Carnes LABA Installation Manual

INSTALLATION, OPERATION, & MAINTENANCE

WALL MOUNTED PROPELLER FANS

BELT AND DIRECT DRIVE

Models LW/LM, LA/LC, LR/LN, LJ/LK

FORM 1426-A

CARNES COMPANY, 448 S. Main St., P. O. Box 930040, Verona, WI.53593-0040 Phone: 608/845-6411 Fax: 608/845-6470 car nes@car nes.com www.carnes.com

INTRODUCTION

This manual is to be used to aid in the proper installation, operation, and maintenance of the above Carnes fans. This

information is meant to serve as a general guide. Due to the variety and complexity of many installations it is the

responsibility of the purchaser to assure that these procedures are handled by qualified personnel.

GENERAL CAUTIONS

1. Installation of this fan requires experienced personnel with knowledge of structural strength, mechanical setup

and electrical wiring. Do not attempt installation without qualified personnel.

2. Do not operate this fan in an environment or atmosphere where combustible or flammable materials, gasses or

fumes are present unless it has been specifically designed and manufactured for use in that environment.

MECHANICAL INSTALLATION CAUTIONS

1. Turn the propeller by hand to check clearances. If needed, adjust the bearing or motor position to center the

propeller.

2. On belt drive units, check that belts are aligned and tensioned properly (see Maintenance section.)

3. Check that set screws are tight and shaft keys are in place.

ELECTRICAL INSTALLATION CAUTIONS

1. Be sure the supply voltage matches the motor plate voltage. On dual voltage motors, check the motor wiring to

determine the voltage.

2. Fans must be grounded.

3. Keep all wiring clear of rotating components and moving parts such as powered or gravity dampers.

4. Make sure power is locked OFF at the service entrance before wiring or otherwise approaching the fan.

5. Electrical work must be done in accordance with local and/or national electrical code by a qualified electrician.

INSTALLATION

1. This fan is designed to be mounted in a wall or other building opening.

2. This fan is either built for supply or exhaust application. Refer to the Model Number or dimensional drawings

in this manual if there is any question.

3. Any optional dampers should be mounted to allow free and unobstructed operation. Allow a minimum of 8”

clearance between the fan and damper.

4. Anchor the fan or fan structure securely to the wall, this will usually require lag bolts. Use all of the provided

mounting holes.

5. Refer to drawings on page 6 for standard installation.

START-UP

1. Operate the fan briefly to check for proper rotation direction. Incorrect fan rotation will over heat the fan motor.

2. Check the operation of any dampers. Be sure they can open and close fully.

3. During the first few hours of operation, periodically check the fan for smooth operation.

4. After the first few hours of operation, shut the fan down and lock the power OFF. Check sheave and propeller set

screws for tightness. On belt drive units, check the belt tension (see Maintenance section.)

FORM 1426-A, Page 1

MECHANICAL AND ELECTRICAL START-UP CAUTION

Be sure the Inlet, Outlet and ductwork are open and free of loose objects

MAINTENANCE CAUTIONS

1. Before performing any maintenance on the fan, be sure power is locked OFF at the service entrance.

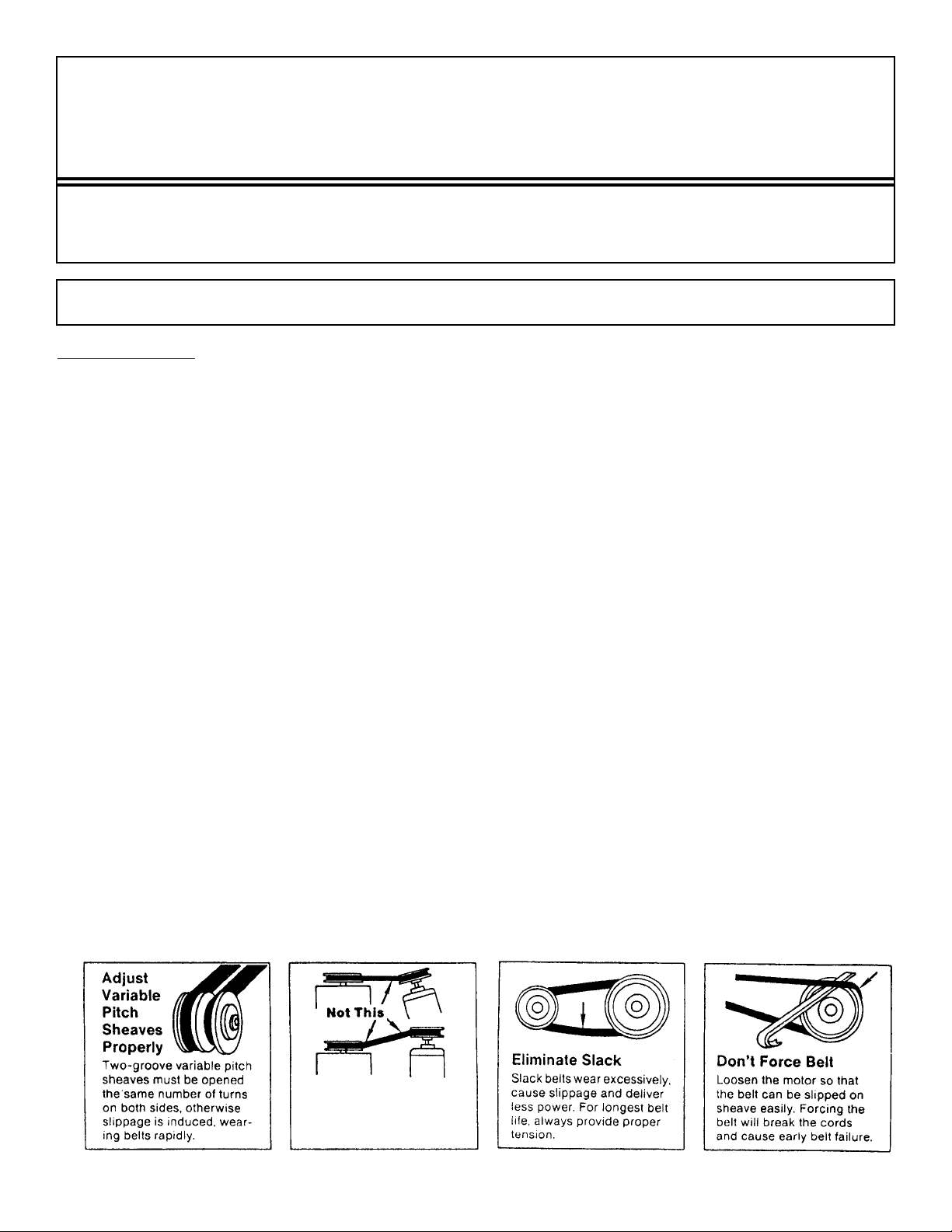

2. When removing or installing a belt,

do not

force the belt over the sheave. Loosen the motor mount bolts so the

belt can be easily slipped over the sheave.

3. Do not readjust blade pitch or fan rpm. If sheaves are replaced

use only

identical size and type.

All motors supplied with Carnes fans carry a one year warranty from the date of shipment. For repairs within warranty

period, the motor must be taken to the motor manufacturer’s authorized ser vice dealer. Contact your Carnes

Representative for additional warranty details.

If a belt driven fan is to be left idle for an extended period (especially over summer months), it is recommended that the

belt(s) be removed and stored in a cool, dry place to avoid premature belt failure.

MAINTENANCE

All fans must be carefully checked

at least

once a year. For critical or rugged applications, a check

should be done

every 2 or 3 months. Lock power OFF before performing any maintenance.

1. A motor check consists of spinning the motor shaft with the power locked OFF to be sure the motor

turns freely and the bearings run smoothly. On belt drive units the belt must be removed.

2. The belt on belt driven units should be checked for cracks, ply separation or irregular wear. Problems in the belt

will result in noisy operation. If the belt has any of these defects it should be replaced.

3. Check the sheaves for any chipping, dents or rough surfaces which could damage the belt.

4. The belt alignment should be checked to make sure the belt is running squarely on the sheaves. Motor shaft and

fan shaft must be parallel.Improper alignment will result in excessive belt wear.

5. Check sheave set screws for tightness. Proper locking keys must be in keyways.

6. Check propeller set screws for tightness. Proper locking keys must be in key ways.

7. Check fan shaft bearings:

All units -

Check the shaft set screws for tightness. Check the bearing mounting bolts for tightness.

Smaller units -

Bearings are permanently lubricated and sealed at the factory.

Larger units (with grease fittings)-

Bearings are factory lubricated and require relubrication annually or more frequently if

operated under dirty, damp or high temperature conditions.

Use #2 lithium grease or equivalent.

Use a hand operated grease gun and give each bearing 1 or 2 pumps.

8. Check belt tension. Belt should not feel tight. A ver y slight squeal on fan startup is OK.

2

Mount Belts Straight

Shafts must be parallel and

sheaves in alignment to prevent rapid belt wear.

Loading...

Loading...