SERVICE

MANUAL

REVISION 1

FY8-13EL-010

MAR. 1997

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV.1 MAR. 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

IMPORTANT

THIS DOCUMENTATION IS PUBLISHED BY CANON INC., JAPAN, TO SERVE AS A SOURCE OF

REFERENCE FOR WORK IN THE FIELD.

SPECIFICA TIONS AND OTHER INFORMATION CONTAINED HEREIN MA Y VARY SLIGHTLY FROM

ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER PRINTED

MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE DIRECTED TO

THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

THIS DOCUMENTATION IS INTENDED FOR ALL SALES AREAS, AND MAY CONTAIN

INFORMATION NOT APPLICABLE TO CERTAIN AREAS.

COPYRIGHT © 1997 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be

strictly supervised to avoid

disclosure of confidential

information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DEPT. 1

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIV.

CANON INC.

30-2, Shimomaruko 3-chome, Ohta-ku, Tokyo 146 Japan

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV.1 MAR. 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

General Description

introduces the copier's features and specifications,

shows how to operate the copier, and explains how copies are made.

Chapter 2

Basic Operation

provides outlines of the copier's various operational

workings.

Chapter 3

Exposure System

discusses the principles of operation used for the

copier's lens drive unit and scanner drive unit. It also explains the timing

at which these drive units are operated, and shows how they may be

disassembled/assembled and adjusted.

Chapter 4

Image Formation System

discusses the principles of how images are

formed. It also explains the timing at which the various units involved in

image formation are operated, and shows how they may be

disassembled/assembled and adjusted.

Chapter 5

Pick-Up/Feeding System

explains the principles used from when copy

paper is picked up to when a copy is delivered in view of the functions of

electrical and mechanical units and in relation to their timing of operation.

It also shows how these units may be disassembled/assembled and

adjusted.

Chapter 6

Fixing System

explains the principles used to fuse toner images to

transfer media in view of the functions of electrical and mechanical units

and in relation to their timing of operation. It also shows how these units

may be disassembled/assembled and adjusted.

Chapter 7

Externals/Auxiliary Mechanisms

shows the copier's external parts, and

explains the principles used for the copier's various control mechanisms

in view of the functions of electrical and mechanical units and in relation

to their timing of operation. It also shows how these units may be

disassembled/assembled and adjusted.

Chapter 8

Installation

introduces requirements for the site of installation, and shows

how the copier may be installed using step-by-step instructions.

Chapter 9

Maintenance and Servicing

provides tables of periodically replaced parts

and consumables/durables and scheduled servicing charts.

Chapter 10

Troubleshooting

provides tables of maintenance/inspection,

standards/adjustments, and problem identification (image

fault/malfunction).

Appendix contains a general timing chart and general circuit diagrams.

INTRODUCTION

This Service Manual provides basic facts and figures needed to service the plain

paper copier NP6045 in the field. The NP6045 is designed to enable automated copying

work and may be configured with the following system components:

1. Stapler Sorter-E2, Stapler Sorter-G1, Sorter-E1, Sorter-G1

2. RDF-H1

For descriptions on the system components, see their respective service manuals.

This Service Manual covers the copier only, and consists of the following chapters:

Chapter 1

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV.1 MAR. 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

i

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the

relationship between electrical and mechanical systems with reference to the

timing of operation.

In the diagrams, represents the path of mechanical drive—where a

signal name accompanies the symbol , the arrow indicates the direction

of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the

front door, and closing the delivery unit door, which results in supplying the machine

with power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal

is "High," while '0' is used to indicate "Low." (The voltage value, however, differs

from circuit to circuit.)

In practically all cases, the internal mechanisms of a microprocessor cannot be

checked in the field. Therefore, the operations of the microprocessors used in the

machines are not discussed: they are explained in terms of from sensors to the

input of the DC controller PCB and from the output of the DC controller PCB to the

loads.

The descriptions in this Service Manual are subject to change without notice for

product improvement or other reasons, and major changes will be communicated in the

form of

Service Information

bulletins.

All service persons are expected to have a good understanding of the contents of this

Service Manual and all relevant

Service Information

bulletins and be able to identify and

isolate faults in the machine.

ii

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV.1 MAR. 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

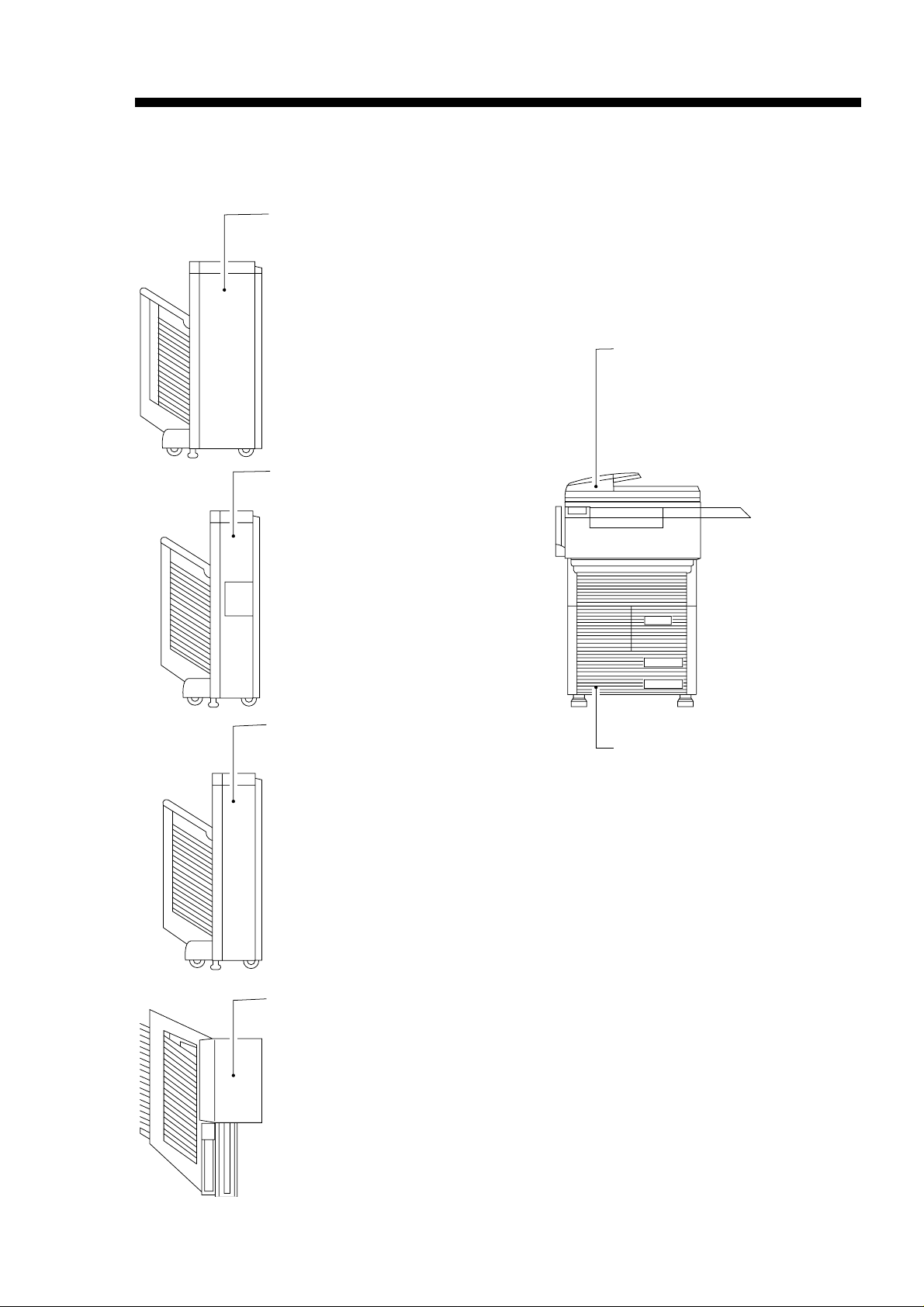

System Configuration

Stapler Sorter-G1

In addition to the functions of a 20-bin sorter,

automatically staples sorted copies.

Sorter-G1

Is a 20-bin sorter capable of automatic

sorting and grouping.

Sorter-E1

Is a 20-bin sorter capable of automatic sorting and grouping.

Stapler Sorter-E2

In addition to the functions of a 20-bin sorter, automatically staples sorted copies.

Further, it swings out copies to the front for removal, and is equipped with a multiple

stacking function, in which two or more sets of copies may be delivered to a single bin.

RDF-H1

Feeds originals one by one from a stack

to the copyboard for copying.

NP6045

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV.1 MAR. 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

iii

blank page

iv

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV.1 MAR. 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

v

CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES.........................................1-1

II. SPECIFICATIONS..............................1-2

1. Type..........................................1-2

2. System .....................................1-2

3. Performance.............................1-3

4. Others.......................................1-6

III. NAMES OF PARTS............................1-9

A. External View.................................1-9

B. Cross Section ................................1-11

1. Cross Section of the Body .......1-11

IV. OPERATIONS ....................................1-12

A. Control Panel.................................1-12

B. Special Features Mode .................1-13

C. User Mode.....................................1-14

1. Types of User Modes...............1-14

V. ROUTINE WORK BY THE USER......1-18

VI. IMAGE FORMATION ..........................1-19

A. Outline ...........................................1-19

CHAPTER 2 BASIC OPERATION

I. BASIC OPERATIONS ........................2-1

A. Functional Construction.................2-1

B. Outline of the Electric Circuitry......2-2

C. Basic Sequence of Operations......2-4

1. Basic Sequence of Operations

at Power-On (1/2).....................2-4

2. Basic Sequence of Operations

at Power-On (2/2).....................2-5

3. Basic Sequence of Operations

during Copying.........................2-7

4. Basic Sequence of Operations

for Page Separation .................2-9

D. Main Motor (M1) Control Circuit....2-11

1. Outline......................................2-11

2. Operations................................2-11

3. Detecting an Error....................2-12

E. Inputs to the DC Controller ............2-13

F. Outputs from the DC Controller .....2-21

G. Inputs to and Outputs from the

Options..........................................2-33

CHAPTER 3 EXPOSURE SYSTEM

I. BASIC OPERATIONS ........................3-1

A. Varying the Reproduction Ratio.....3-1

II. LENS DRIVE MECHANISM...............3-2

A. Moving the Lens............................3-2

1. Outline......................................3-2

2. Moving the Lens.......................3-3

3. Controlling the Lens Motors.....3-3

4. Moving the Lens.......................3-4

III. SCANNER DRIVE MECHANISM.......3-6

A. Driving the Scanner.......................3-6

1. Outline......................................3-6

2. Relationship between Scanner

Sensor and Signals..................3-7

3. Basic Sequence of Operations

for Scanner Movement.............3-8

4. Sequence of Operations for

Scanner Movement (page

separation) ...............................3-9

5. Scanner Motor (M3) Control

Circuit .......................................3-11

IV. OTHERS.............................................3-13

A. Detecting the Size of Originals......3-13

1. Outline......................................3-13

2. Operation..................................3-14

3. Sizes of Originals .....................3-15

V. DISASSEMBLY AND ASSEMBLY......3-17

A. Scanner Drive System ...................3-17

1. Removing the Scanner Drive

Assembly Motor........................3-17

2. Outline of the Scanner Drive

Cable........................................3-19

3. Removing the Scanner Drive

Cable........................................3-20

4. Adjusting the Tension of the

Scanner Drive System .............3-22

5. Positioning the Mirror ...............3-23

6. Adjusting the Position of the

Scanner....................................3-24

B. Lens Drive Assembly .....................3-25

1. Removing the Lens Y Direction

Drive Motor ...............................3-25

2. Removing the Lens Stage

Temporarily...............................3-27

3. Installing the Light-Blocking

Belt ...........................................3-28

4. Removing the Lens X Direction

Drive Motor ...............................3-29

5. Attaching the Lens X Direction

Drive Belt ..................................3-30

6. Attaching the Light-Blocking

Belt ...........................................3-30

7. When Replacing the Light-

Blocking Belt.............................3-31

CHAPTER 4 IMAGE FORMATION SYSTEM

I. PROCESSES .....................................4-1

A. Controlling the Surface Potential

of the Drum....................................4-1

1. Outline......................................4-1

2. Control Method .........................4-2

3. Potential Measurement Circuit.4-5

B. Controlling the Scanning Lamp

Intensity.........................................4-6

1. Outline......................................4-6

2. Operations................................4-6

3. Automatic Exposure Control

(AE) ..........................................4-7

4. Check Points............................4-9

C. Controlling the Primary/Transfer

Corona Current..............................4-10

1. Outline......................................4-10

2. Controlling the Primary

Corona Current.........................4-10

3. Controlling the Transfer

Corona Current.........................4-11

D. Controlling the Separation/Pre-

Transfer Corona Current...............4-13

1. Outline......................................4-13

2. Turning ON and OFF the

Separation/ Pre-Transfer

Corona Current.........................4-15

3. Separation Corona Current

(DC component).......................4-15

4. Pre-Transfer Corona Current

(DC component).......................4-15

5. Controlling the DC Component

Overcurrent of the Separation/

Pre-Transfer Corona Current ...4-16

E. Controlling the Blank Exposure

Lamp (LEDs) .................................4-17

1. Outline......................................4-17

2. Controlling the Activation in

Reduce Mode...........................4-17

3. Controlling the Activation in

Direct Mode..............................4-17

4. Controlling the Activation in

Sheet Frame Erasing Mode.....4-17

5. Controlling the Activation in

Original Frame Erasing Mode..4-18

6. Controlling the Activation in

Book Frame Erasing Mode ......4-18

7. Controlling the Activation in

Hole Image Erasing Mode........4-19

8. Controlling the Activation of

AE Mode...................................4-19

F. Drum Heater Circuit .......................4-20

1. Outline......................................4-20

2. Idle Rotation of the

Photosensitive Drum and the

Developing Cylinder.................4-22

G. Cleaning the Primary Charging

Wire...............................................4-23

1. Outline......................................4-23

2. Operation of the Primary

Charging Wire Cleaning Wire...4-23

H. Cleaning the Pre-Transfer,

Transfer, and Separation

Charging Wires Automatically.......4-24

II. DEVELOPING ASSEMBLY AND

CLEANING ASSEMBLY.....................4-26

A. Outline ...........................................4-26

B. Detecting the Toner Level and

Controlling the Supply Operation ..4-27

C. Controlling the Developing

Bias/Roller Electrode.....................4-29

1. Outline......................................4-29

2. Control Timing..........................4-29

3. Developing Bias Control

Circuit .......................................4-32

4. Roller Electrode Bias Control

Circuit .......................................4-33

D. Detecting the Locking of the

Waste Toner Feeding Screw.........4-35

III. DISASSEMBLY AND ASSEMBLY......4-36

A. Scanning Lamp .............................4-36

1. Removing the Scanning Lamp.4-36

2. Removing the Thermal Fuse ....4-37

B. Standard White Plate Assembly....4-38

C. Pre-Exposure Lamp Unit...............4-40

1. Removing the Pre-Exposure

Lamp Unit.................................4-40

D. Blank Exposure Lamp Assembly ..4-41

vi

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV.1 MAR. 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

1. Removing the Blank Exposure

Lamp Assembly ........................4-41

E. Photosensitive Drum .....................4-42

1. Removing the Drum Unit ..........4-42

2. Replacing the Drum Heater......4-44

3. Installing the Photosensitive

Drum.........................................4-44

F. Potential Sensor Assembly ...........4-44

1. Removing the Potential

Sensor Assembly .....................4-44

G. Primary Charging Assembly..........4-45

1. Removing the Primary

Charging Assembly..................4-45

H. Pre-Transfer Charging Assembly..4-45

1. Removing the Pre-Transfer

Charging Assembly..................4-45

I. Transfer/Separation Charging

Assembly.......................................4-46

1. Removing the Transfer/

Separation Charging

Assembly..................................4-46

2. Installing the Transfer/

Separation Charging

Assembly..................................4-47

J. Charging Wire ...............................4-49

1. Outline......................................4-49

2. Removing the Primary

Charging Assembly Wire

Cleaner.....................................4-49

3. Installing the Charging Wire.....4-49

4. Routing the Grid for the

Primary Charging Assembly.....4-51

5. Adjusting the Height of the

Charging Wire ..........................4-53

6. Cleaning the Primary Charging

Assembly Anti-Stray Toner

Sheet........................................4-54

K. Developing Assembly....................4-55

1. Removing from the Developing

Assembly..................................4-55

2. Removing the Blade Unit .........4-56

3. Installing the Blade...................4-56

4. Removing the Developing

Cylinder and the Magnetic

Seal ..........................................4-57

5. Cleaning the Developing

Assembly Anti-Stray Toner

Sheet........................................4-59

L. Hopper Assembly..........................4-60

1. Removing the Hopper

Assembly..................................4-60

M. Drum Cleaner................................4-61

1. Construction .............................4-61

2. Removing the Cleaning Blade..4-61

3. Installing the Cleaning Blade....4-62

4. Installing the Side Seal.............4-63

5. Cleaning the Cleaning Side

Scraper.....................................4-63

N. Separation Claw/Separation

Claw Drive Assembly ....................4-65

1. Removing the Separation

Claw/Separation Drive

Assembly from the Drum Unit..4-65

O. Waste Toner Feeding Assembly....4-66

CHAPTER 5 PICK-UP/FEEDING SYSTEM

I. PICK-UP/FEEDING SYSTEM............5-1

A. Outline ...........................................5-1

II. PICK-UP FROM THE CASSETTE.....5-3

A. Pick-Up Operation .........................5-3

1. Outline......................................5-4

2. Sequence of Pick-Up

Operations................................5-4

B. Cassette Lifter Operations .............5-5

C. Detecting the Size of Copy

Paper in the Cassette....................5-7

1. Outline......................................5-7

2. Detecting the Size of Paper .....5-7

3. Markings on the Width Guide

Rail ...........................................5-8

4. Paper Sizes..............................5-9

5. Registering Paper Width Basic

Value.........................................5-10

III.

PICK-UP FROM THE PAPER DECK

A. Outline ...........................................5-11

1. Pick-Up Operations..................5-12

....5-11

2. Sequence of Pick-Up

Operations................................5-12

B. Lifter Operations............................5-13

1. Operations................................5-13

2. Deck Limit Detection ................5-14

C. Detecting Paper for the Deck........5-15

1. Detecting the Presence/

Absence of Paper.....................5-15

2. Detecting the Deck Size ...........5-15

D. High-Speed Pick-Up......................5-15

IV. PICK-UP FROM THE

MULTIFEEDER...................................5-16

A. Pick-Up Operation .........................5-16

B. Detecting the Size of Paper in

the Multifeeder...............................5-17

C. Sequence of Operations

(multifeeder) ..................................5-18

V. CONTROLLING THE

REGISTRATION CLUTCH .................5-19

VI. MAKING TWO-SIDED/OVERLAY

COPIES (1st SIDE) ............................5-20

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV.1 MAR. 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

vii

A. Two-Sided/Overlay Copy

Operation .......................................5-20

1. Sequence of Operations for

Making Two-Sided/Overlay

Copies (1st side) ......................5-21

B. Making Two-Sided Copies

(2nd side) ......................................5-22

1. Sequence of Operations for

Making Two-Sided Copies

(2nd side) .................................5-23

C. Making Overlay Copies

(2nd side) ......................................5-24

1. Outline......................................5-24

2. Outline of Operations ...............5-25

3. Sequence of Operations for

Overlay Copies (2nd side)........5-27

D. Reversal Delivery ..........................5-28

1. Sequence of Reversal

Delivery Operations ..................5-29

E. Switching Paper Sizes for Two-

Sided/Overlay/Reversal Delivery

Copies ...........................................5-30

1. Movement of the Paper Size

Guide........................................5-30

2. Movement of the Paper

Jogging Plate and the Rear

Guide Plate...............................5-31

3. Detecting Copy Paper..............5-32

F. Re-Pick Up from the Holding

Tray................................................5-33

G. Skipping.........................................5-34

1. Outline......................................5-34

2. Operation..................................5-34

3. Skip Mode (copying an even

number of originals) .................5-35

4. Skip Mode (copying an odd

number of originals) .................5-37

5. Reverse Delivery......................5-39

VII. DETECTING JAMS............................5-40

A. Outline ...........................................5-40

1. Registration Roller Delay Jam..5-43

2. Registration Roller Stationary

Jam...........................................5-43

3. Pick-Up Vertical Path Feeding

0/1 Delay Jam ..........................5-44

4. Pick-Up Vertical Path Feeding

0/1 Stationary Jam ...................5-44

5. Pick-Up Vertical Path Feeding

2–4 Delay Jam .........................5-45

6. Pick-Up Vertical Path Feeding

2–4 Stationary Jam ..................5-45

7. Fixing Assembly Outlet Delay

Jam...........................................5-46

8. Fixing Assembly Outlet

Stationary Jam .........................5-46

9. External Delivery Delay Jam....5-47

10.External Delivery Stationary

Jam...........................................5-47

11.Internal Delivery Delay Jam .....5-48

12.Internal Delivery Paper

Stationary Jam .........................5-48

13.Holding Tray Inlet Delay Jam...5-49

14.Holding Tray Inlet Stationary

Jam...........................................5-49

15.Holding Tray Re-Pick Up Delay

Jam...........................................5-50

16.Holding Tray Registration

Delay Jam ................................5-50

17.Holding Tray Registration

Stationary Jam .........................5-51

18.Holding Tray Feeding 1/2

Delay Jam ................................5-51

19.Holding Tray Feeding 1/2

Stationary Jam .........................5-52

20.Fixing Assembly Separation

Claw Stationary Jam ................5-52

VIII. DISASSEMBLY AND ASSEMBLY......5-53

A. Multifeeder Assembly ....................5-53

1. Removing the Multifeeder

Assembly..................................5-53

2. Removing the Pick-Up Roller...5-54

3. Installing the Pick-Up Roller.....5-54

4. Removing the Separation

Roller........................................5-55

5. Removing the Feeding Roller...5-57

6. Removing the Multifeeder

Paper Sensor ...........................5-58

7. Attaching the Side Guide

Timing Belt for the Multifeeder

Assembly..................................5-60

8. Installing the Feeding Roller of

the Multifeeder..........................5-60

9. Adjusting the Pick-Up/Feeding

Roller Pressure (multifeeder) ...5-61

10.Positioning the Pick-Up Roller

Releasing Solenoid

(multifeeder) .............................5-61

B. Paper Deck Assembly...................5-62

1. Removing the Paper Deck

Assembly from the Copier ........5-62

2. Removing the Lifter Cable........5-63

3. Changing the Deck Paper

Size ..........................................5-68

4. Adjusting the Registration for

the Deck...................................5-70

C .Cassette/Paper Deck Pick-Up

Assembly.......................................5-71

1. Removing the Pick-Up

Assembly from the Copier ........5-71

2. Removing the Pick-Up Roller...5-71

3. Removing the Feeding Roller...5-73

4. Removing the Separation

Roller........................................5-73

5. Adjusting the Separation

Roller Pressure.........................5-75

6. Orientation of the Separation

Roller........................................5-76

viii

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV.1 MAR. 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

7. Orientation of the Feeding

Roller of the Cassette/Deck

Pick-Up Assembly....................5-76

8. Position of the Pick-Up Roller

Releasing Solenoid of the

Deck .........................................5-77

9. Position of the Pick-Up Roller

Releasing Solenoid for the

Cassette ...................................5-77

10.Adjusting Registration for the

Cassette ...................................5-77

D. Pick-Up Vertical Path Roller

Assembly.......................................5-78

1. Removing the Pick-Up Vertical

Path Roller Assembly...............5-78

E. Registration Feeding Assembly .....5-79

1. Construction .............................5-79

2. Removing the Registration

Feeding Assembly ....................5-79

3. Removing the Registration

Roller (upper rubber)................5-80

F. Feeding Assembly.........................5-82

1. Construction .............................5-82

2. Removing the Fixing/Feeding

Unit...........................................5-82

3. Removing the Feeding Belt ......5-83

G. Holding Tray Assembly..................5-86

1. Construction .............................5-86

2. Removing the Holding Tray

Assembly from the Copier ........5-87

3. Removing the Holding Tray

Re-Pick Up Assembly ..............5-87

4. Removing the Holding Tray

Registration Paper Sensor.......5-88

5. Removing the Re-Pick Up

Roller........................................5-89

6. Removing the Holding Tray

Driver PCB ...............................5-89

7. Removing the Holding Tray Y

Motor ........................................5-90

8. Removing the Y Motor Home

Position Sensor........................5-92

9. Removing the Holding Tray

Inlet Assembly..........................5-92

10.Removing the Feeding

Roller/Separation Belt

Assembly..................................5-94

11.Removing the Feeding Roller...5-95

12.Removing the Separation Belt

Assembly..................................5-96

13.Adjusting the Pressure of the

Separation Roller of the

Holding Tray.............................5-96

14.Position of the Holding Tray

Paper Deflecting Plate Drive

Solenoid ...................................5-97

15.Removing the Side Guide

Plate .........................................5-97

16.Removing the Holding Tray X

Motor ........................................5-98

17.Removing the Holding Tray

Re-Circulating Motor ................5-98

18.Removing the Holding Tray

Paper Jogging Solenoid...........5-99

19.Installing the Holding Tray

Paper Jogging Guide Plate

Assembly..................................5-101

20.Installing the Holding Tray

Assembly Side Guide Plate

Assembly..................................5-101

21.Attaching the Timing Belt for

the Holding Tray Assembly

Paper Jogging Guide Plate......5-102

22.Position of the Holding Tray

Paper Jogging Solenoid...........5-102

H. Holding Tray Feeding Assembly ...5-103

1. Removing the Holding Tray

Feeding Assembly from the

Copier.......................................5-103

2. Removing the Sensor from the

Holding Tray.............................5-104

CHAPTER 6 FIXING SYSTEM

I. BASIC OPERATIONS ........................6-1

A. Outline ...........................................6-1

B. Fixing Drive Assembly...................6-2

C. Controlling the Fixing

Temperature ..................................6-3

D. Reciprocating Mechanism for

the Main Thermistor (TH1)............6-8

E. Reciprocating Mechanism for

the Upper Separation Claw...........6-9

F. Fixing Heater SSR Error

Detection Circuit............................6-10

G. Locking the Fixing/Feeding Unit....6-12

H. Error Detection Circuit...................6-13

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV.1 MAR. 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

II. DISASSEMBLY AND ASSEMBLY......6-16

1. Outline......................................6-13

2. Scanning Lamp Error

Activation Detection Circuit ......6-14

3. Fixing Heater Error Activation

Detection Circuit.......................6-15

A. Fixing Assembly ............................6-16

1. Construction .............................6-16

2. Locking Mechanism..................6-16

3. Removing the Fixing Cleaning

Belt ...........................................6-17

4. Installing the Fixing Cleaning

Belt ...........................................6-19

ix

5. Removing the Upper Fixing

Unit...........................................6-20

6. Removing the Fixing Heater.....6-22

7. Installing the Fixing Heater.......6-24

8. Removing the Upper Fixing

Roller........................................6-24

9. Installing the Upper Fixing

Roller........................................6-26

10.Removing the Thermal Switch .6-27

11.Removing the Main Thermistor

(TH1) ........................................6-27

12.Removing the Lower

Separation Claw Assembly ......6-28

13.Removing the Lower Roller......6-29

14.Removing the Upper

Separation Claw.......................6-30

15.Adjusting the Nip (tightening

the pressure adjusting nut).......6-30

16.Adjusting the Fixing Clutch.......6-31

17.Removing the Sub Thermistor

(TH2) Unit .................................6-32

B. Delivery Assembly.........................6-33

1. Construction .............................6-33

2. Removing the Delivery Upper

Guide (fixing delivery

assembly).................................6-33

3. Removing the Fixing/Feeding

Locking Assembly ....................6-34

4. Removing the External

Delivery Roller..........................6-34

5. Removing the External Delivery

Sensor and the Internal

Delivery Sensor........................6-36

6. Removing the Fixing Assembly

Outlet Paper Sensor

Assembly..................................6-36

7. Removing the Internal Delivery

Roller........................................6-37

CHAPTER 7 EXTERNALS/AUXILIARY MECHANISMS

I. CONTROL PANEL .............................7-1

A. Outline ...........................................7-1

B. Operation.......................................7-1

1. Data Communication ................7-1

2. LCD Processing .......................7-2

3. LCD Contrast Automatic

Adjustment ...............................7-3

4. Touch Switch Input...................7-4

II. FANS..................................................7-5

III. POWER SUPPLY...............................7-8

A. Outline of Power Supply................7-8

B. Power Supply Circuit.....................7-9

C. Power Supply for Date/Time

Display ...........................................7-11

IV. DISASSEMBLY AND ASSEMBLY......7-12

A. External Covers.............................7-12

1. Removing the Front Door .........7-13

2. Removing the Inside Upper

Cover........................................7-15

3. Removing the Fixing/Feeding

Unit Front Cover.......................7-15

4. Removing the Rear Cover........7-16

5. Sliding Out the Hopper

Assembly..................................7-16

6. Removing the Process Unit......7-17

7. Installing the Process Unit........7-19

B. Control Panel.................................7-20

1. Removing the Control Panel

from the Copier ........................7-20

2. Removing the Control Panel

PCB..........................................7-24

3. Removing the Touch Panel......7-24

4. Removing the Control Panel

CPU PCB .................................7-25

C. Door Switch Assembly ..................7-26

1. Removing the Front Door

Switch Assembly......................7-26

2. Removing the Multifeeder

Door Switch Assembly .............7-27

3. Installing the Drum Heater

Switch.......................................7-27

D. Fan Unit.........................................7-28

1. Removing the Scanner

Cooling Fan..............................7-28

2. Removing the Air Exhaust

Fan ...........................................7-28

3. Removing the Fixing Air

Exhaust Fan.............................7-29

4. Removing the Developing

Fan ...........................................7-29

5. Removing the Cleaner Fan......7-30

6. Removing the Feeding Fan ......7-31

E. Removing the Counter Assembly..7-31

F. Main Motor Assembly....................7-32

1. Removing the Main Motor........7-32

G. Fixing/Waste Toner Drive

Assembly.......................................7-32

1. Construction .............................7-32

2. Removing the Waste Toner

Bottle ........................................7-33

3. Removing the Fixing/Waste

Toner Drive Assembly..............7-33

H. Drive Assembly (drum/

developing assembly)....................7-35

1. Construction .............................7-35

2. Removing the Drive Assembly.7-35

I. Vertical Path Drive Assembly........7-36

1. Construction .............................7-36

2. Removing the Vertical Path

Drive Assembly ........................7-37

x

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV.1 MAR. 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

J. Pick-Up Drive Assembly................7-39

1. Construction .............................7-39

2. Removing the Pick-Up Drive

Assembly..................................7-39

K. Duplexing Unit Drive 1 Assembly..7-40

1. Construction .............................7-40

2. Removing the Duplexing Unit

Drive 1 Assembly .....................7-40

L. Lifter Drive Assembly ....................7-41

1. Construction .............................7-41

2. Removing the Lifter Assembly .7-42

M. Cassette Pick-Up Drive

Assembly.......................................7-43

1. Construction .............................7-43

2. Removing the Cassette

Pick-Up Drive Assembly...........7-43

CHAPTER 8 INSTALLATION

N. Attaching the Drive Belt.................7-45

O. DC Controller PCB........................7-46

1. Removing the DC Controller

PCB..........................................7-46

2. Points to Note When Replacing

the DC Controller PCB.............7-46

P. DC Power Supply Assembly.........7-47

1. Removing the DC Power

Supply Assembly ......................7-47

Q. High-Voltage Transformer

Assembly.......................................7-48

1. Remove the High-Voltage

Transformer Assembly.............7-48

R. Power Supply Input Assembly ......7-49

I. SELECTING THE SITE......................8-1

II. UNPACKING AND INSTALLATION....8-3

A. Unpacking ......................................8-4

B. Installing the Scanner....................8-6

C. Installing the Fixing Assembly.......8-7

D. Installing the AP Kit and the

Charging Assembly .......................8-9

E. Installing the Copy Tray.................8-15

1. Replacing the Delivery Gear....8-15

2. Replacing the Leaf Springs of

the Delivery Roller....................8-16

CHAPTER 9 MAINTENANCE AND SERVICING

I.

PERIODICALLY REPLACED PARTS

II. CONSUMABLES AND DURABLES...9-2

A. Copier............................................9-2

B. RDF-H1 .........................................9-3

...9-1

CHAPTER 10 TROUBLESHOOTING

F. Checking the Developing

Assembly.......................................8-17

G. Installing the Pick-Up Assembly....8-19

H. Supplying Toner.............................8-20

I. Setting Images/Functions and

User Mode.....................................8-24

III. RELOCATING THE MACHINE...........8-28

IV. INSTALLING THE CONTROL

CARD V..............................................8-29

III. SCHEDULED SERVICING.................9-4

IV. SCHEDULED SERVICING CHART...9-6

A. Copier............................................9-6

B. RDF-H1 .........................................9-8

I. MAINTENANCE AND INSPECTION ..10-3

A. Image Adjustment Basic

Procedure....................................10-3

B. Points to Note for Scheduled

Servicing......................................10-4

II. STANDARDS AND

ADJUSTMENTS...............................10-5

A. Image Adjustment .......................10-5

1. Adjusting the Leading Edge

Margin ....................................10-5

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV.1 MAR. 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

2. Adjusting the Leading Edge

Non-Image Width

(registration)...........................10-5

3. Adjusting the Left/Right

Registration (paper deck and

cassette position)...................10-5

4. Adjusting the Left/Right

Registration (holding tray

position; 2nd side of a two-

sided/overlay copy)................10-7

xi

5. Adjusting the Left/Right

]4])..................10-53

III. TROUBLESHOOTING IMAGE

FAULTS............................................10-54

A. Making Initial Checks ..................10-54

1. Site of Installation ...................10-54

2. Checking the Originals...........10-54

3. Copyboard Cover, Copyboard

Glass, and Standard White

Plate.......................................10-54

4. Charging Assemblies.............10-54

Margin ....................................10-8

6. AE Auto Adjustment...............10-8

7. Adjusting the AE Slope..........10-9

B. Exposure System ........................10-10

1. Adjusting the Scanner Home

Position...................................10-10

2. Routing the Scanner Drive

Cable......................................10-11

3. Adjusting the Tension of the

Scanner Cable .......................10-12

4. Adjusting the Mirror Position..10-12

5. Cleaning the Mirror (No. 5

mirror) .....................................10-13

6. Installing the Light-Blocking

Belts .......................................10-13

7. Installing the Lens X

Direction Drive Belt ................10-14

C. Image Formation System............10-15

1. Routing the Grid for the

Primary Charging Assembly...10-15

2. Adjusting the Height of the

Charging Wire........................10-17

3. Adjusting the Blank Exposure

Lamp ......................................10-18

4. Position of the Roller

Electrode................................10-19

5. Position of the Side Seal in

the Cleaning Assembly ..........10-19

6. Cleaning the Cleaner Side

Scraper ...................................10-19

D. Pick-Up/Feeding System .............10-21

1. Orientation of the Pick-Up

Roller (cassette/deck) ............10-21

2. Orientation of the Separation

Roller (cassette/deck) ............10-22

3. Orientation of the Feeding

Roller (cassette/deck) ............10-22

4. Orientation of the Pick-Up

Roller (multifeeder).................10-23

5. Orientation of the Feeding

Roller (multifeeder).................10-24

6. Adjusting the Pressure of the

Separation Roller

(cassette/deck).......................10-24

7. Adjusting the Pressure of the

Separation Roller

(holding tray)..........................10-25

8. Adjusting the Pressure of the

Pick-Up/Feeding Roller

(multifeeder)...........................10-25

9. Positioning the Pick-Up Roller

Releasing Solenoid

(cassette)................................10-26

10.Adjusting the Position of the

Pick-Up Roller Releasing

Solenoid (deck)......................10-26

11.Adjusting the Pick-Up Roller

Releasing Solenoid

(multifeeder)...........................10-27

12.Routing the Timing Belt for the

Multifeeder Assembly Side

Guide ......................................10-27

13.Adjusting the Position of the

Delivery Paper Deflecting

Drive Solenoid........................10-28

14.Adjusting the Position of the

Holding Tray Paper Deflecting

Plate Drive Solenoid...............10-28

15.Installing the Holding Tray

Assembly Side Guide

Assembly ................................10-29

16.Installing the Holding Tray

Paper Jogging Guide

Assembly ................................10-29

17.Installing the Timing Belt for

the Holding Tray Assembly

Paper Jogging Guide Plate....10-30

18.Adjusting the Position of the

Holding Tray Paper Jogging

Solenoid .................................10-30

19.Installing the Drive Belt ..........10-31

E. Fixing System..............................10-32

1. Points to Note When

Handling the Fixing Heater ....10-32

2. Position of the Fixing

Assembly Paper Guide ..........10-32

3. Adjusting the Pressure of the

Lower Roller (nip) ...................10-33

4. Adjusting the Fixing Clutch ....10-34

F. Electrical System.........................10-35

1. When Replacing the DC

Controller PCB.......................10-35

2. Checking the Surface

Potential Control System........10-35

3. Checking the Potential

Control System.......................10-39

4. Potential Control System

Conversion Table ...................10-41

5. Checking the Environment

Sensor....................................10-46

6. Checking the

Photointerrupters ....................10-46

7. Registering the Cassette/

Multifeeder Paper Width

Basic Value (

xii

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV.1 MAR. 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

5. Checking the Developing

Assembly ................................10-55

6. Checking the Paper................10-55

7. Checking the Periodically

Replaced Parts.......................10-55

8. Others.....................................10-55

B. Image Fault Samples ..................10-58

C. Troubleshooting Image Faults.....10-59

1. The copy is too light.

(halftone area only)................10-59

2. The copy is too light. (solid

black also)..............................10-60

3. The copy is too light. (overall,

considerably)..........................10-60

4. The copy has uneven density.

(darker at front) ......................10-62

5. The copy has uneven density.

(lighter at front) .......................10-62

6. The copy is foggy. (overall)....10-63

7. The copy has vertical

fogging....................................10-64

8. The copy has black lines.

(vertical, fuzzy, thick)..............10-64

9. The copy has black lines.

(vertical, thin)..........................10-65

10.The copy has white spots.

(vertical)..................................10-66

11.The copy has white lines.

(vertical)..................................10-66

12.The copy has white spots.

(horizontal) .............................10-68

13.The back of the copy is

soiled......................................10-69

14.The copy has fixing faults. .....10-70

15., 16., 17. The copy has

leading edge displacement. ...10-71

18.The copy has a blurred or

fuzzy image............................10-72

19.The copy has horizontal

fogging....................................10-73

20.The copy has poor

sharpness. ..............................10-73

21.The copy is blank...................10-74

22.The copy is completely black...10-74

IV. TROUBLESHOOTING

MALFUNCTIONS.............................10-75

A. Troubleshooting Malfunctions .....10-75

1. E000.......................................10-75

2. E001.......................................10-76

3. E002.......................................10-77

4. E003.......................................10-77

5. E004.......................................10-77

6. E005.......................................10-78

7. E006.......................................10-78

8. E010.......................................10-78

9. E013.......................................10-79

10.E015.......................................10-80

11.E020.......................................10-81

12.E030 (The total copy counter

fails to operate.) .....................10-82

13.E031 (The option counter has

an open circuit.)......................10-82

14.E050.......................................10-83

15.E051.......................................10-83

16.E202 (Locks the keys but

does not indicate a code.) ......10-83

17.E203.......................................10-84

18.E204 (Locks the keys but

does not indicate a code.) ......10-84

19.E210 (The lens X direction

drive system has an error.)....10-84

20.E212 (The lens Y direction

drive system has an error.)....10-84

21.E240.......................................10-85

22.E243.......................................10-85

23.E710/E711..............................10-85

24.E712.......................................10-85

25.E713.......................................10-86

26.E800.......................................10-86

27 E802.......................................10-87

28.AC power is absent................10-88

29.DC power is absent. ...............10-89

30.Pick-up fails............................10-90

31.The deck lifter fails to move

up. ..........................................10-91

32.Pick-up fails. (cassette

pick-up)...................................10-92

33.The lifter fails to move up.

(cassette pick-up)...................10-94

34.Pick-up fails. (multifeeder)......10-95

35.The vertical path roller fails

to rotate..................................10-96

36.The registration roller fails

to rotate..................................10-96

37.The scanner fails to rotate

forward. ..................................10-97

38.The scanner fails to move in

reverse. ..................................10-97

39.The blank exposure lamp fails

to turn ON...............................10-98

40.The pre-exposure lamp fails

to turn ON...............................10-98

41.The pre-exposure lamp fails

to turn ON...............................10-99

42.The hopper motor (M10) fails

to operate...............................10-100

43.The hopper motor (M11) fails

to operate...............................10-101

44.The drum heater fails to

operate...................................10-101

45.The lens fails to move............10-102

46.The Add Toner indicator fails

to turn ON...............................10-103

47.The Add Toner message fails

to turn OFF.............................10-103

48.The Control Card Set

indicator fails to turn ON. .......10-104

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV.1 MAR. 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

xiii

49.The Control Card Set

indicator fails to turn OFF.......10-104

50.Paper jams at the fixing

assembly inlet. .......................10-104

51.The Add Paper indicator fails

to turn OFF.............................10-104

52.The fixing heater fails to turn

ON..........................................10-105

V. TROUBLESHOOTING FEEDING

PROBLEMS......................................10-106

A. Copy Paper Jams........................10-106

1. Pick-up assembly...................10-107

2. Separation/feeding assembly.10-108

3. Fixing/delivery assembly........10-109

4. Fixing/delivery assembly

(reversal delivery)...................10-109

5. Cleaning assembly.................10-110

6. Holding tray assembly

(copying on 1st side of two-

sided/overlay copy)................10-110

7. Holding tray assembly

(re-pick up).............................10-111

8. Holding tray assembly

(overlay re-pick up) ................10-111

9. Holding tray feeding

assembly................................10-112

B. Feeding Failure ...........................10-113

1. Double feeding.......................10-113

2. Wrinkling.................................10-113

VI. ARRANGEMENT/FUNCTIONS OF

THE ELECTRICAL PARTS ..............10-114

A. Sensors .......................................10-114

B. Switches and Solenoids..............10-118

C. Motors and Fans.........................10-122

D. Clutches ......................................10-124

E. Lamps, Heaters, and

Photosensors ..............................10-126

F. PCBs ...........................................10-128

G. Variable Resistors, Light-

Emitting Diodes, and Check

Pins by PCB................................10-130

1. DC Controls PCB...................10-130

2. AC Driver PCB.......................10-133

3. DC Power Supply PCB..........10-133

4. Control CPU PCB...................10-134

5. Holding Tray Driver PCB........10-135

6. Potential Measurement PCB ..10-136

7. HVT1 PCB..............................10-137

8. HVT2 PCB..............................10-138

9. Inverter PCB...........................10-138

10.Lamp Regulator PCB.............10-139

11.Counter PCB..........................10-139

VII. SERVICE MODE..............................10-140

A. Outline.........................................10-140

B. Using Service Mode....................10-140

C. Using Adjustment Mode and

Option Setting Mode ...................10-141

D. Control Display Mode ( 1 ) ....10-142

E. I/O Display Mode ( 2 ) ...........10-157

F. Adjustment Mode ( 3 )...........10-193

G. Function Mode ( 4 ) ...............10-211

H. Options Mode ( 5 ) ................10-222

I. Counter Mode ( 6 )................10-231

]]

]]

]]

]]

]]

]]

VIII. SELF DIAGNOSIS ...........................10-237

A. Copier..........................................10-237

B. RDF Self Diagnosis.....................10-242

C. Sorter Self Diagnosis ..................10-243

APPENDIX

A. GENERAL TIMING CHART ..........A-1

B.

SIGNALS AND ABBREVIATIONS

1. Signals......................................A-2

2. Abbreviations............................A-3

C. GENERAL CIRCUIT DIAGRAM ....A-5

...A-2

D. RDF-H1 GENERAL CIRCUIT

DIAGRAM ......................................A-7

E. SPECIAL TOOLS LIST .................A-9

F. SOLVENTS AND OILS..................A-10

xiv

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV.1 MAR. 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV. 1 MAR. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1

GENERAL DESCRIPTION

I. FEATURES.........................................1-1

II. SPECIFICATIONS..............................1-2

III. NAMES OF PARTS............................1-9

A. External View.................................1-9

B. Cross Section ................................1-11

IV. OPERATIONS ....................................1-12

A. Control Panel.................................1-12

B. Special Features Mode .................1-13

C. User Mode.....................................1-14

V. ROUTINE WORK BY THE USER......1-18

VI. IMAGE FORMATION ..........................1-19

A. Outline ...........................................1-19

This chapter introduces the copier's features and specifications, shows how to operate the copier, and

explains how copies are made.

blank page

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES

1. The NP6045 is capable of making as many as 45 copies (A4, horizontal) every

minute.

2. It uses newly designed pick-up and feeding mechanisms so that it not only helps

save space, but it also is less susceptible to jams.

3. It provides high durability and high image quality required of high-speed copying.

The use of the Canon-unique A-Si (amorphous silicon) photosensitive drum ensures

high durability while the single-component toner projection mechanism promises

high-quality images for a long time.

4. It is equipped with a large-size liquid crystal display, offering easy-to-understand

instructions.

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV. 1 MAR. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-1

CHAPTER 1 GENERAL DESCRIPTION

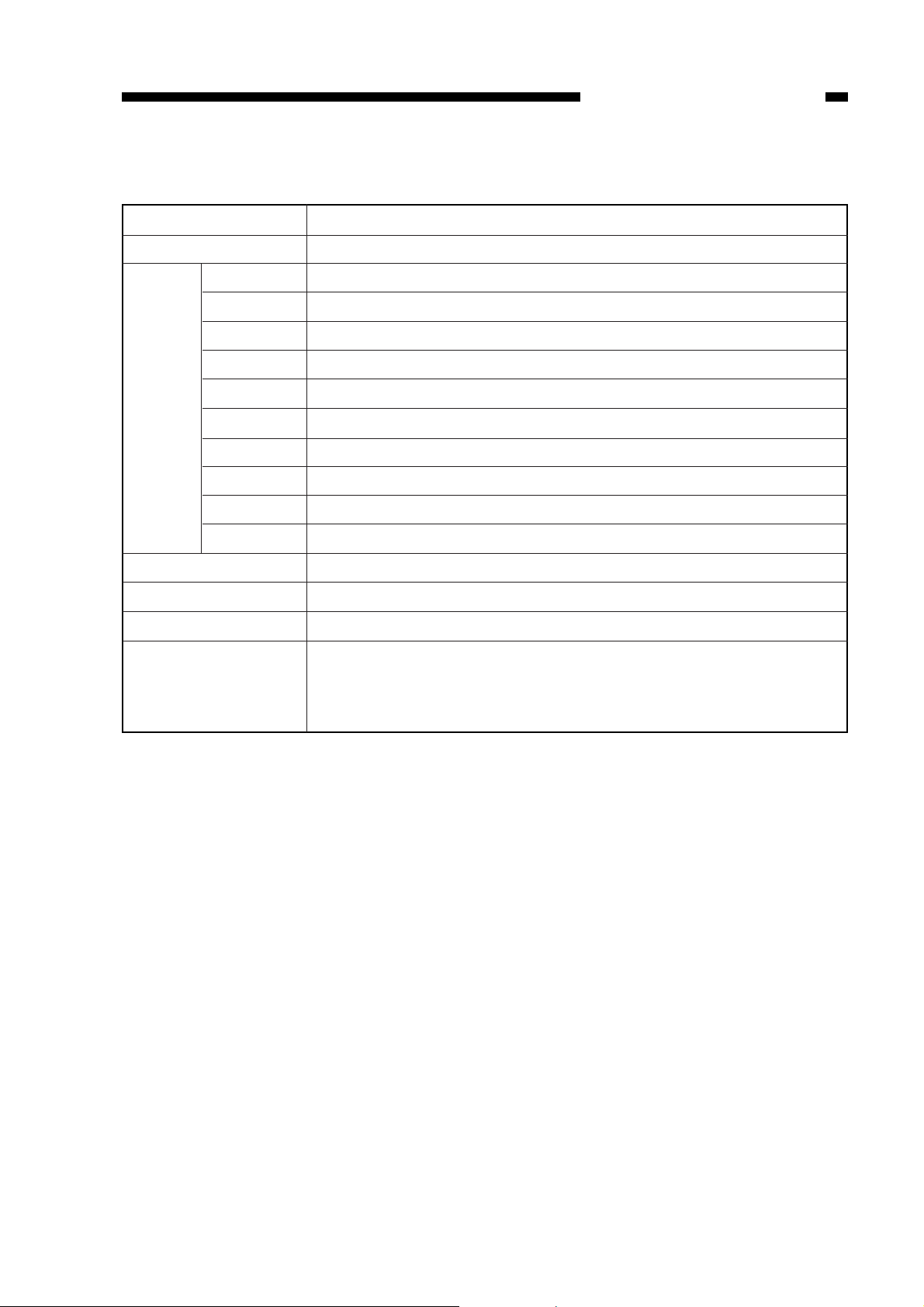

II. SPECIFICATIONS

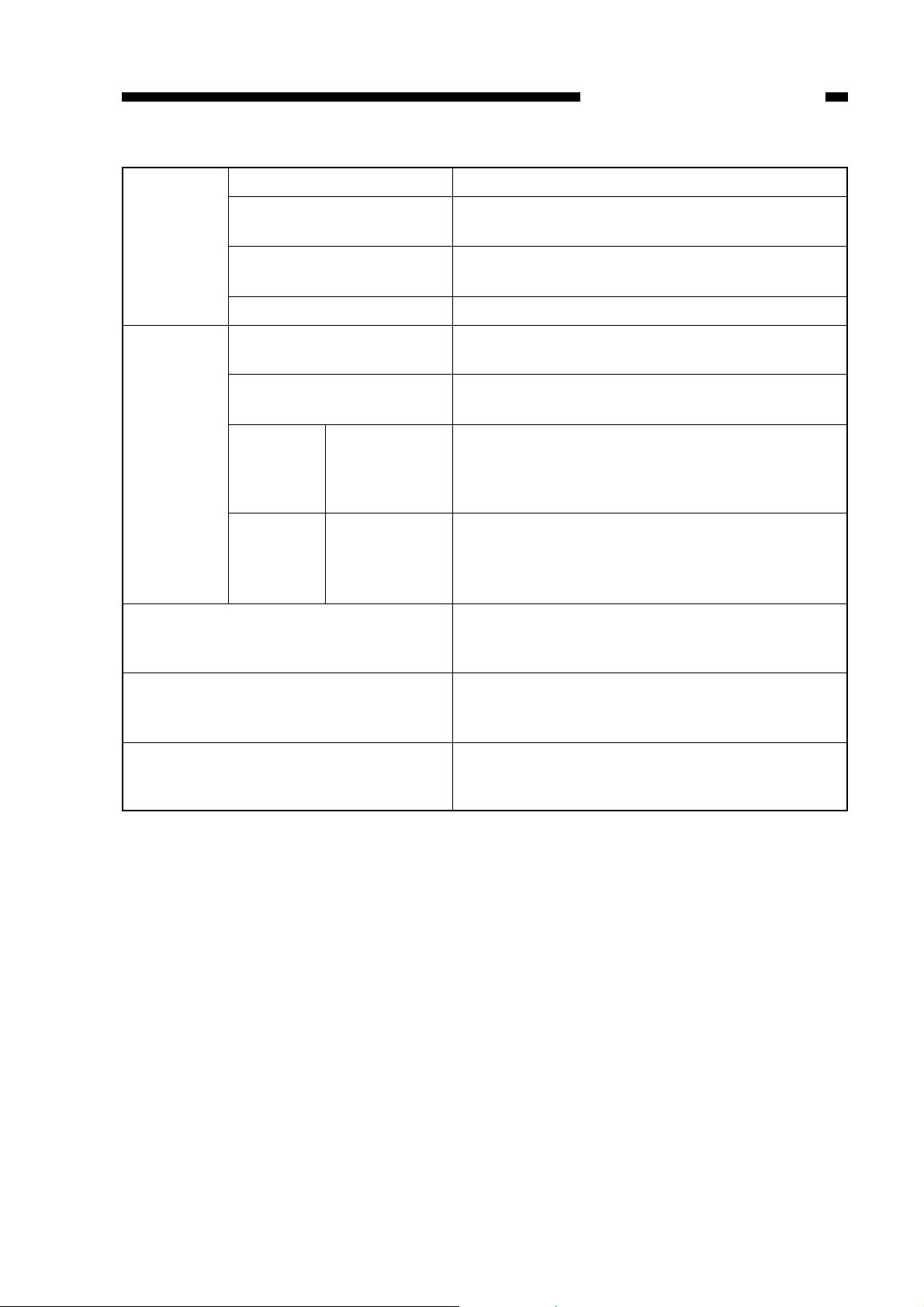

1. Type

Body

Copyboard

Light source

Lens

Photosensitive

medium

2. System

Body

Copying

Charging

Exposure

Copy density

adjustment

Development

Pick-up Automatic

Manual

Console

Fixed

Halogen lamp (70 V, 265 W)

Zoom lens

Amorphous silicon (ø80)

Front deck paper deck type

Indirect electrostatographic

Corona

Slit (moving light source)

Automatic or manual

Dry (toner projection)

2 front cassettes

1 front paper deck

Multifeeder (5.5 mm deep; 50 sheets of 80 g/m

2

paper)

Transfer

Separation

Cleaning

Fixing

Corona

Corona (static separation)

Blade

Heating roller (790 W + 410 W; 120 V), (1200 W; 220/240 V)

1-2

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV. 1 MAR. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

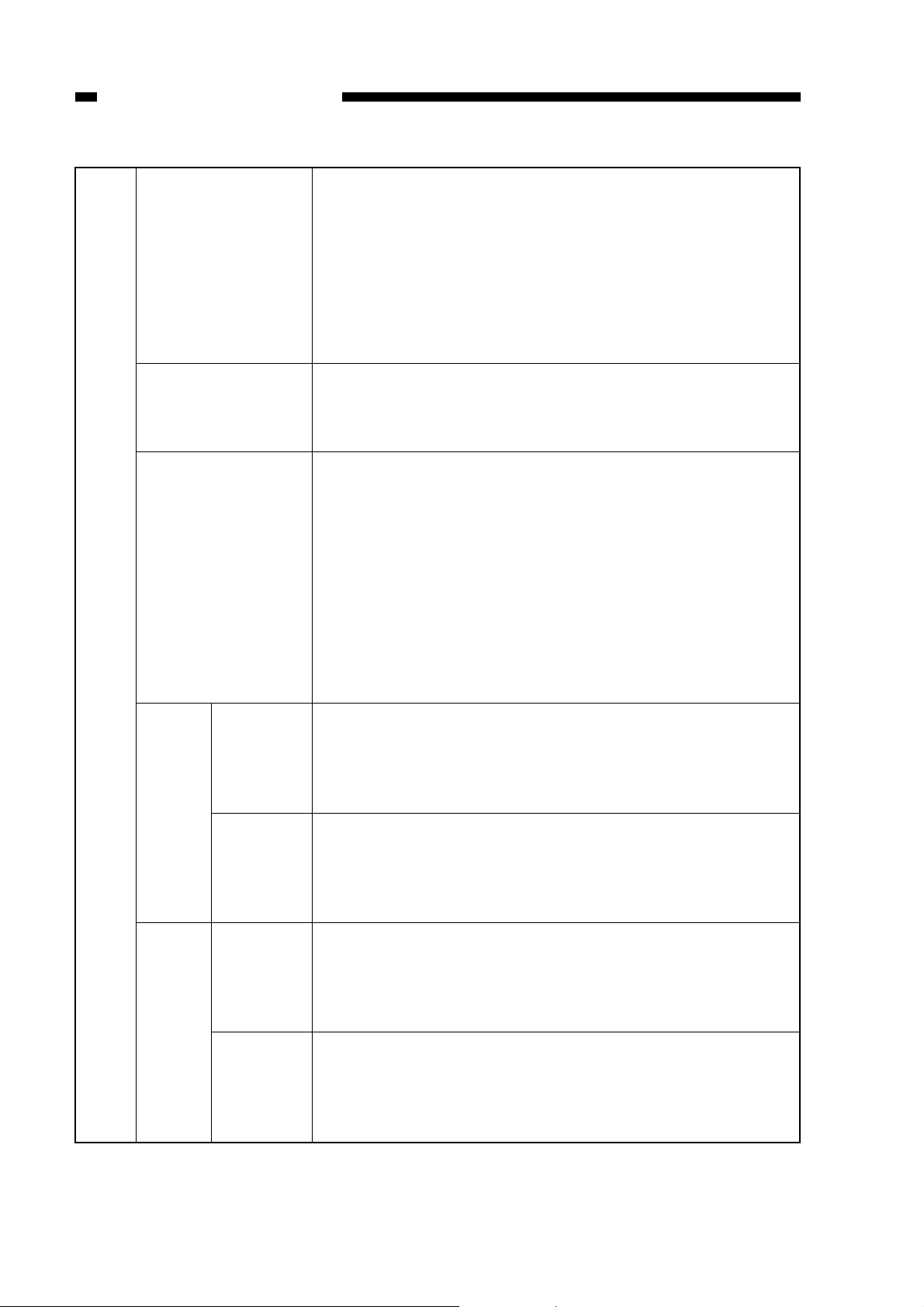

3. Performance

× 17"

1:1

1:0.500

1:0.707

1:0.816

1:0.865

1:2.000

1:1.414

1:1.224

1:1.154

1:0.490 to 2.040 (1% increments)

5 min or less (at 20°C room temperature)

3.0 sec (A4, non-AE, top cassette/paper deck)

999 copies max.

One-sided Metric A3 max. A6 (vertical, postcard) min.

Inch 11" × 17" max. STMT min.

Two-sided Metric A3 max. A5 (horizontal) min.

Inch 11" × 17" max. STMT (horizontal) min.

CHAPTER 1 GENERAL DESCRIPTION

Original type

Maximum original size

Direct

Reduce I

Reduce II

Reduce III

Copying

ratios

Reduce IV

Enlarge I

Enlarge II

Enlarge III

Enlarge IV

Zoom

Wait time

First copy

Continuous copying

Copy size

Sheet, book, 3-D object (2 kg max.)

A3/11"

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV. 1 MAR. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-3

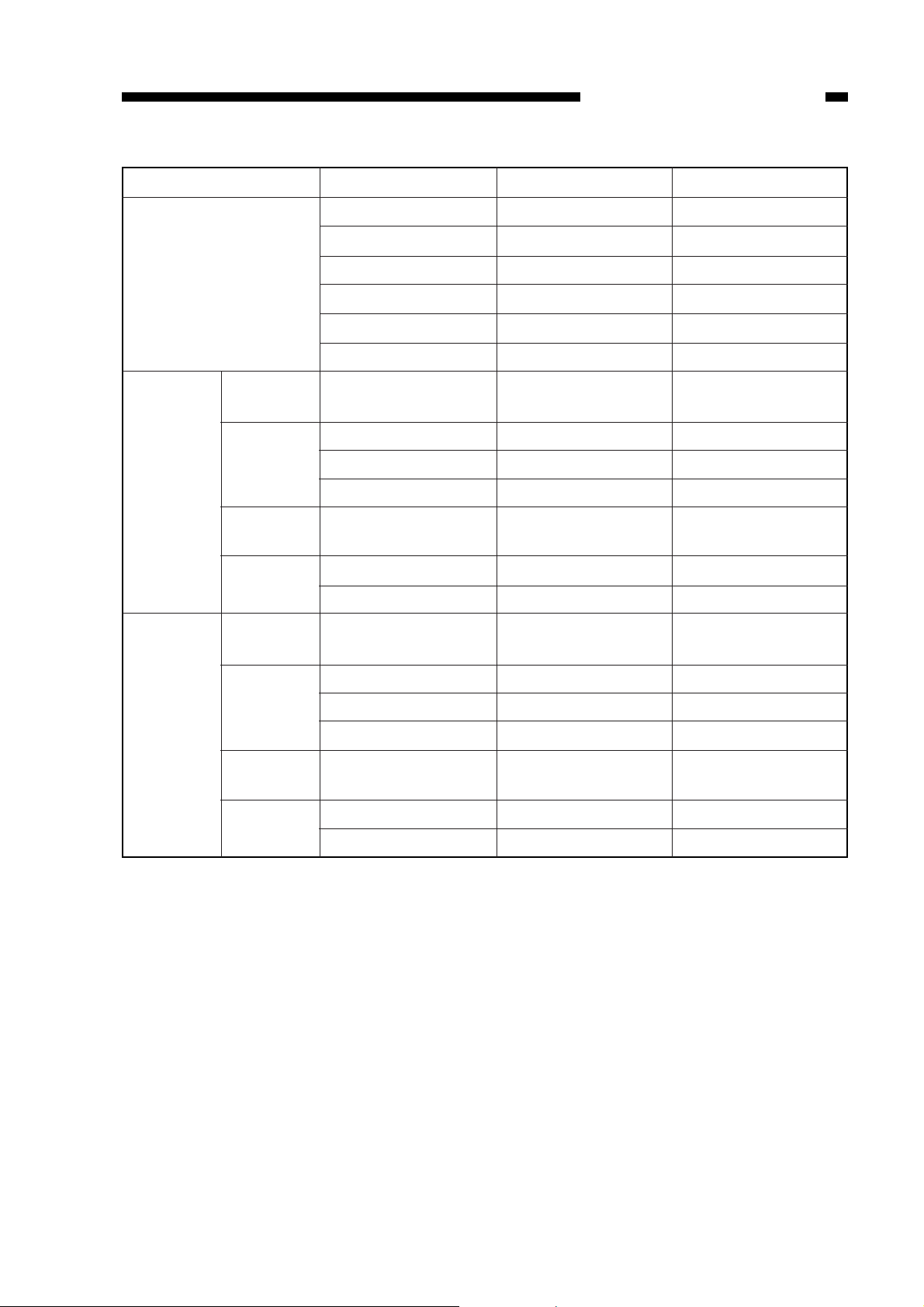

CHAPTER 1 GENERAL DESCRIPTION

Cassette

Paper deck

Automatic

Copy

paper

type

Automatic

Twosided

copying

Multifeeder

Automatic

Overlay

copying

Multifeeder

• Plain Paper (64 to 90 g/m2)

A3, B4, A4, B5, A4R, B5R, 11" × 17", LGL, LTR, LTR-R,

A5, A5R, STMT, STMTR, Foolscap, GLTR, GLTR-R, KLGL,

K-LGL-R, OFFICIO, E-OFFICIO, A-OFFICIO, B-OFFICIO,

A-LTR, ALTR-R, A-LGL

• Tracing Paper* (SM-1)

A3, B4, A4, B5, A4R, B5R

• Colored Paper (Canon-recommended)

B4, A4

• Plain Paper (64 to 90 g/m

2

)

A4, B5, LTR

• Colored Paper (Canon-recommended)

A4

• Plain Paper (64 to 90 g/m

2

)

A3, B4, A4, B5, A4, B5R, 11" × 17", LGL, LTR, LTR-R,

STMT-R*, postcard

• Tracing Paper (SM-1)*

A3, B4, A4, B5, A4R, B5R

• Transparency* (Canon-recommended)

A4, LTR

• Colored Paper* (Canon-recommended)

B4, A4

• Label Sheet (Canon-recommended)

A4, LTR

• Thick Paper* (91 to 200 g/m

• Plain Paper* (64 to 90 g/m

2

)

2

)

A3, B4, A4, B5, A4R, B5R, 11" × 17", LGL, LTR, LTR-R,

A5, STMT

• Colored Paper (Canon-recommended)

B4, A4

• Plain Paper* (64 to 90 g/m

2

)

A3, B4, A4, B5, A4R, B5R, 11" × 17", LGL, LTR, LTR-R,

STMT-R, A5, STMT

• Colored Paper* (Canon-recommended)

B4, A4

• Plain Paper* (64 to 90 g/m

2

)

A3, B4, A4, B5, A4R, B5R, 11" × 17", LGL, LTR, LTR-R,

A5, STMT

• Colored Paper* (Canon-recommended)

B4, A4

• Plain Paper* (64 to 90 g/m

2

)

A3, B4, A4, B5, A4R, B5R, 11" × 17", LGL, LTR, LTR-R,

STMT-R, A5, STMT

• Colored Paper* (Canon-recommended)

B4, A4

1-4

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV. 1 MAR. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

Tray

Non-image

width

Auto Clear

Claw

Cassette

Paper deck

Copy tray

Leading edge

Trailing edge

Left/right

(1st side)

Left/right

(2nd side)

A4 horizontal,

B5 horizontal,

B4, A3, LTR

horizontal

A4 horizontal,

B5 horizontal,

B4, A3, LTR

horizontal

None

55 mm deep

2

(500 sheets each of 80 g/m

paper)

162 mm deep

2

2

paper)

)

(about 1500 sheets each of 80 g/m

250 sheets (approx.; A3, 80 g/m

4.5±1.5 mm in Direct

(4.5±1.5 mm in non-Direct, Overlay, Two-sided)

2.0 ±1.0 mm (2.0 ±1.0 mm in non-Direct,

Overlay, Two-sided)

2.75±2.5mm

2.75±2.5mm

Provided (2 min standard; may be changed from

0 to 9 min in 1-min increments and from 0 to 50

sec in 10-sec increments)

Auto Power-Off

Accessory

Provided (1 hr standard; may be changed from 0

to 2 hr; in 10-min increments up to 1st 1 hr, in 1hr increments up to 24 hr)

• Stapler Sorter-E2 • Sorter-E1

• Stapler Sorter-G1 • Sorter-G1

• CC-V • Cassette Heater

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV. 1 MAR. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-5

CHAPTER 1 GENERAL DESCRIPTION

4. Others

Front paper deck

Operating

environment

Power supply

Power

consumption

Noise

Ozone (avr over 8 hr)

Temperature

Humidity

Atmospheric

pressure

120 V

220/240 V(ITA)

220/240 V(UK)

220/240 V(FRN)

220/240 V(GER)

220/240 V(AMS)

220/240 V(CA)

220/240 V

Maximum

Standby

Continuous

copying

Copying

Standby

7.5° to 32.5°C/45.5° to 90.5°F

5 to 80% RH

810.6hPa to 1013.3hPa (0.8 to 1.0 atm)

NGQ XXXXX

FGB XXXXX

DGB XXXXX

BGB XXXXX

AGB XXXXX

UBW XXXXX, CGB XXXXX

RBJ XXXXX

PCL XXXXX, EGB XXXXX

1.5 kW or less

0.3 kWh or less (reference only)

1.2 kWh or less (reference only)

71 dB or less (sound power level by ISO standards)

50 dB or less (as required)

0.05 ppm or less

Width

Dimensions Depth

Height

Weight

Copy paper

Consumables

Toner

620 mm/24.4 in

725 mm/28.5 in

1136 mm/44.7 in

187 kg/412.2 lb (approx.; w/RDF)

Keep wrapped to protect against moisture.

Avoid direct sunshine, and store at 40°C, 85% or less.

1-6

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV. 1 MAR. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

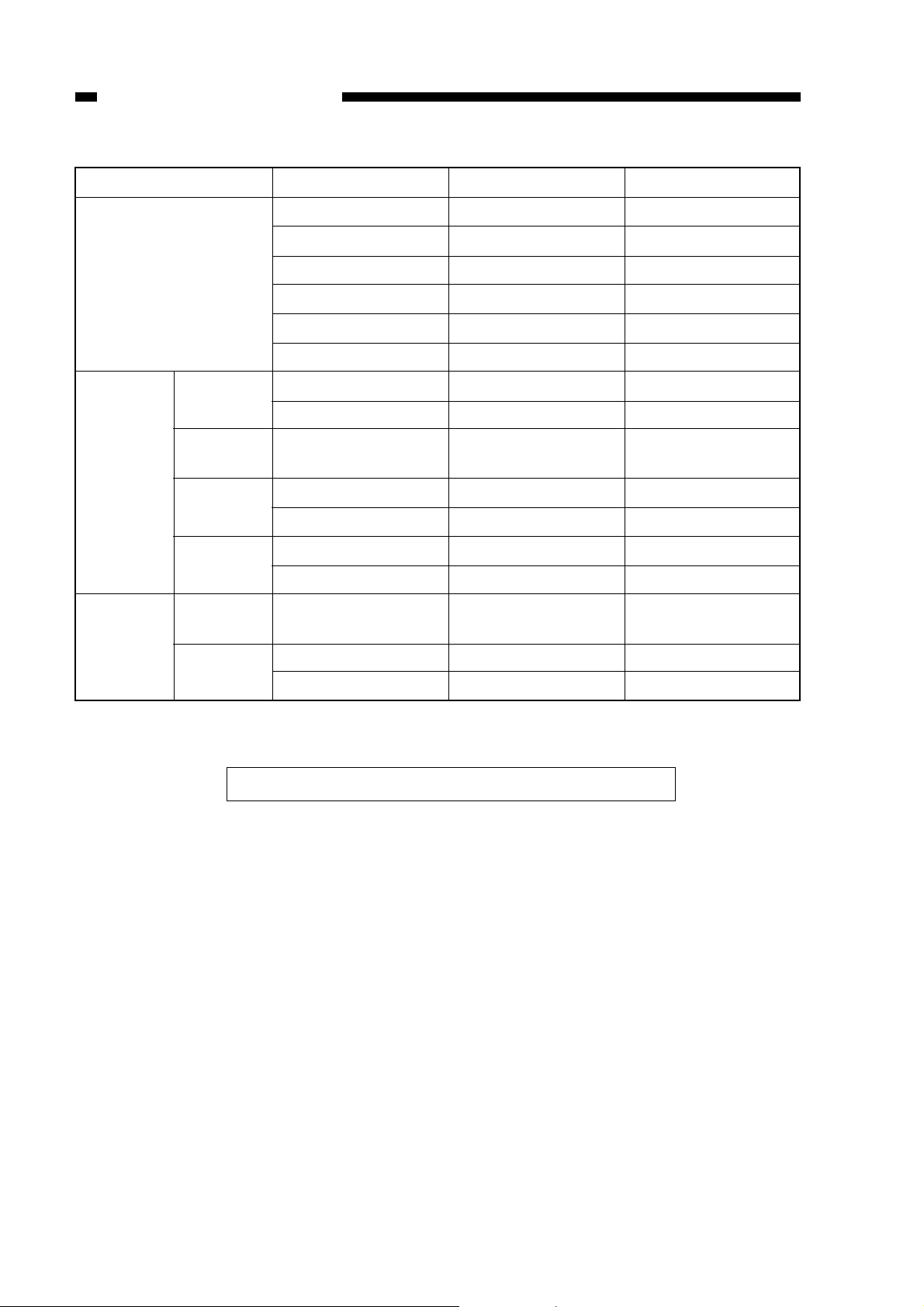

CHAPTER 1 GENERAL DESCRIPTION

I

(50%)

II

(70%)

III

(81%)

IV

(86%)

I

(200%)

II

(141%)

III

(122%)

IV

(115%)

Copies/min

24

45

30

45

35

39

44

35

39

45

35

30

45

23

24

29

45

30

24

45

Copy size

A3

A4

B4

B5

A4R

B5R

A5R

A4R

B5R

A5

A4R

B4

B5

A3

A3

B4

A4

B4

A3

A4

Size

A3(297 × 420mm)

A4(210 × 297mm)

B4(257 × 364mm)

B5(182 × 257mm)

A4R(297 × 210mm)

B5R(257 × 182mm)

A3 → 5R

A3 → 4R

B4 → B5R

A4 → A5

B4 → A4R

A3 → B4

A4 → B5

A5R → A3

A4R → A3

B5R → B4

A5 → A4

A4R → B4

B4 → A3

B5 → A4

Reduce

Ratio

Direct

Enlarge

Table 1-201 Copying Speed (copier only)

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV. 1 MAR. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-7

CHAPTER 1 GENERAL DESCRIPTION

Reduce

Enlarge

Ratio

Direct

I

(50%)

II

(64.7%)

III

(73.3%)

I

(200%)

II

(129.4%)

III

(121.4%)

Size

LTR

11” × 17”

LGL

LTRR

STMT/STMTR

11” × 17” → STMTR

11” × 17” → LTRR

11” × 15” → LTRR

STMR → 11” × 17”

LTRR → 11” × 17”

LGL → 11” × 17”

Copy paper size

LTR

11” × 17”

LGL

LTRR

STMT/STMTR

STMTR

LTRR

LTRR

11” × 17”

11” × 17”

11” × 17”

Copies/min

45

24

30

37

45

43

37

30

24

24

24

Table 1-202 Copying Speed (copier only)

Specifications are subject to change without notice.

1-8

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV. 1 MAR. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

III. NAMES OF PARTS

A. External View

Figure 1-301

q

w

e

r

t

y

u

i

o

!0

!1

!2

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV. 1 MAR. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

1-9

q Copy tray

w RDF

e Toner supply mouth

r Power switch

t Original tray/manual holder

y Multifeeder

u Upper right door

i Lower right door

o Paper deck

!0 Cassette 3

!1 Cassette 4

!2 Front door

@1

@2

@3

@4

@5

@6

@7

@8

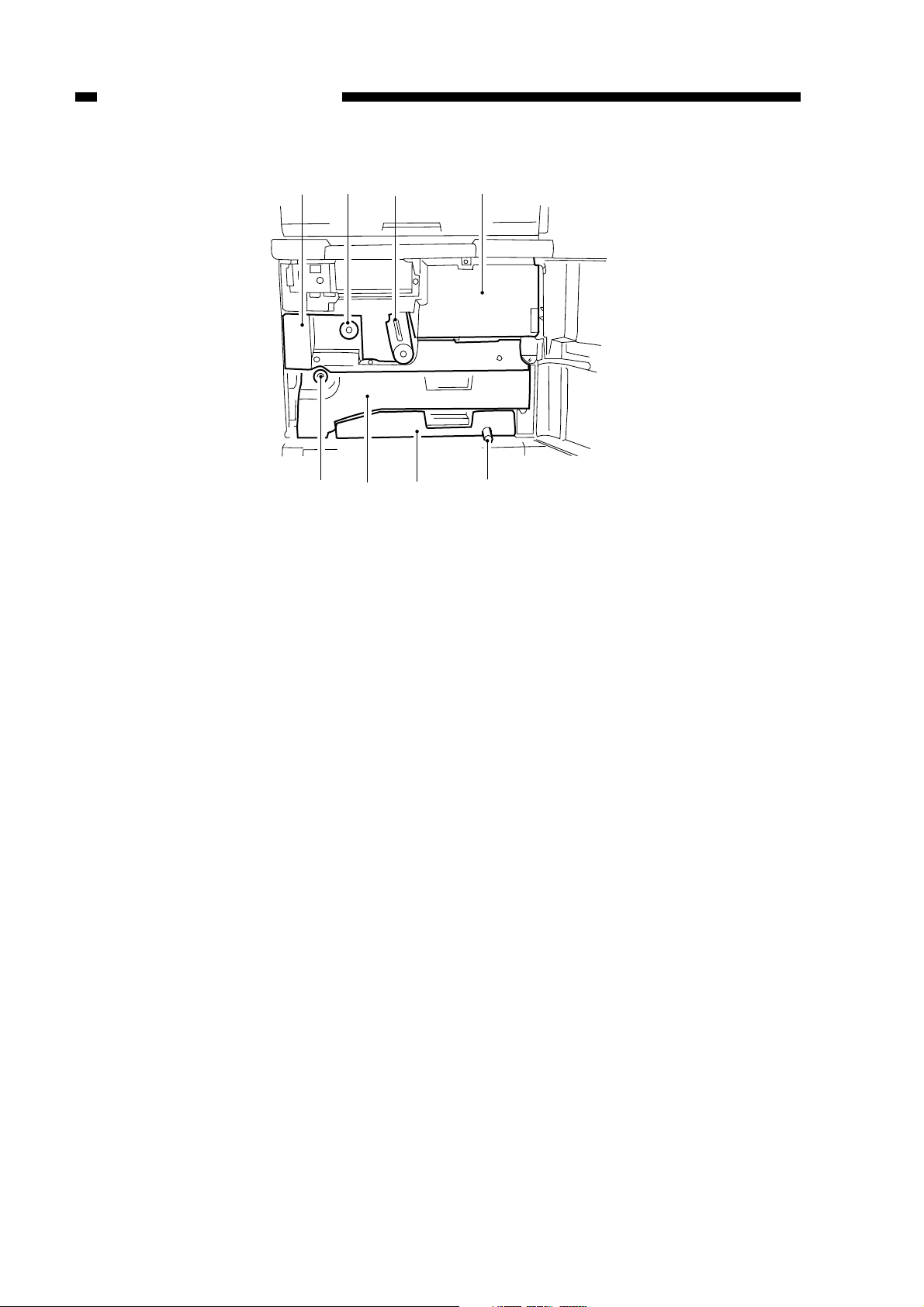

CHAPTER 1 GENERAL DESCRIPTION

@1 Fixing/feeding assembly

@2 Fixing assembly knob

@3 Fixing/feeding assembly releasing

lever

@4 Toner hopper

@5 Holding tray feeding knob

@6 Holding tray feeding assembly

@7 Holding tray assembly

@8 Holding tray knob

Figure 1-302

1-10

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV. 1 MAR. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

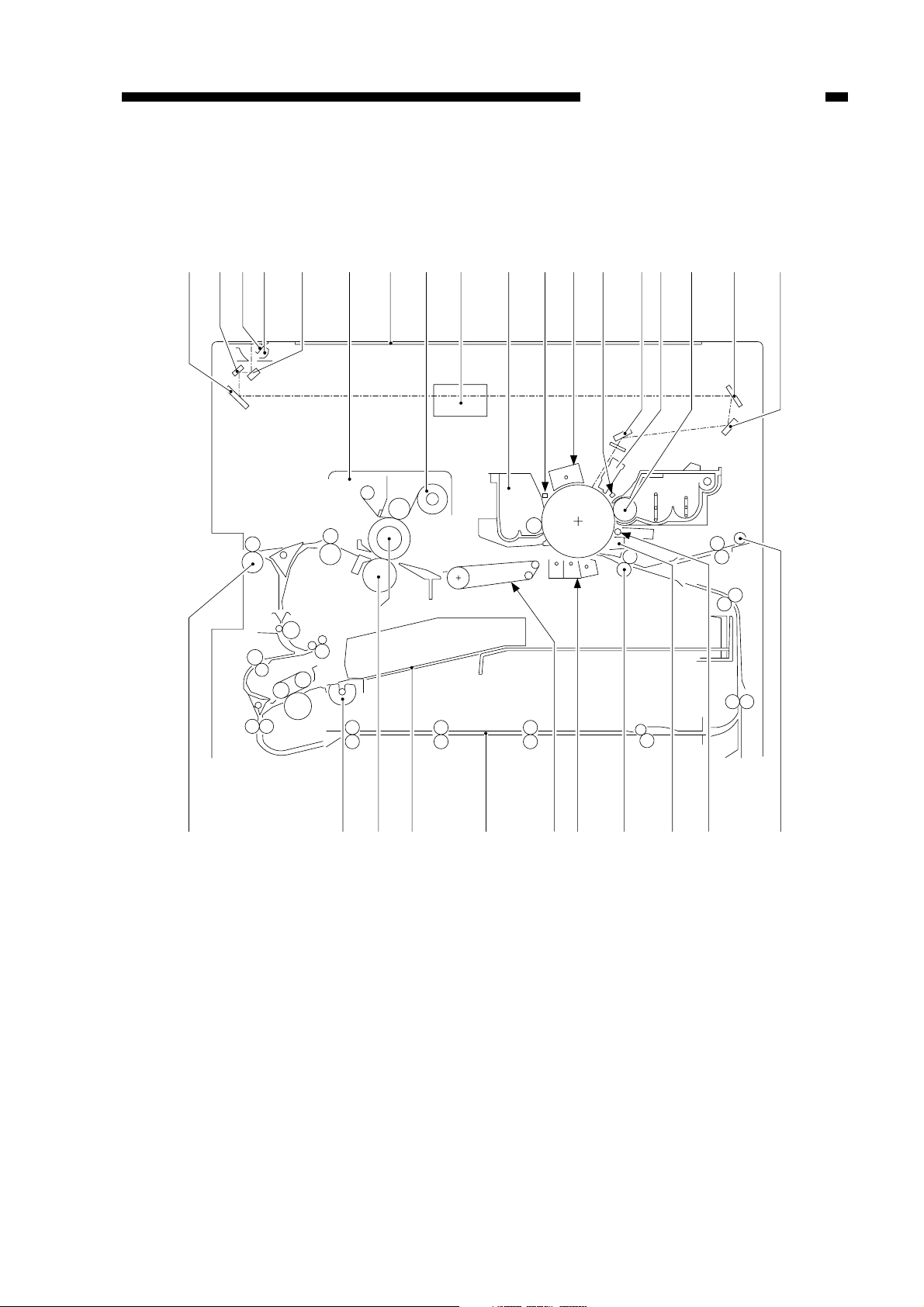

B. Cross Section

qwer

tyuio!0!1!2!3!4!5!6 !8

!7

!9

@0

@1@2@3@4@5@6@7@8@9

1. Cross Section of the Body

CHAPTER 1 GENERAL DESCRIPTION

q No. 3 mirror

w No. 2 mirror

e Heat absorption

r Scanning lamp

t No. 1 mirror

y Fixing assembly

u Copyboard glass

i Fixing cleaner belt

o Lens

!0 Drum cleaning

!1 Pre-exposure lamp

!2 Primary charging

assembly

@2 Registration roller

@3 Transfer/separation

!3 Potential sensor

glass

!4 No. 6 mirror

!5 Blank exposure lamp

@4 Feeding belt

@5 Duplexing unit

!6 Developing cylinder

!7 No. 4 mirror

!8 No. 5 mirror

!9 Multifeeder pick-up

@6 Holding tray

@7 Fixing roller

@8 Holding tray pick-up

roller

@9 Delivery roller

assembly

@0 Roller electrode

@1 Pre-transfer charging

assembly

assembly

feeding assembly

(crescent) roller

Figure 1-303

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV. 1 MAR. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-11

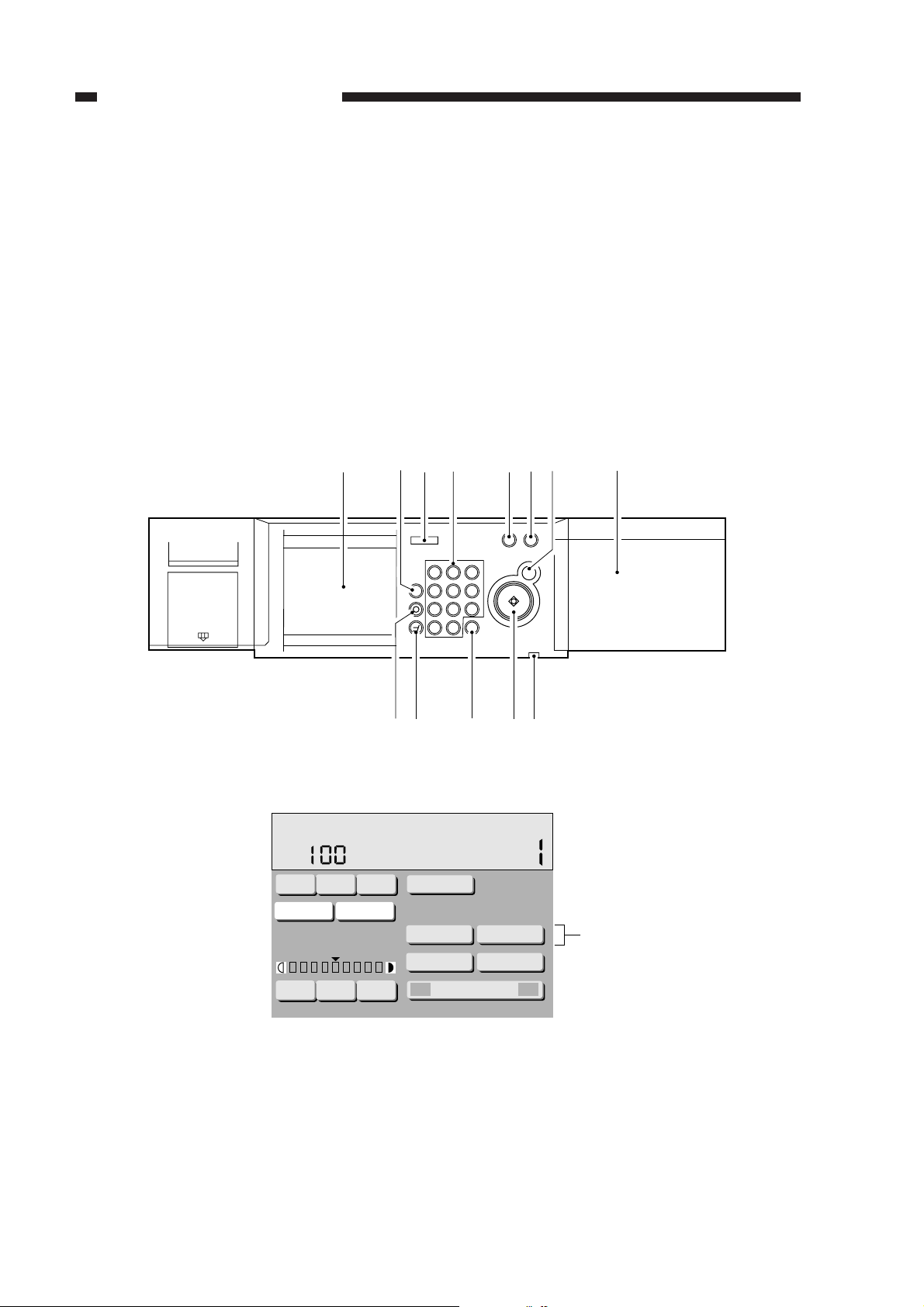

IV. OPERATIONS

A. Control Panel

Figure 1-401

Figure 1-402

Ready to copy.

%

LTR

REDUCE DIRECT ENLARGE

LIGHT DARK

PAPERSELECT

FIT IMAGE

ZOOM

SORTER

2-SIDED

SPECIAL FEATURES

A

!4

1

2

3

4

5

6

7

89

10

0

C

?

C

q

w

r

t

y

u

i

o

!0

!1

!2

!3

START

STOP

e

RESET

COPYRIGHT © 1997 CANON INC. CANON NP6045 REV. 1 MAR. 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

1-12

q Touch panel display

w Guide key

e Reset key

r Keypad

t Display Contrast key

y Energy Saver key

u Stop key

i Toner supply mouth

o Pilot lamp

!0 Copy Start key

!1 Clear key

!2 Interrupt key

!3 User Mode key

!4 Preferences key

Loading...

Loading...