Page 1

Self Cleaning Hood System

Installation, Operation, and Maintenance Manual

Save these instructions. This document is the property of the owner of this equipment and is

required for future maintenance. Leave this document with the owner when installation or

service is complete.

RECEIVING AND INSPECTION

Upon receiving unit, check for any interior and exterior damage, and if found, report it

immediately to the carrier. Also check that all accessory items are accounted for and are

damage free.

WARNING!!

Installation of this module should only be performed by a qualified professional who has read

and understands these instructions and is familiar with proper safety precautions. Improper

installation poses serious risk of injury due to electric shock and other potential hazards. Read

this manual thoroughly before installing or servicing this equipment. ALWAYS disconnect

power prior to working on module.

March 2011 Rev. 10

A0019144

Page 2

2

Page 3

TABLE OF CONTENTS

WARRANTY .................................................................................................................................................. 4

INSTALLATION ............................................................................................................................................. 5

Mechanical ................................................................................................................................................ 5

Plumbing Connections for Self Cleaning .............................................................................................. 5

Piping Loss Calculation for Wall Mount Self Cleaning System ............................................................ 6

Minimum Pressure Requirements for Lengths of Hood ....................................................................... 8

Self Cleaning System Overview ........................................................................................................... 9

Drain Assembly .................................................................................................................................. 11

Electrical ................................................................................................................................................. 12

Copper Wire Ampacity ....................................................................................................................... 12

OPERATION ............................................................................................................................................... 13

Start Up ................................................................................................................................................... 13

Special Tools Required ...................................................................................................................... 13

Start Up Procedure ............................................................................................................................. 13

Start Up Checklists ................................................................................................................................. 15

Self Cleaning Hood Start Up Checklist .............................................................................................. 15

Component Description .......................................................................................................................... 16

Self Cleaning Spray Bar ..................................................................................................................... 16

Water Manifolds .................................................................................................................................. 17

Self Cleaning Manifold ....................................................................................................................... 17

Self Cleaning Manifold Details ........................................................................................................... 18

Self Cleaning Wash Timers ................................................................................................................ 19

Surfactant Tank .................................................................................................................................. 20

Troubleshooting ...................................................................................................................................... 21

Self Cleaning Hood Troubleshooting Chart ........................................................................................ 21

MAINTENANCE .......................................................................................................................................... 22

General Maintenance ............................................................................................................................. 22

Every 3 months ....................................................................................................................................... 22

Every 6 months ....................................................................................................................................... 22

Every 2 Years ......................................................................................................................................... 22

3

Page 4

WARRANTY

This equipment is warranted to be free from defects in materials and workmanship, under normal use and

service, for a period of 12 months from date of shipment. This warranty shall not apply if:

1. The equipment is not installed by a qualified installer per the MANUFACTURER’S installation

instructions shipped with the product,

2. The equipment is not installed in accordance with federal, state and local codes and regulations,

3. The equipment is misused or neglected,

4. The equipment is not operated within its published capacity,

5. The invoice is not paid within the terms of the sales agreement.

The MANUFACTURER shall not be liable for incidental and consequential losses and damages

potentially attributable to malfunctioning equipment. Should any part of the equipment prove to be

defective in material or workmanship within the 12-month warranty period, upon examination by the

MANUFACTURER, such part will be repaired or replaced by MANUFACTURER at no charge. The

BUYER shall pay all labor costs incurred in connection with such repair or replacement. Equipment shall

not be returned without MANUFACTURER’S prior authorization and all returned equipment shall be

shipped by the BUYER, freight prepaid to a destination determined by the MANUFACTURER.

4

Page 5

System Nomenclature

System

Water Connection

W1

1 Hot Water

W2

1 Cold Water

W3

1 Hot, 1 Cold Water

INSTALLATION

Warning

All field connections between hoods and drain lines must be run with Steel, Stainless Steel, or

Copper pipe. Plastic pipe cannot be used for drains or field connections between hoods, as it

could fail and become hazardous.

It is imperative that this unit is installed and operated with the designed airflow and electrical supply in

accordance with this manual. If there are any questions about any items, please call the service

department at 1-866-784-6900 for warranty and technical support issues.

Mechanical

WARNING: APPLY THE APPROPRIATE WATER PRESSURE

AND TEMPERATURE TO ALL FITTINGS TO PREVENT

LEAKAGE AND COMPONENT FAILURE

ATTENTION: SYSTEM MUST BE INSTALLED IN CONDITIONED SPACE BETWEEN 32°F AND 130°F

Ensure there is 36 Inches of service clearance to the front of the panel.

Plumbing Connections for Self Cleaning

Several field plumbing connections are required for proper Self Cleaning hood operation. It is

recommended that all plumbing connections be sealed with Teflon tape or pipe thread sealant. Use care

not to contaminate the interior surfaces of the water lines when plumbing the unit, as small particulate can

clog the orifices of the spray nozzles.

1. All incoming plumbing connections are connected via ¾” quickseals at the top of the utility

cabinet. See Figures 1 and 2 for details.

2. Self Cleaning hoods with the W1 option (Hot Water Wash) require a hot water connection at

140°F to 170°F and 30 to 50 psi operating pressure. If the operating pressure is greater than 50

psi, a water regulator must be connected. Max water static pressure is 125 psi. Typical water

flow rate is 0.7 GPM per foot of hood. The spray lasts for a factory setting of 3 minutes every

time the fans are switched off.

3. Self Cleaning hoods with the W2 option (Constant Cold Water) require an unheated water

connection at an operating pressure of 10 to 20 psi. If the pressure is greater than 40 psi, a water

regulator must be connected. Max water static pressure is 125 psi. Typical water flow rate is 0.4

GPM per foot of hood. The spray runs constantly while the fans are turned on.

4. Self Cleaning hoods with the W3 option (Hot Water Wash and Constant Cold Water) require a hot

water connection at 140°F to 170°F and 30 to 50 psi operating pressure and an unheated water

connection at 10 to 20 psi operating pressure. If the pressure is greater than the max rating, a

water regulator must be connected. Max water static pressure is 125 psi. Typical water flow rate

is 0.4 GPM per foot of hood for cold water and 0.7 GPM per foot of hood for hot water. The cold

spray runs constantly while the fans are turned on and the hot water lasts for a factory setting of 3

minutes every time the fans are switched off.

5. If multiple hoods are arranged in an end-to-end or back-to-back arrangement, plumbing

connecting the hoods must be piped in the field. The plugged end of the spray bar is used to do

this. Remove the plugs on the main hood and the adjacent hood and simply pipe the two

together. The highest part of the connecting pipe must not exceed the height of the vacuum

breaker in the main utility cabinet. See Figure 1A for illustration.

6. There is also a non-pressurized 1-1/2 inch drain connection that must be piped. This allows

water to drain from the hood grease trough. It must be connected to the building grease trap. 30

inch tall hoods will have 2 drains and hoods 10 feet and longer will also have 2 drains. See

Figure 3 for details.

7. Once all supply and drain lines are connected, remove one of the nozzles and flush the lines.

8. The Ansul fire system duct detection bracket and fusible link are shipped loose to be installed in

the exhaust ductwork. The detector must be installed no more than 20 feet from the hood, and

installed per the Ansul fire system guidelines.

5

Page 6

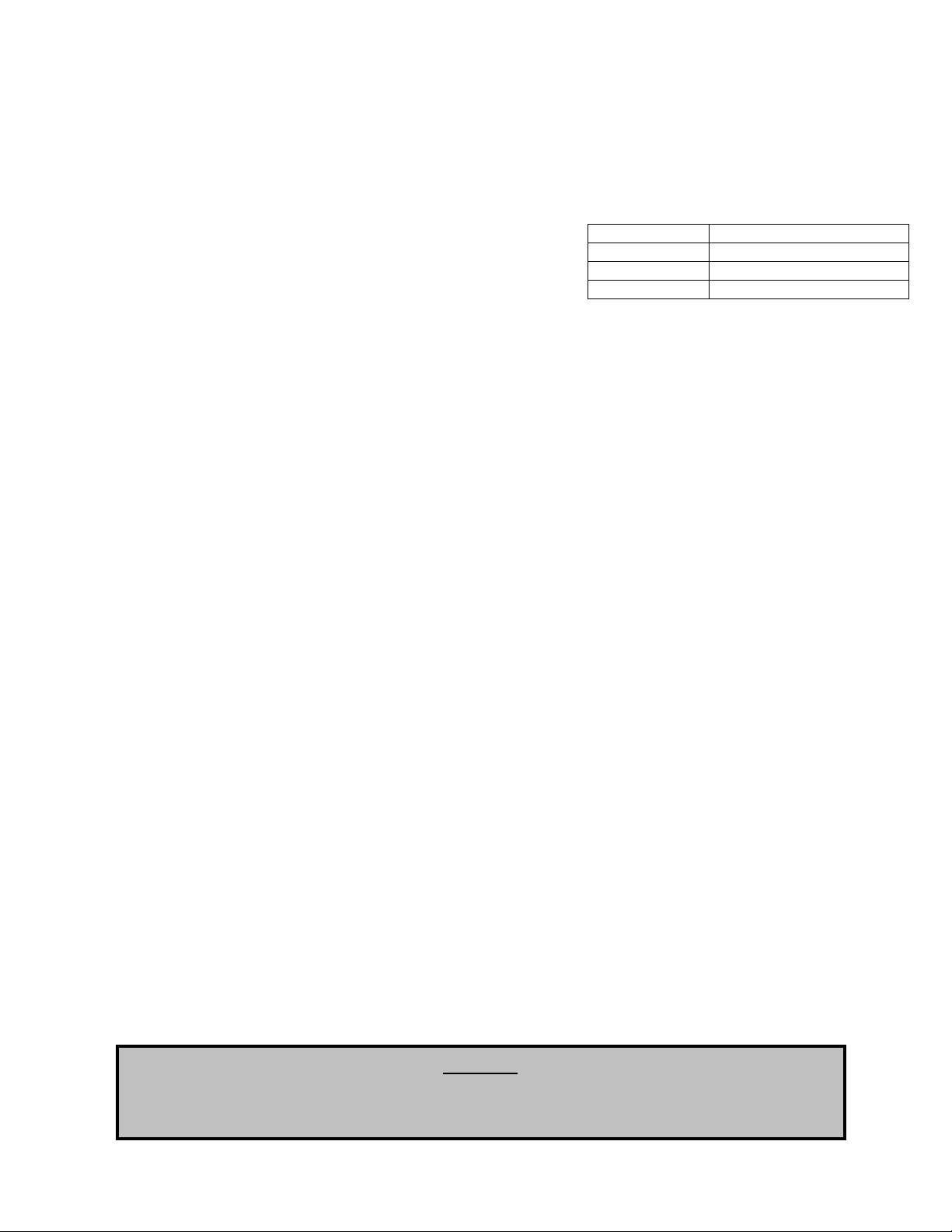

Piping Loss Calculation for Wall Mount Self Cleaning System

Equivalent Pipe Length For Various Pipe Fittings

Pipe Size Inches

45° Elbow

90° Elbow

Tee Thru Run

Tee Thru Branch

3/4"

1.03

2.21

1.23

4.41

1"

1.31

2.81

1.56

5.62

1 ½

2.15

4.31

2.4

8.63

Pressure Drop (PSI) per Equivalent Foot of Waterline - Pipe Size

Gallons per Minute

Waterline Pipe Size (psi per foot of pipe)

3/4”

1”

1 1/2”

10

0.102

0.029

0.004

20

0.368

0.105

0.014

30

0.779

0.222

0.030

40

1.327

0.379

0.052

50

2.005

0.573

0.078

60

2.809

0.803

0.109

70

3.735

1.068

0.146

80

4.782

1.367

0.186

90

5.947

1.700

0.232

100

7.223

2.066

0.282

To ensure proper operation of the Self Cleaning System, a minimum of 30 PSI water operating pressure

during spraying must be achieved at the hood nozzles. For this to occur, proper sizing of the water line is

required. Use the following steps to calculate the piping minimum size.

1. Use the Minimum Pressure Requirements for Lengths of Hood chart and find the Self

Cleaning minimum PSI required at the hood inlet. Subtract this value from the available PSI at

the panel pressure gauge. Maximum panel operating pressure is 50 psi. This will be your

maximum allowable pressure drop for field installed pipes between the panel and the hood.

2. Most fittings add an equivalent pipe length to the total run. Use the chart below to calculate the

equivalent pipe length for installed fittings. If you have multiple fittings of one type, simply multiply

the number below by the total number of the fitting and add to the total run length.

3. To calculate the total flowing pressure drop between the panel and the hood, take the total

equivalent length found in step 2 and add the total linear field installed pipe length. Multiply this

number by the value found in the table below, Pressure Drop (PSI) per Equivalent Foot of

Waterline. (Gallons per minute is calculated by multiplying the length of the hood by 0.7 gpm)

This will be the friction pressure drop between the hood and the panel.

4. Add in the pressure drop due to gravity. This must be evaluated to overcome any rise in pipe

elevation between the panel and the hood. There is .43 psi/ft of vertical rise of pressure drop.

5. Now, compare the maximum allowable pressure drop from step 1 to the calculated pressure drop

from step 3. If the calculated pressure drop exceeds the maximum allowable pressure drop,

increase the pipe size and recalculate steps 2 and 3. Continue this step until the calculated

pressure drop is below the maximum allowable.

6

Page 7

Field Pipe Pressure Drop Calculation Example:

0.01

0.1

1

10

1 10 100 1000

Pressure Loss (PSI/Ft)

FLOW (GPM)

Pressure Loss Water Flow

3/4" pipe

1" Pipe

1 1/2" Pipe

Wall mount panel installed with 30 feet of ¾” linear pipe between panel and hood. (2) 90 degree elbows

are installed in the pipe run and the pipe run has a vertical rise of 5 feet. Length of end-to-en hood

system is 32 feet.

Hood System = 32 feet. Flow rate = 32 feet * 0.7 gpm = 23 gpm

Pressure required at hood = 45 psi.

Pressure at panel gauge = 50 psi.

Allowable pressure drop between panel and hoods: 50 psi – 45 psi = 5 psi

Equivalennt length of pipe = 30 + 2 * 2.21 = 34.42 feet

Friction Pressure Drop through pipe = 34.42 * 0.779 = 26.81 psi

Gravitational Pressure = 0.43 psi/ft * 5 feet = 2.15 psi

Total Pressure Drop in Field Pipe between panel and hood = 26.81 psi + 2.15 psi = 28.96 psi

Allowable pressure drop = 5 psi

This system will not work correctly because calculated pressure drop is greater then allowable

pressure drop. Pipe size will need to be change to 1-1/2 inch diameter.

Re-calculate with 1-1/2 inch pipe instead of ¾” pipe:

Equivalennt length of pipe = 30 + 2 * 4.31 = 38.62 feet

Friction Pressure Drop through pipe = 38.62 * 0.030 = 1.15 psi

Gravitational Pressure = 0.43 psi/ft * 5 feet = 2.15 psi

Total Pressure Drop in Field Pipe between panel and hood = 1.15 psi + 2.15 psi = 3.30 psi

Allowable pressure drop = 5 psi

This system will work correctly because calculated pressure drop is less then allowable pressure

drop.

Pressure Loss Through Typical Water Pipe Chart

7

Page 8

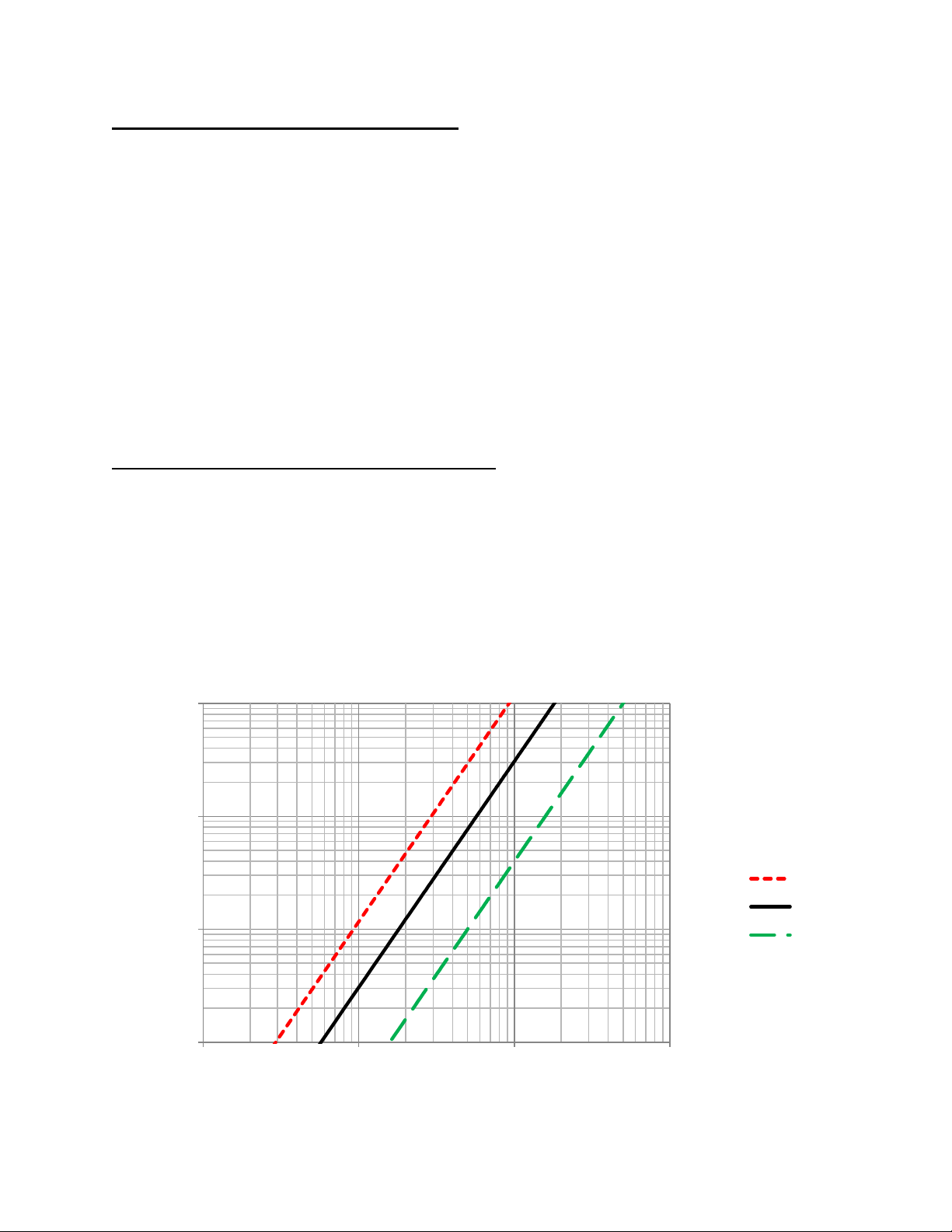

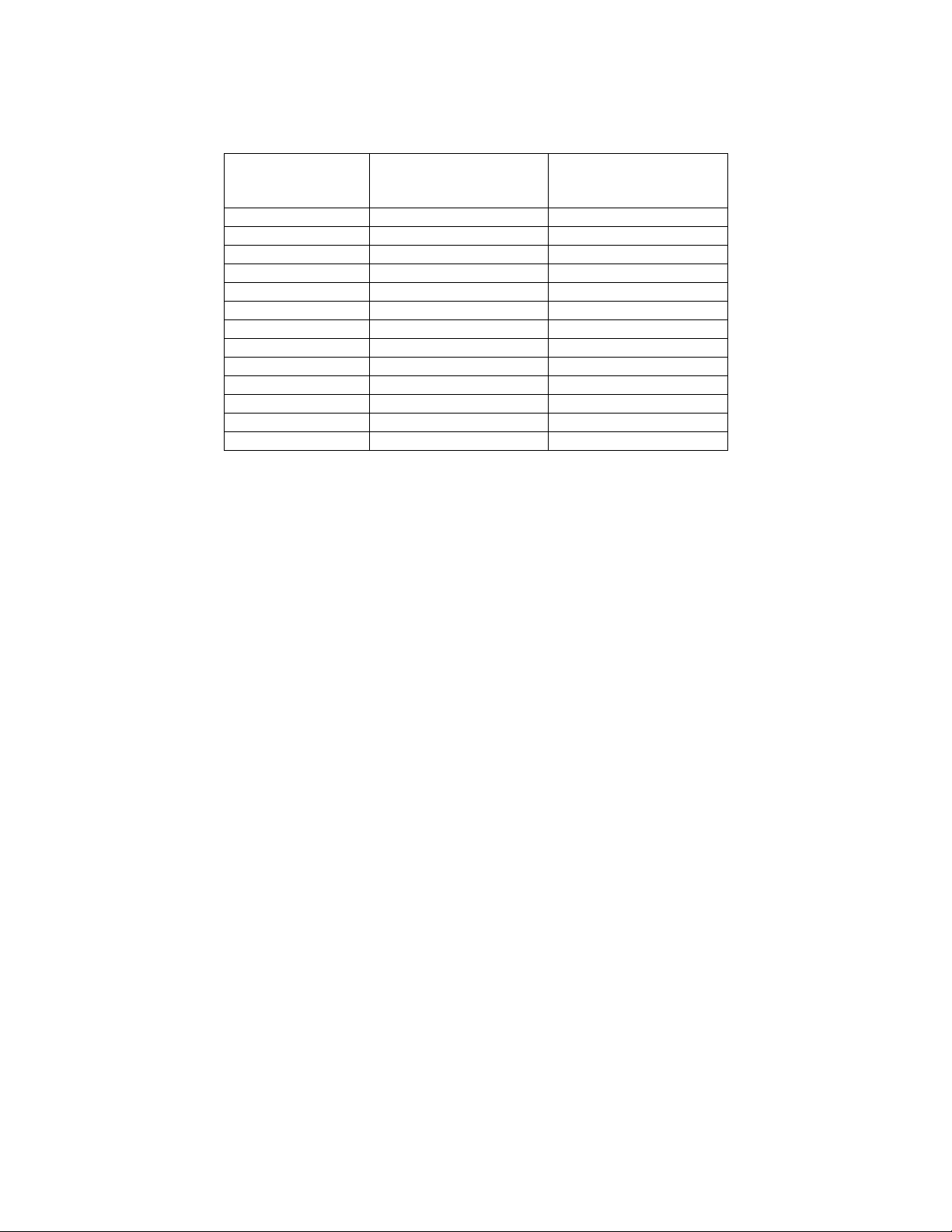

Minimum Pressure Requirements for Lengths of Hood

Length of Hood

(Ft)

Minimum Inlet Water

Pressure for Cold

Mist (PSI)

Minimum Inlet Water

Pressure for Self

Cleaning (PSI)

0

10

30 4 10

30 8 10

30

12

10

30

16

15

30

20

15

31

24

15

32

28

15

34

32

20

37

36

20

39

40

20

42

44

20

46

48

20

50

Table 1

Note: Water pressure may not drop below 30 PSI while the hood hot water is operating. Pressure

may not rise above 50 PSI when the hood is spraying. If the pressure is greater than 50 PSI, a

water regulator must be connected. The chart above is for continuous hood installations. If the

above length is exceeded, water line must be branched for adequate water supply.

8

Page 9

Self Cleaning System Overview

Figure 1A

9

Page 10

Figure 2

Self Cleaning Hood Top and Bottom View

10

Page 11

Drain Assembly

Figure 3

11

Page 12

Copper Wire Ampacity

Wire Size AWG

Maximum Amps

14

15

12

20

10

30 8 50 6 65 4 85

Electrical

WARNING!!

Disconnect power before

installing or servicing control.

High voltage electrical input is

needed for this equipment. A

qualified electrician should

perform this work.

Before connecting power to the control, read and

understand the entire section of this document. As-built

wiring diagrams are furnished with each control by the

factory, and are attached either to the door of the unit or

provided with the paperwork packet.

Electrical wiring and connections should be done in

accordance with local ordinances and the National

Electric Code, ANSI/NFPA70. Be sure the voltage and

phase of the power supply and the wire amperage

capacity is in accordance with the unit nameplate.

1. Always disconnect power before working on or near

this equipment. Lock and tag the disconnect switch or

breaker to prevent accidental power up.

2. There are multiple electrical connections required

for this control. 120VAC should be wired to terminals

H1 and N1. If the hood is equipped with a separate

light circuit, 120VAC should power it per the as-built

schematic. Fan wiring connections should be made

per the schematic. H1 and N1 should not be

connected to a shunt trip breaker.

3. Make certain that the power source is compatible with the requirements of your equipment. The

system wiring schematic identifies the proper phase and voltage of the equipment.

4. Before connecting control to power source, verify power line wiring is de-energized.

5. Secure the power cable to prevent contact with sharp objects.

6. Do not kink power cable and never allow the cable to come in contact with oil, grease, hot

surfaces or chemicals.

7. The hood lights wiring will also need to be wired to terminals “B” and “W”. Verify connections on

wiring schematic.

8. Before powering up the system, make sure that the interior of the control is free of loose debris or

shipping materials.

9. If 3 phase motors are spinning in the incorrect direction, switch any two wires on the

output of the motor starter. Rewire single phase motors per the motor schematic to

change direction.

10. If any of the original internal wire supplied with the system must be replaced, it must be replaced

with type THHN wire or equivalent.

12

Page 13

OPERATION

Figure 4

Prior to starting up or operating the system, check all fasteners for tightness. Ensure that the wiring is

installed properly and that all nozzles and panels are installed.

The Self Cleaning hood is designed to use hot water to wash the hood plenum and immediate duct

section every time the fan switch is switched from the “ON” position on the main control panel. When the

switching action occurs, hot water sprays along the entire length of the hood and towards the back of the

hood for a factory setting of 3 minutes. During this time, surfactant is injected into the water stream for a

duration of 1 second for each minute of wash time. Once the wash cycle is complete, water stops

spraying and the hood filters are to be removed and cleaned.

If the hood is ordered with a cold water mist option, cold water sprays continuously during the cooking

process. Cold water stops spraying when the fan switch is switched from the “ON” position.

Start Up

Special Tools Required

AC Voltage Meter

Standard Hand Tools

Hand-held Propane Torch

Start Up Procedure

1. Check all nozzles to make sure they are installed and tight.

2. Install all hood filters per the filter installation configuration chart below. There are drip blanks

secured to the filters to prevent water from exiting the hood between the filters.

3. Open all water valves to the hood.

4. Fill surfactant tank with surfactant. The “Add Surfactant” light should not be on. Prime the

surfactant pump with the push-button on the face of the electrical control package.

5. There are 2 timers that control the spray and the surfactant injection. The wash timer is set to 3

minutes from the factory. The surfactant timer is factory set for 1 second of injection during each

minute of wash time. The injection occurs at the start of each minute. The timer settings should

be verified. (See section “Self Cleaning Timers for information)

6. Turn the hood fan switch to the “ON” position. Fans should operate. If

they do not, check wiring. If the hood has the cold water mist option,

cold water should begin to spray.

7. To operate the wash cycle, simply turn the fan switch off. The wash

cycle energizes automatically and will remain on for the duration of the

wash timer setting.

8. Verify that surfactant is being injected properly into the water stream.

9. Verify the pressure and temperature of the water via the

pressure/temperature gauge. See Figure 4 for a picture of the gauge.

Self Cleaning pressure should be between 30 and 50 PSI operating

pressure, and Cold Mist operating pressure should be between 10 and

20 PSI.

10. Check all manifold pipe connections to ensure there are no water leaks.

11. Check all filters to make sure that no water is leaking back through the filters.

12. Verify that the hood grease trough is draining properly and there are no clogs in the drain.

Surfactant (Part Number WWDETER for

4 Gallons, WWDETER-1G for 1 Gallon)

Filter Installation Configuration

The hood filters have drip blanks attached to them to prevent water leakage through the filters. The chart

below shows the location of the drip blanks and the last filter to be installed into the hood. See Figure 5

below for details.

13

Page 14

Figure 5

14

Page 15

Start Up Checklists

Action

Completed (Yes/No)

Result

Check All Nozzles for Tightness

Open all Valves to Hood

Fill Surfactant Tank

Prime Surfactant Pump

Set All Timers

Check Fan Operation

Operate Wash Cycle

Verify Surfactant Pump Operation

Verify Operating Hot Water Pressure (30-50 PSI)

Verify Operating Cold Water Pressure (10-20 PSI)

Verify Max Water Static Pressure (125 PSI)

Verify Hot Water Temperature

Check For Leaks in Manifold

Check For Leaks through Filters

Verify that Water is Draining Properly

Self Cleaning Hood Start Up Checklist

15

Page 16

Component Description

Figure 6

The following section lists the major controls and components used in the Self Cleaning hood.

Self Cleaning Spray Bar

The Self Cleaning hood contains a spray bar that extends the entire length of the hood immediately

behind the filters in the hood. The bar is ¾” brass fittings with nozzles that spray directly toward the back

of the hood. The same spray bar is used in hot water wash and cold water mist. Water enters the spray

bar via a ¾” quickseal. The other end of the spray bar is plugged. If hoods are installed back-to-back or

end-to-end, the plugged end of the spray bar can be un-plugged and connected to the next spray bar.

See Figure 6 below for details.

16

Page 17

Water Manifolds

Figure 7

There are several versions of manifold configurations. The Self Cleaning with hot water wash (W1) has

one hot water connection. The cold water mist (W2) has one cold water connection. The hot water wash

with cold water mist (W3) has one hot water and one cold water connection.

Self Cleaning Manifold

17

Page 18

Self Cleaning Manifold Details

Figure 8

18

Page 19

Self Cleaning Wash Timers

The Self Cleaning option includes two timers that ship in the main control panel. These

timers control the wash cycle length and the surfactant injection.

The timer shown to the right is the wash cycle timer. The wash cycle timer is a fleeting off

timer and is triggered by turning the fan switch to the “OFF” position. The time is factory set

to 3 minutes but is adjustable on an application specific basis. It has a range of .5 to 10

minutes and is adjusted by simply rotating the large red dial.

The time shown on the right is the surfactant injection timer. The surfactant timer is an

asynchronous on-off timer. This means that it cycles contacts on and off for adjustable time

ranges. The timer is factory set to inject surfactant for 1 second and every minute. The

interval time (time when not injecting) is set by the top two dials. The small top dial on the

timer allows main unit adjustments. This dial can be set to 1, 3, 10, or 60 seconds (s),

minutes (m), or hours (h). Once the small top dial is set, the top, large red dial adjusts the

percentage of the middle dial. For example, if the small top dial is set to 1 minute, and the

large red dial is set to 1.0, the selected time period would result in 1 (1 minute * 1.0 = 1

minute) minute. The large dial is a percentage of the small dial.

The surfactant injection time is set by the bottom two dials. The small bottom dial on the

timer allows main unit adjustments. This dial can be set to 1, 3, 10, or 60 seconds (s),

minutes (m), or hours (h). Once the small bottom dial is set, the bottom, large red dial

adjusts the percentage of the middle dial. For example, if the small bottom dial is set to 1

second and the large red dial is set to 1.0, the selected time period would result in 1 (1

second * 1.0 = 1 second) second. The large dial is a percentage of the small dial.

The red switch on the right side of the face of the timer should not be adjusted and is factory

set to the bottom position (beginning of time period). The pictures shown illustrate the

factory settings of the timers.

19

Page 20

Surfactant Tank

The surfactant tank contains a liquid level control which energizes when the tank is completely empty. In

the event that the low level sensor is activated, an “Add Surfactant” light will illuminate on the control

panel. To reset light, simply fill the surfactant tank with surfactant. Figure 9 below shows tank details.

NOTE: SC-5 surfactant from 20/10 Products Incorporated must be used.

Figure 9

20

Page 21

Troubleshooting

Problem

Potential Cause

Corrective Action

Plenum not being cleaned

No Water Pressure

Verify Hot Water Pressure >30 PSI

Open Manual Valve if closed

Clogged nozzles

Clean or replace nozzles or strainer

Timer Settings improperly set

Wash timer should be set for

approximately 3 minutes

No water pressure

Turn main building water valve on

Nozzle spray pattern incorrect

Nozzles must be pointed toward

back of plenum

No Surfactant

Add Surfactant

Leaking Manifold Pipes

Pipes not tight or sealed

Reseal and tighten pipes

Water Leaking from Vacuum

Breaker

Riser nozzle installed too high

Verify that vacuum breaker is

installed higher than all downstream

piping components

Add Surfactant Light On

Low Surfactant Level

Add Surfactant

Water leaks out of Filters

Filters have gaps between them

Add Filter Drip Blanks or reorient

filters

Water Overflows Grease

Trough

Clogged Drain

Clean Drain or grease trap

Wrong Filters Installed

Install Proper Filters per

Manufacturer

Water Pressure Too High

Water Pressure should be 70 PSI

max

Wash Timer Set Too Long

Reduce Wash Time

Nozzles are Loose

Tighten Nozzles

Filters are Clogged with Grease

Clean Filters

The following table lists causes and corrective actions for possible problems with Self Cleaning hoods.

Review this list prior to consulting manufacturer.

Self Cleaning Hood Troubleshooting Chart

21

Page 22

MAINTENANCE

To guarantee trouble free operation of this system, the manufacturer suggests following these guidelines.

Most problems associated with unit failures are directly related to poor service and maintenance. Record

any maintenance or service performed on this equipment in the documentation section located at the end

of this manual.

General Maintenance

1. Hood filters must be maintained on a daily basis to ensure proper airflow and grease extraction.

2. All water connections must be verified for tightness and leak-free operation.

3. The “Add Surfactant” indicating light will illuminate when the surfactant tank is empty. Surfactant

must be added immediately to guarantee proper cleaning of the hood plenum and duct

connection. .

Every 3 months

1. Clean all duct sensors in hood duct connections (if equipped).

2. Check all nozzles for proper and evenly distributed water flow. If nozzles are clogged, clean or

replace.

3. Check drain(s) on hood to verify there is no blockage. Improper drainage could cause hood leaks

or water to back up into trough and overflow onto appliances.

Every 6 months

1. Inspect hood plenum and wipe down any areas not being cleaned by the self-cleaning system.

There may be an area where the water spray does not directly contact the metal.

2. Inspect the surfactant pump for proper operation and ensure liquid level sensor in surfactant tank

is operational. Test by manually lowering the sensor to see if the “Add Surfactant” light

illuminates.

3. All nozzle strainers should be removed and cleaned. Nozzles must be re-installed tightly.

4. Fill surfactant tank with surfactant. Verify that liquid level sensor operates correctly.

5. The main line strainer in the manifold must be cleaned.

6. Verify that system has proper water pressure and temperature per the labels on the unit.

Every 2 Years

1. Inspect condition of all wires and plumbing. Plumbing should be free of corrosion and wire

insulation must be in good condition.

22

Page 23

START-UP AND MEASUREMENTS SHOULD BE PERFORMED AFTER THE SYSTEM HAS BEEN

Job Name

Service Company

Address

Address

City

City

State

State

Zip

Zip Phone Number

Phone Number

Fax Number

Fax Number

Contact

Contact

Purchase Date

Start-Up Date

Name Plate and Unit Information

Field Measured Information

Hood Model Number

Input Voltage

Serial Number

Check All Nozzles for Tightness

Volts

Open all Valves to Hood

Hertz

Fill Surfactant Tank

Phase

Set All Timers

Check Fan Operation

Operate Wash Cycle

Verify Surfactant Pump Operation

Verify Operating Hot Water Pressure (30-50 PSI)

Verify Operating Cold Water Pressure (10-20 PSI)

Verify Max Water Static Pressure (125 PSI)

Verify Water Temperature

Check For Leaks in Manifold

Check For Leaks through Filters

Verify that Water is Draining Properly

INSTALLED (Warranty will be void without completion of this form)

Job Information

Self Cleaning Hood Information

Refer to the start-up procedure in this manual to complete this section.

23

Page 24

Maintenance Record

Date

Service Performed

Factory Service Department

Phone: 1-866-784-6900

Fax: 1-919-554-9374

24

Loading...

Loading...