CaptiveAire M511, CAV-M, CAH-M Installation Manual

Installation & Operation

Guide

.

Industrial Direct Fired Heaters

Horizontal / Vertical and Single / Twin Blowers

Re-Circulating Systems

Static Pressure Controller – Potentiometer

FOR YOUR SAFETY

If You smell gas:

1. Open windows

2. Don’t touch electrical switches

3. Extinguish any open flames

4. Immediately call your gas supplier

FOR YOUR SAFETY

The use and storage of gasoline or

other flammable vapors and liquids in

open containers in the vicinity of this

WARNING!!

appliance is hazardous!

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and

maintenance instructions thoroughly before installing or servicing this equipment

ALWAYS disconnect power and gas prior to working on heater.

RECEIVING AND INSPECTION

Upon receiving unit, check for any interior and exterior damage, and if found,

report it immediately to the carrier. Also check that all accessory items are

accounted for and are damage free. Turn the blower wheel by hand to verify

free rotation and check the damper (if supplied) for free operation.

NOTE TO INSTALLER

Please complete and return the

Start-UP Checklist on the back of this

manual to validate warranty

NOTE TO INSTALLER

This manual should be reviewed with

the customer and left with the

equipment user

Revision 7 – 5.25.2010

2

TABLE OF CONTENTS

WARRANTY .................................................................................................................................... 4

INSTALLATION ............................................................................................................................... 4

Gas ................................................................................................................................................ 11

Electrical ........................................................................................................................................ 12

Gas Connection Diagram .............................................................................................................. 12

Copper Wire Ampacity .......................................................................................................... 12

Re-Circulating Damper Control Options ........................................................................................ 14

SEQUENCE OF OPERATIONS .................................................................................................... 16

Sequence of Operation – 80/20 Static Pressure Controller ................................................ 16

Sequence of Operation – 80/20 Manual Potentiometer ....................................................... 16

START-UP PROCEDURE 80/20 .................................................................................................. 18

AIR BALANCING ........................................................................................................................... 24

TEMPERATURE CONTROL SYSTEMS ...................................................................................... 26

UNIT COMPONENTS ................................................................................................................... 27

M4RT1 Flame Safety Control ............................................................................................... 27

DC Flame Signal ................................................................................................................... 27

Air Flow Switch ..................................................................................................................... 28

Modulating Gas System ........................................................................................................ 28

High Temperature Limit ........................................................................................................ 28

TROUBLESHOOTING .................................................................................................................. 30

General Maintenance .................................................................................................................... 42

Burner Orifice Drill Size ........................................................................................................ 43

START-UP CHECKLIST ............................................................................................................... 43

3

WARRANTY

This equipment is warranted to be free from defects in materials and workmanship, under normal

use and service, for a period of 12 months from date of shipment. This warranty shall not apply if:

• the equipment is not installed by a qualified installer per the manufacturer’s installation

instructions shipped with the product

• the equipment is not installed in accordance with federal, state and local codes and

regulations

• the equipment is misused or neglected

• the equipment is not operated within its published capacity

• the invoice is not paid within the terms of the sales agreement

• the Start-Up Checklist has not been filled in by a qualified technician and returned to the

Factory Service Department

The manufacturer shall not be liable for incidental and consequential losses and damages

potentially attributable to malfunctioning equipment. Should any part of the equipment prove to

be defective in material or workmanship within the 12-month warranty period, upon examination

by the manufacturer, such part will be repaired or replaced by manufacturer at no charge. The

buyer shall pay all labor costs incurred in connection with such repair or replacement. Equipment

shall not be returned without manufacturer’s prior authorization and all returned equipment shall

be shipped by the buyer, freight prepaid to a destination determined by the manufacturer.

NOTE TO INSTALLER

Please complete and return the

Start-UP Checklist on the back of this manual to validate warranty

INSTALLATION

It is imperative that this unit is installed and operated with the designed airflow, gas, and electrical

supply in accordance with this manual. Any variance to these instructions may cause the unit to not

perform to specifications and may cause severe damage to the unit or jobsite. Please call the service

department at 1-800-291-2452 for assistance on warranty issues and technical support.

Inspection on Arrival

1. Inspect unit on delivery

2. Photograph any visible damage

3. Report any damage to the delivery carrier

4. Request a written inspection report from the

Claims Inspector to substantiate claim

5. File claims with delivery carrier

Unit Location

1. Do not locate any gas-fired equipment near

corrosive or explosive vapors such as

chlorinated or acid vapors

4

6. Check unit’s rating plate to verify proper

electric and fuel type to meet job

requirements

7. Compare unit received with description of

product ordered

2. Avoid overhead power lines, or other utility

access to prevent accidental contact or

damage.

3. Provide clearance around installation site to

safely rig and lift the equipment into its final

position onto adequate supports. Refer to

the manufacturer’s estimated weights.

4. Consider general service and installation

space when locating the unit.

5. Locate the unit close to the space it will

serve to reduce long, twisted duct runs.

6. Do not allow air intake to face prevailing

winds. Air flow switch may trip in high winds.

7. Situate the unit above ground or at roof level

high enough to prevent precipitation from

being drawn into its inlet.

8. The inlet must also be located at least 10

feet away from any exhaust vents.

9. The heater inlet must be located in

accordance with the applicable building

code provisions for ventilation air.

10. All air to the heater must be ducted from the

outdoors.

11. Recirculation of room air is not permitted. If

in doubt regarding the application, consult

the manufacturer.

12. The unit must have adequate structural

support or the equipment or building could

be damaged.

13. Do not alter or otherwise restrict combustion

or ventilation openings.

14. Direct-fired units should not be installed

downstream from cooling systems which

use refrigerants for cooling.

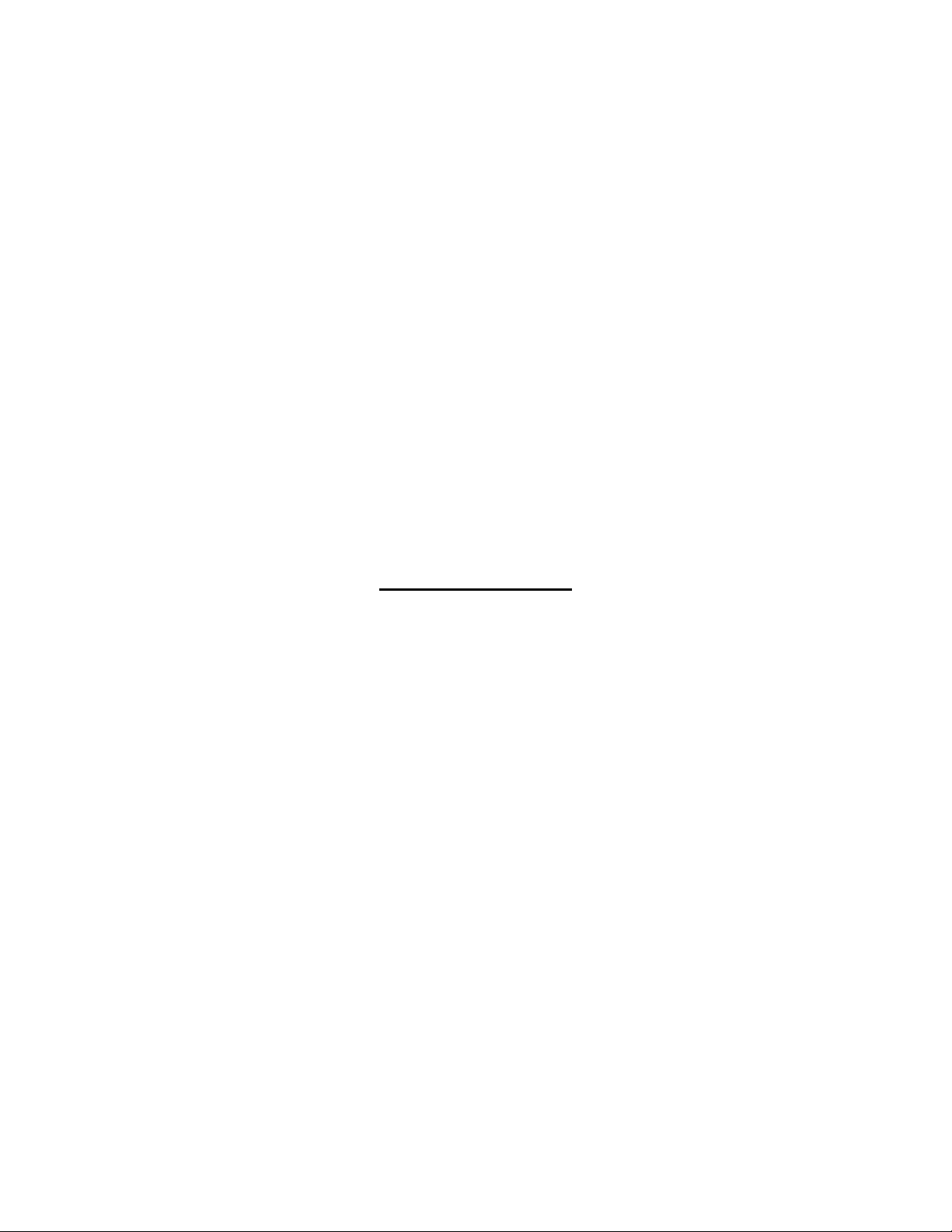

COMBUSTABLE

CLEARANCES

The top, back, and front surfaces

of this heater may not be installed

less than 6 inches from

combustible materials. The heater

base may be installed on

combustible surfaces.

SERVICE CLEARANCES

Allow 24 inches or greater

minimum service clearance on all

sides of this heater. Allow 48

inches or greater on the vestibule

and blower door side.

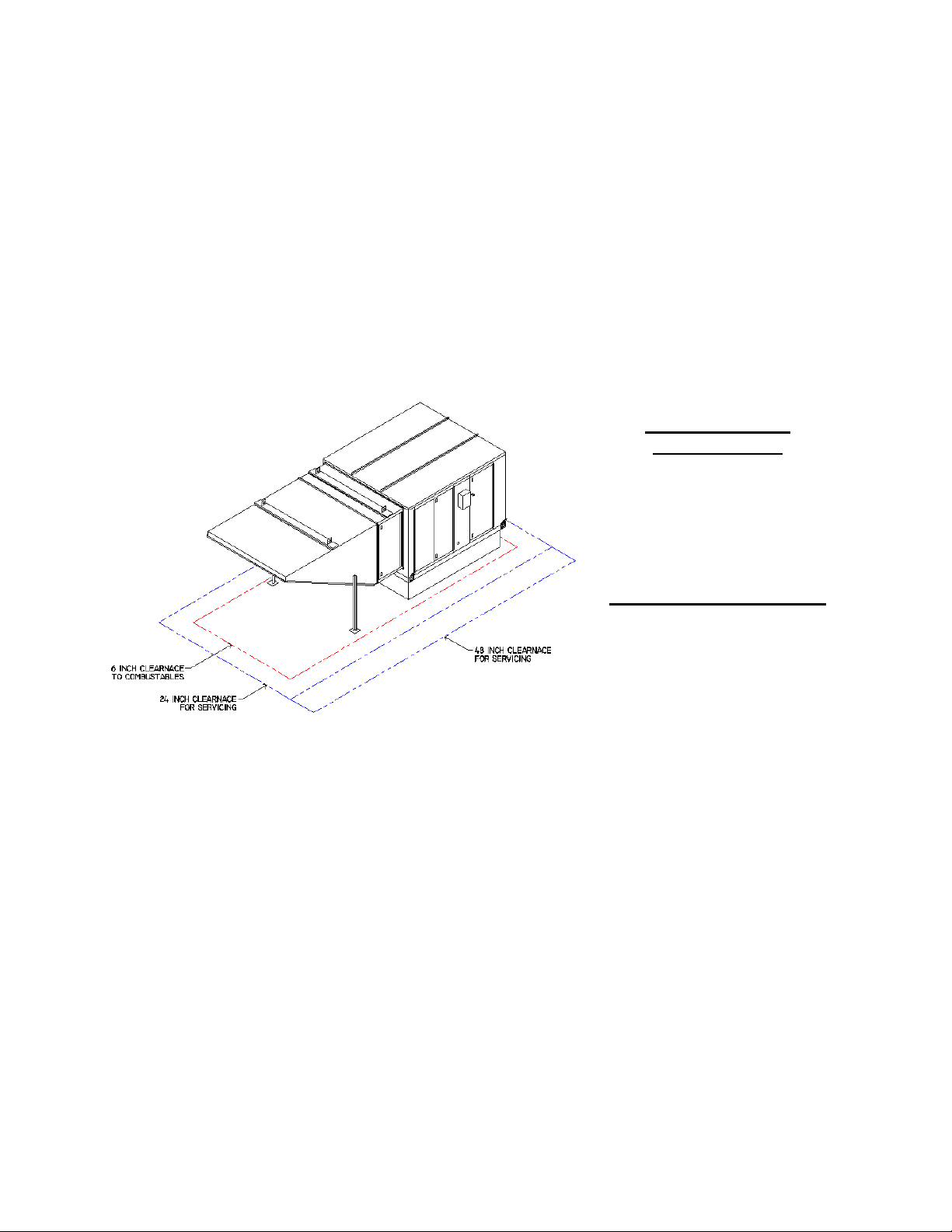

Rigging

1. Size 10, 12, 15, and 18 units are supplied with lifting eyes on the top corners of the casing.

2. All other units are supplied with four mounting and lifting brackets on the bottom corners of the base

with holes for lifting hooks.

3. The main load should be on these lugs.

4. Lift the unit and accessories separately, and attach the accessories to the unit once the unit is in

place.

5. The following diagrams represent the proper methods for lifting the unit and accessories.

6. Always use spreader bars to prevent damage to the unit casing.

5

FIGURE 1: SIZE 10, 12, 15, & 18 FIGURE 2: NO SPREADER BARS

FIGURE 3: WITH SPREADER BARS FIGURE 4: ACCESSORIES

CAUTION!!

These are unbalanced loads

Lift equipment gently

Do not jerk

Spreader bars must be used and should extend

past the edges of the equipment to avoid damage

to the casing. Not using spreader bars may cause

WARNING!!

WARNING!!

damage to the casing

Damage will result if the equipment is raised by the intake hood, blower, motor shaft, or bearings

Use the provided lifting eyes and brackets on the unit

6

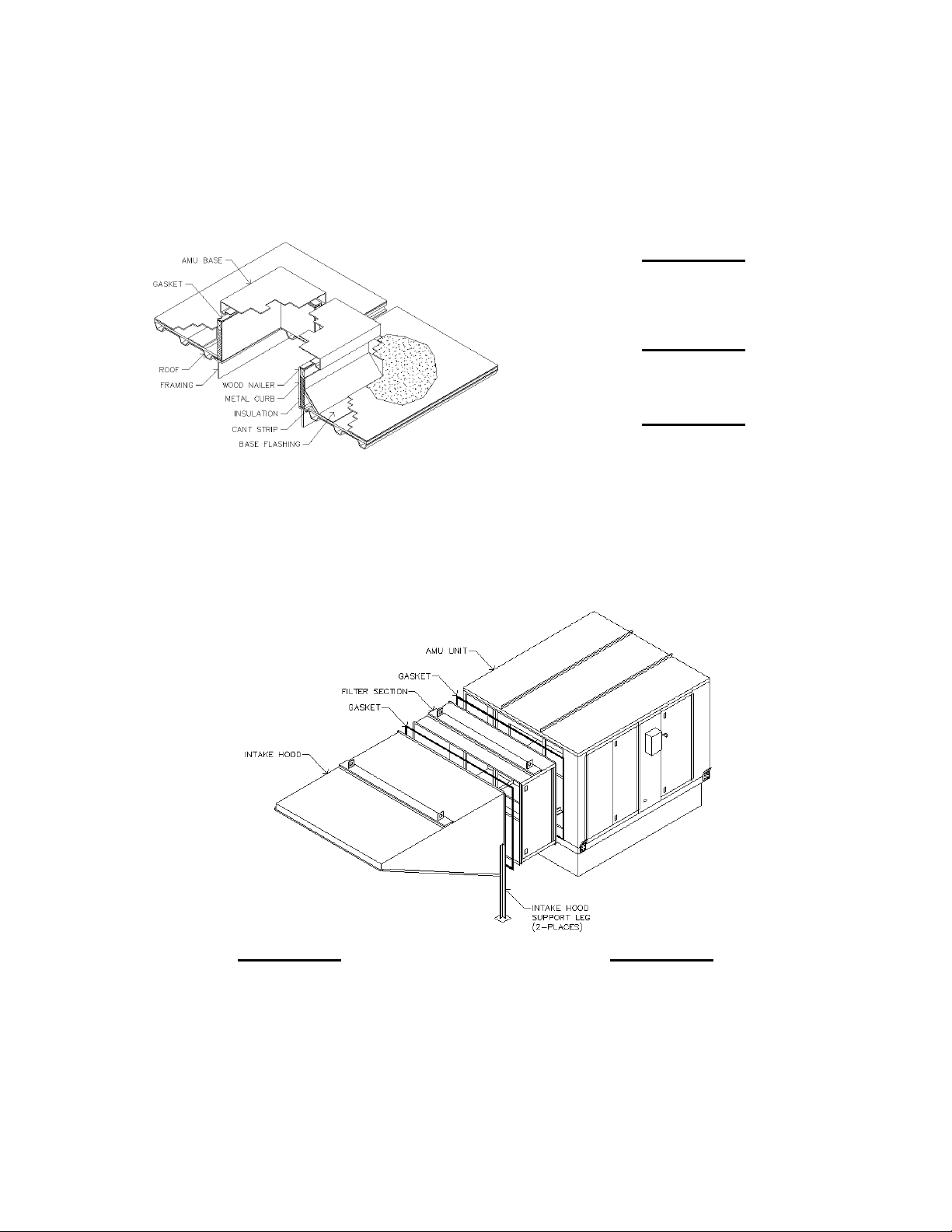

Curbs

The unit must have adequate structural support or the equipment or building could be damaged. The curb

and unit must be leveled or the unit may leak or be damaged. Use gasket and caulk between the curb

and unit. Use shims if necessary to level the unit. Screw or weld the unit’s base to the curb to avoid

damage to the equipment.

WARNING!!

The unit must have adequate structural

support or the equipment or building could

be damaged.

WARNING!!

Screw or weld the unit’s base to the curb

to avoid damage to the equipment.

WARNING!!

The curb and unit must be leveled or the

unit may leak or be damaged.

Accessories

Intake and discharge accessories are shipped loose and unassembled. When attaching the accessories

to the unit use gasket, caulk, and #10 sheet metal screws on all seams. All accessories must be level

them may leak and or be damaged.

WARNING!!

Use gasket, caulk, and #10 sheet metal screws on

all component intersections. Leaking may result if

the intersections are not completed properly.

WARNING!!

The accessories must be level and support legs

attached to the hood and solid part of the roof.

Equipment that is not level or properly supported

may leak or be damaged.

7

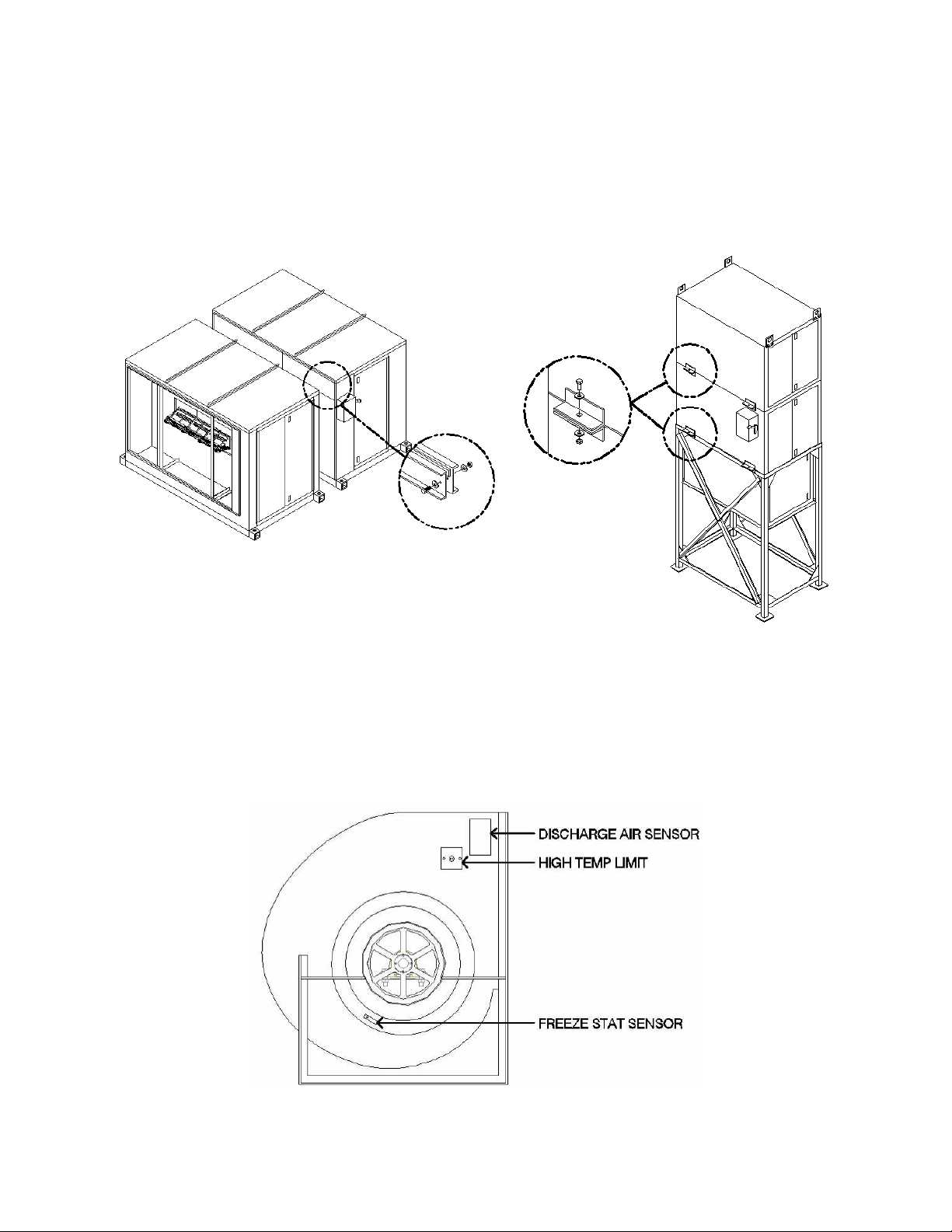

Split Units

1. Apply weather-proof gasket to the seam of the vertical or horizontal unit

2. Use provided fasteners to secure the seam of the unit using the provided pre-punched holes

a. Horizontal units internal channels and a formed frame

b. Vertical units have angles on the outside of the casing

FIGURE 1: HORIZONTAL SPLIT ASSEMBLY FIGURE 2: VERTICAL SPLIT ASSEMBLY

3. Apply silicone to the outside edge of the seam

4. Field wire the discharge air sensor using a minimum 22 gauge wire

5. Mount the high temperature limit bulb to the blower housing

6. Mount the (optional) freeze control sensor to the blower housing

FIGURE 3: BLOWER SENSOR FIELD ASSEMBLY

8

Shipped Loose Intake or Discharge Dampers

In some cases an intake or discharge damper may be shipped loose. This may be requested by the

customer or can be required because of larger units shipping size restrictions. Follow these instructions to

attach and wire the shipped loose damper. Factory mounted dampers may be attached on the unit and

will not require assembly or field wiring.

1. Attach the damper to the intake or discharge using gasket, caulk, and #10

sheet metal screws

2. Field wire the damper using the as built wiring schematic for the specific unit.

Wiring may be different depending on the model and options selected.

3. Refer to the factory supplied wiring print to verify the field wiring terminals.

Ductwork

This fan was specified for a specific CFM and static pressure. The ductwork attached to this unit will

significantly affect the airflow performance.

WARNING!!

• Flexible ductwork and square elbows should not be used

• Transitions and turns in ductwork near the fan outlet will cause system effect and will drastically

increase the static pressure and reduce airflow

• The Ductwork Sizing Chart shows the minimum fan outlet duct sizes and straight lengths

recommended for optimal fan performance

• Units with twin blower must have a common discharge plenum

Follow SMACNA guides and recommendations for the remaining duct run. Fans designed for

rooftop installation should be installed on a prefabricated or factory-built roof curb. Follow curb

manufacturer’s instructions for proper curb installation. The unit should be installed on a curb and/or rail

elevated not less than 20” above any surface. Be sure the duct connection and fan outlet are properly

aligned and sealed.

Adequate building relief is necessary in order to prevent over-pressurizing the building when the heater is

operating at capacity. This can be accomplished by establishing properly-sized relief openings, an

interlocked, powered exhaust system, or both.

Heaters installed with intake ductwork must be purged to replace at least four air changes of the volume

of the intake duct.

In order to avoid hazards to other fuel-burning equipment in the building (i.e., when the heater is providing

make-up air to a boiler room), the unit should be interlocked to open inlet air dampers or other such

devices.

On outdoor installations, it is recommended that the discharge duct be insulated to prevent condensation

during the “OFF” cycle in cold weather.

Units being installed in airplane hangars should be installed in accordance with the Standard for Aircraft

Hangars, ANSI/NFPA 409. Units being installed in public garages should be installed in accordance

with the Standard for Parking Structures, ANSI/NFPA 88A, or the Standard for Repair Garages,

ANSI/NFPA 88B, and with CAN/CGA B149 Installation Codes.

Flexible connectors should be employed on all ductwork connections. Vibration isolators are optional and

can be supplied in the loose parts package.

To isolate the blower and motor, a spring mounted combination blower/motor base can be factory

mounted in the unit. A flexible fabric connector is used to isolate the base from the unit’s discharge

opening flange.

9

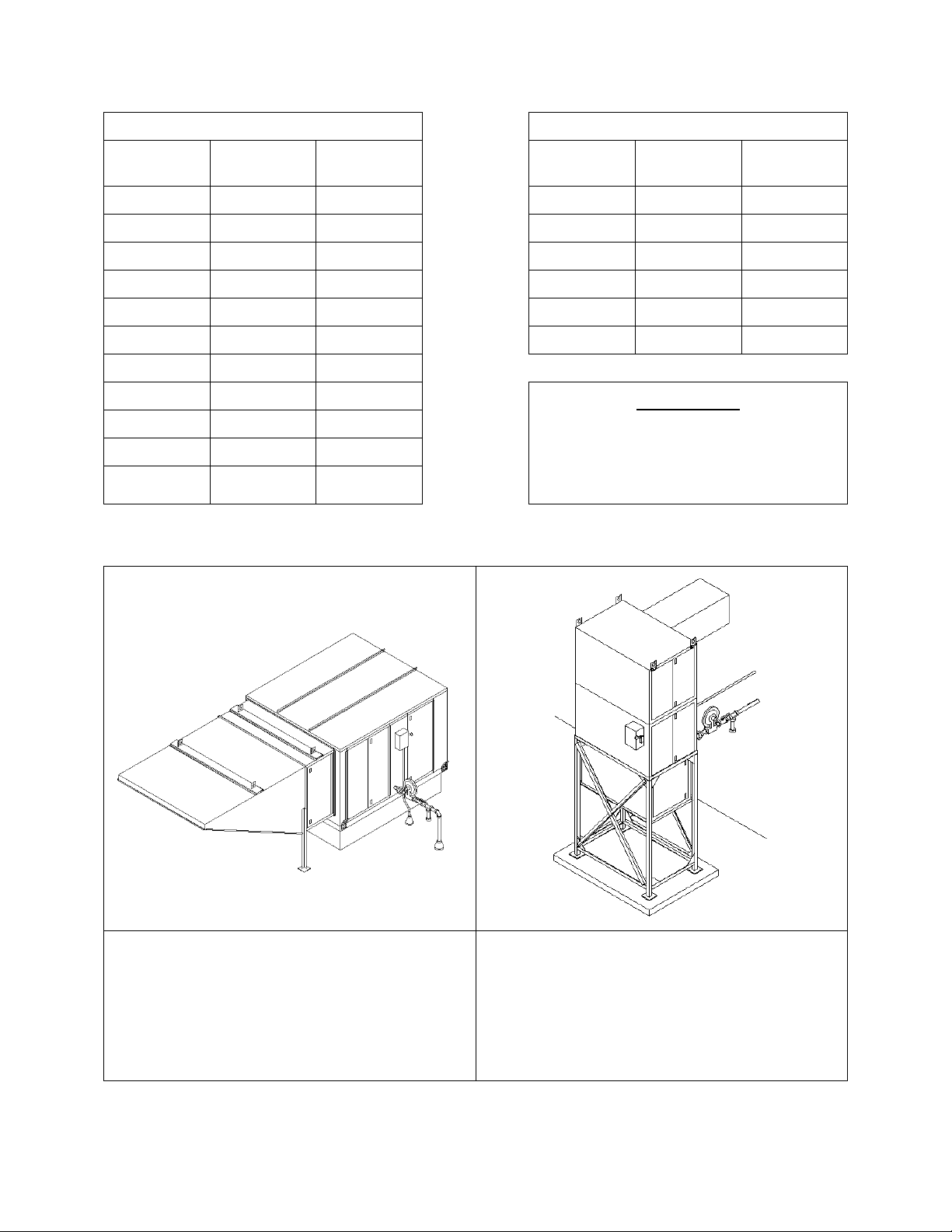

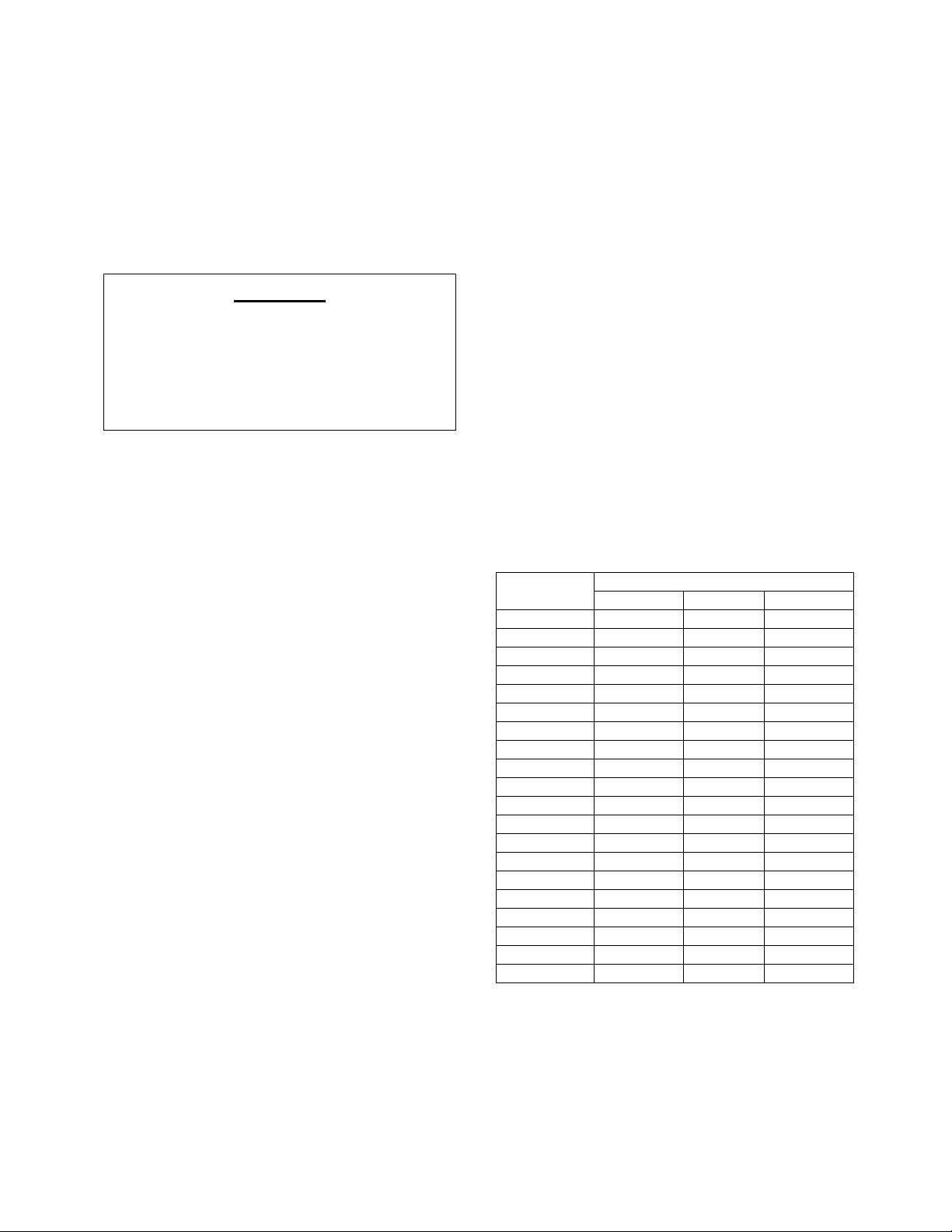

Ductwork Sizing Chart Single Blower

Blower Size

Duct Size

(Inches)

Duct Length

(Inches)

10 14 x 14 30

12 16 x 16 36

15 20 x 20 45

18 24 x 24 54

20 26 x 26 60

22 30 x 30 66

25 32 x 32 75

27 36 x 36 81

30 38 x 38 90

33 44 x 44 99

36 44 x 44 108

Installation Examples

Ductwork Sizing Chart Dual Blowers

Blower Size

Duct Size

(Inches)

Duct Length

(Inches)

222 77 x 28 66

225 88 x 32 75

227 96 x 36 81

230 104 x 38 90

233 116 x 44 99

236 122 x 44 108

WARNING!!

Failure to undersize ductwork size or length

may cause system affect and reduce the

performance of the equipment.

Using the unit to support the ductwork may

cause damage to the units casing.

Figure 1: Horizontal Roof Top Installation

Down discharge AMU reduces ductwork

Hood weight supported by support legs

Union, regulator, and shut-off

Roof curb supports unit

Intake facing away from prevailing winds

Figure 2: Vertical Outdoor Ground Installation

Side discharge AMU reduces ductwork

Support stand on concrete pad

Union, regulator, and shut-off

Filter section inside support stand

Ease of serviceability on ground

10

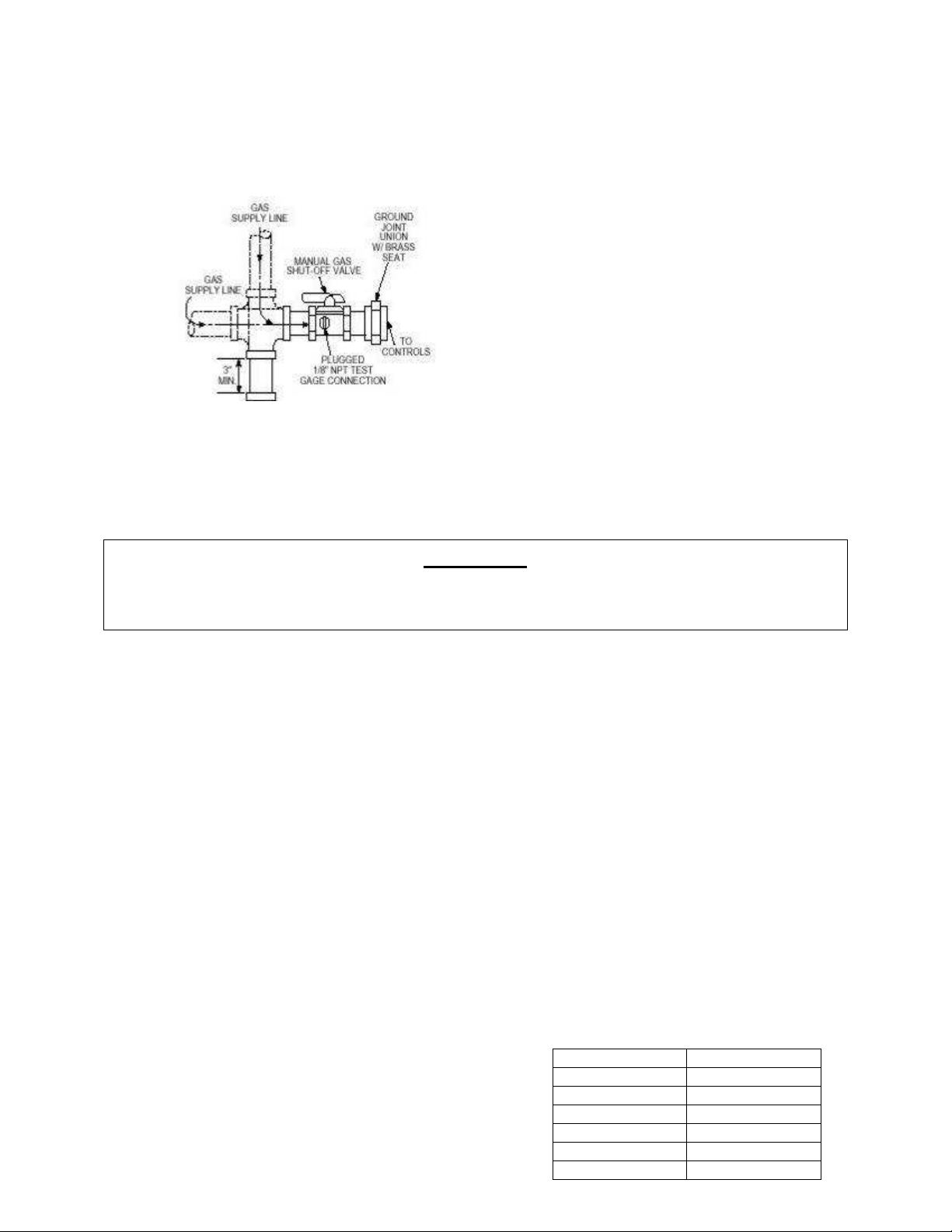

Gas Connection Sizes

Gas

Gas piping must be installed to conform with local building codes, or in the absence of local codes, the

National Fuel Gas Code, ANSI Z223.1 (NFPA 54) – latest edition. In Canada, gas piping must be

installed in accordance with CAN/CGA-B149.1 for natural gas units and CAN/CGA-B149.2 for propane

units.

WARNING

Inlet gas pressure must not exceed pressure

indicated on name plate.

Refer to the heater rating plate for

determining the minimum gas supply

pressure for obtaining the maximum gas

capacity for which this heater is specified.

1. Always disconnect power before working

on or near a heater. Lock and tag the

disconnect switch or breaker to prevent

accidental power-up.

2. Piping to the unit should conform to local

and national requirements for type and

volume of gas handled, and pressure drop

allowed in the line. Refer to the Gas

Engineer’s Handbook for gas line capacities.

3. The incoming pipe near the heater should

be sized to match the connection on the

outside of the unit. Unit inlet sizes are shown

in the table to the right. Avoid multiple taps

in the gas supply so the unit has a steady

supply of gas at all times.

4. Install a ground joint union with brass seat

and a manual shut-off valve external to the

unit casing, as shown below, adjacent to the

unit for emergency shut-off and easy

servicing of controls.

5. Provide a sediment trap, as shown below,

before each unit and where low spots in the

pipe line cannot be avoided.

6. Blow out the gas line to remove debris

before making connections. Before starting

the unit, purge line to remove air. Purge air

from gas lines according to ANSI Z223.1latest edition “National Fuel Gas Code,” or in

Canada: CAN/CGA-B149.

7. All field gas piping must be pressure/leak

tested prior to operating the unit. Use a

soap solution or equivalent for leak testing.

The heater and its individual shut-off valve

must be disconnected from the gas supply

piping system during any pressure testing of

that system at test pressures in excess of ½

PSI. During any pressure testing of the gas

supply piping system at test pressures equal

to or less than ½ PSI, the heater must be

isolated from the gas supply piping system

and its individual manual shutoff valve

closed.

8. This unit requires the gas pressure to be

within the unit’s minimum and maximum gas

pressure ratings. If the pressure is greater

than the maximum, the internal valve

components will be damaged. If the

pressure is below the minimum, the heater

will not perform to specifications.

9. If installing on a paint booth application, a

manual shutoff should be located for access

in case of a fire or explosion at the heater.

BTU Input

158,000

275,000

550,000

990,000

1,375,000

1,650,000

1,925,000

2,475,000

2,750,000

3,300,000

4,125,000

5,225,000

5,775,000

6,325,000

8,525,000

9,075,000

9,625,000

11,825,000

15,552,000

16,848,000

Gas Pressure (Inches W.C. & PSI)

7” – 14” 15” – 1# 1# - 5#

½ ½ ½

¾ ½ ½

¾ ¾ ¾

1 ¾ ¾

1 ¼ ¾ ¾

1 ¼ ¾ 1

1 ½ 1 1

1 ½ 1 ¼ 1

2 1 ¼ 1 ¼

2 1 ½ 1 ¼

2 ½ 1 ½ 1 ¼

2 ½ 1 ½ 1 ½

2 ½ 2 1 ½

3 2 1 ½

3 2 ½ 1 ½

2 ½ 2 ½

3 2 ½

3 3

2 ½ 3

2 ½ 3

11

Gas Connection

Diagram

Electrical

Before connecting power to the heater, read and understand this entire section. Wiring diagrams are

furnished with each fan by the factory, and are attached to the door of the unit.

WARNING!!

Disconnect power before installing or servicing fan. High voltage electrical input is needed for

this equipment. This work should be performed by a qualified electrician.

Electrical wiring must be done in accordance with local ordinances and the National Electric Code,

ANSI/NFPA70. Be sure the voltage and phase of the power supply and the wire amperage capacity

conform to those listed on the motor nameplate. For additional safety information, refer to AMCA

publication 410-96, “Recommended Safety Practices for Users and Installers of Industrial and

Commercial Fans.”

1. Always disconnect power before working on or near a heater. Lock and tag the disconnect switch

or breaker to prevent accidental power-up.

2. A dedicated circuit should supply the units electrical disconnect with circuit protection, according to

the National Electric Code.

3. Make certain that the power source is compatible with the requirements of your equipment. The

heater nameplate identifies the proper phase and voltage of the motor.

4. Units shipped with an optional remote panel have two electrical circuit drops. It is important to run the

motor wires in a conduit separate from the remote control wiring. The DC wires from the unit

temperature controller, located in the control drop, should be either in shielded cable or run in a

separate conduit.

5. Before connecting the heater to the building power source, verify the power line wiring is deenergized.

6. Secure the power cables to prevent contact with sharp

objects.

7. Do not kink power cable and never allow the cable to

come in contact with oil, grease, hot surfaces or

chemicals.

12

Copper Wire Ampacity

Wire Size AWG Maximum Amps

14 20

12 25

10 30

8 40

6 55

4 70

8. Before powering up the heater, check fan wheel for free rotation and make sure that the interior of the

heater is free of loose debris or shipping materials.

9. If necessary, the original wire supplied with the heater may be replaced with type TW wire or the

equivalent.

Remote Control Panel

For units with the optional remote control panel, a terminal strip inside the panel matches the terminals in

the heater unit. This diagram shows an example of the field wiring for a unit with a 401M remote panel.

Consult the as built wiring print supplied with the equipment. Most remote panels and VAV applications

have signal wiring which needs to be shielded cable to avoid high voltage interference.

Power Supply Wiring

The units input power supply is listed on the unit nameplate. If the units power supply does not match the

unit nameplate contact the service department for a new wiring print and parts.

Paint Booth Applications

If a low temperature control is not an integral part of the heater, it is recommended that one be installed in

areas where freeze protection is needed in the event of a burner shutdown. The space should be

ventilated following a bake cycle to purge any contaminants and cool product prior to personnel entering

the space. If the unit was supplied with paint booth controls from the factory, refer to the schematic for

installation of the interlock to disable spraying equipment unless the heater is operating in ventilation

mode. Refer to electrical schematic for interlock to disable facility lighting within the process space during

the bake cycle.

If they unit will be operating as a process heater in the re-circulating position with airborne particulate

matter, install means to facilitate inspection, maintenance, cleaning and access to fire protection devices.

In re-circulating process applications, the system shall be designed to provide 200 cfm per 1000 cfh of

natural gas based on the maximum capacity of the heater plus an allowance to sufficiently dilute the

VOC’s created by the process to maintain the lower explosive level below a 25% threshold value.

13

Re-Circulating Damper Control Options

The Re-Circulating system is for controlling the amount of make-up air being brought into a building. It

can be set from a minimum 20& fresh air, and 80% return air to a maximum of 100% fresh air, and 0%

return air. The Re-Circulating dampers can be controlled by three different options.

Manual Positioning Control (Potentiometer)

The dampers can be control at a remote location by a manual potentiometer to any position from 20% to

100% fresh air. This will allow manually setting the dampers to match the building ventilation

requirements. It will take an extra 3 control wires at the remote location. On a power failure, or if the unit

of turned off, the return air damper will close by spring return.

Two Position Control

The dampers can be controlled by a two position switch (a field supplied switching device) to open the

fresh air to 100%. On opening of the circuit, power failure, or if the unit is shutoff, the return air damper

will close by spring return.

Static Pressure Control (Photohelic)

The dampers can be controlled by a building static pressure control. This controller will sense the

difference between pressure inside the building, and pressure outside the building (sensed at the A306

outdoor sensor), and position the dampers to maintain the pressure setting on the controller. The

controller has two set points and an indicator. The two set points are a minimum desired static pressure

point, and a maximum static pressure point.

The actual building static pressure will be shown by a visual indicator between these two settings. The

controller will modulate the dampers to maintain a static pressure between these set points.

When building static pressure is below the minimum setting, the damper motor will proportion open the

fresh air damper and close the return air damper until static increases above the minimum setting. At this

point, the damper motor will stop and hold this proportion.

If the building static continues to climb and goes above maximum setting, the damper motor will reverse

proportion, closing the fresh air damper and opening the return air damper until static drops below

maximum setting.

During the “OFF” or “Night” cycle of the unit, an internal switching circuit will close the return air damper.

See additional wiring and installation information on the static pressure controller and A306 outdoor

sensor. The static pressure controller can be ordered to be shipped loose or mounted inside the unit to

reduce field wiring and assembly.

14

Loading...

Loading...