Page 1

3900 Dr. Greaves Rd. • Kansas City, MO 64030 • (816) 761-7476 • FAX (816) 765-8955

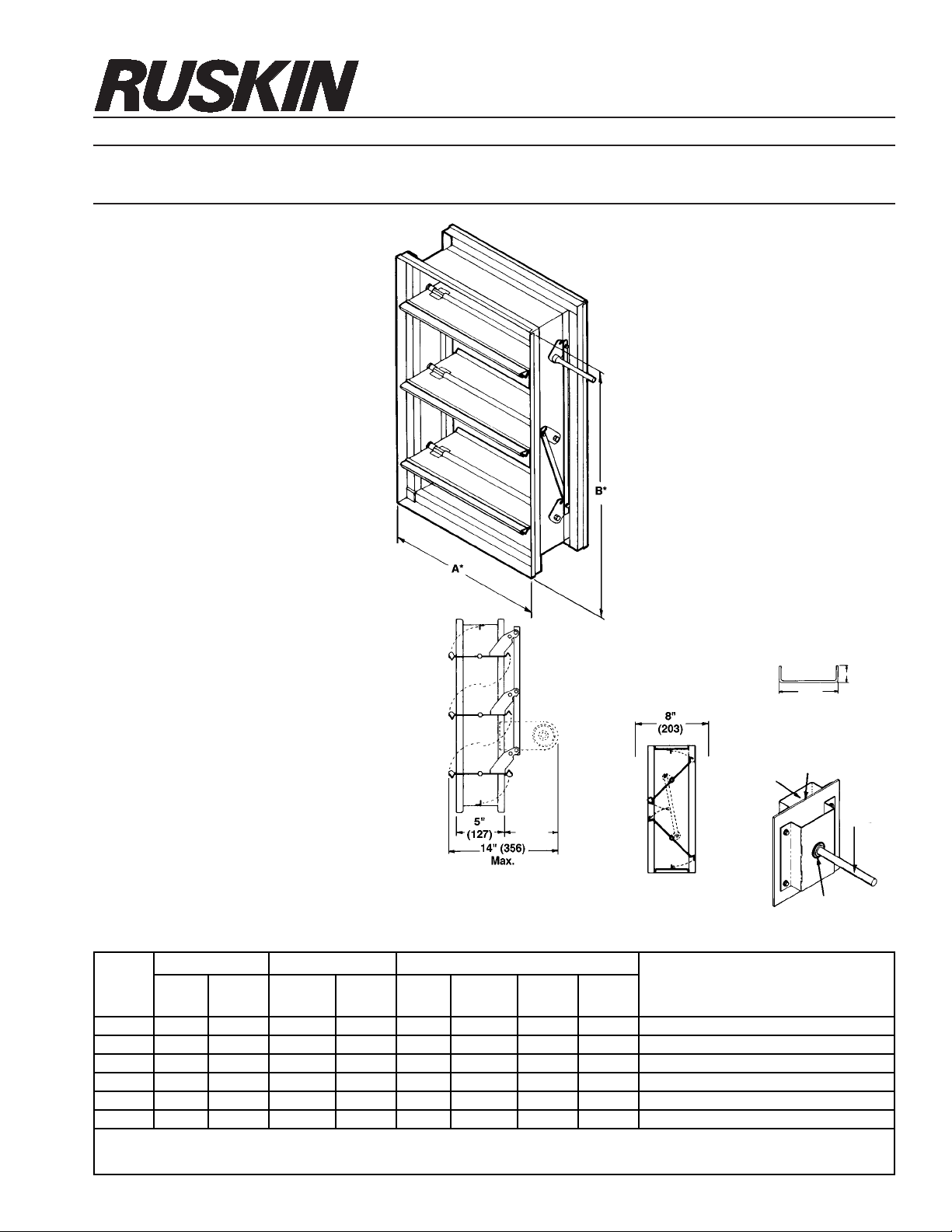

CD36 LOW LEAKAGE CONTROL DAMPER

GALVANIZED STEEL

FEATURES

The CD36 offers sturdy, steel construction with interlocking frame design. Damper locks together without

bolts, screws, or rivets that could shake loose. Frame

corners are internally braced to reduce racking.

Axles positively lock to blades without screws or

welds. Non-stick, noncorrosive bearings assure long

life and ease of operation. Axles and bearings combine with a shake proof linkage for low maintenance

operation.

When tested in accordance with AMCA Standard

500, the reasonably priced CD36 also exhibits low

leakage rates that meet the frequently specified, 10

cfm/sq. ft. at 4" w.g. level.

VARIATIONS

Variations to the CD36 basic design are available at

additional cost. They include:

• Enamel and epoxy finishes.

• Factory-installed, pneumatic and electric actuators

(specific information required with order).

• Ruskin frame-mounted universal actuator bracket

to simplify field installation of most actuators

(specify actuator and action, i.e., N.O. or N.C.,

with order).

• SP100 Switch Package to remotely indicate

damper blade position.

• Heavier frame construction with U-channel frame.

• Front, rear or double flange frame with or without

bolt holes.

• 304 stainless steel construc

tion.

®

ALL STATED SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE OR OBLIGATION.

Spec CD36-399/Replaces CD36-197 ©Ruskin Manufacturing 1999

OPENING DIM. BLADE ACTION FRAME STYLE

QTY.

A* B* PB OB STD.

Front

Flange

FF

Rear

Flange

RF

Double

Flange

DF

VARIATIONS

JOB LOCATION

CONTRACTOR

31/2"

(89)

1"

(25)

OPPOSED BLADE

Low profile frame

illustrated is typical for

units under 13" (330) high.

Outboard Support

Bearing

Bearing

Control

Shaft

Sleeve or Duct

Heavy Construction/

Special Materials

U-channel Frame Option

STANDARD CONSTRUCTION

FRAME

5" x 1" x 16 gage (1 27 x 25 x 1.6) galvanized steel

hat channel reinforced with corner braces for structural strength equal to 13 gage (2.28) channel

frames. Low profile 31/2" x 3/8"

x 16 gage (89 x 10 x

1.5) galvanized steel channel top and bottom frame

on dampers under 13" (330) high.

BLADES

6" (152) wide, 16 (1.6) gage galvanized steel

blades approximately 6" (152) on center. Parallel or

opposed action.

SEALS

Blade edge is PVC coated polyester fabric mechanically locked into blade edge. Jamb is flexible metal,

compression type.

BEARINGS

Synthetic.

LINKAGE

Concealed in frame. Exposed linkage optional.

AXLES

1

/2

" (13) plated steel hex.

CONTROL SHAFT

6" (152) x 1/2

" (13) diameter. Outboard support

bearing supplied with all single section dampers for

field mounted actuators. Factory-installed jackshaft

supplied with all multiple section dampers.

FINISH

Mill.

MAXIMUM SIZE

Single section – 48"w x 72"h (1219 x 1829).

Multiple section assembly – Unlimited size.

MINIMUM SIZE

Single blade – 5"w x 5"h (127 x 127).

Two blades, parallel or opposed action, exposed

linkage – 8"w x 95/8

"h (203 x 245). (Standard)

Two blades, parallel or opposed action, concealed

linkage – 5"w x 8"h (127 x 203). (Optional)

TEMPERATURE LIMITS

-25°F (-32°C) minimum and +180°F (+83°C) maximum.

Maximum section width varies with static pressure.

Consult Ruskin if application involves pressures in

excess of 2.5 inches w.g. or air velocities in excess of

2000 fpm.

NOTE: Dimensions shown in parenthesis ( ) indicate

millimeters.

*Units furnished approximately 1/4

" (6) smaller than

given opening dimensions.

†Jackshaft used only on multiple

section dampers.

PARALLEL

BLADE DEPICTED

Optional Exposed Linkage.

Damper

Frame

6

3

/4"†

(171)

Page 2

CD36 SUGGESTED SPECIFICATION

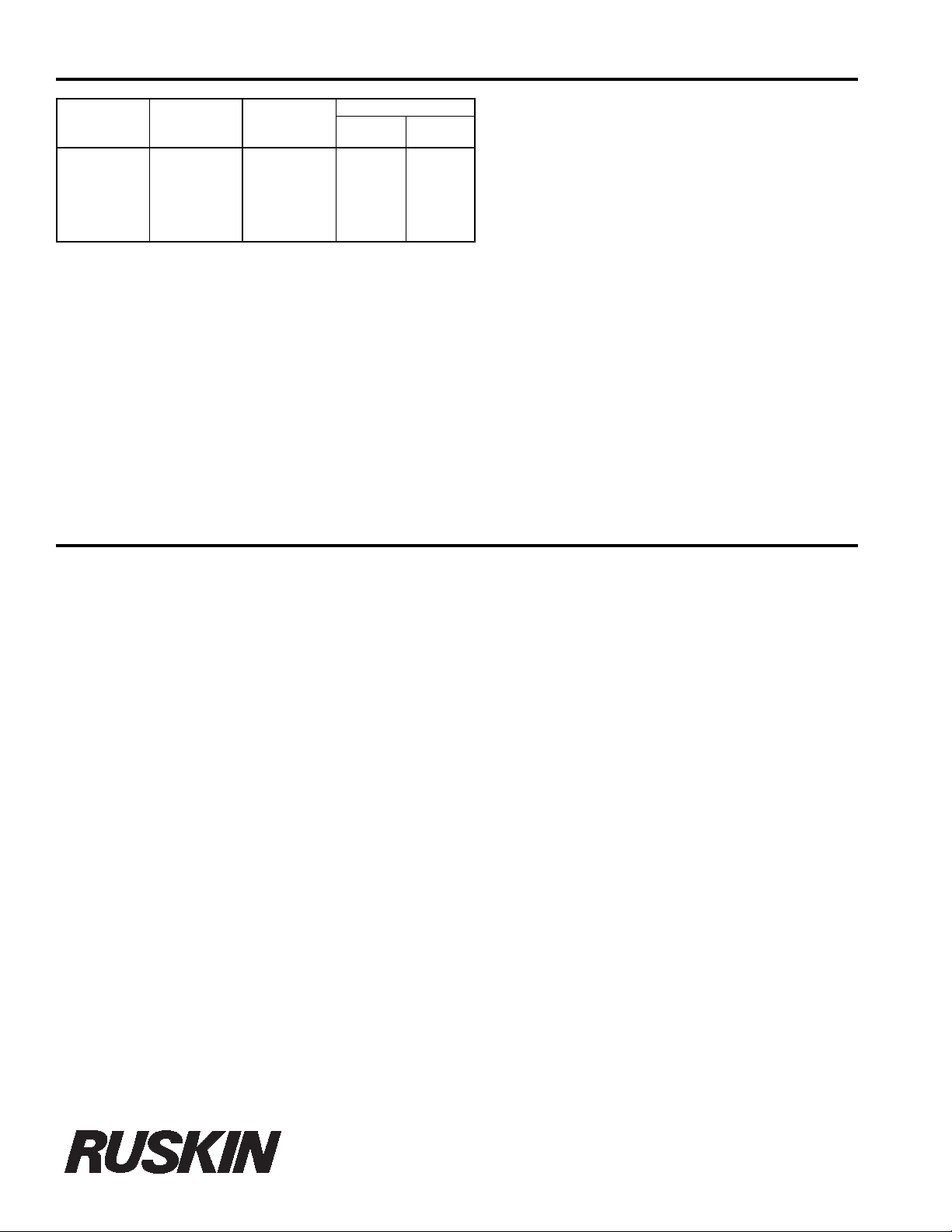

CD36 PERFORMANCE DATA

3900 Dr. Greaves Rd.

Kansas City, MO 64030

(816) 761-7476

FAX (816) 765-8955

Furnish and install, at locations shown on plans, or in accordance

with schedules, control dampers that meet the following minimum

construction standards. Frame shall be 16 gage (1.6) galvanized

steel structural hat channel with tabbed corners for reinforcement.

The blades shall be single skin, 16 gage (1.6) galvanized steel with

three logitudinal grooves for reinforcement. Blade edge seals shall

be PVC coated polyester fabric suitable for -25°F to +180°F

mechanically locked into the blade edge. Adhesive or clip-on type

seals are unacceptable. Jamb seals shall be flexible metal, compression type to prevent leakage between blade end and damper

frame. Blade end overlapping frame is unacceptable. Bearings

shall be corrosion resistant, molded synthetic sleeve type turning in

an extruded hole in the damper frame. Axles shall be hexagonal

positively locked into the damper blade. Linkage shall be concealed

out of airstream, within the damper frame to reduce pressure drop

and noise. Submittal must include leakage, pressure drop, maximum velocity and maximum pressure data based on AMCA

Publication 500. Dampers shall be in all respects equivalent to

Ruskin Model CD36.

Specifier Select Option

Dampers shall be equipped with factory installed damper position

indication switch package. The switch package shall include two

position indication switches linked directly to the damper blade to

provide full open and full closed damper blade position. The switch

package shall provide the capability to interface with the HVAC

control system and provide remote damper blade position status.

Switch packages shall be in all respects equivalent to Ruskin

Model SP-100.

*Leakage information based on pressure differential of 1" w.g. tested per

AMCA Publication 500.

Damper

Width

Maximum

System

Velocity

Maximum

System

Pressure

Leakage*

% of

max. flow

CFM/

sq. ft.

48"

36"

24"

12"

2.5" w.g.

3.0" w.g.

4.0" w.g.

5.0" w.g.

1500 fpm

1500 fpm

1500 fpm

1500 fpm

0.36

0.36

0.39

0.47

3.7

3.7

4.8

7.0

The CD36 is structurally designed for velocities to 2000 fpm

and above. Turbulence may produce objectionable noise in

some conditions with velocities above 1500 fpm.

Dampers may tolerate higher pressures and velocities than

those listed here. Conservative ratings are presented intentionally in an effort to avoid misapplication. Consult Ruskin or

your Ruskin representative when a damper is to be applied in

conditions exceeding recommended maximums.

INSTALLATION

CD36 IS NOT RECOMMENDED FOR INSTALLATION WITH

BLADES RUNNING VERTICALLY. For proper installation, damper

must be installed square and free from racking. Actuator must be

installed on linkage side. Opposed blade dampers must be operated from a power blade or shaft. See "Induct Mount Control

Dampers Installation Instructions" for details.

BRACING OF MULTIPLE SECTION DAMPER ASSEMBLIES

The CD36 is intended to be self supporting only in its largest single

section size. Multiple section damper assemblies may require bracing to support the weight of the assembly and to hold against system pressure. Ruskin recommends appropriate bracing to support

the damper horizontally at least once for every 8' of damper width.

Vertical assemblies and higher system pressures may require more

bracing.

®

Loading...

Loading...