Canon MF720 Series, MF727Cdw, MF726Cdw, MF724Cdw, MF728Cdw Service Manual

...

MF720 Series

Service Manual

Revision 2.0

1x

1x

Introduction

Introduction

Important Notices

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and repair

of products.

This manual covers all localities where the products are sold. For this reason, there may be information in this manual that does

not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products.

When changes occur in applicable products or in the contents of this manual, Canon will release technical information as the

need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new

edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied, reproduced or

translated into another language, in whole or in part, without the consent of Canon Inc.

© CANON INC. 2015

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

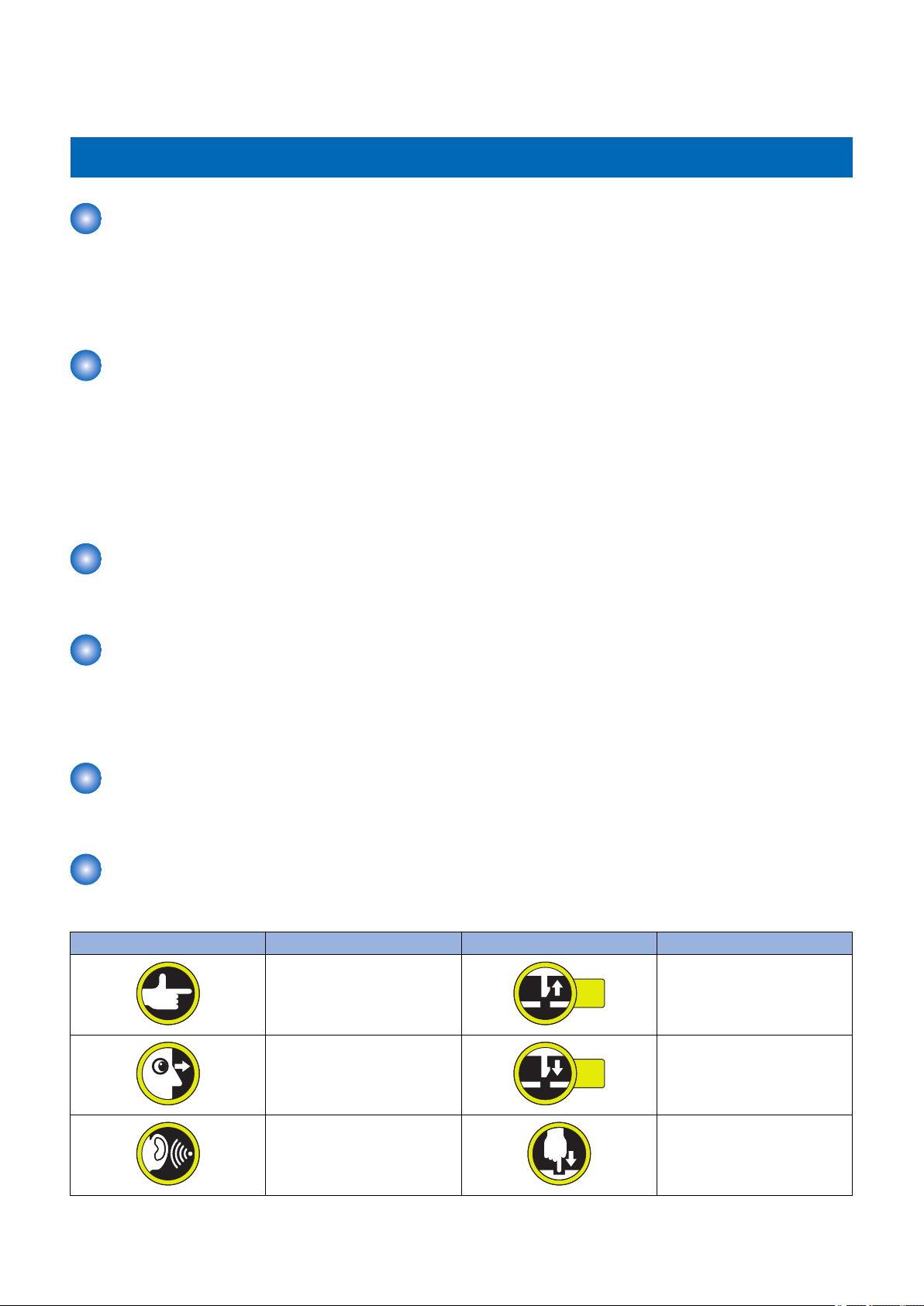

Explanation of Symbols

The following symbols are used throughout this Service Manual.

Symbols Explanation Symbols Explanation

Check.

Remove the claw.

Check visually.

Check a sound. Push the part.

Insert the claw.

1x

1x

1x

1x

1x

1x

1x

1x

Introduction

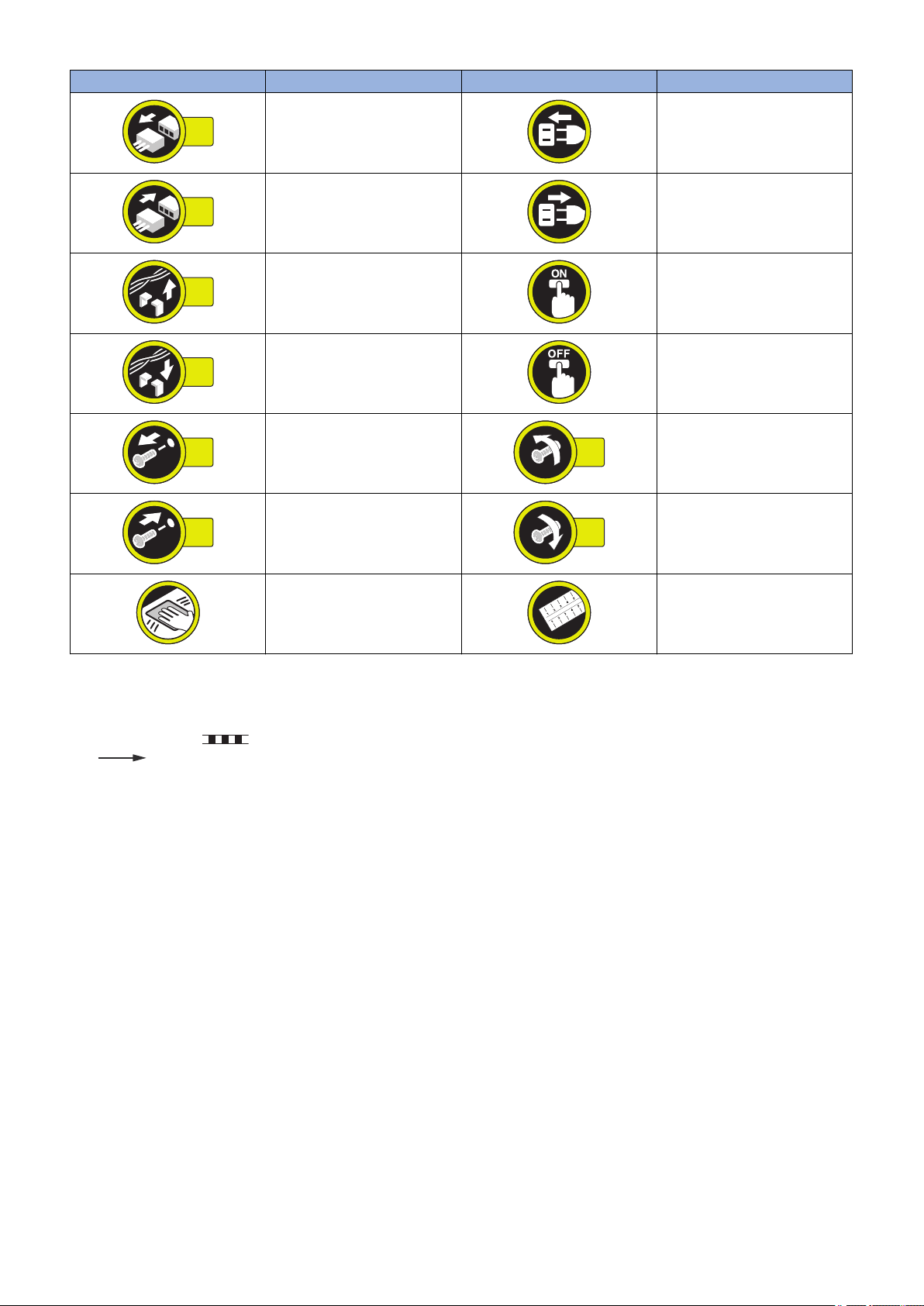

Symbols Explanation Symbols Explanation

Disconnect the connector. Connect the power cable.

Connect the connector. Disconnect the power cable.

Remove the cable/wire from the

cable guide or wire saddle.

Install the cable/wire to the cable

guide or wire saddle.

Remove the screw.

Install the screw.

Cleaning is needed. Measurement is needed.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and

mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol, the arrow

indicates the direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the delivery unit

door, which results in supplying the machine with power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is "High", while '0' is used to indicate "Low".

(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the operations

of the microprocessors used in the machines are not discussed: they are explained in terms of from sensors to the input of

the DC controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and

major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant Service

Information bulletins and be able to identify and isolate faults in the machine.

Turn on the power.

Turn off the power.

Loosen the screw.

Tighten the screw.

Contents

Contents

Safety Precautions...............................................................................................1

Laser Safety........................................................................................................................................ 2

How to Handle the Laser Scanner Unit...............................................................................................2

Toner Safety........................................................................................................................................2

About Toner..........................................................................................................................................2

Handling Adhered Toner........................................................................................................................2

Notes When Handling a Lithium Battery............................................................................................. 3

Notes on Assembly/Disassembly........................................................................................................3

1. Product Overview.............................................................................................4

Product Lineups.................................................................................................................................. 5

Host Machine........................................................................................................................................5

Options................................................................................................................................................ 6

Product Features.................................................................................................................................7

Features...............................................................................................................................................7

Specifications...................................................................................................................................... 8

Specifications of Host Machine.............................................................................................................. 8

ADF Specifications..............................................................................................................................10

Wireless LAN Specifications................................................................................................................ 10

SEND Specifications........................................................................................................................... 11

FAX Specifications.............................................................................................................................. 12

Paper types / Paper size......................................................................................................................13

Name of Parts................................................................................................................................... 14

External View......................................................................................................................................14

Cross Section View............................................................................................................................. 16

Control Panel......................................................................................................................................18

2. Technical Explanation................................................................................... 19

Basic Configuration........................................................................................................................... 20

Configuration function..........................................................................................................................20

Basic Sequence..................................................................................................................................20

Document Exposure/Feeder System................................................................................................ 22

Document Exposure System................................................................................................................22

Document Feeder System................................................................................................................... 23

Controller System..............................................................................................................................26

Overview............................................................................................................................................ 26

Controls..............................................................................................................................................26

Laser Control System........................................................................................................................29

Overview............................................................................................................................................ 29

Controls..............................................................................................................................................29

Image Formation System.................................................................................................................. 30

Overview............................................................................................................................................ 30

Parts.................................................................................................................................................. 30

Image Forming Process.......................................................................................................................30

i

Contents

Controls..............................................................................................................................................35

Fixing System....................................................................................................................................41

Overview............................................................................................................................................ 41

Controls..............................................................................................................................................41

Pickup / Feed System....................................................................................................................... 44

Overview............................................................................................................................................ 44

Parts Configuration..............................................................................................................................44

Drive Configuration..............................................................................................................................45

Controls..............................................................................................................................................45

Embedded RDS................................................................................................................................ 48

Product Overview................................................................................................................................48

Service cautions..................................................................................................................................48

E-RDS Setup...................................................................................................................................... 49

FAQ................................................................................................................................................... 51

Troubleshooting.................................................................................................................................. 53

Error code and strings......................................................................................................................... 54

Setting Information Export/Import Function (DCM)........................................................................... 58

Function Overview.............................................................................................................................. 58

Specifications..................................................................................................................................... 60

Limitations.......................................................................................................................................... 62

Procedure for Exporting/Importing Service Mode Setting Information......................................................64

List of Items Which Can Be Imported....................................................................................................73

3. Periodical Service.......................................................................................... 93

Periodically Replaced Parts.............................................................................................................. 94

Durable Parts.................................................................................................................................... 95

Periodical Services............................................................................................................................96

Cleaning............................................................................................................................................ 97

4. Disassembly/Assembly................................................................................. 98

List of Parts....................................................................................................................................... 99

List of External / Internal Cover............................................................................................................ 99

List of Main Unit................................................................................................................................ 101

List of Motor / Fan............................................................................................................................. 103

List of Clutch / Solenoid / Heater / Thermistor / Switch / Speaker..........................................................104

List of Sensor....................................................................................................................................105

PCB................................................................................................................................................. 106

List of Connector...............................................................................................................................108

External Cover, Internal Cover........................................................................................................116

Location............................................................................................................................................116

External Cover, Internal Cover Disassembly/Assembly Procedure................................................ 118

Removing the Left Cover................................................................................................................... 118

Removing the Right Cover................................................................................................................. 120

Removing the Right Front Cover........................................................................................................ 121

Removing the Front Cover................................................................................................................. 122

Removing the Rear Upper Cover........................................................................................................123

Removing the Rear Cover..................................................................................................................123

Removing the Rear Lower Cover........................................................................................................123

Removing the Rear Cover Rib Unit.....................................................................................................125

ii

Contents

Removing the Upper Cover................................................................................................................125

Removing the Cartridge Tray............................................................................................................. 127

Document Exposure, Feed System.................................................................................................128

Location............................................................................................................................................128

Document Exposure, Feed System Disassembly/Assembly Procedure......................................... 130

Removing the ADF Unit + Reader Unit................................................................................................130

Separating the ADF Unit + Reader Unit.............................................................................................. 131

Removing the ADF Roller Unit............................................................................................................136

Removing the ADF Pickup Roller....................................................................................................... 137

Removing the ADF Separation Roller................................................................................................. 138

Removing the ADF Separation Pad.................................................................................................... 138

Removing the ADF Pickup Feed Unit..................................................................................................140

Removing the ADF Pickup Motor........................................................................................................141

Removing the Scoopup sheet holder.................................................................................................. 142

Removing the Reader Unit Upper Cover............................................................................................. 144

Removing the CIS Unit...................................................................................................................... 146

Removing the Reader Scanner Motor.................................................................................................151

Controller System............................................................................................................................154

Location............................................................................................................................................154

Controller System Disassembly/Assembly Procedure.................................................................... 157

Removing the Controller Cover.......................................................................................................... 157

Removing the Wireless LAN PCB (MF728Cdw / 727Cdw / 724Cdw).....................................................157

Removing the Main Controller PCB.................................................................................................... 157

Removing the Main Controller Support Plate.......................................................................................161

Removing the DC Controller PCB.......................................................................................................162

Removing the High Voltage Power Supply PCB.................................................................................. 163

Removing the Low Voltage Unit..........................................................................................................165

Removing the Fixing Sub PCB........................................................................................................... 166

Removing the Driver PCB.................................................................................................................. 167

Removing the Relay PCB.................................................................................................................. 168

Removing the Control Panel Unit........................................................................................................169

Removing the NFC PCB (MF727Cdw / 726Cdw).................................................................................171

Removing the FAX PCB (MF728Cdw / 727Cdw / 725Cdw).................................................................. 171

Removing the Off Hook PCB (MF728Cdw / 727Cdw / 725Cdn)............................................................ 172

Removing the Main Drive Unit............................................................................................................172

Removing the Duplex Reverse Drive Unit........................................................................................... 179

Removing the Fixing/Fixing Power Supply Cooling Fan Unit.................................................................180

Removing the Duplex Feeding Fan.....................................................................................................181

Removing the Speaker (MF728Cdw / 727Cdw / 725Cdn).....................................................................183

Laser Exposure System.................................................................................................................. 184

Location............................................................................................................................................184

Laser Exposure System Disassembly/Assembly Procedure...........................................................185

Removing the Laser Scanner Unit...................................................................................................... 185

Image Formation System................................................................................................................ 190

Location............................................................................................................................................190

Image Formation System Disassembly/Assembly Procedure.........................................................191

Removing the ITB Unit.......................................................................................................................191

Removing the Patch Density and Registration Sensor unit................................................................... 193

Removing the Developing Motor.........................................................................................................195

Removing the Drum Motor................................................................................................................. 196

Removing the Secondary Transfer Outer Roller...................................................................................198

iii

Contents

Fixing System..................................................................................................................................199

Location............................................................................................................................................199

Fixing System Disassembly/Assembly Procedure.......................................................................... 200

Removing the Fixing Assembly.......................................................................................................... 200

Removing the Fixing Film Unit............................................................................................................201

Removing the Fixing Pressure Roller..................................................................................................205

Removing the Fixing Motor Unit..........................................................................................................205

Pickup Feeder System.................................................................................................................... 208

Location............................................................................................................................................208

Pickup Feeder System Disassembly/Assembly Procedure.............................................................209

Removing the Cassette Pickup Roller.................................................................................................209

Removing the Cassette Separation Roller...........................................................................................210

Removing the MP Tray Pickup Roller..................................................................................................211

Removing the MP Tray Separation Pad.............................................................................................. 211

Removing the Pickup Motor............................................................................................................... 212

Removing the Pickup Unit..................................................................................................................213

Removing the MP Tray Pickup Unit.................................................................................................... 218

Removing the Secondary Transfer Feed Unit...................................................................................... 219

Removing the Delivery Unit................................................................................................................220

Removing the Duplex Feed Unit.........................................................................................................221

Removing the Re-pickup Guide Unit................................................................................................... 222

5. Adjustment................................................................................................... 224

Overview......................................................................................................................................... 225

Adjustment at Parts Replacement...................................................................................................226

Document Exposure / Feed System....................................................................................................226

Controller System..............................................................................................................................234

Laser Exposure System.....................................................................................................................239

6. Troubleshooting...........................................................................................240

Test Print.........................................................................................................................................241

Engine test print................................................................................................................................ 241

Controller test print............................................................................................................................ 241

Trouble shooting items....................................................................................................................243

Recurring faulty image.......................................................................................................................243

Confirming nip width..........................................................................................................................243

Version Upgrade............................................................................................................................. 244

Overview.......................................................................................................................................... 244

Upgrading by UST.............................................................................................................................244

Preparation.......................................................................................................................................244

Downloading System Software...........................................................................................................245

Upgrading via Internet....................................................................................................................... 247

Debug Log ......................................................................................................................................248

Function Overview.............................................................................................................................248

Conditions for collecting logs..............................................................................................................248

Collection procedure..........................................................................................................................248

7. Error/Jam/Alarm........................................................................................... 250

Outline.............................................................................................................................................251

iv

Contents

Outline..............................................................................................................................................251

Jam code..........................................................................................................................................251

Error Codes.....................................................................................................................................252

Jam Code........................................................................................................................................257

8. Service Mode................................................................................................ 259

Overview......................................................................................................................................... 260

Service Mode Menu...........................................................................................................................260

Backing up Service Mode.................................................................................................................. 260

Screen flow of Service mode..............................................................................................................261

Remote UI service mode....................................................................................................................262

COPIER...........................................................................................................................................264

DISPLAY.......................................................................................................................................... 264

I/O....................................................................................................................................................265

ADJUST........................................................................................................................................... 266

FUNCTION.......................................................................................................................................277

OPTION........................................................................................................................................... 290

COUTER.......................................................................................................................................... 295

FEEDER..........................................................................................................................................300

ADJUST........................................................................................................................................... 300

FUNCTION.......................................................................................................................................301

FAX................................................................................................................................................. 302

Lis of SSSW..................................................................................................................................... 302

List of MENU.....................................................................................................................................303

List of NUM.......................................................................................................................................303

Setting of NCU Parameters................................................................................................................304

TESTMODE.................................................................................................................................... 308

PRINT.............................................................................................................................................. 308

FAX..................................................................................................................................................309

APPENDICES....................................................................................................314

Service Tools...................................................................................................................................315

Special Tools.................................................................................................................................... 315

Solvents and Oils.............................................................................................................................. 315

General Circuit Diagram..................................................................................................................316

Print Sequence................................................................................................................................317

Backup Data ...................................................................................................................................318

v

Safety Precautions

Laser Safety..........................................2

How to Handle the Laser Scanner Unit

...........................................................2

Toner Safety..........................................2

Notes When Handling a Lithium

Battery............................................... 3

Notes on Assembly/Disassembly..........3

Safety Precautions

Laser Safety

Since radiation emitted inside the machine is completely confined within protective housings and external covers, the laser beam

cannot escape from the machine during any phase of user operation.

Therefore this machine is classified in Class 1 laser products that are regarded as safe during normal use according to

International Standard IEC60825-1.

How to Handle the Laser Scanner Unit

This machine is classified in Class 1 laser products.

However, inside the scanner unit, there is source of Class 3B laser beam and the laser beam is hazardous when entered into an

eye. So, be sure not to disassemble the laser scanner unit. No adjustment can be made to the laser scanner unit in this machine

in the field.

The label show in the following figure is attached on the laser scanner unit.

The following warnings are given to comply with Safety Principles (EN60950-1).

Diese Maschine ist der Klasse 1 der Laserprodukte zugeordnet.

Innerhalb der Scannereinheit befindet sich jedoch die Laserstrahlquelle der Klasse 3B und es ist gefährlich, wenn dieser Strahl

in die Augen gerät. Die Laserscannereinheit darf unter keinen Umständen entfernt werden. Es dürfen in diesem Umfeld der

Maschine keine Justagen an der Laserscannereinheit vorgenommen werden.

Das Etikett in folgendem Bild ist auf der Laserscannereinheit angebrachtt.

Toner Safety

About Toner

Toner is a nontoxic matter composed of plastic, iron and a trace of pigments.

CAUTION:

Never throw toner in flames to avoid explosion.

Handling Adhered Toner

• Use dry tissue paper to wipe off toner adhered to skin or clothes and wash in water.

2

ACHTUNG

Zweipolige bzw. Neutralleiter-Sicherung

Safety Precautions

• Never use warm water for cleaning up toner to prevent toner particles from being gelated to soak into fibers permanently.

• Toner particles are reactive with vinyl polymers. Avoid contacting these materials.

Notes When Handling a Lithium Battery

CAUTION:

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE INSTRUCTIONS.

The following warnings are given to comply with Safety Principles (EN60950-1).

CAUTION:

Wenn mit dem falschen Typ ausgewechselt, besteht Explosionsgefahr.

Gebrauchte Batterien gemäß der Anleitung beseitigen.

Notes on Assembly/Disassembly

Follow the items below to assemble/disassemble the device.

1. Disconnect the power plug to avoid any potential dangers during assembling/disassembling works.

2. If not specially instructed, reverse the order of disassembly to reinstall.

3. Ensure to use the right screw type (length, diameter, etc.) at the right position when assembling.

4. To keep electric conduction, binding screws with washers are used to attach the grounding wire and the varistor. Ensure to

use the right screw type when assembling.

5. Unless it is specially needed, do not operate the device with some parts removed.

6. Never remove the paint-locked screws when disassembling.

CAUTION:

Double pole/neutral fusing

3

1

Product Overview

Product Lineups.................................... 5

Product Features...................................7

Specifications........................................8

Name of Parts..................................... 14

1. Product Overview

Product Lineups

Host Machine

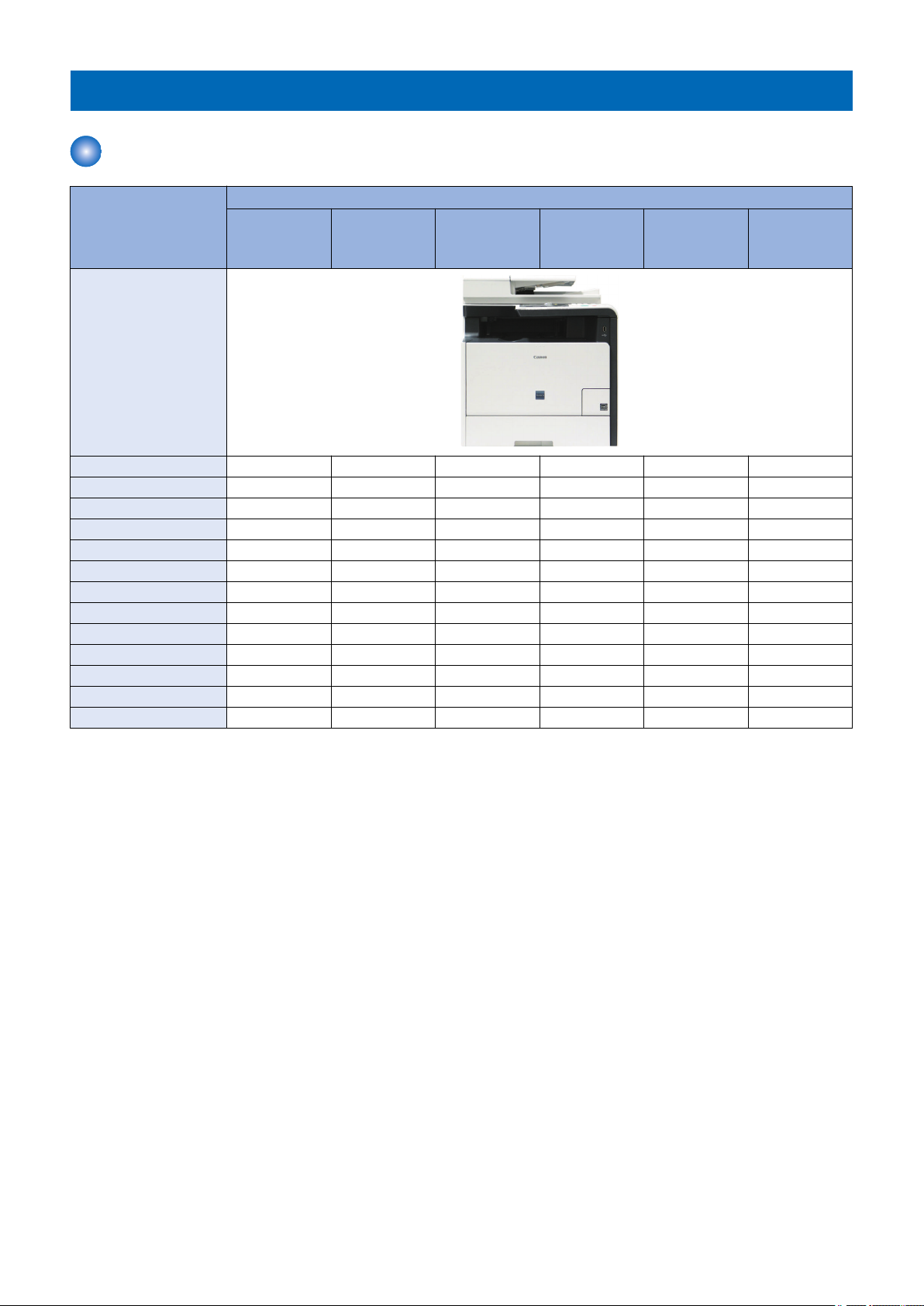

Function MF720 Series (COUNTRY / REGION)

MF728Cdw

(EUR)

Appearance

Copy Yes Yes Yes Yes Yes Yes

Print Yes Yes Yes Yes Yes Yes

Fax Yes Yes Yes Yes No No

USB Scan Yes Yes Yes Yes Yes Yes

Network Scan Yes Yes Yes Yes Yes Yes

Wireless LAN Yes Yes Yes No Yes Yes

Direct Mode Yes Yes Yes No Yes Yes

NFC No Yes Yes No No No

SEND Yes Yes Yes Yes Yes Yes

Sequre Print Yes Yes Yes Yes Yes Yes

Remote UI Yes Yes Yes Yes Yes Yes

ADF (2-side) Yes Yes Yes Yes Yes Yes

Automatic 2-sided Print Yes Yes Yes Yes Yes Yes

MF727Cdw

(CHN, KOR)

MF726Cdw

(USA/CND/

LTN, JP)

MF725Cdn

(CHN)

MF724Cdw

(EUR)

MF722Cdw

(JP)

5

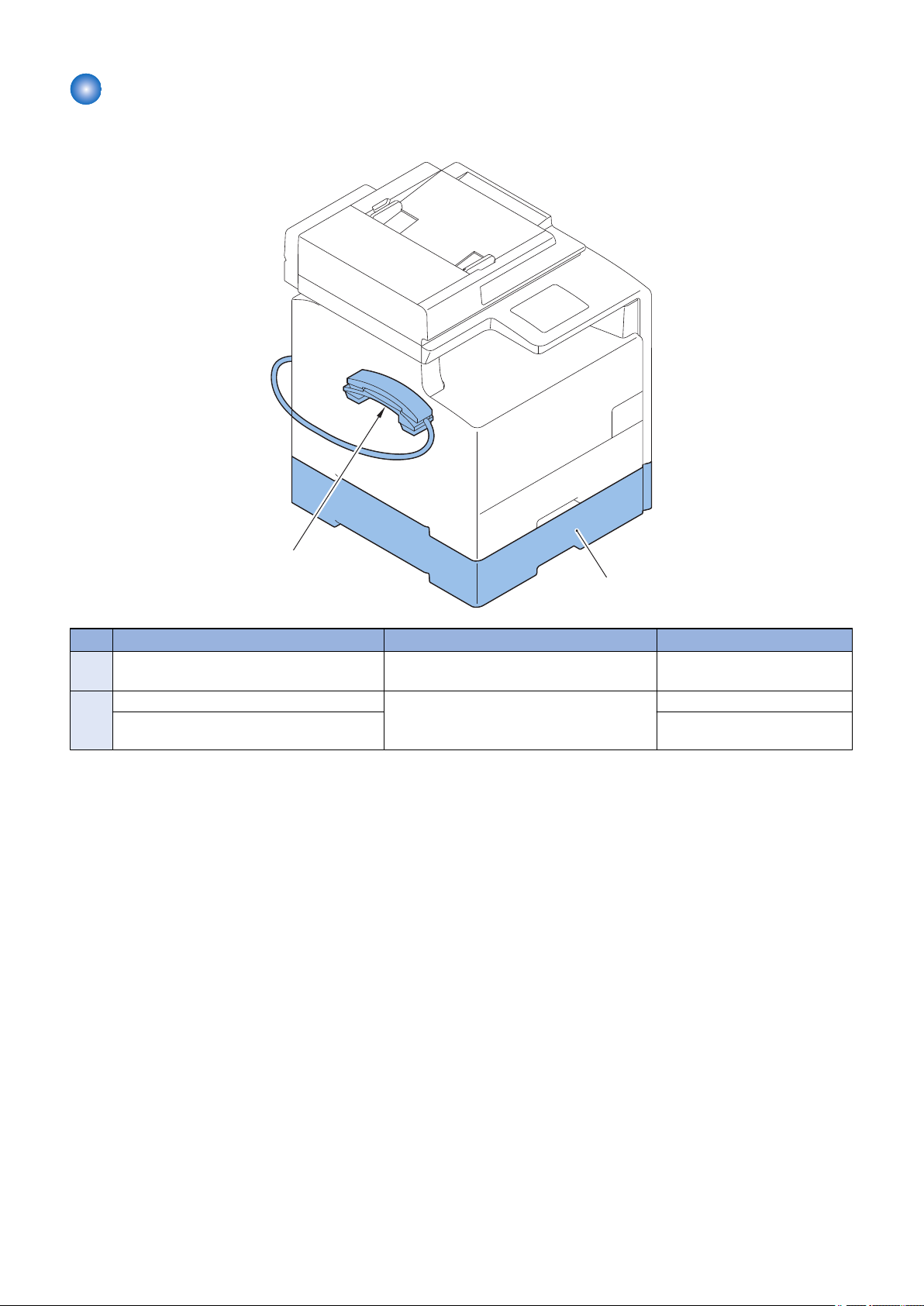

Options

[2]

[1]

■ Hardware Products

1. Product Overview

No. Name Description Remarks

1 Cassette Feeding Module-V1 Expansion of the number of sheets picked up:

250 sheets (60 to 90 g/m2)

2 TELEPHONE 6 KIT Long cord Cool White Addition of phone MF728Cdw

HANDSET KIT 3 Long cord Cool White Standard: MF727Cdw (CHN) /

MF725Cdn

6

434 mm

478.5 mm

1. Product Overview

Product Features

Features

■ Compact Size MFP

A compact body size for A4 color laser MFP has been realized.

■ Improved Control Panel operability

A 3.5-inch color Touch Panel is installed. Support for touch and flick has realized the operability like a smartphone.

In addition, reducing the hard keys and changing them to icons in the display have realized the UI that allows for easy

customization while maintaining the level of operability.

■ Direct Mode supported (supported models only)

Direct communication between the host machine and smartphone, tablet, PC, etc. has been realized.

■ Mobile print supported (Apple Air Print, Google Cloud Print)

Mobile print that enables printing from smartphone, tablet, PC, etc. via an application such as Google DocsTM and GmailTM has

been realized.

■ Wireless LAN supported (supported models only)

Connection between the host machine and PC by wireless communication (radio wave) via wireless LAN router has been realized.

7

1. Product Overview

Specifications

Specifications of Host Machine

Item Specification / Function

Copyboard Fixed

Device Installation Desktop

Light source LED (RGB)

Photoreceptor OPC drum (φ24)

Image scanning CIS (color)

Light exposure method Laser beam exposure

Charging method Roller charging

Developing method Contact development

Transfer method Primary transfer: Sequential 4 colors transfer to Intermediate Transfer Belt

Secondary transfer: 4-color batch transfer onto the transfer material by the Transfer Roller

Separation method Curvature separation

Cassette paper feed Simple separation retard

MP Tray paper feed Pad separation method

Drum cleaning method Cleaning blade

Transfer cleaning method Cleaning brush and roller

Fixing method On-demand fixing

Paper delivery method Face-down

Toner level sensor Mounted

Toner type Non-magnetic one-component toner

Toner supply method All-in-one cartridge (drum + toner)

Toner save mode N/A

Document types Sheet / book

Maximum document size Copyboard Glass: 216 mm × 297 mm

Feeder: 216 mm × 356 mm

Document size sensor N/A

Image size magnification AB series: 25.0%, 50.0%, 70.7%, 81.6%, 86.5%, 100.0%, 115.4%, 122.4%, 141.4%, 200.0%, 400.0%

INCH series: 25.0%, 50.0%, 64.7%, 78.5%, 100.0%, 129.4%, 200.0%, 400.0%

A series: 25.0%, 50.0%, 70.7%, 100.0%, 141.4%, 200.0%, 400.0%

AB/INCH series: 25.0%, 50.0%, 70.7%, 81.6%, 86.5%, 100.0%, 115.4%, 122.4%, 141.4%, 200.0%,

400.0%

Zoom: 25 to 400% (1% increment)

Warm-up Time *1 About 20 seconds or less

Print area Cassette For print jobs (Non-envelope):

• Leading edge: 5.0 +/- 2.0 mm

• Left Side: 5.0 +/- 1.5 mm

For print jobs (envelope):

• Leading edge: 10.0 +/- 2.0 mm

• Left Side: 10.0 +/- 1.5 mm

For copy jobs:

• Leading edge: 5.0 +/- 2.0 mm

• Left Side: 5.0 +/- 1.5 mm

FAX / Report:

• Leading edge: 5.0 +/- 2.0 mm

• Left Side: 5.0 +/- 1.5 mm

8

1. Product Overview

Item Specification / Function

Print area

Reading resolution Color: 600 x 600 dpi, 300 x 600 dpi, 300 x 300 dpi

Reading Speed Fixed (A4/LTR):

Copy resolution 600 x 600 dpi

Print resolution 600 x 600 dpi

First copy time Fixed (A4/LTR):

First print time Color / B&W: 14.5 seconds or less (A4/LTR)

Print Speed 1-sided print (A4/LTR):

Available paper type for cassette

Available paper type for MP

Tray

Available paper size in cassette

MP Tray paper size A4, B5, A5, LGL, LTR, STMT, EXEC, OFFICIO, B-OFFICIO, M-OFFICIO, GLTR, GLGL, FLS, AFLS,

Cassette capacity

MP Tray capacity

Delivery tray stacking capacity

*2

Continuous copying 1 to 99 sheets

Automatic 2-sided Available (A4, B5, LGL, LTR, EXEC, FLS)

Memory capacity 1 GB

Sleep mode Available

Allowable environmental temperature

Allowable humidity 20 to 80% in relative humidity (no condensation)

MP Tray (Non-envelope)

For print jobs:

• Leading edge: 5.0 +/- 2.0 mm

• Left Side: 5.0 +/- 1.5 mm

For copy jobs:

• Leading edge: 5.0 +/- 2.0 mm

• Left Side: 5.0 +/- 1.5 mm

FAX / Report:

• Leading edge: 5.0 +/- 2.0 mm

• Left Side: 5.0 +/- 1.5 mm

(envelope)

For print jobs / For copy jobs:

• Leading edge: 10.0 +/- 2.5 mm

• Left Side: 10.0 +/- 2.5 mm

B&W: 600 x 600 dpi, 300 x 600 dpi

• N/A

Continuous reading, SEND:

• Color: 10 images / minute (A4/LTR)

• B&W: 20 images / minute (A4)

• B&W: 21 images / minute (LTR)

• Color: 16.2 seconds or less

• B&W: 15.5 seconds or less

Continuous reading (A4/LTR):

• Color: 16.7 seconds or less

• B&W: 16.4 seconds or less

• Color / B&W: 20 ppm

2-sided print (A4/LTR):

• Color / B&W: 10 ppm

Plain paper, Recycled paper, Color paper, Thick paper, Coated paper, Label, Postcard, Envelope

(Refer to “Paper types / Paper size” on page 13)

Plain paper, Recycled paper, Color paper, Thick paper, Coated paper, Transparency, Label, Postcard,

Envelope

(Refer to “Paper types / Paper size” on page 13)

A4, B5, A5, LGL, LTR, STMT, EXEC, OFFICIO, B-OFFICIO, M-OFFICIO, GLTR, GLGL, FLS, AFLS,

indLGL, K16, Postcard, Reply Postcard, Envelopes (COM10, Monarch, Nagagata 3, Yougatanaga 3,

C5, DL), Custom Paper Size

(Refer to “Paper types / Paper size” on page 13)

indLGL, K16, Postcard, Reply Postcard, Envelopes (COM10, Monarch, Nagagata 3, Yougatanaga 3,

C5, DL), Custom Paper Size

(Refer to “Paper types / Paper size” on page 13)

Cassette: 250 sheets (60 to 90 g/m2)

Option: 250 sheets (60 to 90 g/m2)

50 sheets (60 to 90 g/m2)

125 sheets (60 to 90 g/m2)

10 to 30 deg C

9

1. Product Overview

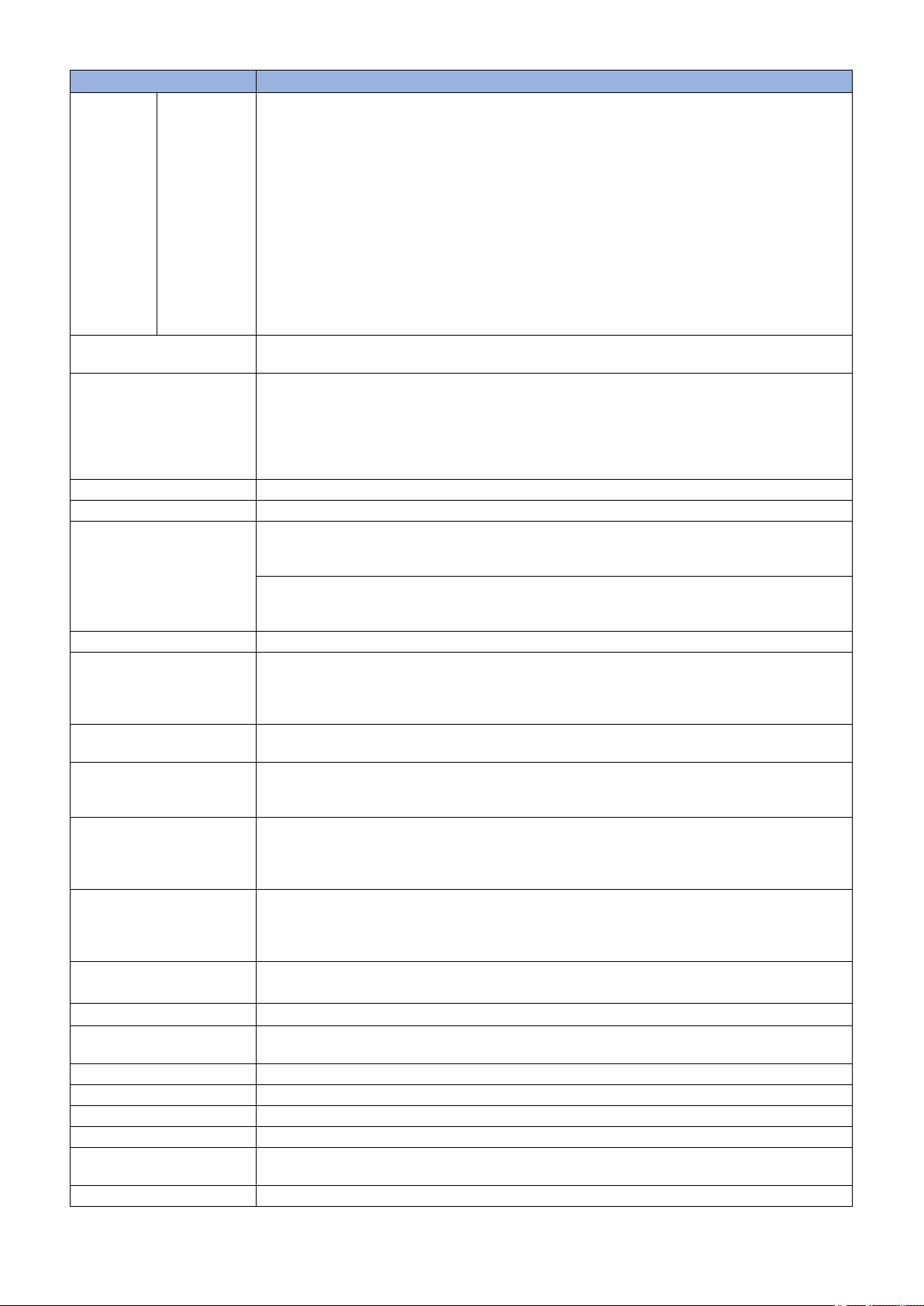

Item Specification / Function

Operational noise At stand-by:

• 43 dB or lower (acoustic power level)

During copy jobs:

• Color: 67 dB or lower

• B&W: 66 dB or lower

Power rating Rated input voltage: 100 V (100 V system), 120 to 127 V (120 V system), 220 to 240 V (200 V system)

Rated input frequency: 50/60 Hz

Maximum power consumption 100 V / 120 V / 230 V: 1200 W or lower

Average power at operation 100 V / 120 V / 230 V: 550 W or lower

Average power at standby 100 V / 120 V: 23 W

230 V: 25 W

Average power at sleep mode 100 V / 120 V / 230 V: 1 W (wired) / 2 W (wireless)

Power consumption at Main

Power Switch OFF

Ozone emission Color: 3.0 mg/h

Dimensions (W x D x H) ADF model: 434 × 484 × 478.5 mm

Weight Device (including toner cartridges): Approx. 31 kg

Accessories Refer to “Options” on page 6

0.5 W or lower

B&W: 1.5 mg/h

ADF model (with the optional cassette): 434 × 484 × 578.5 mm

Optional cassette: Approx. 4 kg

*1 : Warm-up time is an interval between when the machine is turned ON and when the main screen appears on the display.

Warm-up time may vary depending on the use conditions and environment of the machine.

*2 : The actual stack capacity varies depending on the site environment and the type of paper used.

ADF Specifications

Item Specification / Function

Document setting direction Set the document face up (face-up method)

Document setting position Center reference

Document processing mode 1-sided document: 1-sided copy/2-sided copy

2-sided document: 1-sided copy/2-sided copy

Document scanning Continuous reading

Loadable sheets

Mixed paper reading Copyboard Glass: 216 mm × 297 mm

Mixed paper Available

Document AE sensor N/A

Document size sensor N/A

Stamp function N/A

Allowable environment Same as device

A4/LTR: 50 sheets (80 g/m2), LGL: 30 sheets (80 g/m2)

Feeder: 216 mm × 356 mm

Wireless LAN Specifications

Item Specification / Function

Standard IEEE 802.11g / IEEE 802.11b / IEEE 802.11n *

Transmission Scheme DS-SS System / OFDM System

Frequency Range 2412 to 2472 MHz

10

Item Specification / Function

Data Transmission Rate IEEE 802.11g:

• 6 / 9 / 12 / 18 / 24 / 36 / 48 / 54 Mbps

IEEE 802.11b:

• 1/2/5.5/11 Mbps

IEEE 802.11n:

• SGI Invalidated 20 MHz : 6.5 / 13 / 19.5 / 26 / 39 / 52 / 58.5 / 65 Mbps

• SGI Validated 20 MHz : 7.2 / 14.4 / 21.7 / 28.9 / 43.3 / 57.8 / 72.2 Mbps

• SGI Invalidated 40 MHz : 13.5 / 27 / 40.5 / 81 / 108 / 121.5 / 135 Mbps

• SGI Validated 40 MHz : 15 / 30 / 45 / 60 / 90 / 120 / 150 Mbps

Communication Mode • Infrastructure Mode

• Direct Mode

Security WEP, WPA-PSK (TKIP/AES-CCMP), WPA2-PSK (TKIP/AES-CCMP)

*: WPS (Wi-Fi Protected Setup), Connection can be established by manually setting values.

SEND Specifications

Item Specification / Function

File Server Transmission E-mail Sending IFAX

Reception Transmission

Communication Protocol

Data Format

System

Environment

Interface 100BASE-TX, 10BASE-T

Inputted

Image

Color

Mode

Paper Size AB configuration: A4, A5, B5

SMB (TCP/IP) , FTP SMTP

PDF, PDF (Compact), PDF(Compact/OCR),

PDF(OCR), JPEG, TIFF

• Windows XP / Vista / 7 / 8 / Server 2003 /

Server 2008 / Server 2012

• Solaris Version 2.6 or later

• Mac OS X

(Mac OS X 10.7 and 10.8 are not supported.)

• Red Hat Linux 7.2 or later

Text, Text / Photo, Photo

Color, Black/White

Inch configuration: Legal (LGL), Letter (LTR), Statement (STMT)

PDF, PDF (Compact),

PDF(Compact/OCR),

PDF(OCR), JPEG, TIFF

• Windows XP / Vista / 7 / 8 / Server 2003 / Server 2008 / Server 2012

• Solaris Version 2.6 or later

• Mac OS X

• Red Hat Linux 7.2 or later

TIFF (BW) JPEG, TIFF (Profile-S,

1. Product Overview

Profile-F)

*1: Size of recording paper at I-Fax reception is A4 size or larger.

11

FAX Specifications

Item Specification / Function

Suitable line Public Switched Telephone Network (PSTN) *

Telephone line connection: 1

Communication Protocol Super G3, G3

Modulation method Image modulation: V.34 / V.17 / V.29 / V.27ter

Transmission procedure: V.21

Transmission speed 33,600 bps

Compression method JBIG, MMR, MR, MH

Error correction method ECM

Minimum receivable input level V.17 / V.27ter / V.29:

• -6 to -43 dBm

V.34:

• 24.0 k to 28.8 k bps: -43 dBm

• 28.8 k to 33.6 k bps: -38 dBm

• 33.6 k bps: -9 dBm

Modem IC SiliconLabs Si2435

Scanning line density Normal: 200 x 100 dpi

Fine: 200 x 200 dpi

Photo: 200 x 200 dpi

Super fine: 200 x 400 dpi

Ultra fine: 400 x 400 dpi

Half tone 256 tones

Receivable reduction setting Automatic reduction: 75-100% (1% increment)

FAX/TEL switching Available

Answering machine transfer setting Available

Remote reception Available

Auto-dialing Available

Delayed transmission N/A

Broadcast transmission Destinations: up to 210

Dual access Up to 10 schedules

Image data backup Available

1. Product Overview

*: Up to 33.6Kbps in modem speed is currently available in PSTN. Note that available modem speed is telephone-line dependent.

12

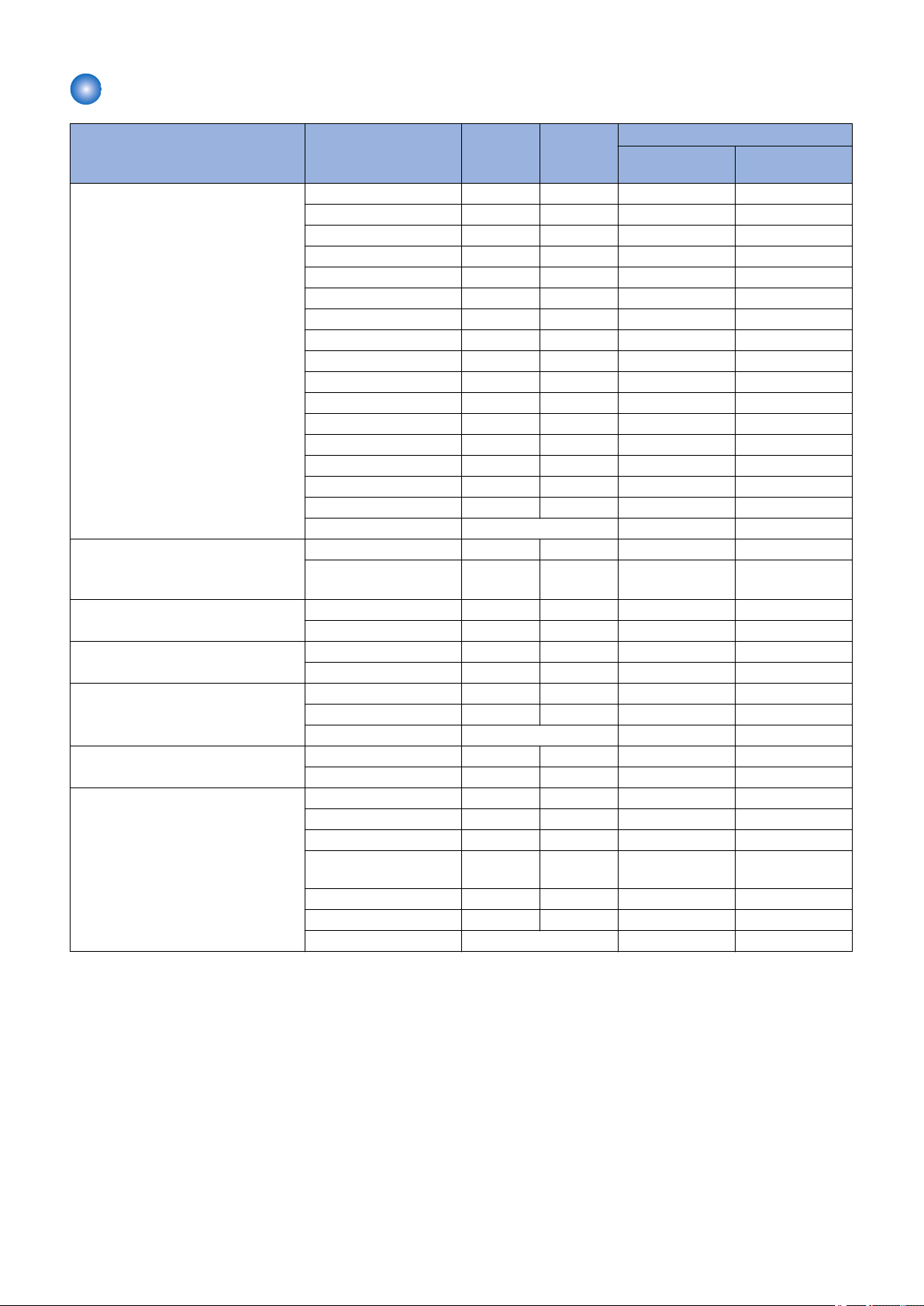

Paper types / Paper size

1. Product Overview

Type Size Width di-

rection

(mm)

Recycled paper (60 to 74 g/m2)

Color paper (60 to 74 g/m2)

Plain paper 1 (60 to 74 g/m2)

Plain paper 2 (70 to 84 g/m2)

Plain paper 3 (75 to 90 g/m2)

Thick paper 1 (86 to 119 g/m2)

Thick paper 2 (120 to 128 g/m2)

Thick paper 3 (129 to 163 g/m2)

Coated paper 1 (100 to 110 g/m2)

Coated paper 2 (120 to 130 g/m2)

Coated paper 3 (155 to 165 g/m2)

Coated paper 4 (210 to 220 g/m2)

Transparency *1 A4 210.0 297.0 Yes No

Label A4 210.0 297.0 Yes Yes

Postcard Postcard 100 148 Yes Yes

Envelopes Envelopes COM10 104.7 241.3 Yes Yes

A4 *2 210.0 297.0 Yes Yes

B5 182.0 257.0 Yes Yes

A5 148.0 210.0 Yes Yes

LGL 215.9 355.6 Yes Yes

LTR *2 215.9 279.4 Yes Yes

STMT 139.7 215.9 Yes Yes

EXEC 184.1 266.7 Yes Yes

OFFICIO 215.9 317.5 Yes Yes

B-OFFICIO 215.9 355.0 Yes Yes

M-OFFICIO 215.9 341.0 Yes Yes

GLTR 203.2 266.7 Yes Yes

GLGL 203.2 330.2 Yes Yes

FLS 215.9 330.2 Yes Yes

AFLS 206.0 338.0 Yes Yes

indLGL 215.0 345.0 Yes Yes

K16 195.0 270.0 Yes Yes

Custom Paper Size - Yes *3 Yes *4

A4 210.0 297.0 Yes Yes

LTR 215.9 279.4 Yes Yes

A4 210.0 297.0 Yes No

LTR 215.9 279.4 Yes No

LTR 215.9 279.4 Yes No

LTR 215.9 279.4 Yes Yes

Custom Paper Size - Yes *3 Yes *4

Reply Postcard 148 200 Yes Yes

Envelopes Monarch 98.4 190.5 Yes No

Envelopes Nagagata 3 120 235 Yes Yes

Envelopes Yougatanaga

3

Envelopes C5 162 229 Yes Yes

Envelopes DL 110 220 Yes Yes

Custom Paper Size - Yes *3 Yes *4

120 235 Yes Yes

Feeding

direction

(mm)

Pickup position

MP Tray Cassette

*1: Use transparency sheets for laser printers. (Canon’s genuine transparency sheets are specially recommended.)

*2: Fax-received documents or reports can be printed. (excluding heavy paper)

*3: Paper of the following custom paper sizes can be loaded.

• Width 3" to 8 1/2" (76.2 to 215.9 mm); Length 5" to 14"(127 to 355.6 mm)

*4: Paper of the following custom paper sizes can be loaded.

• Width 4" to 8 1/2" (100 to 215.9 mm); Length 5 7/8" to 14" (148 to 355.6 mm)

13

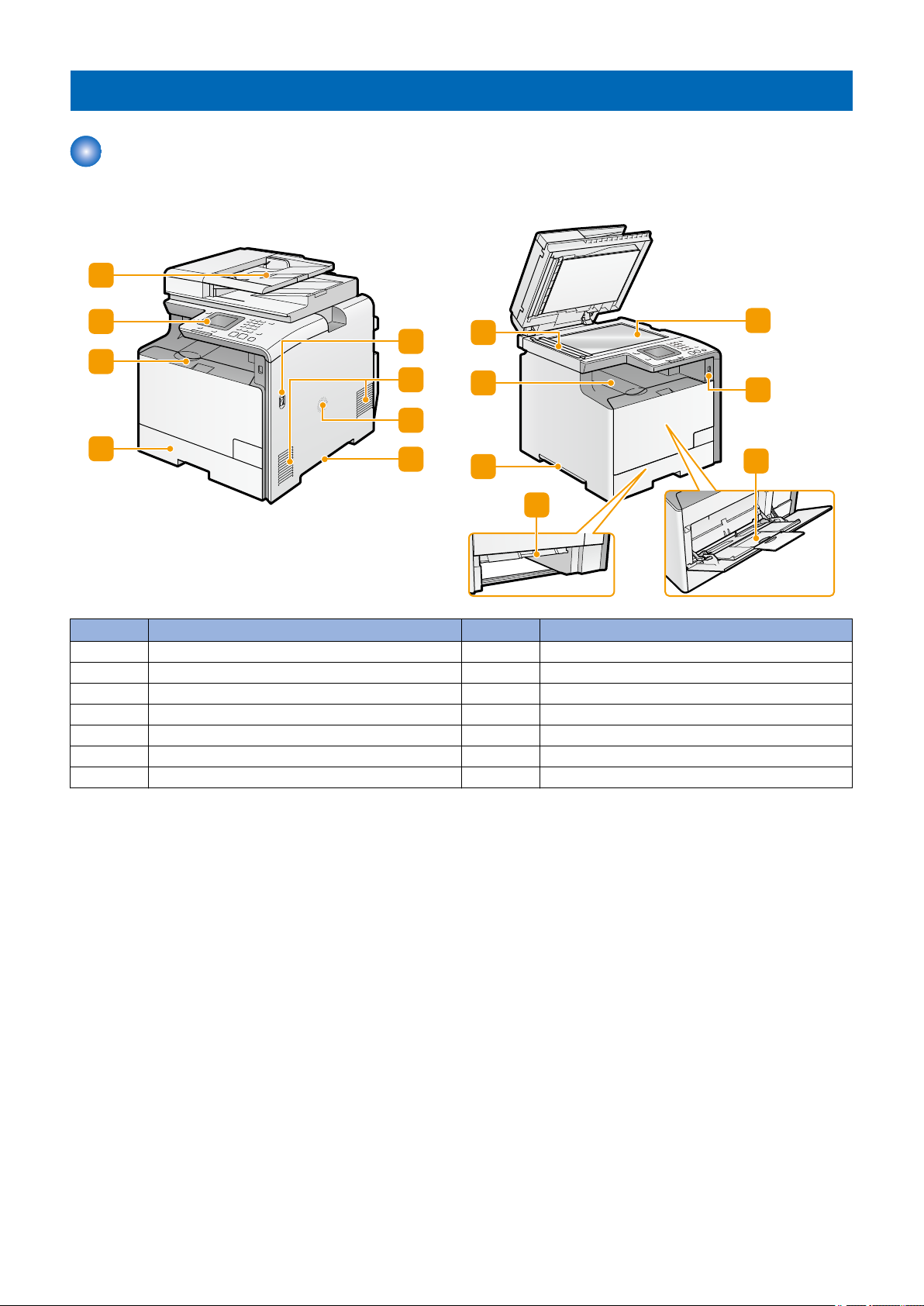

Name of Parts

1

4

6

5

3

2

9

10

8

11

14

13

12

8

7

External View

■ Front Side

1. Product Overview

No. Name No. Name

1 Feeder 8 Grip

2 Control panel 9 Paper scanner for document from feeder

3 Front cover 10 Delivery tray

4 Paper cassette 11 Manual feed guide

5 Main power switch 12 Copyboard glass

6 Vent-hole 13 USB memory port

7 Speaker 14 Multi-purpose tray (MP tray)

14

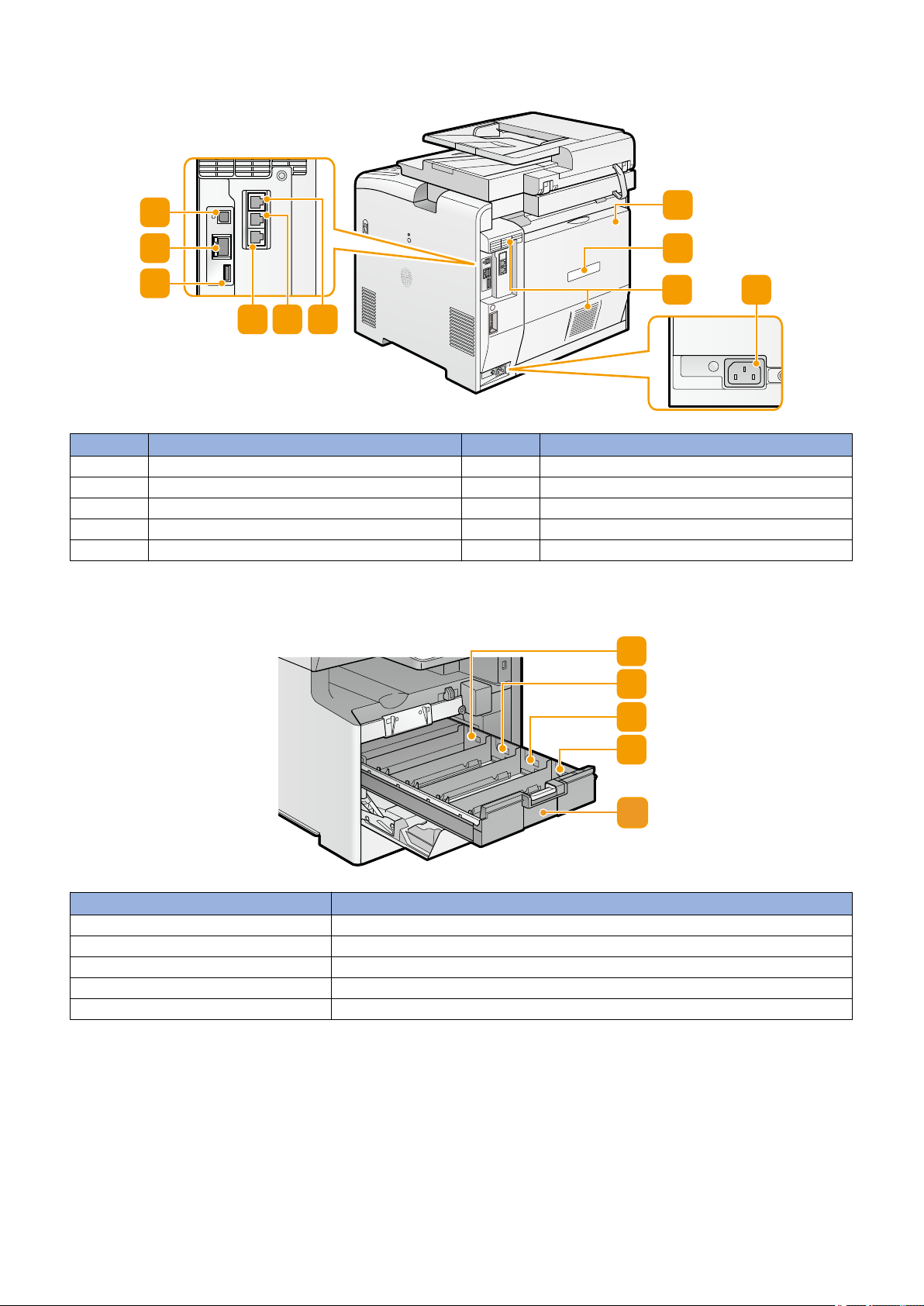

■ Rear Side

3

1

2

4 5 6

7

8

9

10

4

3

2

1

5

No. Name No. Name

1 USB port 6 Handset terminal

2 LAN port 7 Rear cover

3 USB port 8 Rating plate

4 Telephone line terminal 9 Vent-hole

5 External telephone terminal 10 Power socket

1. Product Overview

■ Inside

No. Name

1 Y toner cartridge slot

2 M toner cartridge slot

3 C toner cartridge slot

4 Bk toner cartridge slot

5 Toner cartridge tray

15

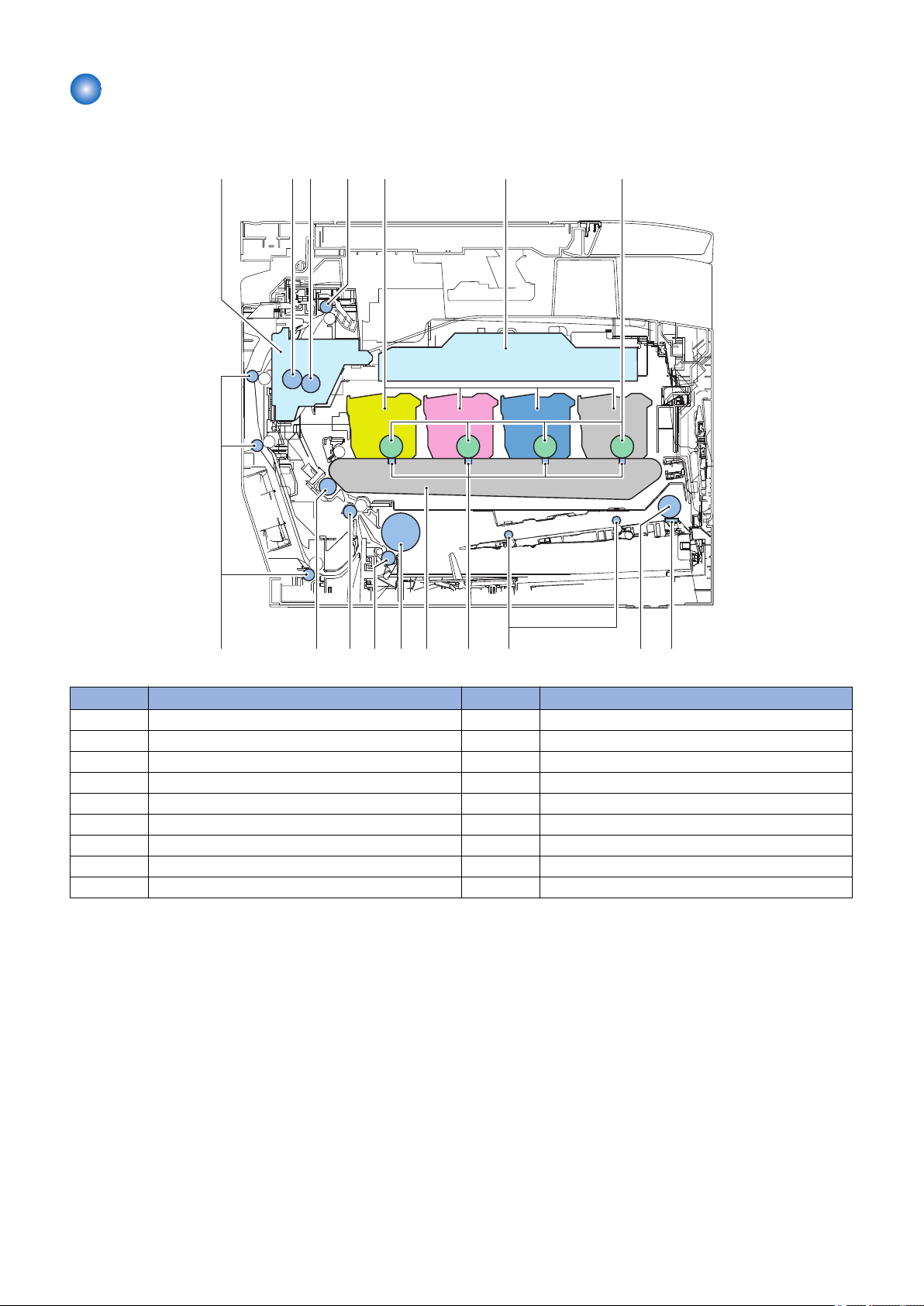

Cross Section View

[1] [2]

[3]

[4]

[5] [6] [7]

[8][9]

[10][11][12][13]

[14][15][16][17]

■ Host Machine

1. Product Overview

No. Name No. Name

1 Fixing assembly 10 MP tray feed roller

2 Pressure roller 11 Primary transfer pad

3 Fixing film unit 12 ITB unit

4 Delivery roller 13 Cassette pickup roller

5 Toner cartridge 14 Cassette separation roller

6 Laser scanner unit 15 Registration roller

7 Photosensitive drum 16 Secondary transfer external roller

8 MP tray separation pad 17 Duplex feed roller

9 MP tray pickup roller

16

■ Reader / ADF Unit

[1] [2] [3] [4]

[5][6][7]

[8]

No. Name No. Name

1 ADF registration roller 5 Reader unit

2 ADF separation roller 6 ADF delivery roller

3 ADF pickup roller 7 ADF separation pad

4 ADF unit 8 CIS unit

1. Product Overview

17

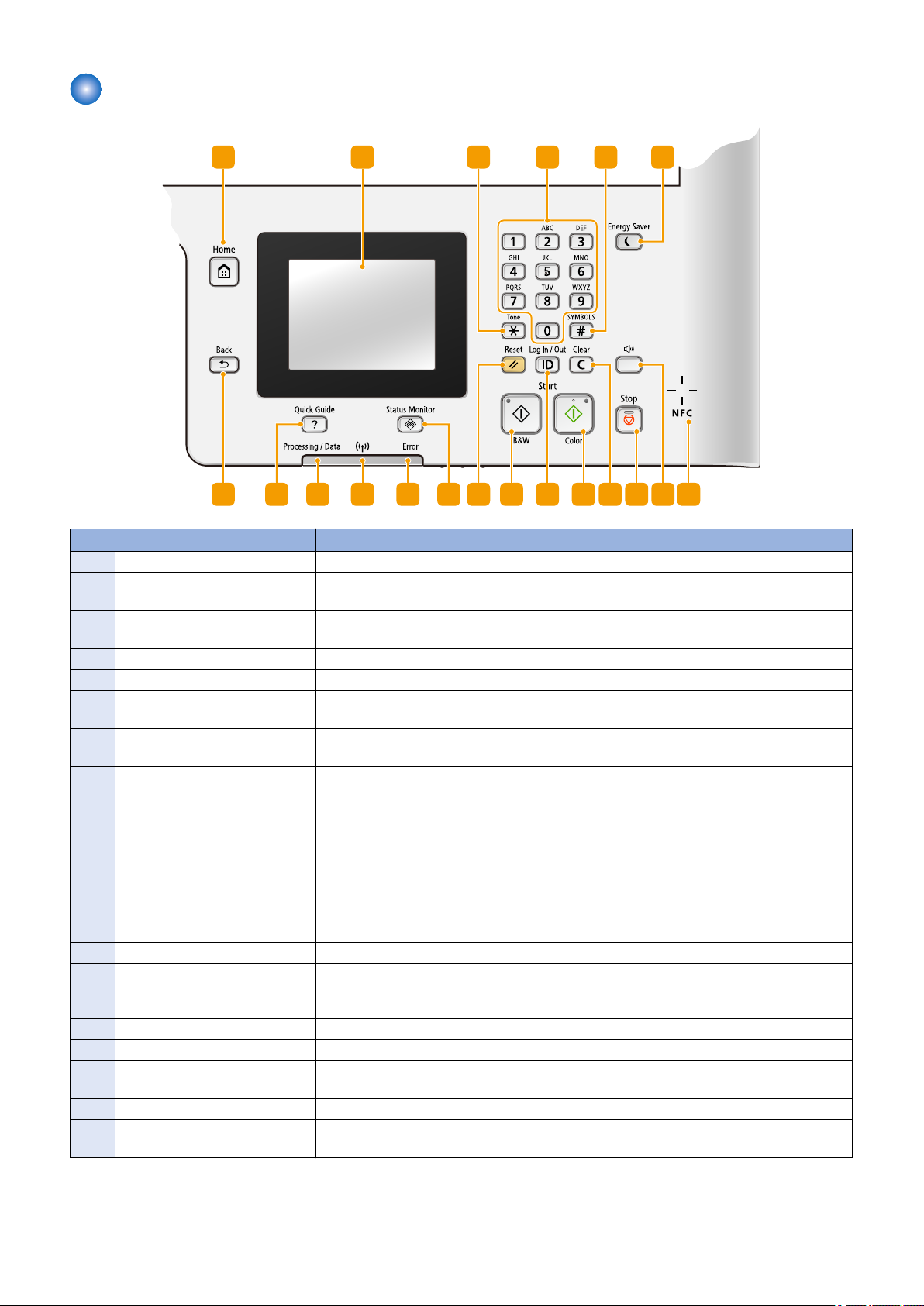

Control Panel

1 2

151617181920

3

4

5

6

78

9101112

1314

1. Product Overview

No. Name Explanation

1 [Home] key Press to display the <Home> Screen.

2 Display You can view the progress of copy, fax, and other jobs and error statuses. The display is a

touch panel, allowing you to operate the screen by touch to specify settings.

3 [*] key • Press to switch the type of text that is entered.

• Press to use tone dialing such as when receiving fax information services.

4 Numeric keys ([0]-[9] keys) Press to enter numbers and text.

5 [#] key Press to enter symbols such as "@" or "/".

6 [Energy Saver] key Press to put the machine into sleep mode. The key lights up green when the machine is in

sleep mode. Press the key again to exit sleep mode.

7 NFC (Near Field Communication)

mark *1

8 [Sound Volume] key Press to adjust volume.

9 [Stop] key Press to cancel copying, faxing, and other operations.

10 [Clear] key Press to delete the entered numbers and text.

11 [Start] (Color) key Press to scan or copy documents in color. In addition, if you press this key when you start

12 [ID] key Press after entering the ID and PIN to log on when Department ID Management is enabled.

13 [Start] (B&W) key Press to scan or copy documents in black and white. In addition, if you press this key when

14 [Reset] key Press to cancel the settings and restore the previously specified settings.

15 [Status Monitor] key Press to check the status of printing or faxing, to view the usage history, or to view the network

16 [Error] indicator Blinks or lights up when an error such as a paper jam occurs.

17 Wi-Fi indicator *2 Lights up when the machine is connected to wireless LAN.

18 [Processing/Data] indicator Blinks while operations such as sending or printing are being performed. Lights up when

19 [Quick Guide] key Press to view operation guidance and error causes/solutions.

20 [Back] key Press to return to the previous screen. If you press this key when specifying settings, for

Pass an NFC-enabled smartphone,etc. with a Canon NFC-compliant application installed on

it over this mark to perform printing and other operations.

printing images from a USB memory device, printouts are printed in color.

After you finish using the machine, press this key again to log off.

you start printing images from a USB memory device, printouts are printed in black and white.

settings such as the IP address of the machine. You can also check the status of the machine,

such as the remaining amounts of paper and toner, or whether any errors occurred.

there are documents waiting to be processed.

example, the settings are not applied and the display returns to the previous screen.

*1 : Models supporting NFC only

*2 : Models supporting wireless LAN only

18

Technical

2

Explanation

Basic Configuration.............................20

Document Exposure/Feeder System

.........................................................22

Controller System................................26

Laser Control System..........................29

Image Formation System....................30

Fixing System......................................41

Pickup / Feed System......................... 44

Embedded RDS.................................. 48

Setting Information Export/Import

Function (DCM)............................... 58

Basic Configuration

Laser Scanner

Laser Exposure System

Main

Controller

DC

Controller

Controller System

Laser beam

㻼㼍㼜㼑㼞㻌㼒㼘㼛㼣

Signal flow

ITB Unit

Secondary

Transfer

Image

Formation

System

Cassette

Manual Feed

Pickup Unit

Pickup

Unit

Pickup/feed System

Fixing

Assembly

Fixing System

Delivery

Assembly

CIS Unit

PC

ADF

Document Exposure/

Feeding System

Drum Drum Drum Drum

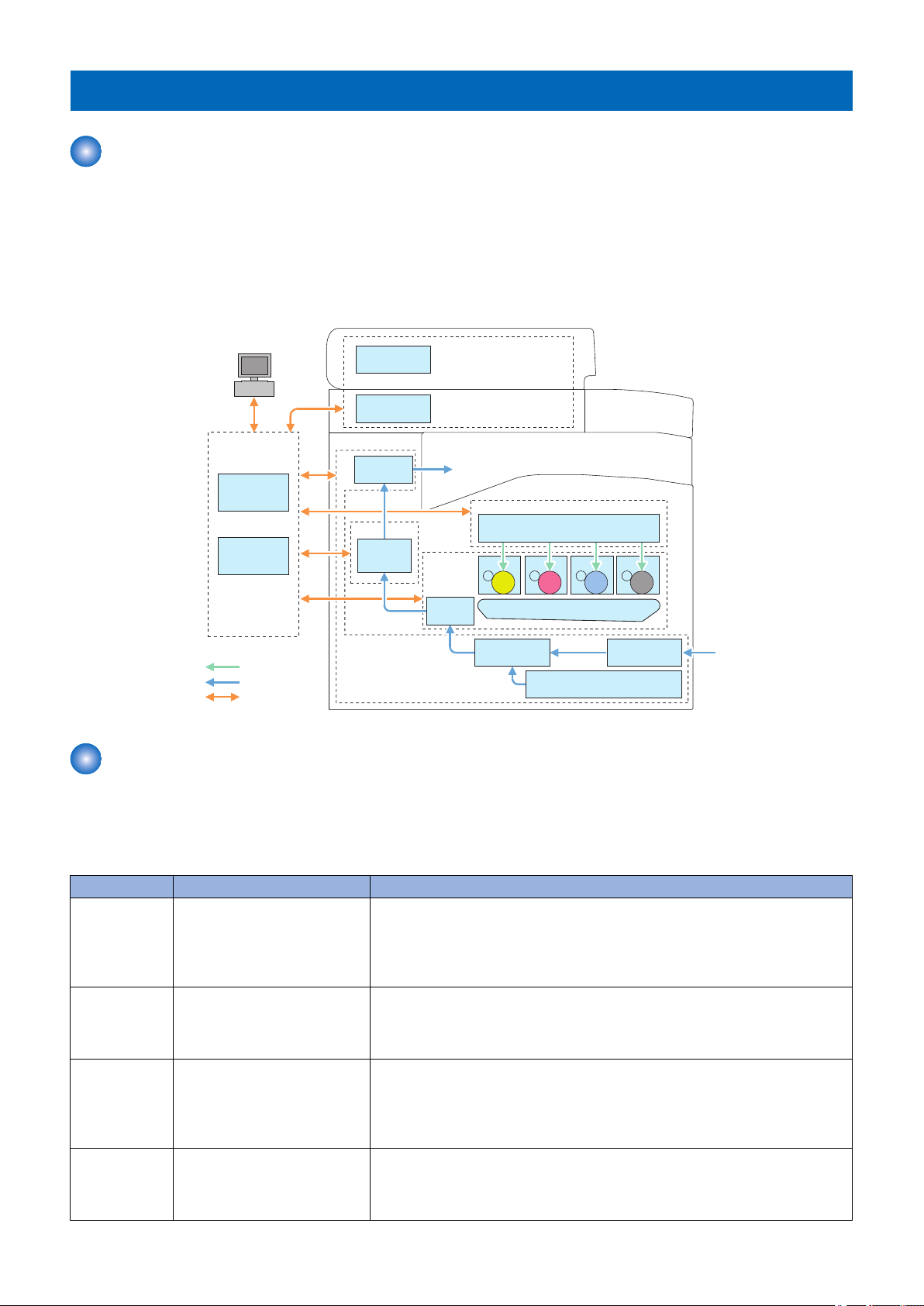

Configuration function

This device is roughly composed of the 6 functional blocks as shown in the figure below

• Document exposure/delivery system

• Controller system

• Laser exposure system

• Image formation system

• Fixing system

• Pickup / Feed System

2. Technical Explanation

■ Basic Operational Sequence

The CPU on the DC controller PCB controls the operational sequence. The table below shows the operation and the purposes

in each status from start-up of the device and to last rotation after print job completion.

WAIT

(Wait)

STBY

(STBY)

INTR

(IINTR)

PRINT

(Print)

Basic Sequence

Section Outline Operation

Interval from power-ON or reactivation from sleep mode upon

shutting the door(s) to entering

the print-ready status

Interval from the wait time or the

last rotation to issuance of a print

command from the main controller or power-OFF.

Interval from issuance of a print

command from the main controller during the stand-by status to

warming up the fixing assembly

to the target temperature.

Interval from the initial rotation to

completion of last page fixation.

Activate the printer to be ready for printing. During WAIT time, the following operations are done: pressure is applied to the pressure roller of the fixing assembly;

check cartridges and units being in place; move the developing unit to the home

position; and, clean the ITB. When needed, color displacement is corrected and the

image is stabilized.

Maintain the print-ready status. The printer enters the sleep mode upon receiving

a “sleep” command from the main controller during the stand-by status. The printer

executes color displacement correction or image stabilization upon receiving corresponding commands from the main controller.

To make the printer ready for print jobs, activate high-voltage bias PCBs, the laser

scanner unit and the fixing assembly.

Based on the video signals input from the main controller, form the static latent

image on the photosensitive drum to transfer and fix the toner image on paper.

When a certain pages are printed after power-ON, the device undergoes color displacement correction and/or image stabilization.

20

Section Outline Operation

LSTR

(Last rotation)

Interval from print job completion

to motor deactivation.

The last page of the print job is completely delivered. In this status, the laser scanner

unit and high-voltage bias PCBs are inactive. The printer starts the initial rotation

upon receiving a print command from the main controller during this status.

■ Print Sequence

See "Appendix" > "Print Sequence" in this manual.

■ Print Mode

The models of this series switch among 3 print modes to optimize the paper feed speed for printing.

2. Technical Explanation

Print mode Paper feed

speed

Normal speed

1/1 speed

mode

1/2 speed mode 1/2 speed

1/3 speed mode 1/3 speed

Paper type Print speed Remarks

Plain paper 1 (60 to 74 g/m2)

Plain paper 2 (70 to 84 g/m2)

Plain paper 3 (75 to 90 g/m2)

Recycled paper (60 to 74 g/m2)

Color paper (60 to 74 g/m2)

Thick paper 1 (86 to 119 g/m2)*

1

Thick paper 2 (120 to 128 g/m2)*

Coated paper 1 (100 to 110 g/m2)*

Thick paper 1 (91 to128 g/m2)*

1

Thick paper 2 (120 to 128 g/m2)*

Thick paper 3 (129 to163 g/m2)*

3

Coated paper 1 (100 to 110 g/m2)*

Postcards*

5

Thick paper 3 (129 to 163 g/m2)*

Coated paper 2 (120 to 130 g/m2)

Coated paper 3 (155 to 165 g/m2)

Coated paper 4 (210 to 220 g/m2)

Transparency

Labels

Postcards*

5

Envelopes

6

20 ppm*

Common to color and B&W

printing

2

4

2

9.7 ppm*

4

2

7.6 ppm*

6

6

*1: For Thick Paper 1 (86 to 119 g/m2), switched to normal mode when environment temperature is 20 deg C and above, and

switched to 1/2 speed mode when the temperature is lower than 20 deg C.

*2: For Thick Paper 2 (120 to 128 g/m2), switched to normal mode when environment temperature is 20 deg C and above, and

switched to 1/2 speed mode when the temperature is lower than 20 deg C.

*3: For Ticick Paper 3 (129 to 163 g/m2), switched to 1/2 speed mode when environment temperature is 20 deg C and above,

and switched to 1/3 speed mode when the temperature is lower than 20 deg C.

*4: For Coated paper 1 (100 to 110 g/m2), switched to normal mode when environment temperature is 20 deg C and above, and

switched to 1/2 speed mode when the temperature is lower than 20 deg C.

*5: For Postcard, switched to 1/2 speed mode when environment temperature is 20 deg C and above, and switched to 1/3 speed

mode when the temperature is lower than 20 deg C.

*6: The fastest print speed in each mode.

21

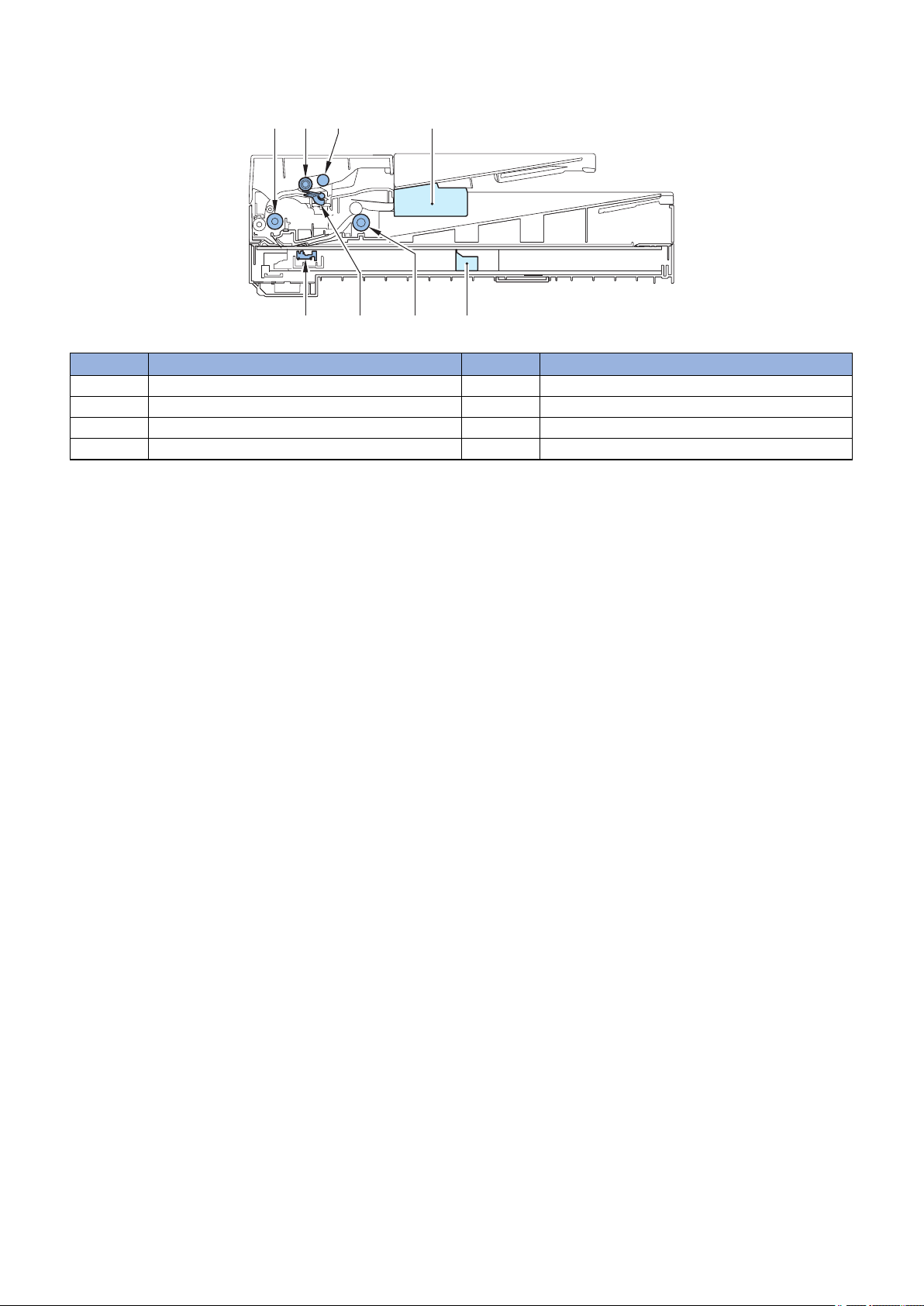

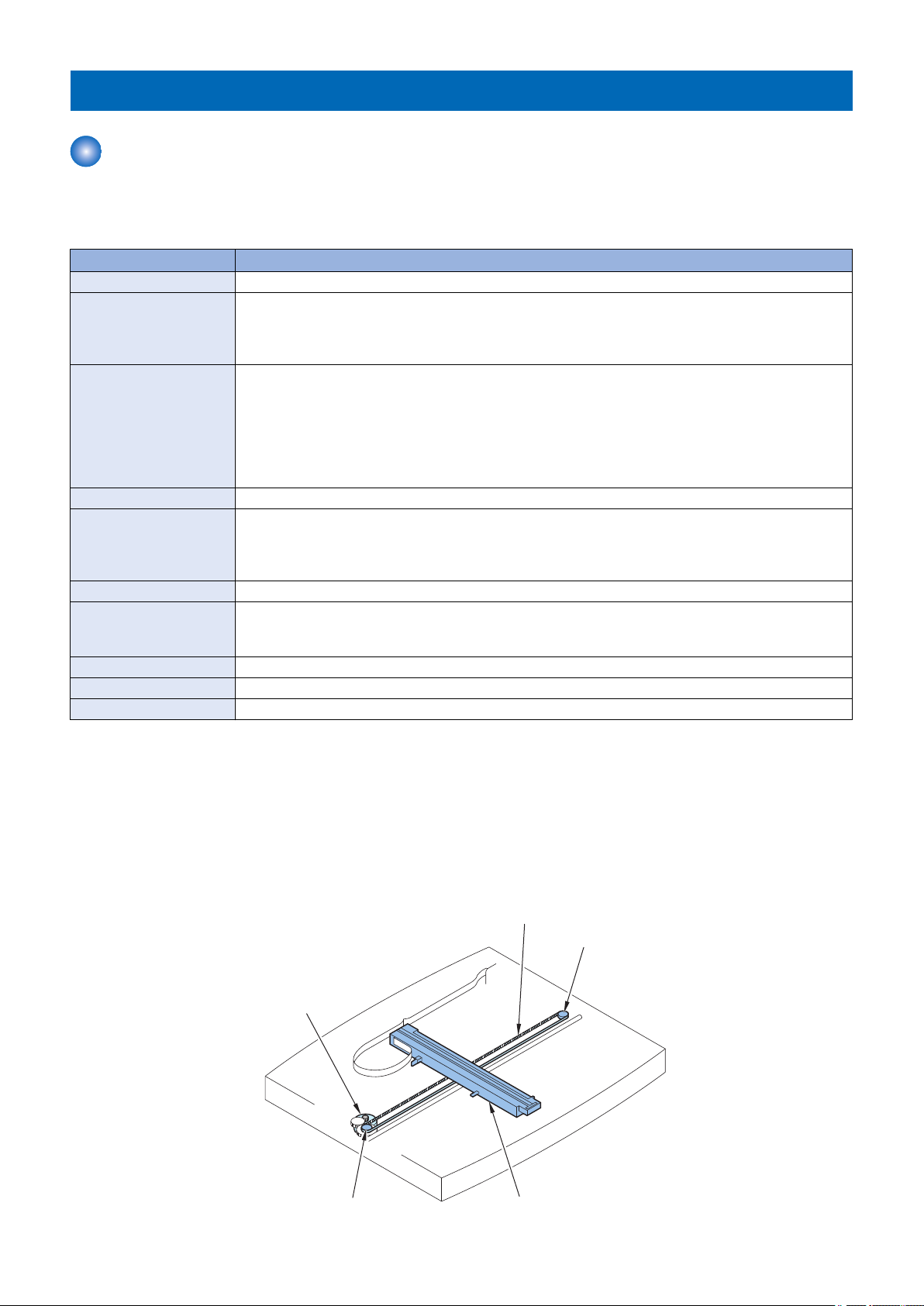

Document Exposure/Feeder System

Drive Belt

Drive Pulley

Drive Pulley

Contact Image Sensor (CIS)

Reader Motor

(M720)

Document Exposure System

■ Overview

Specifications / Control / Function List

Item Function / Method

Document Exposure LED

Document Scan Book Mode:

• Scan by the shift of the contact sensor (CIS)

ADF:

• Document stream reading by fixed contact sensor (CIS)

Scanning Resolution Color:

• 600 dpi (horizontal scanning) x 600 dpi (vertical scanning)

• 300 dpi (horizontal scanning) x 600 dpi (vertical scanning)

• 300 dpi (horizontal scanning) x 300 dpi (vertical scanning)

Black and White:

• 600 dpi (horizontal scanning) x 600 dpi (vertical scanning)

• 300 dpi (horizontal scanning) x 600 dpi (vertical scanning)

Number of Gradations 256 Gradations

Magnification 25% to 400%

Horizontal scanning direction: Image processing by the Main Controller PCB

Vertical scanning direction: The speed at which the carriage moves and image processing by the Main

Controller PCB

Lens CIS/Color

CIS Number of lines: 1 line

Number of pixels: 5184 pixels as total pixels (5107 pixels as effective pixels)

Maximum document scanning width: 216mm

CIS Drive Control Drive Control by Reader Motor (M720)

Document Size Detection None

Dirt Sensor Detection None

2. Technical Explanation

■ Major Components

Followings are the major components for Document Exposure System.

• The contact sensor to scan document.

• The Reader motor (M720), The drive pulley, The drive belt, to shift The contact sensor

In image scanning control, the contact sensor is shifted by rotating the Reader motor based on the drive signal from the Main

Controller PCB and scan the original on the copyboard glass. When ADF is in use, image is scanned by feeding the originals by

ADF instead of shifting the contact sensor.

22

Loading...

Loading...