Page 1

The utility distribution system allows greater flexibility over conventional utility connections. It is designed to provide

(800) 965

-

0420

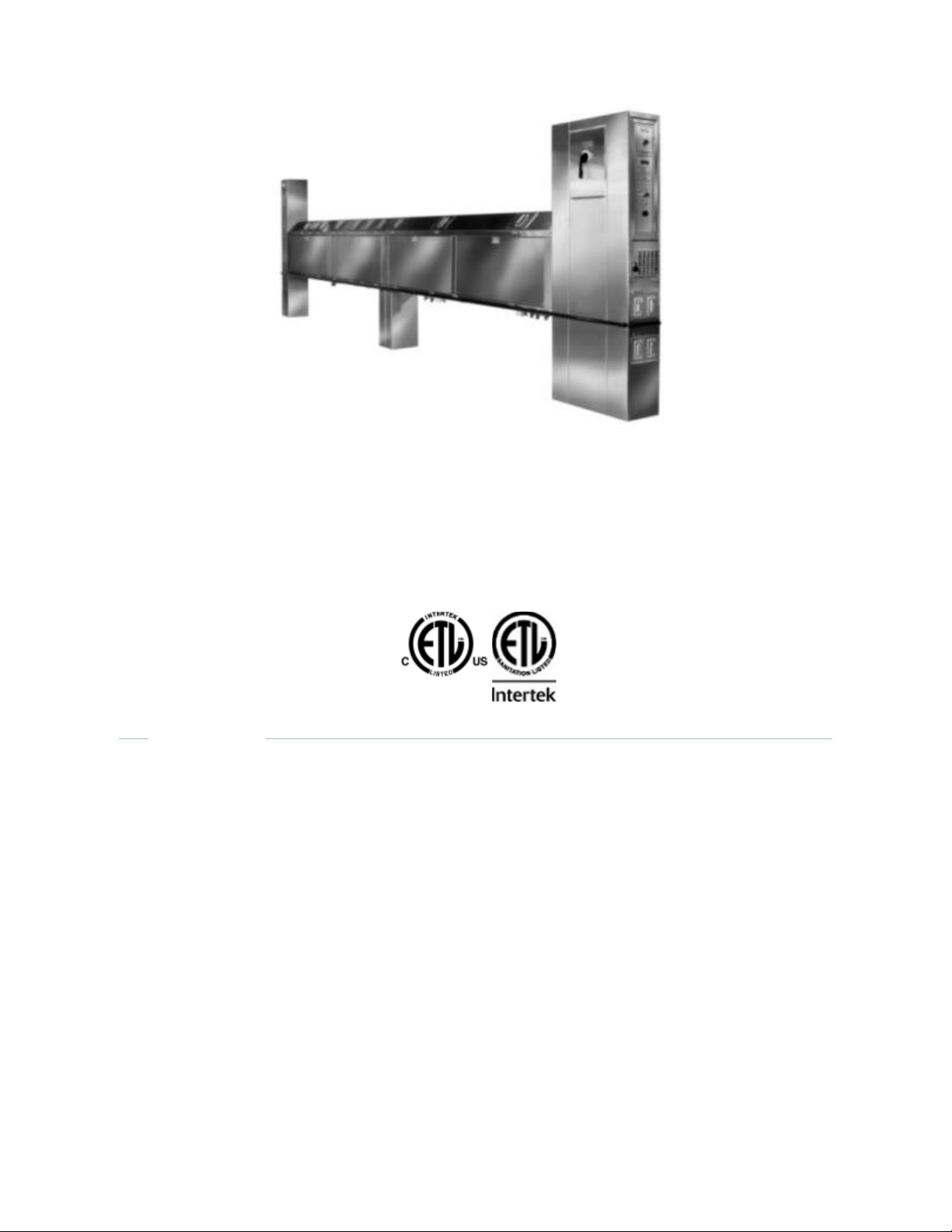

Utility Distribution System

CaptiveAire Systems' UDS provides

unequaled cooking line versatility, flexibility

and convenience.

One connection for all your utility needs

The CaptiveAire Utility Distribution System (UDS) is designed to meet all electrical and plumbing requirements for

your kitchen appliances. A two compartment raceway houses either an electric copper bus bar or wireway which is

completely isolated from the plumbing supply manifolds.

ADVANTAGES

Efficiency for Today - Flexibility for Tomorrow

additional capacity according to job specifications. Spare connection points are provided for future cooking

equipment expansion; therefore adding new equipment requires minimal effort. Rearranging the cooking line-up

can be accomplished in a matter of minutes, especially when equipment is on casters.

Electrical Riser: Main power connection is made to the main circuit breaker which has a shunt trip and is mounted

in the electrical riser.

Bus bar systems: Electrical power is fed through the main circuit breaker to the bus bar system in the raceway.

Each appliance is fed from the bus bar through individually sized circuit breakers located along the raceway.

Wireway systems: Electrical power is fed through a main circuit breaker to a distribution panel which contains

individual branch breakers. Each appliance is fed from the individual breakers which are wired to each receptacle

located along the raceway.

Plumbing Riser: The plumbing riser houses manual (quarter-turn) shut-off valves for each incoming main supply

line located in the UDS. The plumbing manifolds are provided with stub-outs along the raceway for the individual

plumbing connections. Each stub-out is equipped with a manual (quarter-turn) shut-off valve.

Page 2

FEATURES

(800) 965

-

0420

ETL Listed to US and Canadian Standards and ETL Sanitation Listed

2 Models Available:

UDI: Island configuration with equipment connections on both sides

UDW: Wall mounted with equipment connections on one side only.

Expandability: All plumbing manifolds are provided with multiple plumbing stubs for future use. All

electrical systems are designed for additional capacity for future expansion or upgrade of connected

appliances.

Bus Bar Systems: Individual circuit breakers mounted on interchangeable plates for ease of service and

relocation. Spare connection points provided for cooking equipment relocation or expansion.

Wireway: Electrical distribution panel located in the riser is equipped with branch circuit breakers and sized

for expansion.

Serviceability and Accessibility: Lift out doors provide easy access to risers without moving cooking

equipment, in most cases. Removable panels provided along the length of the raceway allow access to

either plumbing or electrical compartments.

Electric Outlets and Cord Sets: All outlets are provided with moisture resistant covers and have been

sized per NEMA standards. Each is supplied with a matching cord and plug set if these are not already

supplied by the equipment manufacturer. Twist-lock sets are standard with the model UDI. Straight blade

sets are standard with the model UDW.

Main Disconnect: One point disconnect through a main circuit breaker equipped with a 120 VAC rated

shunt trip provided in the riser.

Gas Solenoid Valve: Electrical or Mechanical. Electrical valves provided with a manual reset button.

Shunt Trip: Provided with each main breaker.

Appliance Protection: Each electrical outlet connection is protected with an individual circuit breaker.

Dual Convenience Outlets: Located at each riser with integral ground fault protection.

Fire/Fuel Shutoff: In compliance with NFPA 96, terminal connection points provided for field wiring to the

fire protection system to shut off fuel sources and power in the event of a fire.

Customized CAD Drawings Provided

OPTIONS

Remote Status Indicator Panel: Lighted panel indicates status of breakers in wireway system.

Electric Outlets & Cord Sets: Water tight pin and sleeve outlets and cords.

Light & Fan Switches located in riser.

Hood Control Panel built into riser.

Ground Fault Protection

Prison Package

Bumper Strips

Emergency Kill Switch: Single point shutdown of electrical power and electrical gas valves.

Swivel Connectors for gas equipment.

Plumbing Fixtures: Pre-plumbed and installed faucets, mixing valves, hose reels.

Cable Restraints: Available for mobile equipment.

Hinged Doors for internal access to risers.

Temperature/Pressure Gauges for hot/cold water main.

SPECIFICATIONS

Utility Distribution System shall be the CaptiveAire model UDI (or UDW). Overall size shall be as shown on

drawings. Systems shall have two vertical risers, one on each end, with one dedicated to electrical and the other to

plumbing. The horizontal distribution raceway between the risers shall be separated into electrical and plumbing

compartments and each shall be completely enclosed and water tight with removable access panels. The risers

and raceway shall be constructed of 16 gauge, type 304 stainless steel, #4 finish. The system shall be completely

pre-wired and pre-plumbed with one (1) final connection point for all incoming services. A circuit protected dual

convenience outlet shall be provided on each riser. Service connections shall be located behind easy lift out

access panels.

Page 3

ELECTRICAL

water and steam supply and return manifolds shall be insulated. All incoming service connections shall be provided

event of a fire. Electrical gas valves shall be furnished with a manual gas reset button located in the UDS riser. Gas

(800) 965

-

0420

Bus Bar Systems: The electrical raceway shall be a four (4)

conductor copper bus bar system having balanced load and phases

and shall be completely isolated from the plumbing supply manifolds.

Point of use circuit breakers shall be mounted on connection plates

which are located on the peaked top of the raceway and protected

by a water proof stainless steel hinged cover. The breakers shall be

easily accessible to the operator. The connection plates shall be

easily interchangeable with spare blank plates which shall be

provided for future expansion or changes. A main circuit breaker with

a built-in 120 VAC rated shunt trip shall be furnished in the electrical

riser and require a single point incoming connection. Terminal block

connections shall be provided for field interconnection between the

shunt trip and the fire protection system for power shut-off in the

event of a fire.

Wireway Systems: The electrical system shall consist of a main

circuit breaker which feeds power to a distribution panel located in

the electrical riser containing individual branch breakers. Each

appliance is fed from the individual breakers which are wired to each

receptacle located along the raceway and shall be completely

isolated from the plumbing supply manifolds. The main circuit

breaker shall be equipped with a built-in 120 VAC rated shunt trip

and shall be located in the electrical riser requiring a single point

incoming connection. Terminal block connections shall be provided

for field interconnection between the shunt trip and the fire protection

system for power shut-off in the event of a fire. All outlets shall be

equipped with grounding type receptacles having specific NEMA

polarized configurations and located on the under side (Model UDI)

or front side (Model UDW) of the raceway at each equipment location. Outlets are matched to the cord and

plug sets supplied with equipment. On the Model UDI, twist lock cord and plug sets are provided for

equipment supplied without cords. On the Model UDW, straight blade cord and plug sets are provided for

equipment supplied without cords.

Main Circuit Breaker: 15 to 600 Ampere, 1 or 3 phase

120, 208, or 480 VAC System

Branch Circuit Breaker: 15 to 100 Ampere, 1 or 3 phase

120, 208, or 480 VAC System

PLUMBING

The plumbing compartment shall be completely isolated from the electrical with all piping labeled. Hot and cold

with 1/4 shut-off valve. Each branch connection shall be provided with 1/4 shut-off valve, color coded, and located

at each equipment location. Color coded quick disconnect hoses are provided for connection to equipment. Hot

and cold water piping, including branch connections, shall be type "L" copper tubing. All fittings will be copper

sweat soldered (95-5 type). Gas and steam piping, including branch connections, shall be threaded black iron.

There shall be a drip tee on the incoming gas end. The gas manifold shall be furnished with either an electrical or

mechanical gas valve which shall be field interlocked with the fire protection system to shut off fuel sources in the

manifolds are sized for an inlet pressure of 7" WC for natural gas or 11" WC for LP. All plumbing components are

UL, AGA and MA approved.

GAS

Manifold (single or looped): 3/4" to 3" IPS

1/4 turn manual shut-off valve on manifold

Quick disconnect hoses: 1/4" to 1-1/4", up to 6' long

Quick disconnect fittings: 1/4" to 1-1/4" with 1/4 shut-off valves

Page 4

HOT AND COLD WATER

(800) 965

-

0420

Manifold: 3/4" to 1" IPS

1/4 turn manual shut-off valve on manifold

Quick disconnect hoses: 1/4" to 1", up to 6' long

Quick disconnect fittings: 1/4" to 1" with 1/4 shut-off valves

Steam Supply/Steam Return

Steam Manifold: 3/4" to 3" IPS

Condensate Return Manifold: 3/4" to 2" IPS

1/4 turn manual valves on manifolds

Quick disconnect hoses: 1/4" to 1-1/4", up to 6' long

Quick disconnect fittings: 1/4" to 1-1/4" with 1/4 shut-off valves

COMPRESSED AIR

Manifold: 1/2" to 3/4" IPS

1/4 turn manual shut-off valve on manifold

Quick disconnect hoses: 1/4" to 1/2", up to 6' long

Quick disconnect fittings: 1/4" to 1/2" with 1/4 shut-off valves

SUPERIOR SERVICE

State of the art manufacturing

Localized sales and engineering offices nationwide, providing AutoCad

submittal drawings and detailed engineering data.

Expedient Lead Times

CERTIFICATIONS

The UDS Model has been certified by ITS. This certification mark indicates that the product has

been tested to and has met the minimum requirements of a widely recognized (consensus) U.S.

and Canadian products safety standard, that the manufacturing site has been audited, and that

the applicant has agreed to a program of periodic factory follow-up inspections to verify continued

performance.

Model UDS is ETL Listed under file number 3054803-001 and complies with UL891 Standards

and CSA C22.2, No. 31-M89 Standards.

Loading...

Loading...