Canon PowerShot A30, PowerShot A40 Service Manual

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, and

repair of the products.

Corrections

This manual could include typographical errors or technical inaccuracies due to improvements or

changes in the products. When changes occur in applicable products or in the content of this manual,

Canon will release service manual report as the need arises. In the event of major changes in the

contents of this manual over a long or short period, Canon may issue new editions of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent

with local law.

Trademarks

The product names and company names described in this manual are the registered trademarks of

the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not

be copied, reproduced, published (including on the World Wide Web) or translated into another

language, in whole or in part, without the written consent of Canon Inc..

Copyright © 2002 by Canon Inc.

CANON INC.

Digital Imaging Products Service Dept.

30-2, Shimomaruko 3-Chome, Ohta-ku,

Tokyo 146-8501, Japan

SAFETY PRECAUTIONS

The following precautions should be observed when servicing.

1. Since many parts in the unit have special safety-related characteristics, always use genuine CANON replacement parts.

Especially critical parts in the power circuit block should not be replaced with other makes.

Critical parts are marked with ! in the schematic diagrams.

2. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or damaged

by the short circuit.

3. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly installed.

4. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

4-1 Leakage Current Cold Check

1) Unplug the AC cord and connect a jumper between the two prongs on the plug.

2) Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each exposed metallic cabinet part

on the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to

the chassis, the reading should be between 1MΩ and 5.2MΩ. When the exposed metal does not have a return path to the

chassis, the reading must be ∞.

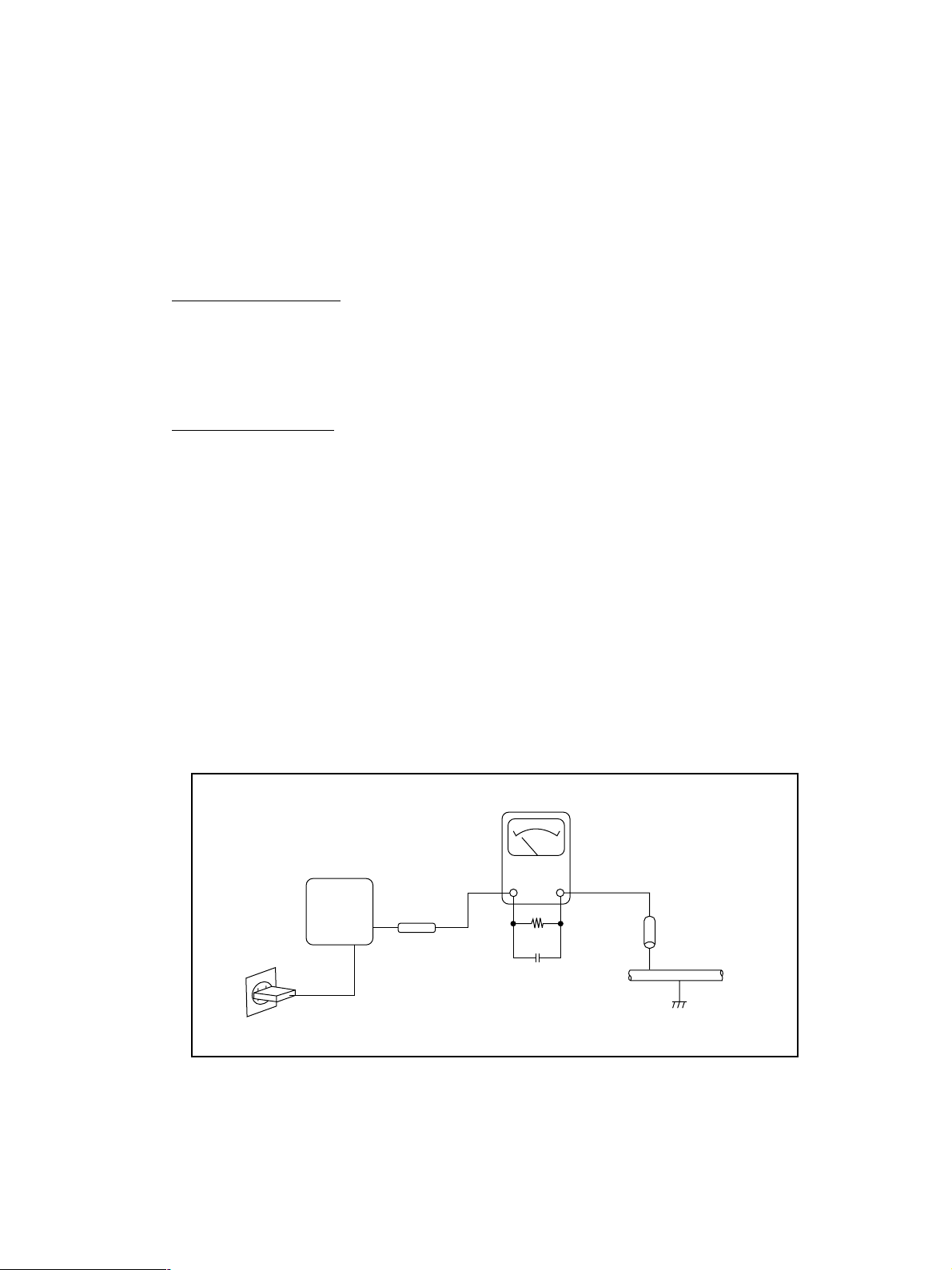

4-2 Leakage Current Hot Check

1) Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2) Connect a 1.5KΩ 10 watt resistor, paralleled by 0.15µF capacitor, between each exposed metallic parts on the unit and a

good earth ground such as a water pipe, as shown in the figure below.

3) Use an AC voltmeter, with 1000Ω/volt or more sensitivity, to measure the potential across the resistor.

4) Check all exposed metallic parts of the cover (Cable connection, Handle bracket, metallic cabinet.

Screwheads, Metallic overlays, etc), and measure the voltage at each point.

5) Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6) The potential at any point should not exceed 0.75V RMS.

A leakage current tester (FLUKE MODEL : 8000A equivalent) may be used to make the hot checks.

Leakage current must not exceed 0.5 milliamp.

In case a measurement is outside of the limits specified, there is a possibility of a shock hazard, and corrective action must

be taken before returning the instrument to the customer.

AC OUTLET

DEVICE

UNDER

TEST

AC VOLTMETER

Test all

exposed

metal parts

Figure. 1 Leakage Current Hot Check

1.5KΩ

0.15µF

Water pipe

(Earth Ground)

CHAPTER 2. TECHNICAL DESCRIPTION

CONTENTS

1. Functions of each unit

1.1 MAIN PCB ASS’Y --------------------------------------------------------------------------------------------------------- 2-1

1.2 DC/DC PCB ASS’Y -------------------------------------------------------------------------------------------------------- 2-1

1.3 FLASH UNIT ---------------------------------------------------------------------------------------------------------------- 2-1

2. Outline of Circuits

2.1 Power Supply Control ------------------------------------------------------------------------------------------------------ 2-2

2.1.1 Power Supply Block Diagram ----------------------------------------------------------------------------------- 2-2

2.1.2 Power Control Sequence ------------------------------------------------------------------------------------------ 2-2

2.2 Signal Processing ------------------------------------------------------------------------------------------------------------ 2-3

2.2.1 System Control ----------------------------------------------------------------------------------------------------- 2-3

2.2.2 Picture Processing ------------------------------------------------------------------------------------------------- 2-4

2.2.3 Audio Processing (During record and playback) -------------------------------------------------------------- 2-4

3. Troubleshooting

3.1 When an Error Code is Displayed ---------------------------------------------------------------------------------------- 2-5

3.2 When a Problem Occurs ---------------------------------------------------------------------------------------------------- 2-7

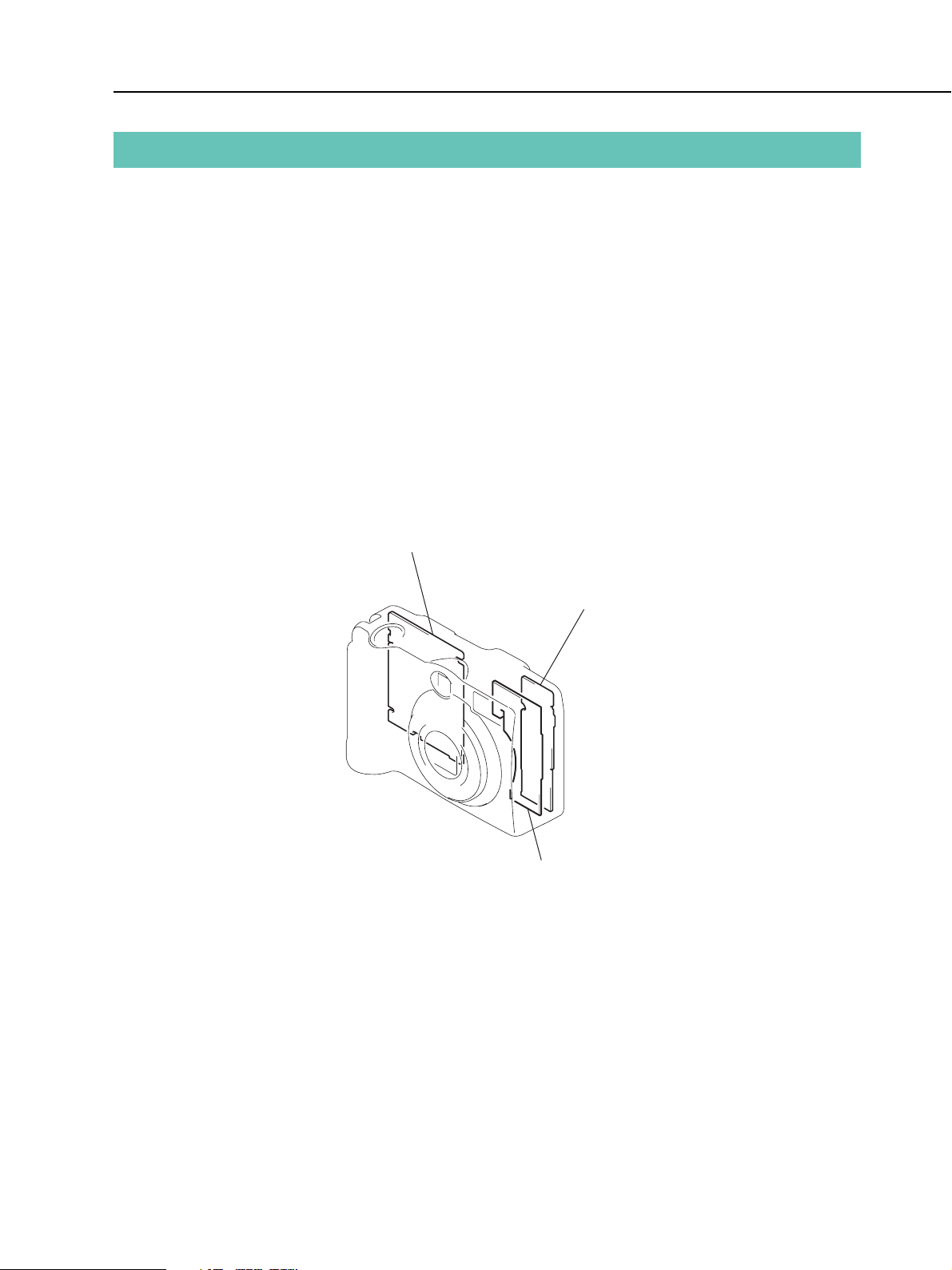

1. Functions of each unit

1.1 MAIN PCB ASS’Y

1) Driving the CCD Sensor.

2) Conversion of the image signal from the analog signal to the digital signal.

3) Controlling the power supply and the system by CPU. (Refer to Sections 2.1 and 2.2.)

4) Image processing, and reading and writing the image signal to and from the CF card using DSP.

(Refer to Section 2.2.2.)

5) LCD drive and amplification of the video and audio output. (A40 model only) (Refer to Section

2.2.3.)

1.2 DC/DC PCB ASS’Y

1) Power supply drive (DC/DC converter).

2) Backlight for LCD drive.

1.3 FLASH UNIT

1) Flash drive and charging circuit for the flash.

CHAPTER 2. TECHNICAL DESCRIPTION

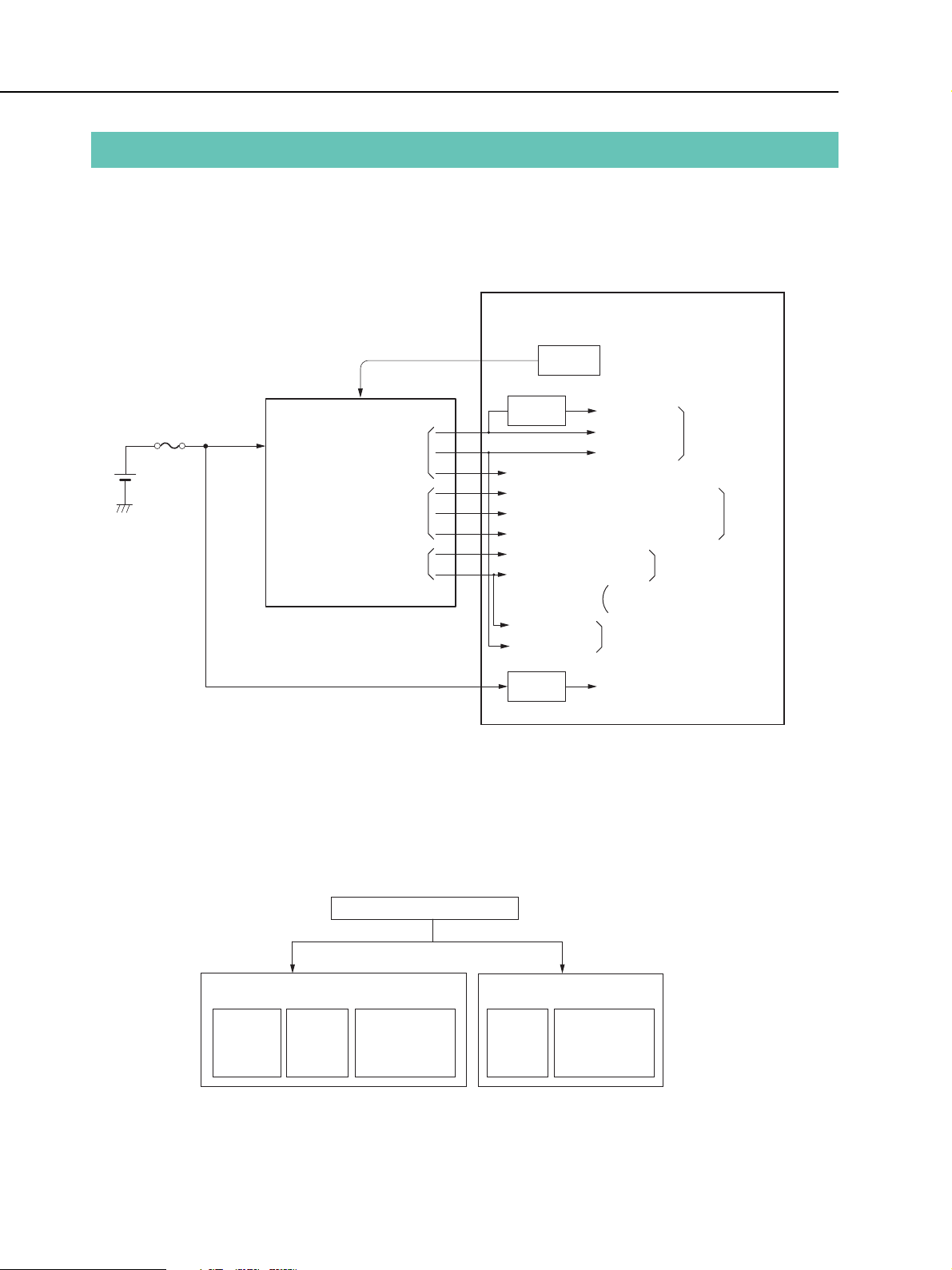

MAIN PCB ASS’Y

Fig. 1

DC/DC PCB ASS’Y

FLASH

UNIT

2-1

CHAPTER 2. TECHNICAL DESCRIPTION

2. Outline of Circuits

2.1 Power Supply Control

The power supply is controlled by the CPU mounted on the main PCB ass’y.

2.1.1 Power Supply Block Diagram

MAIN PCB ASS'Y

BATTERY

or

DC_IN

FUSE

VBATT

E1, E2, E3, E4

DC/DC

CONVERTER

E1

OUTPUT

E2

OUTPUT

E3 or E4

OUTPUT

CPU

REG

VCC1M (3.3V)

VDD2 (15V: A40 / 15.5V: A20 Model)

VEE2 (–7.5V: A40 / –8.0V: A20 Model)

VCC2 (4.2V)

VDD34 (13.5V)

VCC34 (4.2V: E3/5V: E4)

VCC34 (5V)

VCC1A (3.3V)

REG

Fig. 2 Power System Block Diagram

VCC1L (2.5V)

VCC1 (3.3V)

VCC1A (3.3V)

for Motor Drive

for LCD, VIDEO OUT

E3: LCD

E4: Video

for AUDIO OUT

(A40 Model Only)

(3.3V) for RTC

for System Control

for Image

Process

(CCD etc.)

2.1.2 Power Control Sequence

Main Switch ON (E1)

Shooting Mode Playback Mode

LCD OFF

(E2)

LCD ON

(E2, E3)

* A40 Model only

Audio*/Video

out (E2,E4)

2-2

LCD ON

(E3)

Audio*/Video

out (E4)

2.2 Signal Processing

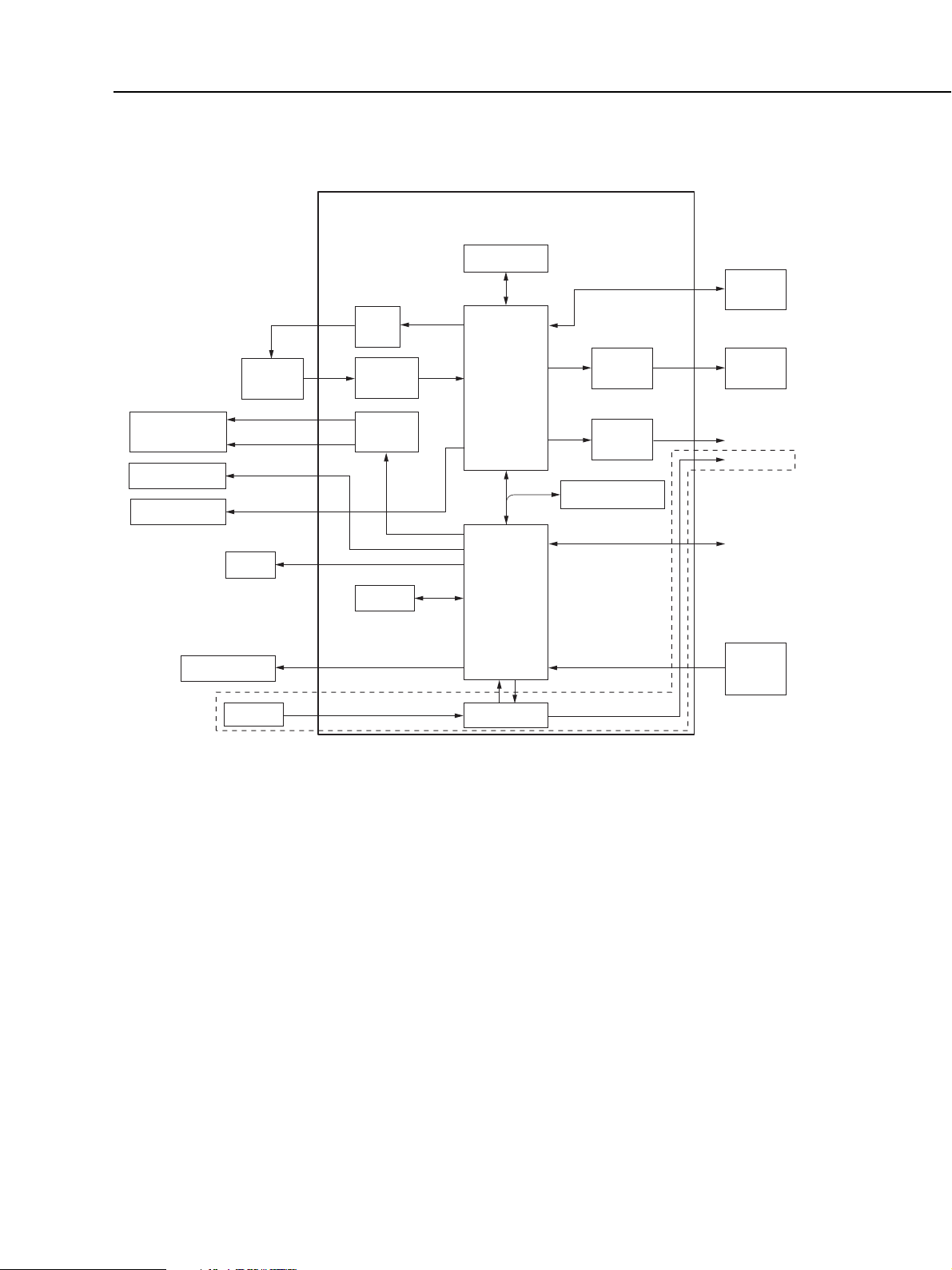

MAIN PCB ASS'Y

CHAPTER 2. TECHNICAL DESCRIPTION

SDRAM

EF LENS

AF Support LED

FINDER LED

Electric FLASH

CCD

Sensor

Buzzer

MIC

(A40 Model Only)

TG

CDS, A/D

Motor

Driver

RTC

HD, VD

CLKDrive Pulse

DSP

CPU

AUDIO AMP

LCD

Driver

Video

Amp

FLASH MEMORY

CF card

LCD

VIDEO OUT

AUDIO OUT

USB

SW

DIAL

KEY

Fig. 3 Signal System Block Diagram

2.2.1 System Control

The CPU on the main PCB ass’y controls the EF lens (motor, shutter), operation switch receiver, USB

communication and flowing circuits.

• TG: Creation of the CCD drive pulse

• CDS, A/D: CCD signal processing and conversion of the digital data

• LCD Driver: Driving the LCD

• FLASH MEMORY: Firmware memory

• DSP: Picture processing

• RTC: Clock count for watch

• AF Support LED: AF auxiliary, self-timer and red-eye protection also serves as a lamp

• Electric Flash: Flash and charging circuit

2-3

CHAPTER 2. TECHNICAL DESCRIPTION

2.2.2 Picture Processing

1) The drive pulse of the CCD sensor is created by both clock from DSP and TG that is operated by

sync. signal.

The picture signal by the drive pulse is output from CCD sensor.

The output signal of the CCD picture is converted to the signal processing and the digital data by

the CDS and A/D converter, and is sent to the DSP.

2) The DSP circuit performs the following signal processing.

• Processes the picture data (using the SDRAM).

• Writes and reads the picture data to and from the CF card.

• Inputs the picture data to the CPU.

• Outputs analog video signal to the LCD and VIDEO OUT.

3) The video signal that is supplied form the DSP is controlled by the LCD driver and is displayed

on the LCD. The video amplifier is activated when the video jack is inserted to the video jack or

AV jack and drives the video signal in 75 Ω.

2.2.3 Audio Processing (During record and playback)

1) During animation recording.

• The microphone audio signal is converted to the digital data by CPU and is recorded.

2) During playback, the data is converted back to the analog audio signal and is output to the AV

jack.

Note: Installed in the A40 model only. (Audio cannot be played back by camera.)

2-4

CHAPTER 2. TECHNICAL DESCRIPTION

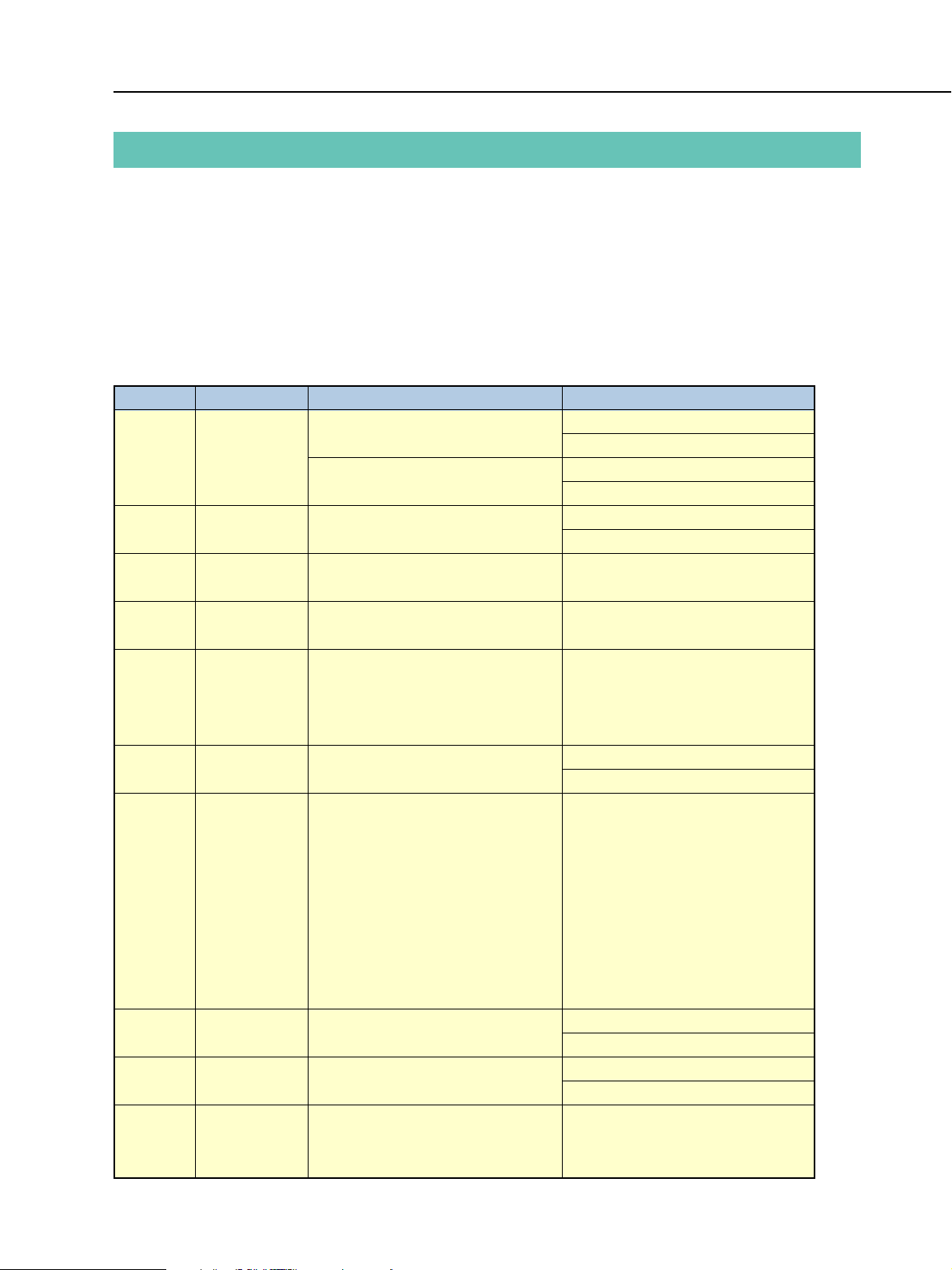

3. Troubleshooting

3.1 When an Error Code is Displayed

[Remedy]

• Check for any abnormalities in the mounting of probable faulty parts or connector connections referring

to the table below.

• Try replacing probable faulty parts referring to the below.

[NOTE]

• The error code is displayed on the LCD Monitor.

• Adjustments must be performed after the part has been replaced. For details, see the chapter of

“Adjustments”.

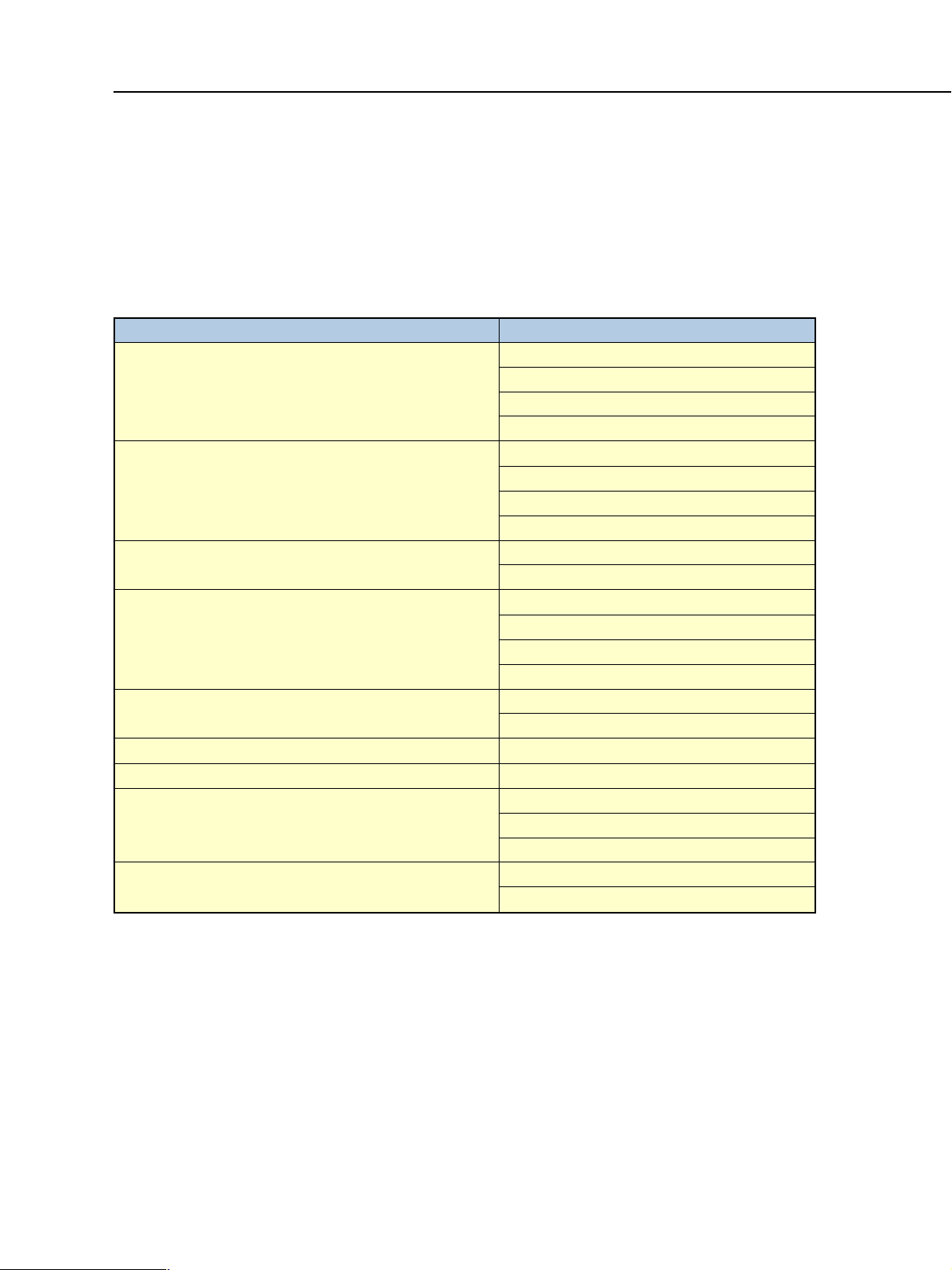

Error Code

E02

E03

E09

E14

E16

E18

E23

E24

E25

E26

Name

AF

TIME OUT

EF

TIME OUT

JPEG DMA

TIME OUT

UNKOWN

IMAGING TIME

OUT

ZOOM LENS

ERROR

CF NO SPACE

POWER ON

ERROR

FOCUS PI

ERROR

CAPTURE

TIME OUT

Occurrence Conditions

AF processing did not end within the

specified time.

The focus lens was not driven.

Auto Flash Control did not end within the

specified time.

JPEG processing did not end within the

specified time.

When unkown error, cause of which is

not known, occurs.

When communication between CPU and

peripheral IC is not completed within the

specified time during recording using

EVF or after completion of recording.

Movement of the lens barrel did not end

within the specified time.

When the CF becomes full during writing

of photographed images to CF, writing is

repeatedly performed with the JPEG

compression ratio successively increased

to reduce the size of the image file until it

can be successfully written to CF.

This error occurs when writing of the

JPEG image file fails after 10 retries at

increasingly higher compression ratios.

The power of the imaging circuit on the

MAIN PCB ASS’Y was not detected.

Detection of the focus PI (photo-

interrupter) failed.

Writing of the photograph image to

SDRAM did not end within the specified

time.

Cause and Probable Faulty Part

MAIN PCB ASS’Y

OPTICAL UNIT

MAIN PCB ASS’Y

OPTICAL UNIT

MAIN PCB ASS’Y

OPTICAL UNIT

MAIN PCB ASS’Y

UNKOWN

MAIN PCB ASS’Y

MAIN PCB ASS’Y

OPTICAL UNIT

MAIN PCB ASS’Y

MAIN PCB ASS’Y

DC/DC PCB ASS’Y

OPTICAL UNIT

MAIN PCB ASS’Y

MAIN PCB ASS’Y

2-5

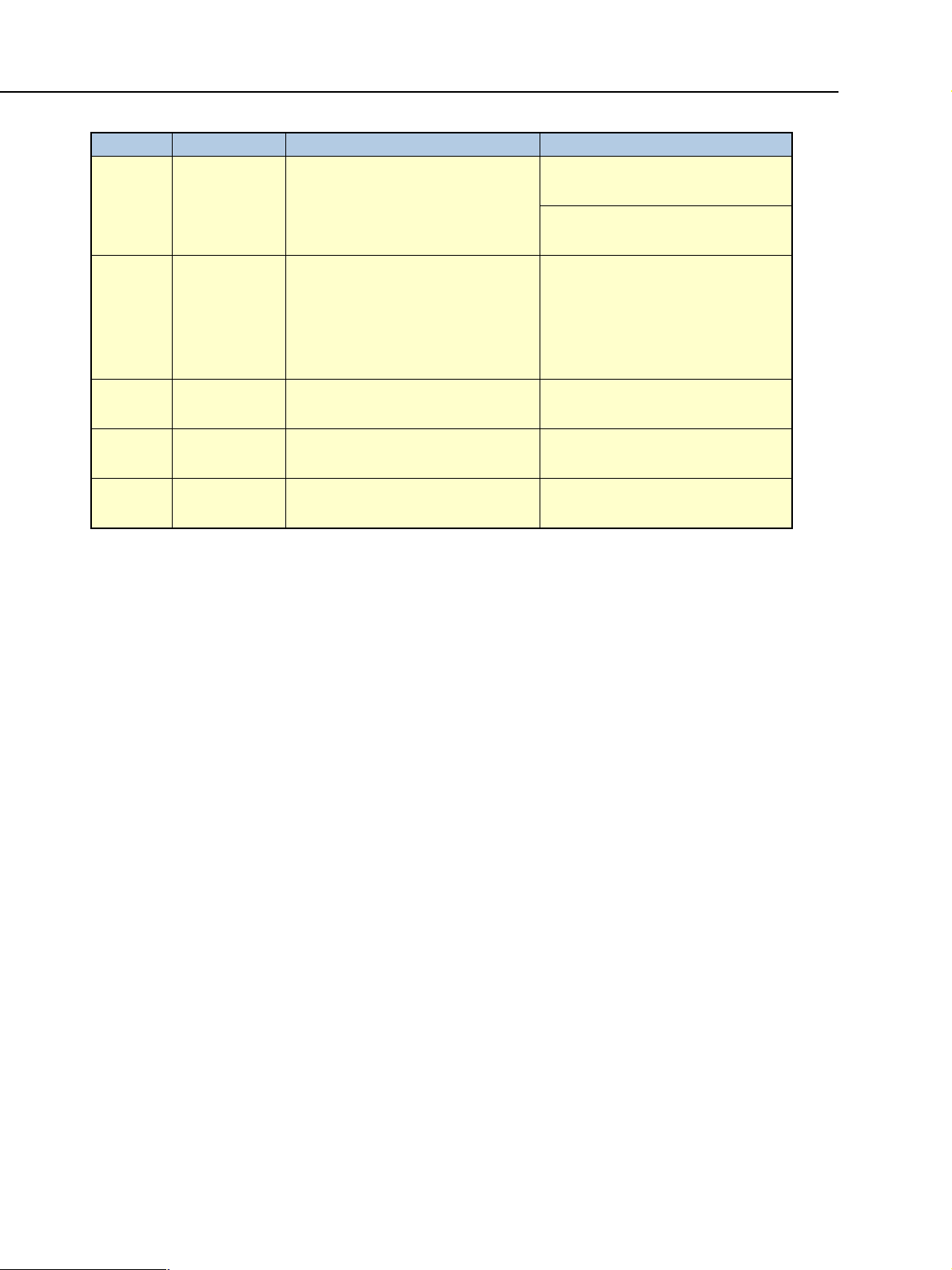

CHAPTER 2. TECHNICAL DESCRIPTION

Error Code

E27

E30

E50

E51

E52

Name

CF WRITE

TIME OVER

POWER OFF

ERROR

CF FORMAT

ERROR

CF ACCESS

ERROR

QUICK REVIEW

ERROR

Occurrence Conditions

Free area could not be secured in the

buffer for the photograph image within

the specified time in the continuous

shooting mode.

The camera power was turned OFF while

the image was being recorded to the CF

Card. (The error code is displayed when

the camera is next turned ON.)

* This error may occur after E23.

The CF Card could not be formatted

properly.

When image data cannot be read from

CF normally.

Review of the photograph image failed.

Cause and Probable Faulty Part

CF CARD

MAIN PCB ASS’Y

The battery or DC plug was removed

while the image was being recorded to

the CF Card.

→ Remedy: Restart the camera.

CF CARD

CF CARD

MAIN PCB ASS’Y

2-6

CHAPTER 2. TECHNICAL DESCRIPTION

3.2 When a Problem Occurs

[Remedy]

• Check for any abnormalities in the mounting of probable faulty parts or connector connections referring

to the table below.

• Try replacing probable faulty parts referring to the table below.

[NOTE]

• Adjustments must be performed after the part has been replaced. For details, see the chapter of

“Adjustments”.

Problem (when an error code is not displayed)

The camera does not work.

The image is not displayed on the LCD Monitor.

The photograph image is abnormal.

The zoom does not function.

The Built-in Flash does not fire.

Video output is strange.

Communications with the personal computer is not possible.

The CF card or Micro Drives is not recognized.

Buttons/The Mode dial do not work.

Cause and Probable Faulty Part

MAIN PCB ASS’Y

REAR COVER UNIT

DC/DC PCB ASS’Y

BATTERY BOX UNIT

MAIN PCB ASS’Y

BUTTON PCB ASS’Y

LCD PANEL

BACK LIGHT UNIT

OPTICAL UNIT

MAIN PCB ASS’Y

OPTICAL UNIT

MAIN PCB ASS’Y

BATTERY BOX UNIT

REAR COVER UNIT

FLASH UNIT

DC/DC PCB ASS’Y

MAIN PCB ASS’Y

MAIN PCB ASS’Y

CF CARD

REAR COVER UNIT

MAIN PCB ASS’Y

REAR COVER UNIT

RLS PCB ASS’Y

2-7

CHAPTER 3. REPAIR INSTRUCTION

CONTENTS

1. Before Starting the Repair Work

1.1 Precaution on Flash High Tension Circuit ------------------------------------------------------------------------------- 3-1

1.2 List of Tools ----------------------------------------------------------------------------------------------------------------- 3-1

1.3 List of Supplies -------------------------------------------------------------------------------------------------------------- 3-1

1.4 Flexible Connectors --------------------------------------------------------------------------------------------------------- 3-2

2. Disassembly/Assembly

2.1 Procedure --------------------------------------------------------------------------------------------------------------------- 3-3

2.2 REAR COVER UNIT ------------------------------------------------------------------------------------------------------ 3-4

2.3 FRONT COVER UNIT, CF COVER ------------------------------------------------------------------------------------ 3-5

2.4 LENS BARREL SHEET, BATTERY COVER UNIT ----------------------------------------------------------------- 3-6

2.5 BACKLIGHT UNIT, LCD PANEL -------------------------------------------------------------------------------------- 3-7

2.6 MAIN PCB ASS’Y --------------------------------------------------------------------------------------------------------- 3-8

2.7 DC/DC PCB ASS’Y -------------------------------------------------------------------------------------------------------- 3-9

2.8 FLASH UNIT ---------------------------------------------------------------------------------------------------------------3-10

2.9 OPTICAL UNIT, FINDER UNIT -------------------------------------------------------------------------------------- 3-11

2.10 CCD UNIT ----------------------------------------------------------------------------------------------------------------- 3-12

2.11 BATTERY BOX UNIT, RLS PCB ASS’Y, LITHIUM BATTERY HOLDER-----------------------------------3-13

2.12 OPTICAL UNIT ---------------------------------------------------------------------------------------------------------- 3-14

2.13 Assembling the FINDER UNIT ------------------------------------------------------------------------------------------ 3-15

2.14 Screw List -------------------------------------------------------------------------------------------------------------------3-16

3. Adjustments

3.1 Replacement Parts and Adjustment Items ----------------------------------------------------------------------------- 3-17

3.2 Adjustment Tools ----------------------------------------------------------------------------------------------------------3-18

3.3 Before Starting Electrical Adjustments --------------------------------------------------------------------------------- 3-19

3.3.1 TWAIN Driver Installation --------------------------------------------------------------------------------------3-19

3.3.2 Installing the Adjustment Software --------------------------------------------------------------------------- 3-19

3.3.3 Preparation -------------------------------------------------------------------------------------------------------- 3-21

3.3.4 Starting up the Adjustment Software --------------------------------------------------------------------------- 3-22

3.3.5 Menu Window-----------------------------------------------------------------------------------------------------3-22

3.3.6 How to Use the Adjustment Software ------------------------------------------------------------------------- 3-22

3.4 Calibration ----------------------------------------------------------------------------------------------------------------- 3-23

3.4.1 Calibration -------------------------------------------------------------------------------------------------------- 3-23

3.5 Adjustment Procedure ----------------------------------------------------------------------------------------------------- 3-27

3.5.1 CCD Adjustment ------------------------------------------------------------------------------------------------- 3-27

3.5.2 Optical Unit Adjustment ---------------------------------------------------------------------------------------- 3-29

3.5.3 Imaging Process Adjustment ------------------------------------------------------------------------------------3-31

3.5.4 Pixel Dot Adjustment --------------------------------------------------------------------------------------------3-35

3.5.5 Flash Adjustment -------------------------------------------------------------------------------------------------3-37

3.5.6 Language (For Oth) ----------------------------------------------------------------------------------------------- 3-39

3.5.7 Language Settings ----------------------------------------------------------------------------------------------- 3-41

CHAPTER 3. REPAIR INSTRUCTION

1. Before Starting the Repair Work

Be sure to read the following precaution before starting the repair work.

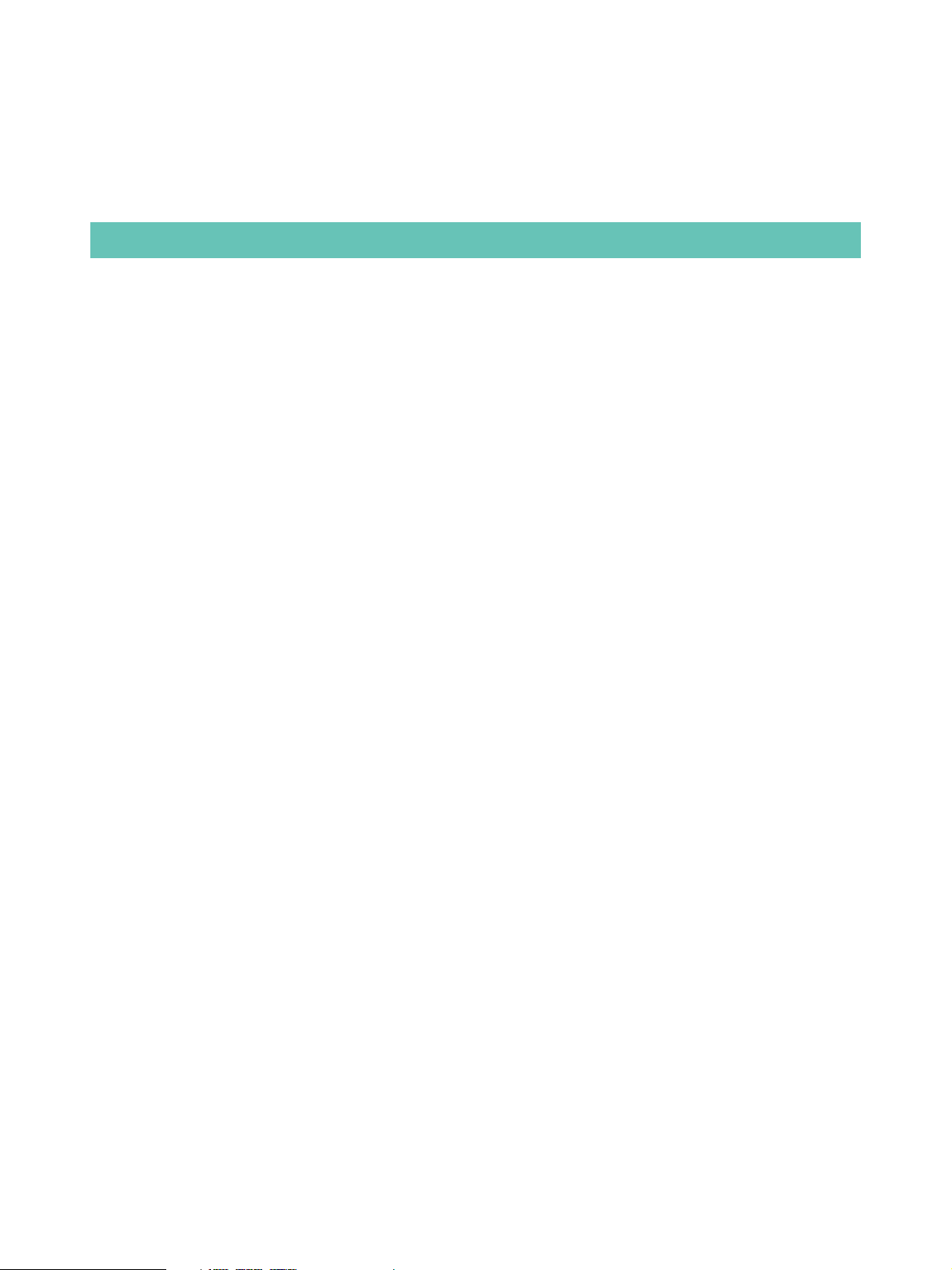

1.1 Precaution on Flash High Tension Circuit

• When the FRONT COVER UNIT is removed, be sure to discharge the main capacitor.

(Discharging resistor: 1 k ohms, approx. 5 W.)

• First contact the GND terminal of the main capacitor with the discharging resistor. Then contact the

positive terminal of the main capacitor.

CAUTION:

Be careful of electric shock because the circuit is the high tension circuit.

FLASH UNIT

Fig. 3-1 Precaution on flash high tension circuit

1.2 List of Tools

The following tools are used for the re-assembling during service.

(1) List of tools

New Name of tools Part No. Areas where supplies are used

DRIVER HANDLE CY9-7014-00 CCD UNIT

– terminal

DC/DC PCB ASS’Y

+ terminal

1.3 List of Supplies

The following supplies are used for the re-assembling during service.

(1) List of supplies

New Name of supplies Part No. Areas where supplies are used

DIA BOND 1663G CY9-8129-000 Attaching the parts together

ADHESIVE TAPE, SONY T4000 CY4-6012-000 Fixing the flexible cable

ADHESIVE TAPE, 3M NO.56 CY4-6018-000 DC/DC SHIELD CASE 1

3-1

CHAPTER 3. REPAIR INSTRUCTION

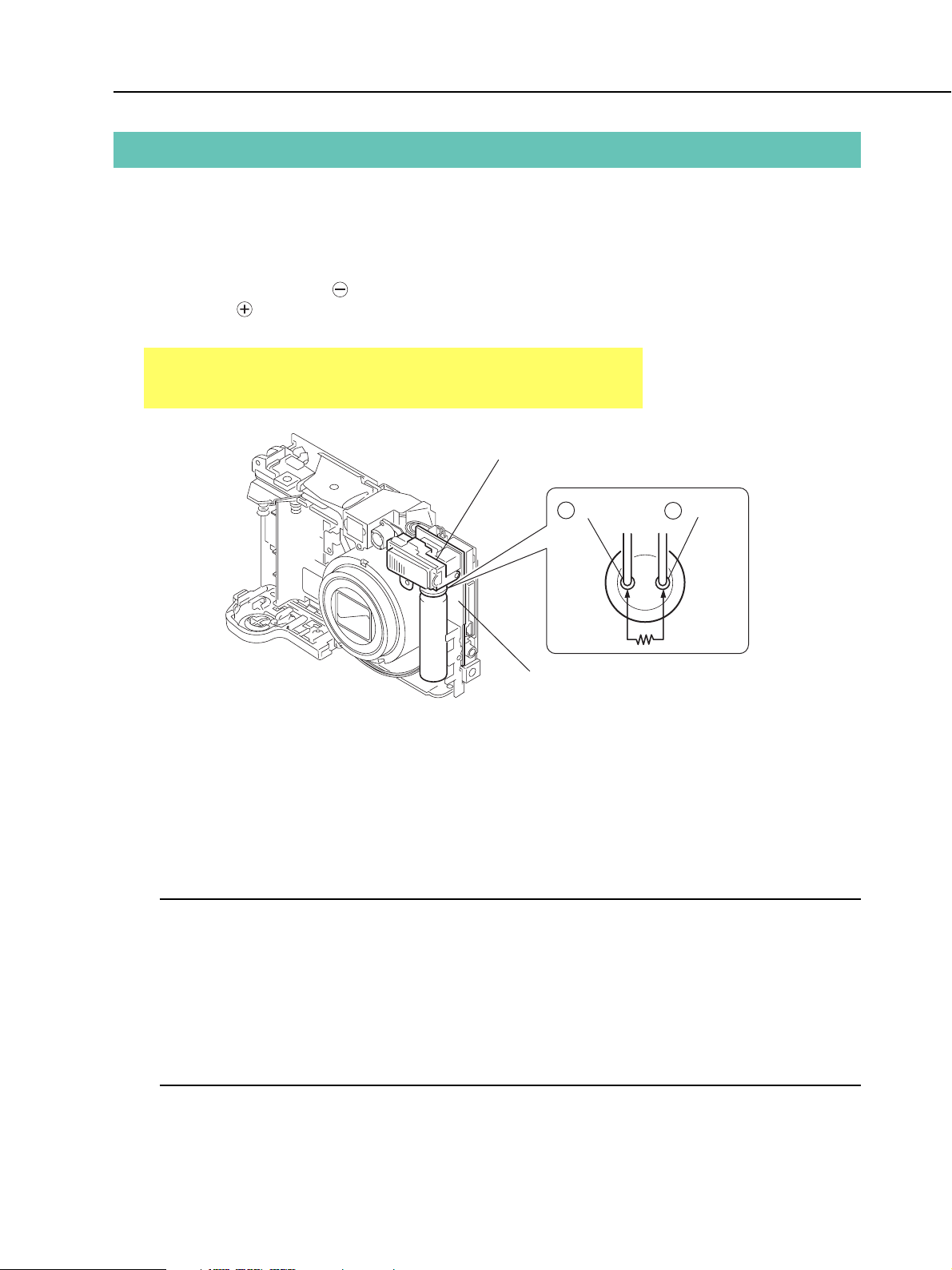

1.4 Flexible Connectors

This product uses the four types of the flexible connectors.

1 Type A

The contact-piece

should face

frontwards

Unconnected state Connected state

2 Type B

3 Type C

4 Type D

The contact-piece

UNLOCK

should face

downwards

Unlocked state Locked state

UNLOCK

The contact-piece

should face

downwards

LOCK

Unlocked state Locked state

UNLOCK

The contact-piece

should face

upwards

LOCK

Unlocked state Locked state

LOCK

Fig. 3-2 Flexible connectors

CAUTIONS:

1. For the connectors of Type B, Type C and Type D, set them to the

unlocked state before removing and inserting flexible card. After flexible card is inserted, set them to the locked state.

2. The flexible card is equipped with the holes as shown. Use them for

removal and insertion by inserting the tweezers into them as required.

3-2

Holes

Fig. 3-3 Holes for removal

CHAPTER 3. REPAIR INSTRUCTION

2. Disassembly/Assembly

2.1 Procedure

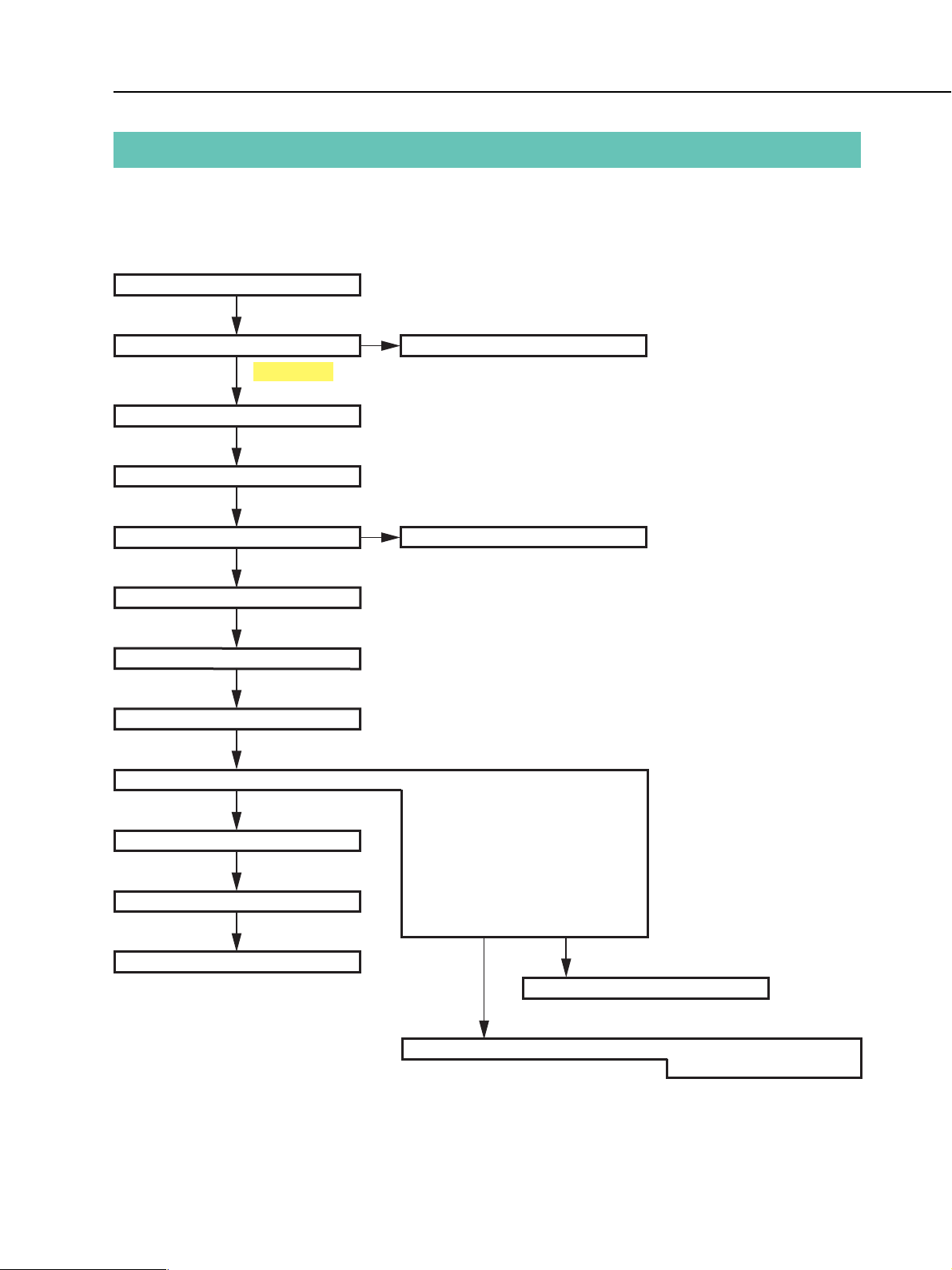

Disassembling procedure of PowerShot A40 (A30) is shown by the following flowchart.

Reverse the disassembling procedure to reassemble them. ∗ The pages to refer are shown in parenthesis ( ).

REAR COVER UNIT (3-4)

FRONT COVER UNIT (3-5)

CAUTION

Be careful high tension

LENS BARREL SHEET (3-6)

BATTERY COVER UNIT (3-6)

BACK LIGHT UNIT (3-7)

MAIN PCB ASS’Y (3-8)

DC/DC PCB ASS’Y (3-9)

FLASH UNIT (3-10)

OPTICAL UNIT (3-11)

BATTERY BOX UNIT (3-13)

RLS PCB ASS’Y (3-13)

CF COVER (3-5)

LCD PANEL (3-7)

LENS PLATE (3-14)

LENS BARREL CAP (3-14)

BARRIER CLOSE SPRING (3-14)

BARRIER PLATE 1 (3-14)

BARRIER PLATE 2 (3-14)

BARRIER PLATE 2 SPRING (3-14)

BARRIER BASE (3-14)

BARRIER OPEN SPRING (3-14)

BARRIER DRIVE RING (3-14)

LITIUM BATTERY HOLDER (3-13)

FINDER UNIT (3-11)

CCD UNIT (3-12)

3-3

CCD RUBBER (3-12)

IR FILTER (3-12)

CHAPTER 3. REPAIR INSTRUCTION

REAR COVER

UNIT

(1)-3

(1)-1

a

(1)-3

(1)-1

b

REAR COVER UNIT

a

(1)-1

(1)-2

(1)-1

CF COVER

a

(1)-1

b

b

(1)-1

CONNECTOR COVER

Fig. 3-4 REAR COVER UNIT

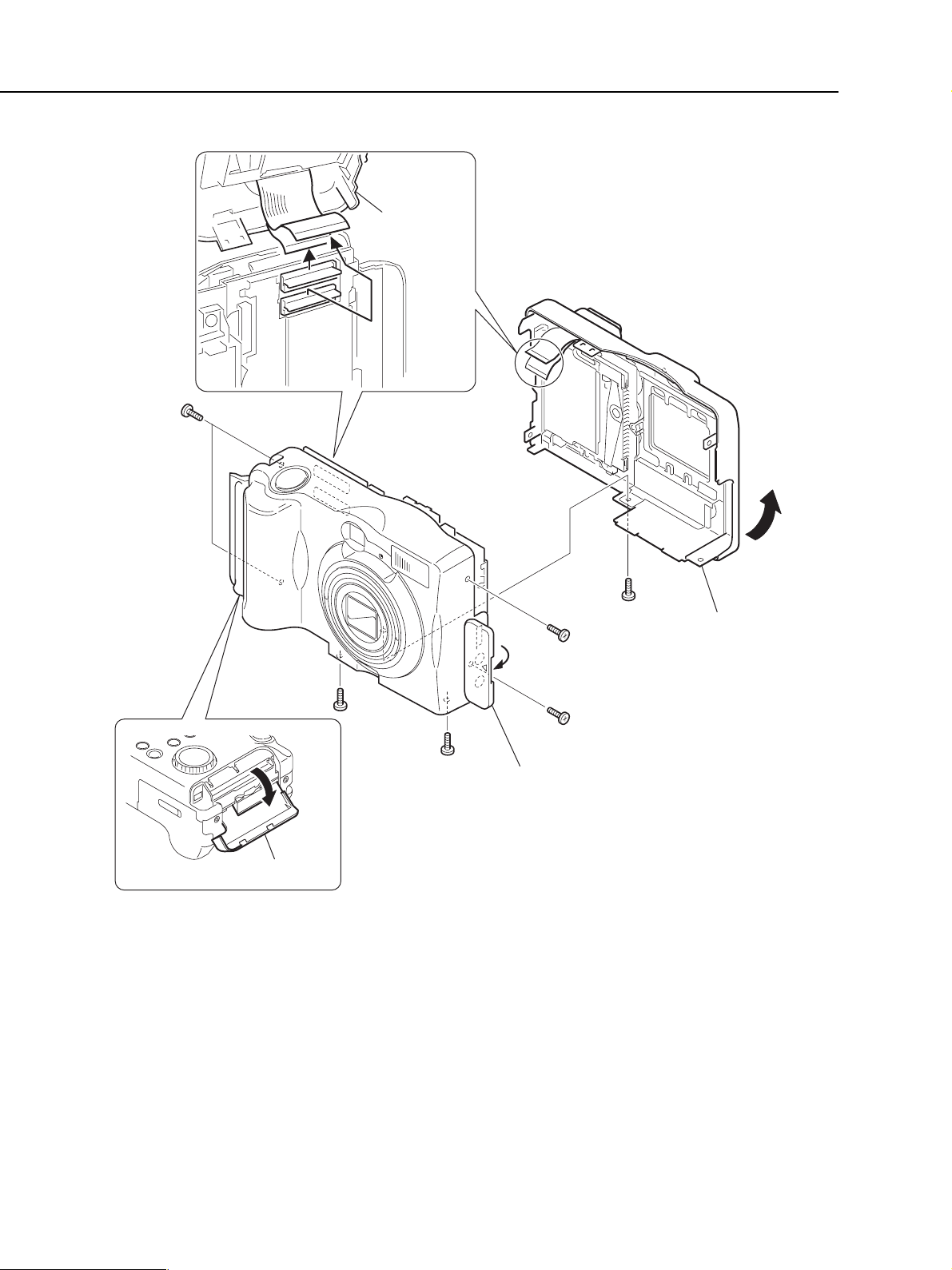

2.2 REAR COVER UNIT

(1) REAR COVER UNIT

1. Remove the six screws.

Remove the one screw by turning over the CONNECTOR COVER.

2. Open the CF COVER.

3. Open the REAR COVER UNIT in the direction of arrow and remove it by disconnecting the two flexible

printed wired board.

3-4

CF COVER

(1)-2

CHAPTER 3. REPAIR INSTRUCTION

(1)-2

BATTERY COVER UNIT

(1)-1

Fig. 3-5 FRONT COVER UNIT, CF COVER

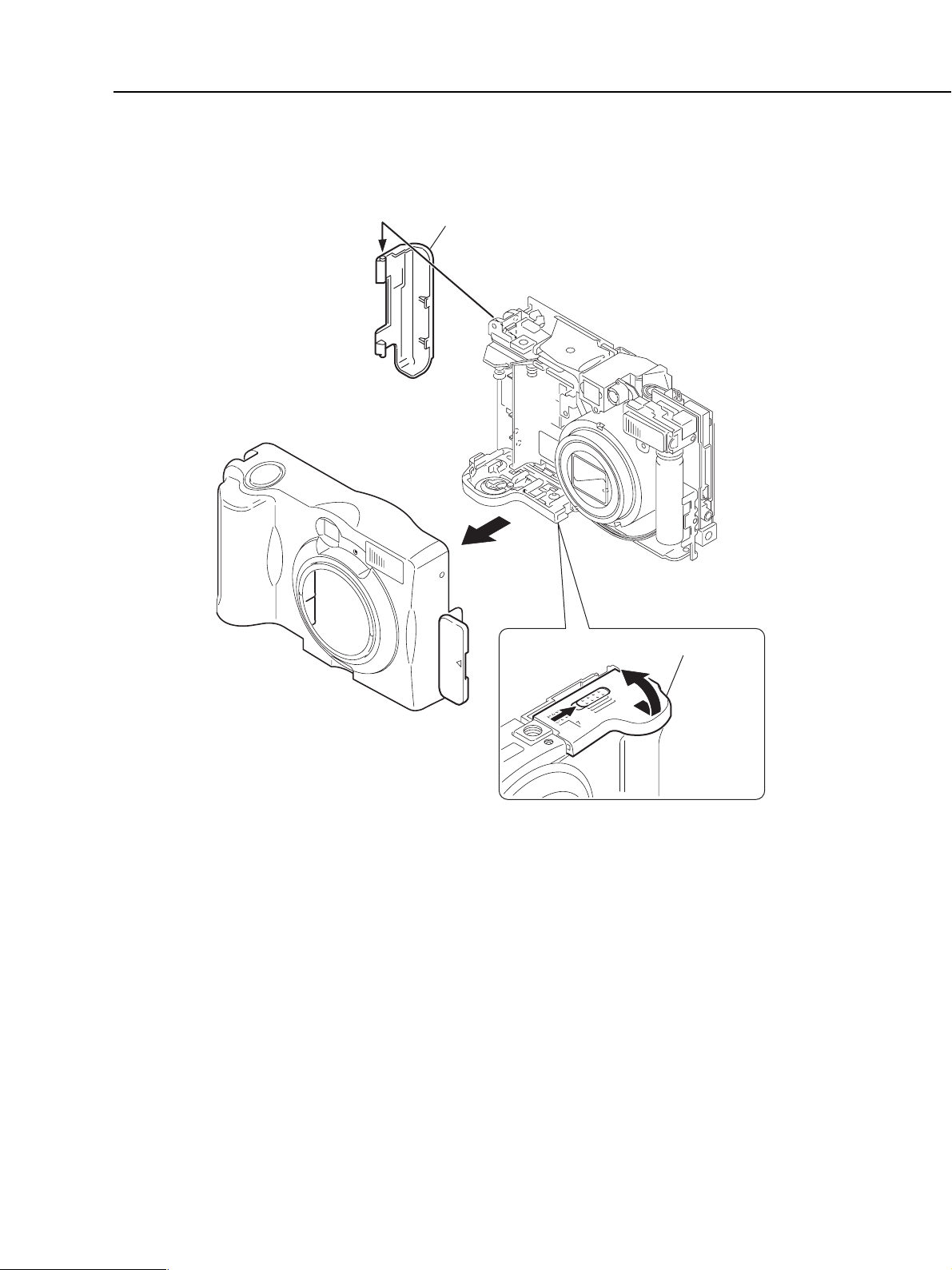

2.3 FRONT COVER UNIT, CF COVER

(1) FRONT COVER UNIT, CF COVER

1. Open the BATTERY COVER UNIT after releasing the look while pushing the BATTERY OPEN

BUTTON in the direction of the arrow .

2. Take the FRONT COVER UNIT in the direction of arrow and at the same time remove the CF COVER.

3-5

CHAPTER 3. REPAIR INSTRUCTION

BATTERY COVER BAR

(1)-1

LENS BARREL SHEET

(2)-2

BATTERY COVER UNIT

(2)-1

BATTERY COVER

BAR

BATTERY COVER UNIT

Groove

NOTE (Assembling)

Lever block

BATTERY COVER UNIT

BATTERY COVER BAR

(Top view)

Fig. 3-6 LENS BARREL SHEET, BATTERY COVER UNIT

2.4 LENS BARREL SHEET, BATTERY COVER UNIT

(1) LENS BARREL SHEET

1. Remove the LENS BARREL SHEET.

(2) BATTERY COVER UNIT

1. Insert tweezers or the like into the groove of the BATTERY COVER BAR and remove it in the direction of

arrow.

2. Remove the BATTERY COVER UNIT.

NOTE (Assembling)

Attach the lever block to the BATTERY COVER UNIT.

3-6

(1)-4

CHAPTER 3. REPAIR INSTRUCTION

BACKLIGHT UNIT

(1)-3

(1)-2

Claws

Claws

(2)-1

(1)-1

(1)-3

Claws

(2)-1

Fig. 3-7 BACKLIGHT UNIT, LCD PANEL

NOTE (Assembling)

The BACKLIGHT UNIT that is

supplied as the service part has

the protection sheet on the back.

Remove it.

c

(2)-1

LCD PANEL

2.5 BACKLIGHT UNIT, LCD PANEL

(1) BACKLIGHT UNIT

1. Remove the flexible printed wired board of the BACKLIGHT UNIT.

2. Remove the screw.

3. Rotate the BACKLIGHT UNIT in the direction of arrow and remove it by releasing the claws.

4. Remove the flexible printed wired board of the LCD PANEL.

(2) LCD PANEL

1. Release the four claws in the top and bottom, and remove the LCD PANEL in the direction of arrow.

3-7

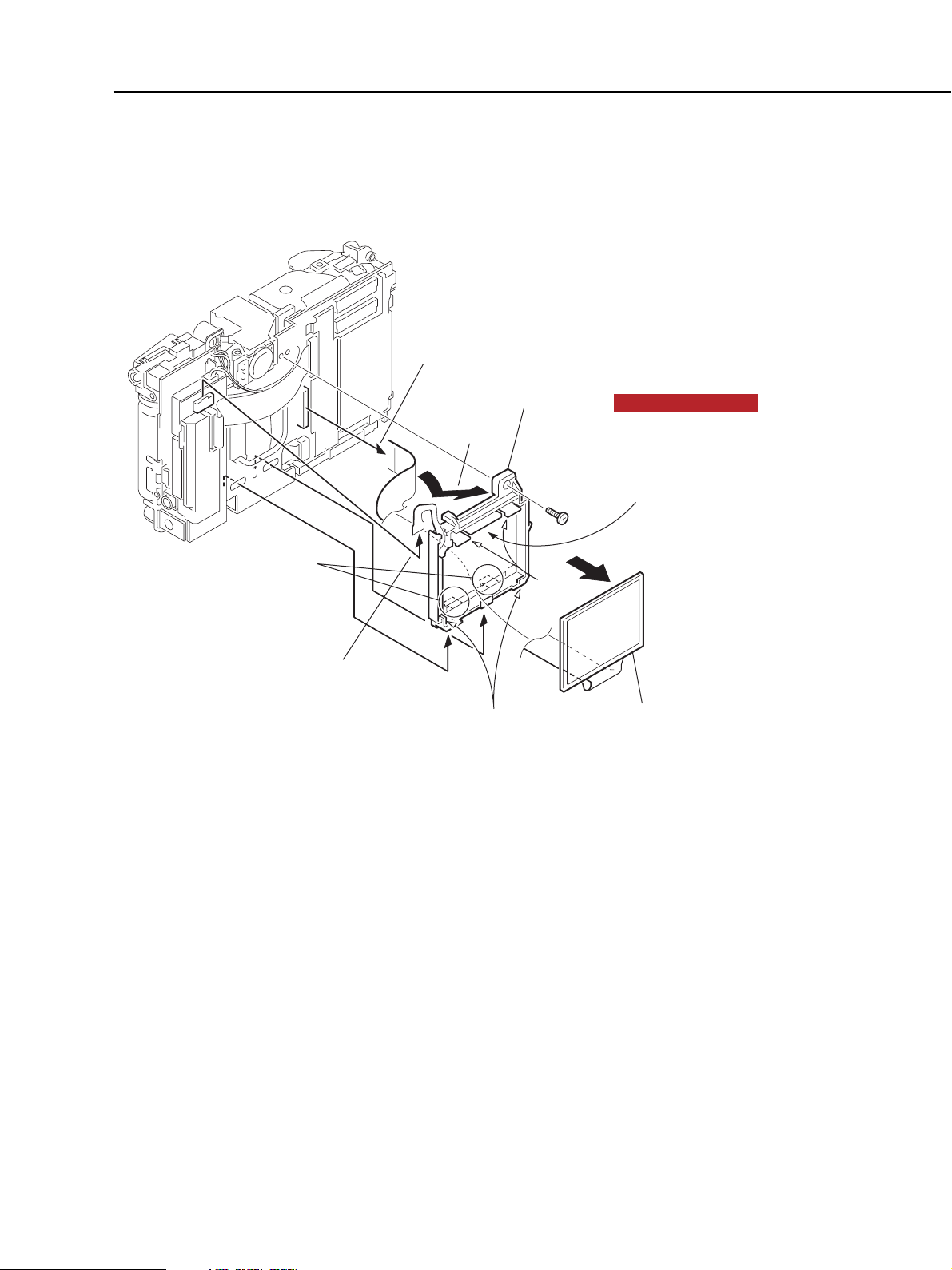

CHAPTER 3. REPAIR INSTRUCTION

How to fold the OPT FPC

OPT FPC

CCD UNIT FPC

(1)-1

EMC SHEET 2

(1)-2

d

M-S FPC

(1)-9

(1)-4

M-R FPC

(1)-3

Claws

(1)-8

(1)-10

(1)-6

(1)-5

M-D FPC

MAIN PCB ASS’Y

Fig. 3-8 MAIN PCB ASS’Y

2.6 MAIN PCB ASS’Y

(1) MAIN PCB ASS’Y

1. Remove the EMC SHEET 2.

2. Remove the screws.

3. Remove the OPT FPC.

4. Remove the M-R FPC.

5. Remove the M-D FPC.

6. Remove the flexible printed wired board of the CCD UNIT.

7. Remove the two screws.

8. While taking care of the claws in the top and bottom, remove the MAIN PCB ASS'Y

in the direction of arrow.

9. Remove the M-S FPC.

10. Disconnect the connector.

(1)-7

c

3-8

(1)-1

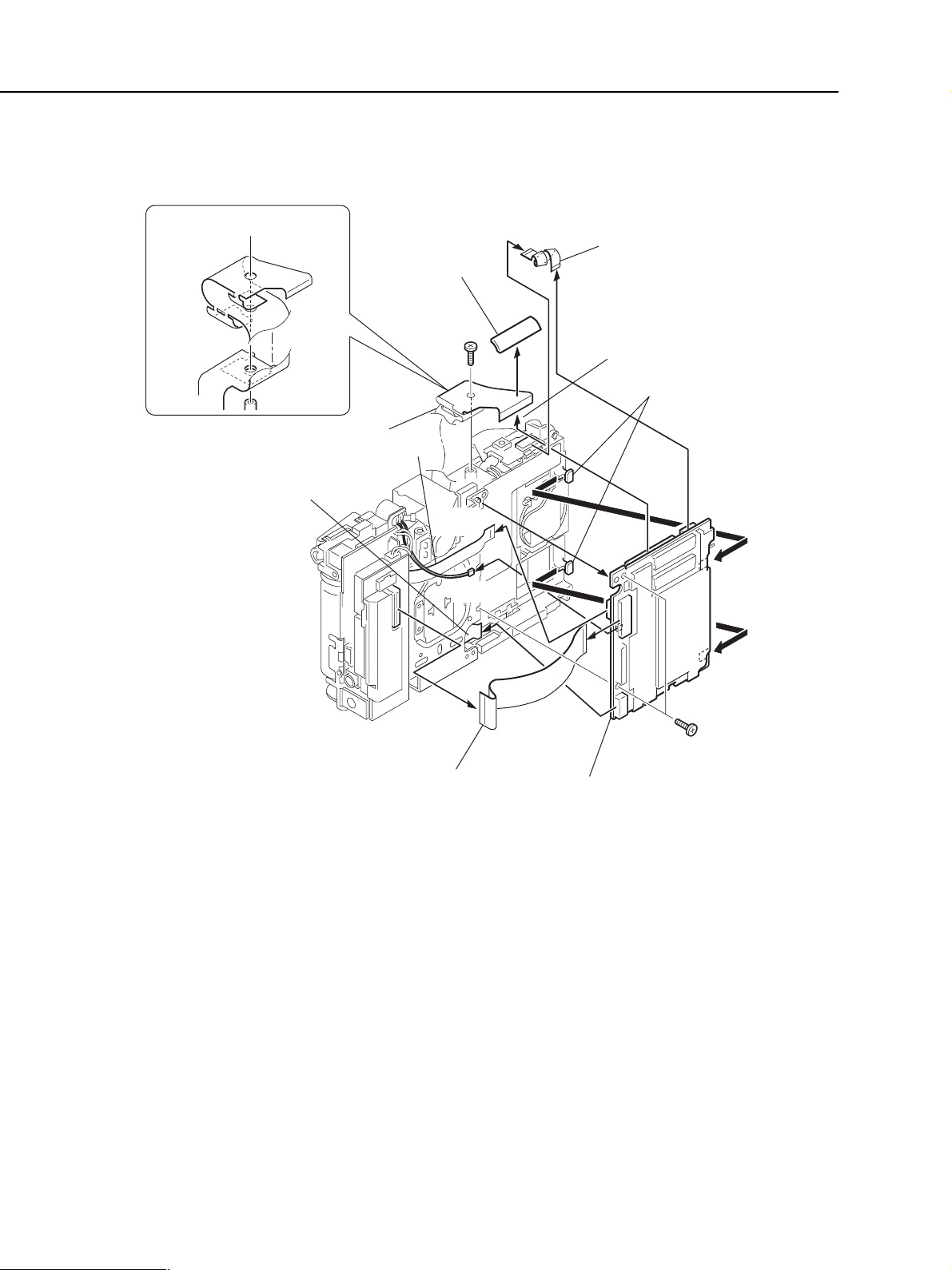

CHAPTER 3. REPAIR INSTRUCTION

(1)-1

(1)-3

NOTE (Assembling)

DC/DC SHIELD

CASE 1

Insulation tape

Fig. 3-9 DC/DC PCB ASS’Y

2.7 DC/DC PCB ASS’Y

(1) DC/DC PCB ASS’Y

1. Disconnect the two connectors.

2. Remove the two screws.

3. Remove the DC/DC PCB ASS’Y in the direction of arrow.

NOTE (Assembling)

Attach the insulation tape to the DC/DC SHIELD CASE 1.

(1)-2

c

DC/DC PCB ASS’Y

3-9

CHAPTER 3. REPAIR INSTRUCTION

(1)-2

Mold part

(1)-6

M-S FPC

FLASH UNIT

(1)-5

EMS SHEET 1

c

(1)-3

c

(1)-3

(1)-4

Fig. 3-10 FLASH UNIT

2.8 FLASH UNIT

(1) FLASH UNIT

1. Remove the HIGH VOLTAGE CAUTION TAPE.

2. Remove the mold part of the FLASH UNIT from the dowel with the sharp point tweezers or the like.

3. Remove the two screws. (One screw from the front and the other from the rear.)

4. Remove the FLASH UNIT by sliding it.

5. Remove the EMS SHEET 1.

6. Remove the M-S FPC.

3-10

CHAPTER 3. REPAIR INSTRUCTION

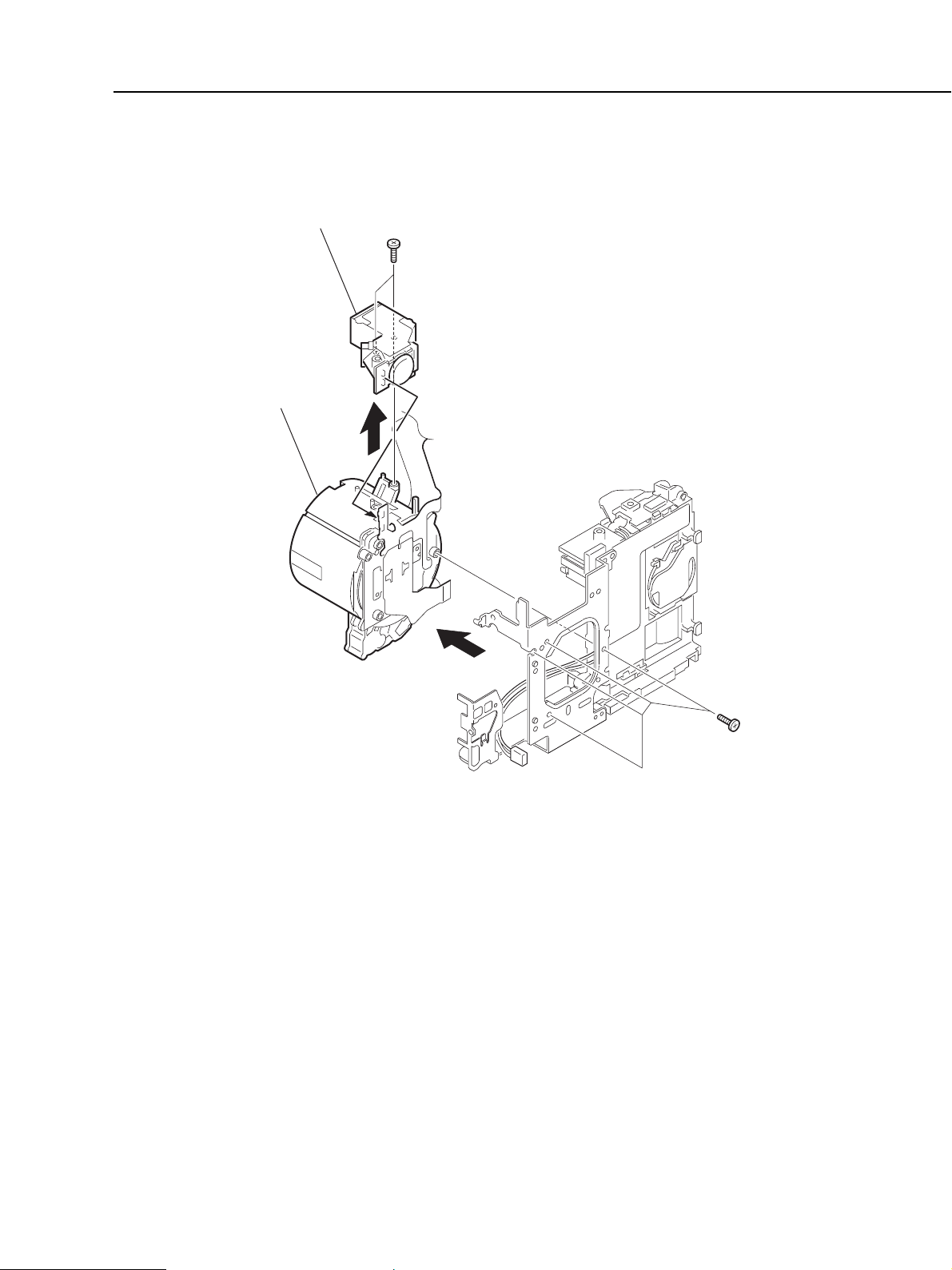

e

FINDER UNIT

OPTICAL UNIT

(2)-3

e

(2)-2

(2)-1

(1)-2

(1)-1

Fig. 3-11 OPTICAL UNIT, FINDER UNIT

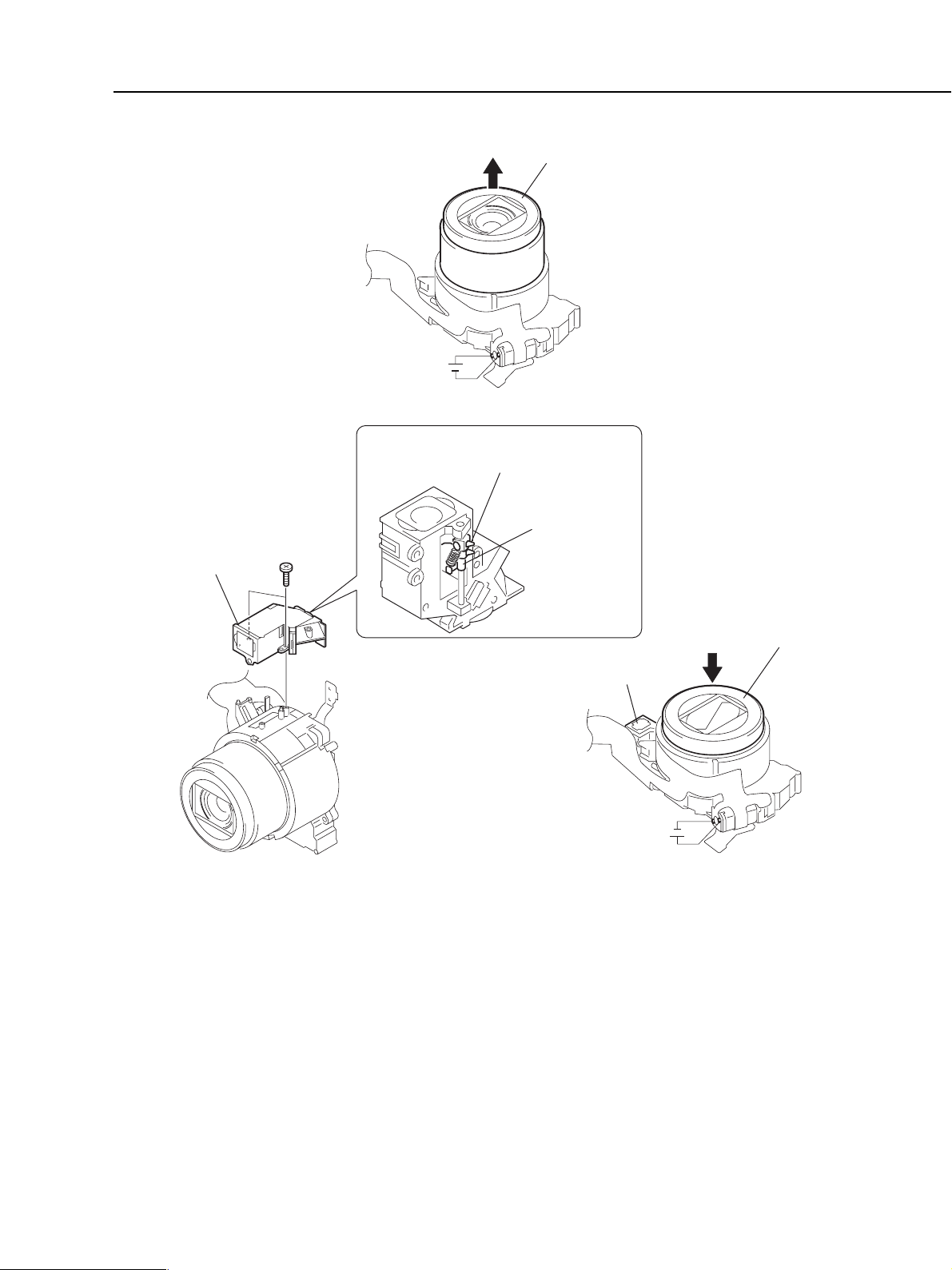

2.9 OPTICAL UNIT, FINDER UNIT

(1) OPTICAL UNIT

1. Remove the four screws.

2. While taking care of flexible printed wired board, remove the OPTICAL UNIT in the direction of arrow.

(2) FINDER UNIT

1. Remove the flexible printed wired board.

2. Remove the two screws.

3. Remove the FINDER UNIT in the direction of arrow.

3-11

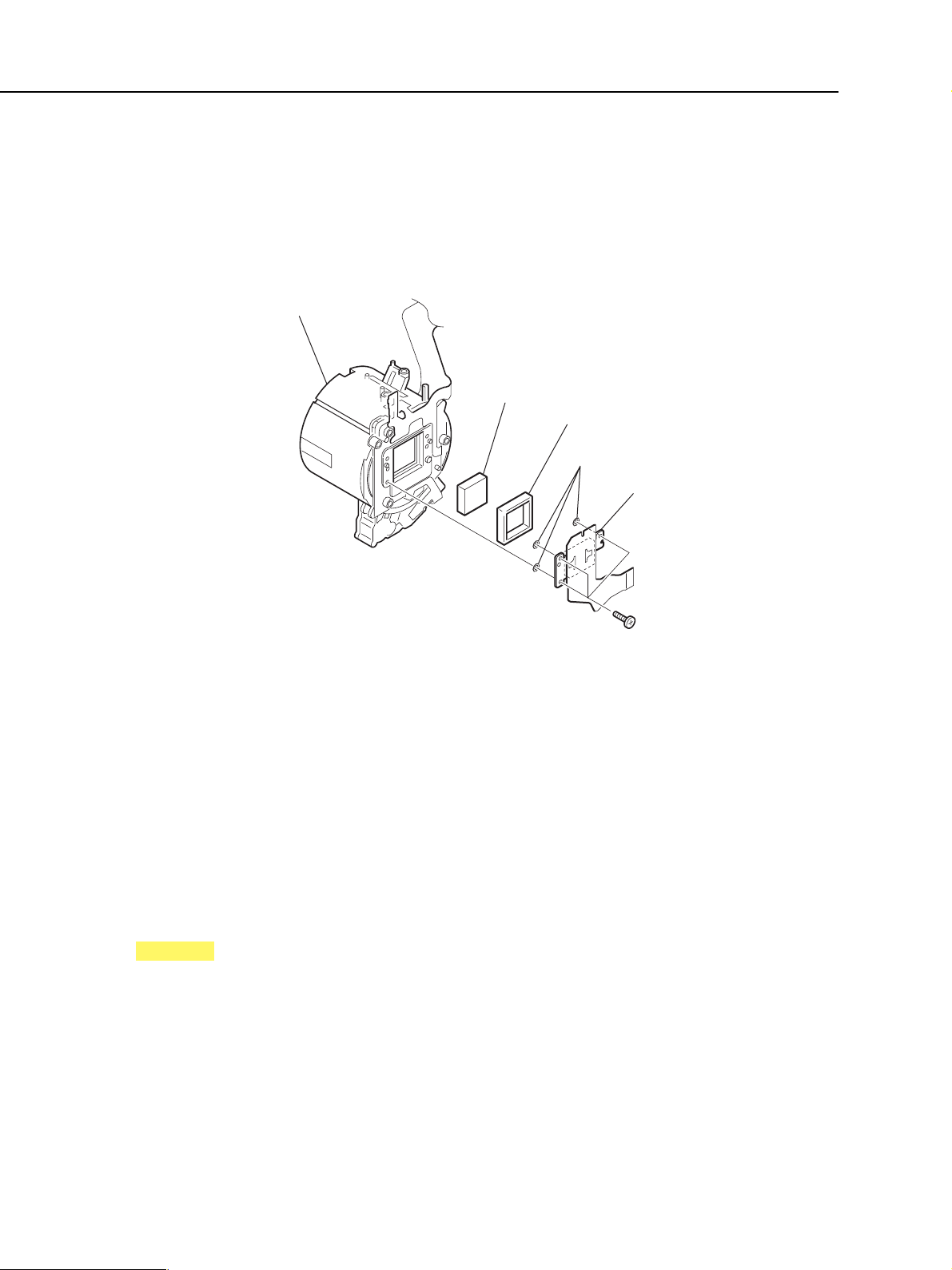

CHAPTER 3. REPAIR INSTRUCTION

OPTICAL UNIT

(1)-3

IR FILTER

(1)-3

CCD RUBBER

(1)-2

CCD WASHER

CCD UNIT

(1)-2

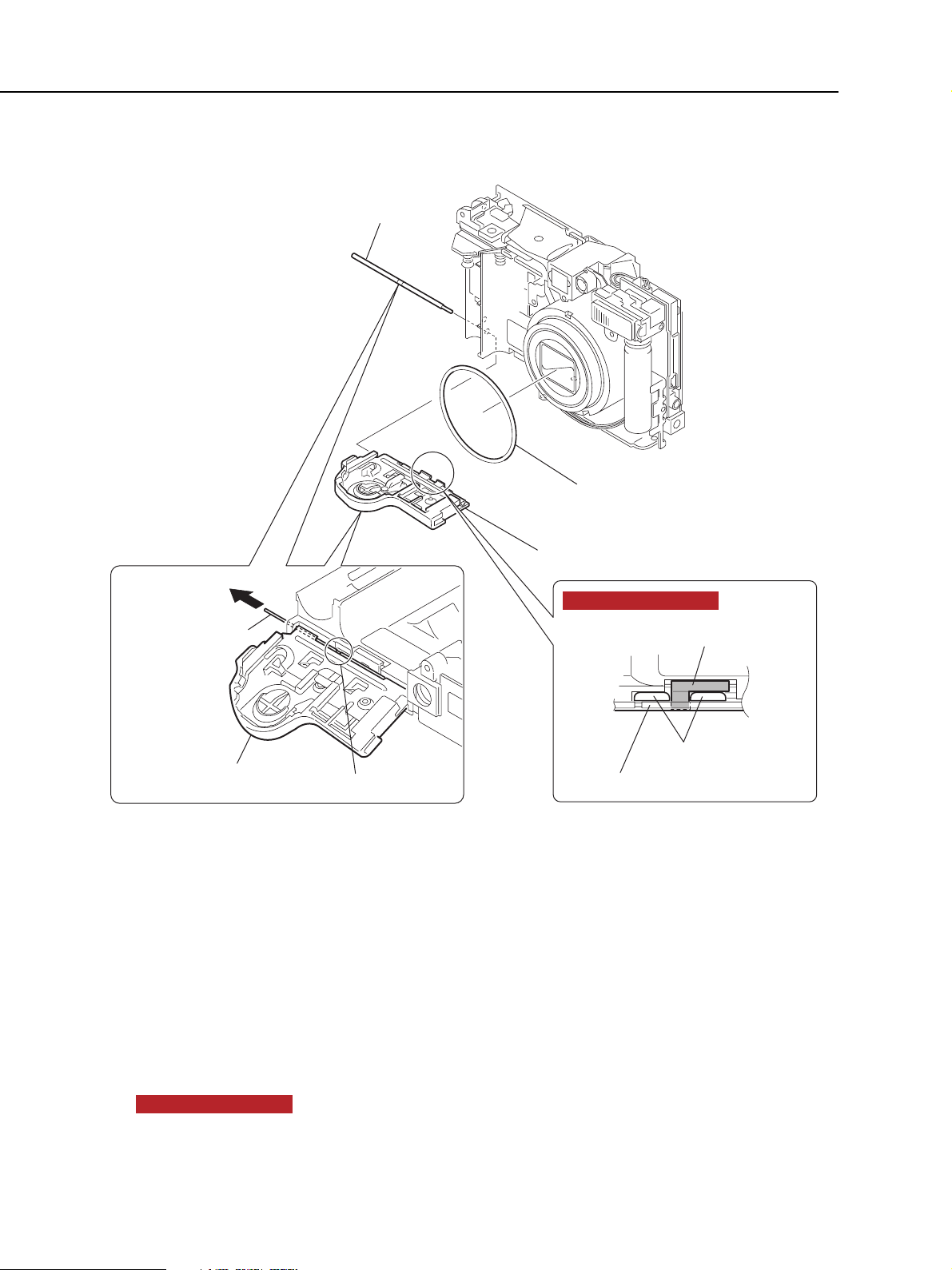

2.10 CCD UNIT

(1) CCD UNIT

1. Remove the three screws.

∗ Use the HAND DRILL BIT (CY9-1548-000).

2. Remove the CCD UNIT.

CAUTION

Be careful not to drop the washers.

3. Remove the CCD RUBBER, IR FILTER.

f

(1)-1

Fig. 3-12 CCD UNIT

3-12

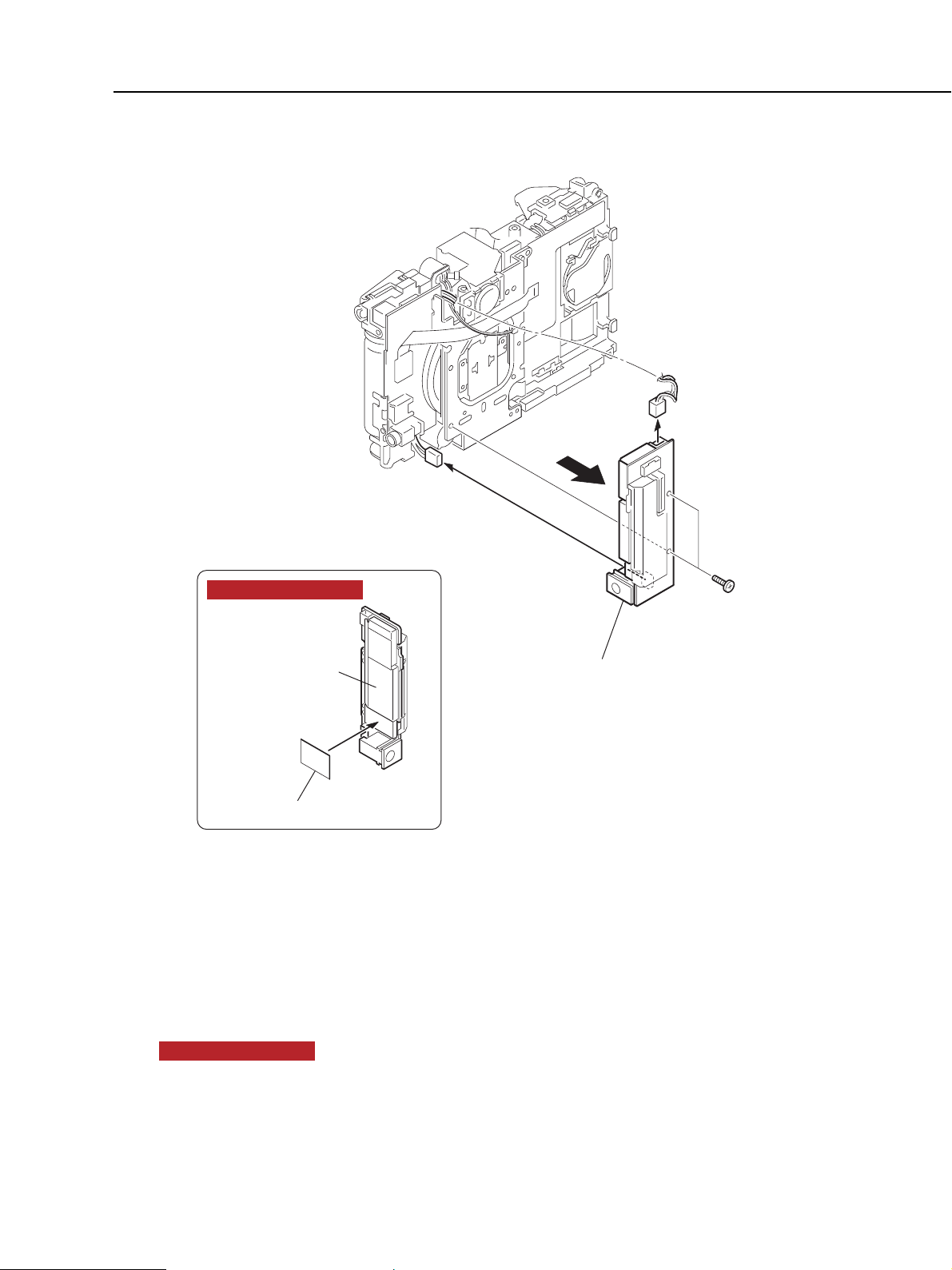

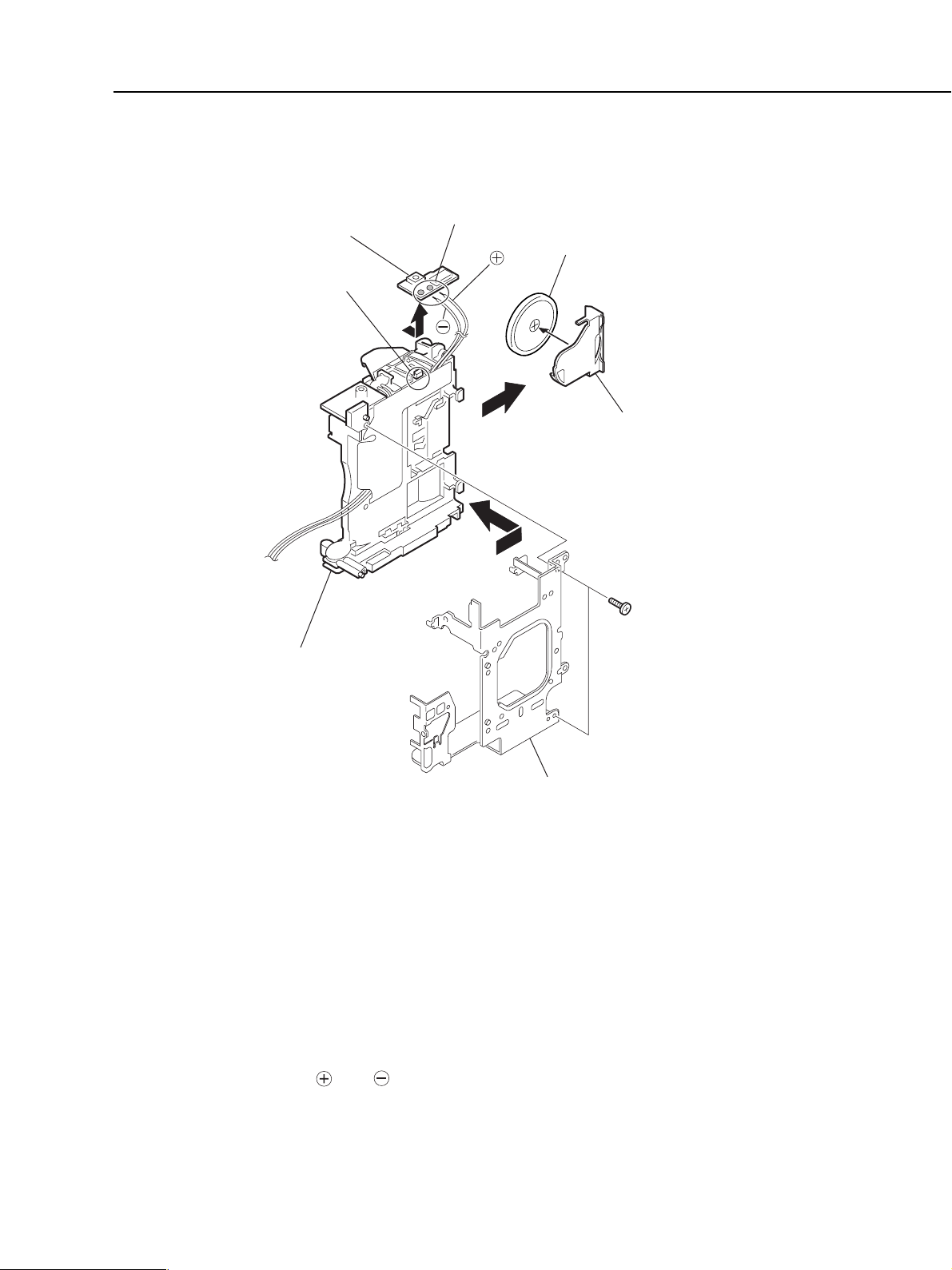

RLS PCB ASS’Y

Claw

(2)-1

Remove soldering

(2)-2

CHAPTER 3. REPAIR INSTRUCTION

(3)-1

LITHIUM BATTERY

(3)-1

LITHIUM BATTERY HOLDER

(1)-2

(1)-1

e

BATTERY BOX UNIT

MAIN FRAME

Fig. 3-13 BATTERY BOX UNIT, RLS PCB ASS’Y, LITHIUM BATTERY HOLDER

2.11 BATTERY BOX UNIT, RLS PCB ASS’Y,

LITHIUM BATTERY HOLDER

(1) BATTERY BOX UNIT

1. Remove the two screws.

2. Remove the BATTERY BOX UNIT in the direction of arrow.

(2) RLS PCB ASS’Y

1. Remove soldering. ( : red, : black)

2. Release the claws and remove the RLS PCB ASS’Y in the direction of arrow.

(3) LITHIUM BATTERY HOLDER

1. Remove the LITHIUM BATTERY from the LITHIUM BATTERY HOLDER.

3-13

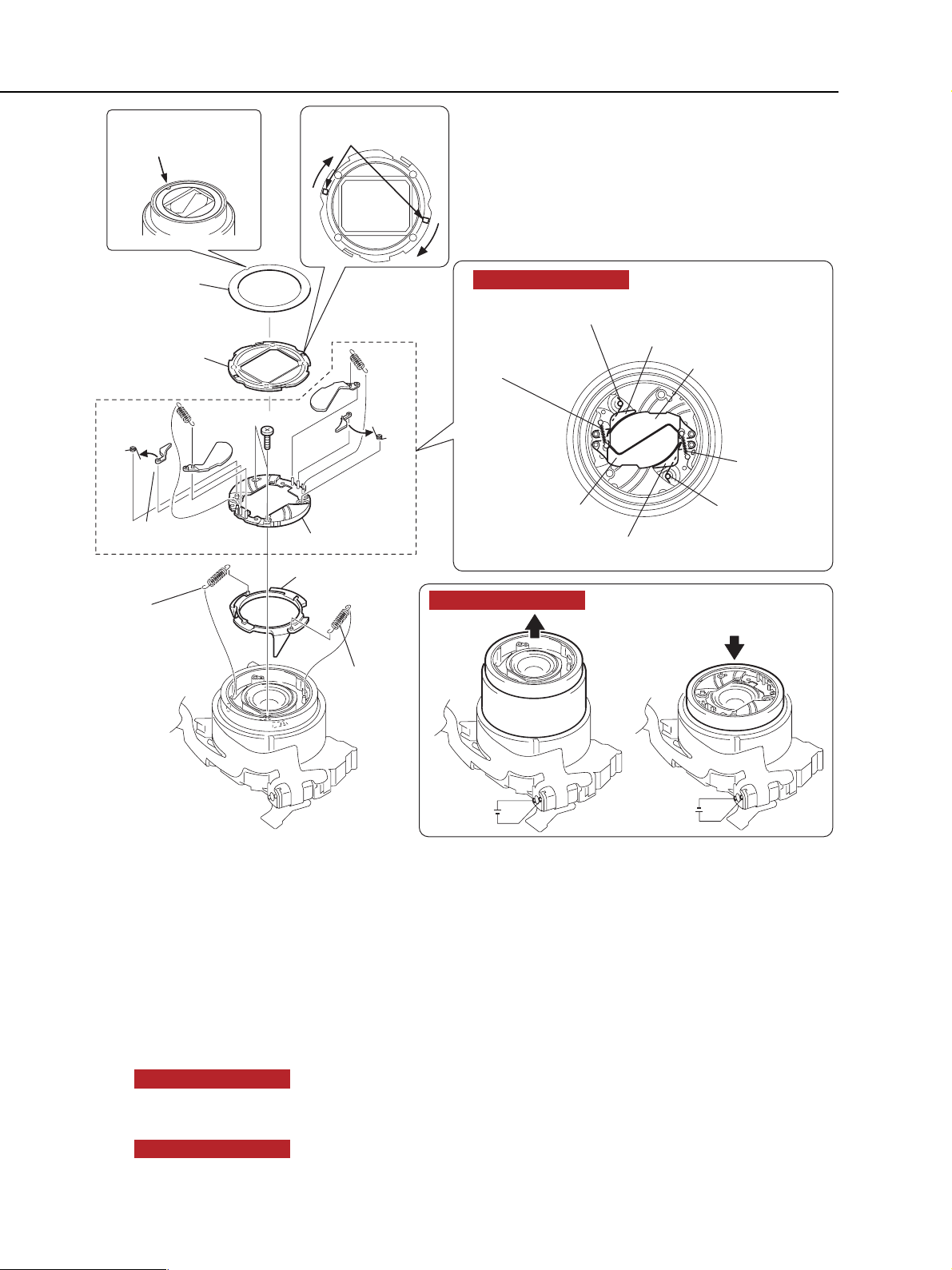

CHAPTER 3. REPAIR INSTRUCTION

Insert tweezers

or the like.

LENS PLATE

LENS BARREL

CAP

(1)-3

(1)-4

(1)-7

(1)-6

BARRIER

OPEN

SPRING

(1)-10

(1)-1

(1)-5

Insert tweezers

or the like.

(1)-3

(1)-8

(1)-6

g

(1)-9

BARRIER BASE

BARRIER DRIVE

RING

(1)-11

BARRIER

OPEN

SPRING

(1)-10

(1)-5

(1)-4

(1)-7

(1)-2

NOTE (Assembling)

BARRIER PLATE 2 SPRING

BARRIER CLOSE

SPRING

BARRIER PLATE 1

NOTE (Assembling)

(1)-3 to (1)-7

BARRIER PLATE 2

BARRIER PLATE 2

(1)-10

BARRIER PLATE 1

BARRIER

CLOSE

SPRING

BARRIER PLATE 2

SPRING

(1)-8

DC2.5V

DC2.5V

Fig. 3-14 OPTICAL UNIT

2.12 OPTICAL UNIT

(1) OPTICAL UNIT

1. Remove the LENS PLATE by inserting tweezers or the like into its groove.

2. Insert tweezers or the like to the LENS BARREL CAP. Rotate it in the clockwise direction and remove it.

3. Remove the BARRIER CLOSE SPRING (2 pieces).

4. Remove an end of the BARRIER PLATE 2 SPIRNG (2 pieces) and loosen the fastening of the BARRIER

PLATE 2.

5. Remove the BARRIER PLATE 1 (2 pieces).

6. Remove the BARRIER PLATE 2 (2 pieces).

7. Remove the BARRIER PLATE 2 SPIRNG (2 pieces).

8. Remove the two screws.

NOTE (Assembling)

9. Remove the BARRIER BASE.

10. Remove the BARRIER OPEN SPRING (2 pieces).

NOTE (Assembling)

11. Remove the BARRIER DRIVE RING.

Apply the voltage (DC 2.5V) across the motor terminal to drive the motor until the

motor stops and the BARREL is fully comes out.

Apply the voltage (DC 2.5V) across the motor terminal to drive the motor until the

motor stops and the BARREL is full housed.

3-14

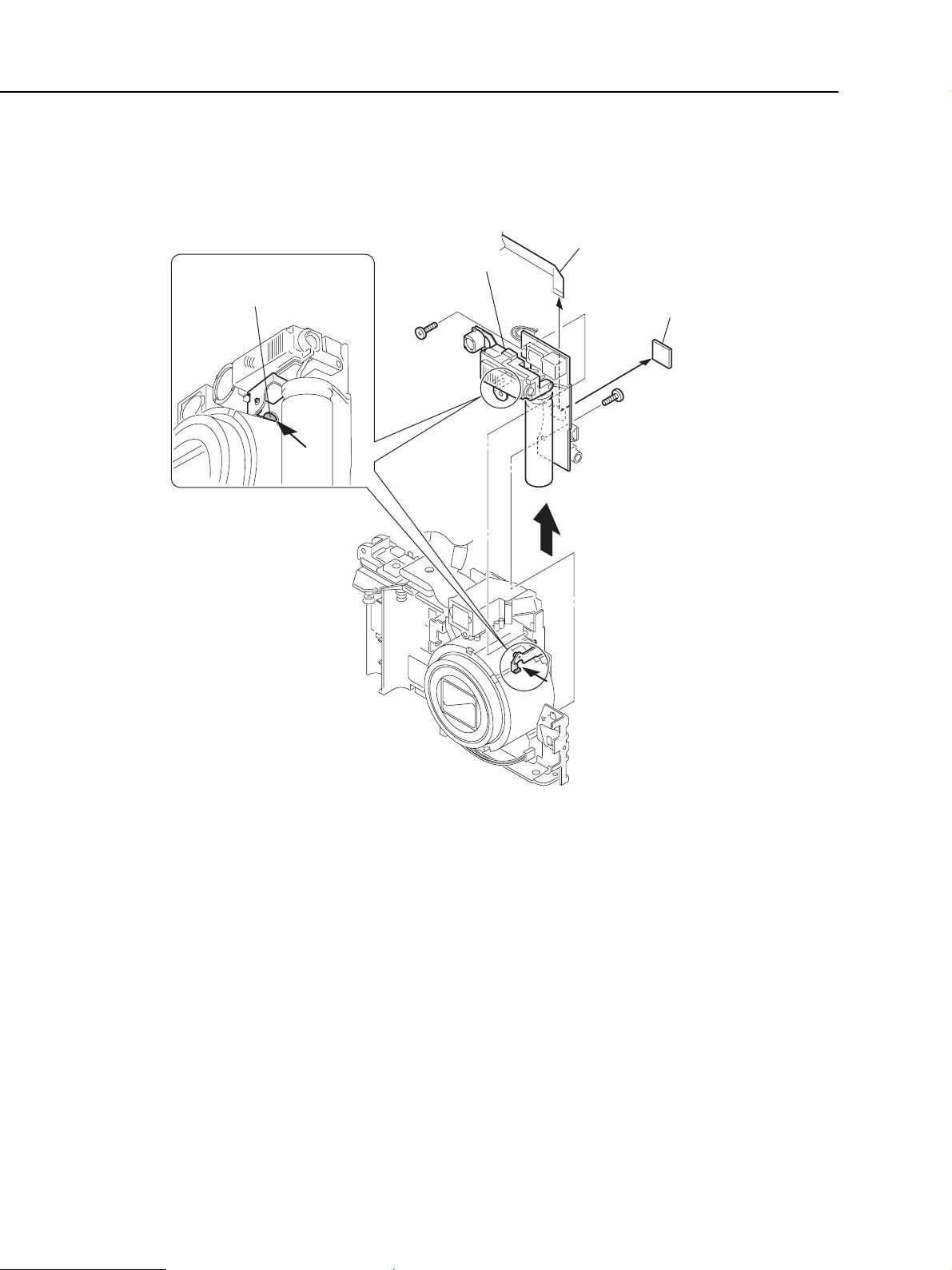

CHAPTER 3. REPAIR INSTRUCTION

FINDER UNIT

(1)-2

e

(1)-1

DC2.5V

(1)-1

The SLIDER must have been moved

fully to the top of the BARREL.

BARREL

(1)-2

SLIDER

(1)-3

FINDER UNIT

DC2.5V

(1)-3

Fig. 3-15 Assembling the FINDER UNIT

2.13 Assembling the FINDER UNIT

(1) Assembling the FINDER UNIT

1. Apply the voltage (DC 2.5V) across the motor terminal to drive the motor until the motor stops and the

BARREL fully comes out.

2. Move the SLIDER fully to the top of the BARREL and secure it with the two screws.

3. Apply the voltage (DC 2.5V) across the motor terminal to drive the motor until the motor stops and the

BARREL is full housed.

BARREL

3-15

Loading...

Loading...