Carnes JDHAA Installation Manual

C-1

ACCESSORIES

Control Dampers - Galvanized

For All Models of Louvers and Penthouses

Model: FDNB Opposed Blade Control Damper, FDQB Parallel Blade Control Damper

Model FDNB

Standard Specifications

Ratings: Level II Rating

Frame: 16 gauge galvanized

Blades: 16 gauge galvanized

Bearings: bronze oilite

Linkage: concealed in frame

Axles: 1/2ӯ plated steel

Control Shaft: Ø1/2” x 6” long outboard support bearing sup-

plied with all single section dampers for field mounted actuators.

Factory-installed jackshaft supplied with all multiple section

dampers.

Maximum Panel Size: 52”w x 72”h (single section)

Maximum assembled multi-section: 72”w x 42”h

Minimum Panel Size: 5”w x 4”h

8”h and under - single blade

Options

• Blade Seals PVC (175°F)

• Compression Jamb Seals (stainless steel)

• Header Plates (end flange)

• Hand Quadrant

• Factory Installed Actuators

• Position Switch

• Face and By-pass Damper

• Chain Operator

• Single Flange

• Double Flange

• Bolt Holes in Flange

• Stainless Steel (epoxy coated linkage)

(must have 6-1/2” deep frame)

• 304 Stainless Steel Construction

• 6-1/2” deep Frame

• 1” Insulated Double Skin Blades

• Heresite Coated (air dry)

• Epoxy Coated (powder coated)

W

H

4-1/2”

1” Insulated Blades

Optional

Double skin

1” insulated blades

Stainless steel

jamb seals

Vinyl blade seals

12” wide -3500 FPM

24” -2800

36” -2300

48” -2100

52” -2300

FPM Table

3 4 5 6 7 8 9 10111213

48”

(1219)

36”

(914)

24”

(610)

12”

(305)

Maximum Damper

Section Width

Maximum Design Total Static Pressure Inches Water Gage

Pressure Limitations

C-2

ACCESSORIES

Low Leakage Control Dampers - Aluminum

For All Models of Louvers and Penthouses

Model: FDCB Opposed Blade Control Damper, FDHB Parallel Blade Control Damper

Model FDCB

Standard Specifications

Frame: .081 extruded aluminum

Blades: .125 extruded aluminum

Bearings: bronze oilite

Linkage: *concealed in frame

Axles: 1/2ӯ cast zinc with thrust bushing

Control Shaft: 1/2” x 6” long outboard support bearing supplied

with all single section dampers for field mounted actuators.

Factory-installed jackshaft supplied with all multi-section

dampers.

Maximum Size: 52”w x 72”h (single section)

Multi-section unlimited.

Minimum Size: 5”w x 4”h. 8” and under single blade.

*Over 36” wide or 48” high, blade linkage will be modified.

Options

• .125 Extruded Aluminum Frame (box frame)

• 1-1/2” .125 Extruded Aluminum Flanged Frame

• Blade Seals PVC (175°F)

• Blade Seals Silicone (400°F & #304 stainless steel bushing)

• Compression Jamb Seals (stainless steel)

• Hand Quadrant

• Factory Installed Pneumatic or Electric Actuators

• Position Switch

• Face and By-pass Damper

• Chain Operator

• Heresite Coated (air dry)

• Epoxy Coated (powder coated at 415°)

• Explosion-proof Enclosure for Actuator

Size Tested: 36”w x 36”h

12” wide -2600 FPM

24” -2200

36” -2000

48” -1700

52” -1600

FPM Table

4-1/2”

6-1/4”

Undersized 1/4”

Jackshafting provided over 52” wide

Pressure - up to 3” w.g. See pressure limit table

0 2 3

48”

36”

24”

12”

Maximum Damper

Section Width

Maximum Design Total Static

Pressure Inches Water Gage

Pressure Limitations

C-3

ACCESSORIES

Low Leakage Control Dampers

Model: FDCB and FDHB

Damper

Width x Height

1 in. w.g. Class 4 in. w.g. Class 8 in. w.g. Class

36” x 36” 0.5 (Class 1A) 5.6 (Class 1A) 20.8 (Class 2)

Leakage Performance

Leakage - L/s/m² (FT³/min/ft²)

Note: At 1” w.g. damper leaks 0.5 cfm per square foot

AMCA Standards

Leakage Classification per AMCA publication 511-99

Leakage,

ft³/min/ft²

Required Rating Extended Ranges (optional)

Class

0.25 kPa (1”) 1.0 kPa (4”) 2.0 kPa (8”) 3.0 kPa (12”)

1A 15.2 (3) 40.6 (8) 55.9 (11) 71.1 (14)

1 20.3 (3) 40.6 (8) 55.9 (11) 71.1 (14)

2 50.8 (10) 102 (20) 142 (28) 178 (35)

3 203 (40) 406 (80) 569 (112) 711 (140)

Pressure

Test device setup with inlet chamber

Ratings shown are based on tests made in accordance with AMCA standard 500.

Free Area Velocity

ft/min (m/s)

Pressure drop

w.g. (PA)

CFM

392 (1.99) .005 (1.24) 3528

789 (4.01) .02 (4.97) 7100

1208 (6.14) .05 (12.42) 10,877

1598 (8.12) .09 (22.35) 14,382

2006 (10.19) .14 (34.77) 18,061

Pressure Drop

Static pressure drop (inches w.g.)

Free Area Velocity (ft/min)

Based on standard air - .075 lbs per cubic foot

FDCB, FDHB size tested: 36 x 36

Test device setup with inlet and outlet ducts

Blade and jamb seal options must be ordered to achieve leakage

rates listed above.

C-4

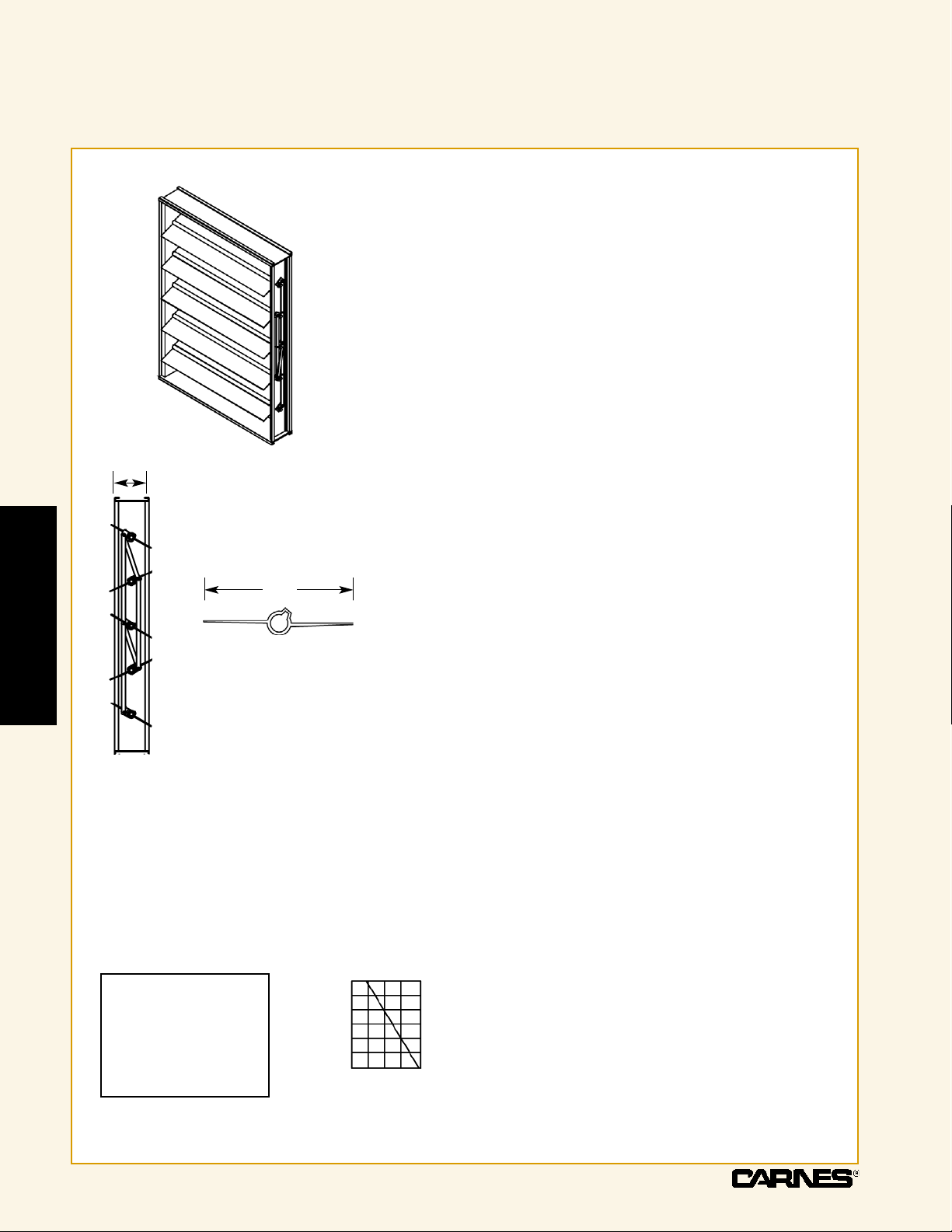

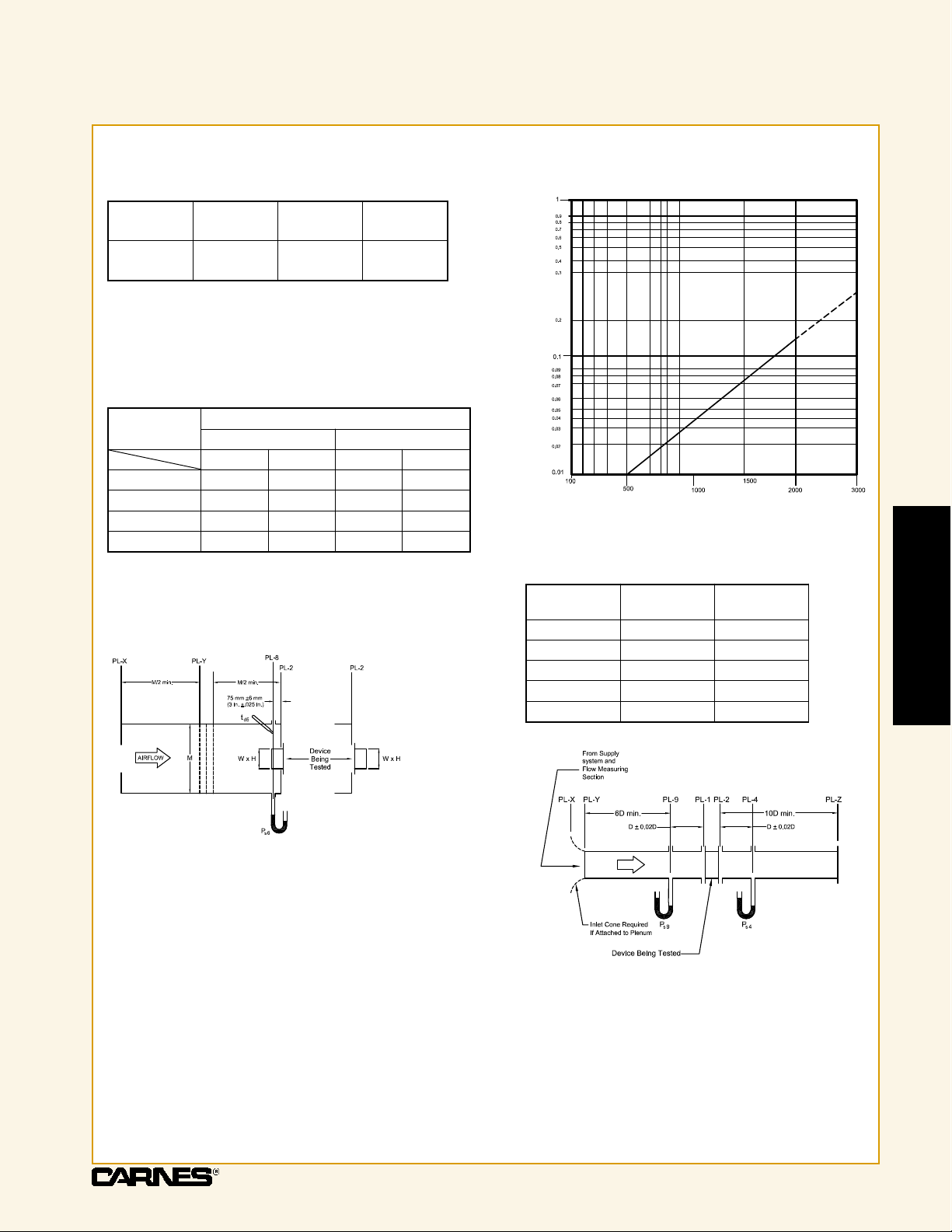

ACCESSORIES

Backdraft Dampers & Motorized Dampers

Horizontal or Vertical Exhaust Dampers; For All Models of Louvers and Penthouses

Model: JDHAA Automatic/Gravity, JDHAM Motorized, JDHAC Chain Operated

Standard Specifications

Frame: .036” (1.6mm) 6063T6 aluminum

Blades: 24 gauge aluminum with double stiffening breaks

Finish: mill aluminum

Bearings: self lubricating nylon

Blade Pivots: 3/16” (5mm) plated steel

Linkage: galvanized steel; double linkage for width exceeding

20” (508mm)

Seals: felt between blades and polyurethane sponge at sill

Maximum Panel Size: 50”w x 72”h (1270mm x 1829mm)

Maximum Velocity: 1500 FPM (8 M/S)

Maximum Differential Pressure: 1” WG (250 N/M

2

)

Maximum Temperature: Damper 250°F (95°C); Motor 130°F

(55°C)

Options

• POSC (Power Open-Spring Close)

• Standard Motor Voltage is 115-230/1/60

• Optional 24 VAC or 575 VAC

• Optional Transformers

• Optional Finishes

120V 240V

Idle Speed (RPM) 1.8 1.8

Idle Amps 0.244 0.137

Stall Amps 0.261 0.146

Face View

Model JDHAA Automatic

Model JDHAC Chain Operated

Model JDHAM Motor Operated

Spring Assist is field installed and is

recommended for face

velocity less than 600 FPM.

CAUTION: Motor kits are not suitable for

use in atmospheres or airflows containing

explosive or flammable products.

Actual Size = Nominal Size -1/4” (6mm)

Motor kits ship loose for field installation

C-5

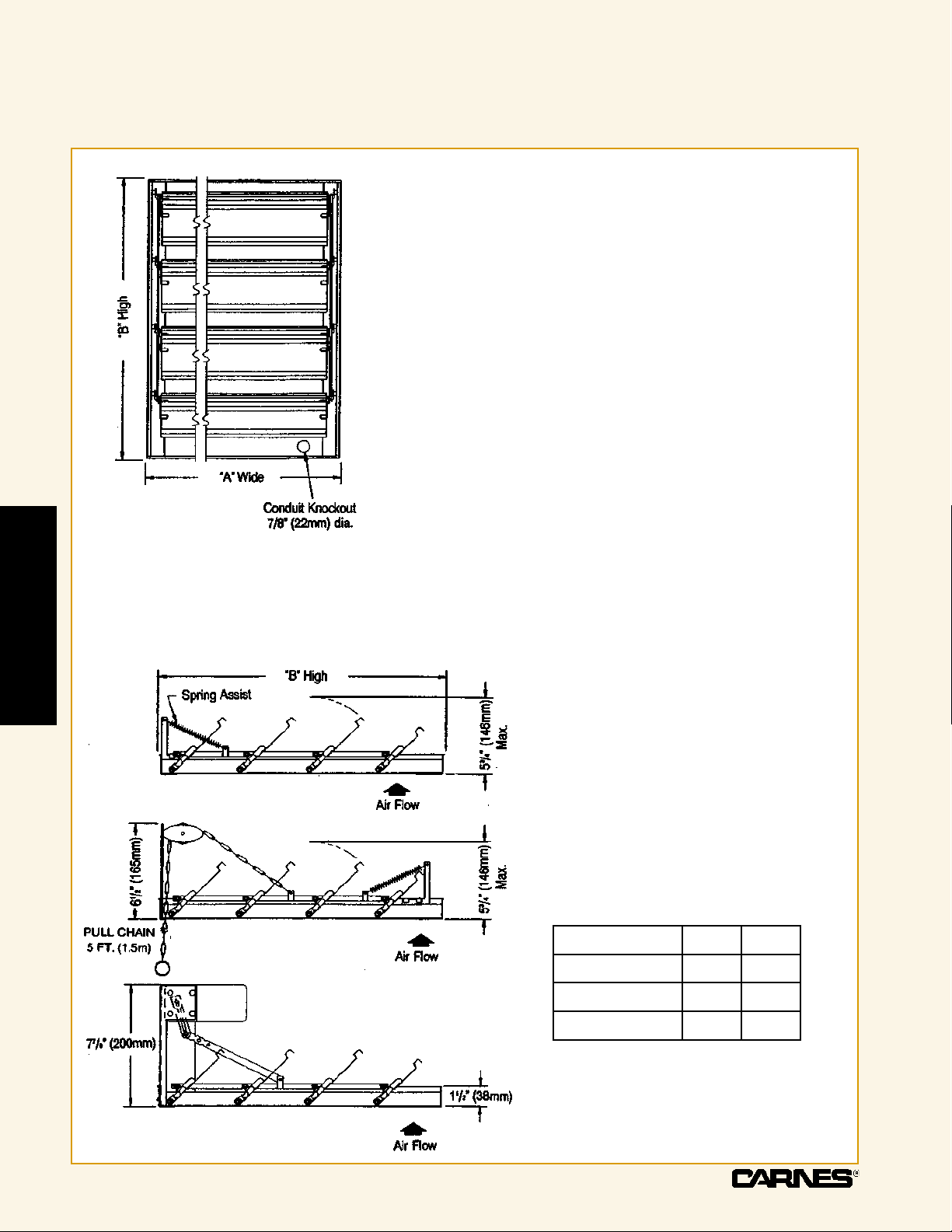

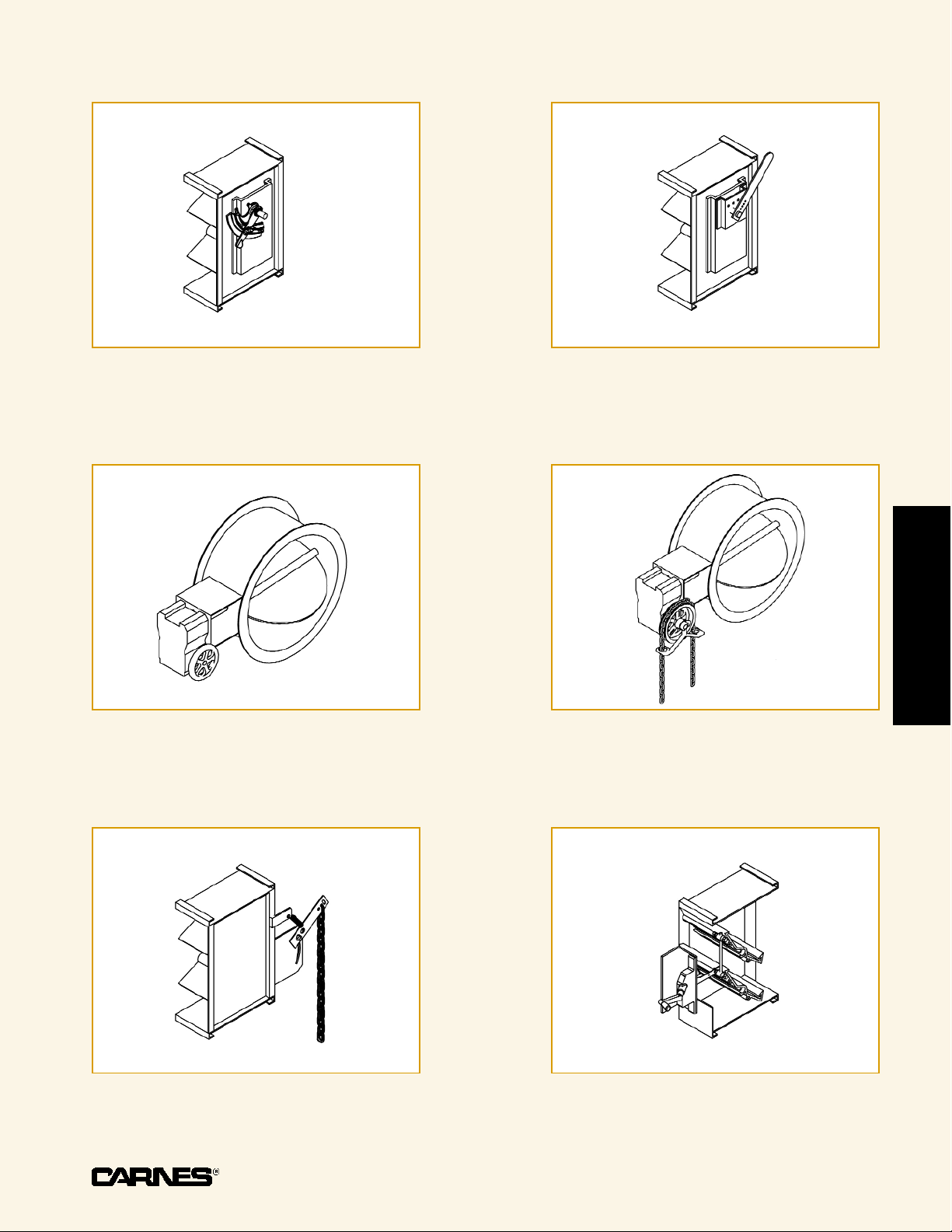

ACCESSORIES

Manual Operators for Louvers & Dampers

Hand Quadrant

Operator #1

1/2” round shaft only

Hand Quadrant

Operator #2

Heavy Duty

1/2” and 3/4” round shafts

Worm Gear with Hand Wheel

Operator #3

Heavy Duty

1/2” and 3/4” round shafts

Worm Gear with Chain Wheel

Operator #4

Heavy Duty

1/2” and 3/4” round shafts

Pull Chain

Operator #5

10 ft. chain standard

Heavy Duty Rotary

Hand Crank Operator #6

Mounted in the airstream

Primarily used on louvers

Loading...

Loading...