Page 1

Canon® A20

Oasis

Imaging Products Inc. Technical Support (8

00) 322

– 8992

ext 110

Canon

® A

-

20 Cartridge Remanufacturing Instructions

…

1 2

Remanufacturing Instructions

Reference Information:

OEM PN: F41-2302-120

OEM Yield: 3,000 @ 5.5%

Recommended Tools:

Tamperproof Torx® screw bit

Phillips head screwdriver

Pin puller

Flat head screwdriver

Approximate Remanufacturing Time:

20-25 min.

Instructions:

1. Remove the right side end cap (two tamperproof torx style screws -Fig. 1).

2. Remove the shutter actuating arm (Fig. 2).

3. Remove the color wheel (wiggling up, down and out- Fig. 2).

4. Remove the upper shutter spring (small one) and the hopper spring (Fig. 2).

5. Remove the two pins holding the waste bin in place, the one screw holding

the drum axle in, then the drum axle itself (you must hold the upper shutter-

bar flat to get the axle out), then remove the large pin holding the hopper in

place (Fig. 2).

6. Rotate the cartridge to the other end and remove the two pins holding the

waste bin in place and the one pin holding the hopper in place (Fig 3).

7. Remove the waste bin from the cartridge shell. Lift the waste bin by the right

side using a flat head screwdriver and jockey it out by lifting up and to the

right (Fig. 4).

Clean the waste bin.

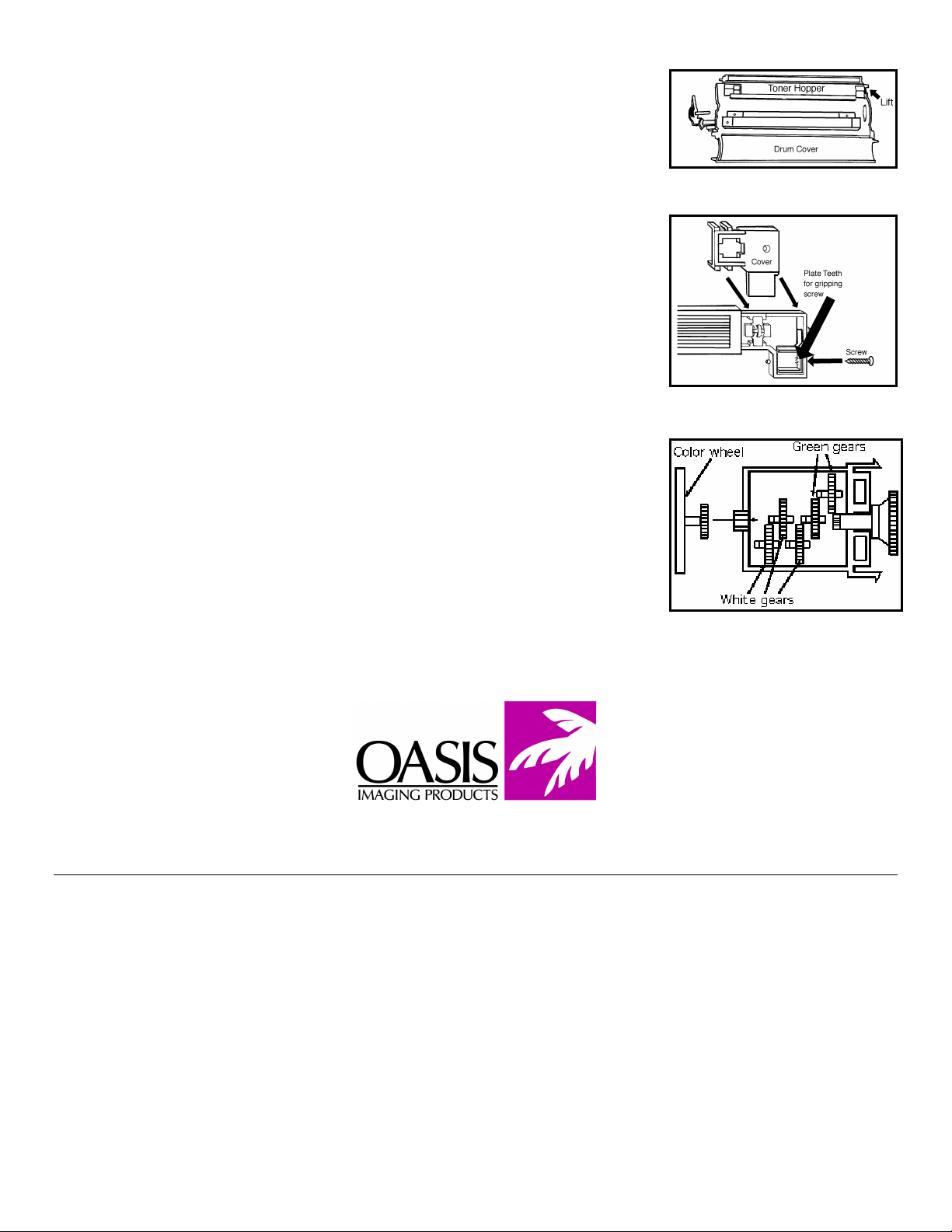

8. Remove the OPC drum. Move the drum cover towards you to expose the

drum and slide the drum to the left and lift out (Fig. 5). Clean, inspect, and

lubricate the drum and store in a dark place. Replace if necessary, if replace ment is required, then perform the following to remove the OEM gears:

a. Grasp the large gear and wiggle it off of the shaft.

d. Rap the rod down onto a hard surface to pop the plug out.

9. Remove the toner hopper from the cartridge shell (Fig. 6).

a. Clean the toner hopper of all old toner.

1. Remove toner hopper plug and dump residual toner.

2. Remove residual toner on the magnetic roller, place a vacuum nozzle

over the toner hopper hole and rotate the roller assembly.

insert the gapping strip between the magnetic roller and doctor blade,

and tighten the doctor blade (2 screws).

4. Recheck the gap to make sure nothing shifted during tightening.

a. Remove the cleaning blade (2 screws). Clean, inspect, and lubricate

the cleaning blade. Replace if necessary.

b. Dump the waste bin toner. Use a vacuum to remove any remaining

toner dust. Note: Be careful not to bend, crimp, tear or damage the

clear plastic strip collection/scavenger blade.

c. Install the cleaning blade.

Figure 4

b. Drill a hole in the end of the metal plug (where the gear was) large

enough for a 1/4” metal dowel to fit through.

c. Slide the metal dowel into the hole and up until it contacts the edge of

the drum plug.

e. Install the gear and plug onto the new drum.

Figure 5

3. Gap the doctor blade to .010”. Loosen the doctor blade (2 screws),

Figure 1

Figure 2

Figure 3

Page 2

b. Insert a toner hoper seal.

c. Fill the toner hopper with toner. Insert toner hopper plug.

9. Remove the corona assembly screw. Remove and clean the corona

assembly (Fig. 7). Pry the corona assembly to the left and lift it out. There

are two industry methods of cleaning this assembly, manual and ultrasonic.

The manual method requires using a Scotchbrite® pad. Use a small piece of

the pad and gently move the pad up and down the length of the wire. The

ultrasonic method requires placing the entire corona assembly in an ultrasonic

Figure 6

cleaner. Note: After removing the corona assembly two or three times, you

need to insure that the contact plate teeth for the corona assembly screw (Fig.

6) have not been spread too far.

11. Clean the shell of the cartridge to remove any toner dust.

12. Install the toner hopper into the cartridge shell (2 plastic pins).

13. Install the OPC drum.

14. Install the toner waste bin (4 plastic pins).

15. Install the smaller spring on the steel shutter and attach the larger toner

Figure 7

hopper spring.

Install drum axle.

17. Install the shutter actuating arm.

18. Install the color wheel. (Note: Make sure to reset the color wheel. Remove

color wheel cover (4 clasps). Lift the gear adjacent to the color wheel, and

turn the color wheel clockwise. Install the adjacent gear and replace cover (Fig 8).

19. Install end cap (2 torx style screws).

Figure 8

Oasis and You … Succeeding Together!

New Hampshire

(603) 880-3991

(800) 322-8992

Fax: (603) 598-4277

Illinois

(800) 322-8992

Fax: (972) 692-6976

© 1998 Oasis Imaging Products, Inc. Any attempt to reproduce any part of these instructions without the written consent of Oasis Imaging

Products, Inc, may result in legal action. All registered trademarks are the property of their respective owners.

Tennessee

(800) 322-8992

Fax: (901) 366-9756

California

(800) 322-8992

Fax: ((714) 908-7788

Texas

(800) 322-8992

Fax: (972) 692-6976

North Carolina

(800) 322-8992

Fax: (603) 386-7575

Canada

(800) 322-8992

Fax: (972) 692-6976

Europe

Netherlands

011-31-24-388-2233

Fax: 011-31-24-355-7373

South America

(800) 322-8992

International:

(603) 880-1552

Fax: (603) 386-7575

Loading...

Loading...