Page 1

Innovative Control Solutions For Your Needs

R850 SERIES

R850V STEP CONTROLLER

WITH INTEGRATED VERNIER STAGE

• Pulsed or analog 0 to 10 Vdc vernier stage

• 4 or 8 step models

• Up to 16 stage total with a slave unit

• Test button

DESCRIPTION

The Viconics R850V series step controller is designed for

cost effective, precise modulation of multi-stage control

application. A common application is a multi step electric

duct heater.

An integrated vernier control output will give a precise and

full modulation of the load from 0 to 100% of the total

capacity.

FEATURES AND BENEFITS

Microcomputer-based design Accuracy and reliability

Adjustable inter-stage delay Provides flexibility in

replacement applications

Adjustable Vernier ratio Simplifies design of

proportional stage

Choice of pulsed or analog

Vernier output

Permits use of SCR or lower

cost SSR

Up to 16 stages One product family can handle

all applications

Choice of LIFO or FIFO

sequencing

Increased flexibility of FIFO

permits even use of contactors

Test button Quick troubleshooting

MODELS AVAILABLE

The R850-V is available in 2 models

• R850V-4 4 stage unit

• R850V-8 8 stage unit

If more than 8 stage are required, the R850-V8 can be used

OVERRIDE TEST BUTTON

The override test button can be used to by-pass the

interstage delay and bring on all stage at one time. This

simplifies the verification of configured maximum number of

stage.

A status LED per step will come on for each of the configured

stage.

SPECIFICATIONS

Operating

Conditions:

0°C to 80°C ( 32°F to 176°F )

0 % to 95 % R.H. non-condensing

Relay outputs: Isolated relay 30 Vac @ 1.0 amps. max. per

output, up to a maximum of 4.0 amps. total

per R850 controller. See application note 02.

Vernier stage: Vdc pulsed: 6 Vdc, 30 mA max.

0 to 10 Vdc 5 mA max.

Input

0 to 10 Vdc into 10 KΩ minimum

impedance:

Power supply: 24 Vac -15%, +10% 50/60 Hz; 4 VA

Use a Class 1 ( properly fused ) or Class 2,

CSA or UL recognized transformer for power

supply & relay outputs.

Specifications and equipment are subject to change without prior notice.

as a master unit with another R850V as a slave unit. Adding

another unit ( R850-V4 or R850-V8 ) can bring the total step

number up to 12 or 16.

INPUT SIGNAL

The R850V has four INPUT dip switch (S1 to S4) to select the control signal input:

They are compatible with industry standard signals.

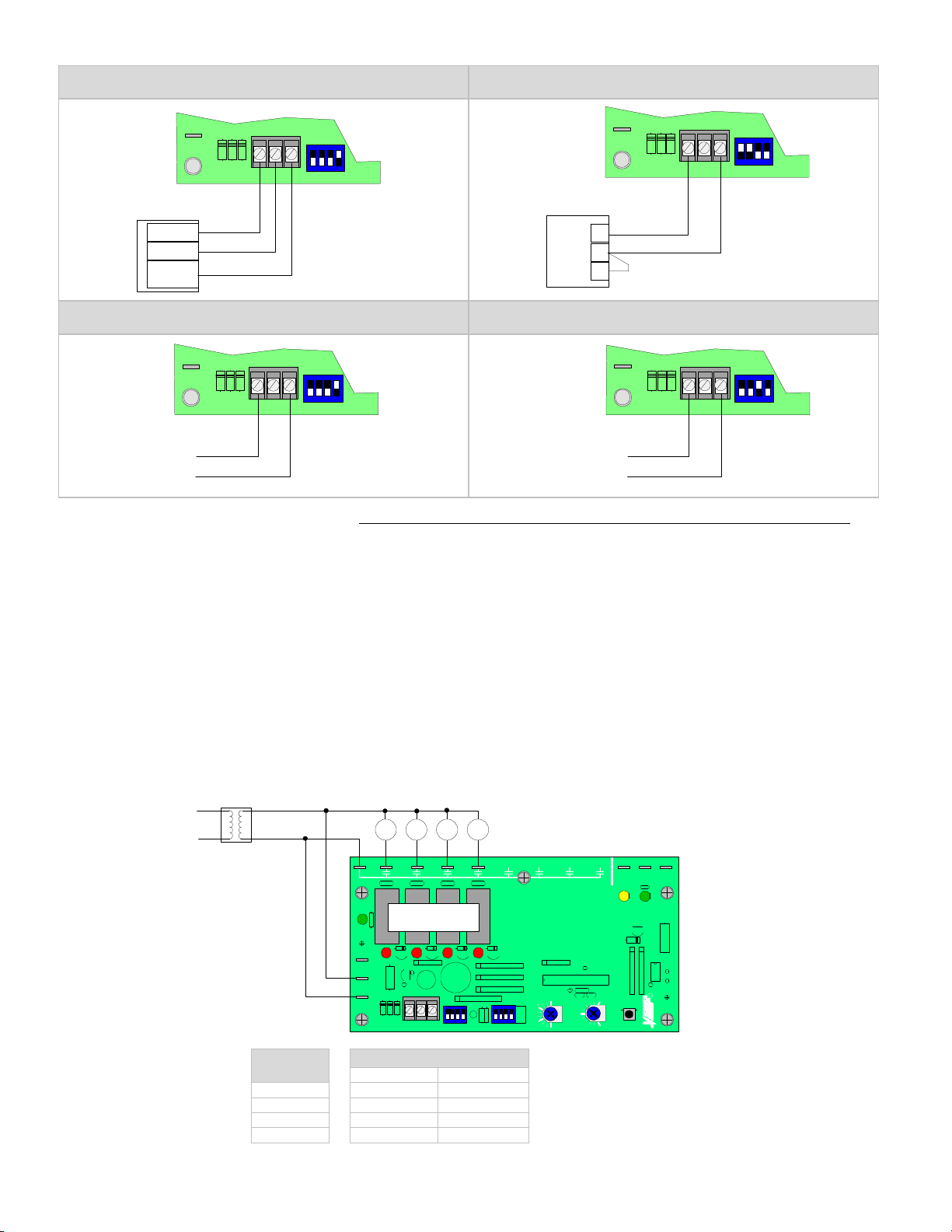

DIP SWITCH ADJUSTMENTS & WIRING CONTROL INPUT

ON

INPUT DIP SWITCH à ß CONTROL DIP SWITCH

(1-4) Input signal selection

0 to 10 Vac

4 to 20 mA

0 to 135 Ω

ON

21 3 4

21ON4

ON

21 3 4

1

2 3 4 5 6321 4

I

P

N

U

3

ON

SW1

T

C

SW2

L

T

R

N

O

O

(3-6) Number of steps selection

(see next pages for details)

(2) Vernier stage selection

OFF = 0 to 10 Vdc (SCR)

ON = Vdc pulsed signal (SSR)

(1) Sequence of operation (LIFO or FIFO)

OFF = LIFO (Last IN, First OUT)

ON = FIFO (First IN, First OUT)

Input Signal Switch Switch #1 Switch #2 Switch #3 Switch #4

0 to 10 Vdc control signal ( 2 to 10 Vdc control range ) Off Off Off On

4 to 20 mA control signal Off Off On Off

0 to 135 Ω control signal

On On Off Off

If a slave unit is used, wire the control signal input to the master unit only

Page 2

2 To 10 Vdc Or 0 To 10 Vdc Stand Alone Thermostat

10 Vdc = 100% capacity

135 Ohms = 100% capacity

10 Vdc = 100% capacity

20 mA = 100% capacity

( Power To The Thermostat Is Supplied By The R850V )

0 To 135ΩΩ Stand Alone Thermostat

1

1 2 3ON4

I

N

T

P

U

2 Vdc = 0% capacity

Common

24 Vac

0 to 10 Vdc

output

123

2 To 10 Vdc Or 0 To 10 Vdc From D.D.C.

Building Automation System

1

1 2 3ON4

123

I

PUT

N

2 Vdc = 0% capacity

-

+

0 Ohms = 0% capacity

Building Automation System

4 mA = 0% capacity

1

1 2 3ON4

123

W

R

B

I

4 To 20 mA From D.D.C.

1

1 2 3ON4

123

+

PUT

N

I

T

P

U

N

24 VAC POWER & RELAY OUTPUT WIRING

The wiring diagrams are for the R850V-8 models with 8 outputs. The wiring for the R850V-4 is the same except that the unit only

has 4 outputs.

Terminals

Screw terminal & connector #1 Common

Screw terminal & connector #2 24 Vac

Screw terminal & connector #3 Control Signal input

• It is not necessary to ground any leg of the transformer to earth with the controller card.

• The controller uses internally a half wave rectifier bridge. On 0 to 10 Vdc control signal, the reference of the control signal is the

Common of the power supply of the SCR controller card.

• Use a Class 1 ( properly fused ) or Class 2, CSA or UL recognized transformer.

• 4 STAGE APPLICATION R850V-4

24 Vac contactor coils

C1

C2 C3 C4

V

S

C8

C7

C6

C5

C4

C3

C2

C1

C

POWER

1 2 3

R850V-4

2 3ON4

1

I

123

P

N

150

DELAY(s)

VR2

200

RATIO(%)

100

TEST

120

90

1 2 3ON4

CONTROL

60

30

T

U

REV.1

COM

JUNE 99

001-0102

Number

of stage

1

2

3

4

R850V-4 Control Switch

Switch #3 Switch #4

Off Off

On Off

Off On

On On

2

Page 3

• 8 STAGE APPLICATION R850V-8

24 Vac contactor coils

C1

C2 C3 C4 C5 C6 C7 C8

C3

C2

C1

C

R850V-8

POWER

1 2 3

2 3ON4

1

I

123

PUTCO

N

C4

1 2 3ON4 5 6

NTR

C5

DELAY(s)

200

150

VR2

TEST

RATIO(%)

100

120

90

60

L

O

30

REV.1

COM

JUNE 99

001-0102

V

S

C8

C7

C6

Number

of stage

1

2

3

4

5

6

7

8

Switch #3 Switch #4 Switch #5 Switch #6

Off Off Off Off

On Off Off Off

Off On Off Off

On On Off Off

Off Off On Off

On Off On Off

Off On On Off

On On On Off

R850V-8 Control Switch

• 12 STAGE APPLICATION R850V-8 MASTER UNIT, R850V-4 SLAVE UNIT ( See also slave application section at the end )

24 Vac contactor coils 24 Vac contactor coils

Use vernier output of master

TEST

RATIO(%)

S

REV.1

JUNE 99

if vernier control is required

V

COM

001-0102

C1 C2 C3 C4 C5 C6 C7 C8 C9

C8

C7

C6

C5

C4

C3

C2

C1

C

R850V-8

POWER

1 2 3

1 2 3ON4 1 2 3ON4 5 6

123

I

UTCONTR

N

P

90

60

L

O

200

120

150

VR2

DELAY(s)

30

100

POWER

C1

C

R850V-4

1 2 3

C10 C11 C12

C3

C2

1 2 3ON4

123

I

T

NPU

C4

200

120

1 2 3ON4

CONTR

90

60

L

O

VR2

150

DELAY(s)

100

RATIO(%)

30

COM

JUNE 99

REV.1

001-0102

TEST

V

S

C8

C7

C6

C5

Number

of stage

9

10

11

12

Switch #3 Switch #4 Switch #5 Switch #6 Switch #3 Switch #4

R850V-8 Master Unit Control Switch R850V-4 Slave Unit

Off Off Off On Off Off

On Off Off On On Off

Off On Off On Off On

On On Off On On On

The intensity of the yellow status LED on the master unit is proportional to the slave output.

3

Page 4

• 16 STAGE APPLICATION R850V-8 MASTER UNIT, R850V-4 SLAVE UNIT ( See also slave application section at the end )

24 Vac contactor coils 24 Vac contactor coils

Use vernier output of master

C1 C2 C3 C4 C5 C6 C7 C8 C9

C8

C7

C6

C5

C4

C3

C2

C1

C

if vernier control is required

V

S

COM

C10 C11 C12 C13 C14 C15 C16

C4

C3

C2

C1

C

C5

COM

V

S

C8

C7

C6

POWER

2 3

1

R850V-8

1 2 3ON4 1 2 3ON4 5 6

123

I

NPU

JUNE 99

REV.1

200

120

90

60

CONTR

L

O

T

VR2

150

TEST

DELAY(s)

30

RATIO(%)

100

Number

of stage

9

10

11

12

13

14

15

16

R850V-8

POWER

REV.1

VR2

200

100

TEST

RATIO(%)

JUNE 99

001-0102

1 2 3

1 2 3ON4 1 2 3ON4 5 6

123

I

UTCONTR

N

P

120

90

150

60

DELAY(s)

L

O

30

R850V-8 Master Unit Control Switch R850V-8 Slave Unit Control Switch

Switch #3 Switch #4 Switch #5 Switch #6 Switch #3 Switch #4 Switch #5 Switch #6

Off Off Off On Off Off Off Off

On Off Off On On Off Off Off

Off On Off On Off On Off Off

On On Off On On On Off Off

Off Off On On Off Off On Off

On Off On On On Off On Off

Off On On On Off On On Off

On On On On On On On Off

The intensity of the yellow status LED on the master unit is proportional to the slave output.

R850V DIMENSIONS & INSTALLATION

7.075"

0.325" 3.450"

C3

C2

C1

C

V

S

C8

C7

C6

C5

C4

0.250"3.050"

COM

0.425"

0.325"

001-0102

Power indicating

green LED

POWER

2.700"

2 3

1

2 3ON4

123

1

I

N

1 2 3ON4 5 6

T

CONTR

U

P

120

90

60

L

O

30

150

DELAY(s)

200

VR2

100

TEST

RATIO(%)

REV.1

JUNE 99

001-0102

0.225"

Vernier output green LED

Slave output yellow LED

3.675"

Install on the mounting plate on the electrical cabinet using five #6 pan head metal screw. Do not over torque the screws to prevent

damage to the board. Specifications and equipment are subject to change without prior notice.

All R850V series controls are for use only as operating controls. Whenever a control failure could lead to personal

injury and/or loss of property, it becomes the responsibility of the user to add safety devices and/or alarm system

to protect against such catastrophic failures.

Page 5

LIFO / FIFO ADJUSTMENT

The R850V series features 2 different staging sequences:

• LIFO LAST IN FIRST OUT ( CONTROL SWITCH #1 OFF, FACTORY DEFAULT )

This is the regular mode, Stage #1 will always be the first to energize and the last stage to de-energize

• FIFO FIRST IN FIRST OUT ( CONTROL SWITCH #1 ON )

In this mode, the stages are rotated to ensure a more uniform wear of the contactors and elements. For example, on an increase in

demand, stage 1 will be energized following by stage 2, etc. On a decrease in demand, stage 1 will de-energized first followed by

stage 2, etc.

Please verify that if this mode is enabled, the manufactured product still complies with active codes and regulations.

VERNIER STAGE SELECTION AND WIRING

The Viconics R850V series step controller has an integrated vernier control output. This output will give a precise and full

modulation of the load from 0 to 100% of the total capacity of the unit. If a master slave application is used, always connect the

vernier output of the master unit.

ADJUSTMENTS

Functions of the units can be configured with six dip switch and 2 potentiometers.

75

60

90

45

105

120

30

150

125

175

200

100

Interstage delay potentiometer setting

A potentiometer is used to adjust the interstage delay from 30 seconds up 120 seconds.

This delay is active in 3 ways.

• Minimum time delay between each step activation when the control signal rises

• Minimum ON time when the step is activated

• Minimum time delay between each step de-activation when the control signal drops

60

30

DELAY(s)

90

120

Vernier stage ratio

A potentiometer is used to adjust the vernier stage ratio from 100% to 200% capacity of the other on/off

stage capacity.

RATIO SETTING ( See also slave application section at the end )

First adjust the vernier stage ratio potentiometer. This will insure a smooth capacity rise of the total load.

Example 1:

The total unit has 100 kW divided in 10 equal stage of 10 kW.

If only 10 kW is used as the modulating stage, then the heater would have 9 on/off mechanical stage plus

100

RATIO(%)

150

VR2

200

one modulating stage. This modulating stage has the same value as all the other stage. Adjust the vernier stage ratio

potentiometer to 100%.

Example 2:

The total unit still has 100 kW divided in 10 equal stage of 10 kW.

If 20 kW are used as the modulating stage, then the heater would have 8 on/off mechanical stage plus one modulating stage.

The modulating stage has twice the value as all the other stage. Adjust the vernier stage ratio potentiometer to 200%.

• TYPE OF VERNIER STAGE SETTING

The vernier stage output can be configured to operate either as a:

• Vdc pulsed output to activate an R810 power module

• 0 to 10 Vdc analog output to activate an R820 SCR power controller.

• VERNIER STAGE WIRING

Control Switch #2 On Vdc pulsed to activate R810 power modules

R810

Do not wire more than six R810 power module on the

vernier stage output

V

S

COM

Respect the polarity between the R850 step controller

board an the R810 power modules

Connect V to +

Connect COM to -

-

+

The green status LED on the master unit will cycle at

the same rate as the time proportioning vernier output

For more information, please refer to the R810 service

manual

Page 6

Control Switch #2 Off 0 to 10 Vdc analog output to activate R820 SCR power controller

Set the R820 SCR power controller to accept a 0 to 10 Vdc control signal input

Switch #1, #2 & #3 Off Switch #4 On

The intensity of the green status LED on the master unit is proportional to vernier output

For more information, please refer to the R820 service manual

C

COM

R820

V

S

C8

C7

C6

C5

C4

C3

C2

C1

SCR Power Controller

POWER

2 3

1

2 3ON4

1

123

1 2 3ON4 5 6

I

T

CONTR

P

U

N

120

90

DELAY(s)

60

L

O

30

JUNE 99

REV.1

200

150

001-0102

VR2

TEST

100

RATIO(%)

1 2 3

SLAVE APPLICATION SECTION

When using a unit for slave applications, it is important that the proper adjustments & setting be made to the unit for proper

operation of the system.

The yellow LED near the vernier output connector is proportional to the vernier output of the master unit ( 0 to 5 Vdc ).

On the slave unit:

• Set vernier ratio potentiometer to 100%

• Set interstage delay potentiometer to the same value as the master unit

• Set all control signal INPUT dip switch to OFF

123

TEST MODE BUTTON

The test mode button can be used to verify if the number of stage have been configured properly.

1. Press and hold the button for 3 to 4 seconds.

2. If a slave unit is used, press & hold the 2 units button simultaneously

3. All the selected stage will come on, one after the other until all selected number of stages are all on.

4. There is a delay of approximately 5 second between each step activation.

5. When all selected stage are on, they will stay on for approximately 30 seconds before shutting down.

1 2 3ON4

I

N

T

P

U

Powering up the R850V controller while holding down the test button will by-pass the interstage delay for 10 minutes. During that

period, the unit will respond to a changing signal input very rapidly. Also hold down slave test button on start-up if a slave unit is

used. After that 10 minute period, the unit will function normally with the interstage delays active

Viconics Electronics Inc. 9245, Langelier Blvd, St-Leonard, Quebec, Canada H1P 3K9

28-5007 M:\1_BINDER\6_R800 Series SCR SSR\Spec sheet english\R850\R850-Vse16.doc 4/30/01

www.viconics.com

Loading...

Loading...