Page 1

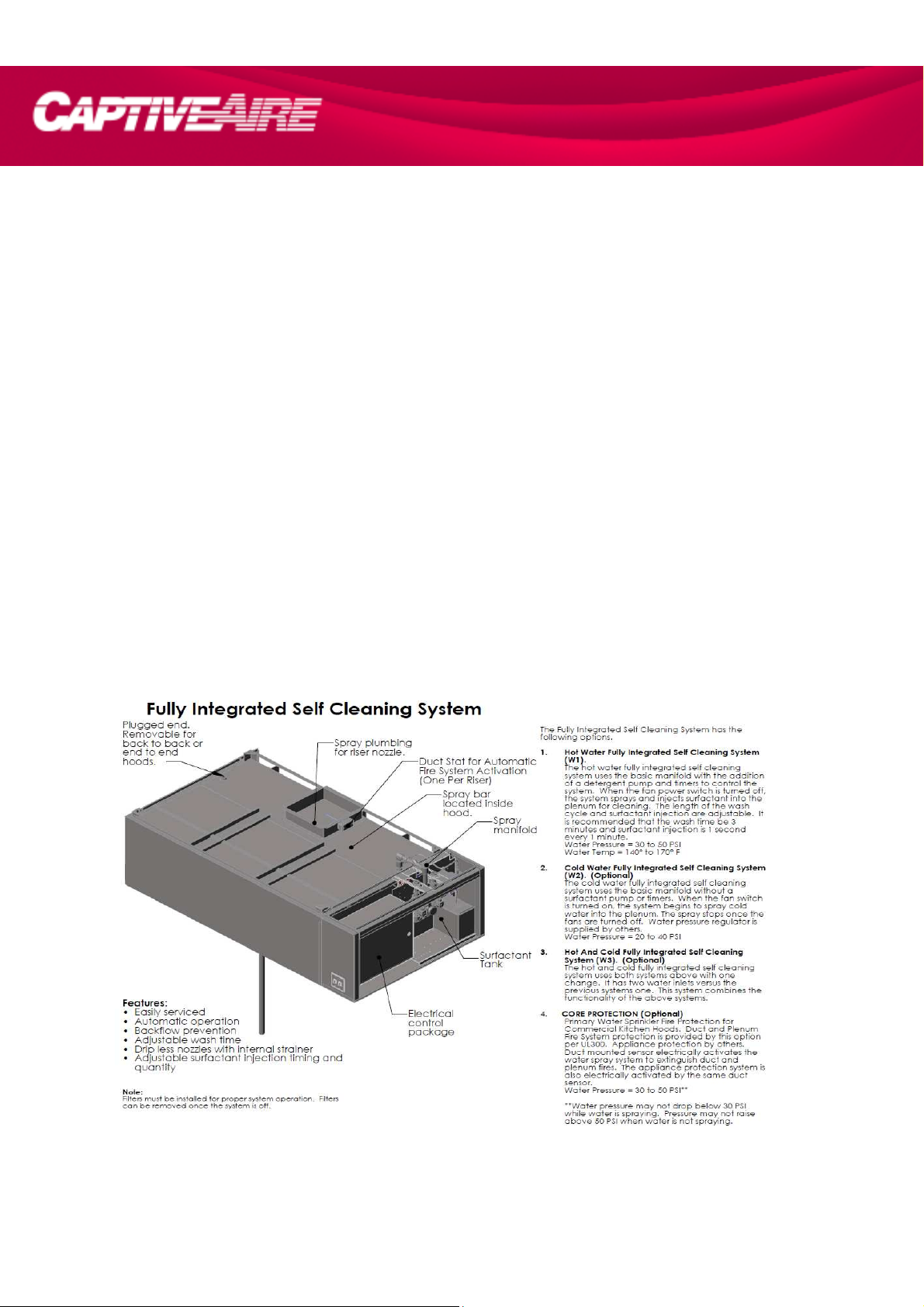

Fully Integrated Self Cleaning System Specification

The hood shall be a Type I exhaust hood with factory installed spray and manifold assembly. Assemblies shall be NSF

listed and ETL listed to conform to UL710, ULC710, and UL508A.

The hood shall be constructed of 100% Stainless steel, either 304 or 430. All welds in the plenum shall be dye-penetrate

tested for leaks. High efficiency baffle filters shall be installed in hood, and the sprayers located inside the plenum will

clean the back of the filters. All plumbing shall be standard brass pipefitting except for penetrations, which shall be

stainless steel. All nozzles shall be wide-angle, full-cone with internal strainer and pressure sensitive check valve.

The water inlet shall be a 3/4" NPT pipefitting. Drains shall consist of one 1 1/2" NPT pipe, unless exhaust hood is over

10' long or 30" tall, in which case two drains shall be installed. A ball valve shall be installed with the manifold for servicing

the self cleaning system. All surfactant injection shall be done after a vacuum breaker backflow prevention valve. Timers

shall be factory set for a three minute wash cycle with a one second surfactant injection before a delay of one minute.

Certifications

The ND-2, SND-2 and CND-2 Models have been certified by ITS. This certification mark indicates that the product has

been tested to and has met the minimum requirements of a widely recognized (consensus) U.S. and Canadian products

safety standard, that the manufacturing site has been audited, and that the applicant has agreed to a program of periodic

factory follow-up inspections to verify continued performance. Models are ETL listed under file number 3054804-001.

Suggested Specifications

Aerodynamic Grease Trough

Fully welded grease sub-assembly and a deep grease trough allows for easy cleaning. Grease trough shall be

integrated into the hood to ensure smooth effluent transition from appliance to filter.

Filter Options

The filters shall be constructed of stainless steel and shall be NSF and UL or ETL classified. Various types of filters

are available based on cooking application. The filters used in the system will come standard with filter drip blanks

and be configured according to filter sizes selected.

Integrated Spray Bar and Nozzles

The spray bar extends the full length of the hood immediately behind the filters in the hood. The bar is ¾” brass

fittings with nozzles that spray directly toward the back of the hood. Water enters the spray bar via a ¾” quick-seal.

All fittings and pipe will be brass. Nozzle(s) covering the riser(s) will be ¼” NPT and is a wide angle, high flow nozzle.

The first six feet of ductwork will be sprayed with the nozzle.

Self Cleaning Wash Timers

Timers shall be factory set for a three minute wash cycle with a one second surfactant injection before a delay of one

minute. The wash cycle timer is a fleeting off timer and is triggered by turning the fan switch to the “OFF” position.

The surfactant timer is an asynchronous on-off timer, which cycles contacts on and off for adjustable time ranges.

Page 2

Manifold

Manifold is configured based on options selected. A ball valve shall be installed with the manifold for servicing the self

cleaning system. All surfactant injection shall be done after a vacuum breaker backflow prevention valve. Parts included

are main shutoff valve, temperature and pressure gauge and surfactant pump.

Optional Suggested Specifications:

CORE Protection

Hood to ship with UL-300 integral plenum and duct fire system

Factory Installed Energy Management System

Factory will install the energy management system (EMS) in the hood’s integral end utility cabinet. Includes factory

wiring of duct temperature sensor, and pre-set timers. EMS shall be capable of reducing exhaust and supply airflow

quantities by 20% using variable frequency drives.

End Panels

Factory supplied end panels will reduce dynamic effects from cross drafts and enhance the capture and containment

of the hood. Exhaust CFM can be reduced by up to 30 percent of the normal exhaust rate.

Drain Kit

Drain(s) shall consist of one 1 1/2" NPT pipe, which comes standard with the hood. Optional drain kit includes slip nut,

90 degree fitting, 45 degree fitting, 6” pipe nipple and 72” of pipe length to make connection to the grease trap or other

approved reservoir. All parts are stainless steel.

Fully Integrated Self Cleaning System Overview

Page 3

Fully Integrated Self Cleaning System Manifold Details

Loading...

Loading...