Cardinal IVAC-PCAM Service Manual

IVAC® PCAM®Syringe Pump

Technical Service Manual

This manual has been prepared for use by qualified service personnel only.

Cardinal Health cannot accept any liability for any breakdown or deterioration in performance of parts or equipment resulting from unauthorised repair or modification.

t Cardinal Health, 1180 Rolle, Switzerland

Alaris®, IVAC® and PCAM® are registered trademarks of

Cardinal Health, Inc. or one of its subsidiaries.

All other trademarks belong to their respective owners.

© 2005-2006 Cardinal Health, Inc or one of its subsidiaries. All rights reserved.

IVAC® PCAM® Syringe Pump |

2/106 |

1000SM00017 Issue 2 |

Contents

Chapter 1 Introduction & Start Up |

4 |

Chapter 2 Configuration & Calibration |

13 |

Chapter 3 Routine Maintenance |

26 |

Chapter 4 Troubleshooting |

38 |

Chapter 5 Circuit Descriptions |

42 |

Chapter 6 Spare Parts Replacement Procedures |

47 |

Appendix A Specifications |

83 |

Appendix B Spare Parts Listing |

90 |

Appendix C Configured Options & Drug Protocol Rec. |

97 |

Appendix D Service Centres |

100 |

Appendix E Disposal |

102 |

Appendix F Document History |

105 |

IVAC® PCAM® Syringe Pump |

3/106 |

1000SM00017 Issue 2 |

Chapter 1

Introduction & Start Up

In this chapter

Introduction |

5 |

General Precautions |

6 |

Front Panel, Controls and Indicators |

7 |

Main Display |

8 |

Loading a Syringe |

9 |

Starting the Pump |

10 |

Modifying a Preset Protocol |

10 |

Basic Features |

11 |

Printer Set Up |

12 |

Patient Hand Set |

12 |

Introduction & Start Up

Introduction

The IVAC® PCAM® Syringe Pump is designed to provide a small, self-administered dose of analgesic, as and when the patient demands it by activating a hand operated button. The clinician can select limits for various parameters, including the size of each individual dose, the minimum time between doses and the number of doses allowed during a period. In parallel to the patient controlled operation the pump allows the clinician to set an automatic loading dose which will be delivered at the onset of treatment. Similarly a continuous background infusion which is delivered irrespective of the patients demands for analgesia, can also be selected.

In addition, the pump will automatically record valuable information about each patients treatment and their individual demands for analgesia. This allows further analysis of the frequency with which analgesia is being requested, the total dose delivered etc.

Product Familiarity

Prior to operation of the pump and prior to attempting any repairs or servicing, carefully read the Directions for Use (DFU)

As part of continuous improvement, product enhancements and changes are introduced from time to time.

Purpose of this Manual

This Technical Service Manual describes how to set up, test and maintain the IVAC® PCAM® Syringe Pump. This manual is intended for use by personnel experienced in medical equipment testing and maintenance procedures.

Conventions Used in this Manual

|

BOLD |

Used for pump Display names, access codes, controls and indicators referenced in this manual, for |

|

|

|

|

example, GENERAL OPTIONS menu, access code 251, LOCK 1 keyswitch. |

|

|

|

|

|

'Single quotes' |

Used to indicate cross-references made to another section of this manual. For example, see Chapter |

|

|

|

|

2, 'Configuration & Calibration'. |

|

|

|

|

|

underline |

Used to indicate links to another section of this manual. |

|

|

|

|

|

|

Italics |

Used to refer to other documents or manuals. For example, refer to the relevant Directions for Use (DFU) |

|

|

|

|

for further information. Also used for emphasis, for example, ...position the narrow end of the tool... |

|

|

|

|

|

|

|

Wherever this symbol is shown a Hints & Tips note is found. These notes provide useful advice or |

|

|

|

information that may help to perform the task more effectively. |

Wherever this symbol is shown a Toolbox note is found. These notes highlight an aspect of test or maintenance that is important to know about. A typical example is drawing attention to a software upgrade that should be checked that it has been installed.

IVAC® PCAM® Syringe Pump |

5/106 |

1000SM00017 Issue 2 |

Introduction & Start Up

General Precautions

wPrior to using this pump, carefully read the Operating Precautions described in the Directions for Use (DFU).

This pump contains static-sensitive components. Observe strict precautions for the protection of static sensitive components when attempting to repair and service the pump.

An explosion hazard exists if the pump is used in the presence of flammable anaesthetics. Exercise care to locate the pump away from any such hazardous sources.

Dangerous Voltage. An electrical shock hazard exists if the casing of the pump is opened or removed. Refer all servicing to qualified service personnel.

This pump is protected against the effects of high energy radio frequency emissions and is designed to

Mbe fail safe if extremely high levels of interference are encountered. Should false alarm conditions be encountered, either remove the source of the interference or regulate the infusion by another appropriate means.

If the pump is dropped, subjected to excessive moisture, humidity or high temperature, or otherwise suspected to have been damaged, remove it from service for inspection by qualified service personnel.

IVAC® PCAM® Syringe Pump |

6/106 |

1000SM00017 Issue 2 |

Introduction & Start Up

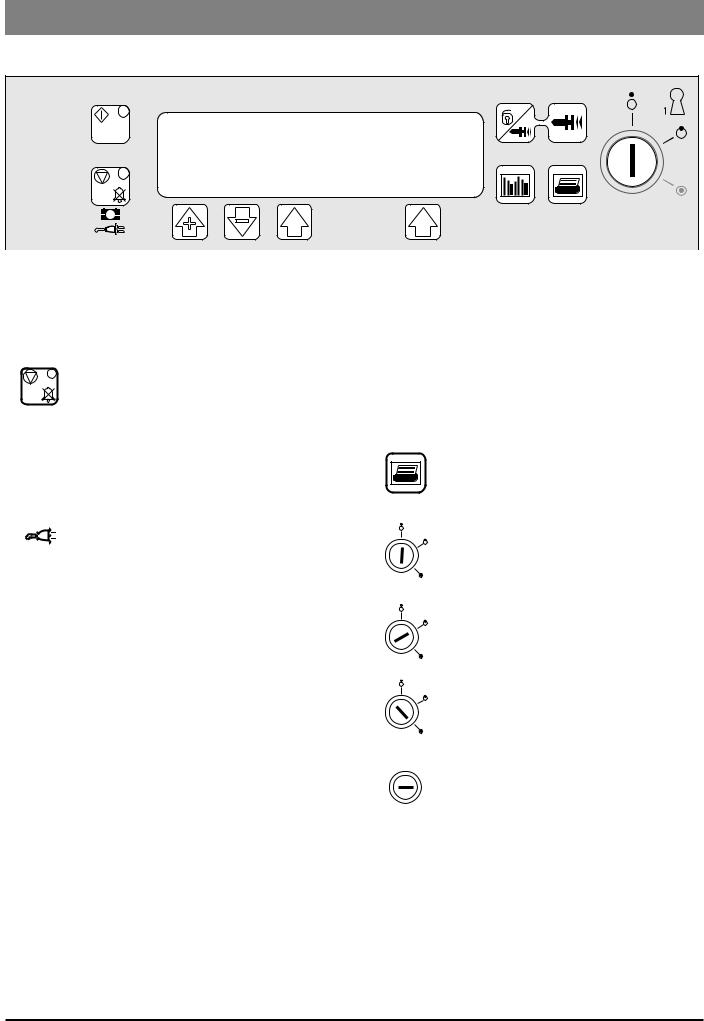

Front Panel, Controls and Indicators

Front Panel

Controls and Indicators

H |

START |

Press to start the infusion. The green |

|||||

|

LED will flash during infusion. |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STOP |

Press to stop/hold the infusion. The |

|

|

|

|

|

|

|

amber LED will be lit while on hold. |

|

|

|

|

|

|

BATTERY |

When illuminated, indicates that |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

the pump is running on the internal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

backup battery. When flashing, |

|

|

|

|

|

|

|

indicates that the battery power is |

|

|

|

|

|

|

|

low, with less than 30 minutes of use |

|

|

|

|

|

|

|

remaining. |

|

|

|

|

|

|

AC POWER |

When illuminated, indicates that the |

|

|

|

|

|

|

|

pump is connected to an AC power |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

supply and the battery is being |

|

|

|

|

|

|

|

charged. |

R |

PLUS/MINUS |

Use to move cursor and to increase |

|||||

BUTTONS |

or decrease values shown on main |

||||||

|

display. |

||||||

Q |

|

|

|||||

S |

ARROW |

Use as softkeys in conjunction with |

|||||

BUTTONS |

the prompts shown on the display. |

||||||

|

For example, to select the CALIBRATE |

||||||

|

|

|

|

|

|

|

option. |

WPURGE/ BOLUS

JHISTORY

LOCK 1

OFF

SET

RUN

LOCK 2

This key lock is located on the left side of the pump

Press and hold both buttons to purge the extension set during set up. See 'Basic Features' for further information.

Press to display PCA demands and drug infused history graphs, 24 hour review and event log.

Press to print patient history. Note: A suitable printer must be connected to the pump.

Insert key into LOCK 1 keyswitch and turn key to switch between OFF, SET and RUN positions.

OFF - Turns the power off.

SET - Use to select or modify protocols and to access configuration and test routines.

RUN - Use to start the infusion.

Note: Switching from RUN mode to SET mode without first pressing the STOP button automatically stops the infusion.

Insert key into LOCK 2 and turn key clockwise to open the syringe cover.

IVAC® PCAM® Syringe Pump |

7/106 |

1000SM00017 Issue 2 |

Introduction & Start Up

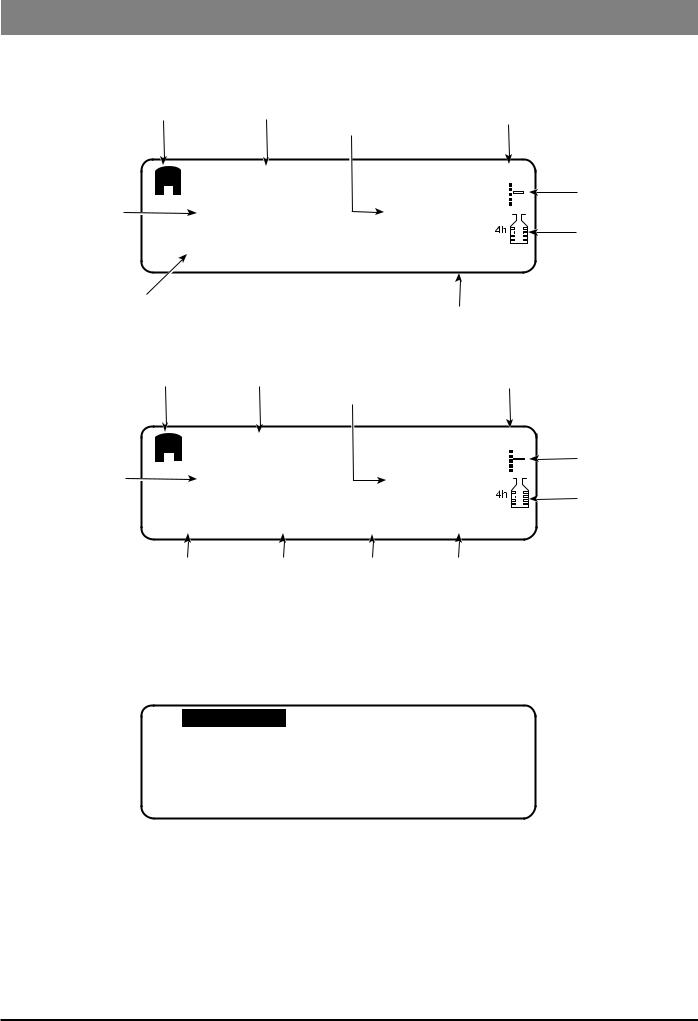

Main Display

Main Display

Example Software V3R2

Current Protocol |

Pump Status |

Volume Infused |

Time |

|

|

(Mass/Volume) |

|

|

|

|

|

|

PCA AVAILABLE |

|

|

|

|

13:07 |

|

||||||||

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

DEMANDS |

|

|

|

DRUG INFUSED |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

PCA Demand |

|

|

|

|

TOTAL |

1 |

|

|

|

1 . 0 μg |

|

|

|

|

|

|

|

||

Status |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

GOOD |

1 |

|

|

|

0 . 1 ml |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

BD PLASTIPAK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

50 ml |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PROTOCOL |

|||||||||||

Syringe Type/Infusion Rate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

View Protocol Summary |

|||||||||

Example Software V2R8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Current Protocol Pump Status |

Volume Infused |

|

|

|

Time |

||||||||||||||

|

|

|

|

|

|

|

(Mass/Volume) |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

13:07 |

|||||||

|

|

|

|

|

PCA AVAILABLE |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

DEMANDS |

|

|

|

DRUG INFUSED |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

PCA Demand |

|

|

|

|

TOTAL |

1 |

|

|

|

1 . 0 ug |

|

|

|

|

|

|

|

||

Status |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

GOOD |

1 |

|

|

|

0 . 5 ml |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

MORPHINE 1 |

PCA DOSE |

|

LOCKOUT |

CONTINUOUS |

||||||||||||||

|

1.0 mg/ml |

1.0 ml |

|

|

|

5 min |

0.0 ml/h |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Protocol Summary

Protocol Summary Screen

Example: Software V3R2 only

PROTOCOL

MORPHINE |

PCA DOSE |

LOCKOUT |

CONTINUOUS |

|

1.0 mg/ml |

1.0 mg |

2 min |

0 μg/h |

|

LOADING |

DOSE LIMIT |

|

DOSE RATE |

|

0 μg |

50.0 mg IN 4 h |

|

STAT |

|

|

|

|

|

|

|

|

|

QUIT |

|

* These icons are not displayed when disabled.

Pumping

Pressure Icon*

Maximum

Dose Icon*

Pumping

Pressure Icon*

Maximum

Dose Icon*

IVAC® PCAM® Syringe Pump |

8/106 |

1000SM00017 Issue 2 |

Introduction & Start Up

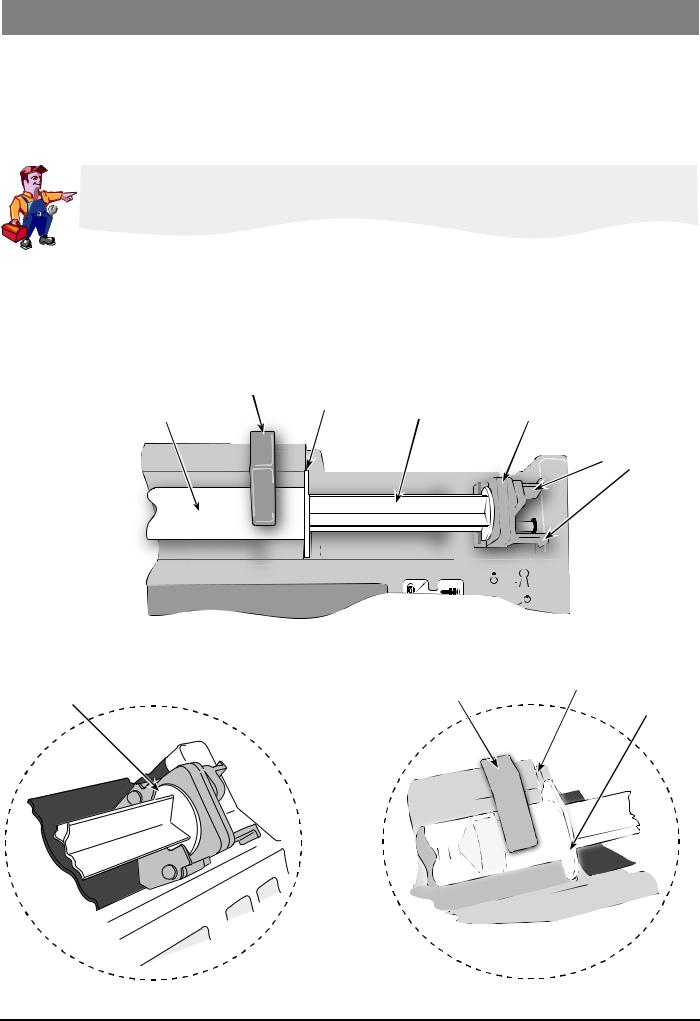

Loading a Syringe

1.Open the cover by turning the key in LOCK 2.

2.Squeeze the finger grips together on the plunger holder and slide the mechanism to the left.

3.Lift the syringe clamp and rotate to the left.

4.Insert the syringe into the slots on the plunger holder (see Figure 1).

5.Squeeze the finger grips on the plunger holder and slide the mechanism to the right until the syringe barrel flange locates into the V slot (see Figure 2).

Ensure that the syringe is advanced until the syringe barrel flange touches the front of the V slot closest to the syringe clamp. This is important to prevent delay at the start of the infusion.

6.Release the finger grips. Apply gentle pressure on the plunger holder to ensure that the drive is engaged.

7.Rotate the syringe clamp until it locks onto the syringe barrel (see Figure 2).

8.Check that the syringe plunger and syringe barrel flange are correctly located into their slots.

|

Syringe clamp |

|

Syringe barrel |

Syringe barrel flange Syringe plunger |

Plunger holder |

Finger grips

|

|

|

|

|

|

|

|

|

|

|

Syringe inserted |

|

Syringe clamp shown |

|

V slot |

||||||

into plunger holder slots |

locked onto syringe barrel |

|

|

|||||||

Syringe barrel flange

Figure 1. |

Figure 2. |

IVAC® PCAM® Syringe Pump |

9/106 |

1000SM00017 Issue 2 |

Introduction & Start Up

Starting the Pump

1.Connect the pump to AC Mains.

2.Open the cover by turning the key in LOCK 2.

3.Load the syringe. See instructions in previous section.

4.Power the pump ON by switching LOCK 1 to the SET position.

5.NEW PATIENT? NO retains patient data then displays the last protocol used. YES clears previous patient data then displays preset protocol A.

6.Check the protocol displayed. If required, select the NEXT PROTOCOL option to choose an alternative preset protocol, or select the MODIFY PROTOCOL option to adjust the current protocol. See 'Modifying a Preset Protocol' below for further information.

7.Switch LOCK 1 to the RUN position and remove the key.

8.CONFIRM PROTOCOL. Select OK.

9.CONFIRM SYRINGE. Select OK.

10.Purge (cover must be open): Press and hold the W buttons together.

11.Close the cover.

12.Connect the pump to test equipment as required (see Chapter 2, 'Configuration & Calibration' and Chapter 3, 'Routine Maintenance').

13.Press the H button to start operation.

Modifying a Preset Protocol

1.Switch LOCK 1 to the SET position. PROTOCOL SUMMARY is displayed.

2.Select the MODIFY PROTOCOL option (this option is not available when disabled). The current protocol parameters/values are listed.

3.Use the R Q buttons to move up/down the list of parameters. To change a parameter, highlight it and select ALTER. Use the R

Q buttons to toggle the values then select OK to confirm and return to the PROTOCOL SUMMARY. Note: A modified protocol has no preset letter in the top left corner of the PROTOCOL SUMMARY.

Note: See 'Preset Protocol Setup' in Chapter 2 for details of protocol parameters.

If enabled, an additional 'generic' drug with parameter limits set to maximum values can be selected when modifying protocols. Indicated by the drug name XXX DRUG , the drug can be selected from the preset list of drug names.

XXX DRUG , the drug can be selected from the preset list of drug names.

IVAC® PCAM® Syringe Pump |

10/106 |

1000SM00017 Issue 2 |

Introduction & Start Up

Basic Features

Purge

Clinician Over-ride

History

Pressure

Maximum Dose

Press and hold the W buttons together to deliver a limited volume of fluid in order to purge the extension line prior to being conected to the patient.

The purge feature cannot be activated when the cover is closed

Ensure the extension line is disconnected from the patient before purging the line

Alarms are not disabled during a purge operation

Press and hold the T button for 2 seconds then enter the pre-programmed clinician over-ride code to use this feature. Clinician over-ride can be used in RUN mode to administer an additional bolus dose or a continuous background infusion of a limited dose and duration, for example, during the PCA lock out period. It can also be used in SET mode to allow modification of the pre-set PCA Protocol when this option has been disabled.

For further information, see 'Access Codes' in Chapter 2.

If the over-ride code is incorrectly entered more than three times, the event

CLIN. ACCESS TAMPER is logged in the event log and a warning appears on the Display

Delivery of the clinician over-ride continuous infusion will automatically halt while a Patient or Clinician over-ride bolus is being administered

To cancel clinician over-ride during delivery, press the STOP button then select YES

Pressing the J button provides records of patient history and events since NEW PATIENT was last selected:

Press x 1 to display an hour-by-hour record of the number of good/failed PCA demands and the total drug infused over the last 24 hours

Press x 2 to display a graph of the good/failed PCA demands over the last 24 hours

Press x 3 times to view a graph of the total drug infused over the last 24 hours

Press x 4 times to view the event log

With a suitable printer connected (see 'Printer Set Up' on the following page), pressing the  button provides printouts of Patient History, Protocol Summary and the Event Log. Refer to the DFU for detailed printing instructions.

button provides printouts of Patient History, Protocol Summary and the Event Log. Refer to the DFU for detailed printing instructions.

Notes:

1)Access to the full Event Log can be enabled by entering access code 794.

2)Continuous printing can be configured, see 'General Options (251)'.

When enabled, this icon is shown on the Display. It provides a visual indicator of current pumping pressure and pressure level at which the alarm will operate.

When enabled, this icon is shown on the Display. It provides a visual indication of the H amount of drug administered during the limit period (as shown to the left of the icon).

If the dose limit reaches the alarm level, the bottle icon will appear full, the pump will stop infusing and the message Max Dose Limit is displayed. The icon will flash until the dosing is less than the maximum dose limit. Clinician over-ride is always available.

IVAC® PCAM® Syringe Pump |

11/106 |

1000SM00017 Issue 2 |

Introduction & Start Up

Printer Set Up

To set up a printer, fit a suitable printer with a serial interface cable and connect to the pump. See list of recommended printers below. See also PRINT button functions on previous page.

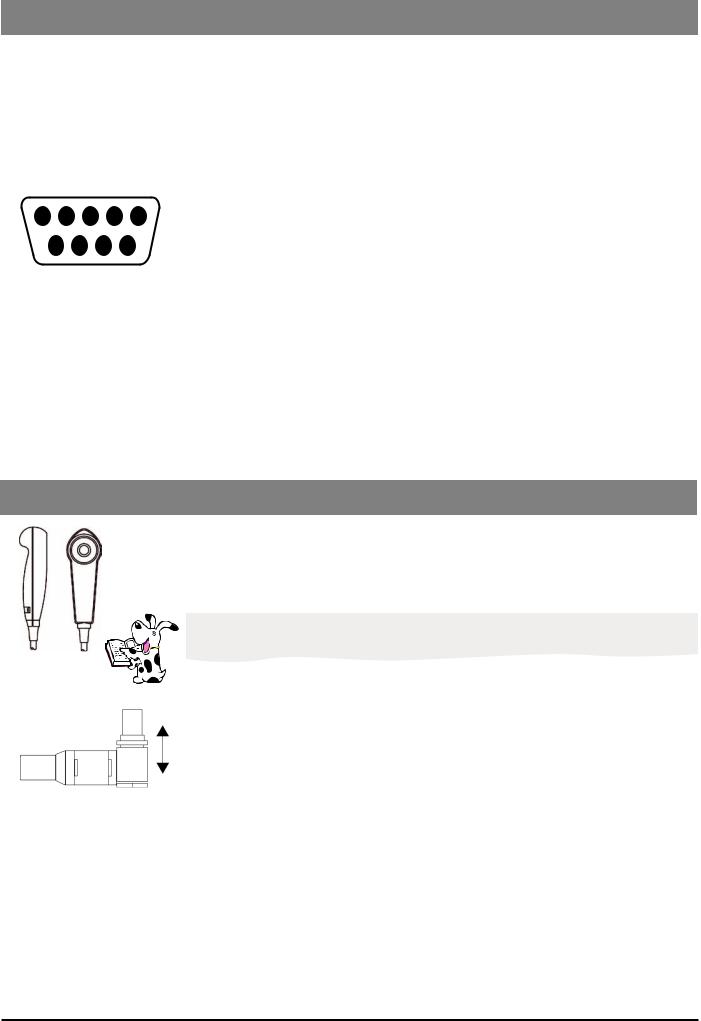

Cable Requirements

RS232 9-pin D type (1000SP01008)

Wiring connections

GND PWR1 TXD2 RXD2 ALM IN |

|

|

|

|

|

|

||||

5 4 |

3 |

2 |

1 |

|

Pump |

|

Printer |

|||

|

|

|

|

|

Female |

Male |

|

|

||

|

|

|

|

|

Pin 5 |

|

GND |

Pin 5 |

|

GND |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pin 8 |

|

CTS1 |

Pin 8 |

|

CTS1 |

6 |

7 |

8 |

9 |

|

|

|

|

|

|

|

|

Pin 9 |

|

TXD1 |

Pin 3 |

|

RXD1 |

||||

NC |

NC |

CTS1 |

TXD1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Recommended printers

Seiko DPU-414, thermal printer (use cable 1000SP01184)

Citizen N60 (use cable 5000SP00010)

Canon Bubblejet (use cable 5000SP00008). Note: A serial to parallel adapter is required.

Continuous Printing

To configure continuous printing of events as they occur, enable the CONTINUOUS PRINT option in GENERAL OPTIONS.

Patient Hand Set

The electronic patient hand set is designed to be ambidextrous and suitable for both adult and paediatric use.

The indicator light can be configured to show when the PCA dose is available or being delivered. Should the clinical situation require it, the indicator light can be disabled. The PCA button will provide feed-back on all, or just good demands. See Chapter 2, 'General Options' for HANDSET MODE configuration details.

The patient handset does not contain any latex.

The hand set connector is a latching (but non-locking) connector. To remove, hold the body of the connector and pull away from the pump. If required, the pump can be operated in continuous or clinician over-ride modes without the hand set connected.

Note: An alarm warning will operate if the hand set is disconnected from the pump while it is in operation, or when the handset is connected to the pump with the PCA button depressed.

IVAC® PCAM® Syringe Pump |

12/106 |

1000SM00017 Issue 2 |

Chapter 2

Configuration & Calibration

In this chapter

Access Codes |

14 |

Entering an Access Code |

14 |

Configuration Options (251) |

15 |

Drug Names and Safety Limits Set Up (251) |

16 |

General Options (251) |

17 |

Preset Protocol Set Up (251) |

19 |

Syringe Range Selection (359) |

20 |

Language Selection (359) |

20 |

Setting the End of Infusion (EOI) Position |

21 |

Calibration Procedures |

22 |

Syringe Size Calibration (243) |

22 |

Occlusion Calibration (717) |

23 |

Battery Charge Circuit Verification |

25 |

Clearing Internal RAM (611) |

25 |

Configuration & Calibration

Access Codes

The syringe pump software contains a number of configuration and test routines that can be accessed using a technical access code as shown in the table below.

Code |

Title |

Description |

|

|

|

111* |

HOSPITAL NAME |

Configure name of hospital/ward to be displayed when pump is powered on and |

|

|

when pump is in 'sleep' mode (when DISPLAY SLEEP is enabled). |

|

|

To set the hospital name, use the R Q buttons to toggle through characters and |

|

|

the S button to adjust, then select OK to store. |

|

|

|

123 |

SELF TEST |

Self test routine begins from the start. See Chapter 3, 'Routine Maintenance' for |

|

|

further information. |

|

|

|

124 |

SELF TEST |

Self test routine begins at internal PSU voltage test. |

|

|

|

125 |

SELF TEST |

Self test routine begins at display test. |

|

|

|

126 |

SELF TEST |

Self test routine begins at declutch test. |

|

|

|

127 |

SELF TEST |

Self test routine begins at handset test. |

|

|

|

167 |

COMMS LEARN MODE |

Configuration set via comms interface. |

|

|

|

168 |

COMMS TEACH MODE |

Configuration output to another device (pump). |

|

|

|

243 |

SYRINGE SIZE CALIBRATION |

Syringe size measurement calibration. See 'Calibration Procedures' on the following |

|

|

pages for instructions. |

|

|

|

251 |

CONFIGURATION OPTIONS |

Configuration of drug limits, options, protocols and real-time clock. See |

|

MENU |

'Configuration Options (251)' on the following pages for further details. |

|

|

|

359 |

BUILD CONFIGURATION |

Configure language and syringe range. |

|

|

|

376 |

SERVICE LOG |

Review and clear service log errors, hours of battery use and hours of pump on |

|

|

time. To reset the service log to zero press the RESET softkey. |

|

|

|

501** |

MASS DOSING |

Enable mass dosing. Drugs and protocols use mass dose mode. |

|

|

|

502** |

VOLUME DOSING |

Enable volume dosing. Drugs and protocols use a mix of mass and volume. |

|

|

|

611 |

TOTAL MEMORY CLEAR |

Reset memory. Note that the pump will require full calibration. |

|

|

|

717 |

OCCLUSION CALIBRATION |

Occlusion calibration. See 'Calibration Procedures' on the following pages for |

|

|

instructions. |

|

|

|

794 |

FULL EVENT LOG |

Enable access to full Event Log. |

|

|

|

835 |

MODIFY CLINICIAN CODE |

Change the 3-digit clinician over-ride code. |

|

|

|

* This option is not available on pumps with software version V2R8 and below.

** These options are no longer in use on pumps with software version V3R2 and above. See DOSE MODE in 'Drugs and Safety Limits' and MIX MASS & VOL MODES in 'General Options (251)'.

Entering an Access Code

Each menu (and certain individual options) has its own three-digit technical access code which is entered using the following procedure:

1.Hold down the H button and switch LOCK 1 to the SET position.

2.When the display shows ACCESS CODE 0 0 0, release the H button.

3.Enter the required access code "XXX" using the R Q buttons in conjunction with the S button (to select the NEXT option to move through the digits).

4.When the required code is shown, select the ENTER option to confirm.

IVAC® PCAM® Syringe Pump |

14/106 |

1000SM00017 Issue 2 |

Configuration & Calibration

Configuration Options (251)

Enter the access code 251 (see 'Entering an Access Code' on the previous page for instructions). The CONFIGURATION OPTIONS menu is displayed:

|

CONFIGURATION OPTIONS MENU |

|

|

Option |

Description |

|

|

DRUG NAMES AND SAFETY LIMITS |

Set drug names and limits. See the next section for further details. |

|

|

GENERAL OPTIONS |

See 'General Options (251)' for further details. |

|

|

PROTOCOL DEFAULT SET-UP |

Set default protocol and alter preset protocols. See 'Preset Protocol Set Up' for further |

|

details. |

|

|

CLOCK SET |

Set the internal clock. |

|

To set the clock, use the R Q buttons and the S button to adjust, then select OK to |

|

store. |

|

The internal clock is the reference against which patient history and |

|

events are stored. Patient history should always be recorded and if |

|

required, printed prior to changing the clock. |

|

Changing the clock will automatically: |

|

Reset the time and date against which all new patient history is |

|

stored and may affect the presentation of the history graphs. |

|

Clear previous patient data. Only NEW PATIENT? YES will be |

|

available at start up. |

|

|

IVAC® PCAM® Syringe Pump |

15/106 |

1000SM00017 Issue 2 |

Configuration & Calibration

Drug Names and Safety Limits Set Up (251)

1.Enter the access code 251 to display the CONFIGURATION OPTIONS menu.

2.Select DRUG NAMES AND SAFETY LIMITS using the R Q buttons then select ENTER. DRUG 1 is displayed.

3.Select NEXT DRUG to choose another drug or select MODIFY DRUG to modify the current drug, as detailed below. Alternatively, select QUIT to return to the CONFIGURATION OPTIONS menu.

4.Step through each DRUG option (see table below) and modify as required.

Use the R Q buttons to toggle/select a value then select OK to confirm and continue to the next option.

Use the S button at any time to go back to the previous option.

5.When set up is complete, switch LOCK 1 to the OFF position.

|

DRUG NAMES AND SAFETY LIMITS |

|

DRUG option |

Description |

|

|

|

|

DRUG NAME |

Enter drug name. |

|

|

Use the R Q buttons in conjunction with the S button (to go to the next drug |

|

|

name letter). |

|

|

|

|

DOSE MODE* |

Select the dose mode: |

|

|

VOLUME |

Volume mode. Drugs and protocols use volume based units. Not |

|

|

available when MIX MASS & VOL MODES is disabled. |

|

MASS |

Mass mode. Drugs and protocols use mass based units only. |

|

|

|

MINIMUM: DRUG CONC. |

Set the minimum drug concentration between 1 μg/ml and 999 μg/ml or 1.0 mg/ml |

|

|

and 99.9 mg/ml. OFF is also available in Volume mode. |

|

|

|

|

MAXIMUM: DRUG CONC. |

Set the maximum drug concentration between 1 μg/ml and 999 μg/ml or 1.0 mg/ |

|

|

ml and 99.9 mg/ml. Maximum value cannot be set below the minimum value. |

|

|

|

|

MINIMUM: LOCKOUT PERIOD |

Set the minimum lockout period (0 - 180 minutes). |

|

|

|

|

MAXIMUM: LOCKOUT PERIOD |

Set the maximum lockout period (0 - 180 minutes). Maximum period cannot be set |

|

|

below minimum period. |

|

|

|

|

MINIMUM: PCA DOSE |

Set the minimum PCA dose. In Mass mode - between 0 μg and 999 μg or 1.0 mg |

|

|

and 99.9 mg. In Volume mode, between 0.0 ml and 99.9 ml. |

|

|

|

|

MAXIMUM: PCA DOSE |

Set the maximum PCA dose. In Mass mode between 0 μg and 999 μg or 1.0 mg and |

|

|

99.9 mg. Volume mode between 0.0 ml and 99.9 ml. |

|

|

|

|

MAXIMUM: CONTINUOUS |

Set the maximum continuous dose. In Mass mode - between 0 μg/h and 999 μg/h |

|

|

or 1.0 mg/h and 99.9 mg/h. In Volume mode - between 0.1 ml/h and 25.0 ml/h |

|

|

(V2R8 or below), between 0.1 ml/h and 35.0 ml/h (V3R2 or above and for syringes |

|

|

>50ml). |

|

|

|

|

MAXIMUM: LOADING DOSE |

Set the maximum loading dose. In Mass mode - between 0 μg and 999 μg or 1.0 |

|

|

mg and 99.9 mg. In Volume mode - between 0.0 ml and 99.9 ml. |

|

|

|

|

MAXIMUM: MAX LIMIT |

Set the maximum limit. In Mass mode - between 0 μg and 999 μg or 1.0 mg and |

|

|

999 mg. In Volume mode - between 0.0 ml and 999 ml. |

|

|

|

|

MAXIMUM: CLINICIAN BOLUS |

Set the maximum clinician bolus dose. In Mass mode - between 1 μg and 999 μg or |

|

|

1.0 mg and 99.9 mg. In Volume mode - between 0.1 ml and 99.9 ml. |

|

|

|

|

* This option is not available on pumps with software version V2R8 and below.

Note: For pumps with software version V2R8 or earlier, the options may vary, or will not be available. Refer to the relevant DFU for comprehensive information.

IVAC® PCAM® Syringe Pump |

16/106 |

1000SM00017 Issue 2 |

Configuration & Calibration

General Options (251)

1.Enter the access code 251 to display the CONFIGURATION OPTIONS menu.

2.Select GENERAL OPTIONS using the R Q buttons then select ENTER.

3.Use the R Q buttons to toggle/alter a value then select NEXT to move to the next option. Select QUIT at any time to go back to

GENERAL OPTIONS menu.

4.When set up is complete, switch LOCK 1 to the OFF position.

GENERAL OPTIONS

Software version: V3R2

|

Option |

Description |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

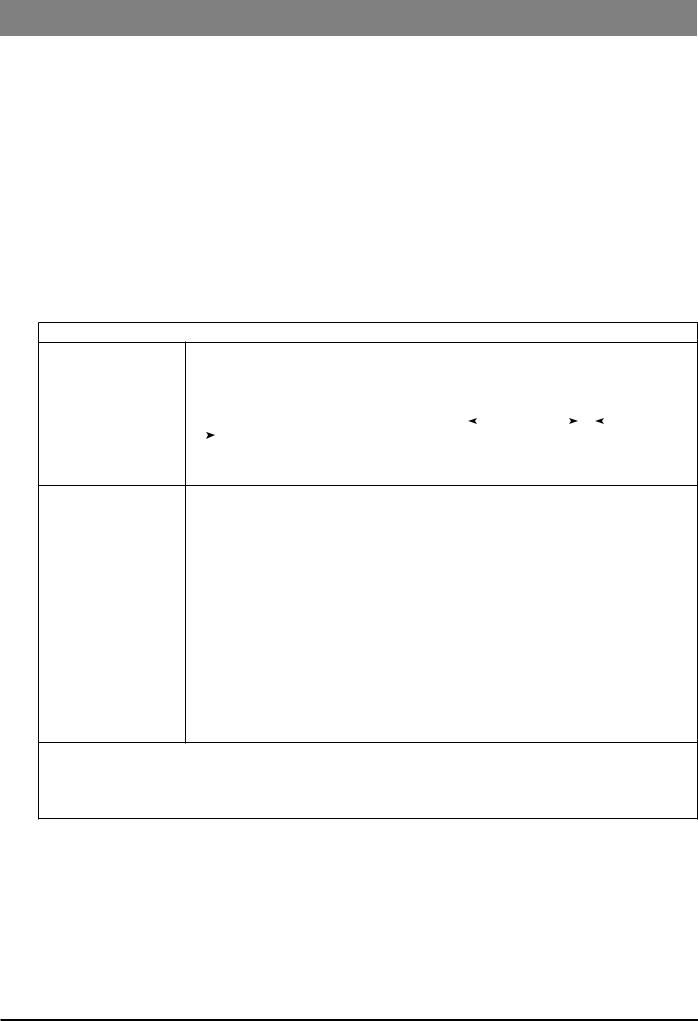

1. |

ICONS ON DISPLAY |

YES: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The |

|

(Pressure) and |

H |

|

|

|

|

(Max dose) icons are shown on the Display. |

||||||||

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|||||||||

|

|

NO: |

|

|

|

|

|

|

|

|

|

|

||||

|

|

No icons are shown on the Display. |

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

2. |

PROTOCOLS IN USE |

Set the number of preset protocols to be available (1 to 10). |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3. |

MODIFY PROTOCOL |

YES: |

Allows protocols to be modified in SET mode. |

|

|

|

||||||||||

|

|

NO: |

MODIFY PROTOCOL option disabled (removed from SET mode). |

|||||||||||||

4. |

HANDSET MODE |

|

MODE |

|

|

|

|

|

A |

|

B |

|

C |

|||

|

|

BEEP |

|

|

|

GOOD |

|

|

|

ALL |

|

|

ALL |

|||

|

|

Handset light: |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

PCA STOPPED |

|

OFF |

|

|

|

ON |

|

|

OFF |

|||||

|

|

PCA AVAILABLE |

|

ON |

|

|

|

ON |

|

|

ON |

|||||

|

|

PCA DELIVERING |

FLASH |

|

|

|

ON |

|

|

FLASH |

||||||

|

|

PCA LOCKOUT |

|

OFF |

|

|

|

ON |

|

|

ON |

|||||

5. |

DELAYED CALL BACK |

YES: |

Call-back alarm can be delayed (10 - 90 minutes). |

|

||||||||||||

|

|

NO: |

Call-back will be cancelled (up to 2 minutes, or extended to 15 minutes). |

|||||||||||||

6. |

DISPLAY SLEEP |

YES: |

During operation, Display goes blank (into sleep mode) after 2 minutes. |

|||||||||||||

|

|

NO: |

Display stays on during operation. |

|

|

|

||||||||||

7. |

CHIRP LOW ALARMS |

YES: |

"Chirp" alarm occurs during use of battery/near end of battery. |

|||||||||||||

|

|

NO: |

No "chirp" alarm during use of battery/near end of battery. |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8. |

CONTINUOUS INFUSIONS |

YES: |

CONTINUOUS infusion option enabled in PROTOCOL set up. |

|

||||||||||||

|

|

NO: |

Continuous infusions are not available. Option not available in PROTOCOL set |

|||||||||||||

|

|

|

up. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

9. |

LOADING DOSES |

YES: |

LOADING DOSE option enabled in PROTOCOL set up. To activate this option, |

|||||||||||||

|

|

|

NEW PATIENT is confirmed. Start the PCA. |

|

|

|

||||||||||

|

|

NO: |

Loading doses are not available. |

|

|

|

||||||||||

10. |

MAX DOSE LIMITS |

YES: |

MAX LIMIT option enabled in PROTOCOL set up. |

|

|

|

||||||||||

|

|

NO: |

Dose limits are not available. Option not available in PROTOCOL set up. |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11. |

VARIABLE DOSE RATES |

YES: |

PCA DELIVERY option enabled in PROTOCOL set up |

|

||||||||||||

|

|

NO: |

Variable PCA doses not available. |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

12. |

COMMS PUMP IDENTITY |

Set pump identity for use with remote communications (000 to 127). |

|

|||||||||||||

13. |

COMMS ENABLED |

YES: |

RS232 communications enabled. |

|

|

|

||||||||||

|

|

NO: |

RS232 communications disabled. |

|

|

|

||||||||||

14. |

NURSE CALL |

YES: |

Nurse Call feature enabled (hardware feature allowing pump to communicate |

|||||||||||||

|

|

|

with the hospital's nurse call system, typically linked to central nurse's station). |

|||||||||||||

|

|

NO: |

Nurse Call feature disabled. |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15. |

NURSE CALL INVERTED |

YES: |

Nurse call hardware output is inverted. |

|

|

|

||||||||||

|

|

NO: |

Nurse call hardware output normal. |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16. |

CONTINUOUS PRINT |

YES: |

Enables printing of events as they occur. |

|

|

|

||||||||||

|

|

NO: |

Continuous printing disabled. |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

17. |

DEFAULT SYRINGE |

Set default syringe type: |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

BD PLASTIPAK |

|

|

|

|

|

|

|

FRESENIOUS INJECT. |

|

|||||

|

|

IVAC |

|

|

|

|

|

|

|

|

|

RAPIJECT |

|

|

|

|

|

|

TERUMO |

|

|

|

|

|

|

|

PHARMA-JECT |

|

|||||

|

|

B. BRAUN OMNIFIX |

|

|

|

|

|

|

BD PRECISE |

|

|

|

||||

|

|

MONOJECT |

|

|

|

|

|

|

|

BRAUN PERFUSOR* |

|

|||||

|

|

R.R PRONTO |

|

|

|

|

|

|

|

JANPOL* |

|

|

|

|||

|

|

BD WORLDWIDE |

|

|

|

|

|

|

|

* with options kit fitted |

|

|||||

|

|

ONCE |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IVAC® PCAM® Syringe Pump |

17/106 |

1000SM00017 Issue 2 |

Configuration & Calibration

General Options (251) continued

|

|

|

GENERAL OPTIONS (continued) |

||||

|

|

|

Software version: V3R2 |

||||

|

|

|

|

|

|

|

|

|

Option |

Description |

|

|

|

||

|

|

|

|

|

|

|

|

18. |

LOCK SYRINGE TYPE |

YES: |

Syringe type locked to default syringe type (as set in previous option). |

||||

|

|

NO: |

Syringe type not locked to default syringe type - can be changed. |

||||

19. |

QUIET MODE |

YES: |

Pump in quiet mode. |

|

|

|

|

|

|

NO: |

Pump in normal mode. |

|

|

|

|

20. |

GENERIC DRUG ENABLED |

YES: |

Generic drug (indicated by |

|

XXX DRUG |

|

) is available when modifying |

|

|

||||||

|

|

NO: |

protocols. See 'Preset Protocol Set Up' for further details. |

||||

|

|

Generic drug is not available. |

|

|

|

||

|

|

|

|

|

|

|

|

21. |

MAX DOSE LIMIT ALARM |

YES: |

Pump alarms when the maximum dose limit is exceeded. |

||||

|

|

NO: |

Pump does not alarm when the maximum dose limit is exceeded. |

||||

|

|

|

|

|

|

|

|

22. |

MIX MASS & VOL MODES |

YES: |

Drugs can be set in either Mass mode or Volume mode. |

||||

|

|

NO: |

All drugs and protocols are in Mass mode only. |

||||

|

|

|

|

|

|

|

|

Notes:

1)For pumps with software version V2R8 or earlier, the options may vary, or will not be available. Refer to the relevant DFU for comprehensive information.

2)For default settings, refer to Appendix C, 'Configured Options and Drug Protocol Records'.

IVAC® PCAM® Syringe Pump |

18/106 |

1000SM00017 Issue 2 |

Configuration & Calibration

Preset Protocol Set Up (251)

The number of protocols available for use is configured in GENERAL OPTIONS.

1.Enter the access code 251 to display the CONFIGURATION OPTIONS menu.

2.Select PROTOCOL DEFAULT SET-UP using the R Q buttons then select ENTER. PROTOCOL DEFAULT A is displayed.

3.Select NEXT PROTOCOL to choose another protocol or select MODIFY PROTOCOL to modify the current protocol, as detailed below. Alternatively, select QUIT to return to the CONFIGURATION OPTIONS menu.

4.Use the R Q buttons to move up/down the list of parameters (see table below).

To enter a parameter, highlight it and select ALTER. Where relevant, the limits set in DRUG NAMES AND SAFETY LIMITS are displayed.

Use the R Q buttons to toggle/select a value then select OK to confirm. Alternatively, use CANCEL to quit.

Select OK at any time to return to PROTOCOL DEFAULT.

5.When set up is complete, switch LOCK 1 to the OFF position.

PROTOCOL DEFAULT SET-UP

PROTOCOL parameter |

Description |

|

|

|

|

|

|

|

DRUG NAME |

Select the drug. Use the R Q buttons to step through the names of the available drugs (as |

|||||||

|

set up in DRUG NAMES AND SAFETY LIMITS). |

|

|

|

|

|

|

|

|

If enabled, a generic drug is available, indicated by |

|

MASS DRUG |

|

or |

|

VOL DRUG |

|

|

|

|

|

|||||

|

|

(only available when MIX MASS & VOL MODES option is enabled). |

|

|

|

|||

|

|

|

|

|

||||

Important: The parameter limits of the generic drug are automatically set to the maximum value.

DRUG CONC. |

Set the drug concentration between the minimum/maximum limits set for the selected drug. |

|

|

PCA DOSE |

Set the PCA dose between the minimum/maximum limits set for the selected drug. |

|

|

LOCKOUT PERIOD |

Set the lockout period between the minimum/maximum limits set for the selected drug. |

|

|

OCCLUSION LEVEL |

Set the occlusion level (L0 to L10). |

|

|

CONTINUOUS* |

Set the continuous rate, below the maximum continuous rate limit set for the selected drug, |

|

or 35ml/h (for syringes >50ml), 20ml/h (for syringes <50 ml and all syringes on pumps with |

|

V2R8 or below), whichever is lowest. |

|

|

LOADING DOSE* |

Set the loading dose, below the maximum loading dose set for the selected drug. |

|

|

MAX LIMIT* |

Set maximum dose, below the maximum max dose set for the selected drug. |

|

|

LIMIT DURATION* |

Set the maximum cumulative period (1 to 8 hours). |

|

|

PCA DELIVERY* |

Set the PCA delivery rate. STAT rate 100 ml/h (80 ml/h for 20 ml syringes), or set by delivery |

|

time (1 to 60 minutes). |

* These options are not available if disabled.

Note: For pumps with software version V2R8 or earlier, the options may vary, or will not be available. Refer to the

relevant DFU for comprehensive information.

IVAC® PCAM® Syringe Pump |

19/106 |

1000SM00017 Issue 2 |

Configuration & Calibration

Syringe Range Selection (359)

Configure the pump to use one of the three standard disposable syringe ranges, as listed in the table below.

Ensure that the required options kit is fitted to the pump before selecting the syringe range.

Ensure that the required options kit is fitted to the pump before selecting the syringe range.

1.Enter the access code 359. See 'Entering an Access Code' for instructions. The display will show the current syringe range.

2.Use the R Q buttons to select the required syringe range:

Syringe Range |

Syringe Types |

Size (ml) |

UNIVERSAL |

BD PLASTIPAK |

20, 30, 50 |

|

IVAC |

50, 100 |

|

TERUMO |

20, 30, 50 |

|

BRAUN OMNIFIX |

20, 30, 50 |

|

MONOJECT |

20, 30, 50 |

|

RR PRONTO |

20, 30, 50 |

|

BD WORLDWIDE |

20, 30, 50 |

|

ONCE |

50 |

|

FRESENIUS INJECT. |

50 |

|

RAPIJECT |

50 |

|

PHARMA-JECT |

50 |

|

BD PRECISE |

20, 50 |

BRAUN PERFUSOR |

B BRAUN PERFUSOR |

50 |

JANPOL |

JANPOL |

50 |

3. Turn LOCK 1 to OFF to complete the configuration.

Language Selection (359)

Configure the pump's language used for messages shown on display.

1.Enter the access code 359. See 'Entering an Access Code' for instructions. The display will show the current syringe range.

2.Press NEXT to go to language selection.

3.Use the R Q buttons to select the required language:

4.Turn LOCK 1 to OFF to complete the configuration.

IVAC® PCAM® Syringe Pump |

20/106 |

1000SM00017 Issue 2 |

Configuration & Calibration

Setting the End of Infusion (EOI) Position

Use the following procedure to check and to set the EOI point.

1.Enter the access code 126 (see 'Entering an Access Code' for instructions).

2.Select NEXT to step through the self-test routines until the display reads EOI opto: x (where x is the current status of the EOI detector).

3.Move the plunger holder to the right. The display will read EOI opto: 0

4.Load an empty 50ml syringe (see list of suitable syringes below), squeeze the finger grips and move the plunger holder slowly to the left.

5.Check the display switches from 0 to 1. The position at which the display changes is the EOI point and it depends on the type of syringe in use. Use the following table to check the EOI point:

Syringe Type |

Syringe Size (ml) |

EOI Point (ml) |

BD Plastipak |

50 |

5.5 |

IVAC |

50 |

6.0 |

Terumo (US manufactured) |

50 |

6.0 |

Braun Omnifix |

50 |

5.0 |

Monoject |

50 |

5.5 |

R.R Pronto |

50 |

7.5 |

Rapiject |

50 |

3.0 |

BD Worldwide |

50 |

6.5 |

Once |

50 |

4.5 |

Fresenius Inject |

50 |

5.0 |

Braun Perfusor |

50 |

3.0 |

Janpol |

50 |

3.0 |

6.If necessary, separate the lower and upper case of the pump (see Chapter 6, 'Spare Parts Replacement Procedures') and adjust the position of the EOI actuator on the bottom of the carriage to the desired position, so that the EOI status changes from 0 to 1 at the position set out in table above.

7.Move the plunger holder and observe that the display changes from 0 to 1 as the syringe passes the EOI position. If it does not repeat procedure from Step 3.

8.Fit and fasten the case halves together and check the EOI point again.

IVAC® PCAM® Syringe Pump |

21/106 |

1000SM00017 Issue 2 |

Configuration & Calibration

Calibration Procedures

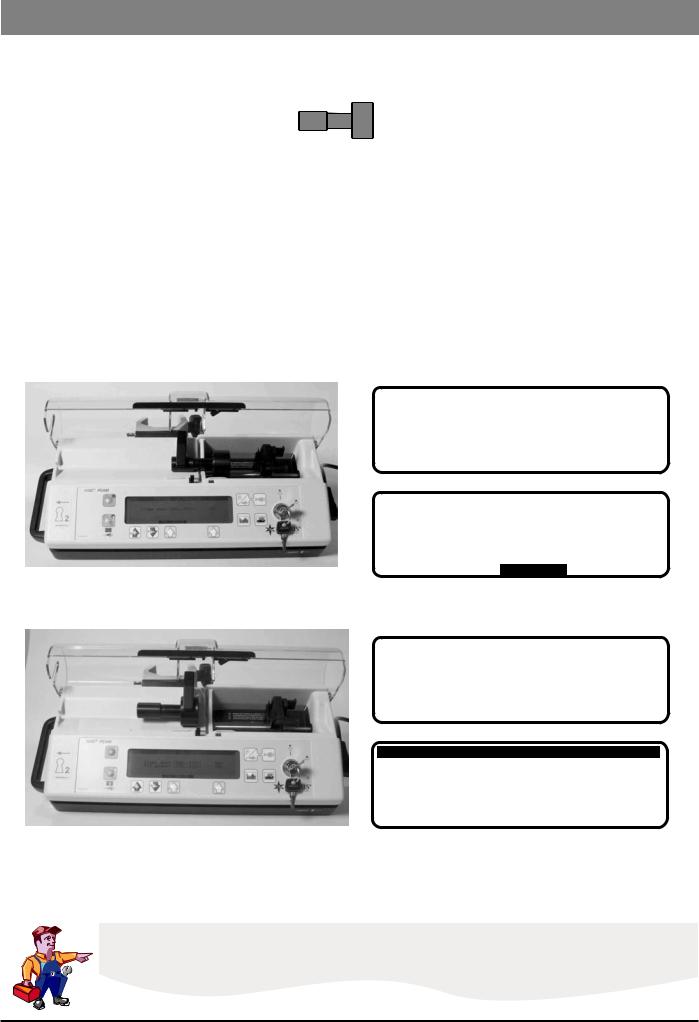

Syringe Size Calibration (243)

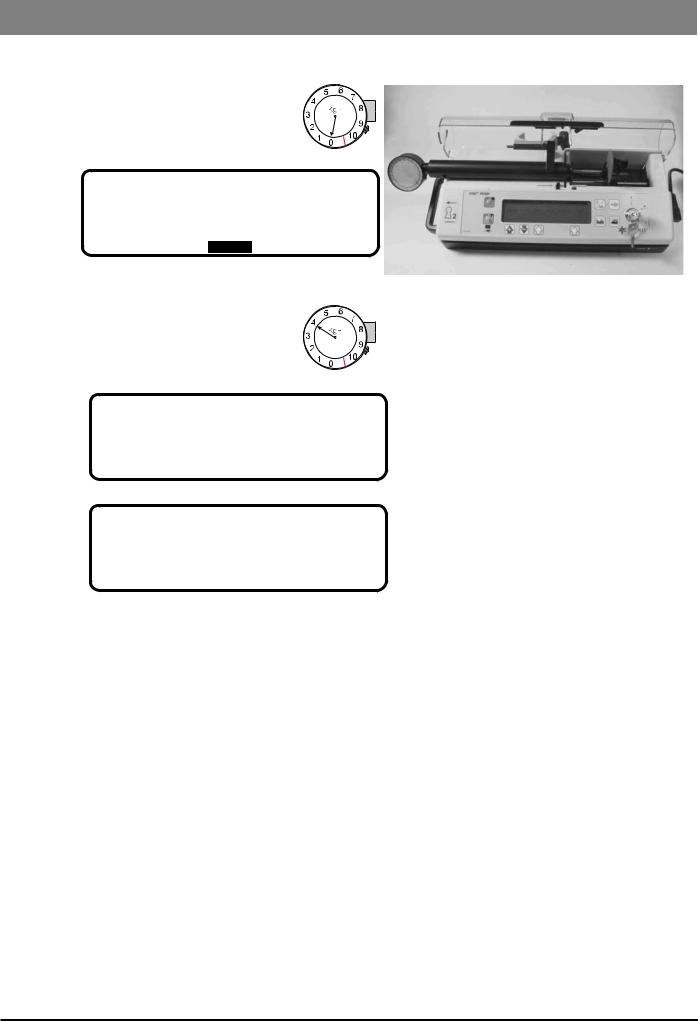

To calibrate the syringe size detection system, follow the two-point calibration procedure described below.

Calibration tools required:

1000TG00055 (Syringe Sizing Spacer)

1000TG00055

Calibration procedure:

Enter the access code 243.

Fit calibration tool into position on the pump and close the clamp, following Steps 1 - 3 below.

At each step, CALIBRATE is displayed if value is within tolerances.

Select CALIBRATE to store calibration point. Select NEXT to continue to the next screen.

Notes:

1)If CALIBRATE is not displayed, check for correct positioning of calibration tool. If calibration cannot be performed, repairs to pump may be necessary.

2)The calibration values shown below are for illustrative purposes only.

Step 1: Position the narrow end of the calibration tool under the syringe clamp

243 |

SYRINGE CALIBRATION |

|

|||

|

Clamp down |

(40.. |

070) : |

|

060 |

|

|

|

|

|

|

|

|

CALIBRATE |

|

||

|

|

|

|||

243 |

SYRINGE CALIBRATION |

|

|||

|

Clamp down |

(40.. |

070) : |

|

060 |

NEXT

Step 2: Re-position the calibration tool with the wide end under the syringe clamp

243 |

SYRINGE CALIBRATION |

|

|||

|

Clamp down |

(40.. 070) |

: |

|

060 |

|

Fit spacer |

(170.. 210) |

: |

|

186 |

|

|

|

|

|

|

|

|

CALIBRATE |

|

||

243 |

SYRINGE CALIBRATION |

|

||

|

Clamp down |

(40.. 070) |

: |

060 |

|

Fit spacer |

(170.. 210) |

: |

186 |

|

Difference |

|

|

126 |

Step 3: Complete calibration

Switch LOCK 1 to the OFF position to complete the calibration sequence.

Confirmatory Check - To confirm that the syringe sizing calibration has been performed correctly, select a syringe (preferably 50ml), load and confirm the correct syringe type. Verify that the correct syringe size is detected and displayed.

IVAC® PCAM® Syringe Pump |

22/106 |

1000SM00017 Issue 2 |

Configuration & Calibration

Calibration Procedures (continued)

Occlusion Calibration (717)

To set the pump occlusion alarm level, follow the calibration procedure described below. To test the occlusion alarm levels, see 'Occlusion Alarm Levels Test' in Chapter 3.

To convert Kilograms of Force (KgF) to Newtons (N) multiply by 9.806650. For example 10 KgF = 98.07N.

Excessive force will damage the plunger mechanism. Do not apply more than 10 KgF ±0.05 KgF to the plunger mechanism at any time.

Calibration tools required:

0000TG00020 (shown) or 0000TG00200 and 0000JG00014

Calibration procedure:

Enter the access code 717.

Select the OK option to start the drive, following Steps 1-5 below.

Notes:

1)If CALIBRATE does not appear in display, check for correct positioning of tool. If calibration cannot be performed, repairs to the pump may be necessary.

2)The calibration values shown on the pump displays are for illustrative purposes only.

Step 1: Start drive (without calibration tool fitted)

717 |

PRESSURE CALIBRATION |

|

|

Base level 0kgf (-020.. +020) : |

+006 |

Allow drive to run for approximately 30 seconds to enable the zero pressure level to settle.

OK

Step 2: Base level

Check pressure reading is within the range displayed.

717 |

PRESSURE CALIBRATION |

|

|

Base level 0kgf (-020.. +020) : |

+000 |

CALIBRATE

If necessary, open up the pump and adjust pot RV1 on the Control PCB until it falls within the range

Strive for a pressure reading as close as possible to +000

IVAC® PCAM® Syringe Pump |

23/106 |

1000SM00017 Issue 2 |

Configuration & Calibration

Calibration Procedures (continued)

Occlusion Calibration (717) continued

Step 3: Fit calibration tools (0KgF)

717 |

PRESSURE CALIBRATION |

|

|

Base level 0kgf (-020.. +020) : |

+000 |

NEXT

Step 4: Test gear 4.0 KgF

Allow pump to run until the dial gauge on the test gear reads 4Kgf.

717 |

PRESSURE CALIBRATION |

|

|||

|

Base level 0kgf |

(-020.. +020) : |

+000 |

||

|

Test gear 4.0kgf |

(+050.. +100) : |

+062 |

||

|

|

|

|

|

|

|

|

CALIBRATE |

|

||

|

|

|

|

|

|

717 |

PRESSURE CALIBRATION |

|

|||

Base level 0kgf Test gear 4.0kgf Difference 0 kgf

(-020.. +020) : |

+000 |

(+050.. +100) : |

+062 |

to 4.0 kgf : |

+062 |

Step 5: Complete calibration

Switch LOCK 1 to the OFF position to complete the calibration sequence.

IVAC® PCAM® Syringe Pump |

24/106 |

1000SM00017 Issue 2 |

Configuration & Calibration

Battery Charge Circuit Verification

Replacement Power Supply PCBs are supplied with the charging voltage set to the correct value. The procedure below can be followed in order to check the DC voltage setting if deemed necessary.

Equipment required: Oscilloscope

1.Ensure that the pump is swtiched OFF and is disconnected from the AC power supply.

2.Access the pump, see Chapter 6, 'Spare Parts Replacement Procedures' for instructions.

3.Disconnect the battery connector from the Power Supply PCB and connect the oscilloscope to PL3 (0V to pin 1).

4.Set the oscilloscope range to 0 to 7 VDC.

5.Connect the pump to AC power supply.

6.Adjust RV1 on the Power Supply PCB until the peak voltage level displayed on the oscilloscope is 7.0 ± 0.1 VDC.

7.Reseal RV1.

8.Disconnect the AC power supply, remove the oscilloscope connections and refit the battery connector.

Clearing Internal RAM (611)

Warning: Do not clear the RAM unless absolutely necessary because all the calibration and configuration in the pump will be cleared.

If the internal RAM or its associated battery is replaced on the Control PCB, or if the pump fails with a 'CODE 5' RAM error it will be necessary to do the following:

Clear the internal RAM:

1.Enter the access code 611.

2.Select ENTER and wait for the RAM to be cleared.

3.When the message RAM CLEARED appears, switch LOCK 1 to the OFF position.

Fully calibrate pump. Perform each of the two calibration procedures, as described in this chapter.

Reconfigure the pump:

Set Configuration, Drugs and Safety Limits and Protocols (it may be possible to use the Teach/Learn facility, see Chapter 3, 'Routine Maintenance' for instructions)

Enter the access code 359 and set syringe range and language

Enter the access code 376 and set service date

Carry out Performance Verification Procedure (PVP). See Chapter 3, 'Routine Maintenance' for instructions.

IVAC® PCAM® Syringe Pump |

25/106 |

1000SM00017 Issue 2 |

Chapter 3

Routine Maintenance

In this chapter

Introduction |

27 |

Self-Test Procedure (123) |

27 |

Upgrading Software |

28 |

Event Log Download |

29 |

Teach Learn |

31 |

Linear Speed Test |

32 |

Syringe Constant Values |

33 |

Occlusion Test |

34 |

Potential Equalisation Terminal Resistance Test (PE Test) |

35 |

Battery Maintenance |

36 |

Physical Inspection and Clean |

36 |

Performance Verification Procedure |

37 |

Routine Maintenance

Introduction

For routine maintenance, the following tests and performance verification procedure should be performed in addition to the tasks described in the section 'Physical Inspection and Clean'.

Refer to the relevant DFU for the recommended routine maintenance period.

Self-Test Procedure (123)

The self-test procedure is designed to allow confirmation of many of the pump functions, defaults and calibrations without requiring internal inspection.

1.Enter the access code 123. See 'Entering an Access Code' in Chapter 2 for instructions.

2.The pump now proceeds through a series of tests. Press the NEXT softkey to move to the next test. Refer to the table below for details of each test.

Important: If the pump fails the test sequence at any stage, it should be taken out of service and inspected by a qualified service engineer.

Test |

Display |

|

Description/Action |

|

|

|

|

|

|

Review software setup |

Software revision |

Displays software version, program CRC, language and hospital name. |

||

|

Program CRC |

|

|

|

|

Language |

|

|

|

|

Hospital name |

|

||

|

|

|

|

|

Review syringe data |

Syr range |

|

Displays syringe range, syringe and occlusion calibration figures. |

|

|

Syr cal |

|

|

|

|

Occ cal |

|

|

|

Internal PSU voltage |

Internal PSU voltage: |

On mains supply: 9.00V approximately |

||

|

_ . _ _ V |

|

On battery supply: 5.20V - 6.50V |

|

|

|

|

|

|

Audible: Alarm |

Audible alarm |

Check that the alarm sounds continuously. |

||

|

|

|

|

|

Visual: Display and |

Display test |

|

Check that the display dots are an even tone as they all go on full |

|

Backlight |

Backlight |

|

backlight, then to dim, then turn off. |

|

|

|

|

|

|

Touch panel buttons |

Press S1 |

|

Press buttons in turn from START (01) to PURGE (10). |

|

|

H 01 |

|

S 06 |

|

|

|

|

|

|

|

I 02 |

|

J 07 |

|

|

|

|

|

|

|

R 03 |

|

V 08 |

|

|

|

|

|

|

|

Q 04 |

|

G 09 |

|

|

|

|

|

|

|

S 05 |

|

T 10 |

|

Visual: LED Indicators |

LEDS flashing |

Check that the STOP and START LED’S are flashing. |

||

|

|

|

|

|

Declutch switch |

Declutch: |

|

Squeeze plunger holder finger grips and check that the display |

|

|

|

|

|

alternates between 1 (engaged) and 0 (disengaged - finger grips |

|

|

|

|

squeezed together). |

|

|

|

|

|

Near End of Infusion |

EOI opto: |

|

Starting with an empty, extended 50ml syringe on the pump, squeeze |

|

|

|

|

|

the finger grips and move the plunger holder slowly to the left. Check the |

|

|

|

|

display switches from 0 to 1. The position at which the display changes (EOI |

|

|

|

|

point) depends on the type of syringe in use. See 'Setting the EOI Position' in |

|

|

|

|

Chapter 2. for values. |

|

|

|

|

|

Linear Grid |

Grid opto: |

|

Squeeze the plunger holder grips together and slide the mechanism |

|

|

|

|

|

to the right. Slowly move the syringe plunger to the left and check the |

|

|

|

|

display alternates between 0 (OPTO over slot) and 1 (OPTO over bar). |

|

|

|

||

Plunger Detector |

Plunger opto: |

Press plunger plate button. Check the display switches from 1 (no syringe |

||

|

|

|

|

plunger fitted) to 0 (syringe plunger fitted). |

|

|

|

||

Motor Encoder |

Motor/encoders: |

Motor is pulsed while encoders are tested. Motor moves forwards and |

||

|

|

|

|

backwards as encoders pass. |

|

|

|

|

|

Cover Detect |

Cover detect: |

|

Open and close the cover. Check that the display changes from 0 (cover |

|

|

|

|

|

open) to 1 (cover closed). |

|

|

|

|

|

IVAC® PCAM® Syringe Pump |

27/106 |

1000SM00017 Issue 2 |

|

Routine Maintenance |

||

|

|||

Self-Test Procedure (123) continued |

|

||

|

|

|

|

|

|

|

|

Test |

Display |

Description/Action |

|

|

|

|

|

Syringe Size Detection |

Syringe pot: |

Lift the syringe clamp and check that the values displayed increase |

|

|

|

within the normal range (approx. 045 to 215). |

|

|

|

|

|

Pumping Pressure |

Beam value: |

Remove the syringe and confirm that the value displayed is within |

|

Detection |

|

normal range (-020 to +020). Gently press back on the plunger holder |

|

|

|

and watch the value increase. |

|

|

|

|

|

Patient Handset |

Handset: |

Connect handset and check that the display changes from OFF to ON |

|

|

|

when the button is pressed. Also check that the handset LED lights up |

|

|

|

then goes off. |

|

|

|

|

|

Key Switch |

Key switch: |

Turn key from SET position to RUN position and the check the display |

|

|

|

changes accordingly. |

|

|

|

|

|

Nursecall |

Nurse call on/off/on |

Check for audible clicks of the relay. |

|

|

|

|

|

Configuration summary |

Summary of configured |

Select the NEXT option and scroll to the next page of configured |

|

|

options |

options, then to normal operation. |

|

|

|

|

|

Upgrading Software

Upgrade of the IVAC® PCAM Syringe Pump software to V2R8 or greater is recommended when serviced.

Perform upgrades by acquiring the software upgrade kits specified in spare parts listings.

Equipment required: Software upgrade kit (includes EPROM fitting and removal instructions)

Software Upgrade Kits Available

Part Number |

Description |

|

|

5000SP00049 |

V3R2 software + DFU English/French/German |

|

|

5000SP00053 |

V3R2 software + DFU English/French/Dutch |

|

|

5000SP00054 |

V3R2 software + DFU English/Spanish |

|

|

5000SP00055 |

V3R2 software + DFU English/Italian/German |

|

|

5000SP00056 |

V3R2 software + DFU English/Swedish |

|

|

IVAC® PCAM® Syringe Pump |

28/106 |

1000SM00017 Issue 2 |

Routine Maintenance

Event Log Download

The Event Log can be downloaded directly to a PC using Microsoft HyperTerminal.

Note: The procedure below uses Microsoft HyperTerminal - Microsoft Windows XP Professional.

Equipment required: |

Cabling connections: |

|

|

|

|

|

|

|

|||

RS232 cable, 9-pin D type |

GND PWR1 TXD2 RXD2 ALM IN |

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||||

PC running Microsoft Windows |

5 |

4 |

3 |

2 |

1 |

|

Pump |

|

PC |

||

|

|

|

|

|

|

Male |

Female |

||||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pin 5 |

|

GND |

Pin 5 |

|

GND |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pin 8 |

|

CTS1 |

Pin 4 |

|

PWR1 |

|

6 |

7 |

8 |

9 |

|

|

|

|

|

|

|

|

|

Pin 9 |

|

TXD1 |

Pin 2 |

|

RXD2 |

||||

|

NC |

NC |

CTS1 |

TXD1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Pump Set Up

1.Connect the RS232 cable to the serial port of the pump and the COM port of the PC.

2.Enter access code 794. See 'Entering an Access Code' in Chapter 2 for instructions. This enables access to the full Event Log.

3.Turn the pump OFF.

4.Turn the pump ON. Select NO to retain previous patient data.

5.Press the J button four times to display the Event Log. Use the R Q buttons to position the cursor at the start point of events to be downloaded.

Set Up HyperTerminal on your PC

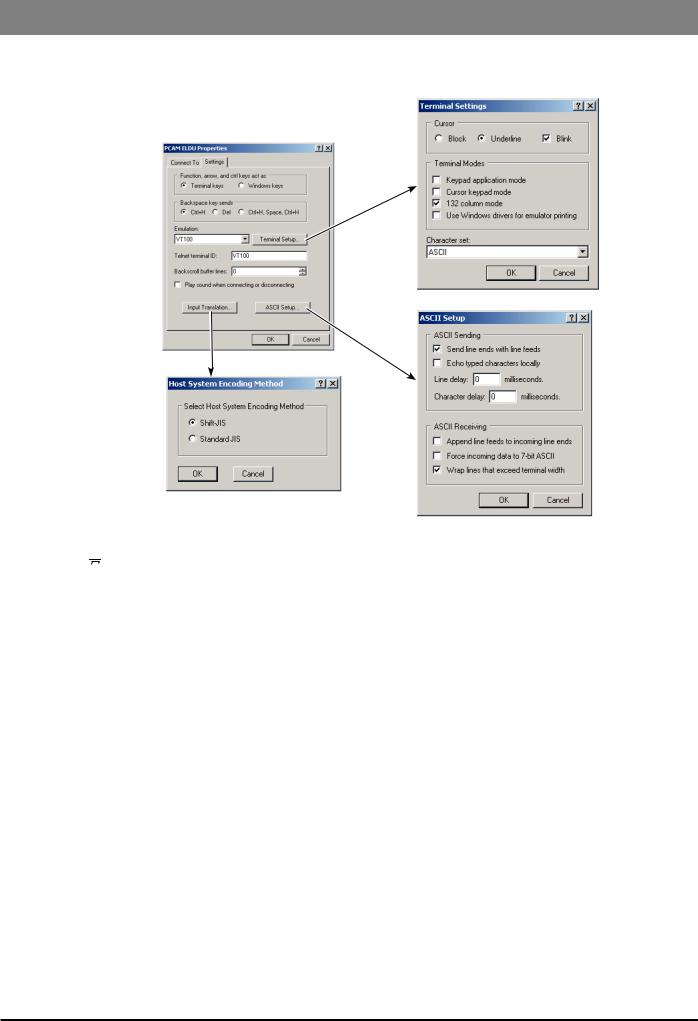

1.Open HyperTerminal on your PC. Click Start, point to All Programs, point to Accessories, point to Communications, and then click HyperTerminal. Enter a HyperTerminal connection name, for example, PCAM ELDU, select an icon and click OK.

2.Select COM1 and click OK (leaving Country/region and Area code as default). Ensure COM1 is not already pre configured, for

example, pre configured for a hand-held PC. Configure COM1 Properties as shown below, click Apply then OK.

IVAC® PCAM® Syringe Pump |

29/106 |

1000SM00017 Issue 2 |

Routine Maintenance

Event Log Download (continued)

Set Up HyperTerminal on your PC (continued)

3.On the File menu, select Properties. Select the Settings tab then configure settings as shown below. Click OK to close the

Properties window.

4.On the Transfer menu, select Capture Text. Enter file name and desired location for data to be saved to (example, D:\DATA\PCAM EVENTLOG). Click Start.

5.Press the  button on the pump.

button on the pump.

6.Once finished, the Event Log data will be displayed on the PC screen.

7.Save and Close HyperTerminal.

8.Locate the saved file (example D:\DATA\PCAM EVENTLOG) and open it using WordPad. Save the WordPad document as a unicode text document:

On the WordPad File menu, select Save As. Enter a File name (i.e. pump serial number). Select file type (Unicode Text Document) from the drop-down box then click Save.

Example Event Log Download

08/06/04 10:07 ---- POWER ON ---- 0 ug 08/06/04 10:07 NEW PATIENT 0 ug

08/06/04 10:07 PROTOCOL CONFIRMED 0 ug 08/06/04 10:07 DRUG UFTU 1

08/06/04 10:07 DRUG CONC. 1.0 mg/ml 08/06/04 10:07 PCA DOSE 1.0 mg 08/06/04 10:07 LOCKOUT 5 min 08/06/04 10:07 OCCLUSION ALARM 4 08/06/04 10:07 CONTINUOUS 0 ug/h 08/06/04 10:07 DOSE LIMIT 50.0 mg 08/06/04 10:07 LIMIT PERIOD 4 h 08/06/04 10:07 50 ml BD PLASTIPAK 08/06/04 10:07 PCAM START 0 ug 08/06/04 10:07 GOOD DEMAND 0 ug

Example (continued)

08/06/04 10:07 PCAM STOP 90 ug 08/06/04 10:07 PCAM START 90 ug 08/06/04 10:08 LOCKOUT START 1.00 mg

IVAC® PCAM® Syringe Pump |

30/106 |

1000SM00017 Issue 2 |

Loading...

Loading...