Page 1

Universal Utility Meter

Contatore Universale

USER MANUAL

MANUALE ISTRUZIONI

WM24-96

Modular system

Tecnologia modulare

CARLO GAVAZZI

Automation Components

Page 2

WM24-96: Modular Universal Utility

Meter and Power Analyzer

Plug and play module system; energy meters, gas and water meter.

These are only a few among many

other functions performed by your

WM24-96. What’s more, Carlo

Gavazzi means ISO9001 certification,

a working experience of many

decades and a widespread presence

all over the world. All this because

we want our customers to have the

top service and the top products.

Welcome in the Carlo Gavazzi world

and compliments for your smart

choice. Visit our website and

evaluate our range of products:

www.carlogavazzi.com

T

H

A

N

K

Y

O

U

F

O

R

C

H

O

O

S

I

N

G

C

A

R

L

O

G

A

V

A

Z

Z

I

CARLO GAVAZZI

Automation Components

Plug and Play

Modules

Page 3

▲

▲

2

Index

Front Panel Description

4

3

CARLO GAVAZZI

WM24-96, modular universal utility meter and power analyzer

FW rev. 01

TO BEGIN WITH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .04

■ Front panel description . . . . . . . . . . . . . . . . . . . .04

■ List and description of displayed measuring pages . . . .04

PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . .09

■ Access to the main menu . . . . . . . . . . . . . . . . . . .09

■ Change password . . . . . . . . . . . . . . . . . . . . . . . .09

■ System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

■ CT ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

■ VT ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

■ Dmd calculation . . . . . . . . . . . . . . . . . . . . . . . . .11

■ Access to the energy meters menus . . . . . . . . . .13

❑ The functions of the Energy Meters submenu. . .13

■ Digital outputs . . . . . . . . . . . . . . . . . . . . . . . . . . .16

❑ Digital output 1 . . . . . . . . . . . . . . . . . . . . . . .16

❑ Pulse digital output . . . . . . . . . . . . . . . . . . . .16

❑ Alarm digital output . . . . . . . . . . . . . . . . . . . .18

❑ Digital output 2 . . . . . . . . . . . . . . . . . . . . . . .19

■ Setting of serial communication port address . . . .20

■ Digital filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

■ End of programming . . . . . . . . . . . . . . . . . . . . . .21

■ Reset of total gas, water, energy meters . . . . . . .21

■ Reset of partial gas, water, energy meters . . . . . .22

■ How to prevent key-pad programming . . . . . . . . .22

USEFUL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . .23

■ Example of how to use the digital filter . . . . . . . . .23

■ What is ASY? . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

■ Retransmitted variables . . . . . . . . . . . . . . . . . . . .24

■ Alarm digital output . . . . . . . . . . . . . . . . . . . . . . .25

Page 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

■ Operations preliminary to the installation . . . . . . .26

■ Front panel cut-out . . . . . . . . . . . . . . . . . . . . . . .27

■ Position of slots and relevant modules . . . . . . . . .28

■ Connection of optional modules . . . . . . . . . . . . . .31

■ 1-phase electrical diagrams . . . . . . . . . . . . . . . . .34

■ 3-phase electrical diagrams . . . . . . . . . . . . . . . . .34

TECHNICAL FEATURES . . . . . . . . . . . . . . . . . . . . .36

We suggest you to keep the original packing in case it is

necessary to return the instrument to our Technical

Service Department. In order to achieve the best results

with your instrument, we recommend you to read this

instruction manual carefully.

HOW TO USE THE SYMBOLS

Go to the page where the previous main subject

is described.

Go to the page where the next main subject is

described.

Go to the page where the subject written on the

top of the current page starts.

Go to the page where the subject written on the

top of the current page ends.

This symbol indicates a particularly important

subject or information.

This symbol indicates that more details are given

on the current subject.

▲

▲

3

Index

Display “tot -1 .Cn”

2

7

▲

▲

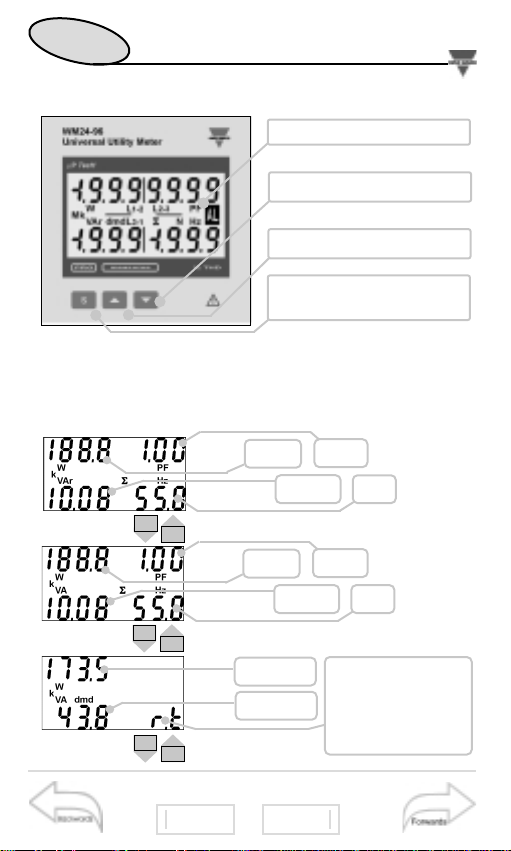

Page 5

When the instrument is switched on it shows the page below:

▲

▲

4

To begin with

Gas, water, en. meters

pages

6

8

Back-lighted LCD Display.

Display previous page.

Display next page.

Access to programming or

setting confirmation.

■Front Panel Description

■ List and Description of Displayed

Measuring Pages

▼

▲

kW∑

PF∑

kvar∑

Hz

▼

▲

kW∑

PF∑

kVA∑

Hz

kW dmd

kVA dmd

Serial communication status: r=Rx;

t=Tx (only with

serial communicat.

module inserted)

▼

▲

Page 6

If displayed in the

measuring mode it

means: the alarm is

ON.

▲

▲

5

To begin with

Programming

3

Index

4

9

8

▼

▲

VL1-N

VL2-N

VL3-N

V∑

A L1

A L2

A L3

▼

▲

W L1

W L2

W L3

▼

▲

PF L1

PF L2

PF L3

PF ∑

▼

▲

kvar L1

kvar L2

kvar L3

▼

▲

kVA L1

kVA L2

kVA L3

▼

▲

A n

Multiplyer

Page 7

▲

▲

6

To begin with

“tot-Prd”

488

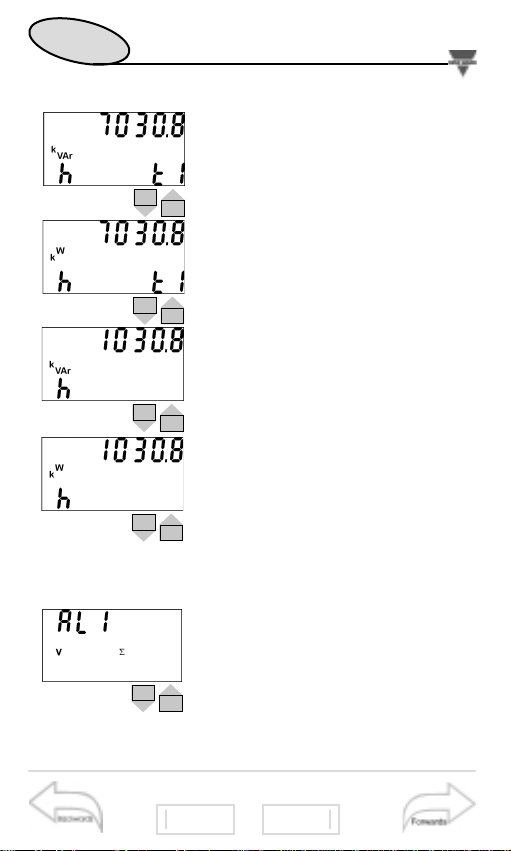

The energy meter pages are different according to the setting of the instrument (see energy meter menu on pag.13).

■ If you choose “tot” the instrument displays:

▼

▲

▼

▲

▼

▲

▼

▲

▼

▲

Generated capacitive reactive

energy: integration of the sum of

single phase reactive powers of

quadrant 4 only.

Consumed capacitive reactive

energy: integration of the sum of

single phase reactive powers of

quadrant 2 only.

Generated inductive reactive

energy: integration of the sum of

single phase reactive powers of

quadrant 3 only.

Consumed inductive reactive

energy: integration of the sum of

single phase reactive powers of

quadrant 1 only.

Generated active energy: integration of the sum of single phase

negative active powers only.

Page 8

▲

▲

7

To begin with

dmd calculation

5

Measuring Pages

4

11

8

■ If you choose “tot-1.Cn” the instrument displays all

the pages displayed in the “tot” selection as well as:

■ If you choose “tot-2.Cn” the instrument displays all

the pages displayed in the “tot” selection as well as:

▼

▲

▼

▲

▼

▲

▼

▲

▼

▲

Consumed active energy: integration of the sum of positive single phase active powers only.

GAS meter as m3, night tariff.

GAS meter as m3, day tariff.

Total WATER meter as m3.

Total GAS meter as m3.

Page 9

▲

▲

8

To begin with

System

3

Index

4

10

■ If you choose “tot-Prd” the instrument displays:

Once the energy meter pages are finished, the instrument

will display some pages related to the variables connected

to the alarm.

▼

▲

▼

▲

▼

▲

▼

▲

Reactive energy consumed during tariff 1: integration of the system active power only if positive

(same is also for tariff 2, 3 and 4).

Active energy consumed during

tariff 1: integration of the system

active power only if positive

(same is for tariff 2, 3 and 4).

Consumed total reactive energy:

integration of the system reactive

power only if positive.

Consumed total active energy:

integration of the system active

power only if positive.

▼

▲

The scrolling of the measuring pages is cyclic, at the end of the

cycle, you go back to the first page (see page 4).

Display of alarm settings (AL1 and

AL2 if both alarms have been set).

It displays the variable connected

to the alarm.

Page 10

▲

▲

9

Programming

En. meters Menu

7

En. meters Display

13

22

When the “AL” box (normally used for the alarm

indication) is active during the programming phase,

it means that the displayed value can be modified.

This rule applies to all the programming menus.

▼

▲

S

S

Access to the

main menu

■Access to the main menu

To access to the programming

menus from the measuring and dis-

play phase, press the key : when

the instrument asks for the password, enter the correct PASS value

by means of the and keys;

afterwards confirm by means of the

key. If the password is correct

(when the instrument is new, the

password is 0), the instrument goes

to the main functions menu.

S

▼▲

S

S

S

▼

▲

■Change Password

This function allows the operator to

choose the desired password value

(from 0 to 1000).

Choose the “CnG.PASS” function

by means of the and keys,

then press to modify PASS,

enter the desired value by means of

the and keys and confirm

the new value with the key.

S

▼▲

S

▼▲

Page 11

▲

▲

10

Programming

Synchronization

5

Measuring Pages

91222

S

▲

▼

S

■System

This function allows the operator to

select the electrical system choosing between three-phase with neutral (3P.n) and three-phase without

neutral (3P).

Choose by means of and

the “SySTEn” function, press

to enter the menu; then, select the

desired system by means of the

and keys and confirm with

.

S

▼▲

S

▼▲

S

S

S

S

▲

1.2..

..2.1

▼

▲

▼

■CT ratio

This function allows the user to

select the value of the CT ratio.

Example: if the CT primary (current

transformer) has a current of 300A

and the secondary has a current of

5A, the CT ratio corresponds to 60

(obtained by carrying out the following calculation: 300/5).

Choose the “Ct.rAtio” function by

means of the and keys; to

enter the menu press ; then

select the desired value by means

of the and keys and con-

firm the new value with .

S

▼▲

S

▼▲

Page 12

▲

▲

11

Programming

Digital Input Table

9

Main Menu

9

15

22

S

S

S

S

▲

1.2..

..2.1

▼

▲

▼

■VT ratio

This function allows the user to

select the value of the VT ratio.

Example: if the primary of the connected VT (voltage transformer) is

of 20kV and the secondary is 100V,

the VT ratio will correspond to 200

(obtained by carrying out the following calculation: 20000/100).

Choose the “Vt.rAtio” function by

means of the and keys; to

enter the menu press , then

select the desired value by means

of the and keys and con-

firm it with .

By changing the VT and

CT ratio, the energy

meters are reset.

S

▼▲

S

▼▲

S

S

▲

1.2..

..2.1

▼

■Dmd calculation

This function allows the user to

select the integration time of the W

and VA demand value. To enter

these functions select “P.int t” from

the main menu by the and

keys; to enter the menu press .

Set the minutes by means of the

and keys and confirm the

new value with .

S

▼▲

S

▼▲

Page 13

If, for example, you select the value “15 minutes”, the instrument calculates the demand value

and updates the value every 15 minutes. See the

diagram below.

▲

▲

12

Programming

Meters Submenu

7

Energy Meters Pages

91422

Where: Pc is the contractual power

t1 is the selected integration period

SYNCHRONIZATION OF THE POWER DEMAND CALCULATION

The synchronization enables the WM24-96, by means of the

digital inputs, to start the integration of the power demand

at the same time as the official watthour meter. The synchronization can be carried out in two ways:

- Without digital input module: the reset and the start of the

energy integration are carried out when the instrument is

switched on;

- With the digital input module: the synch. starts when one

of the digital inputs changes status (that is to say when the

tariff changes). Any following change of status resets and

synchronizes again the calculation of the power demand.

Page 14

▲

▲

13

Programming

Retransmitt. en. Meters

11

VT Ratio

9

17

22

S

▲

S

▼

■ Access to the energy

meters menu

This function allows the user to choose

the parameters for the management of

the energy meters. Choose the function

“COUntEr” by means of the and

keys: to confirm the value and enter

the submenu press . By means of

the and keys, it’s possible to

scroll all the functions relating to the

energy meters that will be described in

detail below.

▼▲

S

▼

▲

S

S

▲

▼

▲

▼

❑ The functions of the Energy

Meters submenu.

Choose the desired function by

means of the and keys,

press to confirm. It’s possible

to choose the following combinations:

tot: it enables the combination of

total and partial meters (see page

6).

tot Prd: it enables the combination

of total and partial meters: tariff t1,

t2, t3 and t4 are managed by the

digital inputs (see page 8);

S

▼▲

Page 15

▲

▲

14

Programming

Digital Outputs

9

Main Menu

91622

S

S

▲

1.2..

..2.1

▼

tot 1.Cn: it enables the combination of

total en. meters and day-time and nighttime GAS meters (see also “Display

pages” on page 7). Press to select

“PrESCAL Cn1”, then enter by means

of the keys the weight of every

pulse of the IN2 digital input of the GAS

meters and confirm with .

The same input IN2 increases alternatively the day-time and night-time GAS

meters depending on the status of IN3.

tot 2.Cn: it enables the combination of

total energy meters and Water and Gas

meters (see also “Display pages” on

page 7). Press to select “PrESCAL

Cn1” then enter by means of the

keys the weight of every pulse of

the IN3 digital input of the water meters,

confirm with and go to the

“PrESCAL Cn2” submenu.

Enter by means of the keys

the weight of every pulse of the IN2

digital input of the Gas meter, then

confirm with .

S

▼▲

S

▼

▲

S

S

▼▲

S

S

▲

1.2..

..2.1

▼

S

S

▲

1.2..

..2.1

▼

The prescaler (PrESCAL) sets the weight of the input

pulses of the digital input module; e.g.: by setting the

prescaler at 10, for each received pulse the meter

increases by 10 (10, 20, 30, etc.). The range of the

prescaler varies from 0.1 to 100.0.

Page 16

▲

▲

15

Programming

Digital Output 2

13

Energy Meters

9

19

22

The increase of the Water, Gas meters, the selection of night/day tariff of the gas meters or the

change of tariff (t1, t2 t3, t4) is carried out thanks to

the combination of the input pulses to the AQ1038

or AQ1042 digital input module, according to the

following table:

SETTING OF

INSTRUMENT

Setting “tot Prd”

Display of total and partial multi-tariff energy

meters.

Setting “tot 1.Cn”

Display of total en.

meters and GAS

day/night tariff.

Setting “tot 2.Cn”

Display of total energy

meters, GAS and

WATER.

RESULT

Tariff 1

Tariff 2

Tariff 3

Tariff 4

GAS night tariff

GAS day tariff

DIGITAL INPUTS

IN 3

ON

ON

OFF

OFF

ON

OFF

OFF

ON

Increase

of

GAS

meters

(*)

Increase

of

WATER

meters

(*)

Increase

of

GAS

meters

(*)

ON

ON

IN 2

(*) The pulse corresponds to an increase of the various

meters by the pre-set weight.

If the IN 1 contact is closed (3 digital inputs module), the

programming from key pad is inhibited.

The synchronisation starts at the status modification of the

digital inputs (IN2 and IN3) when the instrument is set to

“tot” or “tot-Prd”.

Page 17

▲

▲

16

Programming

Alarm Output

11

dmd Calculation

91822

S

S

S

S

▲

▼

▲

▼

Alarm digital out-

put on page 18

Digital output 2

on page 19

■Digital Outputs

❑Digital Output 1

This function enables to set the

parameters of the digital outputs.

Choose the “diGout” function by

means of the and keys, to

enter the menu press . Then,

select one of the following

options;

PUL: access to the retransmission

functions of the totalized energy

by means of pulses (see pulse digital output);

ALr: access to alarm functions

(see alarm digital output); To enter

to relevant menu press ;

rEn: enables the activation of the

output by means of the serial

communication. Confirm with

to enable the function.

❑Pulse digital output

Select “diGout1 PUL” by means of

the and keys: press

to enter the relevant programming

submenu, then choose the meter

to be retransmitted among the

available ones.

S

▼▲

S

S

S

▼▲

S

S

Page 18

▲

▲

17

Programming

End of Programming

15

Digital Input Table

9

21

22

Digital output 2

on page 19

The list displaying the en. meters to be retransmitted

varies depending on the chosen setting of the

instrument, that is, depending on the “en. meter”

selection chosen among: “tot”, “tot-Prd”, “tot-

1.Cn”, “tot-2.Cn”, as reported in the table below:

IF THE SELECTION IS

tot, tot-1.Cn, tot-2.Cn:

kWh (consumed)

kWh- (generated)

kvarh ind (cons. inductive)

kvarh -ind (gen. inductive)

kvarh CAP (cons. capacitive)

kvarh -CAP (gen. capacitive)

IF THE SELECTION IS

tot-Prd:

kWh tot (total energy meter)

kvarh tot (total en. meter)

kWh t1 (energy meter tariff 1)

kvarh t1 (energy meter tariff 1)

and so on for the other

tariffs t2-t3-t4.

EXAMPLE OF DISPLAY

Scroll the energy meters displayed by means of and

choose the desired one by means of , then the instrument displays the page where the pulses to be associated

to the energy are indicated.

S

▼▲

Select the number of pulses by

means of (pulses/kWh from

1 to 100) and confirm with .

The

programming continues for digital

output 2.

S

▼▲

S

▲

1.2..

..2.1

▼

Page 19

▲

▲

18

Programming

Digital Filter

13

Energy Meters Menu

92022

S

▲

▼

❑Alarm Digital Output

This function allows the

user to set the parameters of the

alarm digital output. Choose the

“diGout1- ALr” function by means

of the keys: to enter the

menu press . Then, set the following parameters:

VAr: choose the variable to be

associated to the alarm activation

by means of the and keys

and confirm with .

rnG: choose the decimal point

position.

on: activation set-point, value of the

variable over which the alarm is activated. Select the value of the variable

by means of the and keys

and confirm it with ;

oFF: deactivation set-point, value of

the variable over which the alarm is

deactivated. Select the value of the

variable by means of the and

keys and confirm it with ;

nd: normally de-energized output

when there is no alarm.

nE: normally energized output

when there is no alarm.

Select the output status by means

of the and keys and con-

firm it with ;

S

▼▲

S

▼

▲

S

▼▲

S

▼▲

S

▼▲

▲

▼

▲

1.2..

..2.1

▼

▲

1.2..

..2.1

▼

S

S

S

S

Page 20

▲

▲

19

Programming

Useful Information

17

R

etransmittable en. meters

9

23

22

SEC: delay time from the detection

of the alarm and the activation of

the output. Choose the value of the

delay time in seconds by means of

the and keys (up to 255

seconds) and confirm with .

S

▼▲

S

Digital output 2

▲

1.2..

..2.1

▼

S

S

▲

▼

❑Digital Output 2

PUL: access to the retransmission

functions of the totalized energy by

means of pulses (see pulse digital

output on page 16).

ALr: access to alarm functions (see

alarm output on page 18). To enter

the relevant menu press ;

rEn: enables the activation of the

output by means of the serial com-

munication. Confirm with to

enable the function.

S

S

Page 21

▲

▲

20

Programming

Meters Reset

15

Meters Increase

92222

■ RS422/485 Serial port

address

Select “AddrESS” from the main

menu by means of the and

keys; to enter the menu press ,

then set the desired serial address

value (from 1 to 255) by means of

the and keys and confirm it

with .

S

▼▲

S

▼▲

S

S

▲

1.2..

..2.1

▼

S

S

▲

1.2..

..2.1

▼

S

▲

1.2..

..2.1

▼

■Digital Filter

Select “FiLtEr” by means of the

and keys: to enter the menu press

. Select the parameters to be set

with the and keys, to enter

the menu press .

There are two parameters:

- rnG, sets the operating range of the

digital filter. The value is expressed as

% of the full scale value: set the

desired value (from 0 to 100%) by

means of the and keys and

confirm it with ;

S

▼▲

S

▼▲

S

▼

▲

-

Coe, sets the filtering coefficient of the instantaneous measure-

ments. Set the desired value (from 1 to 16) by means of the and

keys and confirm it with . By increasing the value both the

stability and the settling time of the measurements are increased.

See also “Example 2” in Useful Information on page 23.

S

▼

▲

Page 22

▲

▲

21

Programming

Up/Down Alarm

19

Digital Output 2

9

25

22

■ End of programming

To exit from programming and go

back to the measuring mode, select

“End” from the main menu by means

of the and keys, confirm it

with

.

S

▲▼

Measuring

mode

S

S

S

S

▲

▼

RESET

■

Reset of total meters

Select “rESEt tot” from main

menu by means of the keys,

then confirm with . When the

instrument asks for the reset, choose,

by means of the keys:

“no” to avoid the reset or

“yes” to confirm it.

Then, press to carry out the command.

S

▼▲

S

▼▲

Instrument

revision

Page 23

■How to prevent the programming by key-pad

It is possible to prevent any access to

programming by modifying the switch in

the power supply slot (see the drawing on

the left), or closing the contact N 1 of the

digital input module if present.

▲

▲

22

Programming

What is ASY

17

Retransmittable meters

10

24

■ Reset of partial meters

Select “rESEt Prt” from the main

menu by means of the keys,

then confirm with . When the

instrument asks for the reset, choose,

by means of the keys:

“no” to avoid the reset or

“yes” to confirm it.

Then, press to carry out the command.

S

▼▲

S

▼▲

S

S

▲

RESET

Turn the switch using a little screwdriver.

-

Free programming.

- Lock programming.

Page 24

▲

▲

23

Useful Information

Dimensions

21

End of Programming

27

25

The variables measured by the instrument are

correct if the polarities of the inputs have been

observed (as shown in the figure below); if not,

measuring and retransmission errors may occur due to

the wrong direction of the current flowing in the primary

/ secondary of the connected current transformer.

Example 2 “Use of digital filter”:

it’s necessary to stabilize

the displayed value of the VL1-N variable that varies between

222V and 228V. The parameters of the digital filter are to be

set as follows:

• rnG: the variable varies within the average value, the

amplitude of which is equal to ±1.3% of the variable’s rated

value, calculated as follows:

(228-222)/2=±3V, then ±3*100/231V=±1.3%, where 231V

is the phase-neutral rated value of a 400V input range. The

“range” parameter, that corresponds to the action range of

the digital filter, is set at a value which is slightly higher than

the percentage amplitude of the fluctuation: e.g. 2%.

• CoE: if the new value acquired by the instrument is within the filter’s action range, then the new displayed value is cal-

culated by summing algebraically to the previous value the

variation divided by the filtering coefficient. As a consequence, a value which is higher than this coefficient implies a

longer settling time and therefore improves the stability. The

latter can also be improved by increasing the filtering coefficient: the admitted values are within 1 and 16. Enter the value

in consecutive attempts until you reach the desired stability.

Page 25

▲

▲

24

Useful Information

Installation

19

Digital Output 2

232625

■What is ASY

The ASY variable allows the user to control the symmetry of

the delta voltages (for systems without neutral) and star voltages (for systems with neutral). The variable is calculated

according to the following formula:

Where: Vmax is the max. value among VL1-N, VL2-N, VL3-N

Vmin is the min. value among VL1-N, VL2-N, VL3-N

Vavg is the average: (VL1-N, VL2-N, VL3-N)/3

The variable is not displayed by the instrument, but can be

retransmitted by the analogue or RS422 / 485 output and

can be controlled by means of the alarm.

■Retransmitted variables

Vmax - Vmin

Vavg

*100ASY=

N° Variable 3-ph with 3-ph with- Notes

neutral out neutral

1 V L-NΣ x Σ = system

2V L-LΣ xxΣ = system

3WΣ xxΣ = system

4 varΣ xxΣ = system

5VAΣ xxΣ = system

6PFΣ xxΣ = system

7PF x x

8 VA dmd x x

9 W dmd x x

10 ASY x x asymmetry

11 The energy meters as per table on page 17

12 All instantaneous variables (powers, currents, voltages)

Page 26

▲

▲

25

Useful Information

Available Modules

23

E.g.: Use of Digital Filter

23

29

■Alarm digital output

The activation of the alarm can be up or down depending on

how the ON and OFF parameters have been set, as per the

following table:

■Displaying of programming menu

It may be useful to know that the menus displayed

by the instrument depend on its configuration;

e.g.: the instrument will not display the menu relevant to the digital outputs if the optional module

is not inserted.

It is important that the instrument is switched

off when you plug-in or disconnect the modules.

ON-OFF ALARM TYPE

VALUES STATUS

ON ≥ OFF UP

ON < OFF DOWN

Page 27

▲

▲

26

Installation

Position of Slot

21

End of Programming

28

35

■Preliminary operations

Before switching the instrument on, make sure that the

power supply voltage corresponds to what is shown on the

side label of the relevant module.

■Before mounting the modules

To know in which slot every module is to be mounted,

refer to the figure on page 28. For a correct mounting of the

instrument, insert the modules in the relevant slots, then, at

the end, enter the central module, which can be a blind type

module or an RS232 communication module. The central

module will help fixing also the other modules in the relevant

slots. To remove the modules use a screwdriver as shown in

the picture below.

Gently depress the

two fixing tabs.

Directions 1-4.

1

Remove the central module

from its slot: press your

thumb towards points 2-5.

2

Extract the

central

module.

3

Any other slots that are not

used must be filled with the relevant blind plug modules supplied with the instrument.

Page 28

▲

▲

27

Installation

Optional Modules conn.

25

Up/Down Alarm

26

31

35

■Overall dimensions and panel cut-out

❑Mounting

Insert the instrument (holding

its front) and fasten it (from the

back) by fixing the two lateral

brackets (1) (supplied with the

instrument) to the appropriate

location (2), using the two

screws (3) supplied with the

instrument.

1

3

2

Page 29

▲

▲

28

Installation

Optional Modules

23

E.g.: Use of Digital Filter

263035

■Position of the slots and relevant modules

■Available modules

❑Relay digital output modules

A

B

C

D

PU

PS

IM

AO1058

Single relay

output

AO1035

Dual relay

output

Page 30

▲

▲

29

Installation

Serial connection

27

Mounting

26

33

35

DESCRIPTION A B C D PU PS IM

RS485/RS422 serial port ✓

RS232 serial port ✓

Single relay output ✓✓

Single open collector output ✓✓

Dual relay output ✓✓

Dual open coll. output ✓✓

3 digital inputs ✓

3 digital inputs +AUX ✓

Power supply ✓

Measuring inputs ✓

❑Open collector digital output modules

AO1059

Single open

collector output

AO1036

Dual open

collector output

Page 31

▲

▲

30

Installation

Relay Output conn.

25

Up/down Alarm

263235

AQ1038

3 digital

inputs

AQ1042

3 digital inputs +

aux

AR1034

RS485/422

serial port

AR1039

RS232 serial port

AP1020

90-260 VAC/DC Power supply

AP1021

18-60VAC/DC Power supply

AP1025

24VAC Power supply

AP1024

48VAC Power supply

AP1023

115VAC Power supply

AP1022

230VAC Power supply

❑Digital input modules

❑Serial port modules

❑ Power supply modules

Page 32

▲

▲

31

Installation

3-ph 3-wire connection

29

Modules Position

26

35

35

Connection by

NPN transistor.

AQ1042

Digital input

module.

Connection by

contacts.

AQ1042

Digital input

module.

Connection by

contacts.

AQ1038

Digital input

module.

Connection by

PNP transistor.

AQ1042

Digital input

module.

■Optional module connections

❑ Digital inputs

Page 33

▲

▲

32

Installation

Electrical diagrams

27

Dimensions

263435

This diagram is valid also

for the single output open

collector module.

The value of the load

resistances (Rc) must be

chosen so that the shortcircuit current is lower

than 100mA; the VDC

voltage must be lower

than or equal to 30 VDC.

❑Relay output

❑Open collector output

AO1058

Single relay output

AO1035

Dual relay output

AO1059

Single open collector output

AO1036

Dual open collector output

Page 34

▲

▲

33

Installation

Technical features

31

Digital Input Conn.

26

37

35

❑RS485/422 (AR1034) serial port

4-wire connection. Additional devices provided with

RS485/RS422 (that is RS 1,2,3...N) are connected in parallel.

2-wire connection. Additional devices provided with

RS485/RS422 (that is RS 1, 2, 3 ...N) are connected in parallel.

The termination of the serial output is carried out

only on the last instrument of the network, by

means of a jumper between (Rx+) and (T).

We recommend you to use the 4-wire connection:

by means of the serial port the data are exchanged

faster.

Page 35

▲

▲

34

Installation

Accuracy

29

Available Modules

263635

■Electrical diagrams

❑Single-phase connection

❑Three-phase, 4-wire, unbalanced load

L

1

N

L1

N

L3

L2

U

1

3 5

2

4 6

I

L1

L2

L3

8 7 10

9

CT and VT connectionsCT connection

L

1

N

L1

N

L3

L2

U

1

3 5

2

4 6

I

L1

L2

L3

8 7 10

9

CT connection

(4-wire system)

CT and VT connections

(4-wire system)

Page 36

▲

▲

35

Installation

Technical Features

33

Serial Connection

26

39

CT connection

(3-wire system) ARON

CT and VT connections

(3-wire system) ARON

❑ARON connection, 3-phase, 3-wire, unbalanced load

CT and VT connections

(3-wire system)

3 CT and 3 VT connections

(3-wire system)

Page 37

▲

▲

36

Technical Features

Digital Inputs

31

Digital Inputs Connection

38

40

■Number of inputs

Current: 3; Voltage: 4

■Accuracy

(display, RS232, RS485) In=5A; Pn= In* Un

Current: 0.003Ib to 0.2Ib: ±(0.5% rdg + 3DGT);

0.2Ib to Imax: ±(0.5 rdg + 1DGT);

Phase-neutral voltage: Un range: ±(0.5% rdg + 1DGT)

Frequency: ±0.1% Hz

Active power/energy: class 1 according to EN61036

Reactive power/energy: class 2 according to EN61268

Apparent power/energy: ±(1% Pn+2dgt), (@25°C ±5°C, R.H. ≤60%)

■Temperature drift

≤ 200ppm/°C

■Display refresh time

700ms

■Display

Back-lighted LCD 70 x 38mm

4x3

1

/2 dgt: instantaneous variables;

1x7

1

/

2

dgt: energy meters.

■Measurements

Current, voltage, power, power factor, frequency, energies.

TRMS measurements of distorted waves.

Coupling type: direct.

■Input impedance

208VLL 5(6)AAC (AV4): >200 kΩ (phase-neutral)

400VLL 5(6)AAC (AV5): >900 kΩ (phase-neutral)

100VLL 5(6)AAC (AV6): >200 kΩ (phase-neutral)

660VLL 5(6)AAC (AV7): >900 kΩ (phase-neutral)

■Input/Output modules technical features

RS422/RS485 (on request)

Multidrop bidirectional (static and dynamic variables)

Page 38

▲

▲

37

Technical Features

35

Electrical diagrams

36

40

Connections: 2 or 4 wires, max. distance 1200m, termination directly on the instruments.

Addresses: from 1 to 255, selectable by key-pad

Protocol: MODBUS/JBUS (RTU)

Data (bidirectional) Dynamic (reading only)

System and phase variables: see “display pages” on page 41

All configuration parameters, activation of the static output.

Data format: 1 start bit, 8-data bit, no parity,1 stop bit.

Baud-rate: 9600.

Insulation: By means of optocouplers, 4000 V

RMS

between

output and measuring input, 4000 V

RMS

between output and

power supply input.

RS232 (optional)

Bidirectional (static and dynamic variables)

Connections: 3 wires, max. distance: 15m.

Data format: 1 start bit, 8 data bit, no parity, 1 stop bit.

Baud-rate: 9600 bauds. Protocol: MODBUS (JBUS)

Other features: as per RS422/485

Pulse outputs (optional)

Number of outputs: Up to 2

Type:

from 1 to 100 programmable pulses

VON1.2 VDC/ max.

100 mA. V

OFF

30 VDC max.

The outputs can be connected to total and/or partial en. meters.

Pulse duration: ON=

220 ms, OFF≥ 220 ms

according to

DIN43864

Insulation: By means of opto-couplers, 4000 V

RMS

between

output and measuring input, 4000 V

RMS

between output and

power supply input.

Notes: outputs can be open collector or relay type (for the

relay output refer to the technical features described in the

alarms).

Page 39

▲

▲

38

Technical Features

General Specifications

33

Electrical diagrams

364040

Alarm outputs (optional)

Number of outputs: up to 2, independent

Alarm type: up or down alarm, phase asymmetry

Control on the variables: All variables listed in the paragraph

“retransmitted variables” on page 24 can be controlled.

Alarm set-point: can be modified from 0 to 100% of the displayed electrical scale.

Hysteresis: From 0 to 100% of the displayed scale

On-time delay: from 0 to 255 sec

Relay status: selectable, normally disabled or normally

enabled.

Output type: Relay, SPDT AC 1-8A, 250VAC; DC 12-5A,

24VDC; AC 15-2.5A, 250VAC; DC 13-2.5A, 24VDC

Min. response time: ≤ 150 ms, filters excluded, FFT exclud-

ed, on-time delay: ”0”

Insulation: 4000 V

RMS

between output and measuring input,

4000 V

RMS

between output and power supply input.

Notes: Outputs can be open collector type or relay type (for

the open collector type refer to the technical features

described in the pulse outputs).

Digital inputs

AQ 1038: N. of inputs: 3 (free-of-voltage)

Reading voltage: 24VDC/1mA

AQ1042: N. of inputs: 3 + power supply inputs

Power supply inputs:

output voltage: 16V<+Aux<24VDC;

output current: Max 15mA.

Input frequency: Max 20Hz, duty cycle 50%

Close contact resistance: Max 1kΩ

Open contact resistance: Min 100kΩ

Insulation: 4000VRMS

Use of contact 1: lock of the programming from key-pad

(when the contact is closed).

Page 40

▲

▲

39

Technical Features

37

Pulse outputs

36

40

Contacts 2-3: to be used in one of the following ways:

• tariff selection (t1-t2-t3-t4) and synchronization;

• total meters for day-night GAS tariffs;

• total GAS and WATER meters ;

■Software functions

Password: Numerical code of 4 dgts; 2 protection levels of

the programming data

1st level: Password “0”, no protection

2nd level: Password from 1 to 1000, all data are protected

Transformer ratio: CT from 1 to 5000

VT from 1.0 to 1999, with CT x VT ≤10000 max

Power dmd: Integration time programmable from 1 to 30 min

Filter: operating range: from 0 to 100% of the electrical input

scale

Filtering coefficient: 1 to 16

Filtering action: measurements, alarms, serial output

Display: up to 4 variables per page, 3-phase system with

neutral:

Page 1:

V L1, V L2, V L3, V LN∑

Page

2: AL1, AL2, AL2

Page 3:

W L1, W L2, W L3

Page 4: VA L1, VA L2, VA L3

Page 5: var L1, var L2, var L3

Page 6: PF L1, PF L2, PF L3, PF ∑

Page 7: W ∑, var ∑, PF ∑, Hz

Page 8: W ∑, VA ∑, PF ∑, Hz

Page 9: W dmd, VA dmd

Counter pages depending on the instruments setting:

Wh+ tot, Wh- tot, Wh tot, varh tot, varh L+ tot, varh L-,

varh C+, varh C-, m3 day GAS, m3 night GAS,

m3 GAS, m3 WATER, Wh t1, Wh t2, Wht 3, Wht4, varht1,

varht2, varht3, varht4.

Page 41

▲

▲

40

Technical features

35

Electrical diagrams

36

■ Power supply specifications

90 to 260 VDC/VAC;18 to 60VDC/VAC;

24 VAC -15%+10% 50-60Hz; 48 VAC -15%+10% 50-60Hz;

115VAC -15%+10% 50-60Hz; 230 VAC -15%+10% 50-60Hz

■General features

Operating temperature:

0 to +50°C (32 to 122°F) (H.R. < 90% non condensing)

Storage temperature:

-10 to +60°C (14 to 140°F) (HR. < 90% non-condensing)

Installation category: Cat. III (IEC 664)

Key-pad lock: by means of switch placed behind the dis-

play or by means of contact (if module 3 - input contacts is present).

Insulation: 4000 V

RMS

between inputs/outputs and ground

Dielectric strength: 4000 V

RMS

for 1 minute

■EMC

Emissions: EN50082-1 (class A) residential, commercial

and light industry environment. Immunity: EN 61000-6-2

(class A) industrial environment.

■Other standards

Safety: IEC 61010-1, EN 61010-1

Product: IEC 60688-1, EN 60688-1

Approvals: CE

5(6)A connections: screw-type, max. section 2.5 mm

2

(2 x 1.5mm2)

Housing: Dimensions: 96x96x140 mm

Material: ABS, NORYL, PC (front); self-extinguishing: UL 94 V-0

Protection degree: Front: IP65

Connections: IP20

Weight: approx. 400 g (packing included)

Page 42

OUR PRODUCTION SITES

Carlo Gavazzi Industri A/S

Hadsten - DENMARK

Inductive and Capacitive

Proximity

Sensors in full metal and

plastic

housings. Photoelectric

Sensors.

Level Sensors: Optical,

Conductive

and Capacitive.

Ultrasonic Sensors and

Magnetic

Switches. Limit Switches.

Dupline Field and Installation

Bus.

Building Automation Systems.

Carlo Gavazzi Ltd

Zejtun - MALTA

Solid States Relays.

Versions for PCB and panel

mounting.

AC Semiconductor Motor

Controllers

Soft starters.

Industrial and PCB Relays.

Carlo Gavazzi Controls SpA

Belluno - ITALY

Energy Management.

Timers and Monitoring

Relays.

Digital Panel Meters and

Temperature Controllers.

SAIET Elettronica SpA

Castel Maggiore (BO) - ITALY

Safety and Magnetic

Switches,

Safety Modules.

Mat Systems, Light Curtains,

Electrical Transient,

Protections.

Measuring Systems and

Encoders.

OUR SALES NETWORK

Carlo Gavazzi GmbH

Wien - AUSTRIA

Carlo Gavazzi NV/SA

Vilvoorde - BELGIUM

Carlo Gavazzi Inc.

Mississauga, ON - CANADA

Montreal, PQ - CANADA

Carlo Gavazzi Handel A/S

Hadsten - DENMARK

Carlo Gavazzi OY AB

Helsinki - FINLAND

Carlo Gavazzi Sarl

Roissy - FRANCE

Carlo Gavazzi GmbH

Weiterstadt - GERMANY

Carlo Gavazzi UK Ltd

Aldershot - GREAT BRITAIN

Carlo Gavazzi SpA

Lainate (MI) - ITALY

Carlo Gavazzi Automation Sdn Bhd

Petaling Jaya, Selangor - MALAYSIA

Carlo Gavazzi BV

Beverwijk - NETHERLANDS

Carlo Gavazzi AS

Porsgrunn - NORWAY

Carlo Gavazzi Lda

Lisboa - PORTUGAL

Carlo Gavazzi SA

Leioa (Bizkaia) - SPAIN

Carlo Gavazzi AB

Karlstad - SWEDEN

Carlo Gavazzi AG

Steinhausen - SWITZERLAND

Carlo Gavazzi Inc.

Buffalo Grove IL - USA

Further information on

www.carlogavazzi.com

CARLO GAVAZZI

Automation Components

WM24 ita-eng code 8020593 02/2003

Loading...

Loading...