Carnes L1 Installation Manual

CARNES COMPANY, VERONA, WISCONSIN

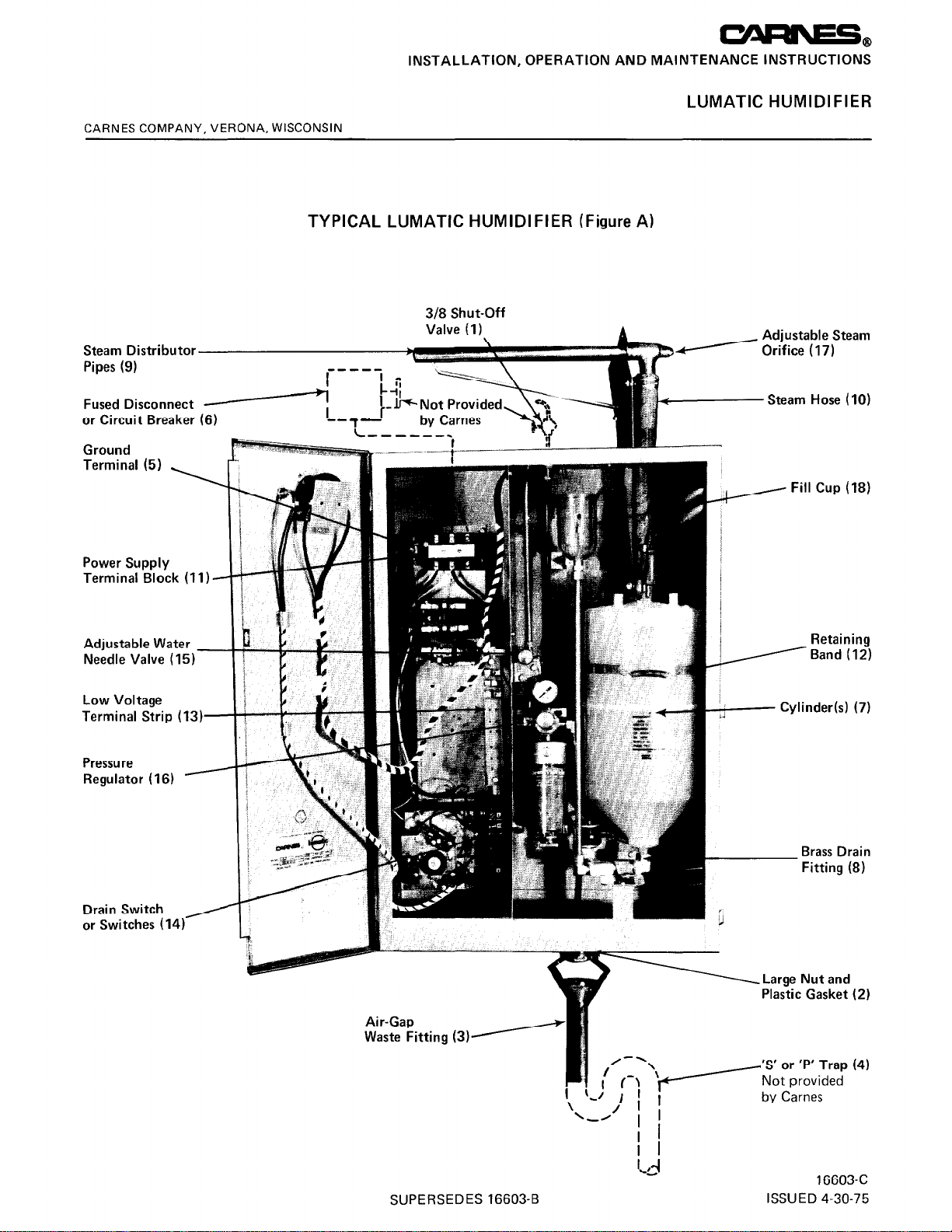

TYPICAL LUMATIC HUMIDIFIER (Figure A)

Steam Distributor

Pipes (9)

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

LUMATIC HUMIDIFIER

318 Shut-Off

Valve (I)

/ Orifice (17)

rr”,usrault: aLedill

Fused Disconnect

or Circuit Breaker (6)

Ground

Terminal (5)

Power Supply

Terminal Block (11)

Adjustable Water _

Needle Valve (15)

Low Voltage

Terminal Strip (13)-

Pressure

Regulator (16) -

Steam Hose (101

Fill Cup (18)

Retaining

/Band (12)

- Cylinder(s) (7)

Drain Switch

or Switches (14)

Brass Drain

Fitting (8)

/

Large Nut and

Plastic Gasket (2)

Air-Gap

Waste Fitting (3)

16603-C

SUPERSEDES 16603-B

ISSUED 4-30-75

INSTALLATION

UNPACKING AND INSPECTION

1. A manilla envelope attached to the outside of the

Lumatic cabinet contains the following items:

A. Two cabinet keys

B. Wiring Diagram - Form 16602

C. Parts List - Form 16623

D. Installation instructions - Form 16663

E. Cable ties for hoses

2. Unlock the cabinet and check for concealed shipping

damage. Report any damage immediately to the carrier

who delivered the shipment.

3. The following components are packed in the shipping

carton for connection when installing the Lumatic:

A. Distributor pipe(s).

B. Cylinder(s). The cylinders packed within the Lumatic

cabinet are upside down to prevent shipping damage.

C. Air-gap waste fitting.

D. Steam hose (Total number of feet for all circuits).

E. Condensate return line (Total number of feet for

all circuits).

4. Table 1 indicates the number of components supplied

with each Lumatic. Optional accessories (e.g., humidistats, standpipe, etc.) may be packed with the cabinet

or in the same shipping carton. Large accessories may

ship in separate cartons.

Table 1 - Lumatic Components

Model

Number Catnet

Ll & L4 1

I

L2 & L5 1

L3 & L6 3

Cylinders

2

Spare

Cylinders

Distributor AkaG:F

Pipes

1

2 2 1

3 3 1

1 1

Fitting

I

5. Inside the cabinet are the following items:

A. Pipe dope.

B. Steam hose clamps (two per circuit)

C. Condensate return line clamps (one per circuit).

D. One key for resetting drain cycle timer.

E. Distributor pipe mounting template (one for each

distributor pipe).

MOUNTING THE LUMATIC

Mount the Lumatic cabinet level and plumb on a surface

near the ductwork, and 16” or more below the point at

which thedistributor pipe(s) will be installed. An accessory

mounting frame may be used if surface is not plumb or

studding is uneven. Allow 6” or more on each side for

proper ventilation and a minimum of 16” from bottom

to the floor to allow for drain connection. (See Figure B

below)

---_

I

I

7 DUCT

16” MIN.

WATER SUPPLY CONNECTION

Use only ordinary tap water - DO NOT use hot or de-

ionized water. A 3/8” female FPT fitting is provided

at the top of the Lumatic to connect to the tap water

supply. A shut-off valve, not provided by Carnes, should

be provided just ahead of this fitting.

DRAIN LINE CONNECTION

Refer to Figure A

Remove the large nut and plastic gasket located on the

fitting on the bottom of the cabinet (2). The nut and

gasket may be used with standard type waste fitting if

an air-gap waste fitting is not required by local codes.

If required, connect the air-gap waste fitting (31 to the

cabinet drain connection. Drop plastic insert into the

top of the air-gap waste fitting before connecting. It

may be necessary to cut off some of the air-gap fitting

depending on the available space.

Connect the drain or air gap fitting to an S or P trap

(41. Note: If the condensate pump accessory package

is used, follow instructions included with the condensate pump package.

INSTALLATIONS OF CYLINDER(S)

Refer to Figure A

POWER MUST BE OFF BEFORE MAKING ANY

ELECTRICAL CONNECTIONS.

1. Lumatic cylinder(s), (7) contained in the cabinet are

shipped upside down to prevent shipping damage. Re-

move cylinder(s) and remove plastic protective caps on

both ends of the cylinder.

2. Remove plastic plug from the brass drain fitting (8)

I

located on the bottom of the Lumatic cabinet.

3. Apply pipe dope to threads on neck at the bottom of

the cylinder.

4. Screw cylinder into fitting (8) - hand tighten only.

5. Connect retaining band (72) to secure cylinder in place.

6. Connect electrical quick connect terminals to cylinder

terminals. Push them on securely (they are not

threaded).

INSTALL STEAM DISTRIBUTOR PIPE(S)

Refer to Figure A

1. Steam distributor plate must be mounted on a plumb

surface. When mounted on a plumb surface, the standard distributor pipe pitches downward. This is required so the condensate which forms in the distributor pipe will drain to the return line and back to the

unit.

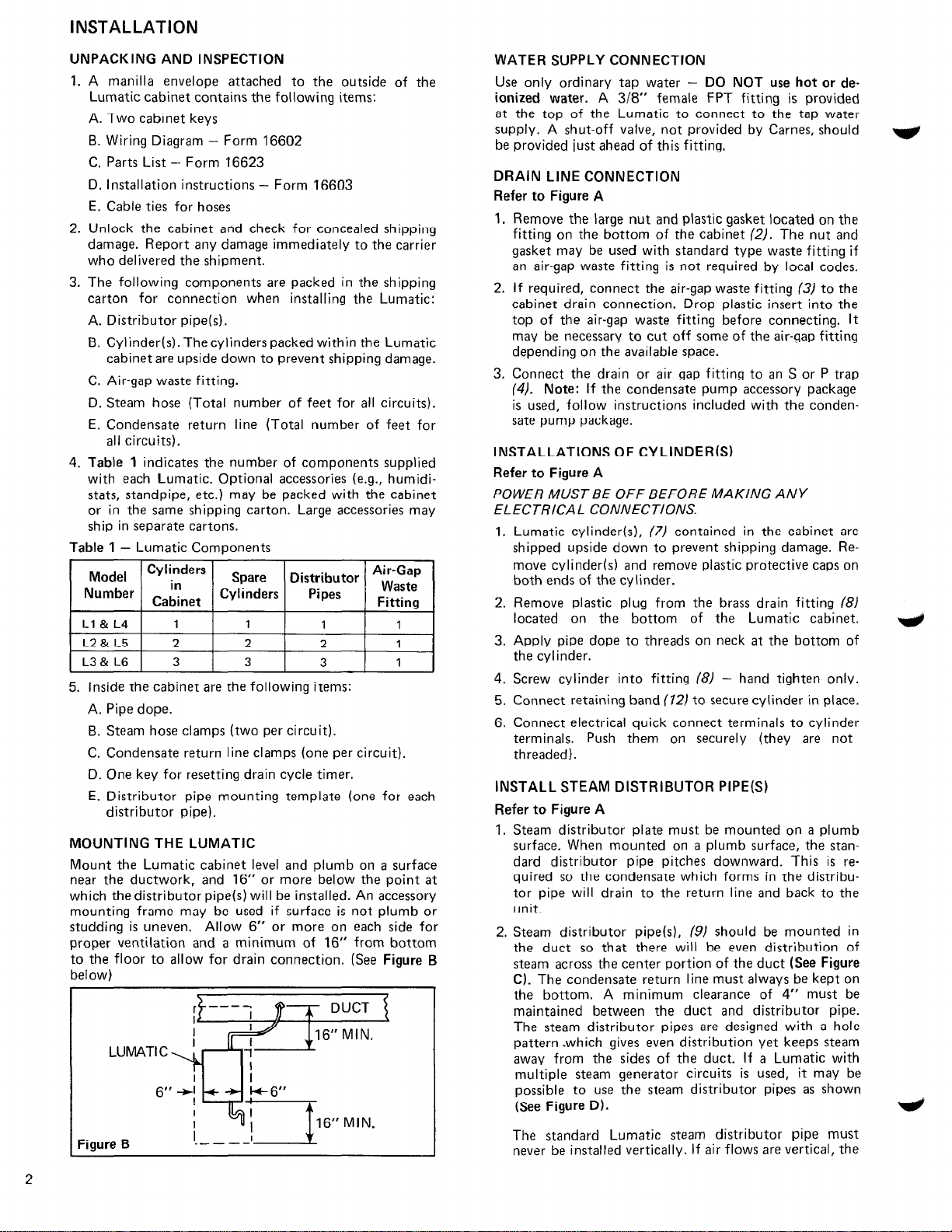

2. Steam distributor pipe(s), 191 should be mounted in

the duct so that there will be even distribution of

steam across the center portion of the duct (See Figure

C). The condensate return line must always be kept on

the bottom. A minimum clearance of 4” must be

maintained between the duct and distributor pipe.

The steam distributor pipes are designed with a hole

pattern .which gives even distribution yet keeps steam

away from the sides of the duct. If a Lumatic with

multiple steam generator circuits is used, it may be

possible to use the steam distributor pipes as shown

(See Figure D).

Fiaure B

The standard Lumatic steam distributor pipe

never be installed vertically. If air flows are vertical, the

must

2

Figure C

3

Figure D

l-

1-48”-1

48”+

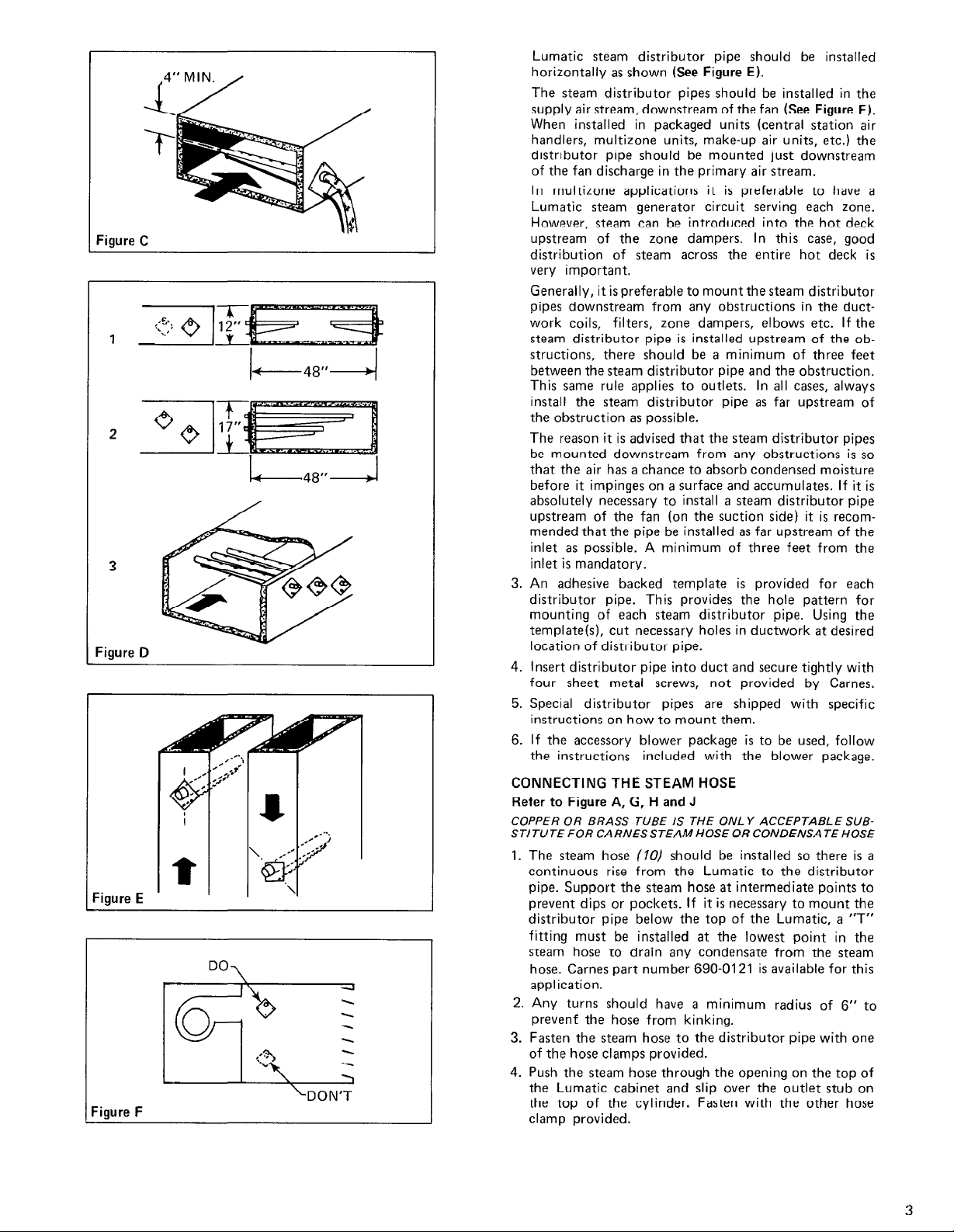

Lumatic steam distributor pipe should be installed

horizontally as shown (See Figure E).

The steam distributor pipes should be installed in the

supply air stream, downstream of the fan (See Figure F).

When installed in packaged units (central station air

handlers, multizone units, make-up air units, etc.) the

distributor pipe should be mounted just downstream

of the fan discharge in the primary air stream.

In multizone applications it is preferable to have a

Lumatic steam generator circuit serving each zone.

However, steam can be introduced into the hot deck

upstream of the zone dampers. In this case, good

distribution of steam across the entire hot deck is

very important.

Generally, it is preferable to mount the steam distributor

pipes downstream from any obstructions in the duct-

work coils, filters, zone dampers, elbows etc. If the

steam distributor pipe is installed upstream of the obstructions, there should be a minimum of three feet

between the steam distributor pipe and the obstruction.

This same rule applies to outlets. In all cases, always

install the steam distributor pipe as far upstream of

the obstruction as possible.

The reason it is advised that the steam distributor pipes

be mounted downstream from any obstructions is so

that the air has a chance to absorb condensed moisture

before it impinges on a surface and accumulates. If it is

absolutely necessary to install a steam distributor pipe

upstream of the fan (on the suction side) it is recommended that the pipe be installed as far upstream of the

inlet as possible. A minimum of three feet from the

inlet is mandatory.

3. An adhesive backed template is provided for each

distributor pipe. This provides the hole pattern for

mounting of each steam distributor pipe. Using the

template(s), cut necessary holes in ductwork at desired

location of distributor pipe.

4. Insert distributor pipe into duct and secure tightly with

four sheet metal screws, not provided by Carnes.

5. Special distributor pipes are shipped with specific

instructions on how to mount them.

6. If the accessory blower package is to be used, follow

the instructions included with the blower package.

Figure E

Figure F

\DON’T

CONNECTING THE STEAM HOSE

Refer to Figure A, G, H and J

COPPER OR BRASS TUBE IS THE ONLY ACCEPTABLE SUBST/TLJTEFORCARNESSTEAMHOSEORCOND&NSATEHOSE

1. The steam hose (70) should be installed so there is a

continuous rise from the Lumatic to the distributor

pipe. Support the steam hose at intermediate points to

prevent dips or pockets. If it is necessary to mount the

distributor pipe below the top of the Lumatic, a “T”

fitting must be installed at the lowest point in the

steam hose to drain any condensate from the steam

hose. Carnes part number 690-0121 is available for this

application.

2. Any turns should have a minimum radius of 6” to

prevent the hose from kinking.

3. Fasten the steam hose to the distributor pipe with one

of the hose clamps provided.

4. Push the steam hose through the opening on the top of

the Lumatic cabinet and slip over the outlet stub on

the top of the cylinder. Fasten with the other hose

clamp provided.

3

Loading...

Loading...