Canon SmartBase PC1210D, SmartBase PC1230D, SmartBase PC1270D Service Manual

SmartBase

PC1210D/1230D/

1270D

REVISION 1

MAR. 2002

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

HY8-10AU-010

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical

theory, installation, maintenance, and repair of products. This manual covers all

localities where the products are sold. For this reason, there may be information in this

manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to

improvements or changes in products. When changes occur in applicable products or in

the contents of this manual, Canon will release technical information as the need arises.

In the event of major changes in the contents of this manual over a long or short period,

Canon will issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered

trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this

manual may not be copied, reproduced or translated into another language, in whole or

in part, without the written consent of Canon Inc.

COPYRIGHT © 2002 CANON INC.

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

INTRODUCTION

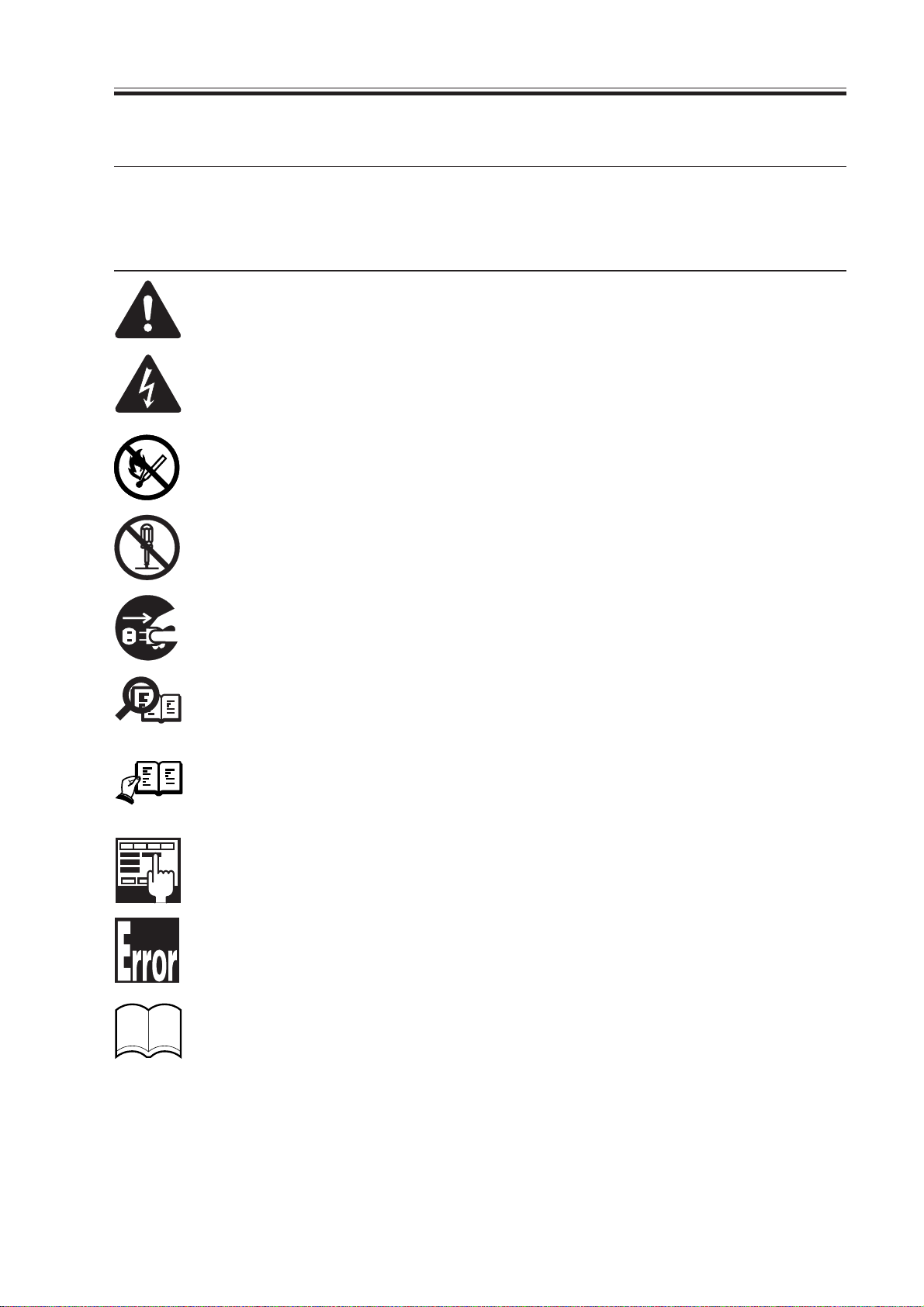

1 Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution,

or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Memo

REF.

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Indicates an item requiring disconnection of the power plug from the electric

outlet.

Indicates an item intended to provide notes assisting the understanding of the

topic in question.

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

COPYRIGHT

©

Refers to the Copier Basics Series for a better understanding of the contents.

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

i

INTRODUCTION

2 Outline of the Manual

This Service Manual provides basic facts and figures needed to service the SmartBase

PC1210D/1230D/1270D products in the field, and it consists of the following chapters:

Chapter 1 Product Outline: specifications, names of parts, safety and warnings

Chapter 2 Using the Machine: control panel, user mode, service mode

Chapter 3 Installation: site requirements, installation procedure, work for reloca-

tion

Chapter 4 Operation: mechanical system by function, principles of operation of

electrical systems

Chapter 5 Mechanical System: mechanical construction, disassembly/assembly

Chapter 6 Maintenance and Inspection: periodically replaced parts, durables (life), basic servicing

chart, cleaning

Chapter 7 Troubleshooting: standards/adjustments, troubleshooting image faults,

troubleshooting malfunctions

Appendix: general timing chart, general circuit diagrams

ii

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

INTRODUCTION

The descriptions in this Service Manual are based on he following rules:

1. In each chapter, the uses of the function in question and its relationship to electrical and

mechanical systems are discussed and the timing of operation of its associated parts is

explained by means of outlines and diagrams.

In the diagrams, the symbol

represents a mechanical path, while the symbol

with a name next to it indicates the flow of an electric signal.

The expression “turn on the power” means turning on the power switch, closing the

front cover, and closing the delivery cover so that the machine will be supplied with

power.

2. In circuit diagrams (digital), a signal whose level is High is expressed as being ‘1’,

while a single whose level is Low is expressed as being ‘0’; the level of voltage, however, varies from circuit to circuit.

The machine uses CPUs, whose internal mechanisms cannot be checked in the field,

and, therefore, are not explained. In addition, the machine’s PCBs are not intended for

repairs at the user’s and, therefore, are explained by means of block diagrams: two types

are used, i.e., between sensors and inputs of PCBs equipped with a control or drive

function and between outputs equipped with a control or drive function and loads; in addition, functional block diagrams are used at times.

Changes made to the machine for product improvement are communicated in the form of

a Service Information bulletin as needed. All service persons are expected to go through all

service documentation including the bulletins and be equipped to respond to the needs of

the field (as by being able to identify possible causes of problems).

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

iii

INTRODUCTION

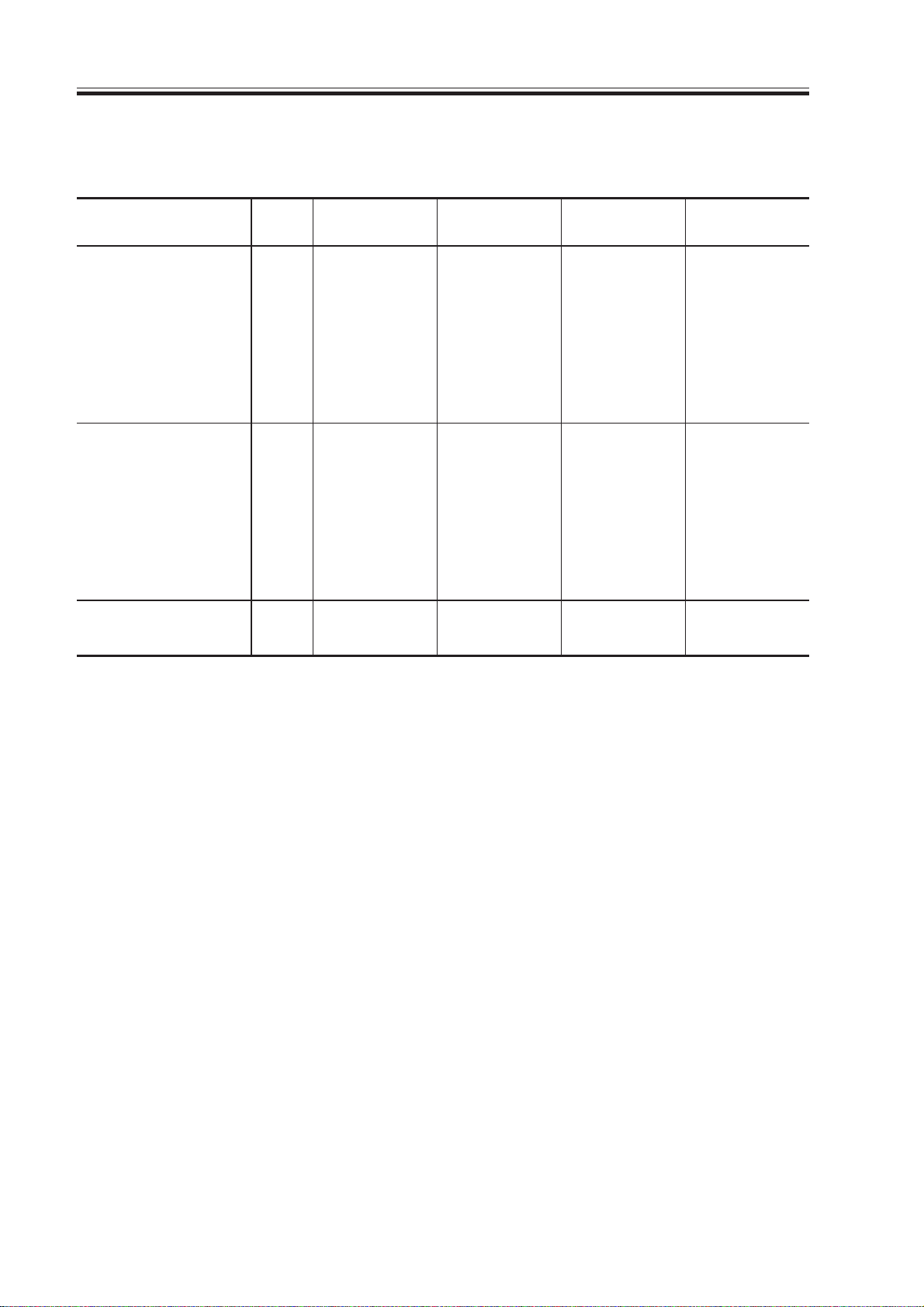

This service manual covers the models shown in the following table. Be sure to have a

good understanding of the difference from model to model before referring to this manual.

Model

SmartBase PC1210D

SmartBase PC1230D

SmartBase PC1270D

Type

code

QTJ

TTG

UGA

UUK

UUU

UUV

UUW

QTK

TTH

UHA

UUM

UUX

UUY

UUZ

UIA

ULA

ADF

function

√

√

Printer

function

√

√

√

Fax

function

√

Counter

function

The notation “√” indicates that the item in question is available.

iv

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

Contents

CHAPTER 1 PRODUCT OUTLINE

CONTENTS

1 Specifications......................................1-1

1.1 T ype............................................ 1-1

1.2 Mechanisms ............................... 1-1

1.3 Functions.................................... 1-2

1.4 Others......................................... 1-4

1.5 Copying Speed ........................... 1-5

1.6 ADF (if equipped with ADF

functions) ................................... 1-6

1.7 FAX (if equipped fax functions) 1-7

1.7.1 Communications

specifications ........................ 1-7

1.7.2 Scanner section

specifications ........................ 1-8

1.7.3 Printer section

specifications ........................ 1-8

1.7.4 Functions ............................. 1-9

2 Names of Parts .................................. 1-13

2.1 External V iew ........................... 1-13

2.1.1 Body (ADF type) ............... 1-13

2.1.2 Body (copyboard type) ...... 1-14

2.1.3 ADF (if equipped with ADF

functions) ........................... 1-16

2.2 Cross Section ........................... 1-17

2.2.1 Body .................................. 1-17

2.2.2 ADF (if equipped with ADF

functions) ........................... 1-18

3 Safety and Warnings.......................... 1-19

3.1

3.1.1 Safety of the Laser Scanner

3.1.2 CDRH Requirements ......... 1-19

3.1.3 Handling the Laser Scanner

3.2 Safety of the Toner ................... 1-21

3.3 Storing and Handling the

3.3.1 Storing a Cartridge Before

3.3.2 Storing or Handling the

3.3.2.1 Storing After Unpacking1-22

3.3.2.2 Points to Note When

Safety of Laser Light .......... 1-19

Unit .................................... 1-19

Unit .................................... 1-20

Cartridge ................................... 1-21

Unpacking .......................... 1-21

Cartridge After Unpacking . 1-22

Handling the Cartridge .. 1-23

CHAPTER 2 USING THE MACHINE

1 Using the Machine.............................. 2-1

1.1 Control Panel ............................. 2-1

2 User Mode .......................................... 2- 5

2.1 User Mode Menu ....................... 2-5

2.2 User Report .............................. 2-18

2.2.1 Manually Generating a

Report ................................ 2-18

2.2.2 Automatically Generating

Reports (if equipped with fax

functions) ........................... 2-19

2.2.2.1 Memory Clear List ........ 2-20

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

3 Service Mode .................................... 2-21

3.1 Outline ...................................... 2-21

3.2 Using Service Mode ................. 2-23

3.3 List of Service Mode Menus .... 2-24

3.4 Bit Switch Settings

(#1 SSSW) ............................... 2-32

3.5 Menu Switch Settings

(#2 MENU) .............................. 2-45

3.6 Numeric Parameter Setting

(#3 NUMERIC Param.) ........... 2-47

3.7 SPECIAL Setting

(#4A SPECIAL) ...................... 2-50

3.8 NCU Setting (#4B NCU) ......... 2-50

v

CONTENTS

3.9 ISDN Setting (#4C ISDN) ....... 2-50

3.10 Country/Region of Installation

(#5 TYPE) ................................ 2-50

3.11 Setting the Original Reading

Functions (#6 SCANNER) ...... 2-51

3.12 Setting the Printer Parameters

(#7 PRINTER) ......................... 2-52

3.12.1 #1 SSSW Setting ............... 2-52

3.12.2 #2 NUMERIC Param.

Setting ................................ 2-53

3.12.3 #3 PRINT COUNT ........... 2-53

3.12.4 #4 PRINT RESET ............. 2-53

3.12.5 #5 MLT CLEANING ........ 2-53

3.13 PDL (#8 PDL) ......................... 2-53

3.14 Counter (#9 COUNTER) ......... 2-54

3.14.1 Counter .............................. 2-54

3.14.2 Clearing the Counter

Readings ............................ 2-55

3.15 Generating a Report

(#10 REPORT) ......................... 2-55

3.16 Downloading

(#11 DOWNLOAD) ................ 2-55

3.17 Clearing (#12 CLEAR) ............ 2-56

3.18 ROM Indication (#13 ROM) ... 2-56

3.19 Resetting the Contact Sensor

Position (#14 CS SET) ............. 2-56

3.20 Service Mode Default Setting ... 2-57

3.21 Test Mode (TEST MODE) ....... 2-67

3.21.1 Outline ............................... 2-67

3.21.2 List of Test Mode Items ..... 2-68

3.21.3 D-RAM Test (1: DRAM) .. 2-75

3.21.4 CCD Test (2: CCD TEST) . 2-76

3.21.5 PRINT Test (3: PRINT) ..... 2-77

3.21.6 MODEM NCU Test

(4: MODEM NCU) ........... 2-78

3.21.6.1 Relay T est...................... 2-78

3.21.6.2 Frequency Test .............. 2-79

3.21.6.3 G3 Signal Transmission

Test................................ 2-79

3.21.6.4 DTMF Signal Transmission

Test................................ 2-80

3.21.6.5 T onal/DTMF Signal

Reception T est ............... 2-80

3.21.7 AGING Test

(5: AGING TEST) ............. 2-81

3.21.8 FACULTY (function) Test

(6: FACULTY TEST) ........ 2-81

3.21.9 BOOK Read Test

(8: BOOK TEST) .............. 2-87

3.22 Service Report .......................... 2-88

3.22.1 Manually Generating

Reports ............................... 2-88

3.22.1.1 SYSTEM (SERVICE)

DATA LIST .................. 2-88

3.22.1.2 SYSTEM DUMP

LIST .............................. 2-89

3.22.1.3 KEY HISTORY

REPORT ....................... 2-91

3.22.1.4 COUNTER REPORT ... 2-92

3.22.1.5 PRINT SPEC

REPORT ....................... 2-93

3.22.2 Automatically Generated

Reports ............................... 2-93

3.22.2.1 Error TX Report

(for service) ................... 2-94

3.22.2.2 RX Report (for service) 2-95

CHAPTER 3 INSTALLATION

1 Selecting the Site ................................ 3-1

2 Unpacking and Installing the

Machine .............................................. 3-2

2.1 Before Starting ........................... 3-2

2.2 Installation Procedure ................3-2

2.3 Unpacking .................................. 3-3

2.4 Fitting the Cartridge................... 3-5

vi

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

2.5 Putting Paper in the Cassette ..... 3 -7

2.6 Putting Paper in the Manual

Feed Tray ...................................3-8

2.7 Connecting the Interface Cable.. 3-9

2.8 Connecting the Modular Cable

(if equipped with fax functions) 3-9

2.9 Connecting the Power Cord..... 3-10

CONTENTS

2.10 Fitting the Delivery Tray.......... 3-10

2.11 Checking the Copy Images ...... 3-10

2.12 Setting the Printer Functions ... 3-11

2.13 Setting Fax Functions (if equipped

with fax functions) ................... 3-12

CHAPTER 4 OPERATION

1 Basic Operation .................................. 4-1

1.1 Reproduction Processes ............. 4 -1

1.1.1 Outline ................................. 4-1

1.2 Functional Construction ............ 4-4

1.3 Outline of the Electrical

Circuitry ..................................... 4-5

1.3.1 Functional Block Diagram .. 4 -5

1.3.2 Outlines of Functions .......... 4-6

1.3.2.1 Image Processor PCB ..... 4-6

1.3.2.2 DC Controller PCB ........ 4-7

1.3.2.3 Control Panel PCB ......... 4-8

1.3.2.4 Power Supply PCB ......... 4-8

1.3.2.5 Analog Processor PCB ... 4-9

1.3.2.6 Sensor PCB..................... 4-9

1.3.2.7 Laser Driver/BD PCB..... 4-9

1.3.2.8 Main Motor/Scanner

Motor Driver ................... 4-9

1.3.2.9 Printer Controller PCB .... 4-9

1.3.2.10 NCU PCB (if equipped

with fax functions) ........ 4-10

1.3.2.11 Modular Jack PCB

(if equipped with fax

functions) ...................... 4-10

1.4 Power-On Sequence ................. 4-11

1.5 Controlling the Main Motor .... 4-12

1.5.1 Outline ............................... 4-12

2 Image Reading/Processing System... 4-13

2.1 Outline ..................................... 4-13

3 Laser Exposure System .................... 4-14

3.1 Outline ..................................... 4-14

4 Image Formation System .................. 4-16

4.1 Outline ..................................... 4-16

5 Pickup/Feeding/Delivery System .....4-17

5.1 Outline ..................................... 4-17

2.13.1 Setting the Date/Time

(user mode) ........................ 3-12

2.13.2 Setting the Dial T ype .......... 3-13

2.13.3 Executing Communications

T esting ................................ 3-13

3 When Relocating the Machine ........... 3-14

5.2 Pickup Operation ...................... 4-18

5.2.1 Pickup from the Cassette .... 4-18

5.2.1.1 Outline .......................... 4-18

5.2.1.2 Retry Pickup ................. 4-19

5.2.1.3 Detecting the Size of

Paper ............................. 4-19

5.2.2 Pickup from the Manual

Feed Tray ........................... 4-20

5.2.2.1 Outline ..........................4-20

5.2.2.2 Retry Pickup ................. 4-21

5.2.2.3 Detecting the Size of

Paper ............................. 4-21

5.3 Feeding Operation/Delivery

Operation ................................. 4-22

5.3.1 Outline ............................... 4-22

5.3.2 Auto Delivery Control ....... 4-22

5.4 Reducing the Copying Speed .. 4-23

5.4.1 Outline ............................... 4-23

5.5 Detecting Jams ......................... 4-24

5.5.1 Outline ............................... 4-24

5.5.2 Types of Jams .................... 4-24

6 Fixing System ................................... 4-26

6.1 Outline ..................................... 4-26

6.2 Controlling the Fixing

Operation ................................. 4-27

6.2.1 Controlling the Fixing

Temperature .......................4-27

6.2.2 Controlling the Fixing

Film Bias ............................ 4-29

6.2.3 Fixing Heater Safety

Mechanism......................... 4-29

6.2.4 Detecting a Fault in the

Fixing Assembly ................ 4-29

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

vii

CONTENTS

7 Power Supply System ....................... 4-31

7.1 Low Voltage Circuit .................. 4-31

7.1.1 Low Voltage Power Supply

Circuit ................................ 4-31

7.1.2 Protective Functions .......... 4-33

7.2 High-Voltage Power Supply

Circuit ...................................... 4-33

7.3 Controlling the ESS

Mechanism ............................... 4-33

7.3.1 Outline ............................... 4-33

7.3.2 Operation ........................... 4-33

8 Others................................................ 4-34

8.1 Fan ........................................... 4-34

8.1.1 Outline ............................... 4-34

8.2 Back-Up Batteries .................... 4-35

8.2.1 Back-Up Function ............. 4-35

8.2.1.1 Outline ..........................4-35

8.2.1.2 Lithium Battery

(BAT1) .......................... 4-35

8.2.1.3 Vanadium Lithium

Secondary Battery

(BAT2) .......................... 4-37

8.2.2 Back-Up Data .................... 4-38

8.2.2.1 Types of Data................ 4-38

8.2.2.2 Printing the Backup Data

List ................................ 4-40

9 ADF (if equipped with ADF

functions) .......................................... 4-41

9.1 Outline ..................................... 4-41

9.2 Picking Up and Moving

Originals................................... 4-42

9.2.1 Outline ............................... 4-42

9.2.2 Moving Down the Original

Pickup Roller and Moving Up

the Original Stopper .......... 4-43

9.3 Detecting an Original Jam ....... 4-44

9.3.1 Outline ............................... 4-44

9.3.2 Types of Jams .................... 4-44

CHAPTER 5 MECHANICAL SYSTEM

1 Points to Note When Disassembling/As-

sembling the Machine......................... 5-1

2 Disassembly ........................................ 5-3

2.1 Externals/Auxiliary System ....... 5-3

2.1.1 External Covers ................... 5 -3

2.1.1.1 Removing the Left Cover/

Rear Cover ........................... 5-4

2.1.1.2 Removing the Right

Cover .............................. 5-4

2.1.1.3 Removing the Front

Cover .............................. 5-5

2.1.1.4 Removing the Delivery

Cover .............................. 5-5

2.1.1.5 Removing the Delivery

Upper Cover/Delivery

Rear Cover ...................... 5-6

2.1.1.6 Removing the Cartridge

Cover .............................. 5-6

2.1.1.7 Removing the Upper

Cover .............................. 5-7

2.1.1.8 Removing the Right

Door................................ 5-8

2.1.2 Removing the Control

Panel .................................... 5-8

2.1.3 Removing the Copyboard

Glass .................................. 5-10

2.1.4 Removing the Main Motor

Unit .................................... 5-10

2.1.5 Remove the Fan ................. 5-14

2.1.6 Removing the Reader Unit

Slide Detecting Switch ......5-16

2.2 PCBs ........................................ 5-17

2.2.1 Removing the Image

Processor PCB ................... 5-17

2.2.2 Removing the Analog

Processor PCB ................... 5-17

2.2.3 Removing the Sensor

PCB.................................... 5-20

2.2.4 Removing the DC Controller

PCB/Power Supply PCB ... 5-21

2.2.5 Removing the Printer

Controller PCB .................. 5-25

viii

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

CONTENTS

2.2.6 Removing the NCU PCB

(if equipped with fax

functions) ........................... 5-25

2.2.7 Removing the Modular Jack

PCB.................................... 5-26

2.3 Original Reading/Processing

System ...................................... 5-27

2.3.1 Removing the Contact

Sensor ................................ 5-27

2.3.2 Removing the Reader Motor

Drive Unit .......................... 5-28

2.3.3 Removing the Reader

Unit .................................... 5-30

2.4 Laser Exposure System............ 5-32

2.4.1 Removing the Laser Scanner

Unit .................................... 5-32

2.5 Image Formation System ......... 5-34

2.5.1Removing the Transfer Charging

Roller ....................................... 5-34

2.6 Pickup/Feeding System ........... 5-35

2.6.1 Removing the Cassette

Pickup Roller ..................... 5-35

2.6.2 Removing the Cassette

Pickup Solenoid ................. 5-37

2.6.3 Removing the Manual Feed

Tray (upper) ....................... 5-39

2.6.4 Removing the Manual Feed

Tray (lower) ....................... 5-39

2.6.5 Removing the Manual Feed

Pickup Roller ..................... 5-40

2.6.6 Removing the Separation

Pad ..................................... 5-41

2.6.7 Removing the Manual Feed

Pickup Solenoid/Manual

Feed Tray Paper Sensor ..... 5-41

2.6.8 Removing the Vertical Path

Roller ................................. 5-42

2.6.9 Removing the Registration

Roller Unit ......................... 5-45

2.7 Fixing System .......................... 5-47

2.7.1 Removing the Fixing

Assembly ........................... 5-47

2.7.2 Removing the Fixing Film Unit/

Fixing Pressure Roller ....... 5-49

2.7.3 Removing the Delivery

Sensor ................................ 5-50

2.8 ADF System (if equipped with

ADF functions) ........................ 5-51

2.8.1 Externals/Auxiliary Control

System ............................... 5-51

2.8.1.1 Removing the ADF ....... 5-51

2.8.1.2 Removing the ADF

Drive Unit ..................... 5-53

2.8.1.3 Removing the ADF

Motor Unit .................... 5-54

2.8.1.4 Removing the Slide Guide

(front, rear).................... 5-55

2.8.1.5 Mounting the Slide Guide

(front, rear).................... 5-56

2.8.2 Pickup System ................... 5-57

2.8.2.1 Removing the Separation

Roller Unit .................... 5-57

2.8.2.2 Removing the Original

Pickup roller/Original

Separation roller ............ 5-59

2.8.2.3 Removing the Original

Sensor/Registration

Sensor ........................... 5-59

2.8.2.4 Removing the Separation

Pad ................................ 5-60

2.8.2.5 Removing the ADF

Registration Roller ........ 5-61

2.8.3 Feeding System .................. 5-63

2.8.3.1 Removing the White

Roller ............................ 5-63

2.8.3.2 Removing the Feeding

Outside Guide ............... 5-64

2.8.3.3 Removing the Feed

Roll ............................... 5-65

2.8.3.4 Removing the Original

Feed Roller .................... 5-66

2.8.4 Delivery System ............ 5-67

2.8.4.1 Removing the Delivery

Stacking Tray/Original

Delivery Roller .............. 5-67

2.8.4.2 Removing the Original

Delivery Sensor ............ 5-68

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

ix

CONTENTS

CHAPTER 6 MAINTENANCE AND INSPECTION

1 Periodically Replaced Parts ................ 6 -1

2 Durables .............................................. 6-1

3 Scheduled Servicing Chart ................. 6-1

4 Cleaning .............................................. 6-2

4.1 Cleaning by the User

(machine) ................................... 6-2

4.1.1 Cleaning the Fixing Pressure

Roller ................................... 6-2

4.1.2 Other Cleaning..................... 6-2

4.2 Cleaning by the User (ADF)...... 6-3

4.2.1 Cleaning the White Roller ... 6-3

4.2.2 Other Cleaning..................... 6-3

4.3 Cleaning at Time of a Service

V isit (machine) ........................... 6-4

4.3.1 Selfoc Lens Array of the

Contact Sensor..................... 6-4

4.3.2 Cassette Pickup Roller......... 6-5

4.3.3 Manual Feed Pickup

Roller ................................... 6-5

4.3.4 Separation Pad ..................... 6-5

4.3.5 Registration Roller ............... 6-5

4.3.6 Transfer Guide ..................... 6-5

4.3.7 Transfer Charging Roller ..... 6-5

4.3.8 Separation Static

Eliminator ............................ 6-5

4.3.9 Paper Path ............................ 6-5

4.3.10 Fixing Inlet Guide ............... 6-5

4.3.11 Fixing Pressure Roller ......... 6-5

4.3.12 Delivery Roller .................... 6-6

4.3.13 Back of Copyboard Glass

(Back of Shading Plate)....... 6-6

4.4 Cleaning at Time of a Service

Visit (ADF) ................................ 6-7

4.4.1 Original Pickup Roller......... 6-7

4.4.2 Original Separation Roller... 6-7

4.4.3 Original Separation Pad ....... 6-7

4.4.4 ADF Registration Roller...... 6-7

4.4.5 Original Feed Roller ............ 6-7

4.4.6 Original Delivery Roller ...... 6-7

4.4.7 Copyboard Glass

(Original Reading Area) ...... 6-8

CHAPTER 7 TROUBLESHOOTING

1 Standards and Adjustments ................. 7-1

1.1 Checking Against the Standards 7- 1

1.1.1 Checking the Pressure (nip) of

the Fixing Pressure Roller ... 7-1

1.2 Making Adjustments .................. 7-3

1.2.1 Making Adjustments When

Replacing Major Parts .......... 7-3

1.2.2 Preparing a T est Sheet for

Adjustment ........................... 7-4

1.2.3 Adjusting the Mechanical

Systems ................................ 7-5

1.2.4 Adjusting the Electrical

Systems ................................ 7-5

1.2.4.1 Contact Sensor LED Inten-

sity Auto Adjustment ...... 7-5

1.2.4.2 Leading Edge Read Start

Position Adjustment ........ 7-6

1.2.4.3 Left/Right Edge Read Start

1.3 Making Adjustments (ADF) ...... 7-8

1.3.1 Items of Adjustment and

Sequence of Work ................ 7-8

1.3.2 Preparing a T est Sheet for

Adjustment ........................... 7-8

1.3.3 Adjusting the Mechanical

Systems ................................ 7-9

1.3.3.1 Removing the Skew ........ 7-9

1.3.3.2 Left/Right Registration

1.3.4 Adjusting the Electrical

Systems .............................. 7-12

1.3.4.1 Registration Arch Auto

1.3.4.2 Original Read Position

Position Adjustment ....... 7-7

Adjustment .................... 7-10

Adjustment .................... 7-12

Adjustment .................... 7-12

x

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

CONTENTS

1.3.4.3 Original Speed

Adjustment ................... 7-13

1.3.4.4 Leading Edge Read Start

Position Adjustment ..... 7-14

1.3.4.5 Trailing Edge Read End

Position Adjustment ..... 7-15

1.4 When Replacing a Component 7-16

1.4.1 When Replacing the Image

Processor PCB ................... 7-16

1.4.1.1 Before Starting the

Work ............................. 7-16

1.4.1.2 After Finishing the

Work ............................. 7-17

1.4.2 When Replacing the

NCU PCB .......................... 7-17

2. Troubleshooting................................ 7-18

2.1 Making Initial Checks.............. 7-18

2.1.1 Site Environment ............... 7-18

2.1.2 Checking the Cartridge...... 7-18

2.1.3 Checking the Paper............ 7-18

2.1.4 Others ................................ 7-18

2.2 Troubleshooting Flow Chart .... 7-19

2.3 Making Checks in Response

to an Image Fault ...................... 7-20

2.3.1 Checking the Originals Against

the Symptom...................... 7-20

2.3.2 Copyboard Glass and White

Sheet .................................. 7-20

3 Troubleshooting Image Faults .......... 7-21

3.1 Troubleshooting Procedure for

Image Faults............................. 7-21

3.1.1 The output is too light. ...... 7-22

3.1.2 The output is too dark........ 7-24

3.1.3 The output is foggy

vertically. ........................... 7-25

3.1.4 The output has fuzzy, black

vertical lines. ...................... 7-25

3.1.5 The output is foggy

horizontally . ....................... 7-26

3.1.6 The output has fuzzy, black

horizontal lines. ................. 7-26

3.1.7 The output has black lines

(vertical)............................. 7-27

3.1.8 The output has black lines

(horizontal). .......................7-27

3.1.9 The output has white spots

(vertical)............................. 7-27

3.1.10 The output has white lines

(vertical)............................. 7-27

3.1.11 The output has white spots

(horizontal). .......................7-28

3.1.12 The output has white lines

(horizontal). .......................7-28

3.1.13 The output is soiled. .......... 7-29

3.1.14 The back of the output is

soiled.................................. 7-30

3.1.15 The output has a fixing

fault. ................................... 7-31

3.1.16 The output has left/right

displacement. ..................... 7-32

3.1.17 The output has a blurry

image. ................................ 7-32

3.1.18 The output has poor sharpness

(out of focus). .................... 7-33

3.1.19 The output is blank. ........... 7-34

3.1.20 The output is solid black. .. 7-36

4 Troubleshooting Malfunctions ......... 7-37

4.1 Troubleshooting Malfunctions

(service error)........................... 7-37

4.2 Troubleshooting Malfunctions

(other than service error) ......... 7-41

4.2.1 Power is absent. ................. 7-41

4.2.2 The LCD fails to operate. .. 7-41

4.2.3 The contact sensor fails to

move. ................................. 7-42

4.2.4 The contact sensor LED fails

to go ON. ........................... 7-42

4.2.5 The speaker fails to generate

sound. ................................ 7-43

4.2.6 The message “INSTALL

CARTRIDGE” fails to go

OFF. ................................... 7-43

4.2.7 The message “SUPPLY REC.

PAPER” fails to go OFF.

(cassette) ............................ 7-44

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

xi

CONTENTS

4.2.8 The message “SUPPLY REC.

PAPER” fails to go OFF.

(manual feed tray).............. 7-44

4.2.9 The message “REC. PAPER

JAM” fails to go OFF......... 7-45

4.2.10 The message “PLATEN IS

OPEN CLOSE THE PLATEN”

fails to go OFF. .................. 7-46

4.3 Troubleshooting Malfunctions

(if equipped with ADF

functions) ................................. 7-47

4.3.1 Original pickup fails. ......... 7-47

4.4 Troubleshooting Malfunctions

(printer functions) .................... 7-48

4.4.1 Printing fails to start ..........7-48

4.4.2 Printing stops in the

middle ................................ 7-48

4.5 Troubleshooting

(faults unique to models equipped

with fax functions) ................... 7-50

4.5.1 Troubleshooting

Communication Faults ....... 7-50

4.5.2 Service Error Code

Output ................................ 7-52

4.5.3 Error Codes........................ 7-52

4.5.3.1 Transmission Level (ATT):

No.07 of Service Soft Switch

#2 MENU ..................... 7-52

4.5.3.2 NL Equalizer: No.05 of

Service Soft Switch #2

MENU .......................... 7-52

4.5.3.3 Transmission Page Timer:

SW12 of Service Soft Switch

#1 SSSW....................... 7-52

4.5.3.4 T0 Timer: No.10 of Service

Soft Switch #3 NUMERIC

param. ........................... 7-52

4.5.3.5 T1 Timer: No.11 of Service

Soft Switch #3 NUMERIC

param. ........................... 7-53

4.5.3.6 RTN Signal Transmission

Condition: No. 02, 03, and

04 of Service Soft Switch #3

NUMERIC param......... 7-53

4.5.3.7 Echo Remedy ................ 7-53

4.5.3.8 Echo Protect T one: SW03

bit 1 of Service Soft

Switch #1 SSSW .......... 7-53

4.5.3.9 Number of Final Flag

Sequences: SW04 bit 2 of

Service Soft Switch #1

SSSW............................ 7-53

4.5.3.10 Subaddress .................... 7-54

4.5.3.11 Password ....................... 7-54

4.5.3.12 Signals .......................... 7-54

4.5.3.13 Timer............................. 7-55

4.5.4 How to Record the

Protocol .............................. 7-56

4.5.5 Causes and Remedies for User

Error Codes........................ 7-57

4.5.6 Causes and Remedies for

Service Error Codes........... 7-62

4.5.7 Common Faults ................. 7-82

5 Troubleshooting Feeding Faults ....... 7-83

5.1 Outline ..................................... 7-83

5.2 Paper Jams ............................... 7-84

5.2.1 Pickup Assembly

(cassette) ............................ 7-84

5.2.2 Pickup Assembly (manual feed

tray).................................... 7-86

5.2.3 Feeding Assembly ............. 7-88

5.2.4 Fixing Delivery

Assembly ........................... 7-90

5.2.5 Checking the Rotation of the

Rollers and Gears .............. 7-91

5.2.5.1 Checking the Rotation of the

Cassette Pickup Roller and

the Vertical Path

Roller ............................ 7-91

5.2.5.2 Checking the Rotation of the

Registration Roller and the

Gear for the Photosensitive

Drum ............................. 7-91

5.3 Original Jams (if equipped with

ADF functions) ........................ 7-92

5.4 Feeding Faults.......................... 7-93

5.4.1 Double Feeding ................. 7-93

5.4.2 Wrinkles ............................. 7-94

xii

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

CONTENTS

5.5 Faulty Feeding of Originals

(if equipped with ADF

functions) ................................. 7-95

5.5.1 Double Feeding ................. 7-95

5.5.2 Skew .................................. 7-95

6 Arrangement of the Electrical Parts.. 7-96

6.1 Checking the

Photointerrupters...................... 7-96

6.2 Arrangement and Functions of

Electrical Components ............. 7-98

6.2.1 Solenoids, Motors, Fans .... 7-98

6.2.1.1 Body ............................. 7-98

6.2.1.2 ADF (if equiped with ADF

functions) ...................... 7-99

APPENDIX

1 General Timing Chart ........................ A-1

2 General Circuit Diagram.................... A-3

3 List of Special Tools .......................... A-5

4 List of Solvents and Oils ................... A-6

6.2.2 Sensors............................. 7-100

6.2.2.1 Body ...........................7-100

6.2.2.2 ADF (if equiped with ADF

functions) .................... 7-101

6.2.3 Others .............................. 7-102

6.2.4 PCBs ................................ 7-104

6.3 Variable Resistors, Light Emitting

Diodes (LED), and Check Pins by

PCB ........................................ 7-106

6.3.1 Image Processor PCB ...... 7-106

6.3.2 DC Controller PCB ......... 7-107

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

xiii

CHAPTER 1

PRODUCT OUTLINE

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

1 Specifications

1.1 T yp e

CHAPTER 1 PRODUCT OUTLINE

Item

Body

Copyboard glass

Light source

Lens

Photosensitive medium

1.2 Mechanisms

Item

Reproduction

Charging

Exposure

Copy density adjustment

Development

Pickup

Transfer

Separate

Cleaning

Fixing

Specifications

Desk top (ADF standard type, copyboard standard type)

Fixed

LED

CIS (contact sensor)

OPC drum (30-mm dia.)

Specifications

Indirect electrostatic

Roller contact

Semiconductor laser

Auto or manual

Dry, 1-component toner projection

Cassette: 1 cassette

Multifeeder: 1 feeder

Roller transfer

Static (static eliminator) + curvature

Rubber blade

SURF (on-demand)

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

1-1

CHAPTER 1 PRODUCT OUTLINE

1.3 Functions

Item

Original type

Maximum original size

Reproduction ratio

Direct

Reduce I

Reduce II

Enlarge I

Enlarge II

Zoom

Wait time

First copy time

Continuous reproduction

Reproduction size

250-sheet cassette

Manual feed tray

Paper type

250-sheet cassette

Manual feed tray

Cassette

Manual feed tray capacity

Delivery tray capacity

Non-image width

Specifications

Sheet, book, 3-D object (2 kg max.)

A4 (297 × 210 mm / 11.7" × 8.3"), LGL (356 × 216 mm / 14.0" × 8.5")

2R2E

1:1.000

1:0.500

1:0.707

1:1.414

1:2.000

50% to 200% (1% increments)

8.5 sec (after plug in) / 1.0 sec (after pressing Energy Saver key)

21.5 sec (after plug in)

18 sec (after pressing Energy Saver key)

99 pages max.

A4

Width: 76.2 to 216 mm (3.0" to 8.5")

Length: 127 to 356 mm (5.0" to 14.0")

Weight: 56 to 128 g/m

Plain paper (64 to 80 g/m2)

Transparency, label, tracing paper, postcard, thick paper (to 128

2

), envelope

g/m

Claw separation, front loading

10 mm deep, (about 100 sheets of 80 g/m

100 sheets max.

Leading edge: 3.0 ± 2.0 mm (0.12" ± 0.08"), left/right edge: 2.5 ±

1.5 mm (0.10" ± 0.06")

2

2

paper)

1-2

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

CHAPTER 1 PRODUCT OUTLINE

Item

AE

Image mode

Toner save mode

Special mode

Auto power-off

Power save mode

N-on-1

1-on-N memory copy

Auto copy start

Jam recovery

Auto clear

Date/time set

Weekly timer

Toner level detection

Cassette paper level detection

LGL size detection

Specifications

Yes

Yes (text, text/photo, photo)

Yes

Yes: Tracing paper mode, transparency mode, special paper1

mode, special paper2 mode

No

Yes (manually ON/OFF, auto OFF after specific time, auto ON

after fax reception/print data reception)

Yes (in some functions, 2-on-1)

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

1-3

CHAPTER 1 PRODUCT OUTLINE

1.4 Others

Item

Operating environment

Temperature range

Humidity range

Atmospheric pressure

range

Power supply

Serial number

Power consumption

Maximum

Standby

Operation

Noise

Standby

Copying

Ozone

(after 50000 pages)

Dimensions

Width

Depth

Height

Weight

Consumables storage

Paper

Toner

Specifications

0° to 35°C / 32° to 95°F

35% to 85%

0.61 to 1.01 hPa (0.6 to 1 atm)

230V (50/60Hz)

QTJxxxx QTKxxxx TTGxxxx TTHxxxx

UGAxxxx UHAxxxx UIAxxxx ULAxxxx

UUKxxxx UUMxxxx UUUxxxx UUVxxxx

UUWxxxx UUXxxxx UUYxxxx UUZxxxx

780 W or less

16 Wh (approx.; reference only)

280 Wh (approx.; reference only)

Copyboard type: 40 dB or less (impulse mode)

ADF type: 40 dB or less (impulse mode: reference)

Copyboard type: 66 dB or less (fast mode)

ADF type: 69 dB or less (fast mode: reference)

0.05 ppm (Ave.)

Copyboard type: 475 mm (18.7"), ADF type: 475 mm (18.7")

Copyboard type: 442 mm (17.4"), ADF type: 442 mm (17.4")

Copyboard type: 295 mm (11.6"), ADF type: 352 mm (13.9")

Copyboard type: 20.5 kg

ADF type: 22.6 kg

Keep wrapped to avoid humidity.

Avoid direct sunshine, and store between 0° and 35°C / 32°

and 95°F, between 35% and 85%.

1-4

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

1.5 Copying Speed

CHAPTER 1 PRODUCT OUTLINE

Ratio

Size

Paper

size

copies/min

Cassette

Manual

feed tray

Direct

Reduce I (50.0%)

Reduce II (70.7%)

Enlarge I

Enlarge II (200.0%)

(141.4%)

A4 (210 × 297mm / 8.3" × 11.7")

A5 (149 × 210mm / 5.9" × 8.3")

A4R → postcard

A4R → A5R

A5R → A4R

postcard → A4R

A4

A5

postcard

A5

A4

A4

12

-

-

-

12

12

12

13

6

13

12

12

*1: If the manual feed tray is in use, the copying speed is indicated assuming that the paper

size setting is correct.

The machine performs 3-step copying speed reduction control designed to prevent cracking of the fixing heater, otherwise possibly occurring as a result overheating of the ends of

the fixing assembly. (See 5.4 of Chapter 4.)

*1

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

1-5

CHAPTER 1 PRODUCT OUTLINE

1.6 ADF (if equipped with ADF functions)

Items

Pickup

Original type

Original size

Original orientation

Original position

Original processing mode

Original reading

Stack

Mixed original sizes

Original AE detection

Original size recognition

Stamp

Power supply

Operating environment

Specifications

Auto pickup/delivery (top separation by double-pad)

2

Single-sided sheet (50 to 128 g/m

A4R, B5R, A5R, B6, LGL, LTRR, STMTR

Length: 128 to 356 mm (5" to 14"), width: 139 to 216 mm (5.5" to

8.5")

Face-down

Center reference

From single-sided to single-sided

Stream reading

30 sheets or less (if A4/LTR or smaller)

15 sheets or less (if LGL)

Yes (only if of the same paper configuration)

No

No

No

From host (5 VDC and 24 V)

Same as host

)

The machine may not be able to handle the following types of originals:

• original with a carbon back

• original made of multiple layers (pasted, bound)

• original with a cut-off, 5 or more holes, or tear

• original with a clip, adhesive tape, or glue

• original with curling, wrinkling, or appreciable bending

• transparency

Advise the user to remove as much curling as possible, if any, and place the original in the

original tray so that the side with the curling is the trailing edge.

1-6

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

CHAPTER 1 PRODUCT OUTLINE

1.7 FAX (if equipped fax functions)

1.7.1 Communications specifications

Applicable lines

Analog line (one line)

• PSTN (Public Switched Telephone Network)

Transmission method

Half-duplex

Transmission control protocol

ITU-T T.30 binary protocol/ECM protocol

Modulation method

G3 image signals ITU-T V.27ter (2.4kbps, 4.8kbps)

ITU-T V.29 (7.2kbps, 9.6kbps)

ITU-T V.17 (14.4kbps, 12kbps, TC9.6kbps, TC7.2kbps)

G3 procedure signals ITU-T V.21 (No.2) 300bps

Transmission speed

14.4k, 12k, TC9.6k, TC7.2k, 9.6k, 7.2k, 4.8k, 2.4kbps

With automatic fallback function

Coding

MH, MR, MMR, JBIG

Error correction

ITU-T ECM

Canon express protocol

None

Transmission output level

from 0 to -15 dBm

Minimum receive input level

-43 dBm

Modem IC

CONEXANT FM214

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

1-7

CHAPTER 1 PRODUCT OUTLINE

1.7.2 Scanner section specifications

Scanning method

Contact sensor scanning method

Scanning line density

Horizontal:

Standard/Fine/Superfine 203.2 dpi (8 dots/mm)

Ultrafine 406.4 dpi (16 dots/mm) (Interpolated)

Vertical:

Standard 97.79 dpi (3.85 lines/mm)

Fine 195.58 dpi (7.7 lines/mm)

Superfine/Ultrafine 391.16 dpi (15.4 lines/mm)

Scanning density adjustment

Light, Standard, Dark: The density level of each mode can be selected

by the user mode menu.

Half tone

64-gradation error diffusion system

1.7.3 Printer section specifications

Printing resolution

600dpi × 600dpi

Reduction for reception

Fixed reduction (75%, 90%, 95%, 97%)

Auto reduction (70~100%)

1-8

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

1.7.4 Functions

ST AMP

None

FAX/TEL switching

Method CNG detection

Message None

Pseudo CI None

Answering machine connection

Yes (Telephone answering pr iority type)

CNG detection

DPRD

Yes

CHAPTER 1 PRODUCT OUTLINE

Polling

Polling transmission

None

Polling reception

Receives from a fax in automatic transmission mode

One touch locations Max. 12

Confidential reception

None

Confidential transmission

None

Remote reception

Method ID call# (ID input method)

Remote ID (with ID call#) 2 digits (Default : 25)

Memory reception

Yes

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

1-9

CHAPTER 1 PRODUCT OUTLINE

Auto dialing

Telephone number digits Average 39 digits

One-touch dial Max. 12

Coded speed dial Max. 100

Group dial Max. 111 (One-touch : 11, Coded speed dial : 100)

Redial Numeric button redial function (max. 120 digits)

Delayed transmission

Locations Max. 122 (One-touch : 12, Coded speed dial : 100)

Numeric button: 10)

No. of reseruation Max. 20

Broadcast transmission

Locations Max. 122 (One-touch : 12, Coded speed dial : 100)

Numeric button: 10)

Group button addresses Max. 111 (One-touch : 11, Coded speed dial : 100)

Relay broadcasting originating

None

Relay broadcasting

None

Closed network

None

Direct mail prevention

None

Dual access

File No. of reservation Max. 21 files

1-10

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

Activity management

a)User report

Activity report

(Every 20 transactions)

TX/RX report

1-touch spd dial list

Coded speed dial list

Group dial list

Memory clear list

User data list

Multi activity report

Document memory list

b)Service report

System data list

System dump list

Key history report

Counter report

Print spec report

CHAPTER 1 PRODUCT OUTLINE

Transmitting terminal identification

Items Time, telephone No. (max 20 digits), senders ID, address,

number of transmitted pages (max 3 digits)

Address Can be registered with one-touch/ coded speed dial keys

(16 characters)

Senders ID 20 characters (1 name)

Program key

None

Redial

Interval 2 min. (from 2 to 99 min. can be selected in user data)

Count 2 times (from 1 to 10 times can be selected in user data)

Memory backup

Backup contents dial registration data, user data, service data, time

Backup IC 128 Kbyte SRAM

Backup battery Lithium battery 3.0 V DC / 560 mAh

Battery life Approx. 5 years

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

1-11

CHAPTER 1 PRODUCT OUTLINE

Image data backup

Backup contents Memory reception, delayed transmission

and broadcast transmission image data, activity

management report

Backup IC 8 Mbyte SDRAM

Backup coding method JBIG

Backup battery Rechargeable vanadium lithium battery 3.0V DC/ 50 mAh

Battery life 40 cycles with 100% discharge

(Temperature 77°F (25°C))

Time

precision ±60 sec per month

The foregoing specifications are subject to change for product improvement.

1-12

COPYRIGHT

©

2002 CANON INC. 2000 2000 2000 2000 CANON SmartBase PC1210D/1230D/1270D REV . 1 MAR. 2002

Loading...

Loading...