READ AND SAVE THESE INSTRUCTIONS

STEAM MANIFOLD MODEL HXMA

INSTALLATION INSTRUCTIONS

CARNES COMPANY, 448 S. Main St., P. O. Box 930040, Verona, WI 53593-0040 - Phone: 608/845-6411- Fax: 608/845-6504 carnes@carnes.com www.carnes.com

FORM 16823

ISSUED: 12-12

LOCATION OF MANIFOLD

The manifold is usually located in the supply duct downstream of the fan, heating coil, cooling coil, and/or filter.

When installed in packaged units, the manifold is to be

mounted just downstream of the fan discharge where there

is even flow throughout the duct. The unit must be mounted the minimum distance calculated in the catalog

upstream of any obstruction to prevent condensation.

The non-wetting dimension is the distance necessary to

prevent condensation on any obstruction downstream from

the manifold that is the same temperature as the air.

Condensation could occur on a cooling coil because of

lower temperatures. Steam plumes may be visible beyond

the non-wetting dimension and may moisten high efficiency

filters. Additional distance is required for installation

upstream of high efficiency filters.

Absorption is also dependent on uniform air flow across the

steam manifold. Uneven flow will result in greater

absorption distances.

Carnes humidifiers operate at .5 psi or less so there are

limitations on the maximum length of hose or piping that

may be used between the humidifier cabinet and the steam

manifold. The maximum distance depends on the static

pressure in the duct and the losses in the piping between

the humidifier and manifold and is shown in Table 1.

Table 1 MAXIMUM STEAM HOSE LENGTH

Duct Static

012345

Pressure “wg

Maximum Steam

40 35 30 25 15 10

Hose Length (Ft.)

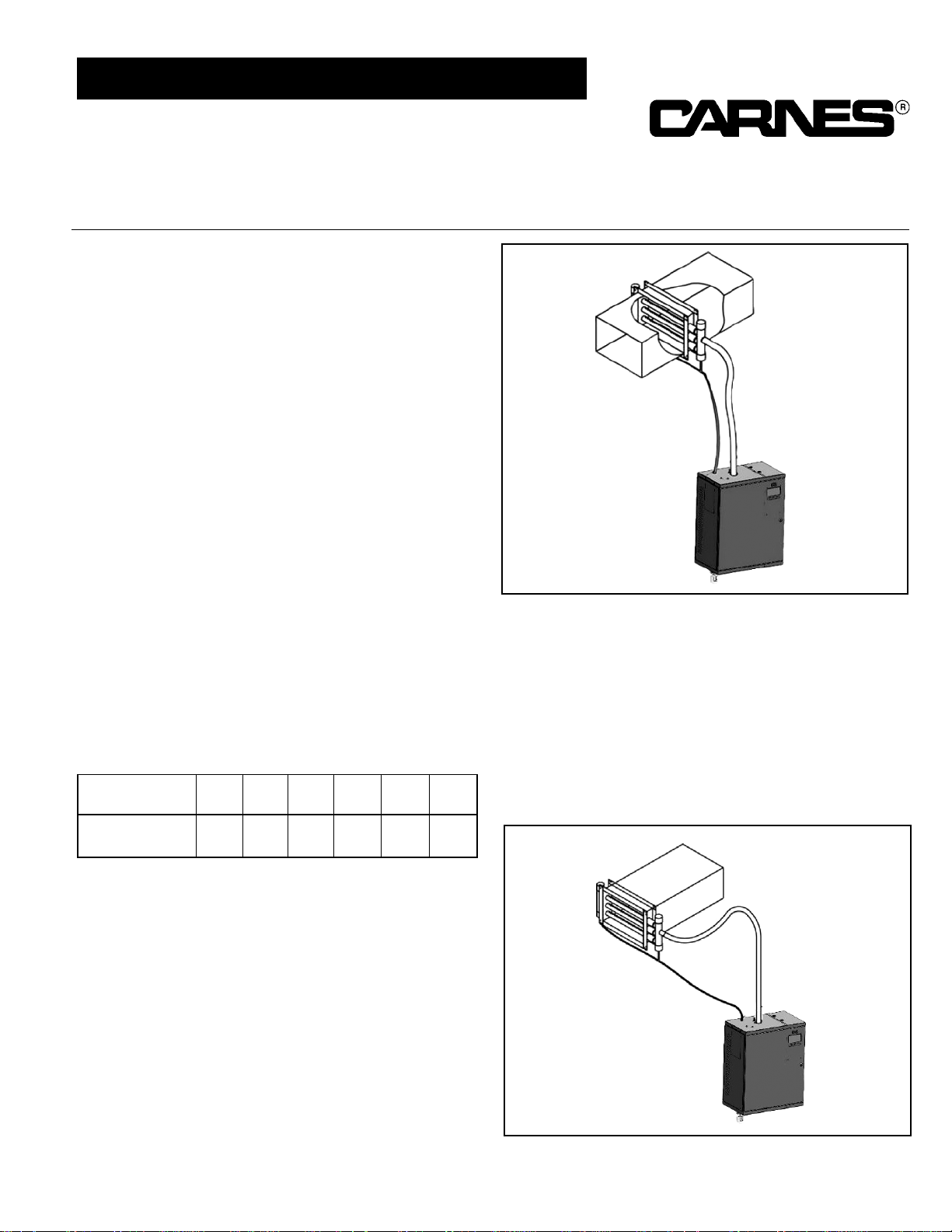

In a typical installation, the humidifier is located below the

duct and the steam manifold is installed as shown in Figure

A. In this installation any condensation in the manifold is

returned through a condensate return line to the humidifier

for maximum efficiency. The maximum recommended

length of steam hose for this type of installation is 12 feet.

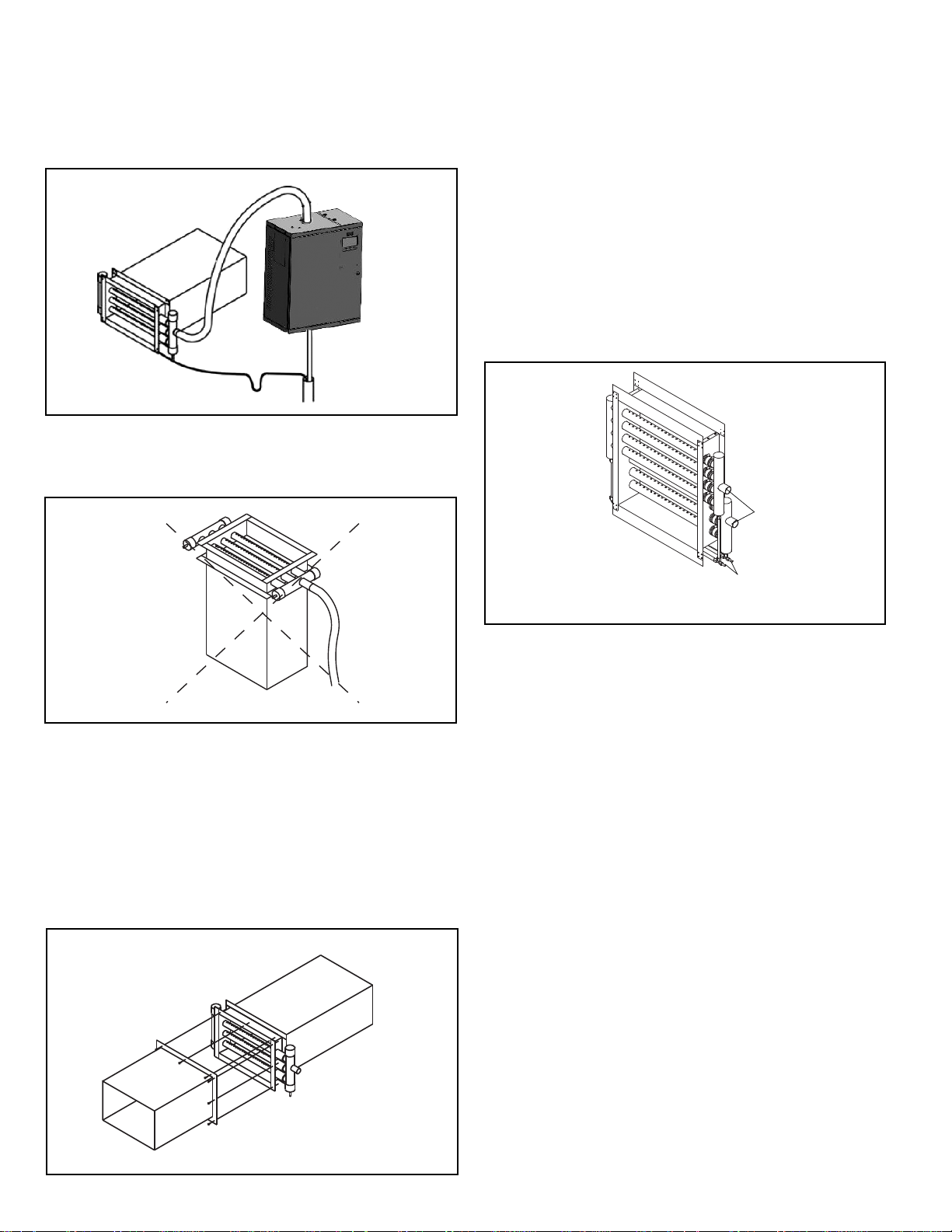

For lengths beyond 12 feet additional steps shown in

Figure B are recommended so that condensate will drain

from the steam manifold. It is preferable to have the steam

hose rise vertically from the humidifier and then slope

downward to the manifold. Steam flow will assist moving

condensate toward the return line rather than opposing

condensate flow back toward the cylinder if the hose is

running with only a small upward rise. If sufficient headroom is not available, it is possible to install the steam hose

with an upward slope with a minimum rise of 2” for every

12” of run.

Figure A

Figure B

2

The steam manifold may be located below the humidifier if

the installation is made in accordance with Figure C. In this

installation the condensate return line is routed to a drain

below the humidifier and a steam trap is necessary to

prevent live steam from flowing through the condensate line.

The steam manifold cannot be installed in a vertical duct as

shown in Figure D because condensate will not drain

properly and will discharge into the duct.

INSTALLATION OF MANIFOLD

1.

2.

3.

The manifold has an integral mounting flange for ease

of installation. Separate mounting flanges, supplied by

others, are needed for the duct to mate with the

manifold. Refer to Figure E.

Make sure the manifold is oriented properly with the

steam discharge holes facing upward.

Use #12x3/4” self-tapping screws spaced no farther

than 12” to secure the unit to the duct.

Figure D

Figure E

Figure C

INSTALLATION OF STEAM HOSE ANDCONDENSATE

RETURN LINE

It is very important that both the steam hose and condensate return line be installed so that sags are prevented.

The steam is at very low pressure and cannot overcome

resistance caused by water standing in the steam hose.

Water accumulating in sags in the return line will restrict

the flow of condensate and may cause water to be discharged into the duct.

INSTALL THE STEAM HOSE:

If the steam manifold is used with a humidifier having two

cylinders it will require two separate lengths of steam hose

to connect to the two inlets on the steam manifold. Do not

combine the outputs of two cylinders into one steam

hose. See Figure F.

Figure F

If it is difficult to prevent sags, it is recommended that

copper tube be used as a substitute. If copper tube is

used, a minimum of one inch of insulation must be applied

to prevent excessive condensation and contact with the

hot pipe. A short length of steam hose must be used to

connect the plastic cylinder in the humidifier to the copper

tube and another short length to connect the copper tube

to the steam manifold. Size 3/4” copper tube can be used

with steam cylinders having output rates up to 30 pounds

per hour. Size 1-1/2” copper tube should be used with

steam cylinders over 30 pounds per hour. Length

restrictions shown in Table 1 also apply where copper

tube is used and any 90° elbows add approximately three

feet of equivalent length.

Connect the steam hose to the plastic steam cylinder and

steam manifold using the clamps provided.

INSTALL THE CONDENSATE RETURN LINE:

If it is impossible to maintain a 6” drop from the bottom of

the manifold to the top of the humidifier cabinet the return

line can be run to a separate drain. A trap (usually 8” is

sufficient) may be necessary to prevent loss of steam

through the return line. Do not install a trap if the

condensate is returned to the top of the humidifier

cabinet.

If the humidifier has two cylinders, two return lines will be

required. Connect the return line to the inlet at the top of

the humidifier and to the steam manifold using the clamps

provided.

Two Cylinder

Operation

Steam

Inlets

Return Line

Connections

Loading...

Loading...