Page 1

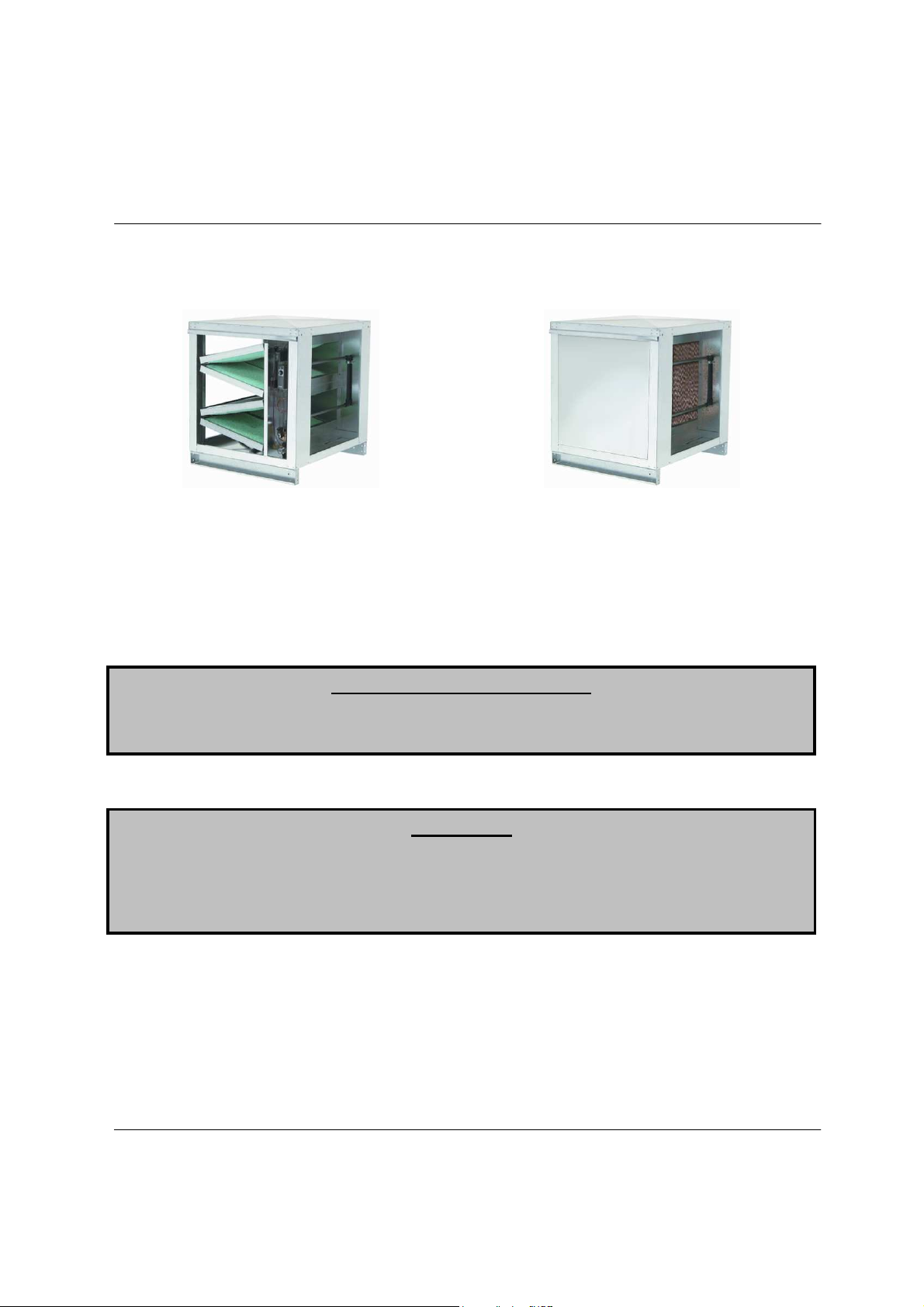

Standard and

CELDEK

Evaporative Cooler

Modules

Installation, Operation, and Maintenance Manual

Save these instructions

RECEIVING AND INSPECTION

WARNING!!

Standard Evaporative Cooler

Upon receiving unit, check for any interior and exterior damage, and if found, report it

immediately to the carrier. Also check that all accessory items are accounted for and are

damage free.

CELDEK Evaporative Cooler

Installation of this module should only be performed by a qualified professional who has read

and understands these instructions and is familiar with proper safety precautions. Improper

installation poses serious risk of injury due to electric shock, and other potential hazards.

Read this manual thoroughly before installing or servicing this equipment. ALWAYS

disconnect power prior to working on module.

. This document is the property of the owner of this equipment and is

required for future maintenance. Leave this document with the owner when installation or

service is complete.

November 2010 Rev. 12

A0011028

Page 2

TABLE OF CONTENTS

WARRANTY ............................................................................................................................................ 3

INSTALLATION ....................................................................................................................................... 4

Mechanical .......................................................................................................................................... 4

Site Preparation .............................................................................................................................. 4

Assembly ........................................................................................................................................ 4

Roof Mount Installation .................................................................................................................... 5

Indoor (Inline) Installation ................................................................................................................ 6

Electrical ............................................................................................................................................. 6

Copper Wire Ampacity .................................................................................................................... 6

Freeze Protection ............................................................................................................................ 7

OPERATION ........................................................................................................................................... 8

Timer Settings: .................................................................................................................................... 8

Nozzle Replacement: ........................................................................................................................ 10

Start Up ............................................................................................................................................. 12

Special Tools Required ................................................................................................................. 12

Start Up Procedure ....................................................................................................................... 12

Component Description/Detail ....................................................................................................... 13

Electrical Cabinet Detail:.................................................................................................................... 13

Units with Freeze Protection Option: .................................................................................................. 13

3-way Solenoid Valve Detail (Field Installed under Roofline): ............................................................. 13

Troubleshooting ................................................................................................................................ 14

Troubleshooting Chart ................................................................................................................... 14

MAINTENANCE .................................................................................................................................... 15

General Maintenance ........................................................................................................................ 15

Every 3 months ................................................................................................................................. 15

Yearly................................................................................................................................................ 15

Cooling Media Size and Quantity ................................................................................................... 15

Start-Up and Maintenance Documentation ........................................................................................ 16

Evaporative Cooler Information ..................................................................................................... 16

Maintenance Record ..................................................................................................................... 16

Factory Service Department .......................................................................................................... 16

November 2010 Rev. 12

A0011028

Page 3

WARRANTY

This equipment is warranted to be free from defects in materials and workmanship, under normal use and

service, for a period of 12 months from date of shipment. This warranty shall not apply if:

1. The equipment is not installed by a qualified installer per the MANUFACTURER’S installation

instructions shipped with the product,

2. The equipment is not installed in accordance with federal, state and local codes and regulations,

3. The equipment is misused or neglected,

4. The equipment is not operated within its published capacity,

5. The invoice is not paid within the terms of the sales agreement.

The MANUFACTURER shall not be liable for incidental and consequential losses and damages

potentially attributable to malfunctioning equipment. Should any part of the equipment prove to be

defective in material or workmanship within the 12-month warranty period, upon examination by the

MANUFACTURER, such part will be repaired or replaced by MANUFACTURER at no charge. The

BUYER shall pay all labor costs incurred in connection with such repair or replacement. Equipment shall

not be returned without MANUFACTURER’S prior authorization and all returned equipment shall be

shipped by the BUYER, freight prepaid to a destination determined by the MANUFACTURER.

3

Page 4

INSTALLATION

Condui

Evaporative

Equipment

Screen

Drain Trap

Liquid

It is imperative that this unit is installed and operated with the designed airflow and electrical supply in

accordance with this manual. If there are any questions about any items, please call the service

department at 1-866-784-6900 for warranty and technical support issues.

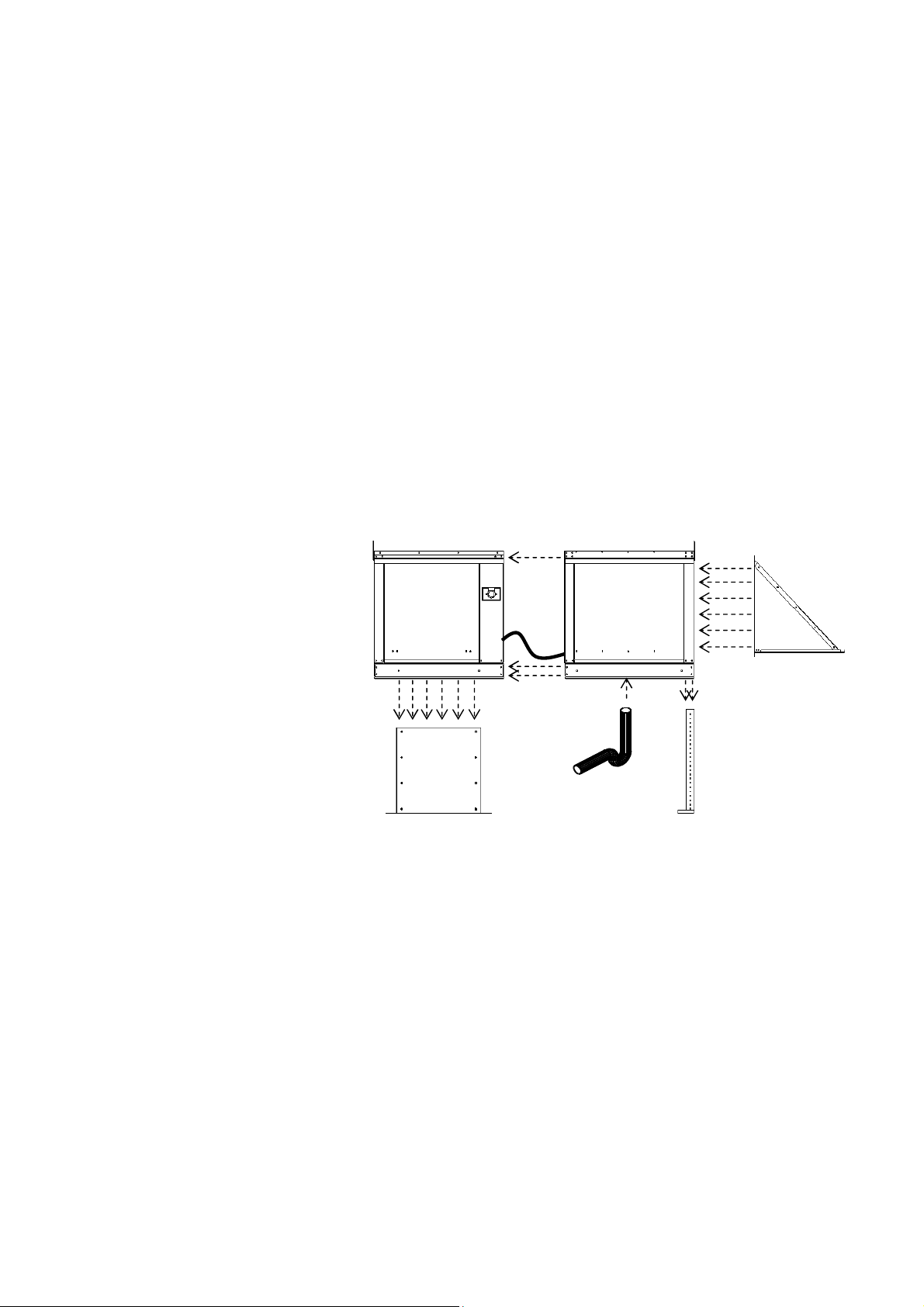

Mechanical

WARNING: DO NOT RAISE VENTILATOR BY THE INTAKE HOOD, FILTER

TRACKS, OR PIPING – USE LIFTING LUGS PROVIDED OR A SLING

Site Preparation

1. Provide clearance around installation site to safely rig and lift equipment into its final position.

Supports must adequately support equipment. Refer to manufacturer’s estimated weights.

2. Consider general service and installation space when locating unit.

3. Do not allow air intake to face prevailing winds. Support unit above ground or at roof level high

enough to prevent precipitation from being drawn into its inlet. The inlet must also be located at

least 10 feet away from any exhaust vents.

Assembly

There are several items shipped

loose with the evaporative coolers.

These items include the drain trap

components, sheet metal screws,

nuts and bolts, screen intakes (for

outdoor installations), equipment

legs (for outdoor installations), and

hanging cradles (option for indoor

applications). Upon unit arrival,

follow the following procedure to

assemble the evaporative cooler:

1. Attach the evaporative

cooler to the ventilator or

duct using the sheet metal

screws and nuts and bolts

included. Ensure that there is a liquid tight seal formed between the evaporative cooler and the

ventilator.

2. Screw the flanges of the intake screen to the unit with the supplied sheet metal screws. (Outdoor

installations only)

3. Fans designed for outdoor installation are provided with adjustable equipment legs. The

adjustable legs should be used to support and level the front end of the evaporative cooler.

Ventilator

Curb

Tight

Liquid

Conduit

Tight

Assembly

Cooler

Intake

Legs

4

Page 5

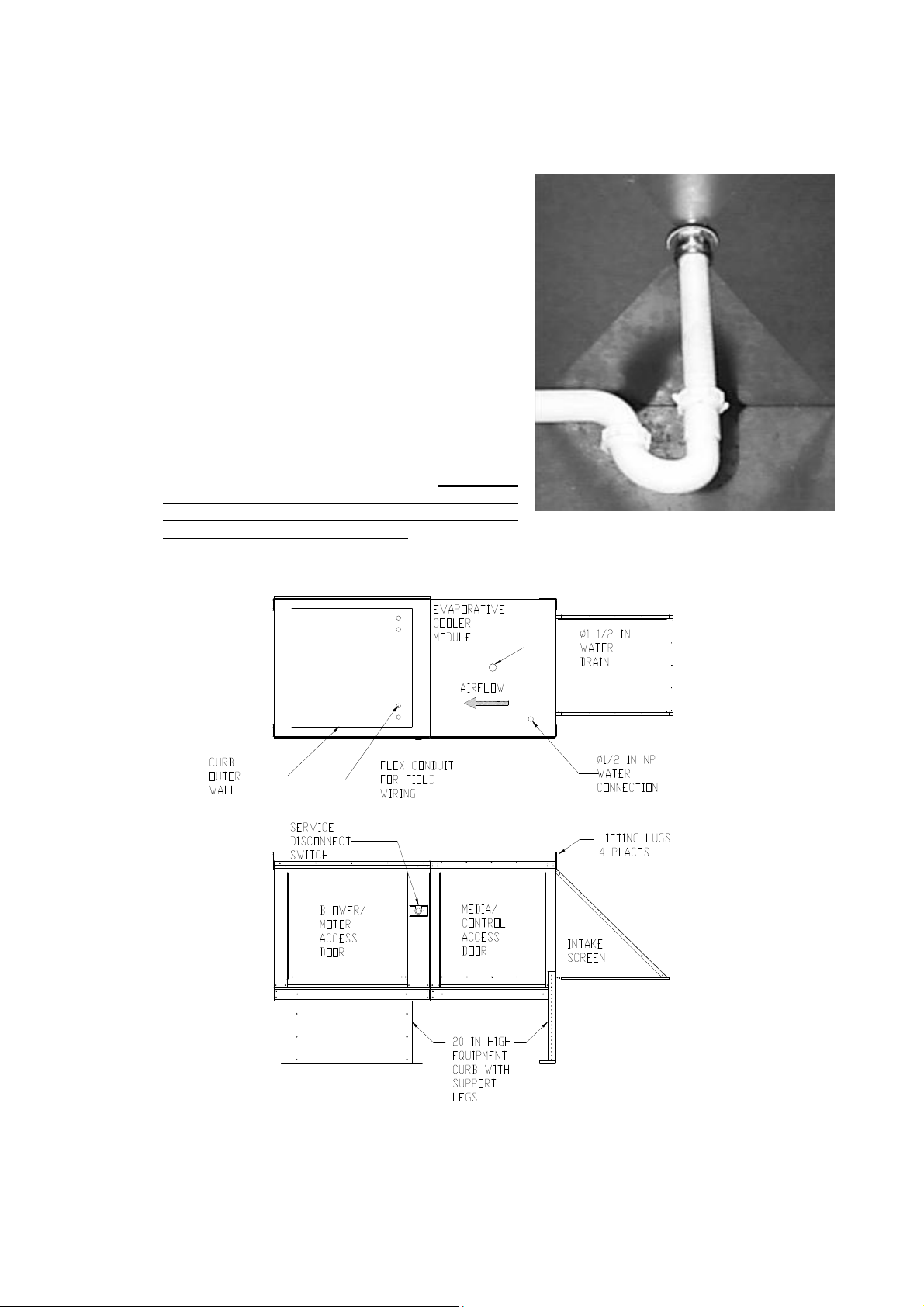

Plumbing Connections

There are two field plumbing connections required for proper

evaporative cooler operation. It is recommended that all

plumbing connections be sealed with Teflon tape or pipe

dope. Use care not to contaminate the interior surfaces of

the water lines when plumbing the unit, as small particulate

can clog the orifices of the spray nozzles.

1. The P-Trap drain should be attached underneath the

cooler (hardware is provided and drain is installed).

The trap is important for two reasons. First, it can be

piped to drain in the most convenient area. Second,

it keeps air from being drawn through the drain hole

in the bottom of the pan, impeding drainage.

2. Pipe the main water supply line (50 psi. max.) to

quick seal on the bottom of the unit. Install a strainer

with sediment trap on the water inlet. It is highly

recommended that a water-softener be installed

up-stream of the unit to extend cooling media life

and prevent scale build-up in unit.

Roof Mount Installation

5

Page 6

Indoor (Inline) Installation

WARNING!!

Electrical

Before connecting power to the module, read and understand

the entire section of this document. As-built wiring diagrams

are furnished with each module by the factory, and are

attached either to the door of the unit or provided with a

paperwork packet.

Electrical wiring and connections should be done in

accordance with local ordnances and the National Electric

Code, ANSI/NFPA70. Be sure the voltage and phase of the

power supply and the wire amperage capacity is in accordance

with the unit nameplate. For additional safety information refer

to AMCA publication 410-96, Recommended Safety Practices

for Users and Installers of Industrial and Commercial Fans.

1. Always disconnect power before working on or near

this equipment. Lock and tag the disconnect switch or

breaker to prevent accidental power up.

2. An electrical drop containing the line voltage power

wiring is shipped with every evaporative cooler. The

electrical drop should be brought through one of the

conduit openings located in the front of the module and

Disconnect power before

installing or servicing module.

High voltage electrical input is

needed for this equipment. This

work should be performed by a

qualified electrician.

Copper Wire Ampacity

Wire Size AWG Maximum Amps

14 15

12 20

10 30

8 50

6 65

4 85

6

Page 7

connected to an appropriate power source.

3. Make certain that the power source is compatible with the requirements of your equipment. The

evaporative cooler wiring schematic identifies the proper phase and voltage of the equipment.

4. Before connecting evaporative cooler to power source, verify power line wiring is de-energized.

5. Secure the power cable to prevent contact with sharp objects.

6. Do not kink power cable and never allow the cable to come in contact with oil, grease, hot

surfaces or chemicals.

7. Before powering up the evaporative cooler make sure that the interior of the unit is free of loose

debris or shipping materials.

8. If any of the original wire supplied with the cooler must be replaced, it must be replaced with type

THHN wire or equivalent.

Freeze Protection

On units shipped with the optional freeze protection drain kit, additional field wiring and piping is required.

A 3-way water solenoid is provided; containing a normally open and a normally closed valve, and should

be installed below the roof line and be wired and piped as shown to the right. Additional details on how

to install this 3 way solenoid valve are included in the “Component Detail” section of this manual.

A 2-stage thermostat is also provided in the evaporative cooler when the freeze protection option is

ordered. The evaporative cooler will automatically drain when the ambient temperature falls below the

internal two stage thermostat set-point.

7

Page 8

OPERATION

Prior to starting up or operating the evaporative cooler, check all fasteners for tightness. Ensure that the

cooling media is installed properly and that the interior of the cooler is free of loose debris.

The evaporative cooler is equipped with a 2 setting timer control. The LOWER 2 dials are used to denote

the length of time the manifold sprays water while the UPPER 2 dials control the amount of time between

spray periods. Both of these settings are factory set and should not have to be adjusted during initial

installation of the unit. It is important to understand that the spray timing pattern is cyclic in nature with

the manifold discharging water on and off continuously based on the timers dial settings. Both the

standard and Celdek evaporative coolers are shipped from the factory with specific nozzles with varying

characteristics regarding flow rates and anti-drip protection. It is imperative that the correct nozzle is

used in the correct location and type of cooling module to ensure quality performance and

leakage prevention. Information regarding the nozzles and timer control should be read and

understood before commencing unit start-up procedures.

Timer Settings:

Both the upper and lower timer settings are adjusted using the same procedure. The LOWER section

controls the length of time the manifold sprays water, while the UPPER section controls the amount of

time between spray periods. Both of these parameters are set in the factory and should not have to

be adjusted during initial start-up. If adjustments to airflow are made, the timer settings will need

to be adjusted to sustain proper performance.

The procedure for setting the Timer control is as follows:

1) Set the two smaller, coarse adjustment dials located in the middle of the timer to “1 MIN”. THIS

IS ALWAYS SET TO “1 MIN” FOR ALL UNITS REGARDLESS OF SIZE AND TYPE.

2) Set the larger fine adjustment dial located on the UPPER portion of the timer. THIS IS ALWAYS

SET TO “1.0” FOR ALL UNITS REGARDLESS OF SIZE AND TYPE.

3) Using the table at the bottom of this page, calculate the time parameter of how many seconds the

manifold will spray based on the given CFM of the unit.

8

Page 9

4) Set the larger fine adjustment dial located on the LOWER portion of the timer. For each time

*

Time "Spray

- On" (

LOWER

timer setting

parameter, the values of both the large fine adjustment and small coarse adjustment dials are

multiplied by one another to denote the total time of the parameter. This large red dial is the

percentage of the small dial. For example, if the small dial is set to 1 minute, and the large red

dial is set to 0.5, the selected time period would result in 30 (1 minute * 0.5 = 30 Sec) seconds.

Check to ensure that the parameter for “spray time on” matches the amount of time

calculated in step 3.

Unit Size

in SEC.)

1 CFM*(15/3000) + 6.5

2 CFM*(15/4000) + 1.5

3 CFM*(15/4500) - 1

4 CFM*(15/9000) - 1

5 CFM*(15/12,000) - 3.5

6 CFM*(15/15,000) - 5

*NOTE: THE VALUE GENERATED FROM THE EQUATIONS IN THE

TABLE IS FOR SECONDS THAT THE MANIFOLD IS TO SPRAY WATER. IT IS NOT

THE LARGER DIAL SETTING. STEP “4” MUST BE CARRIED OUT IN ORDER TO

PROPERLY SET THE LARGE DIAL.

9

Page 10

Nozzle Replacement:

The standard and Celdek style evaporative units each have each been designed with their own

specific water manifolds and nozzles in order to deliver maximum spray coverage and correct

quantity of water to the cooling media. It is imperative that in the event of a nozzle change-out,

the nozzles match what is specified in this section of the manual. Nozzle threads must be

wrapped in Teflon tape to prevent leakage.

CELDEK Evaporative Cooler Water Manifold:

10

Page 11

Standard Evaporative Cooler Water Manifold:

11

Page 12

Start Up

Special Tools Required

• AC Voltage Meter

• Amperage Meter

• Standard Hand Tools

Start Up Procedure

1. Remove the access door and check all electrical connections for tightness and continuity.

2. Inspect the air-stream for obstructions and install cooling media if missing.

3. Compare the supplied voltage with the unit’s nameplate voltage. If this does not match, correct

the problem.

4. Set the internal thermostat to a set-point cooler than the entering air temperature for start-up

purposes. The cooling circuit will be energized when the entering air temperature is hotter than

the thermostat set-point.

5. Check the timers dial settings. Ensure that the timers settings match what is specified in the

above section of this manual under “Timer Settings”.

6. Install the access door and apply power to the unit. If the entering air temperature is hotter than

the thermostat set-point, the cooling circuit will be energized and water will begin spraying from

the nozzles. If no water sprays, the unit is either not powered, has no water pressure or the

entering air temperature is cooler than the thermostat set-point.

7. Observe the spray timing sequence. Make sure that the sequence observed matches what is

specified based on CFM to optimize evaporative cooler performance. The unit should spray

enough to keep the media wet with minimal run-off and light drainage. It takes roughly 20

minutes for the cooling media to become fully saturated and come up to steady state operating

conditions. If there is no water in the drain pan and no run-off of the media, the “spray-time on”

parameter should be increased to lengthen the time water is sprayed. If there is excessive runoff

and quantities of drainage, the “spray-time on” parameter should be decreased to shorten the

time water is sprayed. Set the thermostat back to the desired cooling temperature (typically

about 75°F). Remember, the cooling circuit will only be energized when the entering air

temperature is higher than the set-point.

12

Page 13

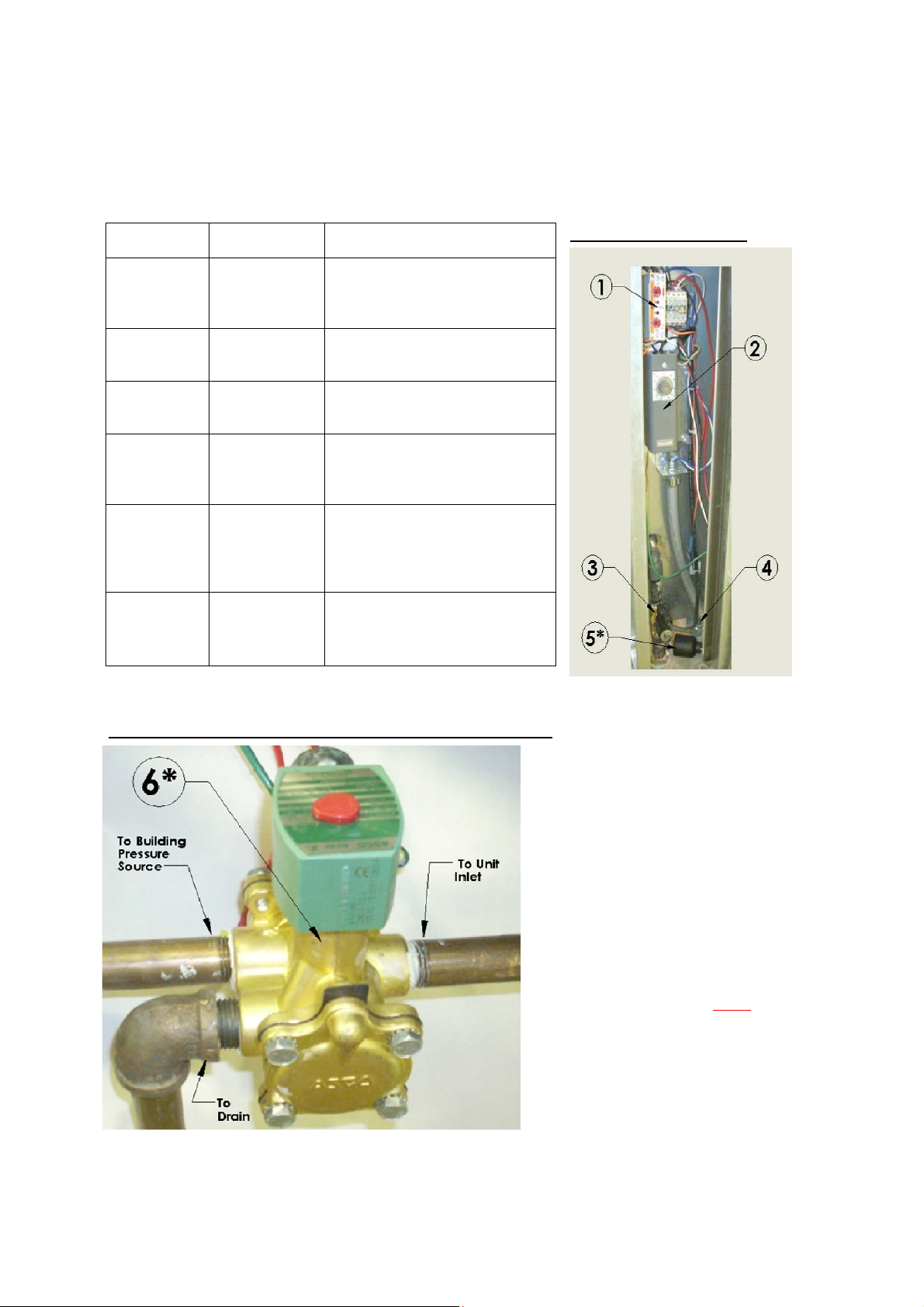

Component Description/Detail

Component

The following table lists controls used in the evaporative cooler and their function:

Number

1 Timer

2 Thermostat

3

4

5*

6*

Component Description of Operation

Solenoid

Overflow

switch

Pressure

Switch

3 Way

solenoid Valve

Valve

Electrical Cabinet Detail:

Controls spray timing

sequence. Runs continuously

from spray time on and spray

time off.

Energizes cooling circuit when

entering air temperature

exceeds set-point

Normally closed valve.

Energized when liquid level

controller senses “dry” condition

Normally closed switch.

Detects clogged drain to

prevent overflow.

Normally closed switch.

Prevents unit from continually

spraying if 3way solenoid valve

used for freeze protection is not

installed in field.

Installed under roof-line. Allows

gravity-fed drainage in sub-

freezing ambient conditions.

Units with Freeze Protection Option:

3-way Solenoid Valve Detail (Field Installed under

Roofline):

*NOTE: Only installed on units

with Freeze protection.

NOTICE: IT IS THE

RESPONSIBILITY OF THE

INSTALLER TO ENSURE 3-WAY

SOLENOID VALVE IS

INSTALLED UNDER THE ROOFLINE ON THE WATER-LINE

UPSTREAM OF THE UNIT. THE

MANUFACTURER IS NOT

RESPONSIBLE FOR ANY

DAMAGE RESULTING FROM

THE FAILURE OF INSTALLING

THIS 3-WAY SOLENOID VALVE

PRIOR TO START-UP.

13

Page 14

Troubleshooting

Cooling media dirty

Clean or replace cooling media

The following table lists causes and corrective actions for possible problems with evaporative coolers.

Review this list prior to consulting manufacturer.

Troubleshooting Chart

Problem

Insufficient Cooling Media not wet Check for even spray pattern

Potential Cause

Clogged nozzles Clean or replace nozzles

Timer Settings improperly set Ensure that the timers dial

Internal thermostat set to high Set thermostat to lower setting.

No water pressure Turn main building water valve

Clogged drain causing pan overflow

switch to activate

Excessive ambient humidity Wrong application for

Corrective Action

from all nozzles

setting settings correspond to

those specified in the reference

table of this manual based on

face velocity.

Cooling circuit will be energized

when the outside air temperature

is higher than thermostat setpoint

on

Clear any debris from drain and

ensure bottom pan drains

properly. Ensure that the

overflow switch float mechanism

is able to travel up and down

freely

evaporative cooling

Insufficient Airflow Cooling media clogged Clean or replace cooling media

Excessive Airflow Cooling media missing Install cooling media

14

Page 15

CELDEK Installation

Intake

Quantity

Size

MAINTENANCE

To guarantee trouble free operation of this evaporative cooler, the manufacturer suggests following these

guidelines. Most problems associated with unit failures are directly related to poor service and

maintenance.

Please record any maintenance or service performed on this equipment in the documentation section

located at the end of this manual.

WARNING: DO NOT ATTEMPT MAINTENANCE ON THE EVAPORATIVE COOLER

UNTIL THE ELECTRICAL SUPPLY HAS BEEN COMPLETELY DISCONNECTED

General Maintenance

1. Inlet and approaches to evaporative cooler should be kept clean and free from any obstruction.

2. All fasteners should be checked for tightness each time maintenance checks are performed prior

to restarting unit.

3. Evaporative coolers require little attention when moving clean air. Occasionally oil and dust may

accumulate on cooling media causing low airflow or reduced cooling. Cooling media should be

inspected and cleaned every 3 months and replaced every cooling season.

Every 3 months

1. Cooling media needs to be cleaned and/or replaced (if damaged)

quarterly, and more often in severe conditions. Cooling media can

be washed with a standard water hose. When re-installing cooling

media, be sure to install with the airflow in the correct direction.

The standard v-bank style evaporative cooler media should be

installed with the metal mesh side of the pad on the leaving air

side of the media. The CELDEK media should be installed with

the 15° holes along the air stream path as indicate d in the

CELDEK installation illustration.

2. Check all fasteners, sensors and electrical connections for proper tightness and continuity.

3. Check all nozzles for proper and evenly distributed water flow. If nozzles are clogged, clean or

replace.

Yearly

1. Replace cooling media prior to cooling season.

Cooling media should be replaced yearly to guarantee

proper cooling performance. The following table

illustrates proper media quantities and sizes.

2. Check the piping manifold and evaporative cooler

housing for water tightness. Replace or repair any

leaking or damaged components.

3. Every cold season requires that the evaporative cooler

water piping system be drained to prevent freezing

and cracking of the water piping. The main water

supply should also be turned off for the cold season.

Standard mesh filters may be used in standard v-bank

coolers in cold seasons.

15

Cooling Media Size and Quantity

Size 1 V-Bank/Evap

Size 2 V-Bank/Evap

Size 3 V-Bank/Evap

Size 4 V-Bank/Evap 15 16” x 20”

Size 5 V-Bank/Evap 12 20” x 25”

Size 1 CELDEK 1 24” x 20”

Size 2 CELDEK 1 32” x 25”

Size 3 CELDEK 1 36” x 30”

Size 4 CELDEK 1 43” x 38”

Size 5 CELDEK 1 54” x 45”

3 20” x 25”

8 16” x 20”

8 20” x 25”

Page 16

Start-Up and Maintenance Documentation

START-UP AND MEASUREMENTS SHOULD BE PERFORMED AFTER THE SYSTEM HAS BEEN

AIR BALANCED (Warranty will be void without completion of this form)

Job Information

Job Name Service Company

Address Address

City City

State State

Zip Zip

Phone Number Phone Number

Fax Number Fax Number

Contact Contact

Purchase Date Start-Up Date

Evaporative Cooler Information

Refer to the start-up procedure in this manual to complete this section.

Name Plate and Unit Information

Model Number

Serial Number

Volts

Hertz

Phase

Field Measured Information

Voltage

Thermostat Set-Point °F

Time spray on (Sec)

Time spray off (Sec)

Airflow Direction Correct

Incorrect

Maintenance Record

Date Service Performed

Factory Service Department

Phone: 1-866-784-6900

Fax: 1-919-554-9374

16

Loading...

Loading...