CaptiveAire UDS Installation Manual

1

Utility Distribution Systems

08/2004 A0011037

2

CONSTRUCTION & LISTING

The Utility Distribution System (UDS) furnished for this job has been built in strict compliance

with the National Electric Code and the National Sanitation Foundation Standards. This system

is listed under ETL File-3054803-001 and NSF Standard 2.

The utility distribution system was designed to meet all the utility requirements of your kitchen

appliances intended for hook-up to this system.

The major components of the system are:

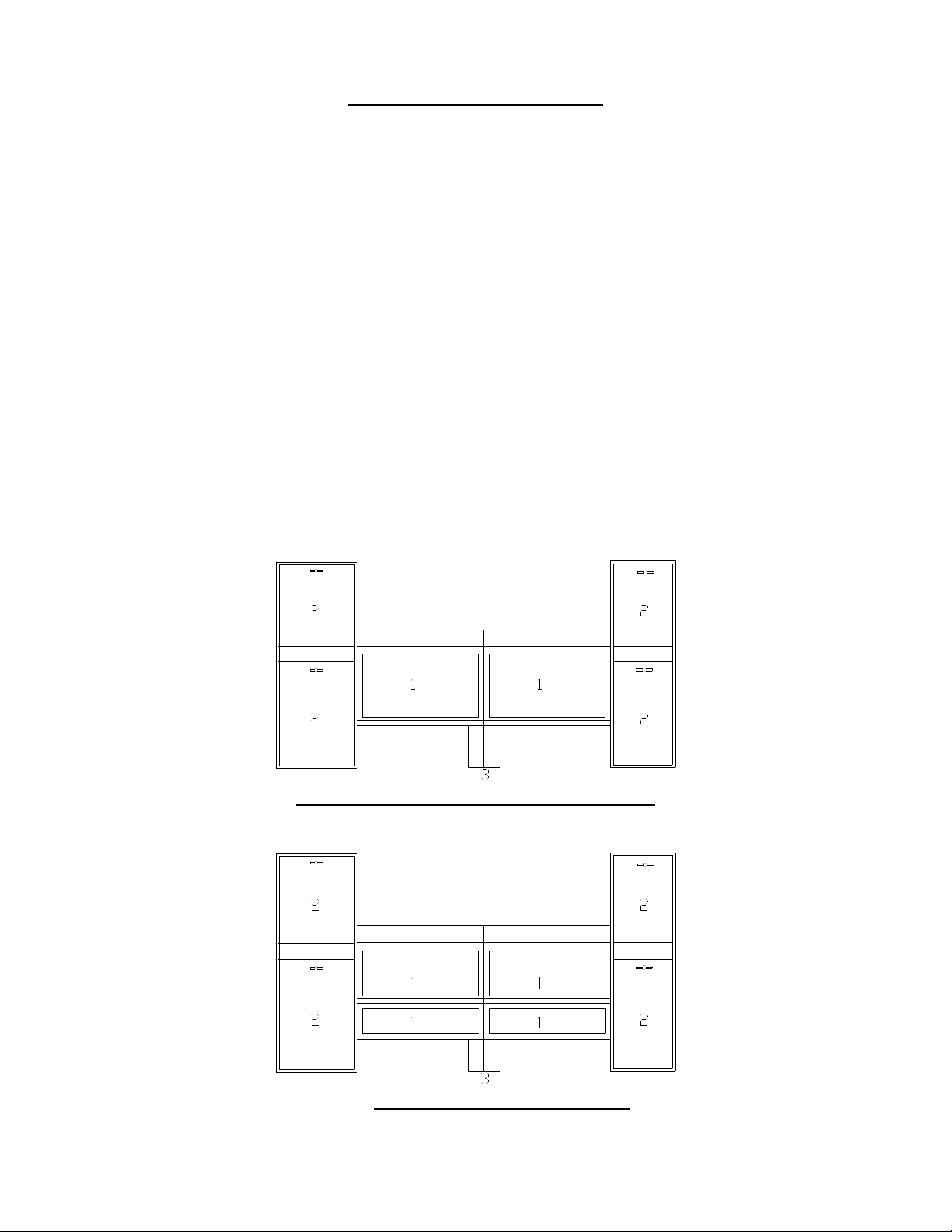

A. Utility Housing: The raceway system includes risers, pedestals, and exterior panels

and is constructed completely of 16-gauge stainless steel. All utility components are

housed within this stainless steel enclosure.

1. Utility Raceway: Plumbing and electrical compartments are entirely enclosed and are

accessible through removable panels.

2. Risers: Single point field connections are done in the vertical chases. These house

the main electrical disconnect and plumbing manifold shut off valves, which are

accessible through removable panels.

3. Pedestals: May be provided on multiple sections to support the weight of the system.

FIG. B

UDS- (ISLAND CONFIRURATIONS)

FIG. C

UDS- (WALL MOUNTED)

3

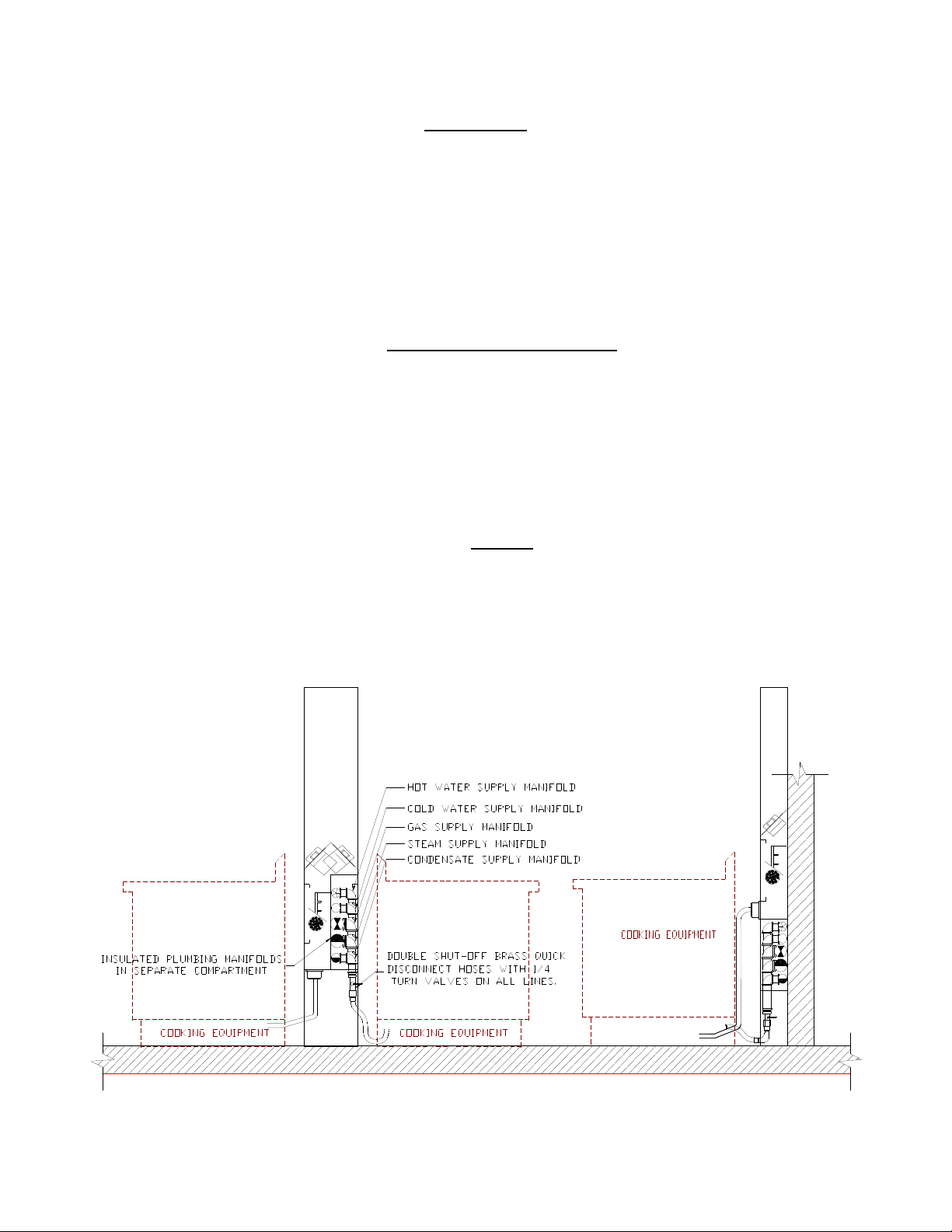

PLUMBING

The plumbing section, if supplied, may include gas, hot water, cold water, steam supply, and

steam return. The main manifold and individual connections are sized and located for the

equipment in the specified design with a 25% future add-on capacity. Plumbing lines are color

coded and labeled for identification in field installation. The hot and cold water, steam supply

and return manifolds are fiberglass insulated. A main shut off valve is provided for each

individual line (¼ turn ball valve) and they are located behind the riser panels (#2 on FIG. B, and

C). All valves are UL, AGA and MA approved.

PLUMBING ELECTRICAL

Electrical (120VAC) gas solenoid valve(s) will be factory installed in the plumbing riser or

provided separately for field installation. NFPA-96 requires that the fuel and electrical supply be

shut off to all appliances in the event of a surface fire on any cooking appliance connected to the

UDS. Connections must be made per local codes or as suggested in FIG. D. Provisions are

made on the shunt trip terminal blocks for connections between surface fire protection and your

electrical solenoid gas valve.

HOSES

Dual shut-off quick disconnect flexible hoses up to 6 feet long are provided to allow easy access

for cleaning, replacement, or removal of equipment. Restraints need to be installed on all mobile

equipment to prevent over extending the hoses maximum length. Hoses are UL, AGA and MA

approved.

Island Style Wall Style

FIG. D

4

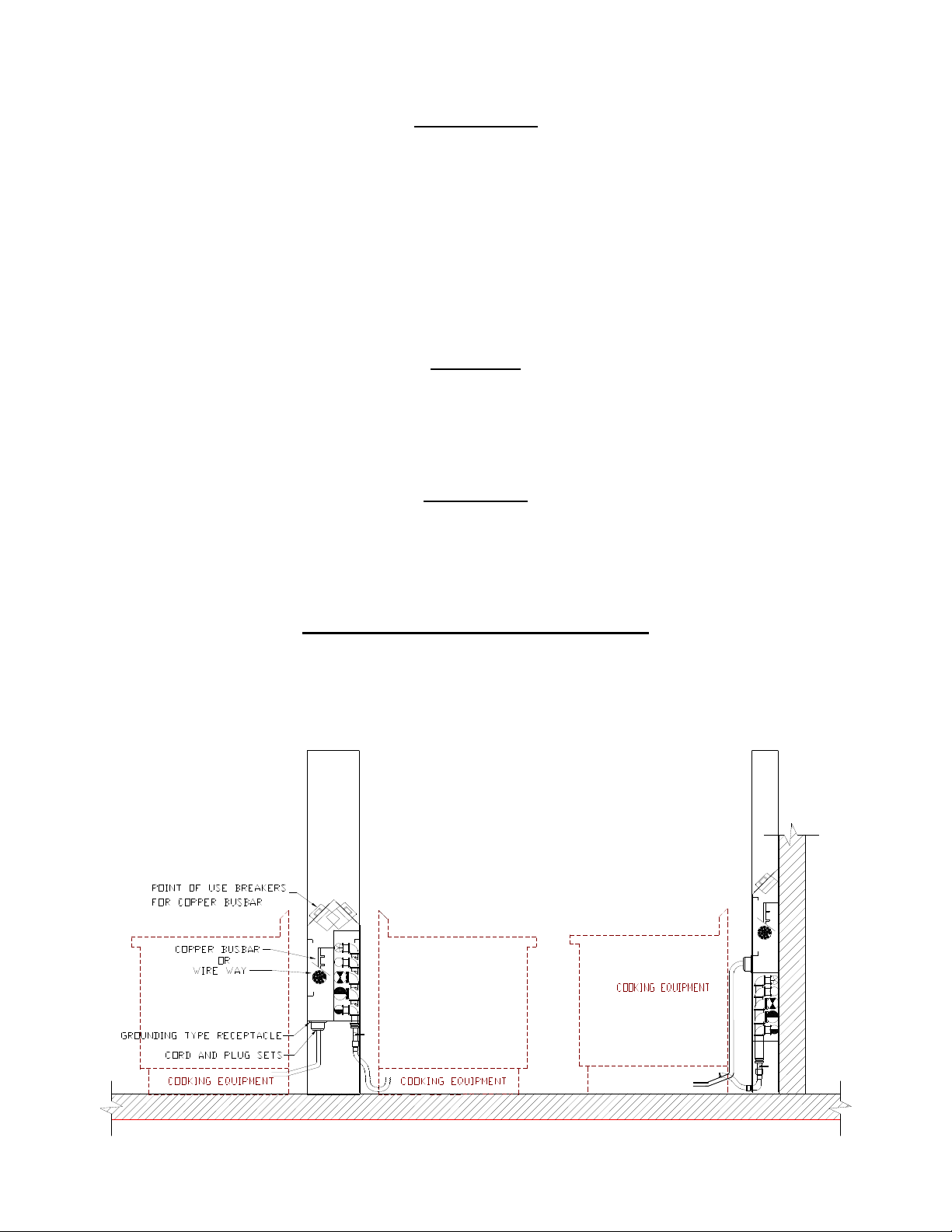

ELECTRICAL

Electrical service is supplied to the equipment either from a Buss bar or wire-way. These two systems

power the equipment in the same manner. Both have shunt trip mechanisms on the main breaker to shut

off all electric if the fire system is activated or the emergency kill switch is pressed. The Buss Bar

design has point of use breakers located on the top of the horizontal raceway. In the Wire Way design

the breakers are located in one of the vertical risers in a breaker panel. Receptacles are usually located at

the bottom of the horizontal raceway. If the UDS was designed with duplex convenience outlets they

will be located at each end in the vertical risers. This system has been designed for the equipment

specified in the job specifications, with a 25% future add-on capacity.

BUSS BAR

Each electric service may contain up to (4) conducting copper bars having a balanced load across them.

Power from the main breaker feeds the Buss bar. The line side of the branch breakers is connected to the

Buss bar and the load side to the appliance receptacle. Extra connection points are located along the

Buss to allow relocation or addition of receptacles. These are accessible though doors # 1 on FIG. B, C.

WIRE-WAY

The wire way system consists of a main breaker, which provides electrical power to the Buss in a circuit

breaker panel located in one of the vertical risers. In this configuration the branch breakers are located

in the breaker panel. Wiring from the breakers run through the horizontal raceway to the receptacle for

each appliance. This system may have extra receptacle drops for future equipment.

ELECTRICAL OUTLETS & CORD SETS

Each receptacle is provided with a moisture resistant cover and has been located and sized according to

the equipment layout specified. Each is supplied with a matching cord and plug set if these are not

already supplied with the appliance. Twist-lock sets are standard with UDI. Straight blade sets are

standard with UDW.

Loading...

Loading...