Carnes LYDK Installation Manual

RECEIVING, HANDLING AND STORAGE

1. Handle the fan with care. Avoid severe jarring or dropping of the unit.

2. Carefully inspect the unit for damage upon delivery. If the unit has been damaged in transit it is the responsibility of

the recipient to make all claims against the carrier.

3. Provide adequate, protected storage prior to installation. Upon unpacking, inspect the unit for any damage that

may have occurred in transit and check for loose or missing parts.

INSTALLATION

1. Upon unpacking, inspect the unit for any damage that may have occurred in transit. Check also for loose or

missing parts.

2. This fan is designed and manufactured for either supply or exhaust application. Fans cannot be reversed in the

field to provide airflow other than as designed.

3. CAUTION! This fan contains rotating parts and requires electrical service. Appropriate safety precautions should

be taken during installation, operation and maintenance.

4. WARNING! Do not install or operate this fan in environment or atmosphere where combustible or flammable

materials, gasses or fumes are present, unless it has specifically designed and manufactured for use in that

environment. Explosion or Fire could result!

5. This ventilator is designed to be mounted in a wall or other building opening.

6. A damper, if used, should be securely mounted within the ductwork or opening in a manner which allows free and

unobstructed operation. Allow a minimum of 8” of clearance from between the fan and damper.

7. CAUTION! All electrical work must be done in accordance with local and/or national electrical code as applicable.

If you are unfamiliar with methods of installing electrical wiring, secure the services of a qualified electrician.

8. WARNING! This product must be grounded.

9. DANGER! Make sure power is turned off and locked in the OFF position at the service entrance before installing,

wiring or servicing fan.

10. CAUTION! Before wiring the motor, check the supply voltage against the motor nameplate voltage. High or low

voltage can damage the motor and void the motor warranty.

11. WARNING! Be sure to keep all wiring clear of rotating or moving parts.

12. WARNING! Before starting the fan, turn the propeller to assure it rotates freely. If needed, adjust the

propeller/shaft/bearing/motor position as required to achieve necessary clearances.

13. WARNING! Check all set screws and keys. Tighten as necessary prior to fan startup.

14. Anchor the fan securely to the opening. Use a minimum of four lag bolts or other suitable fasteners.

OPERATION

1. CAUTION! Assure the fan inlet/ductwork/exhaust openings are clean and free of obstructions.

2. WARNING! This fan contains rotating parts. Appropriate safety precautions should be taken during operation.

3. Operate under power and check for correct rotation direction.

4. CAUTION! Incorrect rotation can damage the fan motor.

Form 1416-B, Page 1

CARNES COMPANY, 448 S. Main St., P. O. Box 930040, Verona, WI. 53593-0040 Phone: 608/845-6411 Fax: 608/845-6504 carnes@carnes.com www.carnes.com

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

DIRECT DRIVE PROPELLER WALL FANS

MODELS LYDK (Exhaust) and LZDK (Supply)

CAUTION!

DO NOT INSTALL, USE OR OPERATE THIS EQUIPMENT UNTIL THIS MANUAL HAD BEEN READ

AND UNDERSTOOD. READ AND SAVE THESE SHEETS FOR FUTURE USE.

FORM 1416-B

MAINTENANCE

1. DANGER! Before performing any maintenance on the fan, be sure power is turned off and locked in the OFF

position at the service entrance before servicing the fan.

2. Ventilators should be carefully checked at least once a year. For critical or rugged applications, a routine check

every two or three months is suggested.

3. All motors supplied with CARNES ventilators carry a one year warranty from date of shipment. For repairs within

the warranty period, the motor must be taken to the motor manufacturer’s authorized service dealer. Contact your

CARNES representative for additional warranty details.

4. A periodic motor check should consist of spinning the motor shaft with the power off to be sure the motor turns

freely.

5. The propeller should not require maintenance except for removing foreign materials that may accumulate on the

blades. The balance weights should not be disturbed. If a propeller has to be removed from the shaft, do not apply

force that will damage the bearing or warp the propeller. Use a wheel puller.

2

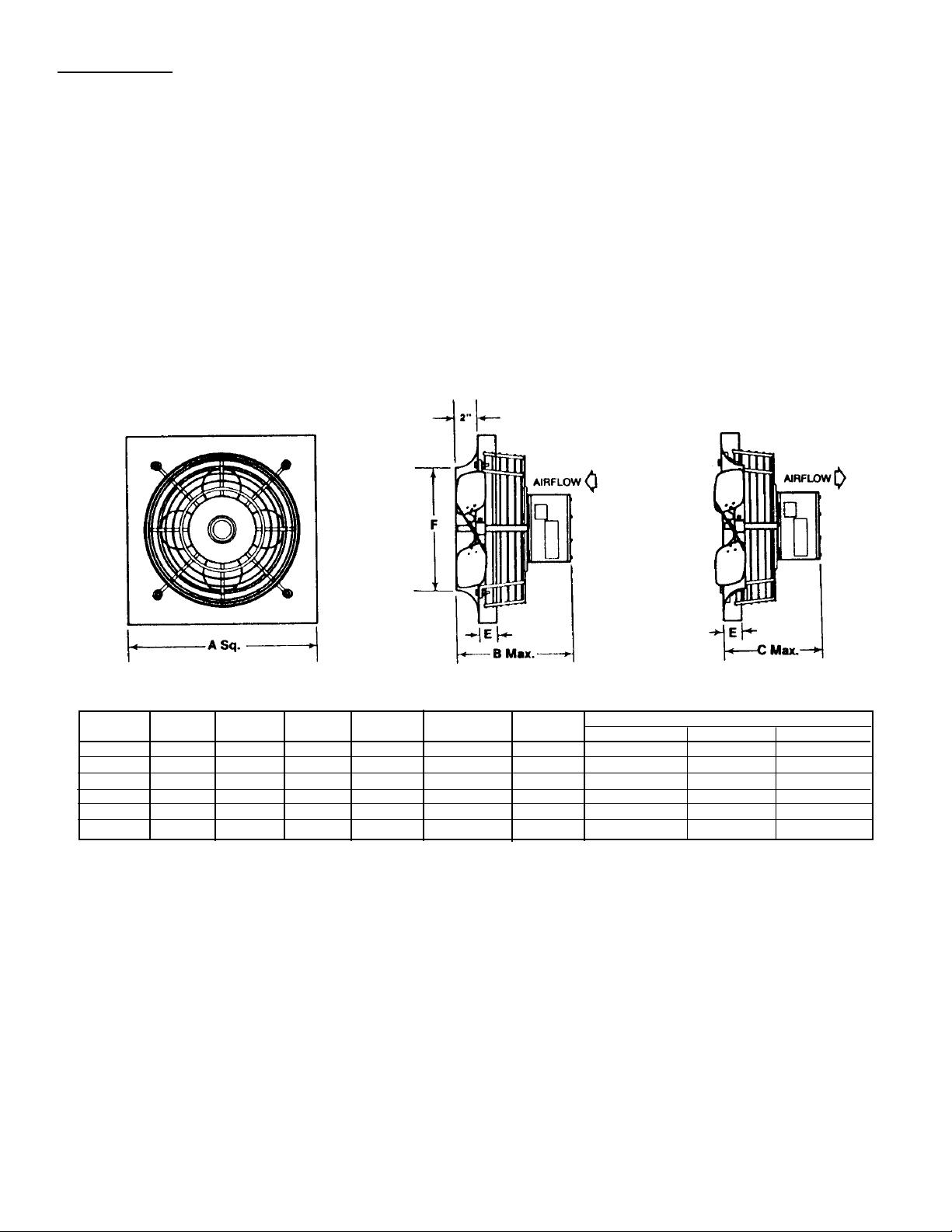

DIMENSIONS (Listed In Inches)

Fan A Weight Material Thickness

Size SQ. B C E F (LBS.) Panel/Venturi Wire Guard MotorSupport

9-10 16 11 10 1-1/2 10-1/4 20 16 ga. 12 ga. 1/4 in.

11-12 16 11 10 1-1/2 12-1/4 20 16 ga. 12 ga. 1/4 in.

13 20 12 11 1-1/2 14-1/4 25 16 ga. 12 ga. 1/4 in.

15-16 20 13 12 1-1/2 16-1/4 30 16 ga. 12 ga. 1/4 in.

17-18 24 13 12 1-1/2 18-1/4 35 16 ga. 12 ga. 1/4 in.

19-21 24 13 12 1-1/2 20-1/4 40 16 ga. 12 ga. 1/4 in.

MODEL LYDK

EXHAUST

MODEL LZDK

SUPPLY

DIRECT DRIVE WITH INTEGRAL MOTORSIDE GUARD - MEETS OSHA REQUIREMENTS.

ONE PIECE FAN PANEL/VENTURI WITH PREPUNCHED MOUNTING HOLES.

PANEL MATERIAL - GALVANEALED STEEL WITH ELECTROCOAT BAKED ENAMEL (GREY).

OSHA MOTORSIDE GUARD - WELDED STEEL WIRE, FINISH TO MATCH PANEL.

MOTORS - 115/1/60 ODP SPEED CONTROLABLE - PERMANENT SPLIT CAPACITOR.

NEOPRENE VIBRATION MOUNTS BETWEEN MOTOR MOUNTS AND FAN PANEL.

PROPELLER STATICALLY AND DYNAMICALLY BALANCED.

ALUMINUM 3 OR 4 BLADE PROPELLER WITH STEEL HUB AND SET SCREWS.

MOTORS FACTORY WIRED TO CONDUIT/WIRING BOX.

PANEL FLANGES TURNED TO THE MOTORSIDE (BOTH EXHAUST & SUPPLY) FOR EASY MOUNTING.

CONDUIT KNOCKOUT IN FAN PANEL FOR FIELD WIRING MOTORIZED DAMPER.

FACTORY RUN-TEST FOR DEPENDABLE OPERATION.

STANDARD SPECIFICATIONS AND CONSTRUCTION

Loading...

Loading...