Page 1

3900 Dr. Greaves Rd. • Kansas City, MO 64030 • (816) 761-7476 • FAX (816) 765-8955

CD60 LOW LEAKAGE CONTROL DAMPER

High Performance Airfoil

Class 1A Leakage Rated

®

ALL STATED SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE OR OBLIGATION.

Spec CD60-704/Replaces CD60-302 ©Ruskin Co. July 2004

B Height

FEATURES

• Airfoil blade design for low pressure drop and less noise generation.

• One piece interlocking frame design to reduce racking.

• Positive lock axles, noncorrosive bearings and shake proof linkage for low maintenance operation.

• Blade edge seals mechanically lock into the blade for superior

sealing.

OPTIONS

• Factory-installed, pneumatic and electric actuators.

• Enamel and epoxy finishes.

• SP100 Switch Package to remotely indicate damper blade position.

• Heavier frame construction with U-channel frame.

• Front, rear or double flange frame with or without bolt holes.

• Face and bypass configurations.

NOTE: Dimensions shown in parenthesis ( ) indicate millimeters.

*Units furnished approximately 1/4"

(6) smaller than given opening

dimensions.

APPLICATION

The CD60 is a low leak, galvanized steel damper designed with airfoil blades for higher velocity and pressure HVAC stystems. It meets

the leakage requirements of the International Energy Conservation

Code by leaking less than 3 cfm/sq. ft. at 1" of static pressure and

is AMCAlicensed as a Class 1A damper.

STANDARD CONSTRUCTION

FRAME

5" x 1" x 16 gage (127 x 25 x 1.6) galvanized steel hat channel

reinforced with corner braces for structural strength equal to 11

gage (3.05) channel frames. Low profile 31/2" x 3/8" x 16 gage (89

x 10 x 1.6) galvanized steel channel top and bottom frame on

dampers under 12" (305) high.

BLADES

Galvanized steel airfoil shaped, double skin construction of 14

gage (2.0) equivalent thickness, 6" (152) wide. Parallel or

opposed action.

SEALS

Ruskiprene blade edge seals and flexible metal compressible

jamb seals.

BEARINGS

Stainless steel sleeve.

LINKAGE

Concealed in frame.

AXLES

1

/2" (13) plated steel hex. Removable control shaft extends 6"

(152) beyond frame.

MAXIMUM SIZE

Single section – 60"w x 72"h (1524 x 1829).

Multiple section assembly – Unlimited size.

MINIMUM SIZE

Single blade – 8"w x 6"h (203 x 152).

Two blades, parallel or opposed action: 8"w x 10"h (203 x 254).

TEMPERATURE LIMITS

-72°F (-60°C) minimum and +275°F (+135°C) maximum.

AMCA LICENSED

See Page 2

A

Width

Page 2

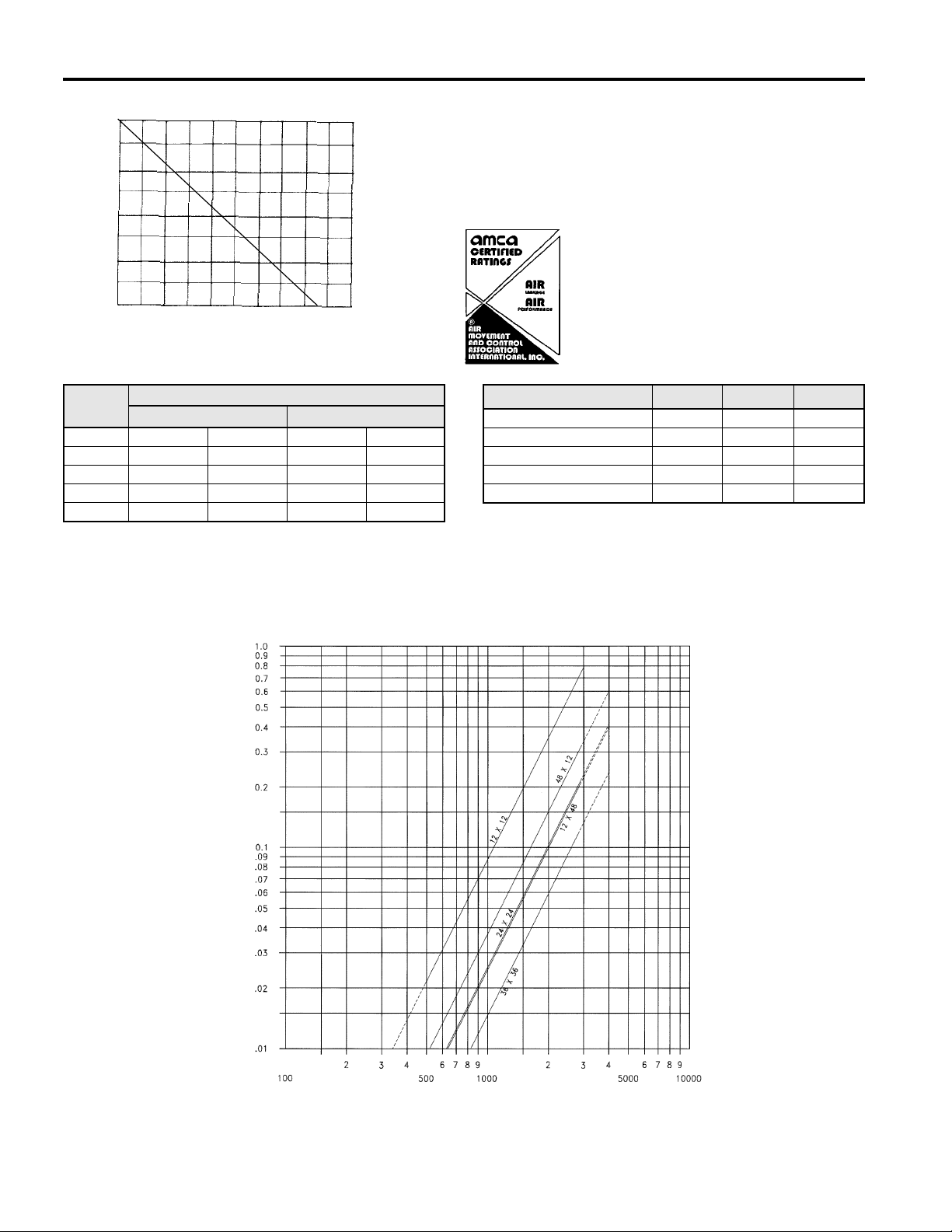

The CD60 may be used in systems with total pressures exceeding 3.5" by reducing

damper section width as indicated. Example: Maximum design total pressure of 8.5" w.g.

would require CD60 damper with maximum section width of 36" (914).

Pressure limitations shown above allow maximum blade deflection of 1/180 of span on

60" (1524) damper widths. Deflections in other damper widths (less than 48" [1219]) at

higher pressures shown will result in blade deflection substantially less than 1/180 of

span.

CD60 PRESSURE LIMITATIONS

Maximum Design Total Static Pressure

Inches Water Gage

3

4

5 6 7 8 9 10 11 12 13

60"

(1524)

48"

(1219)

36"

(914)

24"

(610)

12"

(305)

FACE VELOCITY - FEET/MINUTE

AMCA FIG. 5.3

CD60 sizes 12 x 12, 24 x 24, 48 x 12, 12 x 48, 36 x 36 (305 x 305, 610 x 610, 1219 x 305, 305 x 1219, 914 x 914)

All data corrected to represent standard air at a density of 0.075 lbs/ft3.

VELOCITY VS. PRESSURE DROP

Maximum Damper Section Width

CD60 AMCA LICENSED PERFORMANCE DATA

PRESSURE DROP - INCHES W.G.

Leakage testing conducted in accordance with AMCAStandard 500D-98. Torque applied holding damper closed, 5 in. lbs./sq. ft. on

opposed blade dampers and 7 in. lbs./sq. ft. on parallel blade

dampers. Air leakage is based on operation between 50°F to 104°F.

All data corrected to represent standard air density 0.075 lbs/ft3.

1 IN. W.G. 4 IN. W.G. 8 IN. W.G.

12" (305)

24" (610)

36" (914)

48" (1219)

60"(1524)

IA

IA

IA

IA

IA

I

I

I

I

I

II

II

NA

NA

NA

Ruskin Company certifies that the CD60

shown herein is licensed to bear the AMCA

Seal. The ratings shown are based on tests

and procedures performed in accordance with

AMCA Publication 511 and comply with the

requirements of the AMCA Certified Ratings

Program.The AMCA International Certified

Ratings Seal applies to Air Performance and

Air Leakage.

DAMPER WIDTH (INCHES)

1A

1

2

3

1" (0.25 kPa )

3 (15.2)

4 (20.3)

10 (50.8)

40 (203)

4" (1.0 kPa)

N/A

8 (40.6)

20 (102)

80 (406)

8" (2.0 kPa)

N/A

11 (55.9)

28 (142)

112 (569)

12" (3.0 kPa)

N/A

14 (71.1)

35 (178)

140 (711)

Pressure/

Class

Leakage, L/s/m2(ft3/min/ft2)

Required Rating Extended Ranges (Opt.)

Page 3

CD60 SUGGESTED SPECIFICATION

DIMENSIONAL INFORMATION

Furnish and install, at locations shown on plans, or in accordance

with schedules, control dampers that meet the following minimum

construction standards. Frame shall be 16 gage (1.6) galvanized

steel structural hat channel with tabbed corners for reinforcement for

11 gage (3.05) structural equivalence. Blades shall be 14 gage (2.0)

equivalent thickness galvanized steel, roll-formed airfoil type for low

pressure drop and low noise generation. Blade edge seals shall be

Ruskiprene type or equivalent suitable for -72°F (-60°C) to +275°F

(+135°C) mechanically locked into the blade edge. Adhesive or clipon type seals are unacceptable. Jamb seals shall be flexible metal,

compression type to prevent leakage between blade end and

damper frame. Blade end overlapping frame is unacceptable.

Bearings shall be corrosion resistant, permanently lubricated stainless steel sleeve type turning in an extruded hole in the damper

frame. Axles shall be hexagonal positively locked into the damper

blade. Linkage shall be concealed out of airstream, within the

damper frame to reduce pressure drop and noise. Submittal must

include leakage, maximum air flow and maximum pressure ratings

based on AMCA Publication 500. Damper shall meet the leakage

requirements of the International Energy Conservation Code by

leaking less than 3 cfm/sq. ft. at 1" of static pressure and shall be

AMCA licensed as a class 1A damper. Dampers shall be Ruskin

CD60 model.

Specifier Select Options.

SP100: Dampers shall be equipped with factory installed damper

position indication switch package. The switch package shall

include two position indication switches linked directly to the damper

blade to provide full open and full closed damper blade position. The

switch package shall be capable of interfacing with the HVAC control system and provide remote damper blade position status.

Switch package shall be Ruskin Model SP-100.

Factory Mounted Damper Actuators: If control damper actuators

are required, they shall be furnished and mounted by the damper

manufacturer in their factory. Each damper shall be cycle tested at

the factory prior to shipment.

7"

(178)

7"

(178)

5"

(127)

5"

(127)

2

7

/8"

†

Low profile frame

illustrated is typical for

units under 12" (305) high.

OPPOSED

BLADE

7"

( 178)

5"

(127)

PARALLEL

BLADE

Loading...

Loading...