Cardinal 225 User Manual

225

WEIGHT INDICATOR

INSTALLATION and TECHNICAL MANUAL

8200-M538-O1 Rev A |

PO BOX 151 y WEBB CITY, MO 64870 |

Printed in USA |

07/08 |

PH (417) 673-4631 y FAX (417) 673-5001 |

|

|

www.cardinalscale.com |

|

Technical Support: Ph: 866-254-8261 y techsupport@cardet.com |

Page 1 |

|

8200-M538-O1 y 225 Installation |

||

8200-M538-O1 y 225 Installation |

Page 2 |

TABLE OF CONTENTS |

|

INTRODUCTION |

Page 1 |

SPECIFICATIONS |

Page 2 |

FEATURES |

Page 3 |

Standard |

Page 3 |

Optional |

Page 3 |

PRECAUTIONS |

Page 5 |

Static Electricity |

Page 5 |

SITE PREPARATION |

Page 6 |

Environmental |

Page 6 |

Electrical power |

Page 7 |

Transient Suppression |

Page 7 |

INSTALLATION |

Page 8 |

Mounting the 225 |

Page 8 |

Load Cell Cable Connection with RFI Suppression |

Page 9 |

Load Cell Cable Connection UwithoutU RFI Suppression |

Page 12 |

Load Cell Connections with Over 30 Feet of Cable |

Page 12 |

Serial I/O Cable Installation |

Page 13 |

Optically Isolated Remote Inputs |

Page 14 |

AC Input Relay Board(s) |

Page 14 |

Preset Weight Comparator/Checkweigher Logic Level Output |

Page 16 |

AC Output Relay Board(s) |

Page 16 |

Re-Installing the Rear Panel |

Page 18 |

Main PC Board I/O Functions Table |

Page 19 |

Relay Box Cable Wire Number to Relay Number Table |

Page 19 |

MAIN PC BOARD |

Page 20 |

Jumpers |

Page 21 |

KEYPAD FUNCTIONS |

Page 22 |

ANNUNCIATORS |

Page 29 |

TIME, DATE AND CONSECUTIVE NUMBER |

Page 31 |

DISPLAY CONTRAST ADJUSTMENT |

Page 32 |

CALIBRATION AND SETUP |

Page 33 |

Security Seals |

Page 33 |

ENTER CALIBRATION AND SETUP |

Page 35 |

SETUP MENU #1 |

Page 35 |

SETUP MENU #2 |

Page 40 |

SERIAL INPUT/OUTPUT SETUP |

Page 40 |

DIO SETUP (PWC Status) |

Page 48 |

PRINT TABS SETUP |

Page 49 |

SETUP SCALE |

Page 55 |

Filter Setting Recommendations |

Page 59 |

8200-M538-O1 y 225 Installation |

Page 3 |

TABLE OF CONTENTS, CONT.

CALIBRATE |

Page 62 |

|

CALIBRATION METHODS |

Page 64 |

|

CALIBRATION MODES |

Page 64 |

|

Calibration Parameters |

Page 69 |

|

Calibration “C” Numbers |

Page 70 |

|

SETUP MENU #3 |

Page 72 |

|

ACCUMULATORS |

Page 72 |

|

BACK LIGHT |

Page 72 |

|

PASSWORD |

Page 73 |

|

VIEW AUDIT TRAIL COUNTERS |

Page 75 |

|

ID STORAGE SETUP (Mode of Operation = 1) |

Page 76 |

|

PRESET WEIGHT COMPARATORS SETUP (Mode of Operation = 3) |

Page 78 |

|

ELECTRONIC TALLEY ROLL (ETR) FILE |

Page 80 |

|

COUNT OPERATION |

Page 81 |

|

ID STORAGE OPERATION |

Page 82 |

|

PRESET WEIGHT COMPARATORS OPERATION |

Page 90 |

|

ACCUMULATORS |

Page 92 |

|

CONTINUOUS OUTPUT FORMATS |

Page 95 |

|

ASCII COMMANDS |

Page 100 |

|

INFRARED (IR) DATA PORT |

Page 102 |

|

TROUBLESHOOTING |

Page 103 |

|

Error Codes |

Page 103 |

|

Before You Call Service |

Page 106 |

|

TEST MODE AND ERASING MEMORY |

Page 107 |

|

|

|

|

|

SERIAL NUMBER _____________________ |

|

|

DATE OF PURCHASE _________________ |

|

|

PURCHASED FROM __________________ |

|

____________________________________ |

|

|

____________________________________ |

|

|

____________________________________ |

|

|

RETAIN THIS INFORMATION FOR FUTURE USE

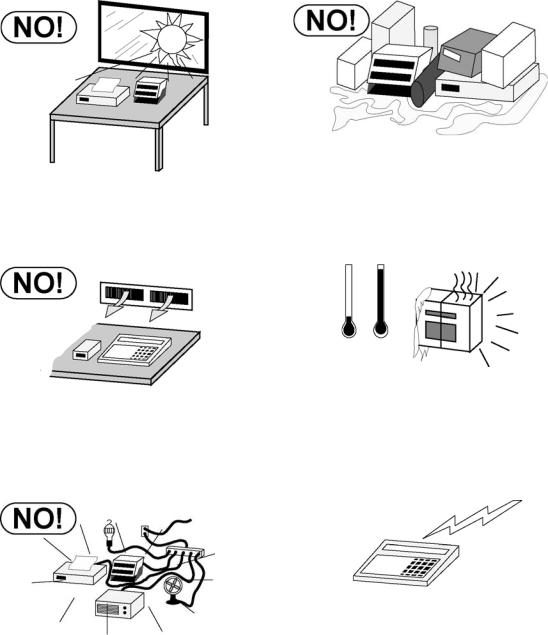

PRECAUTIONS

Before using this instrument, read this manual and pay special attention to all "WARNING" symbols:

|

|

|

|

|

|

|

|

|

STATIC |

|

|

|

IMPORTANT |

|

|

ELECTRICAL |

|

|

|

|

|

|

|

|

|

WARNING |

|

|

SENSITVE |

8200-M538-O1 y 225 Installation |

|

|

|

|

Page 4 |

||||

INTRODUCTION

Thank you for selecting and purchasing the Cardinal Model 225 Weight Indicator. The Model 225 indicator was built with quality and reliability at our factory in Webb City, Missouri and incorporates the latest in digital technology and innovative features for the weighing industry. Configuration and upgrades can easily be performed in the field, while still maintaining the rigid control the most demanding installations require. This flexibility insures the Model 225 will be able to meet your weight indicating needs for years to come.

The purpose of this manual is to provide you with a guide through installation, setup and calibration of your new Model 225 Weight Indicator. Please read it thoroughly before attempting to install your indicator and keep it handy for future reference.

FCC COMPLIANCE STATEMENT

WARNING! This equipment generates uses and can radiate radio frequency and if not installed and used in accordance with the instruction manual, may cause interference to radio communications. It has been tested and found to comply with the limits for a Class A computing device pursuant to Subpart J of Part 15 of FCC rules, which are designed to provide reasonable protection against such interference when operated in a commercial environment. Operation of this equipment in a residential area may cause interference in which case the user will be responsible to take whatever measures necessary to correct the interference.

You may find the booklet “How to Identify and Resolve Radio TV Interference Problems” prepared by the Federal Communications Commission helpful. It is available from the U.S. Government Printing Office, Washington, D.C. 20402. Order stock no. 001-000-00315-4.

PROPER DISPOSAL

When this device reaches the end of its useful life, it must be properly disposed of. It must not be disposed of as unsorted municipal waste. Within the European Union, this device should be returned to the distributor from where it was purchased for proper disposal. This is in accordance with EU Directive 2002/96/EC. Within North America, the device should be disposed of in accordance with the local laws regarding the disposal of waste electrical and electronic equipment.

It is everyone’s responsibility to help maintain the environment and to reduce the effects of hazardous substances contained in electrical and electronic equipment on human health. Please do your part by making certain that this device is properly disposed of. The symbol shown to the right indicates that this device must not be disposed of in unsorted municipal waste programs.

All rights reserved. Reproduction or use, without expressed written permission, of editorial or pictorial content, in any manner, is prohibited. No patent liability is assumed with respect to the use of the information contained herein. While every precaution has been taken in the preparation of this manual, the Seller assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from use of the information contained herein. All instructions and diagrams have been checked for accuracy and ease of application; however, success and safety in working with tools depend to a great extent upon the individual accuracy, skill and caution. For this reason the Seller is not able to guarantee the result of any procedure contained herein. Nor can they assume responsibility for any damage to property or injury to persons occasioned from the procedures. Persons engaging the procedures do so entirely at their own risk.

8200-M538-O1 y 225 Installation |

Page 1 |

|

SPECIFICATIONS |

|

|

|

|

90 to 264 VAC (50/60 Hz) at 0.4A |

|

|

|

Power Requirements: |

|

|

||

Enclosure Type: |

NEMA 4X/IP66 Stainless Steel |

|

|

|

Enclosure Size: |

10 7/8"W x 8 3/16"H x 3 1/8"D (276mm W x 208mm H x 79mm D) |

|||

Weight: |

9.2lbs (Size and Weight DOES NOT include Gimbal) |

|||

Operating Environment: |

Temperature: 14 to 104 ºF (-10 to +40 ºC) |

|||

|

Humidity: 90% non-condensing (maximum) |

|||

Display: |

240 x 64 (5” x 1.33”) Graphics LCD w/ LED Backlight |

|||

Transducer Excitation: |

12 VDC |

|

|

|

Signal Input Range: |

1.0 mV min. to 40 mV max. (with dead load boost) |

|||

Scales |

1 ea Standard, 3 ea with optional 225-DS Dual Scale Input Board |

|||

Number of Load Cells: |

14 each, 350 OHM minimum resistance |

|

|

|

Load Cell Cable Length: |

1500 feet maximum with sense lines. |

|

|

|

|

Consult factory for |

|

||

|

30 feet maximum without sense lines |

|

other requirements |

|

|

1, 2, or 5 x 10, 1, 0.1, 0.01, 0.001 and 0.0001 commercial |

|||

Division Value: |

||||

|

0 to 99, non-commercial |

|

|

|

Sensitivity: |

|

|

|

|

NON-COMMERCIAL |

0.15 uV/e |

|

|

|

NTEP |

0.3uV/e (Class III/IIIL) |

|

|

|

CANADA |

0.3uV/e (Class III/IIIHD) |

|

|

|

OIML |

0.7 uV/e (Class III) |

|

|

|

Scale Divisions: |

|

|

|

|

NON-COMMERCIAL |

100 to 240,000 |

|

|

|

NTEP |

100 to 10,000 (Class III/IIIL) |

|

|

|

CANADA |

100 to 10,000 (Class III/IIIHD) |

|

|

|

OIML |

100 to 10,000 (Class III) |

|

|

|

Internal Resolution: |

1 part in 16,777,216 |

|

|

|

Tare Capacity: |

Six Digits (999,999) |

|

|

|

Sample Rate: |

1 to 100 samples per second, selectable |

|||

Auto Zero Range: |

0.5 or 1 through 9 divisions |

|

|

|

Weighing Units: |

Tons, Pounds, Ounces, Tonnes ”Metric Tons”, Kilograms, Grams, |

|||

Keypad: |

Membrane type with 60 color-coded keys |

|||

Standard I/O: |

U4ea Serial I/O Ports configured as: |

|

|

|

|

3 ea bi-directional RS-232 ports or 3ea 20mA output-only ports |

|||

|

1 ea bi-directional 20mA/IR port |

|

|

|

|

1 ea output only RS-232/20mA port |

|

|

|

|

8 ea Remote Isolated Inputs |

|

|

|

|

16 ea Remote Isolated Outputs |

|

|

|

8200-M538-O1 y 225 Installation |

Page 2 |

FEATURES

Standard

¾Time and Date with selectable 12 or 24 hour operation

¾200 ID Storage with an additional 100 temporary ID’s

¾Count Feature with accumulator

¾Adjustable Filtering

¾Multi-Point Calibration and High-Resolution Mode

¾Selectable Key Disable

¾Gross, Tare and Net Conversion

¾Multi-Interval (Dual Range) Feature

¾Gross, Net, 32 ID, 8 Bin and Piece Count Accumulators

¾Push Button and Keypad Tare Function

¾8 Preset Weight Comparators

¾Checkweigher (3 or 5 Zone, Setup Selectable)

¾Digital Fill Control (1 or 2 Speed with Static or Dynamic Trim)

¾Batcher (1 Speed, 7 Ingredient or 2 Speed, 3 Ingredient with Static or Dynamic Trim)

¾6 Programmable Print Formats Using nControl

¾SMA Level 2 Compliant Serial Communications (See www.scalemanufacturers.org)

¾Color-coded keypad with Alpha-Numeric, Special Function “Soft” and Navigation Keys

¾Remote Input of Gross, Net, Tare, Print, Zero, Start Stop and Dump Commands

Optional

Allen-Bradley Interface*, ControlNet Interface*, DeviceNet Interface*, Dual Scale*, Ethernet/IP Interface*, USB Interface*, Additional Serial Port (RS-232 or Plastic or Glass Fiber Optic) *, 802.11 WiFi*, Checkweigher Light Bar* and External Relay Box*

*These feature requires additional hardware and includes additional documentation.

8200-M538-O1 y 225 Installation |

Page 3 |

This page intentionally left blank.

8200-M538-O1 y 225 Installation |

Page 4 |

PRECAUTIONS

Static Electricity

CAUTION! This device contains static sensitive circuit cards and components. Improper handling of these devices or printed circuit cards can result in damage to or destruction of the component or card. Such actual and/or consequential damage IS NOT covered under warranty and is the responsibility of the device owner. Electronic components must be handled only by qualified electronic technicians who follow the guidelines listed below:

ATTENTION! ALWAYS use a properly grounded wrist strap when handling, removing or installing electronic circuit cards or components. Make certain that the wrist strap ground lead is securely attached to an adequate ground. If you are uncertain of the quality of the ground, you should consult a licensed electrician.

ALWAYS handle printed circuit card assemblies by the outermost edges. NEVER touch the components, component leads or connectors.

ALWAYS observe warning labels on static protective bags and packaging and

NEVER remove the card or component from the packaging until ready for use.

ALWAYS store and transport electronic printed circuit cards and components in antistatic protective bags or packaging.

8200-M538-O1 y 225 Installation |

Page 5 |

SITE PREPARATION

Environmental

The Model 225 Weight Indicator meets or exceeds all certification requirements within a temperature range of 14 to 104 °F (-10 to +40 °C).

In order to keep cooling requirements to a minimum, the indicator should be placed out of direct sunlight and to provide adequate air circulation, keep the area around the indicator clear.

Make certain the indicator is not directly in front of a heating or cooling vent. Such a location will subject the indicator to sudden temperature changes, which may result in unstable weight readings.

Insure that the indicator has good, clean AC power and is properly grounded. In areas subject to lightning strikes, additional protection to minimize lightning damage, such as surge suppressors, should be installed.

8200-M538-O1 y 225 Installation |

Page 6 |

SITE PREPARATION, CONT.

The Model 225 Weight Indicator is a precision weight-measuring instrument. As with any precision instrument, it requires an acceptable environment to operate at its peak performance and reliability. This section is provided to assist you in obtaining such an environment.

Electrical Power

The 225 has been designed to operate from 90 to 264 VAC at 50/60 Hz. Note that a special order is UnotU required for operation at 230 VAC.

CAUTION! - To avoid electrical hazard and possible damage to the indicator, DO NOT, under any circumstance, cut, remove, alter, or in any way bypass the power cord grounding prong.

On installations requiring 230 VAC power, it is the responsibility of the customer to have a qualified electrician install the proper power cord plug which conforms to national electrical codes and local codes and ordinances.

The power outlet for the indicator should be on a separate circuit from the distribution panel. This circuit should be dedicated to the exclusive use of the indicator. The wiring should conform to national and local electrical codes and ordinances and should be approved by the local inspector to assure compliance.

To prevent electrical noise interference, make certain all other wall outlets for use with air conditioning and heating equipment, lighting or other equipment with heavily inductive loads, such as welders, motors and solenoids are on circuits separate from the indicator. Many of these disturbances originate within the building itself and can seriously affect the operation of the instrument. These sources of disturbances must be identified and steps must be taken to prevent possible adverse effects on the instrument. Examples of available alternatives include isolation transformers, power regulators, uninterruptible power supplies, or simple line filters.

Transient Suppression

The following recommendations will help to reduce transients:

yAlways use shielded cables to connect signal wires to the weight indicator.

ySecure the cables in the cable clips provided inside the indicator.

yConnect the cable shield (indicator end only) to a ground point inside the indicator.

Keep wires that extend beyond the shield as short as possible.

yDo not run load cell or signal cables from the weight indicator along side or parallel to wiring carrying AC power. If unavoidable, position the load cell and signal cables a minimum of 24" away from all AC wiring.

yAlways use arc suppressors across all AC power relay contacts (see recommendations at HUhttp://www.paktron.com/pdf/Quencharch_QRL.pdfUH).

yUse zero voltage switching relays, optically isolated if possible.

8200-M538-O1 y 225 Installation |

Page 7 |

INSTALLATION

Before beginning installation of your Model 225 Weight Indicator, make certain that it has been received in good condition. Carefully remove it from the shipping carton and inspect it for any evidence of damage (such as exterior dents or scratches) that may have taken place during shipment. Keep the carton and packing material for return shipment if it should become necessary. It is the responsibility of the purchaser to file all claims for any damages or loss incurred during transit.

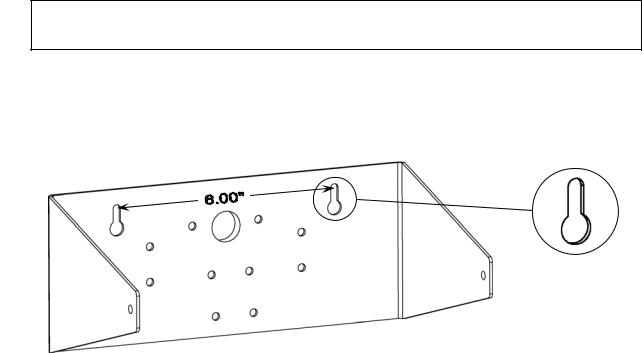

Mounting the 225

NOTE! If your 225 indicator is already installed on a scale, the following information describing its installation does not apply.

The Model 225 Indicator is housed in a NEMA 4X/IP66 stainless steel wall or desk-mount enclosure. The 225 gimbal may be mounted on a desk, table or other smooth, flat, horizontal surface or may be mounted on a wall. Refer to Figure No. 1 for a layout of wall-mounting.

Figure No. 1

Clearance for #10 size screw

If wall mounted, make certain the mounting surface is strong enough to support the instrument.

The mounting location should be where the display is easily viewed while being close enough to provide the operator easy access to the keypad. Carefully lay out the mounting hole locations, then drill and install the anchor bolts. Attach the gimbal to the wall and securely tighten the retaining bolts.

8200-M538-O1 y 225 Installation |

Page 8 |

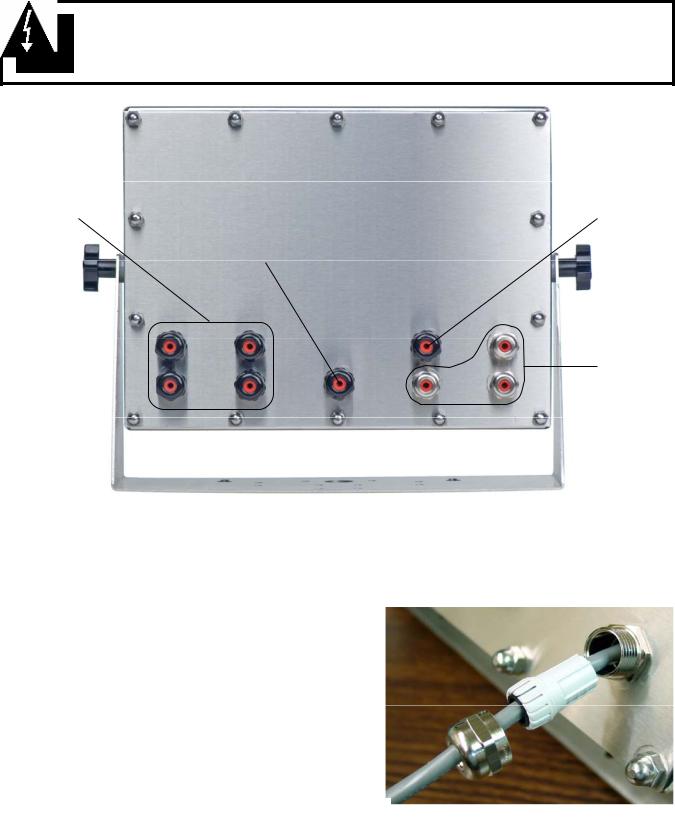

INSTALLATION, CONT.

Load Cell Cable Connection with RFI Suppression

CAUTION! Disconnect any external load cell power supply before connecting load cells to the indicator. Failure to do so will result in permanent damage to the indicator.

I/O |

|

I/O |

(Serial, |

|

(Serial, |

Isolated |

|

Isolated |

Inputs or |

|

Inputs or |

Outputs) |

AC Power |

Outputs) |

|

|

|

|

90-264 VAC |

|

|

0.4 Amp |

|

Scales 1, 2 and 3

Figure No. 2

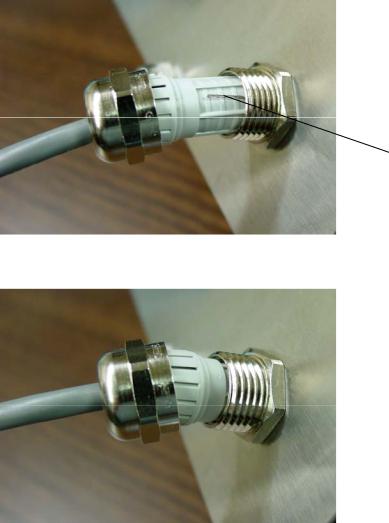

To eliminate RFI, the load cell cable should be routed through the one of the special metallic gland connector and the shield wire from the load cell cable must be connected to this gland connector for grounding. Refer to Figure No. 2 for the gland connector layout.

1.Remove the 14 acorn nuts securing the rear panel to the main housing.

2.Loosen and remove the metal gland connector nut and remove the plastic insert.

3.Referring to Figure No. 3, route the single cable from the load cell or load cell junction box through the nut and plastic insert and into the enclosure.

Figure No. 3

8200-M538-O1 y 225 Installation |

Page 9 |

INSTALLATION, CONT.

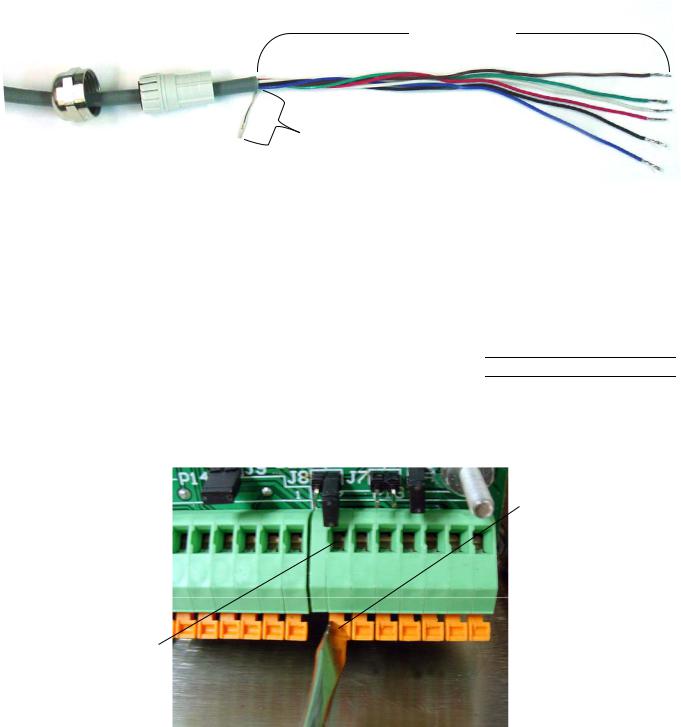

4.With the load cell cable routed into the enclosure, refer to Figure No. 4 and then remove approximately 5 to 6 inches of the cable outer insulating jacket exposing the internal wires.

5.Next, cut the shield wire so that it extends past the outer jacket approximately 3/4 inch.

6.Now, remove 1/4 inch of insulation from the end of each of the 4 wires (without sense leads) or 6 wires with sense leads.

5 to 6 inches

Figure No. 4 |

3/4 inch |

|

1/4 inch

7.Referring to the table below (or on the circuit board) for terminal connections, connect each wire to terminal block P13. Refer to Figure No. 11 for terminal block location.

|

LOAD CELL CONNECTOR P13 |

|

|

UPIN NO.U |

UFunctionU |

UPIN NO.U |

UFunctionU |

1 |

+ EXCITATION |

5 |

- SIGNAL |

2 |

+ SENSE |

6 |

- SENSE |

3 |

+ SIGNAL |

7 |

- EXCITATION |

8.To terminate a wire, use a small flat blade screwdriver and press down on the release bar for the terminal. Insert the wire into the opening and remove the screwdriver, allowing the release bar to return to its original position, locking the wire in place. See Figure No. 5.

Press

Down

Insert

Wire

Figure No. 5

8200-M538-O1 y 225 Installation |

Page 10 |

INSTALLATION, CONT.

9.Repeat the procedure until all wires are in place.

10.After all terminations have been made, remove the excess cable from the enclosure.

11.Referring to Figure No. 6, fold the shield wire back over the plastic insert and then insert the plastic insert (with the shield wire) into the gland connector.

Figure No. 6

Shield

Wire

12.The shield wire is secured when tightening the gland connector nut. See Figure No. 7.

Figure No. 7

13.Do not over-tighten the connector but make certain it is snug.

8200-M538-O1 y 225 Installation |

Page 11 |

INSTALLATION, CONT.

Load Cell Cable Connection UwithoutU RFI Suppression

The following instructions describe the load cell connection without RFI Suppression should it not be required.

1.Remove the 14 acorn nuts securing the rear panel to the main housing.

2.Referring to Figure No. 2, choose a gland connector for the load cell cable and loosen it.

3.Slip the single cable from the load cell or load cell junction box through the gland connector and into the enclosure.

4.Referring to Figure No. 4, remove 3 inches (not 5 to 6 inches) of the outer insulation jacket

5.Next, remove 1/4 inch of insulation from each of the 4 wires and shield (without sense leads) or 6 wires and shield (with sense leads).

6.Referring to the table below (or on the circuit board) for terminal connections, connect each of the wires to terminal block P13. Refer to Figure No. 11 for terminal block location.

|

LOAD CELL TERMINAL – (P13) |

|

|

|

|

|

UFunctionU |

UPIN NO.U |

UFunctionU |

UPIN NO.U |

|

1 |

+ EXCITATION |

5 |

- SIGNAL |

2 |

+ SENSE |

6 |

- SENSE |

3 |

+ SIGNAL |

7 |

- EXCITATION |

4 |

SHIELD |

|

|

7.To terminate a wire, use a small flat blade screwdriver and press down on the release bar for the terminal. Insert the wire into the terminal opening. Remove the screwdriver, allowing the release bar to return to its original position, locking the wire in place. See Figure No. 5.

8.Repeat the procedure until all wires are in place.

9.The load cell cable shield wire should be connected to terminal 4 on terminal block P13.

Load Cell Connections with Over 30 Feet of Cable

For installations with over 30 feet of cable between the indicator and the load cells, sense wires should be used. The sense wires must be connected between the +SENS, -SENS terminals on the indicator and the +EXCITATION, -EXCITATION wires of the load cells or the +SENS, -SENS terminals of the load cell trim board or the section seal trim board. For the indicator to use the sense wires, the +SENS jumper J7 and the -SENS jumper J9 must be open (see Figure No. 11).

8200-M538-O1 y 225 Installation |

Page 12 |

INSTALLATION, CONT.

Serial I/O Cable Installation

The 225 may be connected to a printer to record weight and associated data or it may be connected to a remote display or even to a computer for transmission of weight data. The weight data may be transmitted on demand (pressing the PRINT key or on receipt of a command from the computer).

1.If the rear panel of the indicator has been removed, proceed to step 2. Otherwise, remove the 14 acorn nuts securing the rear panel to main housing

2.Loosen the gland connector for the serial cable. Refer to Figure No. 2 for the gland connector layout.

3.Slip the serial cable through the gland connector and into the enclosure.

4.Referring to Figure No. 4, remove 2 inches (not 5 to 6 inches) of the outer insulation jacket

5.Next, remove 1/4 inch of insulation from each of the wires.

6.Connect each of the wires to the Serial I/O terminal block (P18) referring to Figure No. 11 for terminal block locations.

7.To terminate a wire, use a small flat blade screwdriver and press down on the release bar for the terminal. Insert the wire into the terminal opening. Remove the screwdriver, allowing the release bar to return to its original position, locking the wire in place. See Figure No. 5.

8.Repeat procedure until all of wires are in place.

PRINTER |

– TERMINAL (P14) |

|

COM2/3 SERIAL – TERMINAL (P18) |

||

COM1 SERIAL |

|

||||

UPIN NO.U |

|

UFunctionU |

|

UPIN NO.U |

UFunctionU |

1 |

|

TxDPRINT-RS232 |

|

1 |

TxD2-SRC |

2 |

|

GND |

|

2 |

TxD2-20mA+ |

|

|

|

|

3 |

TxD2-20mA- |

3 |

|

TxD1-SRC |

|

4 |

RxD2-SRC |

4 |

|

TxD1-20mA+ |

|

5 |

RxD2-20mA+ |

5 |

|

TxD1-20mA- |

|

6 |

RxD2-20mA- |

6 |

|

RxD1-RS232 |

|

7 |

RxD2-RS232 |

7 |

|

TxD1-RS232 |

|

8 |

TxD2-RS232 |

8 |

|

GND |

|

9 |

GND2 |

9 |

|

CTS |

|

10 |

RxD3-RS232 |

|

|

|

|

11 |

TxD3-RS232 |

|

|

|

|

12 |

TxD3-20mA active |

|

|

|

|

13 |

GND3 |

¾When connecting a serial printer (using the Cardinal serial data cable, 8539-B108-1A) only

2 wires are used. The RED wire should be connected to Pin 7 (TXD1-RS232) and the

BLACK wire to Pin 10 (GND 1).

8200-M538-O1 y 225 Installation |

Page 13 |

INSTALLATION, CONT.

Optically Isolated Remote Inputs

Included with the I/O are 7 programmable inputs that may be used to remotely (up to 100 feet) initiate various functions within the indicator. These inputs are accessed via a terminal block (P17) on the back of the PC board (see Figure No. 11). The 7 inputs are defined as follows:

|

REMOTE INPUTS TERMINAL – (P17) |

|

||

|

|

|

|

UFunctionU |

UPIN NO.U |

UFunctionU |

|

UPIN NO.U |

|

1 |

+ SRC(12 to 24VDC) |

|

6 |

- - - - (Not Used) |

|

|

|

|

STOP |

2 |

ZERO |

|

7 |

|

|

|

|

|

START |

3 |

TARE |

|

8 |

|

|

|

|

|

DUMP |

4 |

G/N (Gross/Net) |

|

9 |

|

|

|

|

|

GND/SHIELD |

5 |

|

10 |

||

Remember that the input must be connected to GND to initiate the function.

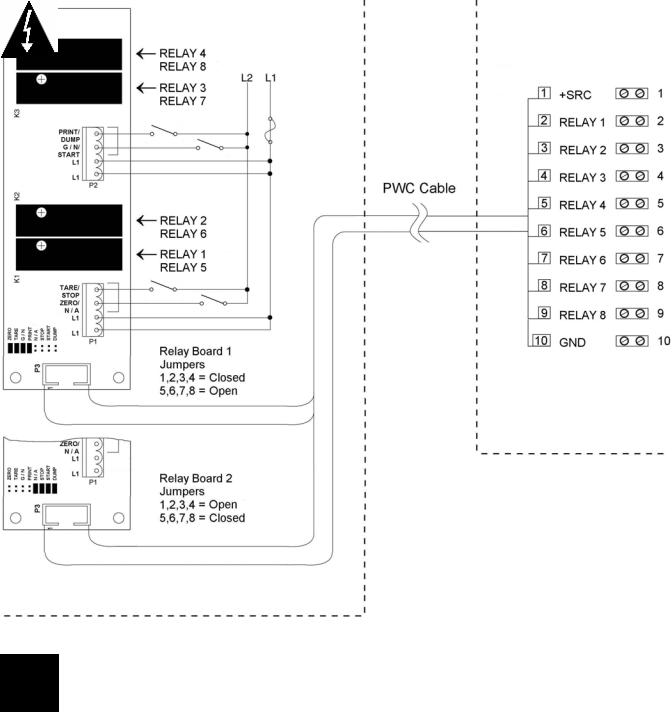

AC Input Relay Board(s)

The AC Input Relay Board(s) are mounted in an external junction box for use with the 225 Indicator. The RB4-ACIN (115 VAC) or RB4-ACINV (230 VAC) contain one board and supports 4 inputs (jumper selectable). The RB8-ACIN (115 VAC) or RB8-ACINV (230 VAC) contain two boards and supports 7 inputs that are jumper selectable. The relay board used in the 115 VAC versions is Cardinal p/n 8200-C324-0A. The 230 VAC version uses relay board Cardinal p/n 8200-C324-1A. Connect the devices as shown in Figure No. 8.

INPUT RELAY TYPE IAC-5 |

90 to 140 VAC @ 6mA maximum for each plug-in relay |

|

|

INPUT RELAY TYPE IAC-5A |

180 to 280 VAC @ 6mA maximum for each plug-in relay |

|

|

OUTPUT |

5VDC @ 12mA from the 225 main pc board assembly P9 |

|

12VDC @ 12mA maximum from external source |

CONNECTION |

Removable plug-in screw terminals for up to 14 AWG wire |

|

|

8200-M538-O1 y 225 Installation |

Page 14 |

INSTALLATION, CONT.

AC Input Relay Board(s), Cont.

P17

225 Indicator

Figure No. 8

Relay Box Assembly RB4-ACIN or RB8-ACIN

Relay Box Assembly RB4-ACINV or RB8-ACINV

NOTE! AC INPUT RELAYS ARE VOLTAGE DEPENDENT. A DIFFERENT RELAY IS REQUIRED FOR 115 VAC AND 230 VAC!

8200-M538-O1 y 225 Installation |

Page 15 |

INSTALLATION, CONT.

Preset Weight Comparator/Checkweigher Logic Level Output

If you so choose, you may use the logic level outputs from your Model 225 indicator’s preset weight comparators or checkweigher to control peripheral devices used to manage the flow of material or signal when the weight is within preset limits. Note that these outputs are at logic level and cannot drive external devices directly. Solid-state relays can be used to accept the logic level output from the 225 and in turn, drive the external device.

1.If the rear panel of the indicator has been removed, proceed to step 2. Otherwise, remove the 14 acorn nuts securing the rear panel to main housing

2.Loosen the gland connector for the cable. Refer to Figure No. 2 for the gland connector layout.

3.Slip the cable through the gland connector and into the enclosure.

4.Referring to Figure No. 4, remove 2 inches (not 5 to 6 inches) of the outer insulation jacket

5.Next, remove 1/4 inch of insulation from each of the wires.

6.Connect each of the wires to the Remote Outputs terminal block (P15 or P16) referring to

Figure No. 11 for terminal block locations.

7.To terminate a wire, use a small flat blade screwdriver and press down on the release bar for the terminal. Insert the wire into the terminal opening. Remove the screwdriver, allowing the release bar to return to its original position, locking the wire in place. See Figure No. 5.

8.Repeat procedure until all wires are in place.

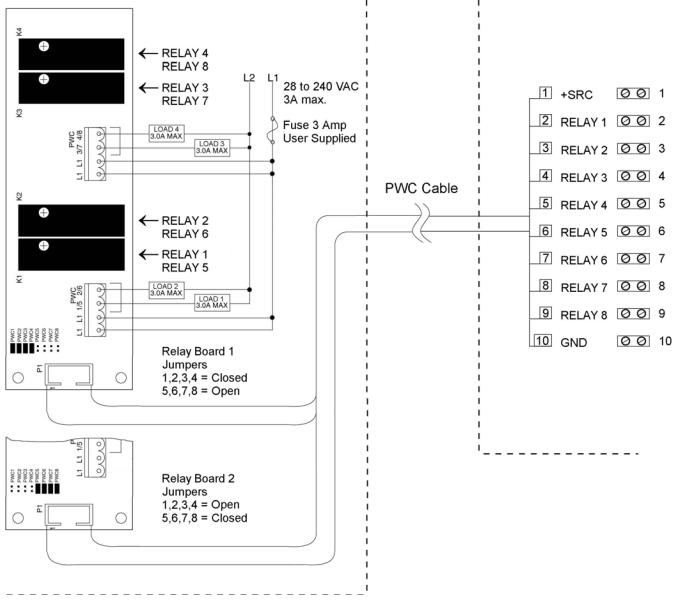

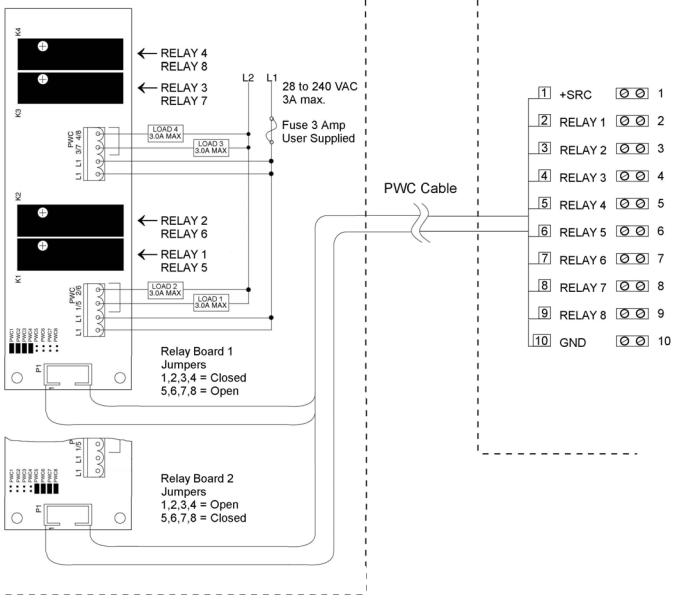

AC Output Relay Board(s)

The AC Output Relay Boards are mounted in an external junction box for use with the 225

Indicator. The RB4-ACOUT contains one board and supports 4 outputs (jumper selectable).

The RB8-ACOUT contains two boards and supports 8 outputs. The relay board used in both is (Cardinal p/n 8539-C062-0A). Connect the devices to be controlled as shown in Figure No. 9 and 10.

The individual relays can be configured to be on (closed) or off (open) at weights under the preset weight then switch at the preset weight from on-to-off or off-to-on by setting the under weight condition to on or off during setup and calibration or setup review.

OUTPUT (closed) |

28-240VAC @ 3A maximum for each plug-in relay |

|

|

CONTROL INPUT |

5VDC @ 12mA from the 225 main pc board assembly P8 |

|

|

CONNECTION |

Removable plug-in screw terminals for up to 14 AWG wire |

|

|

NOTE! All relays are the normally-open type that will open when power to indicator is lost.

8200-M538-O1 y 225 Installation |

Page 16 |

INSTALLATION, CONT.

AC Output Relay Board(s), Cont.

P15

225 Indicator

Figure No. 9

Relay Box Assembly RB4-ACOUT or RB8-ACOUT

8200-M538-O1 y 225 Installation |

Page 17 |

INSTALLATION, CONT.

AC Output Relay Board(s), Cont.

P16

225 Indicator

Figure No. 10

Relay Box Assembly RB4-ACOUT or RB8-ACOUT

Re-Installing the Rear Panel

After all terminations have been made;

1.Remove the excess cable from the instrument enclosure and securely tighten each of the cable gland connectors.

yDo not over-tighten these connectors but make certain they are snug.

yDO NOT USE TOOLS! Finger-tighten only!

2.Ensure any unused gland connectors are plugged and replace the rear panel.

3.Secure the rear panel with the 14 acorn nuts removed earlier, following a diagonal pattern when tightening the acorn nuts.

8200-M538-O1 y 225 Installation |

Page 18 |

INSTALLATION, CONT.

Main PC Board I/O Functions Table

Refer to Figure No. 8 for the AC Input Relay board, Figure No. 9 and Figure No. 10 for the AC Output Relay boards and Figure No. 11 for the Main PCB.

INPUTS |

|

|

|

OUTPUTS |

|

|

|

||

|

|

|

PWC |

CHECKWEIGHER |

DFC |

BATCHER |

|||

P17 |

INPUTS |

P15 |

Presets |

Check 3 |

Check 5 |

Fill 1 |

Fill 2 |

Batch 1 |

Batch 2 |

2 |

ZERO |

2 |

PWC 1 |

Under |

Under |

Fill |

Fast |

Fill 1 |

Fast 1 |

3 |

TARE |

3 |

PWC 2 |

Accept |

Lo Under |

|

Slow |

Fill 2 |

Slow 1 |

4 |

Gross/Net |

4 |

PWC 3 |

Over |

Accept |

|

|

Fill 3 |

Fast 2 |

5 |

5 |

PWC 4 |

|

Lo Over |

|

|

Fill 4 |

Slow 2 |

|

6 |

N/A |

6 |

PWC 5 |

|

Over |

|

|

Fill 5 |

Fast 3 |

7 |

STOP |

7 |

PWC 6 |

|

|

|

|

Fill 6 |

Slow 3 |

8 |

START |

8 |

PWC 7 |

|

|

|

|

Fill 7 |

|

9 |

DUMP |

9 |

PWC 8 |

|

|

Dump |

Dump |

Dump |

Dump |

|

|

|

|

|

|

|

|

|

|

|

|

P16 |

Presets |

Check 3 |

Check 5 |

Fill 1 |

Fill 2 |

Batch 1 |

Batch 2 |

|

|

2 |

PWC 9 |

Under |

Under |

Fill |

Fast |

Fill 1 |

Fast 1 |

|

|

3 |

PWC 10 |

Accept |

Lo Under |

|

Slow |

Fill 2 |

Slow 1 |

|

|

4 |

PWC 11 |

Over |

Accept |

|

|

Fill 3 |

Fast 2 |

|

|

5 |

PWC 12 |

|

Lo Over |

|

|

Fill 4 |

Slow 2 |

|

|

6 |

PWC 13 |

|

Over |

|

|

Fill 5 |

Fast 3 |

|

|

7 |

PWC 14 |

|

|

|

|

Fill 6 |

Slow 3 |

|

|

8 |

PWC 15 |

|

|

|

|

Fill 7 |

|

|

|

9 |

PWC 16 |

|

|

Dump |

Dump |

Dump |

Dump |

Relay Box Cable Wire Number to Relay Number Table

The relay box cable wire numbers correspond to the indicator main PC board remote input

(P17) and output (P15 and P16) terminal connection pins.

CABLE WIRE |

RELAY NUMBER |

CABLE WIRE |

RELAY NUMBER |

NUMBER |

(Set Proper Jumpers) |

NUMBER |

(Set Proper Jumpers) |

1 |

+SRC (For AC Input Relays) |

6 |

5 |

2 |

1 |

7 |

6 |

3 |

2 |

8 |

7 |

4 |

3 |

9 |

8 |

5 |

4 |

10 |

GND |

8200-M538-O1 y 225 Installation |

Page 19 |

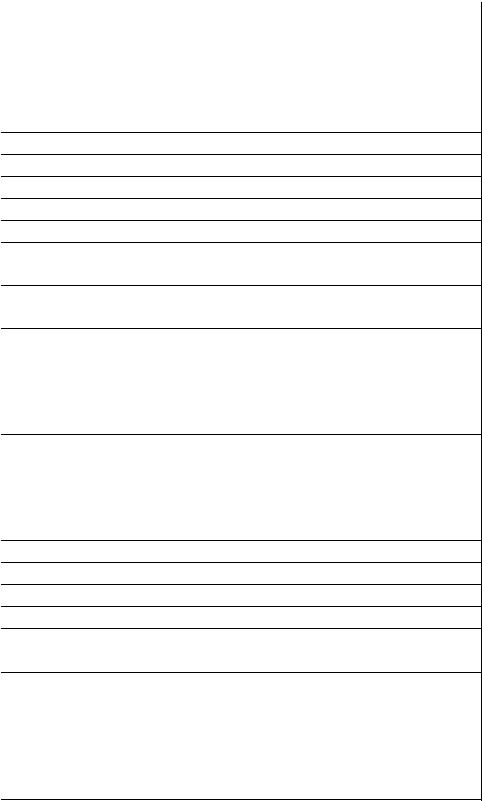

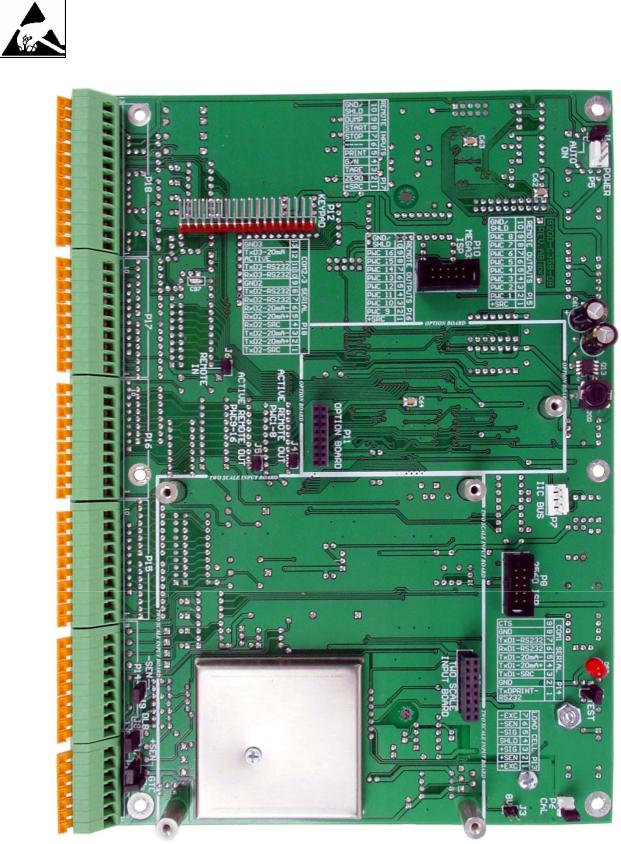

MAIN PC BOARD

CAUTION! This board contains static sensitive components. Improper handling can result in damage to or destruction of the components or board. Such actual and/or consequential damage IS NOT covered under warranty.

I/O) (SERIAL |

P18 COM2/3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P5 |

POWER |

|||

P17 INPUTS |

REMOTE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P10 MEGA3 ISP |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

P15 OUTPUTS P16 OUTPUTS |

|

|

|

|

|

|

J6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

REMOTE REMOTE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

P11 Option Board |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

BUS IIC |

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

J4 |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

J5 |

|

|

|

|

|

|

|

|

P7 |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ISP 2560 |

P8 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

SERIAL COM1 |

P14 PRINTER |

|

|

|

|

|

|

|

|

|

|

|

BOARD INPUT |

SCALE TWO |

|

|

|

|

|

|

|||

|

|

J9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

J2 |

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||

|

|

J8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

LOAD P13 CELL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

J7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

CAL P6 SEAL |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

J3 |

|

|

||||||||||||

J10 |

|

Figure No. 11 |

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

8200-M538-O1 y 225 Installation |

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

Page 20 |

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||||||

MAIN PC BOARD, CONT.

J1 (AUTO ON) – AUTO-ON JUMPER

When installed, this jumper will cause the indicator to power on automatically whenever power is applied to the power input connector. If power is lost momentarily and then reapplied, the indicator will turn on without pressing the ON key.

J2 (TEST) – TEST JUMPER

When installed, this jumper will turn the backlight on, ignoring the BACK LITE= setting.

J3 (8V) – 8V EXCITATION JUMPER

When installed, this jumper allows the 225 indicator to supply 8 VDC excitation voltage when a remote (external) 12 VDC battery is used to power the indicator. To operate from the 12 VDC battery, the load cell excitation voltage MUST be set to 8 VDC (J3 closed). Operating with the load cell excitation voltage set to 12 VDC will result in an unstable weight display.

J4 (PWC1-8) and J5 (PWC9-16) – ACTIVE REMOTE OUT JUMPERS

When installed, these jumpers allow the 225 indicator to supply (source) 5 VDC to a solid-state relay or other load of 200 ohms or greater. To operate from the 5 VDC source, the positive connection from the relays must be connected to P15 (P16) pins 2 through 9 and the negative wire from the relays to P15 (P16) pin 10 (GND). See Figure No. 9 for connector P15 location and Figure No. 10 for connector P16 location.

For completely isolated outputs, J4 (J5) must be open (on one pin only or removed) and the user must provide 5 to 12 VDC to P15 (P16) pin 1 (+SRC) and a ground return to the load. The load must still be 200 ohms or greater and P15 (P16) pin 10 (GND) is not connected.

J6 (REMOTE IN) – REMOTE IN JUMPER

When installed, this jumper allows the 225 indicator to supply (source) 5 VDC to a remote input circuit. Connecting P17 pins 1 through 9 to P17 pin 10 (GND) through a switch will cause the selected action. See Figure No. 8 for connector P17 location.

For completely isolated inputs, J6 must be open (on one pin only or removed) and the user must provide 5 to 12 VDC to P17 pin 1 (+SRC) and a ground return to the switch connected to P17 pin 2 through 9. Note that P17 pin 10 (GND) is not connected.

J7 (+SEN) and J9 (-SEN) – SENSE JUMPERS

If the sense leads are NOT used, you must install jumpers at J7 and J9 (near the P13 and P14 terminal blocks). These jumpers connect the sense leads to the excitation leads. If sense leads ARE used (as in motor truck scales), these jumpers should be open (on one pin only or removed).

J8 (DLB) – DEAD LOAD BOOST JUMPER

For very low dead loads (less than 10% of the combined load cell capacity) connect J8, the DLB (dead load boost) jumper on the printed circuit board.

J10 (GTC) – GND TO CHASSIS JUMPER

When installed, this jumper connects the analog circuit ground to the indicator chassis ground.

8200-M538-O1 y 225 Installation |

Page 21 |

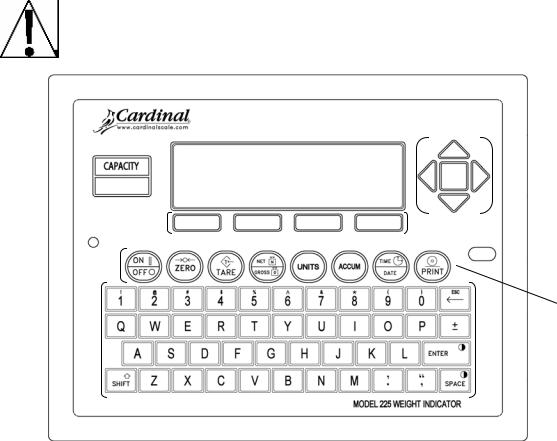

KEYPAD FUNCTIONS

The Model 225 indicator has 8 standard function keys, a full “QWERTY” alpha-numeric keypad, 4 soft (programmable) keys and 4 navigation keys with an interactive ENTER key.

The keypad is used to enter commands and data into the indicator. This section describes each key along with its normal function. Refer to Figure No. 12 or the actual indicator while reading this section.

The membrane keypad is not to be operated with pointed objects (pencils, pens, fingernails, etc). Damage to keypad resulting from this practice is NOT covered under warranty.

Navigation

Keys

Keys

Soft Keys

Soft Keys

Standard

Function Keys

Alpha-numeric

Alpha-numeric

Keys

Figure No. 12

Standard Function Keys

ON/OFF KEY

Pressing this key when the indicator is off will apply power and turn it ON. If the indicator is already on, pressing this key will turn the indicator OFF.

ZERO KEY

This key is used to reset the gross weight to zero. If the gross weight exceeds the preset limit for this key, an error message will be displayed when the key is pressed. The zero limit may be set to either 4% or 100% of scale capacity. The limit is set during Calibration and

Setup of the scale.

8200-M538-O1 y 225 Installation |

Page 22 |

KEYPAD FUNCTIONS, CONT.

Standard Function Keys, Cont.

TARE KEY

This key is a dual function key. Pressing the TARE key alone (Pushbutton Tare mode) will cause the current gross weight to be stored as the new tare weight and cause the weight display to change to the net weight display mode (NET will be shown on right side of display). Pressing this key after entering a numeric value (Keypad Tare) will cause the value entered to be accepted as the new tare weight.

NOTE: Tare weights equal to or greater than scale capacity cannot be entered. In addition, the keypad tare weight division value must be the same as the scale division value. For example, a unit with .005 lb as the division value will display ERROR if you attempt to enter 1.003 for the tare weight.

NET/GROSS KEY

This key is used to toggle between the Net and Gross weight mode. The selected mode is indicated by showing G for Gross weight or NET for Net weight on the display. Note that the display will show an error (-NO TARE-) and the indicator will remain in the Gross weight mode if the key is pressed and valid tare weight has not been entered.

UNITS KEY

Pressing this key will change the weighing units to the alternate units if selected during the calibration and setup of the indicator. The available units of measure (BASE UNITS= and CNVT UNITS=) are enabled or disabled in calibration and setup. The available units include tons, pounds only, ounces, tonnes (metric tons), kilograms, grams and custom. Note that not all combinations are supported.

ACCUM KEY

This key is used to display the contents of the 32 ID accumulators, the total Gross and Net weight accumulators, the 200 ID storage accumulators, the Batcher bin accumulators and the Count Function piece count accumulators. Note that the Total Gross, Total Net and

Count accumulators are updated with every print command. Refer to the NET/GROSS

ACCUMULATORS, ID STORAGE OPERATION (ID ACCUMULATORS) OR COUNT OPERATION sections of this manual for more information.

TIME/DATE KEY

This key is used to program the time, date and consecutive number. Refer to the TIME, DATE AND CONSECUTIVE NUMBER section of this manual more information.

8200-M538-O1 y 225 Installation |

Page 23 |

KEYPAD FUNCTIONS, CONT.

Standard Function Keys, Cont.

PRINT KEY

Pressing this key will add the displayed Gross or Net weight or Piece Count to the associated accumulator and initiate the transmission of weight and other data selected during setup to the printer output port UunlessU the continuous data feature of the port was enabled during calibration and setup.

NOTE! The indicator will not respond to the Print command unless the weight display is stable. If displaying Gross weight, the only weight printed is Gross weight. If displaying Net weight, the Gross, Tare, and Net weights are printed.

The Model 225 includes support for Cardinal’s |

|

|

|

|

|

#2 |

|

|

|

||

proprietary VISUALIZER Ticket and Label |

|

|

|

||

10:19 |

07/23/2008 |

||||

Generation Software. VISUALIZER is a PC based |

|||||

100.00 |

lb |

G |

|

||

program that can design a ticket or label then |

|

||||

20.00 |

lb |

T |

|

||

download the ticket information to the indicator. |

|

||||

80.00 |

lb |

N |

|

||

The program also allows file transfer between the |

|

||||

0.00 |

lb |

GROSS |

|||

indicator and the PC. |

|||||

ACCUM |

|

|

|||

|

|

|

|||

The 225 allows six programmable formats in |

272.00 |

lb |

NET ACCUM |

||

addition to the standard print tab settings format. |

|

|

|

|

|

|

|

|

|

||

Print formats are selected by using the SHIFT and |

|

SAMPLE TICKET |

|||

PRINT keys in combination (refer to the Shift Key |

|

||||

section for details). NOTE! When the PRINT key is pressed the indicator looks for the selected format. If no VISUALIZER ticket is found it reverts to the print tab settings.

8200-M538-O1 y 225 Installation |

Page 24 |

KEYPAD FUNCTIONS, CONT.

Alpha-Numeric Keys

The alpha-numeric keys are used to enter commands and data into the indicator during Calibration and Setup as well as during normal operations.

NUMERIC KEYS (1 to 9 and 0)

These keys are used to enter numeric data during the setup and calibration as well as during normal operation of the indicator. Note that they have alternate meanings. In the alphanumeric mode, when combined with the SHIFT key, their alternate meaning is output.

For example, pressing the SHIFT key and then the 4 key will output the $ dollar sign.

← /ESC KEY

This key has several functions. During Setup, when a setup parameter is displayed, pressing this key will "backup" to the previous selection. Also note that on prompts requiring a value to be entered, pressing the ← /ESC key will clear the value.

In normal operation, this key is used during numeric data input to delete a number entered. If the last number entered is incorrect, press the ← /ESC key once to deleted the number.

If more than the last number is incorrect, press the ← /ESC key for each number to be deleted. Note that if a number has not been entered, the indicator will ignore this key.

QWERTY KEYS

These keys are used to enter alpha data during Calibration and Setup as well as during normal operations. Pressing the SHIFT key before pressing an alpha key will toggle the key to output its alternate meaning. For example, pressing the SHIFT key then the A key will output a lower case “a” (not a capital letter).

ENTER KEY

The ENTER key serves several purposes. During Calibration and Setup (as well as during normal operations), pressing the key will retain the current setting and return the display to the menu display. It is also used when entering or changing data to signal the completion of data entry. The data entered will then be processed or saved.

During normal operations it is used in combination with the SHIFT key to increase the LCD contrast.

SPACE

This key is used to enter a blank space during alpha-numeric data input for Calibration and Setup as well as during normal operations. When combined with the SHIFT key, it is used to decrease the display contrast.

8200-M538-O1 y 225 Installation |

Page 25 |

KEYPAD FUNCTIONS, CONT.

Alpha-Numeric Keys, Cont.

SHIFT

This key is used for several functions. It is used in combination with the Navigation ENTER key (red square key in center of the Navigation arrows) to enter the Calibration and Setup mode.

During Calibration and Setup (as well as during normal operations), pressing the key before pressing an alpha-numeric key will toggle the key to output its alternate meaning. For example, when combined with an alphabetic key, the SHIFT key causes a lower case letter

(not a capital letter) to be output.

Shift Key Combinations

SHIFT, ESC, ACCUM KEY

The 225 will retain and display on command the maximum weight value measured since the indicator has begun operation or since the maximum value was last cleared. The maximum value is displayed by pressing the SHIFT key, the ESC key and then the ACCUM key when the display is showing the FUNCTION= prompt. Press the ENTER key to exit and return to normal operation.

SHIFT, ESC, PRINT KEY

This combination is used to change the selected print ticket format. Pressing the SHIFT key, the ESC key and then the PRINT key when the display is showing the FUNCTION= prompt. The display will change to show PRINT=X. Note that X is the current ticket format selected.

If the setting displayed is acceptable, press the ENTER key to exit and return to normal operation. Otherwise, using the numeric keys enter the new value for the ticket format and then press the ENTER key to exit and return to normal operation.

0 |

= Print Tab Settings |

|

|

1 |

= Default Print Format |

2 = VISUALIZER Ticket |

3 = VISUALIZER Ticket |

4 |

= VISUALIZER Ticket |

5 = VISUALIZER Ticket |

6 = VISUALIZER Ticket |

In addition to using the above key combination to change the print ticket format, the operator (just prior to printing the ticket) can change the print ticket format at the end of the weighing operation. This is accomplished by performing the normal weighing operation and then pressing the desired format number (0, 1, 2, 3, 4, 5 or 6), followed by pressing the

PRINT key.

NOTE! When a print format is selected by either method, it will remain active until changed by the operator.

8200-M538-O1 y 225 Installation |

Page 26 |

Loading...

Loading...