Page 1

DROP-IN PERFORATED SUPPLY PLENUM

4. ATTACH SUPPLY DUCT TO PLENUM NECK

USING A STEEL CLAMP OR 16 SWG MINIMUM

STEEL WIRE. THE DUCT CONNECTION MUST

NOT INTERFERE WITH DAMPER OPERATION.

INSTALLATION

1. ATTACH SLIDING RADIAL DAMPER

TO TOP SIDE OF NECK.

2. PLACE THE PLENUM IN THE DESIRED LOCATION

OF THE 24” X 24” T-BAR CEILING GRID.

3. USE MINIMUM 12 SWG STEEL WIRE TO

SUPPORT THE CORNERS OF THE DI-PSP.

MINIMUM OF TWO DIAGONAL CORNERS

MUST BE SUPPORTED BY CEILING JOISTS.

MODEL: DI-PSP

Page 2

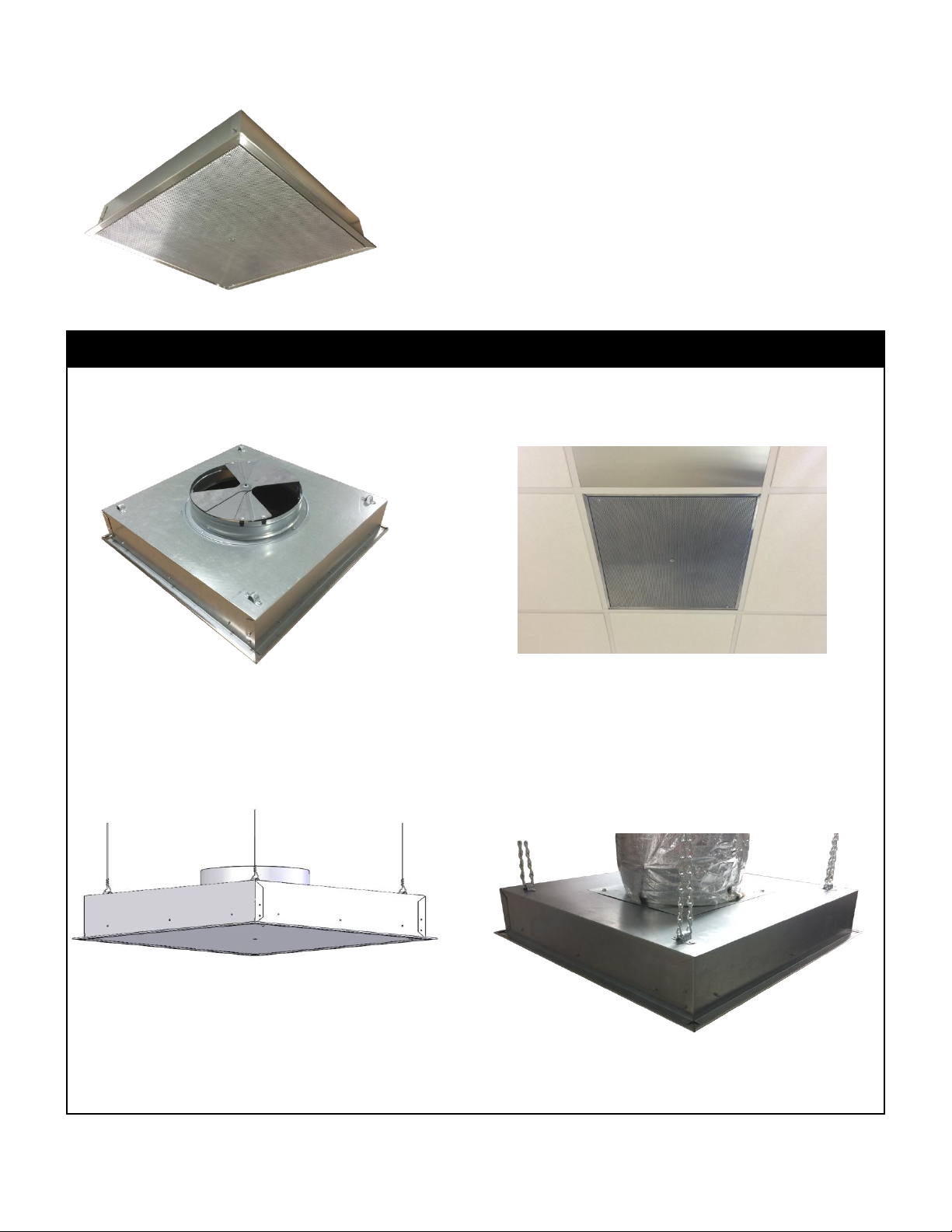

OPERATION

GENERAL MAINTENANCE

TO ACCESS THE SLIDING RADIAL DAMPER FOR

VOLUME ADJUSTMENT, REMOVE THE STEEL PLUG AT

THE CENTER OF THE BOTTOM PERFORATED PANEL.

THE DAMPER CAN BE ADJUSTED USING A FLAT-HEAD

SCREWDRIVER OR 3/8” SOCKET (MINIMUM 8” BLADE

LENGTH REQUIRED).

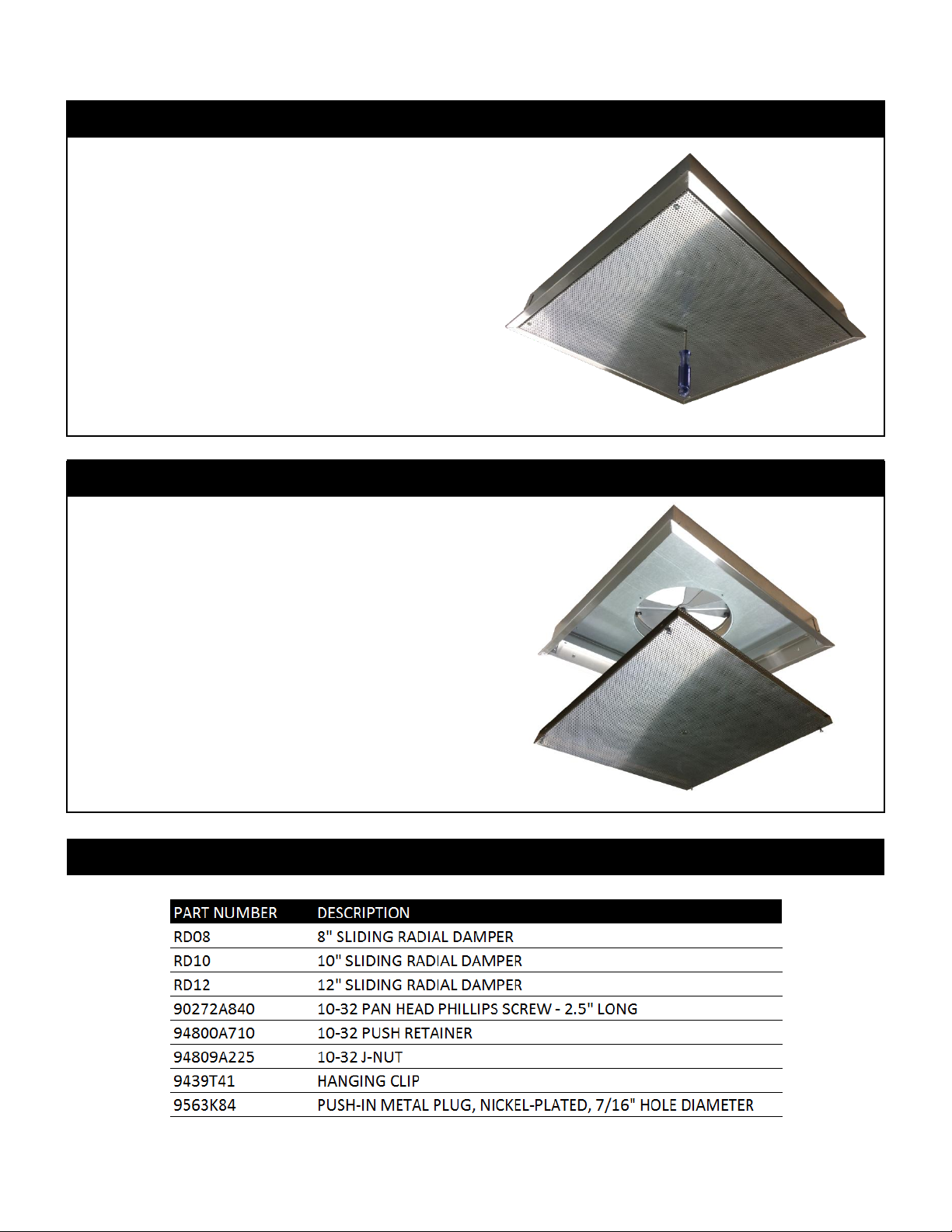

REGULARLY CLEAN THE PLENUM BY REMOVING

THE PERFORATED FACE AND WIPING ALL METAL

SURFACES WITH A DAMP CLOTH.

THE PERFORATED FACE OF THE PLENUM CAN BE

REMOVED FOR CLEANING OR MAINTENANCE BY

REMOVING THE SCREWS AT EACH CORNER.

REPLACEMENT PARTS

Loading...

Loading...