Carnes DTBA, DTCA, DTDA User Manual

Imperial [IP] Dimensions Metric (SI) in Parentheses

SPECIFICATION SHEET

Models DTAA, DTBA, DTCA, DTDA

Extruded Aluminum Slot Diffuser

T-Bar Mount

CARNES COMPANY © 2010 COPYRIGHT

ALL RIGHTS RESERVED

SUPERSEDES 13100 13100-A

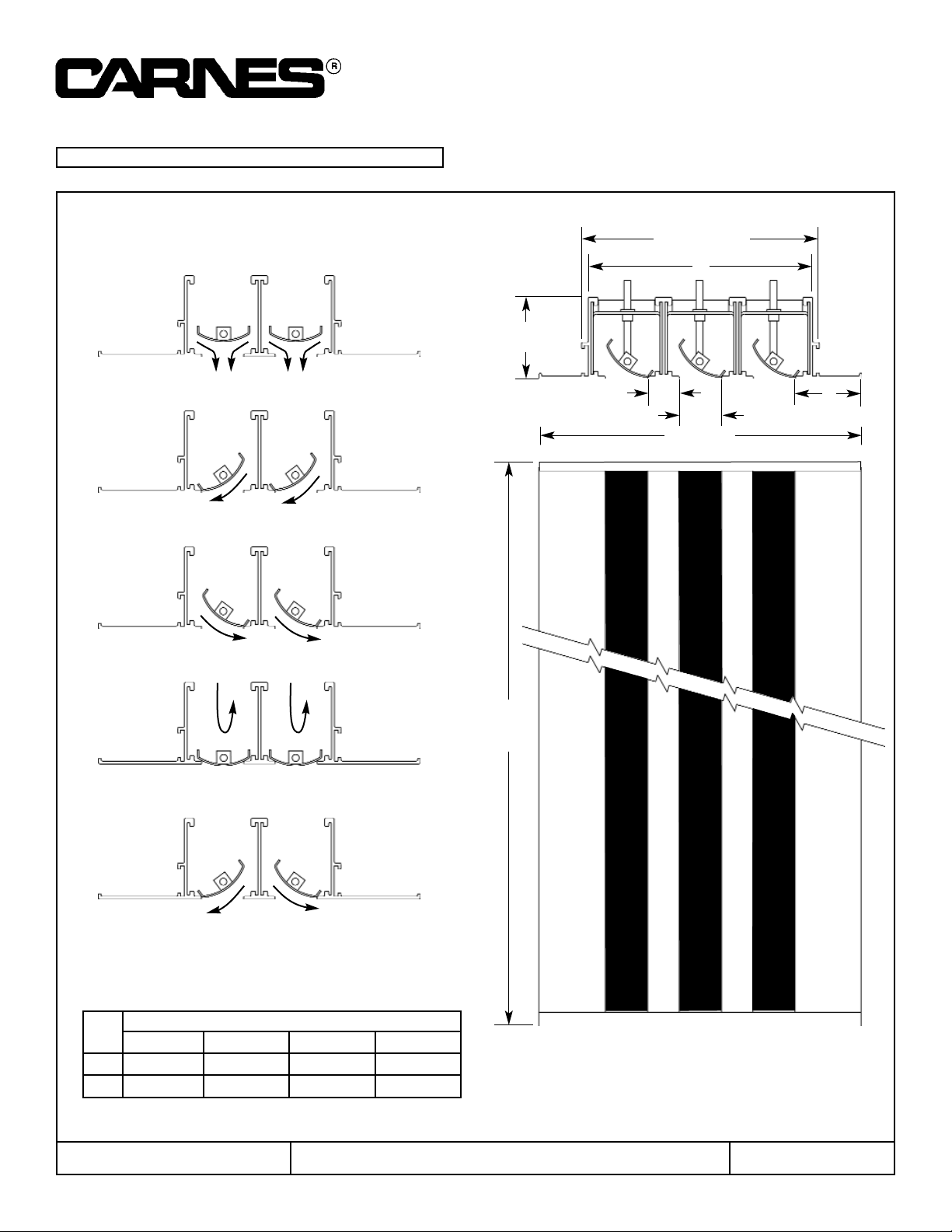

Perpendicular

Slot Pattern Adjustments

Parallel Left

Parallel Right

Blankoff

Two Way

DIM

No. of Slots

1 2 3 4

A 1-3/8 (35) 2-11/16 (66) 4 (102) 5-5/16 (135)

B 2-1/2 (64) 1-13/16 (46) 1-3/16 (30) 17/32 (13)

Dimensions List in Inches (Millimeters)

Duct= A + 1/4”

A

1-7/16”

(37)

9/16” (14)

3/4” (19)

B

Length

Size

-1/4”

Armstrong®TechZone™Compatible

CARNES COMPANY 448 S. Main St., P. O. Box 930040, Verona, WI 53593-0040 Phone: (608)845-6411 Fax: (608)845-6470 www.carnes.com

5-3/4” (146)

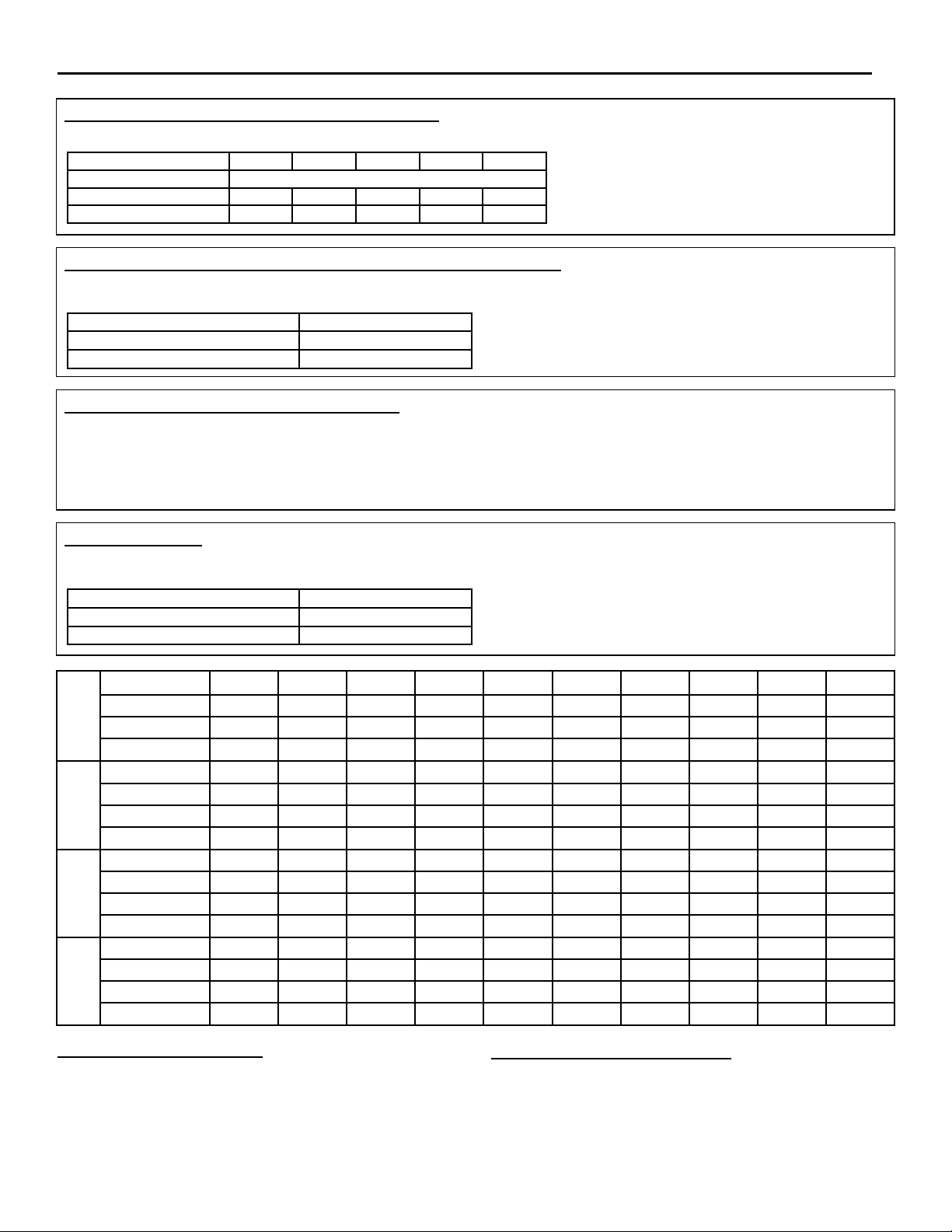

Performance Data - Armstrong TechZone™ Compatible Linear Supply Diffuser (Models DT, DG, DH)

Correction Factors for Lengths Other than Shown.

Performance data is given for a 4-foot long diffuser. When other lengths are used, apply these corrections to the table data below.

Correction Factors for Vertical Discharge Adjustment of Model CD.

Performance data is given for horizontal discharge. When the deflector is set for vertical discharge, apply these corrections to the

table data below.

Correction Factors for Cold Air Performance.

Performance data is based on tests conducted in isothermal conditions. When 20°DT cooling conditions exist, horizontal throw

(assuming the presence of a ceiling) is reduced by approximately 35%. To get horizontal throws corrected for 20°DT cooling conditions, multiply the table throw data by .65.

This correction does not apply in vertical discharge situations.

Notes on Performance Data

• Performance data is based on tests conducted in accordance

with ANSI/ASHRAE Standard 70-1991.

• Actual performance in the field may vary.

• Tests were conducted in isothermal conditions.

• Sound levels are based on a room absorption of 10 db re 10

-12

watts.

Notes on Units of Measure Used

• Air flow is given in cubic feet per minute (CFM).

• Static Pressure is given in inches of water (w.g.).

• Sound data is given in NC.

• Throws are given in feet to terminal velocities of 150, 100 and

50 fpm, respectively.

NC/RC Correction (Add) -3

Throw Correction (Multiply)

No Correction Necessary

Pressure Correction (Multiply) 0.8

Length 24” 36” 48” 60” 72”

Pressure Correction No pressure correction is necessary

NC Correction (Add)

-3 -1 0 1 3

Throw Correction (Multiply)

0.75 0.88 1 1.12 1.25

One

Slot

Airflow per foot 10 15 20 25 30 40 50 60

Static Pressure 0.008 0.018 0.032 0.050 0.072 0.128 0.202 0.288

Sound (NC) ~ ~ ~ 13 17 25 31 37

Throw 1 2 5 3 5 10 5 8 12 19 11 15 23 15 20 28 18 23 32 20 25 35

Two

Slot

Airflow per foot 15 30 45 60 75 90 105 120

Static Pressure 0.005 0.017 0.040 0.072 0.115 0.162 0.222 0.291

Sound (NC) ~ ~ 12 20 28 31 36 40

Throw 1 1 3 5 8 16 10 14 23 13 18 28 16 22 32 19 25 36 22 27 38 24 31 42

Three

Slot

Airflow per foot 20 40 60 80 100 120 140 160 180

Static Pressure 0.003 0.012 0.030 0.054 0.087 0.127 0.173 0.231 0.294

Sound (NC) ~ ~ 10 17 24 29 34 38 42

Throw 1 2 5 5 9 18 9 15 25 14 19 30 17 23 34 20 26 38 22 28 40 24 30 43 26 32 46

Four

Slot

Airflow per foot 40 60 80 100 120 140 160 180 200 240

Static Pressure 0.008 0.017 0.031 0.049 0.070 0.098 0.127 0.162 0.198 0.288

Sound (NC) ~ ~ 13 19 23 27 31 34 38 43

Throw 4 6 15 7 11 22 10 16 28 13 20 32 16 23 35 19 26 38 21 28 40 23 30 42 24 31 44 27 35 48

Return Air Factors

When Channelaire is used as an air return, either ducted or plenum, the pattern control is used for dampering only. With pattern control set at wide open these correction factors apply to the performance data.

NC/RC Correction (Add) -3

Throw Correction (Multiply)

Not Applicable

Pressure Correction (Multiply) 0.8

Loading...

Loading...