Carnes PDBB User Manual

Specification Sheet

Model PDBB

Extruded Aluminum Drainable Blade Penthouse

CARNES COMPANY 448 S. Main St., P. O. Box 930040, Verona, WI 53593-0040 Phone: (608)845-6411 Fax: (608)845-6470 www.carnes.com

COPYRIGHT © 2010 CARNES COMPANY

ALL RIGHTS RESERVED

SUPERCEDES 17142 17142-A, pg 1

Tag Qty.

Size

Variations

Width Length Height

Project Location

Arch./Engr. Contractor

Representative Date

Model PDBB

Standard Specifications

Blades: 6063-T6 extruded aluminum with .081” (2.1mm) thickness. All units incorporate hidden mullions at 60” (1219mm)

centers for blade support.

Roof: Fabricated at .050” (1.3mm) thickness 3003-H14 formed

aluminum, roof is secured with sheet metal screws for ease in

removal. Models with pitched roofs have a 1” in 12” or 3” in 12”

(25.4mm in 305mm or 76mm in 305mm) pitch.

Internal Framing: 1-1/2” x 1-1/2” x 1/8” (38mm x 38mm) framing angles of 6063-T6 extruded aluminum on 48” (1219mm)

maximum centers.

Screen: 3/4” x .051” flattened aluminum bird screen

Finish: all aluminum mill finish for low maintenance and resist-

ance to corrosion.

Sizing: Order size is actual throat dimensions. Throat is

undercut 1/4” (6 mm) in both “A” and “B” dimensions for installation allowance.

Maximum: 72”w x 220”L x 80”h (1829mm x 5588mm x

2032mm) Unlimited size with multiple section assembly.

Minimum: 12”w x 12”L x 10”h (305mm x 305mm x 267mm)

Options (at additional cost)

- Filter Racks

- Security Bars

- Hinged Roof

- Duct Liner

- Curb Cap

- Variety of Screens

- Selection of finishes; prime coat, kynar, baked enamel, clear

and color anodize, epoxy and heresite.

Consult Carnes for other special requirements.

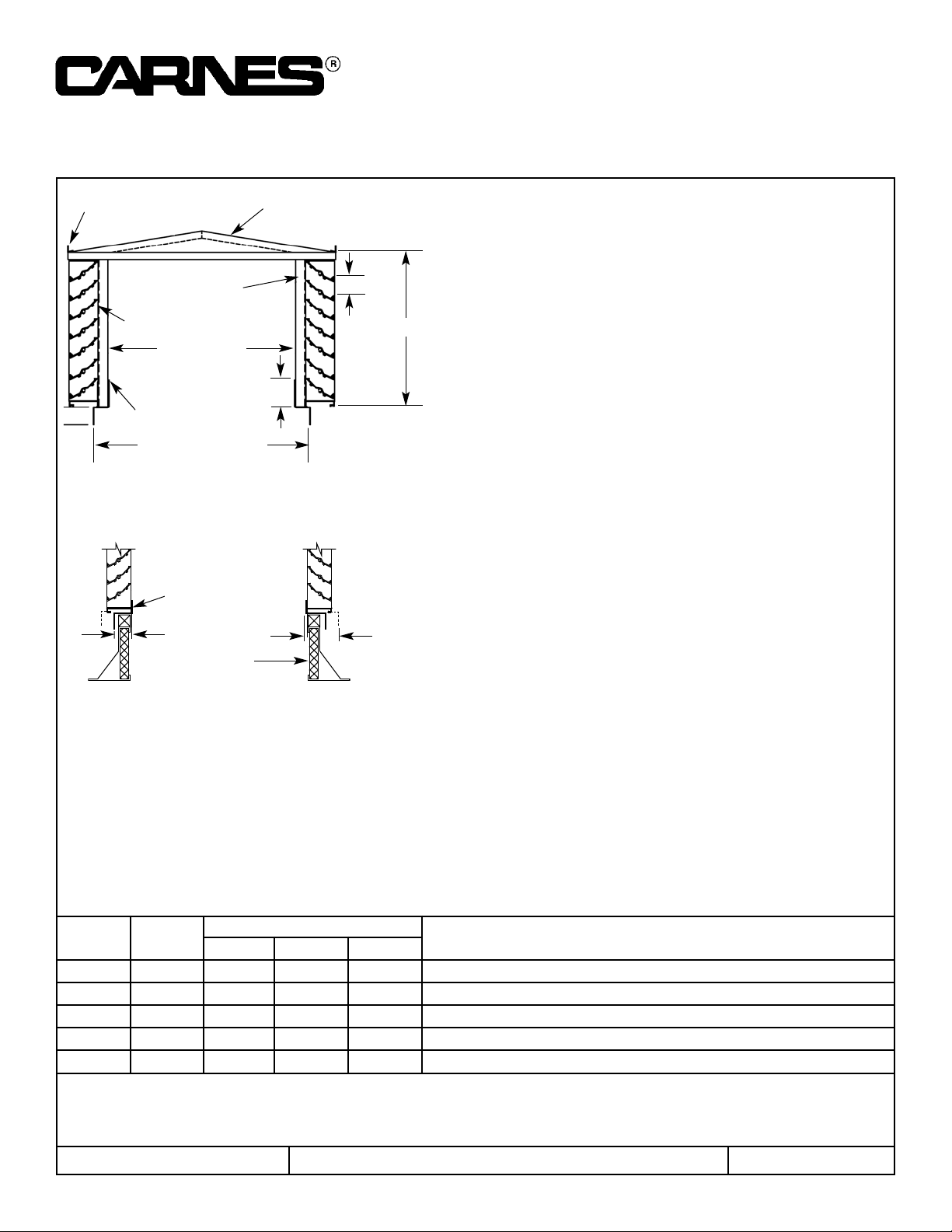

Standard Curb Cap Installation

Roof

Curb

Curb Cap

Special

curb cap

dimension

2-3/4”

(std.)

Curb Cap I.D.

(Throat Dim. + 4-1/2”, std.)

3”

2”

C

Water Diverter

Pitched Roof

Option Shown

1-1/2”

Internal Support

Structure

Screen

2.879”

typ. blade

spacing

Internal Sill/Water Catch

Throat Dimension

A x B

A and B dimensions approximately 1/4” under listed size.

17142-A, pg 2

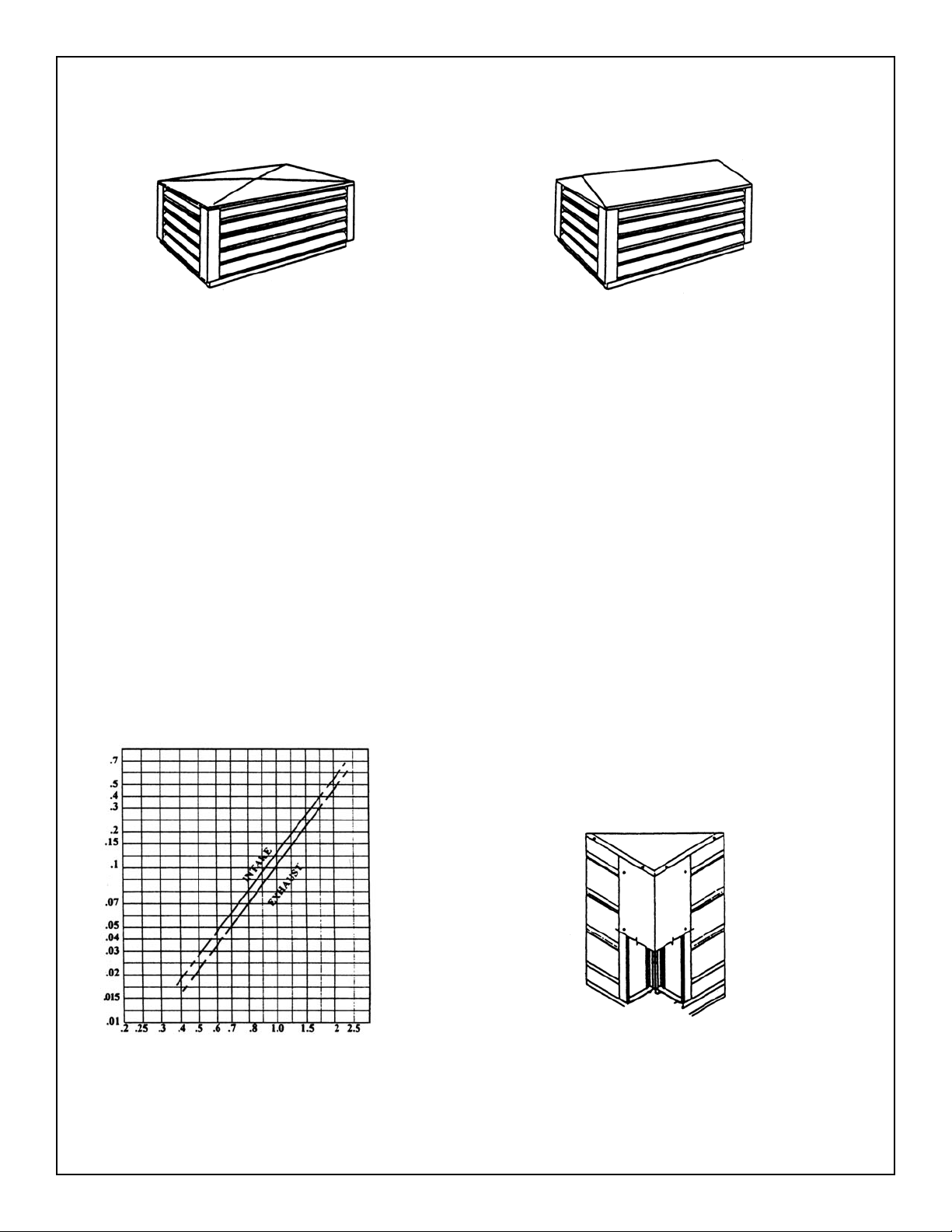

Flat roofs are cross broke for adequate element

run off. Roofs are supported by angle bracing

which prevents oil canning. When size requires the

unit be sectioned, it is joined with a standing seam

to prevent leakage. This style of roof is available

on units up to 72” on the shortest dimension only,

larger units must incorporate a pitched style roof.

Pitched roofs (pitched on short width) are supported with a superior truss system which not only

create the structural integrity comparable to that of

a building, but eliminates the rolling sound of wind

across the roof. Trusses are placed at a maximum

24” centers and anchored to the internal frame of

the structure. When size requires the unit be sectioned, it is joined with a standing seam to prevent

leakage.

Flat

Pitched

Performance Data

AMCA Standard 500 provides a reasonable basis for testing and

rating louvers. Testing to AMCA 500 is performed under a certain

set of laboratory conditions. This does not guarantee that other

conditions will not occur in the actual environment where louvers

must operate.

The louver system should be designed with a reasonable safety

factor for louver performance. To ensure protection from water carryover, design with a performance level somewhat below maximum

desired pressure drop and .01 oz./sq.ft. of water penetration.

Corner Style Selection

Drainable units available in post corner only.

Independent louver panels (sides) are built and

mounted to the internal framing with corner covers

installed.

Beginning point of WATER PENETRATION lies

above 1250 fpm the maximum recommended

FREE AREA VELOCITY

Pressure Drop

Static Pressure Drop (inches w.g.)

FREE AREA VELOCITY (FT/MIN)

Standard air - .075 lbs per cu ft

Ratings do not include the effects of a wire bird screen

Test based on a 48” x 48” test size, 15 min test duration

Roof Style Selection

Loading...

Loading...