handling or making contact with circuit boards or module

connections. Always touch a chassis (grounded) part to

dissipate body electrostatic charge before working inside

control center or use a grounding strap before handling

printed circuit boards.

Use extreme care when handling tools near boards and when

connecting or disconnecting terminal plugs. Circuit boards can

easily be damaged. Always hold boards by the edges and

avoid touching components and connections.

This equipment uses, and can radiate, radio frequency energy. If not installed and used in accordance with the instruction manual, it may cause interference to radio communications. The PIC6 control boards have been tested and found to

comply with the limits for a Class A computing device pursuant to International Standard in North America EN 610002/3 which are designed to provide reasonable protection

against such interference when operated in a commercial environment. Operation of this equipment in a residential area

is likely to cause interference, in which case the user, at his

own expense, will be required to take whatever measures

may be required to correct the interference.

Always store and transport replacement or defective boards

in anti-static shipping bag.

ABBREVIATIONS AND EXPLANATIONS

Frequently used abbreviations in this manual include:

AWG — American Wire Gage

BMS — Building Management System

CCN — Carrier Comfort Network

DCIB — Digital Control Interface Board

DVM — Digital Volt-Ohmmeter

EC — Envelope Control

ECDW — Entering Condenser Water

ECW — Entering Chilled Water

EMS — Energy Management System

HMI — Human Machine Interface

HVIB — High Voltage Interface Board

I/O — Input/Output

IGBT — Insulated-Gate Bipolar Transistor

IGV — Inlet Guide Vane

IOB — Input Output Board

LCDW — Leaving Condenser Water

LCW — Leaving Chilled Water

LED — Light-Emitting Diode

MAWP — Maximum Allowable Working Pressure

NSTV — Network Service Tool V

OLTA — Overload Trip Amps

PIC — Product Integrated Controls

PPE — Protective Personal Equipment

PWM — Pulse Width Modulating

RLA — Rated Load Amps

RMS — Root Mean Square

SCCR — Short Circuit Current Rating

SCR — Silicon Controlled Rectifier

SIOB — Starfire 2 Input Output Board

TXV — Thermostatic Expansion Valve

VFD — Variable Frequency Drive

VPF — Variable Primary Flow

Factory-installed additional components are referred to as options

in this manual; factory-supplied but field-installed additional components are referred to as accessories.

®

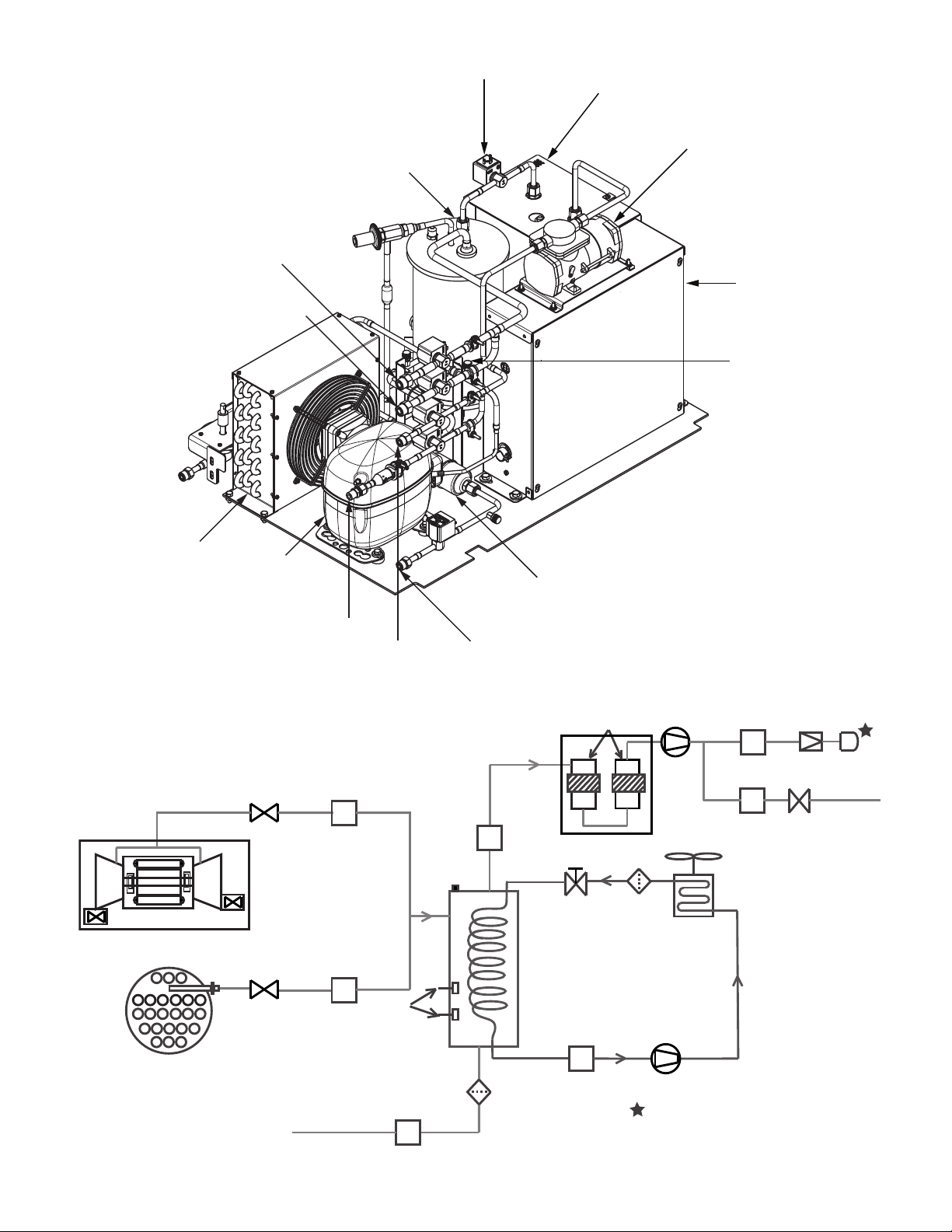

CHILLER FAMILIARIZATION (Fig. 1 and 2)

Chiller Information Nameplate

The information nameplate is located on the left side of the

chiller control panel.

System Components

The main components include the evaporator and condenser

heat exchangers in separate vessels, motor-compressor, refrigerant, lubrication package, control panels, PIC6 Touch Screen

HMI, economizer, VFD, and purge system.

Evaporator

This vessel is located underneath the compressor. The evaporator is maintained at a lower temperature/pressure so evaporating refrigerant can remove heat from water flowing through its

internal tubes. Water flows through the internal tubes to provide comfort or process cooling.

Condenser

The condenser operates at a higher temperature/pressure than the

evaporator and has water flowing through its internal tubes in order to remove heat from the refrigerant. It contains a metering device that regulates the flow of refrigerant into the economizer.

Economizer

This chamber reduces the refrigerant pressure to an intermediate

level between the evaporator and condenser vessels. In the economizer, vapor is separated from the liquid, the separated vapor

flows to the second stage of the compressor, and the liquid flows

into the evaporator. The energy removed from the vaporized refrigerant in the economizer allows the liquid refrigerant in the

evaporator to absorb more heat when it evaporates and benefits

the overall cooling efficiency cycle. It contains a float assembly

that regulates the flow of refrigerant into the evaporator.

Motor-Compressor

This component maintains system temperature and pressure

differences and moves the heat-carrying refrigerant from the

evaporator to the condenser. The 19DV utilizes a two-stage

back to back direct drive configuration.

Purge Unit

This is a small independent condensing unit with compressor, separator, regenerative carbon filters, heater and vacuum pump. The

purge extracts gas from condenser (or from compressor if unit is

not in operation) and purifies it by removing non-condensable

gases and any water vapor that may be present.

Variable Frequency Drive (VFD)

The VFD variable frequency is a voltage source design that

converts line voltage into PWM (pulse width modulating) motor input for motor speed and torque control.

Refrigerant Lubrication System

This system provides lubrication to the compressor bearing by

means of a refrigerant pump.

Chiller Control Panel

This control panel includes the input and output boards (IOBs),

control transformer, relays, contactors, and circuit breakers. It provides the power distribution and protection to the electrical components installed on chiller and has the following functions:

• Communication with PIC6 touch screen

• Communication with purge panel

• Communication with VFD

• Sensor input and outputs

• Actuators control

• Refrigerant pump control

4

Page 5

Purge Control Panel

Description

19 —

High Efficiency Semi-Hermetic

Centrifugal Chiller

19 G 4

DV

–

V — Variable Speed Drive

Evaporator Frame Size, Length,

Pass Arrangement, and Tube Count

4

4

G

4

4

Condenser Frame Size, Length,

Pass Arrangement, and Tube Count

44

Compressor Frame Size

Compressor Impeller Diameter Code

Motor Voltage Code

Code Volts-Phase-Hertz

3 — 380-3-60

4 — 416-3-60

5 — 460-3-60

9 — 400-3-50

Special Order Indicator

– — Standard

S — Special Order

VFD Code*

5 — 850 Amp Std Tier VFD

5

H4

Compressor Shroud Code

3 — Smallest shroud

4 — Small-Mid shroud

5 — Mid-Large shroud

6 — Largest shroud

Motor Code*

B — Smallest HP

D — Small-Mid HP

F — Mid-Large HP

H — Largest HP

2 — Small diameter

4 — Large diameter

G20 - G4K — Frame G

H20 - H4K — Frame H

G22 - G4K — Frame G

H22 - H4K — Frame H

*Refer to 19DV NG E-Cat Builder

for motor and VFD size details.

4 — 500-800 nominal tons (1758-2813 kW)

D — Low Pressure

The purge panel includes the input and output boards, control

transformer, relays, and fuse. It provides the power distribution

and protection to the electrical components which installed in

the purge system and has the following functions:

• Communication with PIC6 touch screen

• Sensor input and outputs

• Solenoid valve control

• Control of purge compressor, vacuum pump, heater, and fan.

PIC6 Touch Screen HMI

This panel is the user interface for controlling the chiller and

has the following functions:

• Chiller operation

• Chiller diagnostic

• Chiller status display

• Chiller parameter configuration

• Provide open protocol interface to outside BMS (Building Management System)

Week of Year

Ye ar of Manufacture

Fig. 1 — 19DV Chiller Model Number Identification

SERIAL NUMBER STRUCTURE

12 17 Q 26788

Unique Number

Place of Manufacture

a19-2271

5

Page 6

1

1—Interconnecting Compressor Piping

2—VFD Drain (Field Drain Piping Required)

3—Condenser

4—Condenser Waterbox Return End

5—Economizer Isolation Valve (Option)

6—Economizer

7—Evaporator Waterbox Return End

8—Vacuum/Charging Valve (Hidden)

9—PIC6 HMI Touchscreen Panel

10 — Evaporator Bundle Sight Glasses

11 — Rupture Disc

12 — Suction Elbow

13 — Evaporator Charging Valve and

Evaporator Pressure Transducer

14 — First Stage Guided Vane Actuator

15 — Compressor Motor

16 — Moisture Indicator (Hidden)

17 — Evaporator

18 — Second Stage Guided Vane Actuator

19 — Evaporator Waterbox Nozzles

20 — Condenser Waterbox Nozzles

21 — Condenser Pressure Transducer

22 — Condenser Charging Valve

23 — Envelope Stability Control Pipe

24 — Purge Assembly

25 — Purge Vent (Hidden)

26 — Motor VFD Cooling Moisture Indicator

(Hidden)

27 — Control Panel

28 — Chiller Name Plate Label

29 — Lubrication Assembly

30 — Economizer Pipe

31 — VFD

32 — Discharge Pipe

2

FRONT VIEW

18

19

17

30

16

15

14

13

12

31

3

4

5

6

11

10

9

32

8

7

REAR VIEW

20

21

22

29

28

23

24

25

26

27

Fig. 2 — Typical 19DV 500-800 Ton Two-Stage Compressor Chiller Components

(DV4 Shown)

6

Page 7

REFRIGERATION CYCLE

HIGH SIDE FLOAT

CHAMBER

COOLER

ECONOMIZER

LOW SIDE

FLOAT CHAMBER

CONDENSER

COMPRESSOR

The compressor continuously draws refrigerant vapor from the

evaporator at a rate set by the amount of first stage guide vane

opening and motor speed. As the compressor suction reduces

the pressure in the evaporator, the remaining refrigerant boils

at a fairly low temperature (typically 38 to 42°F [3 to 6°C]).

The energy required for boiling is obtained from the water

flowing through the evaporator tubes. With heat energy removed, the water becomes cold enough to use in an air-conditioning circuit or process liquid cooling.

After taking heat from the water, the refrigerant vapor is compressed by a back-to-back compression connected by means of interstage piping. Compression adds heat energy and the refrigerant

is quite warm (typically 98 to 102°F [37 to 40°C]) when it is discharged from the compressor into the condenser.

Relatively cool (typically 65 to 90°F [18 to 32°C]) water flowing into the condenser tubes removes heat from the refrigerant,

and the vapor condenses to liquid. The liquid drains into a high

side float valve chamber between the condenser and the economizer. The refrigerant is then metered into the economizer. In

the economizer, due to lower pressure, as liquid enters the

chamber, some liquid will flash into a vapor and cool the remaining liquid. The separated vapor flows to the second stage

of the compressor for greater cycle efficiency. The second

stage guide vane on the compressor acts as a pressure regulating device to stabilize operating conditions. At part load the

second stage guide vane will back up gas flow and thereby

raises the economizer pressure to allow appropriate refrigerant

flow from economizer to the compressor.

The cooled liquid left in the economizer flows through a low

side float valve and then into the evaporator. The float valve

forms a liquid seal to keep vapor from entering the evaporator.

The refrigerant is now at a temperature and pressure at which the

cycle began. Figure 3 summarizes the refrigeration cycle.

The 19DV unit utilizes R-1233zd(E) refrigerant. At atmospheric pressure its boiling point is 65.5°F (18.6°C). The result is

that at normal operating conditions the evaporator typically

will be in a vacuum condition and the condenser will operate at

a pressure above atmospheric pressure. Unit near room temperature will be close to atmospheric pressure.

Fig. 3 — Refrigeration Cycle — 19DV Two-Stage Compressor

7

Page 8

CAUTION

PURGE SYSTEM

CONDENSER

HIGH SIDE FLOAT

CHAMBER

REFRIGERANT

LUBRICATION

SYSTEM

VENT LINE

COOLER

ECONOMIZER

LOW SIDE

FLOAT CHAMBER

COMPRESSOR

EDUCTOR

= PURGE

= LUBE SYSTEM

= MAIN REFRIGERANT SYSTEM

LEGEND

To avoid adverse effects on chiller operation, considerations

must be made to condenser water temperature control. For

steady state operation, the minimum operating refrigerant

pressure differential between evaporator and condenser is approximately 7 psid (48 kPa) with a maximum evaporator refrigerant temperature of 65°F (18°C). Consult Chiller Builder for required steady state operational limits and low lift options. Inverted start conditions are acceptable for short

durations of time, but for periods exceeding 5 minutes, a special control solution strategy should be used to allow the

chiller to establish a minimum refrigerant pressure differential (and thereby adequate equipment cooling).

REFRIGERANT LUBRICATION CYCLE

Summary

The 19DV Series chiller uses refrigerant to lubricate the bearings.

The lubrication control is automatically controlled by the chiller

controls. In normal RUN mode refrigerant is pumped by means of

a refrigerant pump from the high side condenser float chamber to

the bearings. Prior to start-up, liquid level in the high side condenser float chamber is maintained by pumping refrigerant liquid

from the evaporator to the high side float chamber until level sensor is satisfied. If liquid high side float level is not satisfied, the

pump will move refrigerant from the evaporator to the condenser.

During pre-lube and post-lube cycles, refrigerant is drawn from

the evaporator for bearing lubrication.

Figures 4 and 5 identify the refrigerant lubrication assembly. Supply refrigerant is pulled through a filter drier by the refrigerant

pump and is pumped to the bearings through two protective filters

and then returned to the evaporator.

There are two pressure sensors located across the refrigerant

pump. During RUN mode a minimum of 12 psid is required for

the refrigerant pump delta difference. An alert will trigger if

this value is less than 13 psid while the machine is in normal

operating mode. Consult the 19DV with PIC6 Controls Operation and Troubleshooting manual for details.

Bearings

The 19DV motor-compressor assembly includes two matched

sets of refrigerant-lubricated bearings. The motor shaft is supported by a combination set of journal bearing and roller element bearings on each end of compressor. The refrigerant lubrication pressure difference is defined as the bearing input

pressure minus the bearing output pressure plus the Refrigerant

Delta P Offset.

Fig. 4 — Refrigerant Lubrication Cycle

8

Page 9

STRAINER

PUMP

PUMP

SUCTION

DISCHARGE

ACTUATOR

Fig. 5 — Refrigerant Lubrication Assembly

Inhibitor Reclaim System

The inhibitor reclaim system moves inhibitor from the evaporator

and returns it to the first stage suction inlet which allows it to be

mixed in the system since it has a tendency to have higher concentration in the evaporator compared with the rest of the system. The

reclaim is powered by an eductor driven by the gas pressure difference between first stage suction and discharge of second stage.

Motor Cooling System

The motor is cooled by liquid refrigerant taken from the bottom of the high side condenser float chamber. Refrigerant flow

is maintained by the pressure differential that exists due to

compressor operation. After the refrigerant flows past an isolation valve, an in-line filter drier, and a sight glass/moisture indicator, it is directed over the motor by spray nozzles. The refrigerant collects in the bottom of the motor casing and is then

drained back into the evaporator through the motor refrigerant

drain line. The motor is protected by temperature thermistors

embedded in the stator windings. An increase in motor winding temperature past the motor override set point overrides the

temperature capacity control to hold, and if the motor temperature exceeds 10°F (5.5°C) above this set point, the controls

close the inlet guide vanes. If the temperature rises above

122°F (50°C), the compressor shuts down. See Fig. 6.

VFD Cooling System

The VFD enclosure is sealed from the atmosphere to protect electronics from outside contaminants. Refrigerant is routed through a

coil in the VFD enclosure to regulate enclosure temperature while

still maintaining a temperature high enough to prevent condensation. The VFD cooling line is branched off the motor cooling supply. The refrigerant is then drained back into the evaporator

through the motor/VFD drain line. Rectifier and inverter sections

are air-cooled and protected by temperature sensors embedded in

the inverter. An increase in inverter temperature past the override

set point overrides the temperature capacity control to hold, and if

the temperature exceeds 10°F (5.5°C) above this set point, the

controls close the inlet guide vanes. If the IGBT temperature rises

above 144°F (80°C), the compressor shuts down. See Fig. 6.

NOTE: VALVES SHUT AT FACTORY TO CONTAIN

INHIBITOR IN LUBRICATION ASSEMBLY.

IMPORTANT: OPEN THESE VALVES

PRIOR TO STARTUP.

FROM EVAPORATOR

TO COMPRESSOR/

MOTOR BEARINGS

REFRIGERANT

F

PUMP

ILTER

FROM

HIGH SIDE

FLOAT

CHAMBER

VFD

All 19DV units are equipped with a VFD to operate the centrifugal semi-hermetic compressor motor. The VFD and control panel are the main field wiring interfaces for the installing contractor. The VFD and control panel are mounted on the chiller. See

Manufacturer VFD specific information and VFD schematics.

VFD model 32VS is designed to operate in an ambient range of

up to 104°F (40°C). The drive has two control circuit boards.

The Digital Control Interface Board (DCIB) controls the fans for

cooling operation, controls insulated-gage bipolar transistors

(IGBTs), measures three phase line current, controls temperature

input and cooling solenoid, controls outputs for pilot relays, and

controls communication with HMI controller.

The High Voltage Interface Board (HVIB) steps down incoming voltage to 24 VAC and sends this to the DCIB for monitoring. The HVIB measures DC Bus voltage, controls the precharge circuit, and controls SCR gating. It contains watchdog

LED to confirm DC Bus potential is depleted.

If the drive needs to be removed, use the 4 lifting lugs. See Fig. 7.

A 32VS 850A weighs approximately 1500 lbs. The drive is compatible with the Network Service Tool V (NSTV) for diagnostics.

Purge System

The purge system is located under the condenser. See Fig. 8. It has

two gas inlets coming from condenser and compressor. When

chiller is running, the condenser line is active/open and non-condensable gas is pulled out from condenser; when chiller is idle the

compressor line is active and non-condensables are pulled out

from compressor volute. This is implemented due to non-condensable gas density being less than refrigerant and therefore it will accumulate at the highest point when chiller is not running.

In the purge tank the purge gas is cooled by a separate integral

R-134a cooling system. The cooling system consists of an

compressor, an air cooled condenser coil, an expansion valve,

and a cooling coil in purge tank. Cooling the purge gas results

in condensation of R-1233zd(E) vapor as it touches the coil, resulting in a vacuum with the result that more refrigerant is

pushed to the coil. As the purge tank fills up with refrigerant it

will be drained through the purge drain to the refrigerant pump

assembly. See Fig. 9.

9

Page 10

SOLENOID VALVE

VFD

COOLER

COMPRESSOR

LIFTING LUGS

MOISTURE

INDICATOR

MOISTURE

INDICATOR

P

P

Fig. 6 — Motor/VFD Cooling System

CONDENSER

MOTOR COOLING

SYSTEM

Fig. 7 — 32VS 850A

10

LIFTING LUGS

Page 11

COMPRESSOR

VOLUTE (SV02)

CONDENSER

(SV01)

MOTOR

DRAIN

(SV05)

VENTING

(SV06)

PURGE TANK

PURGE PUMPOUT (SV03)

VACUUM PUMP

COMPRESSOR

SUCTION

CONTROL

PANEL

PURGE DRAIN (SV04)

(REFRIGERANT PUMP INLET)

COMPRESSOR

CONDENSER

ASSEMBLY

STRAINER

EXTRA FILTERS

WITH STRAP HEATERS

(NOT SHOWN)

CONDENSER

COMPRESSOR

SV01

SV02

COMPRESSOR VALVE

COMPRESSORSUCTION TEMP

STRAINER

134A CIRCUIT

LEVEL

SV04

PURGE DRAIN

CARBON FILTERS VACCUM PUMP SV06

SV05

STRAINER

SIGHT GLASS

CONDENSER ASSY

REGULATOR

SV03

PUMP OUT

VALV E

CHECK VALVE

(TO MOTOR DRAIN)

(TO LUBE ASSY)

FIELD CONNECTION / PURGE VENT

3/8 SAE FLARE

SWITCHES

VENT LINE

REGENERATED

REFRIGERANT

THROTTLE

DEVICE

CONDENSER VALVE

Fig. 8 — Purge System

Fig. 9 — Purge Tank

11

Page 12

Non-condensables that come into contact with the cold coil in

the purge tank will not condense and will accumulate at the top

of the purge tank, raising the pressure and reducing the flow of

refrigerant vapor. When the controls sense that there is sufficient non-condensable gas in the purge tank, the control will

open the pumpout valve, activate the purge evacuation pump,

and force the gas through the active carbon filters. To capture

any remaining refrigerant the gas is routed through two active

carbon filters that will absorb the refrigerant. As the carbon filters become saturated the system will regenerate the filters by

applying heat to the filters while under vacuum and then

disperse the regenerated refrigerant back to the evaporator

while releasing the non-condensables to atmosphere.

The 19DV purge control is automatic. Purge control should be

active when purge inlet temperature (evaporator refrigerant liquid temp when chiller compressor OFF or condenser saturated

temperature when chiller compressor ON) is greater than purge

active temperature set point (65°F default [18.3°C)].

If chiller compressor is running, condenser solenoid valve

should be opened to purge refrigerant from condenser.

If chiller compressor is not running, open the compressor solenoid valve to purge refrigerant from compressor. If Purge

Comp Suction Temp is less than purge compressor off temp

(default to 4°F [–15.5°C]) and the refrigerant level flag is ON,

close compressor solenoid valve and condenser solenoid valve,

and open pump out solenoid valve. Purge vent valve and purge

vacuum pump shall be kept ON for about 10s. After 10s discharge, pump out solenoid valve, purge vent valve, and purge

vacuum pump shall be kept OFF. Condenser solenoid valve

shall be opened if chiller compressor is running or compressor

solenoid valve shall be opened if chiller compressor is not running. After 10s discharge, it will start 20s delay. Then, check

purge compressor suction temperature again; if it is less than

6°F (–14°C), it will continue cycle as before.

If refrigerant level in the purge tank is high (both PGLE_HI

and PGLE_LO are ON), or purge compressor suction temperature is less than 12°F (–11°C) and PGLE_LO is ON, then

drainage solenoid valve should be opened to drain refrigerant

from purge tank to evaporator (open CV1, SV04, SV01, SV02

when chiller is off, open SV04, SV01 when chiller is on). After

PGLE_LO is OFF, keep drain process for another 1s, then set

the refrigerant level flag to ON. If purge level in the purge tank

is low (both PGLE_HI and PGLE_LO are OFF), drainage solenoid valve should be closed.

If pump out solenoid valve is accumulated ON for 100 minutes,

purge system should do regeneration process for reg_tim minutes

(default = 120 minutes – 19DV Configuration Menu), regardless

whether purge is active. When regeneration process is active, the

Purge Regeneration Valve and Purge Heater should be on for

reg_tim minutes, purge vacuum pump should be on for 3 minutes

and then 10 minutes off, alternating during reg_tim minutes.

Upon regeneration completion, purge system will wait for another 4 hours to let carbon filter cool down before it will operate normally.

WARNING

The main circuit breaker (if equipped) on the front of the

starter disconnects the main motor power only. Power may

be still energized for other circuits. Always check wiring

diagrams before initiating any work on the chiller and follow applicable lock-out/tag-out procedures. Failure to disconnect power will result in personal injury.

CONTROLS

Definitions

ANALOG SIGNAL

An analog signal varies in proportion to the monitored source. It

quantifies values between operating limits. (Example: A temperature sensor is an analog device because its resistance changes in proportion to the temperature, generating many values.)

DISCRETE SIGNAL

A discrete signal is a 2-position representation of the value of a

monitored source. (Example: A switch produces a discrete signal indicating whether a value is above or below a set point or

boundary by generating an on/off, high/low, or open/closed

signal.)

General

The 19DV centrifugal liquid chiller contains a microprocessorbased control center that monitors and controls all operations

of the chiller. The microprocessor control system matches the

cooling capacity of the chiller to the cooling load while providing state-of-the-art chiller protection. The system controls

cooling load within the set point plus the deadband by sensing

the leaving chilled water or brine temperature and regulating

the inlet guide vanes and compressor speed. The guide vane is

a variable flow pre-whirl assembly that controls the refrigeration effect in the evaporator by regulating the amount of refrigerant vapor flow into the compressor. An increase in guide

vane opening increases capacity. A decrease in guide vane

opening decreases capacity. The microprocessor-based control

center protects the chiller by monitoring the digital and analog

inputs and executing capacity overrides or safety shutdowns, if

required. The variable frequency drive (VFD) allows compressor start-up and capacity control by modulating the motor frequency based on the operating condition.

PIC6 System Components

The chiller control system is called the PIC6 (Product Integrated

Control 6). See Table 1. As with previous PIC versions, the PIC6

system controls the operation of the chiller by monitoring all operating conditions. The PIC6 control system can diagnose a

problem and let the operator know what the problem is and what

to check. It positions the guide vanes and VFD speed to maintain

leaving chilled water temperature. It controls the refrigerant

pump providing compressor bearing lubrication and can interface with auxiliary equipment such as pumps and cooling tower

fans to turn them on when required. It continually checks all

safeties to prevent any unsafe operating condition. It regulates

the envelope control valve for stabilized aerodynamic operation,

if installed. The PIC6 controls offer an operator trending function to help the operator monitor the chiller status more easily

and for critical compressor motor protection. The PIC6 system

provides open protocols to support the competitive BMS system

and can be integrated into Carrier’s Lifecycle System Management for remote monitoring and data management.

Table 1 — Major Controls Components and

Panel Locations

PIC6 COMPONENT PANEL LOCATION

Variable Frequency Drive Top of condenser

Purge Panel Under condenser

Remote Monitoring Control Panel

NOTE: For detailed information about the PIC6 HMI (human machine interface), see the 19DV with PIC6 Controls Operation and

Troubleshooting manual.

12

Page 13

START-UP/SHUTDOWN/

RECYCLE SEQUENCE

Local Start/Stop Control

Local start-up (or manual start-up) is initiated by pressing the

gray Start/Stop icon on the HMI interface. See Fig. 10.

Fig. 10 — Chiller Start/Stop Icon

This initiates the PIC6 starting sequence by displaying the list of

operating modes. Press Local On to initiate start-up. See Fig. 11.

Fig. 11 — Local On

Prior to start-up the start-to-start timer and the stop-to-start

timer must have elapsed and all alarms must be cleared (see

Troubleshooting Guide section).

When start-up is initiated the status screen displays the start-up

progress and the Start/Stop icon blinks green.

Once local start-up begins, the PIC6 control system performs a

series of prestart tests to verify that all prestart alerts and safeties are within acceptable limits. Table 2 shows appropriate

Prestart Alerts/Alarms conditions. If a test is not successful, the

start-up is delayed or aborted. If the tests are successful, the

start-up will be in progress and the COMPRESSOR RUN

STATUS will be “Startup.” The control will then energize the

chilled water/brine pump relay.

Five seconds later, the condenser pump relay energizes. Thirty

seconds later the PIC6 control system monitors the chilled water

and condenser water flow devices and waits until the WATER

FLOW VERIFY TIME (operator-configured, default 5 minutes)

expires to confirm flow. After flow is verified, the chilled water

temperature is compared to CONTROL POINT plus 1/2

CHILLED WATER DEADBAND. If the temperature is less than

or equal to this value, the PIC6 control system turns off the condenser pump relay and goes into a Recycle mode.

If the water/brine temperature is high enough, the start-up sequence continues and checks the guide vane position. If the

guide vanes are more than 4% open, the start-up waits until the

PIC6 control system closes the vanes. If the vanes are closed

and the refrigerant pump pressure difference is less than

2.5 psid (17.2 kPa), the refrigerant pump relay energizes. The

PIC6 control system then waits until the refrigerant pressure

(REF PRESS VERIFY TIME, operator-configured, default of

40 seconds) reaches 12 psid (82.7 kPa). After refrigerant pressure is verified, if high side float chamber has adequate liquid

level, refrigerant pump will be kept ON for 20 seconds for prelube; if not, refrigerant pump will be kept ON pumping refrigerant from evaporator to the high side float chamber until liquid level is satisfied. Upon pre-lube satisfied the compressor

start relay is energized.

Compressor ontime and service ontime timers start, and the

compressor STARTS IN 12 HOURS counter and the number of

starts over a 12-hour period counter advance by one.

Failure to verify any of the requirements up to this point will

result in the PIC6 control system aborting the start and displaying the applicable prestart alert alarm state number near the

bottom of the home screen on the HMI panel. A prestart failure

does not advance the STARTS IN 12 HOURS counter. Any failure after the 1CR relay has energized results in a safety shutdown, advances the starts in 12 hours counter by one, and displays the applicable shutdown status on the display.

The minimum time to complete the entire prestart sequence is

approximately 185 seconds. See Fig. 12 for normal start-up

timing sequence. See Table 2 for a list of prestart checks.

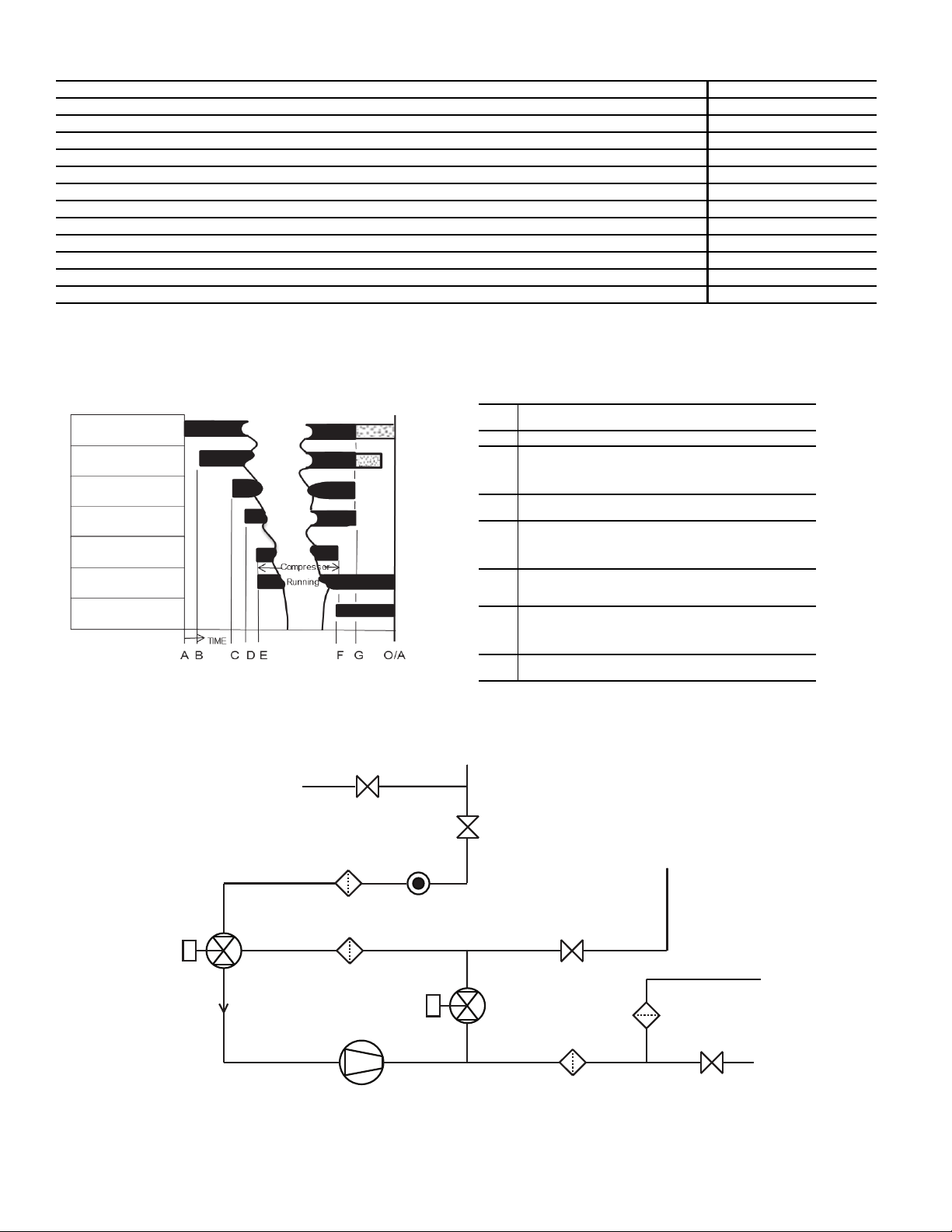

Lubrication Control

For the 19DV system, refrigerant is used to lubricate and cool

the compressor bearings. The refrigerant lubrication system includes refrigerant pump pressure transducers, control valves,

filters, liquid level switch and inhibitor reclaim system. See

Fig. 13 for the lube assembly schematic.

When the chiller is powered on, the controller will maintain the

liquid level in the condenser float chamber. If liquid level is

low, refrigerant will be pumped from evaporator to the condenser high side float chamber until the liquid level switch is

ON. Once the operator pushes the start button, the system will

go into prestart check process.

When Refrigerant Pump request is on for pre-lube and the bearing

pressure difference is OK for start, if evaporator temperature plus

leaving condenser water temperature is less than 10°F (–12.2°C),

pump refrigerant from evaporator to condenser until compressor is

ON. Else, if evaporator temperature plus leaving condenser water

is equal or larger than 10°F (–12.2°C), pump refrigerant from condenser to bearing and drain to condenser until compressor is ON.

During pre-lubrication, if the bearing pressure difference is less

than 8 psid (55.2 kPa) for 8 seconds continuously, the chiller will

shut down. To proceed to start-up, the bearing pressure difference

needs to exceed 12 psid (82.7 kPa) during the pressure verification

time. The compressor will run after the pre-lubrication process.

Refrigerant from the high side condenser float chamber will be

pumped to bearings and will drain to evaporator. When chiller

shuts down, the condenser control valve will be opened and the refrigerant evaporator control valve will open (3-way valve will

connect evaporator to pump suction). This position allows refrigerant to be pumped from evaporator to condenser high side float

chamber. When the chiller is OFF, always open evaporator control

valve. While running, if compressor is ON and the bearing pressure difference is less than 10 psid (68.9 kPa) for 10 seconds continuously, the chiller will shut down.

13

Page 14

Table 2 — Prestart Checks

A

START INITIATED: prestart checks are made; evaporator

pump started.*

B Condenser water pump started (5 seconds after A).

C

Water flows verified (30 seconds to 5 minutes maximum

after B). Chilled water temperatures checked against control

point. Guide vanes checked for closure. Refrigerant pump

started; tower fan control enabled.

D

Ref pressure verified (15 seconds minimum, 300 seconds

maximum after C).

E

Compressor motor starts; compressor on-time and service

on-time start, 15-minute inhibit timer starts (10 seconds after

D), total compressor starts advances by one, and the number of starts over a 12-hour period advances by one.

F

SHUTDOWN INITIATED; Compressor motor stops; compressor on-time and service on-time stop, and 2-minute

inhibit timer starts.

G

Refrigerant pump and evaporator pumps de-energized

(120 seconds after F).Condenser pump and tower fan control may continue to operate if condenser pressure is high.

Evaporator pump may continue if in RECYCLE mode.

O/A

Restart permitted (both inhibit timers expired: minimum of

15 minutes after E; minimum of 2 minutes after F).

* Auto Restart After Power Failure Timing sequence will be faster.

MACHINE SAFETIES

EVAPORATOR PUMP

CONDENSER

WATER PUMP

WATER FLOW, CHILLED WATER

TEMP, GUIDE VANES, REF PUMP,

TOWER FAN CONTROL

REF PUMP

COMPRESSOR,

COMPRESSOR ONTIME,

SERVICE ONTIME

15-MINUTE

START-TO-STA RT

2-MINUTE

STOP-TO-START

PUMP

REFRIGERANT FILTER

PURGE DRAIN

COOLER

SIGHT GLASSSTRAINER

STRAINER

PUMPOUT

DRAIN

BEARING FILTER

BEARING

SUPPLY

HS FLOAT CHAMBER

2-WAY

ACTUATED VALVE

3-WAY

ACTUATED

VALV E

PRESTART CHECK CONDITION* STATE NUMBER

STARTS IN 12 HOURS 8 (not counting recycle restarts or auto restarts after power failure) Alert – 100

COND PRESSURE COND PRESS OVERRIDE – 20 psi Alert – 102

#RECYCLE RESTARTS LAST 4 HOURS > 5 Alert – 103

COMP BEARING TEMP >= COMP BEARING ALERT– 10°F (5.6°C) Alarm – 230

COMP MOTOR WINDING TEMP COMP MOTOR WINDING– 10°F (5.6°C) Alarm – 231

COMP DISCHARGE TEMPERATURE COMP DISCHARGE ALERT– 10°F (5.6°C) Alarm – 232

EVAP_SAT <Evap trip point** + EVAP OVERRIDE DELTA T Alarm – 233

EVAP REFRIG LIQUID TEMP <Evap trip point** + EVAP OVERRIDE DELTA T Alarm – 233

AVERAGE LINE VOLTAGE UNDERVOLTAGE THRESHOLD

AVERAGE LINE VOLTAGE OVERVOLTAGE THRESHOLD

CHECK FOR GUIDE VANE 1 CALIBRATION Alarm – 236

CHECK FOR GUIDE VANE 2 CALIBRATION Alarm – 238

* If Prestart Check Condition is True, then resulting State is as indi-

cated in the State Number column.

† See the Controls Operation and Troubleshooting guide for alarm

and alert codes.

††

††

Alarm – 234

Alarm – 235

** Evap trip point = 33°F (0.6°C) (water) or EVAP REFRIG TRIP-

POINT (brine).

†† Condition ignored for Eaton/Rockwell VFDs.

†

Fig. 12 — Control Timing Sequence for Normal Start-Up

Fig. 13 — Lube Assembly Schematic

14

Page 15

Shutdown

Unit Start/Stop

The unit can be stopped locally using the HMI by pressing the

green Start/Stop icon . The Unit Start/Stop screen is displayed. Press Confirm Stop (see Fig. 14).

Fig. 14 — Confirm Stop

Chiller shutdown begins if any of the following occurs:

• Local OFF button is pressed

• A recycle condition is present

• The time schedule has gone into unoccupied mode when in

Network or Local Schedule control mode

• The chiller protective limit has been reached and chiller is

in alarm

• The start/stop status (CHIL_S_S) is overridden to stop

from the network when in Network mode

If the chiller is normally shut down from running, soft stop shutdown will be performed. The soft stop feature closes the guide

vanes of the compressor automatically if a non-alarm stop signal

occurs before the compressor motor is de-energized.

Any time the compressor is directed to stop (except in the cases

of a fault shutdown), the guide vanes are directed to close and

VFD is directed to minimum speed for variable speed compressor, and the compressor shuts off when any of the following is true:

• PERCENT LOAD CURRENT (%) drops below the SOFT

STOP AMPS THRESHOLD

• ACTUAL GUIDE VANE OPENING drops below 4%

• 4 minutes have elapsed after initializing stop.

When any one of the above conditions is true, the shutdown sequence stops the compressor by deactivating the compressor

start relay. Then the guide vane shall be closed and stay at the

fully closed position, the refrigerant pump relay will be turned

off after 120 seconds post lube, and the chilled water/brine

pump and condenser water pump will be shut down.

BEFORE INITIAL START-UP

Job Data Required

• list of applicable design temperatures and pressures (product data submittal)

• chiller certified prints

• VFD details and wiring diagrams

• diagrams and instructions for special controls or options

• 19DV Installation Instructions

Equipment Required

• mechanic’s tools (refrigeration)

• digital volt-ohmmeter (DVM)

• true RMS (root mean square) digital multimeter with

clamp-on current probe or true RMS digital clamp-on ammeter rated for at least 480 vac

• electronic refrigerant leak detector

• absolute pressure manometer or electronic micron gage

(see Fig. 15)

• drum charging valve (unless refrigerant bottles already

have charging valves)

• charging hose

Fig. 15 — Digital Vacuum Gage

Remove Shipping Packaging

Remove any packaging material from the unit, VFD, and control

panels. Inspect the unit for damage that occurred during shipping

or installation. Document any damage that was identified.

Tighten All Gasketed Joints

Gaskets normally relax by the time the chiller arrives at the

jobsite. Tighten all gasketed joints to ensure a leak-tight chiller

(does not apply to refrigerant joints covered by factory insulation). Gasketed joints (excluding O-rings) may include joints at

some or all of the following:

• Waterbox covers

• Compressor first suction elbow flanges (at compressor and

at the evaporator)

• Compressor secondary suction flanges (at compressor and

low side float chamber)

• Compressor discharge flange

• Evaporator inlet line spacer (both sides)

• Envelope control flange (both sides of valve)

• ICP piping flange

• High and low side float chamber covers

See Tables 3 and 4 for bolt torque requirements.

Check Chiller Tightness

Figure 16 outlines the proper sequence and procedures for leak

testing.

The 19DV chillers are shipped without the refrigerant charge.

The chiller is shipped with a 15 psig (103 kPa) dry nitrogenholding charge.

If the 15 psig factory nitrogen charge is present, then release pressure and proceed to pull a deep vacuum on the unit. Vacuum

should be pulled through 1

tom of first stage side of the evaporator. Upon completion of pulling the required vacuum the chiller can be charged with refrigerant. The

1

/

-in. charging valve on top of the evaporator shell should

2

1

/

-in. female NPT located under bot-

2

15

Page 16

be used for charging by lifting charge cylinder and gravity feed

into the evaporator. The chiller should be charged with refrigerant.

If the holding charge is not present, the chiller must be examined

for leaks. To test for leaks add a small refrigerant holding charge to

unit and pressurize with nitrogen up to 20 psig to determine and

correct the origin of the leak. Use an electronic leak detector to

check all flanges and solder joints after the chiller is pressurized. If

the 15 psig factory nitrogen charge is present, then release pressure and proceed to pull a vacuum on the unit. The chiller should

Table 3 — Bolt Torque Requirements, Foot Pounds

be charged with refrigerant. Follow the leak test chiller procedure

(page 18).

If the chiller is spring isolated, keep all springs blocked in both

directions to prevent possible piping stress and damage during

the transfer of refrigerant from vessel to vessel during the leak

test process, or any time refrigerant is being transferred. Adjust

the springs when the refrigerant is in operating condition and

the water circuits are full. Any piping weights are to be separately supported.

SAE 8

HEX HEAD

SA354 GR BD

BOLT SIZE

(in.)

SAE 2, A307 GR A

HEX HEAD

NO MARKS

LOW CARBON STEEL

SOCKET HEAD OR HEX

WITH 3 RADIAL LINES, OR SA499

MEDIUM CARBON STEEL

SAE 5

WITH 6 RADIAL LINES OR

MEDIUM CARBON STEEL

MINIMUM MAXIMUM MINIMUM MAXIMUM MINIMUM MAXIMUM

1

/

4

5

/

16

3

/

8

7

/

16

1

/

2

9

/

16

5

/

8

3

/

4

7

/

8

46 69913

8 11 13 18 20 28

13 19 22 31 32 46

21 30 35 50 53 75

32 45 53 75 80115

46 65 75 110 115 165

65 95 105 150 160 225

105 150 175 250 260 370

140 200 265 380 415 590

1 210 300 410 580 625 893

1

/

1

8

1

1

/

4

3

1

/

8

1

/

1

2

5

1

/

8

3

1

/

4

7

/

1

8

330 475 545 7809851,410

460 660 770 1,100 1,3801,960

620 885 1,020 1,460 1,840 2,630

740 1060 1,220 1,750 2,200 3,150

1010 1450 1,670 2,390 3,020 4,310

1320 1890 2,180 3,110 3,930 5,610

1630 2340 2,930 4,190 5,2807,550

2 1900 2720 3,150 4,500 5,670 8,100

1

2

/

4

1

/

2

2

3

2

/

4

2180 3120 4,550 6,500 8,200 11,710

3070 4380 5,000 7,140 11,350 16,210

5120 7320 8,460 12,090 15,710 22,440

3 6620 9460 11,040 15,770 19,900 28,440

Table 4 — Bolt Torque Requirements, Foot Pounds (Metric Bolts)

BOLT SIZE

(METRIC)

MINIMUM MAXIMUM MINIMUM MAXIMUM

M4 1.75 2.5 2.5 3.5

M6 698 12

M8 14 20 20 30

M10 28 40 40 57

M12 48 70 70 100

M16 118 170 170 240

M20 230 330 330 470

M24 400 570 570 810

M27 58 0 830 820 1175

CLASS 8.8 CLASS 10.9

16

Page 17

19DV Field Procedure for new units with

less than 15 psig holding charge or units

suspected of leaking.

1. Attach compound gage to vessel

2. Note ambient temperature

Raise pressure to 20 psig (138 kPa)

using Nitrogen with added tracer gas for

electronic leak detection

Leak check

Pass

Evacuate vessel and

perform standing

vacuum test

Locate and mark all

leak sources

Dehydrate

Pass

Charge unit

NOTE: Be sure to add refrigerant

as gas until chiller pressure exceeds

15 in Hg (vac) / 380 mmHg (vac)

to avoid possible tube freezing.

Repair all leaks

No

Yes

Yes

No

Fig. 16 — 19DV Leak Test Procedures

17

Page 18

Refrigerant Tracer

Carrier recommends the use of an environmentally acceptable

refrigerant tracer for leak testing with an electronic refrigerant

detector.

Ultrasonic leak detectors can also be used if the chiller is under

pressure.

WARNING

Do not use air or oxygen as a means of pressurizing the

chiller. Mixtures of HFO R-1233zd(E) and air at elevated

pressure can undergo combustion, resulting in equipment

damage and possible personal injury.

Leak Test Chiller

Due to regulations regarding refrigerant emissions and the difficulties associated with separating contaminants from the refrigerant, Carrier recommends the following leak test procedure.

Refer to Table 5 for refrigerant pressure/temperature values.

1. If the pressure readings are normal for the chiller condition:

a. Evacuate the charge from the vessels, if present.

b. Raise the chiller pressure, if necessary, by adding

refrigerant until pressure is at the equivalent saturated

pressure for the surrounding temperature.

CAUTION

Never charge liquid refrigerant into the chiller if the pressure in the chiller is less than 15 in. Hg (vac) / 380 mm Hg

(vac) for HFO R-1233zd(E). Charge as a gas only, with the

evaporator and condenser pumps running, until this pressure is reached, using PUMPDOWN/LOCKOUT (located

in the Maintenance menu) and END LOCKOUT mode on

the PIC6 control interface. Flashing of liquid refrigerant at

low pressures can cause tube freeze-up and considerable

damage.

c. Leak test chiller as outlined in Steps 3 to 7.

2. If the pressure readings are abnormal for the chiller condition:

a. Prepare to leak test chiller.

b. For cooling machines, check for leaks by connecting a

nitrogen bottle with added tracer to allow for electronic leak detection if possible; otherwise, soap bubble solution is to be used. Raise the pressure to

20 psig (138 kPa). If electronic leak detector is avail-

able, ensure small amount of tracer material is added.

c. Plainly mark any leaks that are found.

d. Release the pressure in the system.

e. Repair all leaks.

f. Retest the joints that were repaired.

NOTE: Suggested test pressure is 20 psig (138 kPa); maximum allowable test pressure 45 psig (310 kPa).

3. Check the chiller carefully with an electronic leak detector

or soap bubble solution.

4. Leak Determination — If an electronic leak detector indicates a leak, use a soap bubble solution, if possible, to confirm. Total all leak rates for the entire chiller. Leakage at

rates greater than 0.1% of the total charge per year should

be repaired. Local regulation governs the requirements for

when repair of leaks become mandatory. Note the total

chiller leak rate as well as the full charge amount on the

start-up report.

5. If no leak is found during the initial start-up procedures,

complete the transfer of refrigerant gas from the storage

tank to the chiller. Recover any gas used for leak detection

purposes as required per local jurisdiction.

6. If no leak is found after a retest:

a. Perform a standing vacuum test as outlined in the

Standing Vacuum Test section, below.

b. If the chiller fails the standing vacuum test, repeat

leak test and repair.

c. If the chiller passes the standing vacuum test, dehy-

drate the chiller. Follow the procedure in the Chiller

Dehydration section, page 20. Charge the chiller with

refrigerant.

7. If the chiller is opened to the atmosphere for an extended

period, evacuate it before repeating the leak test. A nitrogen purge should be maintained to reduce the potential for

corrosion when open to the atmosphere.

NOTE: Alternate optional leak testing method is to isolate the water circuits and use a portable water heater to raise the temperature

of the evaporator and condenser water circuits to approximately

100°F (38°C) which corresponds to a pressure of approximately

14.40 psig (99.3 kPag).

Standing Vacuum Test

When performing the standing vacuum test or chiller dehydration, use a manometer or a wet bulb indicator. Dial gages cannot indicate the small amount of acceptable leakage during a

short period of time.

1. Attach an absolute pressure manometer or wet bulb indicator to the chiller.

2. Evacuate the vessel to at least 18 in. Hg vac (41 kPa [abs]),

using a vacuum pump or a pumpout unit.

3. Valve off the pump to hold the vacuum and record the

manometer or indicator reading.

a. If the leakage rate is less than 0.05 in. Hg (0.17 kPa

in 24 hours, the chiller is sufficiently tight.

b. If the leakage rate exceeds 0.05 in. Hg (0.17 kPa)

24 hours, re-pressurize the vessel and test for leaks.

4. Repair the leak, retest, and proceed with dehydration.

)

in

18

Page 19

Table 5 — HFO R-1233zd(E) Pressure and Temperature

TEMP. PRESSURE

F C PSIA PSIG IN HG KPAG KPA ABS MMHG (VAC) % VACUUM

20.0 –6.7

22.0 –5.6

24.0 –4.4

26.0 –3.3

28.0 –2.2

30.0 –1.1

32.0 0.0

34.0 1.1

36.0 2.2

38.0 3.3

40.0 4.4

42.0 5.6

44.0 6.7

46.0 7.8

48.0 8.9

50.0 10.0

52.0 11.1

54.0 12.2

56.0 13.3

58.0 14.4

60.0 15.6

62.0 16.7

64.0 17.8

66.0 18.9

68.0 20.0

70.0 21.1

72.0 22.2

74.0 23.3

76.0 24.4

78.0 25.6

80.0 26.7

82.0 27.8

84.0 28.9

86.0 30.0

88.0 31.1

90.0 32.2

92.0 33.3

94.0 34.4

96.0 35.6

98.0

100.0 37.8

102.0 38.9

104.0 40.0

106.0 41.1

108.0 42.2

110.0 43.3

112.0 44.4

114.0 45.6

116.0 46.7

118.0 47.8

120.0 48.9

122.0 50.0

124.0 51.1

126.0 52.2

128.0 53.3

130.0 54.4

36.7

5.16

5.43

5.72

6.01

6.32

6.64

6.98

7.33

7.69

8.06

8.45

8.86

9.28

9.72

10.17

10.64

11.13

11.63

12.15

12.69

13.25

13.83

14.43

15.05

15.69

16.34

17.03

17.73

18.46

19.20

19.98

20.77

21.59

22.44

23.31

24.21

25.13

26.08

27.06

28.07

29.10

30.17

31.26

32.39

33.54

34.73

35.95

37.20

38.48

39.80

41.16

42.54

43.97

45.42

46.92

48.45

–9.54

–9.27

–8.98

–8.69

–8.38

–8.06

–7.72

–7.37

–7.01

–6.64

–6.25

–5.8

–5.42

–4.98

–4.53

–4.06

–3.57

–3.07

–2.55

–2.01

–1.45

–0.87

–0.27

0.35

0.99

1.64

2.33

3.03

3.76

4.50

5.28

6.07

6.89

7.74

8.61

9.51

10.43

11.38

12.36

13.37

14.40

15.47

16.56

17.69

18.84

20.03

21.25

22.50

23.78

25.10

26.46

27.84

29.27

30.72

32.22

33.75

–19.4 –65.8 35.6 493.5 65

–18.9 –63.9 37.4 479.4 63

–18.3 –61.9 39.4 464.6 61

–17.7 –59.9 41.5 449.3 59

–17.1 –57.8 43.6 433.3 57

–16.4 –55.6 45.8 416.7 55

–15.7 –53.2 48.1 399.3 53

–15.0 –50.8 50.5 381.3 50

–14.3 –48.3 53.0 362.6 48

–13.5 –45.8 55.6 343.2 45

–12.7 –43.1 58.3 323.0 42

4

–11.9 –40.3 61.1 302.0 40

–11.0 –37.4 64.0 280.2 37

–10.1 –34.3 67.0 257.6 34

–9.2 –31.2 70.1 234.2 31

–8.3 –28.0 73.4 209.9 28

–7.3 –24.6 76.7 184.8 24

–6.2 –21.2 80.2 158.7 21

–5.2 –17.6 83.8 131.7 17

–4.1 –13.887.5 103.8 14

–2.9 –10.0 91.4 74.9 10

–1.8 –6.0 95.4 45.0 6

–0.6 –1.9 99.5 14.0 2

0.7 2.4 103.7 — —

2.0 6.8 108.1 — —

3.3 11.3 112.7 — —

4.7 16.0 117.4 — —

6.2 20.9 122.2 — —

7.6 25.9 127.2 — —

9.2 31.1 132.4 — —

10.7 36.4 137.7 — —

12.4 41.9 143.2 — —

14.0 47.5 148.9 — —

15.8 53.4 154.7 — —

17.5 59.4 160.7 — —

19.4 65.6 166.9 — —

21.2 71.9 173.3 — —

23.2 78.5 179.8 ——

25.2 85.2 186.6 — —

27.2 92.2 193.5 — —

29.3 99.3 200.7 — —

31.5 106.7 208.0 — —

33.7 114.2 215.5 — —

36.0 122.0 223.3 — —

38.4 129.9 231.3 — —

40.8 138.1 239.5 — —

43.3 146.5 247.9 — —

45.8 155.1 256.5 — —

48.4 164.0 265.3 — —

51.1 173.1 274.4 — —

53.9 182.4 283.8 ——

56.7 192.0 293.3 — —

59.6 201.8 303.1 — —

62.6 211.8 313.2 — —

65.6 222.1 323.5 — —

68.7 232.7 334.1 — —

19

Page 20

Check the Installation

Use the following instructions to verify the condition of the

installation. Note that the contractor should not apply power

to the chiller before the Carrier Start-up Technician arrives at

the job site.

1. Inspect the water piping to the chiller to confirm it is correct. Confirm it is adequately supported from the chiller

and there are isolation valves installed.

2. Turn off, lock out, and tag the input power to the drive.

3. Wait a minimum of 5 minutes for the DC bus to discharge.

4. All wiring should be installed in conformance with the

applicable local, national, and international codes (e.g.,

NEC/CSA).

5. Remove any debris, such as metal shavings, from the

enclosure.

6. Check that there is adequate clearance around the

machine.

7. Verify that the wiring to the terminal strip and the power

terminals is correct and that no external voltage potential

is connected to any of the inputs.

8. Verify that all of the VFD power module circuit board connectors are fully engaged and taped in place.

9. Check that the field-installed wire size is within terminal

specifications and that the wires are tightened properly and

adequately supported.

10. Check that specified branch circuit protection is installed

and correctly rated.

11. Check that the incoming power is within ±10% of chiller

nameplate voltage.

12. Verify that a properly sized ground wire is installed and a

suitable earth ground is used. Check for and eliminate any

grounds between the power leads. Verify that all ground

leads are unbroken to the power supply. Only a wye secondary power supply transformer with solidly grounded

neutral is acceptable as a power supply to this chiller. If a

ground wire is not present or the transformer secondary is

any other type than a wye with solidly grounded delta,

please contact the Technical Service Manager or Service

Engineering.

Inspect Wiring

WARNING

Do not check the voltage supply without proper equipment

and precautions. Serious personal injury may result. Follow

power company recommendations.

CAUTION

Do not apply any kind of test voltage, even for a rotation

check, if the chiller is under a dehydration vacuum. Insulation breakdown and serious damage may result.

WARNING

Do not apply power unless a qualified Carrier technician is

present. Serious personal injury may result.

1. Examine the wiring for conformance to the job wiring diagrams and all applicable electrical codes.

2. Ensure that the VFD is protected by fused disconnects or

circuit breakers as per electrical code.

3. Compare the ampere rating on the VFD nameplate to rating on the compressor nameplate.

4. Check that there is adequate service clearance around the

machine.

5. Check that specified branch circuit protection is installed

and correctly rated.

6. Ensure there is capability to turn off, lock out, and tag the

input power to the drive.

7. If power is applied to the drive then wait a minimum of

5 minutes for the DC bus to discharge and check DC bus

voltage prior to starting any work.

8. Inspect the control panels and VFD enclosure to ensure