Carnes EACA Installation Manual

FORM 40001

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

Fire Dampers - Static and Dynamic

CAUTION! DO NOT INSTALL, USE OR OPERATE THIS EQUIPMENT UNTIL THIS

MANUAL HAS BEEN READ AND UNDERSTOOD. READ AND SAVE THESE INSTRUCTIONS FOR FUTURE USE.

GENERAL NOTES:

When UL is referred to in this document, it represents UL/ULC. This installation instruction

applies to Fire Dampers (static, dynamic, curtain, single, and multi blade types) mounted in the plane

of an UL approved fire partition. The dampers are designed for operation in the vertical or horizontal position with blades running horizontal. The dampers shall not be compressed or stretched into

the opening. Transportation and installation of the dampers shall be handled with the sleeve or

frame. Do not lift the damper with the blades or actuator. Special care shall be given to the damper

before installation and after to insure it is protected against dirt, weather, mortar and drywall dust, wall textures, and paint. Any of these

conditions could cause the damper not to operate correctly and void the warranty. Suitable access to inside duct is to be provided for

inspection and replacement of parts such as heat response devices and actuators per NFPA 90A and local authority having jurisdiction.

As with all joints, contractor must seal duct collar connections in the field after installation.

1. Opening Preparation/Clearances:

The fire barrier opening shall be larger than the damper to allow for thermal expansion and ease of installation. When steel stud/

gypsum or wood stud/gypsum partitions are being used then refer to Fig. 1-3 for additional information and details.

A. Dampers Assemblies Using Two Angles Methods (see note 4a) shall be a minimum of 1/8” (3mm) per linear foot

(305mm) of height and width of sleeved assembly up to a maximum of 1-1/2” (38mm) and a minimum of 1/4” (6mm). For Static Systems

the maximum single section curtain damper is 60” x 60” (1524mm x 1524mm) vertical and 40” x 40” (1016mm x 1016mm) or 48” x 48”

(1219mm x 1219mm) in vertical or horizontal mountings. For Dynamic Systems the maximum single section curtain damper is

36” x 36” (914mm x 914mm) in horizontal mountings, based on type “A” dampers. The maximum single section curtain damper is

36” x 48” (914mm x 1219mm) in vertical mountings and 24” x 24” (610mm x 610mm) in horizontal mountings, based on type “A”

dampers. The maximum single section multi blade damper is 36” x 48” (914mm x 1219mm) in vertical or horizontal mountings. This

method is acceptable for 1-1/2 and 3 hour fire dampers. See Underwriters Laboratories Listings for maximum multiple assembly sizes.

B. Dampers Assemblies Using One Angle Methods (see note 4b) shall be minimum of 1/8” (3mm) per linear foot (305mm)

of height and width of sleeved assembly up to a maximum of 1-1/2” (38mm) and a minimum of 1/4” (6mm). The maximum single

section is the same as in A above. The maximum multi-section is 108” wide or 108” height up to 36 square feet. This method is

acceptable for 1-1/2 hour fire dampers mounted in a masonry/concrete or steel stud/gypsum wall only.

C. Dampers Assemblies Using No Angles Methods (see note 4c) shall be a minimum of 1/4” (6mm) and a maximum of

1/2” (13mm). The maximum single section is the same as in A above. The maximum multi-section is 42” wide x 48” high. This method

is acceptable for 1-1/2 hour fire dampers mounted in a masonry/concrete or steel stud/gypsum wall only.

2. Sleeves shall be of the SAME GAUGE or heavier as the duct to which it is attached, if one of the breakaway connection is used as

defined in the SMACNA Fire, Smoke, and Radiation Damper Guide for HVAC Systems (Fig. 4-6) and in NFPA 90A. Gauges shall

conform to SMACNA or ASHRAE duct standards. Sleeves shall not extend beyond the fire barrier more than 6” (152mm) unless an

actuator or factory installed access door is supplied, then the sleeve may extend up to 16” (406mm). Sleeve shall terminate at both sides

of wall within dimensions shown. If a rigid connection is used, then the sleeve shall be minimum of 16 gauge for dampers up to

36” (914mm) wide by 24” (610mm) high and 14 gauge for dampers exceeding 36” (914mm) wide by 24” (610mm) high.

Round and oval breakaway connections must use either a 4” (102mm) wide draw band or #10 (M5) sheet metal screws spaced equally around the circumference of the duct as follows: 3 screws for duct sizes 22” (559mm) and smaller; 5 screws for duct sizes greater

than 22” (559mm) and up to and including 36” (914mm); 8 screws for duct sizes greater than 36” (914mm). Refer to SMACNA Fire,

Smoke, and Radiation Damper Guide for HVAC Systems for information on Ductmate, Nexus, Ward, TDC and TDF systems and any

additional information (Fig. 5-6). A sleeve may not be required if the damper frame is of sufficient size and shape so the mounting angles

can be directly fastened to it.

FORM 40001, Page 1

CARNES COMPANY 448 S. Main St., P. O. Box 930040, Verona, WI 53593-0040 Phone: (608)845-6411 Fax: (608)845-6470 www.carnes.com

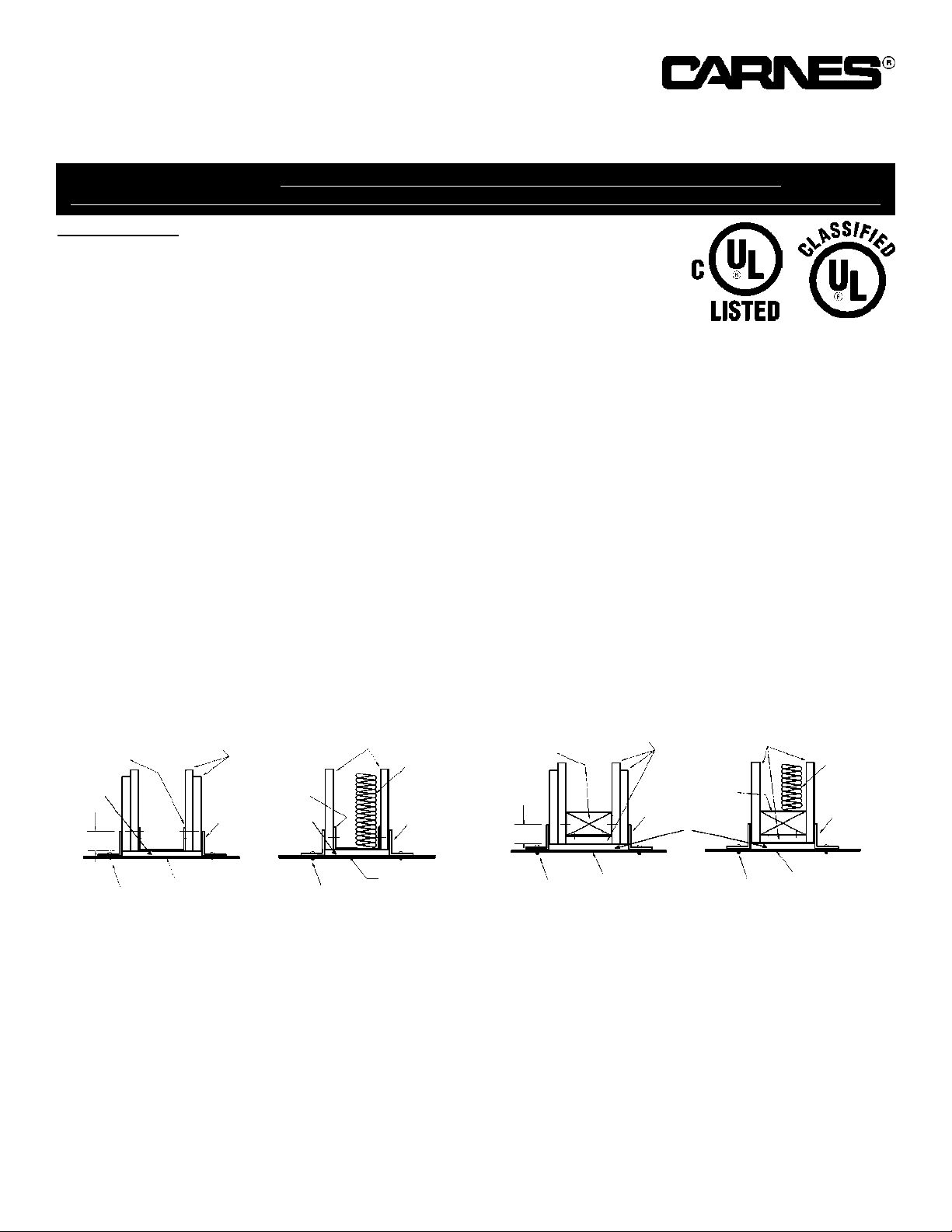

Fig. 1: Metal Stud/Gypsum Wall Design

1” Min.

Thermal

Gap

Thermal

Gap

2-1/2” Min. Stud

or Runner

1/2” Min. Gypsum

Wallboard

2-1/2” Min. Stud

or Runner

1/2” Min. Gypsum

Wallboard

Retaining

Angle

Damper Sleeve

Fasten with a 1/4” bolt/nut

1/2” welds, #10 sheet metal

screws, or 3/16” pop rivets

on 10” centers.

Damper Sleeve

Fasten with a 1/4” bolt/nut

1/2” welds, #10 sheet metal

screws, or 3/16” pop rivets

on 10” centers.

Retaining

Angle

1-1/2” Mineral

Fiber Blanket

In Cavity, If

Required

Fig. 2: Wood Stud/Gypsum Wall Design

1” Min.

Thermal

Gap

2-1/2” Min. Stud

or Runner

1/2” Min. Gypsum

Wallboard

2-1/2” Min.

Stud or

Runner

1/2” Min. Gypsum

Wallboard

Retaining

Angle

Damper Sleeve

Fasten with a 1/4” bolt/nut

1/2” welds, #10 sheet metal

screws, or 3/16” pop rivets

on 10” centers.

Damper Sleeve

Fasten with a 1/4” bolt/nut

1/2” welds, #10 sheet metal

screws, or 3/16” pop rivets

on 10” centers.

Retaining

Angle

1-1/2” Mineral

Fiber Blanket

In Cavity, If

Required

WALL RATING - 2 HR.

WALL RATING - 1 HR.

WALL RATING - 2 HR.

WALL RATING - 1 HR.

4. Methods of Securing Damper in Opening:

A. Two Angle (Two Sided) Method: This method is the oldest and commonly used. This method is approved for use in UL

approved concrete/masonry partitions, steel stud/gypsum walls, and wood stud/gypsum walls. In this method 2 sets of angles are used

to secure the damper in the opening, one on each side of the partition (see Fig. 7). Two Angle Method is approved for 1-1/2 and 3 hour

dampers, vertical or horizontal orientation, and any maximum size multi-section UL approved damper (see Underwriters Laboratories

Listings for maximum assembly sizes). Angles shall be minimum of 1-1/2” x 1-1/2” (37mm x 37mm) by 16 gauge. Angles are to be

fastened to the sleeve on 6” centers with #10 (M5) sheet metal screws, 3/16” (5mm) steel pop rivets, 1/2” (13mm) tack welds, or 1/4”

(6mm) diameter nut and bolts with not more than 2” (51mm) from each end with a minimum of two connections per side/leg.

The angles are to overlap the partition a minimum of 1” (25mm). These angles may be of a unit type construction and may or may not

be fastened to each other at the corners. When the duct work terminates at the damper or installation prohibits angles from turning

out/away from the wall, the retaining angle shall be reversed (leg turned into the opening) providing the size of the opening is increased

by an amount equal to twice the combined thickness of the angle and the height of the screw or bolt head to maintain expansion

clearances. See note 1A for information on clearances. See Fig. 7 for detailed drawings of installations.

B. One Angle (Single Sided) Method: In this method one set of angles are used to secure the damper in the opening. This

method is approved for use in UL approved concrete/masonry partitions and steel stud/gypsum walls. Only one side of the fire partition

will have the angles installed (see Fig. 8). One Angle Method is approved for 1-1/2 hour dampers only, vertical and horizontal (angles

on top side only) orientations, and the maximum size shall be 108” wide or 108” high up to 36 square feet and up to the maximum multisection UL approved damper size (see Underwriters Laboratories Listings for maximum assembly sizes). Angle shall be a minimum of

1-1/2” x 1-1/2” (37mm x 37mm) by 16 gauge. Angles are to be fastened to the sleeve on 6” centers with #10 (M5) sheet metal screws,

3/16” (5mm) steel pop rivets, 1/2” (13mm) tack welds, or 1/4” (6mm) diameter nut and bolts with not more than 2” (51mm) from each

end with a minimum of two connections on each side/leg top and bottom. The angles are also to be fastened to the fire partition with: in

concrete/masonry partitions with #10 (M5) self-tapping concrete anchors or concrete screws on 6” (152mm) centers and must engage

the fire partition a minimum of 1-1/2” (38mm); in steel stud/gypsum partitions secure the angles to the partition with #10 (M5) screws

long enough to penetrate the J-Runners and E-Stud by a minimum of 3/8” (10mm). Use a minimum of two fasteners per side. The angles

are to overlap the partition a minimum of 1” (25mm). These angles may be of a unit type construction and may or may not be fastened

to each other at the corners. When the duct work terminates at the damper or installation prohibits angles from turning out/away from

the wall, the retaining angle shall be reversed (leg turned into the opening) providing the size of the opening is increased by an amount

equal to twice the combined thickness of the angle and the height of the screw or bolt head to maintain expansion clearances. Angles

can be placed in front of or behind the drywall attaching directly to the steel studs or masonry. Carnes’ Frame Retaining Angles can be

used in place of the angle mentioned above. See note 1B for information on clearances. See Fig. 8 for detailed drawings of

installations.

C. No Angles Method: In this method No Angles are used to secure the damper in the opening. This method is approved for

use in UL approved concrete/masonry partitions and steel stud/gypsum walls. This method uses a minimum 3/4” (19mm) flange on one

end of the sleeve. The damper/sleeve assembly is placed in the opening so that the flange rest flush up to the partition, then the

fasteners are placed through the sleeve into the partition (see Fig. 9). No Angle Method is approved for 1-1/2 hour dampers only,

vertical and horizontal (flange on top side only) orientations, and the maximum size shall be 42” (1067mm) wide by 48” (1219mm) high

up to the maximum multi-section UL approved damper size (see Underwriters Laboratories Listings for maximum assembly sizes). The

sleeve flange shall be a minimum of 3/4” (19mm) high by 20 gauge steel. If a flange/angle is added, it shall be a minimum of 1” x 1”

(25mm x 25mm) by 18 gauge steel and fastened with #10 (M5) bolts or screws, 1/2” (13mm) welds, or 3/16” (5mm) rivets to the sleeve,

at a maximum spacing of 6” (152mm) o.c., not more than 2” (51mm) from each end with a minimum of two fasteners per side. The sleeve

is to be fastened to the fire partition with: in concrete/masonry partitions with #10 self-tapping concrete anchors or concrete screws on

6” (152mm) centers and must engage the fire partition a minimum of 1-1/2” (38mm); in steel stud/gypsum partitions secure the angles

to the partition with #10 (M5) screws long enough to penetrate the J-Runners and E-Stud by a minimum of 3/8” (10mm). Use a

minimum of two fasteners per side. The sleeve flange can be placed in front of or behind the drywall attaching directly to the steel studs

or masonry. Be sure to not stretch the damper when securing it into the partition. Stretching the damper can cause it to bind up and

prevent it from operating properly. Carnes’ Frame Retaining Angles can be used in place of the angle mentioned above. See note 1C

for information on clearances. See Fig. 9 for detailed drawings of installations.

FORM 40001, Page 2

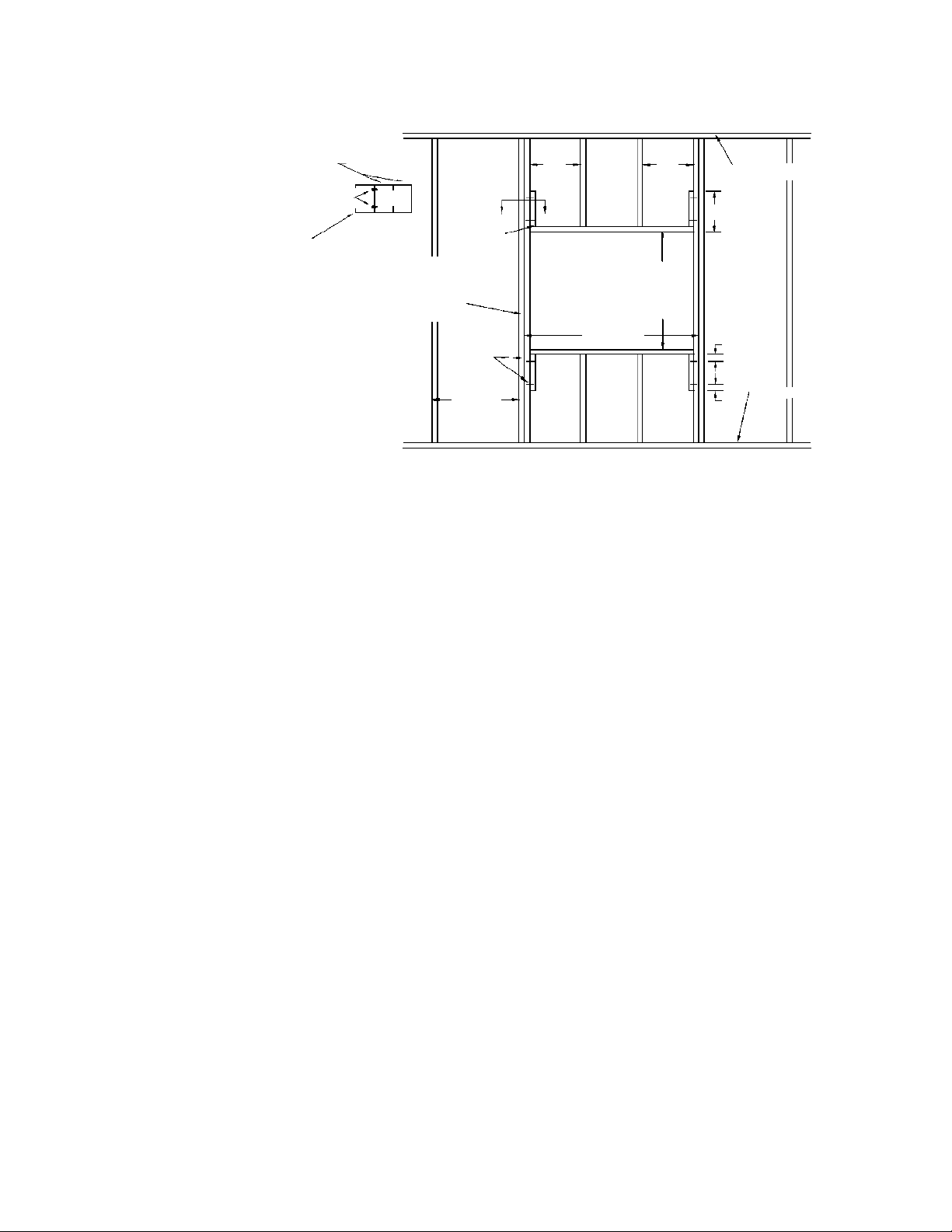

Fig. 3: Metal or Wood Stud Wall

24” O.C.

Max.

2 Panhead

Screws

Floor

Runner

Ceiling Runner

Runner

90 Blend

Width

Height

See UL Directory for

Maximum Allowable

Opening Size Per

Fire Damper Model.

12”

2”

2”

16”

16”

A

A

Double Stud Not

Required on

Penetrations

36” x 36”

Or Smaller

2-1/2” Min. Runner

2-1/2” Min. Stud

Screws

Section A-A

Note: Gypsum panels screwed to all

studs and runner flanges, 12”

o.c. maximum surrounding

opening. All fasteners are to be

UL approved per UL design.

3. Multi-Section and “Damper to Sleeve” Connections:

Damper shall be secured to the sleeve and to each other (when joined to make multiple damper assemblies) with #10 sheet metal

screws, 1/4” (6mm) nut and bolts, 1/4” (6mm) tack welds, 3/16” (5mm) steel rivets, or clinching (toggle) on 6” (152mm) centers.

Loading...

Loading...