Page 1

CARLO GAVAZZI

Automation Components

UDM 35/40 Digital Panel Meter

Programming Guide

Page 2

UDM 35/40 PANEL METER USER MANUAL

Index

Description 2

Programming Fundamentals 3

Access to Programming Mode/Password Protection 4

Programming 5-18

Inputs 5-6

Temperature Compensation 6-7

Display Configuration 7

Scaling the Inputs 8

Decimal Point Position 9

Display Span Configuration 9

Linearization 11-12

Alarm Set Point Configuration 12-16

Digital Filtering 16-17

Analog Output/Retransmission of Display Value 17-18

Serial Port Output 18

Fahrenheit/Celsius Conversion 19

External Command Function 20

UDMSoft User Guide 21

1

Page 3

UDM 35/40 PANEL METER USER MANUAL

UDM Description

The UDM 35/40 series is a universal Digital Panel Meter that has been

developed to meet the most advanced application requirements. The UDM 35

offers:

• Quick assembly and maintenance using plug & play modules

• Quick & easy parameter programming and parameter cloning to

other UDMs by means of UDMSoft or PC HyperTerminal

• Powerful variable control by means of up to four (4) alarm outputs

• Alarms can be up-down functions with automatic reset, up-down

with manual reset, and down alarm with disable function at powerup.

The UDM 40 offers the same features as the UDM 35, with the following

additional benefits:

• Display color adaptable to Green, Red and Amber

• Management of non-linear signals using the available 16-point

linearization capability

• “Alarm status at a glance” using a sequence of display colors that

can be programmed by the user

2

Page 4

UDM 35/40 PANEL METER USER MANUAL

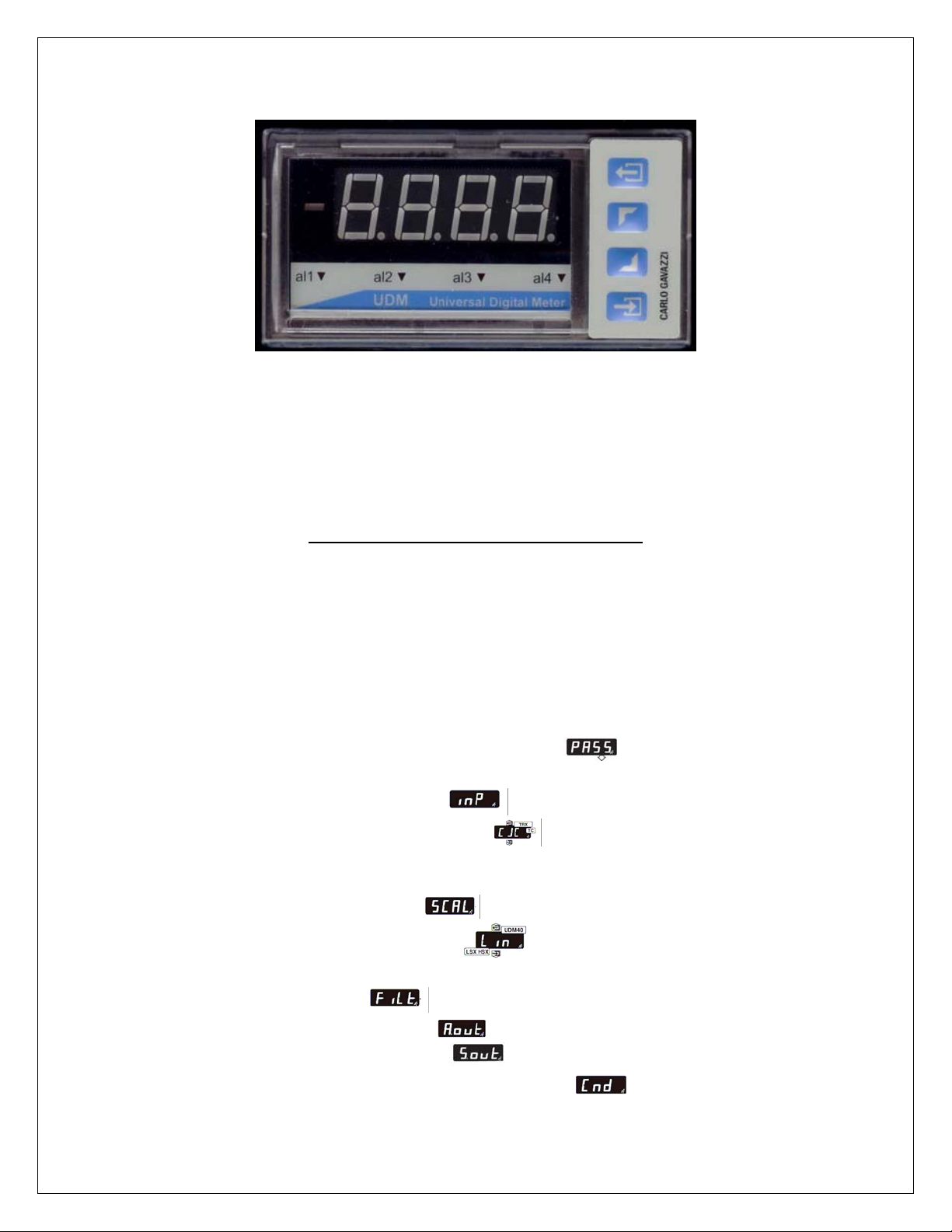

UDM 35/40 Programming Fundamentals

There are no jumpers to consider when programming the UDM 35/40. The

programming mode allows the user to define all of the instrument’s parameters.

Shown below are a description and the UDMxx display symbol for each basic

parameter grouping:

• Password for access to programming

• Input Probe Selection / Signal Range (current, voltage,

temperature, resistance)

• Cold Junction Compensation

• Display Selection (diSP)

• Display Color (CoLr)

• Scaling of Input Value

• Input Signal Linearization

• Alarm Set-Point (SP1 – SP4)

• Digital Filtering

• Analog Output Scaling

• Serial Port Configuration

• External Command from Input Contact

3

Page 5

UDM 35/40 PANEL METER USER MANUAL

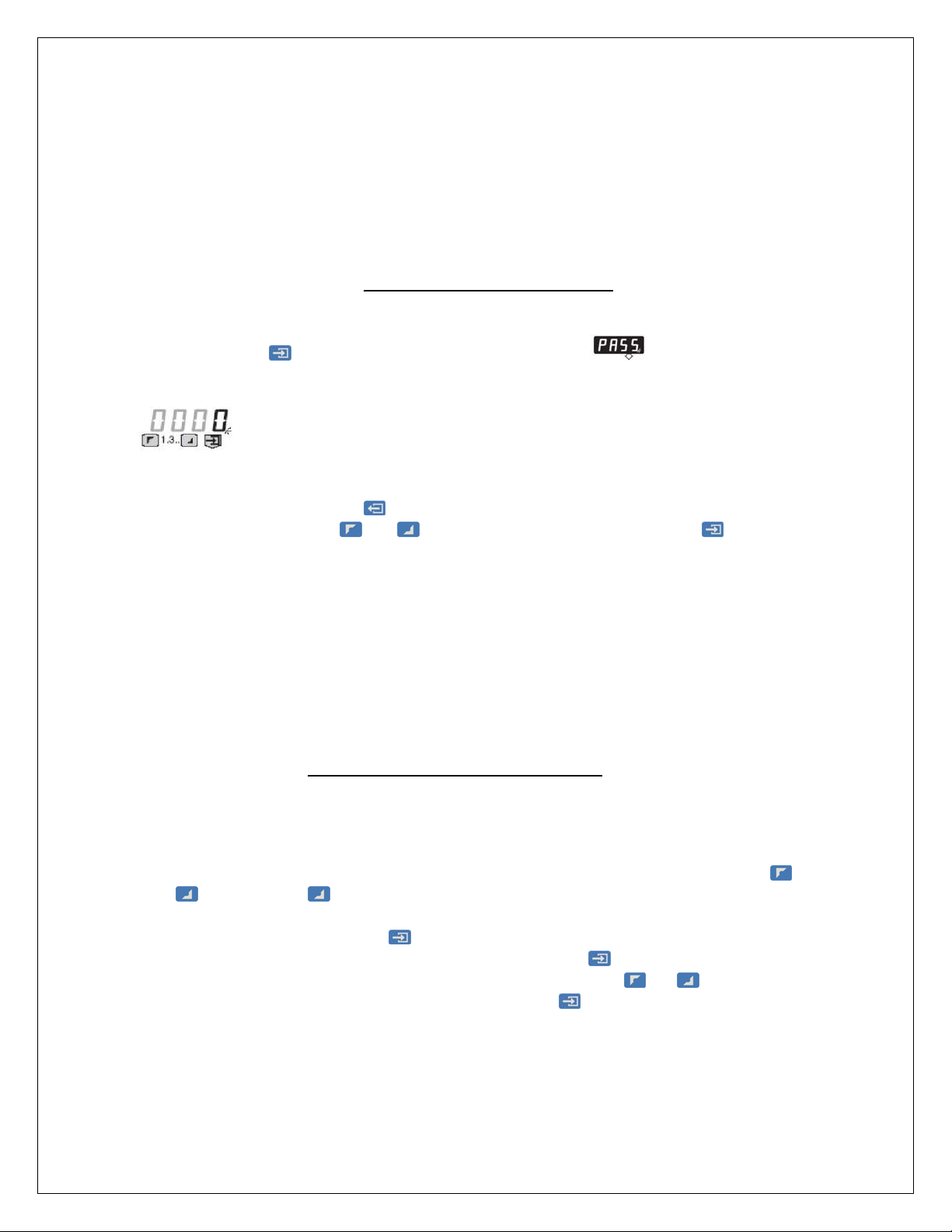

Access to Programming Mode

Press and hold for 2 seconds. Display will indicate (password).

Within 2 seconds, four zeros “0000” will be displayed as follow:

This is your prompt to enter your password. Each individual digit is selected from

left to right by toggling the key. Changing the value of each digit is

accomplished using the and arrows. When completed, press to

confirm this step. If the password you entered is not correct, you will not be

allowed access to program. Factory default password is set to “0000”.

Note: Choice of a password value is significant. Values from “0000” to “4999”

protect direct access to both set points and all other parameters. A password

value from “5000” to “9000” allow direct access to alarm set points only.

Negotiating the Programming Menu

After password is verified, you are in the Programming Mode. After

approximately 20 seconds, the unit will revert to RUN mode if no further entry is

made. Movement across the flow chart (see product carton instruction sheet for

BD35 and BD40) to a specific parameter heading is accomplished using the

and arrow keys. Pressing the UP key tabs from left-to-right across the flow

chart. Pressing the key tabs from right-to-left. Upon reaching the desired

parameter to configure, press

the first sub-parameter in this group. Each successive will scroll through the

remaining sub-parameters. To change a setting, press the

value of a sub-parameter is displayed, followed by to confirm the change and

advance to the next sub-parameter.

. The display will indicate the current setting for

or keys when a

4

Page 6

UDM 35/40 PANEL METER USER MANUAL

Programming the Input Modules

Press and hold for 2 seconds. Display will indicate PASS (password). Within

2 seconds, four zeros “0000” will be displayed. This is your prompt to enter your

password. If zero “0000” is your password, simply press to confirm. You

have approximately 20 seconds to begin programming before the unit reverts

back to run mode. (To enter a unique password, see Access to Programming

Mode, above.)

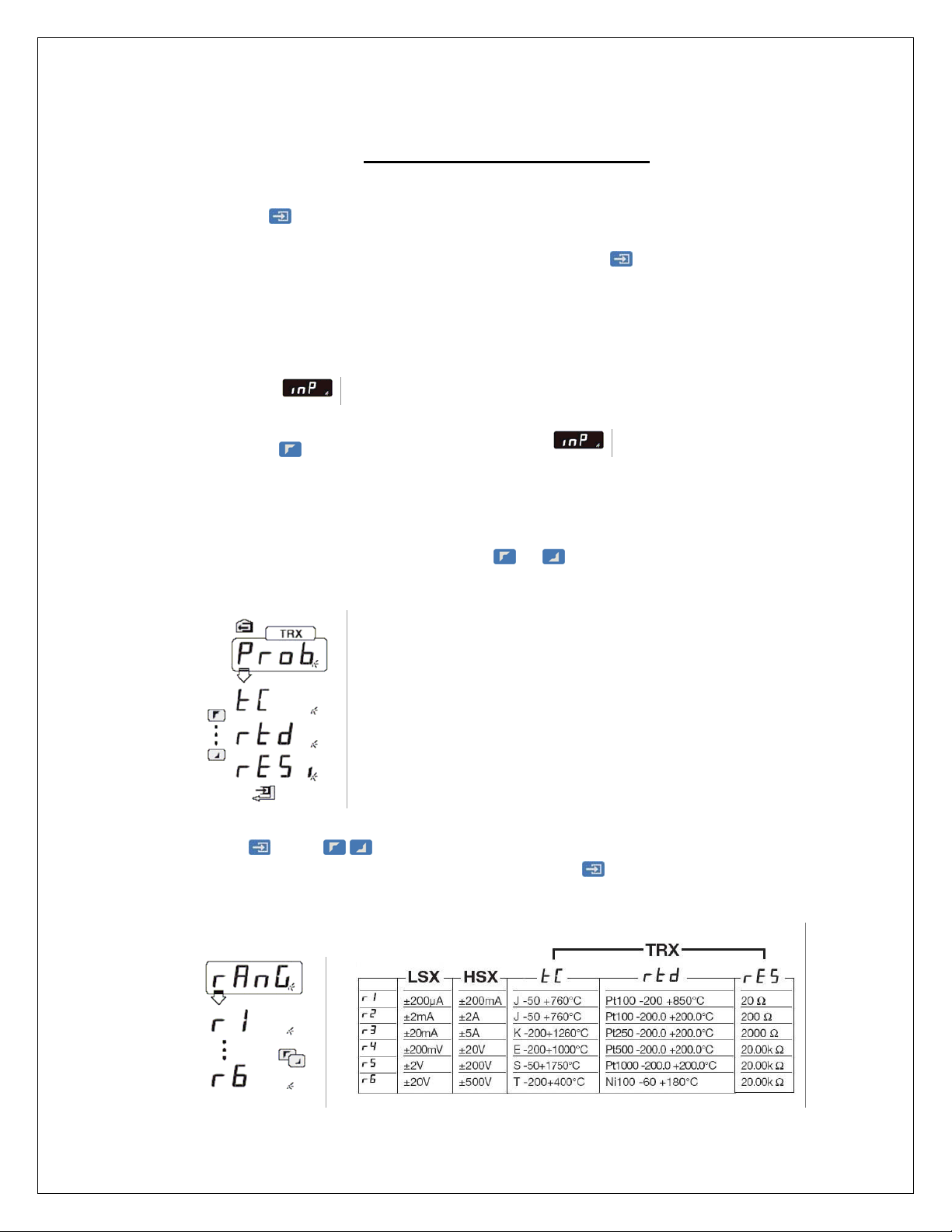

Input Selection

Press the key once to advance to Input

When the TRX module is installed, you must first indicate probe choice:

TRX input modules offer three Probe (Prob) choices: thermocouple* (tc),

RTD (rtd), plus resistive (rES). Use or keys to make selection.

Press . Use keys to select Range (r1, r2, r3, r4, r5, r6) according

to table below and on instruction sheet. Press

.

5

Page 7

UDM 35/40 PANEL METER USER MANUAL

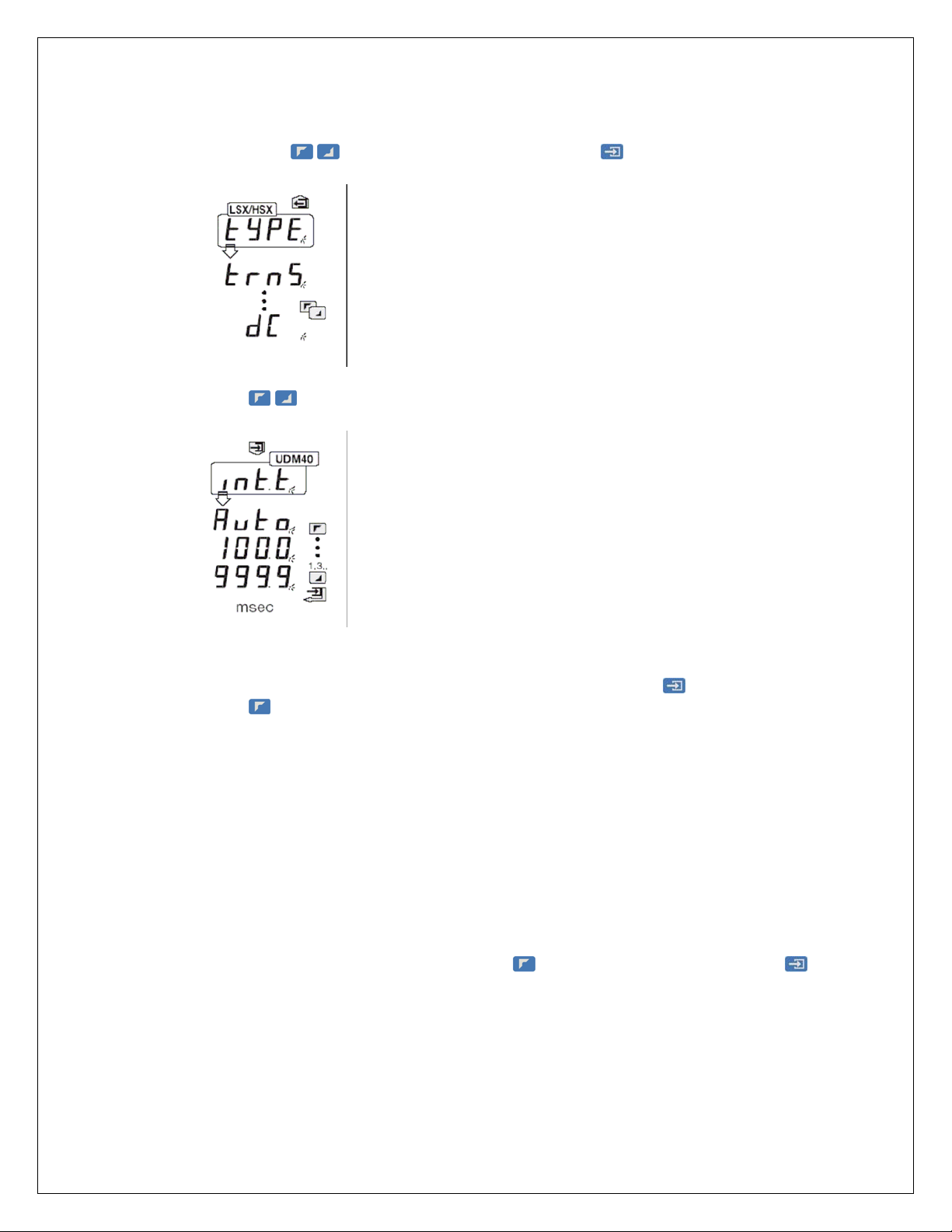

LSX and HSX input modules offer True RMS (trnS) or DC measurement

(dC). Use keys to make selection. Press .

Press keys to select Input signal integration time value (intt).

If all zeros “0000” is selected, “Auto” will be displayed and the value will be

automatically calculated from 100ms – 999.9 ms. Press to confirm.

Press to advance to next program step sequence.

Cold Junction Compensation (CJC) Temperature Compensation

Available only when TRX input module is installed.

TRX module with Thermocouple (tC) requires configuration of Cold

Junction Compensation (CJC). Press

to enter.

key to advance to CJC Then

6

Page 8

UDM 35/40 PANEL METER USER MANUAL

Press key to select Auto (Auto). Press to confirm. . Press to

advance to next program step sequence.

Manual compensation should only be used in special applications. Consult

factory.

Configuring the Display (diSP) UDM35 only

UDM 35 (BD35) base unit displays may be configured as 3 ½ digit (1999)

or 3 digit + dummy zero (9990). When “diSP” is displayed, press .

Then press keys to make selection. Press to confirm. Press

to advance to next program step sequence.

Selection of Display Color (CoLr) UDM40 only

UDM40 (BD40) base unit offers three display colors. When “CoLr” is

visible on the display, press

.

Use

Press to confirm. Press to advance to next program step sequence.

keys to select RED (rEd), Orange (orAn) or Green (GrEn).

7

Page 9

UDM 35/40 PANEL METER USER MANUAL

Scaling the Inputs

When is displayed, access is available for configuring the

electrical input range, the decimal point position and display span as

follows:

Electrical Input Range (HiE and LoE)

Allows the operator to define an electrical input range different from the

standard range setup at the “inP” programming step. As example, a UDM

with a full-scale 20mA (19.99mA) setting, it is possible to select an

electrical input range from 4.00mA (Lo.E) to 19.99mA (Hi.E) by

proceeding as follows:

When is displayed, press . “LoE” will appear.

Using the key, toggle to select a digit, then press the or key to

choose the desired value. Using the key, repeat as necessary until all

digits have proper values. Press .

“HiE” will now appear.

Using the same procedure as above, toggle through the digits using the

key and choose the desired values with the or key. Press to

confirm and advance to the next parameter, Decimal Point Position.

8

Page 10

UDM 35/40 PANEL METER USER MANUAL

Decimal Point Position (dP)

The decimal point position is relative to the Display Value, which will be

discussed next.

When “dP” is displayed, press .

decimal point position and press

“Lod” and “Hid”, the display span parameters.

Display Span (Lod and Hid)

Allows the user to define the actual display span (in engineering units)

corresponding to the previously defined electrical input range (HiE and

LoE). The “Lod” value represents the minimum displayed value; “Hid”

represents the maximum displayed value.

Using the and keys, select the

to confirm and advance to next step,

When “Lod” appears, press key to toggle to proper digit. Use the

and keys to select desired value. Repeat procedure until all digits

have been set, press to confirm and advance to the next step, “Hid”.

Repeat the same procedure to select and confirm the “Hid” values. Press

to confirm. Press to advance to the next program step sequence.

9

Page 11

UDM 35/40 PANEL METER USER MANUAL

Linearization

Introduction

When

may be modified by setting the input (in. 01 – in. 16) and output (ou. 01 –

ou.16) linearization points so that the accuracy of the displayed value is

maximized. This programming step is available when using the UDM40

and LSX/HSX input modules only. On the illustration below, the nominal

output characteristics of an analog inductive proximity sensor is 4-20mA.

Note the non-linear curve. The nominal characteristics need to be divided

into a number of segments. In this example, we can divide the curve into

9 segments (9 segments + 1) corresponding to the vertical axis. The

menu must be activated and the number of linearization points

set (10 in this example). Then the input/output coordinates must be

determined and entered into the program. In this example, going from

right to left on drawing, Input 1 (shown on drawing as “1.0”; displayed as

“in.01”) = 4. Output 1 (displayed as “ou.01) = 1.0. Likewise “in.02” (shown

on drawing as 0.9) =4.5, ou.02=0.9……Fast-forward to “in.09”=12,

ou.09=0.2, and “in.10”=20, “ou.10=0.1.

It is important to note that the first and last linearization points must

is displayed, a signal from a non-linear transducer-sensor

correspond to those points defined in the scale menu . In this

example: “in.01”= LoE, “ou.01”=Lo.d, “in.10”=HiE, “ou.10”=Hi.d.

Inputs are noted on the “X” axis and the analog current values along the

“Y” axis. Input 1.0 has a value of 4. The second input, 0.9, has a value of

4.5, etc.

10

Page 12

UDM 35/40 PANEL METER USER MANUAL

Navigating & Programming within the Linearization Menu

As appears, press followed by and keys to choose to

ignore or enable linearization . Press to confirm your choice

and advance to next step. If you chose YES, you will be prompted to

enter the number of Linearization Points, using the escape

button to select the position, and the up /down buttons to select

the numerical value, from 01-16. Press enter to confirm and advance.

Next, the correlation between the inputs and outputs must be defined in

the program.

“In.01” will be displayed. Press to toggle through the positions, and

use the and keys to select the value. Press to confirm and

advance. “Ou.01” will display next. Again, using the escape key ,

toggle to the appropriate position. Use the and keys to select the

value. Press enter to confirm and advance. Repeat this procedure for

each set of Inputs and Outputs, up through a maximum of 16. Press the

enter key to confirm. Press to advance to the next program step

sequence.

Alarm Set-point Programming

Up to 4 alarm set-points may be configured. You may configure each set

point using the following parameters, in order, as shown below:

Minimum set-point limit

Maximum set-point limit

Set-point setting

11

Page 13

UDM 35/40 PANEL METER USER MANUAL

Hysteresis selection

Off-Delay Value (0-255s)

On-Delay Value (0-255s)

Relay Selection (normally energized or de-energized)

Alarm Type (off, down, up, up with latch, down with latch)

Color of display during alarm (red, orange, green, none)

If “none” is selected, basic display color remains.

12

Page 14

UDM 35/40 PANEL METER USER MANUAL

Navigating through this program sequence

Minimum Set-Point

The lowest value, below which, it is not possible to program a set-point.

When is first displayed, you have reached the Set-point program

sequence. Press to enter program. The first parameter, Minimum Set-point

Limit, will be displayed. To skip this step and advance to the next

parameter, press the enter key . Otherwise, press the escape key to

select the proper numerical position to enter a value. Press the up/down arrow

keys to select the numerical value for each position. When completed,

press enter to confirm and advance to next programming sequence.

Maximum Set-Point

The highest value, above which, it is not possible to program a set-point.

Maximum Set-Point Limit . Using the same procedure as above,

press the escape key to toggle to the appropriate position. Then use the

up/down arrows to select the appropriate value for each position. Press

to confirm your choice and advance to the next programming step.

Set-Point

The actual value that must be reached to trigger an output.

When is displayed, press the key to toggle to the desired numerical

position. Use the keys to select the appropriate value for each position.

Press

sequence.

to confirm and advance to the next parameter in the program

13

Page 15

UDM 35/40 PANEL METER USER MANUAL

Hysteresis

The point at which an active alarm output must revert to for the alarm output to

turn off. Example: If an “up” alarm set point is “10.5”, and you want to have the

alarm reset at “10.3”, then the Hysteresis value to set in the program must be

“.2”, not 10.3. You need not be concerned about whether that value is to be in a

positive or negative direction. That is automatically configured when you select

the Down Alarm or Up Alarm.

When Hysteresis is displayed, use the key to toggle to the desired

numerical position. Using the keys, select the value for each position.

Then press to confirm and advance to the next step.

Off Delay

When Off Delay is displayed you may opt to choose a value of 0-255

seconds. Use the key to toggle to the desired position and select the correct

value with the keys. Press enter to confirm and advance to the next step.

On Delay

When On Delay is displayed, you may opt to choose a value of 0255 seconds by using the same procedure as Off Delay.

Relay Configuration

The set point alarm relay may be configured as “Normally Energized or Normally

De-Energized”. When

your choice. Press

The configuration of Alarm type allows for selection of “OFF” or disabled, “DOWN

alarm”, “DOWN alarm with disable at power on”, “UP alarm”, “UP alarm w/latch”,

“DOWN alarm w/latch”. When the displays shows use the

keys to make your choice. Press

the sequence.

to confirm and advance to the next step.

is displayed, press either or key to make

to confirm and advance to the next step in

14

Page 16

UDM 35/40 PANEL METER USER MANUAL

Configuring the Display Color for Alarm Event (UDM40/BD40 only)

When is displayed, the color of the display may be set to be RED,

ORANGE, or GREEN during the alarm event. Selecting NONE results in the

basic display color being used during alarm event. Use the keys to make

your selection and press

program step sequence.

to confirm. Press to advance to the next

Digital Filtering

The digital panel meters are extremely fast to follow the trend of input signals and

to display the relevant values. Unlike in analog panel meters, which tend to filter

the input and present a more stable indication, the fluctuations in digital panel

meters can be quite fast and prevent the user from clearly reading the displayed

value. Fluctuations can also be introduced when the resolution of the displayed

value is higher than the input resolution. The use of a digital filter results in

higher stability of the displayed value.

There are two types of filter parameters.

The first is and it defines the operating range of the filter. Generally,

Fil.S represents the resolution (in digits) wanted to assign to the display. It is

suggested to set this parameter to evaluate the amplitude of the fluctuation on

the display and use this value as Fil.S. If, for example, a display value fluctuates

between 2.5 and 3.4, it means that the fluctuation is 9 digits and the Fil.S must

be set as “9”.

When is displayed, you may elect to program filter values by pressing the

key. This results in being displayed. Using the key, toggle to

the desired position and select the value to enter by using the

to confirm and advance to the next step in the sequence.

keys. Press

15

Page 17

UDM 35/40 PANEL METER USER MANUAL

The second filter parameter is . It represents the filtering coefficient.

The higher the value of Fil.C, the smoother the curve of the displayed value.

There is no theoretical rule to define this parameter, but it is suggested to start

with the same value of the Fil.S coefficient and then increase it until the desired

stability is reached. The digital filter affects the values retransmitted via both

serial communications and analog output.

Once is displayed, use the key to toggle to the desired position.

Use the keys to select the value to enter. Press to confirm. Press

to advance to the next program step sequence.

Analog Output Programming

Many times the displayed value must be retransmitted as an analog output. The

relationship between parameters is as follows:

Low Display Value >>>>> Low Analog Output

High Display Value >>>>> High Analog Output

To assure proper coordination and retransmission, it is important to note that the

parameters are programmed as a percentage of the analog output full scale

value (20mA or 10 Vdc) according to the TYPE selection (see below). Therefore,

to set 4mA as Lo.A, the correct value to be entered must be 20 (20% of the full

scale 20mA range). The Hi.A must be 100 (100% = 20mA). Because of this

programming technique, it is possible to set a reverse slope analog output

characteristic.

16

Page 18

UDM 35/40 PANEL METER USER MANUAL

Programming example:

Retransmit a 4-20mA signal proportional to the following displayed values:

Lo.D = 0 and Hi.D = 18.

When is displayed, the Analog Output program may be addressed. Press

to enter sequence. is displayed. Press to toggle to the first

position. Use the keys to select value “0”. Press to toggle to the left to

“tens” position. Using keys, select value “2” and press enter to confirm

all choices and advance to the next program sequence.

will be displayed. Press to toggle to “hundreds” position and use

keys to select “1”. Press to toggle to each remaining position and

select “0” for each. When completed, press to confirm and advance to the

next program sequence.

will be displayed. Using the keys choose either “A” for 20mA

output full range, or “U” for 10v output. In this example, the selection would be

“A”. Press to confirm. Press to advance to the next program step

sequence.

Serial Port Output

When is displayed you may elect to configure a serial port address and

baud rate. Press . will be displayed. Using the key, toggle to the

desire position and select the proper value(s) using the

confirm.

When

indicated in kbits/sec. Press

last, program step sequence.

is displayed, use the keys to select the desired baud rate

to confirm. Press to advance to the next, and

keys. Press to

17

Page 19

CONVERTING CELSIUS TO FAHRENHEIT

The UDM35/40 digital panel meters use the Celsius temperature scale.

However, the displayed value can easily be scaled to indicate Fahrenheit values

by using the following guidelines:

The LoE and HiE are always expressed as Celsius values.

To display Fahrenheit values, manually convert the LoD to a Fahrenheit value

and then convert the HiD to a Fahrenheit value.

Ex:

LoE is 0

HiE is 100

Manual conversion to Fahrenheit:

LoD would be 32 (F)

HiD would be 212 (F)

Page 20

UDM 35/40 PANEL METER USER MANUAL

External Command Function

When is displayed, the user may elect to dedicate a Command signal

(contact closure) from the input module, terminals 6 & 7, to perform one of the

following:

C1 HOLD Function

C2 Disable-Keypad

C3 Reset latch Alarms

Press

the

to select Command sequence. Choose either C1, C2 or C3 by using

keys to make your selection. Press to confirm.

18

Page 21

UDMsoft Programming

The software is menu driven. Just fill-in-the-blanks with your parameters. There

is little explanation required. It is actually a simple process. Any confusion and

concern that has surfaced has surrounded the issue of setup with the PC/laptop.

The following segment is meant to clarify how to establish solid communication

between UDM and PC.

Do not connect or disconnect either end of the UCABLE when the input signal is

connected to the input module. This may result in failure of the input module, the

BD35/40 display, and possibly the PC.

Follow these steps when using UDMsoft:

1. With no power connected. Plug-in the UCABLE to the INPUT module

only. You will see the connector port on the inside face of the module.

2. With the UCABLE now installed on the Input module, connect a line

cord (power source) to the power supply module (BPH or BPL) and

power up the meter. The display will illuminate.

3. Connected the DB9 end of the UCABLE to the serial port on your PC

or laptop. The display will change. It may go completely dark or it may

revert to just a single digit being illuminated. All this is normal.

4. Launch the UDMsoftware. Once launched, this software may be left

open to accommodate the programming of additional UDM meters.

If the DB9 is connected prior to power being applied to the meter, the unit will not

be recognized. Programming will be locked out. The unit will appear to be dead.

Follow the sequence above, in order to assure reliable communication between

the UDM and your PC/laptop.

Page 22

UDM 35/40 PANEL METER USER MANUAL

Links: Resources & Data Sheets

UDM 35 Datasheet

https://www.gavazzionline.com/images/UDM35DS5ENG0404.pdf

UDM 40 Datasheet

https://www.gavazzionline.com/images/UDM40DS5ENG0404.pdf

UDM3540 Program Flow Chart

UDM3540 Input-Output Modules

UDM3540 FAQ (English)

Panel Meter Selection Guide: https://www.gavazzionline.com/usameters.htm

UDMSoft Downloads: https://www.gavazzionline.com/usadwnload.htm

Supplemental Announcements:

Connecting Programming Cable to PC, use with UDMSoft: Item # UCABLE

19

Loading...

Loading...