Page 1

LR1

SERVICE

MANUAL

Canon

Page 2

QY8-1367-000

REVISION 0

COPYRIGHT 1999 CANON INC. CANON LR1 1299 AB 0.02-0 PRINTED IN JAPAN (IMPRIME AU JAPON)

DEC. 1999

Page 3

1299 AB 0.02-0

Page 4

Page 5

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation,

maintenance, and repair of products. This manual covers all localities where the products are sold. For

this reason, there may be information in this manual that does not apply to your locality.

Corrections

This manual could include technical inaccuracies or typographical errors due to improvements or

changes in the products. When changes occur in applicable products or in the content of this manual,

Canon will release technical information as the need arises. In the event of major changes in the

contents of this manual over a long or short period, Canon will issue a new editions of this manual

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names described in this manual are the registered trademarks of the

individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be

copied, reproduced or translated into another language, in whole or in part, without the written consent

of Canon Inc., except in the case of internal business use.

Copyright 1999 by Canon Inc.

CANON INC.

BJ Printer Technical Support Dept. 21

16-1, Shimonoge 3-chome, Takatsu-ku, Kawasaki, Kanagawa 213-8512, Japan

This manual has been produced on an Apple Power Macintosh 7300/180 personal computer and OKI

MICROLINE 803 PSIIV laser beam printer; artworks of printing films were printed on Agfa SelectSet

Avantra 25. All page layouts, logos, and parts-list data were saved with Canon Optical Disc Subsystem

mo-5001S™ and Optical Disc Cartridge mo-502M™, and Interface Kit mo-IF2™ for Macintosh. All

graphics were produced with MACROMEDIA FREEHAND™ 7.0J. All documents and all page layouts were

created with QuarkXpress™ 3.3 Japanese version.

Page 6

I

I. ABOUT THIS MANUAL

This manual is divided into five sections, and contains information required for serving the

unit.

Part 1: Product Specifications

This section contains outlines and product specifications of the unit.

Part 2: Maintenance

This section explains how to maintain the unit. Descriptions and adjustment of

assembly/disassembly and verification methods after assembly/disassembly are

included.

Part 3: Operation

This section explains how to operate the unit properly. Operation procedures for service

modes are explained.

Part 4: Troubleshooting

This section explains how to find out possible causes of troubles and units/parts to be

replaced. It is divided into two parts: troubleshooting by error indications and by

symptoms.

Part 5: Appendix

This section includes block diagrams of the unit and information to technically

understand the hardware (applied for new techniques only). This section also includes

pin arrangements.

Sufficient information regarding assembly/disassembly is not given in this

manual. Refer to the illustrations in the separate

Parts Catalog

.

Product

Outline

Maintenance

Operation Troubleshooting Appendix

Page 7

II. TABLE OF CONTENTS

Page

Part 1:

PRODUCT OUTLINE

1 - 1 1. PRODUCT OUTLINE

1 - 1 1.1 Product Outline

1 - 2 1.2 Features

1 - 3 2. SPECIFICATIONS

1 - 3 2.1 Printer Specifications

1 - 3 2.1.1 Printer specifications

1 - 4 2.1.2 Printer life

1 - 4 2.2 Paper Specifications

1 - 4 2.2.1 Paper sizes and weights

1 - 4 2.2.2 Paper types and handling

1 - 5 2.2.3 Printable area

1 - 6 2.3 BJ Cartridge Specifications

1 - 7 2.4 Interface Specifications

1 - 7 2.4.1 Parallel interface

1 - 7 2.4.2 Serial interface

1 - 8 2.5 Printer Drivers

1 - 9 3. PACKING

1 -10 4. INSTALLATION

1 -10 4.1 Installation Location

1 -10 4.2 Installation Procedure

1 -10 4.2.1 Connecting the centronics interface cable

1 -10 4.2.2 Connecting the USB interface cable

1 -10 4.2.3 Connecting to a power supply

1 -11 5. NAMES AND FUNCTION OF PARTS

1 -12 6. PARTS CODE LIST

Part 2: MAINTENANCE

2 - 1 1. PERIODIC REPLACEMENT PARTS AND MAINTENANCE

2 - 1 1.1 Periodic Replacement Parts

2 - 1 1.2 Consumables

2 - 1 1.3 Periodic Maintenance

2 - 2 2. DISASSEMBLY AND REASSEMBLY

2 - 2 2.1 Tools

2 - 3 2.2 Cautions for Disassembly and Reassembly

2 - 3 2.2.1 Cautions for ink stains (ink path/ink mist)

2 - 4 2.2.2 Damage by static electricity

2 - 5 2.2.3 Preparation for transportation

2 - 6 2.3 Disassembly and Reassembly

2 - 6 2.3.1 Removing plastic parts

2 - 6 2.3.2 Removing and installing tap screws

2 - 6 2.3.3 Cable positions

2 - 6 2.3.4 Deformation of spur tips

2 - 7 2.3.5 Feed gear cautions

2 - 7 2.3.6 Installing and removing the upper case unit

2 - 8 2.3.7 Positioning the MODE switch

2 - 8 2.3.8 Installing and removing the home position sensor

2 - 9 2.4 Applying Grease

2 - 9 2.5 Adjustments and Settings After Disassembly and Reassembly

2 - 9 2.5.1 Adjustments

2 -10 2.6. Spur Cleaner

II

Page 8

Page

2 -10 2.6.1 Usage

2 -11 3. OPERATION CHECK AFTER DISASSEMBLY AND ASSEMBLY

2 -11 3.1 Check Procedure

Part 3: OPERATION

3 - 1 1. PRINTER OPERATION FUNCTIONS

3 - 1 1.1 Status Indications

3 - 2 1.1.1 Status indicators

3 - 3 1.1.2 Error description

3 - 4 1.1.3 Ink-low indicator

3 - 5 1.1.4 BJ status monitor (Used only when connected to a computer)

3 - 6 1.2 Operation With a Computer

3 - 6 1.2.1 Function settings with the printer driver

3 - 7 1.3 Operation From the Printer Itself

3 - 7 1.3.1 Cleaning and head refreshing

3 - 8 1.3.2 Printing the nozzle check pattern

3 - 8 1.3.3 Resetting the dot counter

3 - 9 1.3.4 Cleaning the pick-up roller

3 - 9 1.3.5 Auto power on/off setting

3 -10 1.3.6 Mode switch

3 -11 2. SERVICE-RELATED FUNCTION

3 -11 2.1 Service Mode Operations

3 -12 2.2 Printing the EEPROM Data

3 -13 2.3 Setting the Waste Ink Amount

Part 4: TROUBLESHOOTING

4 - 1 1. TROUBLESHOOTING ACCORDING TO ERROR DISPLAY

4 - 1 1.1 Initial Flow Chart

4 - 4 1.2 Error List

4 - 5 1.3 Troubleshooting Errors

4 -16 2. TROUBLESHOOTING BY SYMPTOMS

4 -16 2.1 Troubleshooting By Symptoms

Part 5: APPENDIX

5 - 1 1. TECHNICAL REFERENCE

5 - 1 1.1 Description of Paper-feed Section

5 - 1 1.1.1 Construction of paper-feed section

5 - 1 1.1.2 Pick-up section

5 - 2 1.1.3 Transport section

5 - 2 1.1.4 Paper delivery section

5 - 3 1.1.5 Remaining paper indication function

5 - 3 1.1.6 Pick-up retry function

5 - 3 1.1.7 The form alignment function

5 - 4 1.2 Purge Section

5 - 4 1.2.1 Cleaning function

5 - 5 1.2.2 Description of Purge Section

5 - 7 1.3 Description of Carriage Section

5 - 7 1.3.1 BJ cartridge mounting function

5 - 7 1.3.2 Carriage drive control

5 - 8 1.4 Electronic Circuit Description

5 - 8 1.4.1 Printer block diagram

5 - 8 1.4.2 Power source line block diagram

5 - 9 1.4.3 USB interface

III

Page 9

Page

5 -10 1.4.4 Automatic interface switching

5 -10 1.4.5 Detection functions

5 -11 1.5 BJ Cartridge Description

5 -11 1.5.1 BJ cartridge and ink cartridge configuration

5 -11 1.5.2 BJ cartridge construction

5 -11 1.5.3 BJ cartridge printing drive control

5 -11 1.5.4 BJ cartridge identification

5 -12 1.5.5 Printing mode list

5 -13 2. CONNECTOR LOCATIONS AND PIN ARRAY

5 -13 2.1 Control Board

5 -18 2.2 Operation Panel Board

5 -19 2.3 Sensor Board

5 -19 2.4 Pick-up Roller Position Sensor Board

5 -20 2.5 BJ Cartridge

5 -21 2.6 Carriage Motor

5 -21 2.7 Paper-Feed Motor

5 -22 2.8 Pick-up Motor

5 -23 2.9 Circuit Diagram

IV

Page 10

III. ILLUSTRATION INDEX

Page

Part 1:

PRODUCT OUTLINE

1 - 1 Figure 1 - 1 Exterior of Printer

1 - 2 Figure 1 - 2 Possible System Configurations

1 - 5 Figure 1 - 3 Printable Area

1 - 9 Figure 1 - 4 Packing

1 -10 Figure 1 - 5 Installation Space

1 -11 Figure 1 - 6 Parts Names and Major Functions

Part 2: MAINTENANCE

2 - 3 Figure 2 - 1 Ink Path

2 - 4 Figure 2 - 2 Parts Exposed to Ink Mist

2 - 6 Figure 2 - 3 Spurs

2 - 7 Figure 2 - 4 Feed Gear Cautions

2 - 7 Figure 2 - 5 Installing and Removing the Upper Case Unit

2 - 8 Figure 2 - 6 MODE Switch Positioning

2 - 8 Figure 2 - 7 Installing and Removing the Home Position Sensor

2 - 9 Figure 2 - 8 Applying Grease

2 -10 Figure 2 - 9 Spur Cleaner

2 -10 Figure 2 -10 Set the Spur Cleaner

Part 3: OPERATION

3 - 1 Figure 3 - 1 Operation Panel

3 - 5 Figure 3 - 2 BJ Status Monitor (Sample)

3 - 6 Figure 3 - 3 Printer Driver Utilities (Sample)

3 - 7 Figure 3 - 4 Printer Buttons

3 - 8 Figure 3 - 5 Printing the Nozzle Check Pattern (Sample BC-11e)

3 -12 Figure 3 - 6 EEPROM Data Printout (sample)

3 -13 Figure 3 - 7 Waste Ink Absorber (50% of capacity)

Part 5: APPENDIX

5 - 1 Figure 5 - 1 Paper-Feed Path

5 - 1 Figure 5 - 2 Pick-up Section

5 - 2 Figure 5 - 3

5 - 3 Figure 5 - 4 Indicating the Remaining Amount of Paper

5 - 3 Figure 5 - 5 Fixing Skewed Paper

5 - 5 Figure 5 - 6 Purge Section

5 - 6 Figure 5 - 7 Wiping Operation

5 - 7 Figure 5 - 8 Carriage Section Structure

5 - 8 Figure 5 - 9 Block Diagram

5 - 8 Figure 5 -10 Power Source Line Block Diagram

5 - 9 Figure 5 -11 USB Data Transfer

5 - 9 Figure 5 -12 NRZI

5 -10 Figure 5 -13 Sensor Locations

5 -11 Figure 5 -14 Cartridge Configuration

5 -11 Figure 5 -15 Nozzle Array

5 -13 Figure 5 -16 Control Board

5 -13 Figure 5 -17 Printer Diagram

5 -18 Figure 5 -18 Operation Panel Board

5 -19 Figure 5 -19 Sensor Board

5 -19 Figure 5 -20 Pick-up Roller Position Sensor Board

5 -20 Figure 5 -21 BJ Cartridge

V

Page 11

Page

5 -21 Figure 5 -22 Carriage Motor

5 -21 Figure 5 -23 Paper-Feed Motor

5 -22 Figure 5 -24 Pick-up Motor

VI

Page 12

IV. TABLE INDEX

Page

Part 1:

PRODUCT OUTLINE

1 -12 Table 1- 1 PARTS CODE

Part 3: OPERATION

3 - 2 Table 3- 1 STATUS INDICATORS

Part 4: TROUBLESHOOTING

4 - 4 Table 4- 1 ERROR DISPLAY

Part 5: APPENDIX

5 - 4 Table 5- 1 INK CONSUMPTION DURING CLEANING

5 -10 Table 5- 2 DETECTION FUNCTIONS

5 -12 Table 5- 3 PRINTING MODES AND DRIVE METHOD

5 -17 Table 5- 4 HEAD INSTALLATION STATUS AND SIGNAL DETECTION

VII

Page 13

Page 14

Part 1

PRODUCT

OUTLINE

Page

1 - 1 1. PRODUCT OUTLINE

1 - 1 1.1 Product Outline

1 - 2 1.2 Features

1 - 3 2. SPECIFICATIONS

1 - 3 2.1 Printer Specifications

1 - 4 2.2 Paper Specifications

1 - 6 2.3 BJ Cartridge Specifications

1 - 7 2.4 Interface Specifications

1 - 8 2.5 Printer Drivers

1 - 9 3. PACKING

1 -10 4. INSTALLATION

1 -10 4.1 Installation Location

1 -10 4.2 Installation Procedure

1 -11 5. NAMES AND FUNCTION OF PARTS

1 -12 6. PARTS CODE LIST

Page 15

Page 16

1. PRODUCT OUTLINE

1.1 Product Outline

This is Canon’s first bubble-jet printer for use with a set top box (STB).

The design is a complete departure from conventional printers geared for personal

computers. The printer is designed to resemble an AV component to match the living

room interior.

It also has a MODE SELECTION switch, ink-low warning, and other functions which

are required as a non-PC printer. The large-capacity ink cartridges also make ink

cartridge replacements less frequent.

1-1

LR1

Part 1: Product Outline

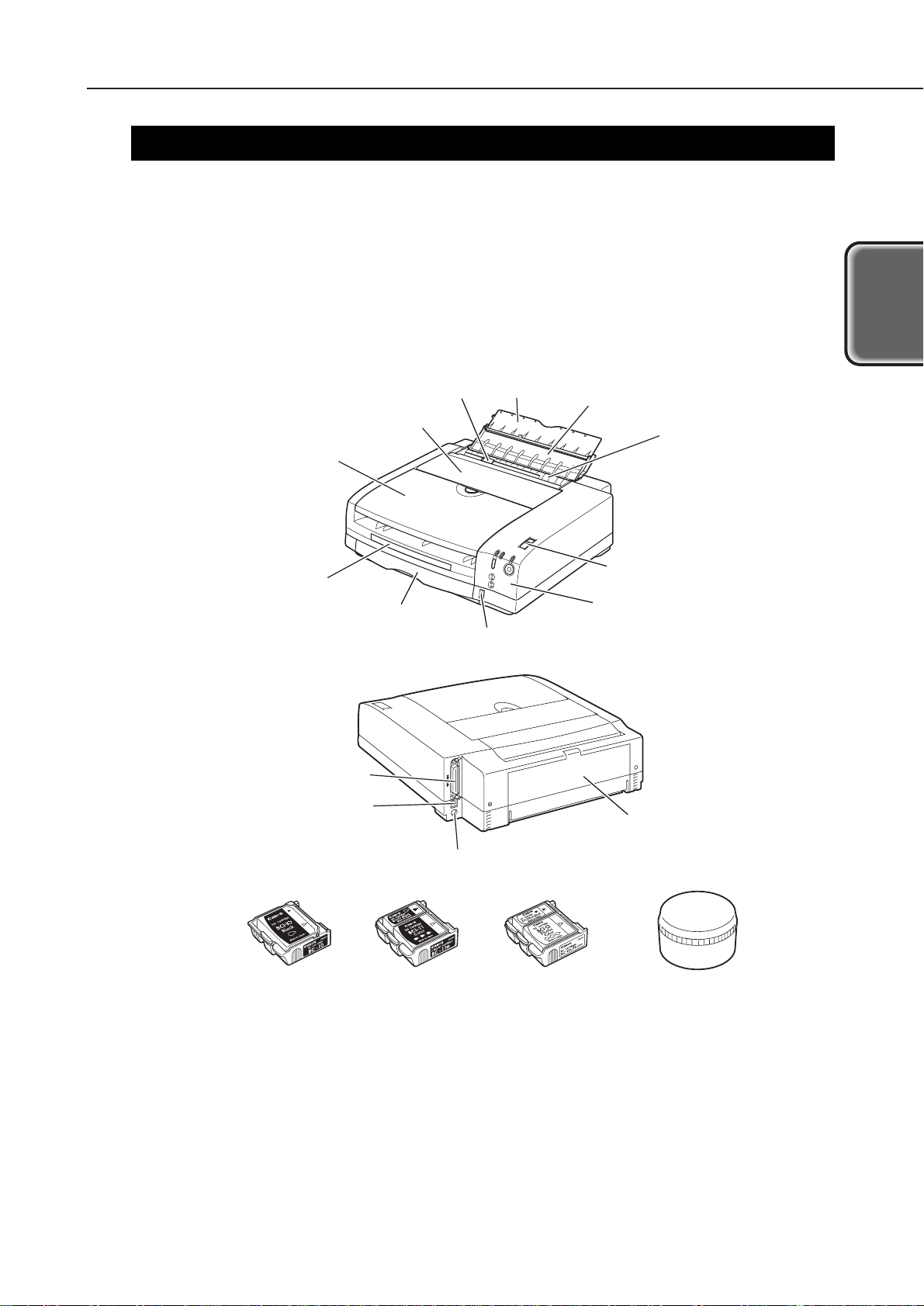

Product

Outline

Manual-feed slot

Manual-feed tray

Extension tray

Cartridge cover

Paper delivery cover

Paper delivery tray

Parallel interface connector

USB interface connector

Power connector

Black Color Photo

Storage box

BJ cartridge

Manual-feed guide

Operation panel

MODE switch

Paper cassette

Remaining paper indication window

Rear cover

Figure 1-1 Exterior of Printer

Page 17

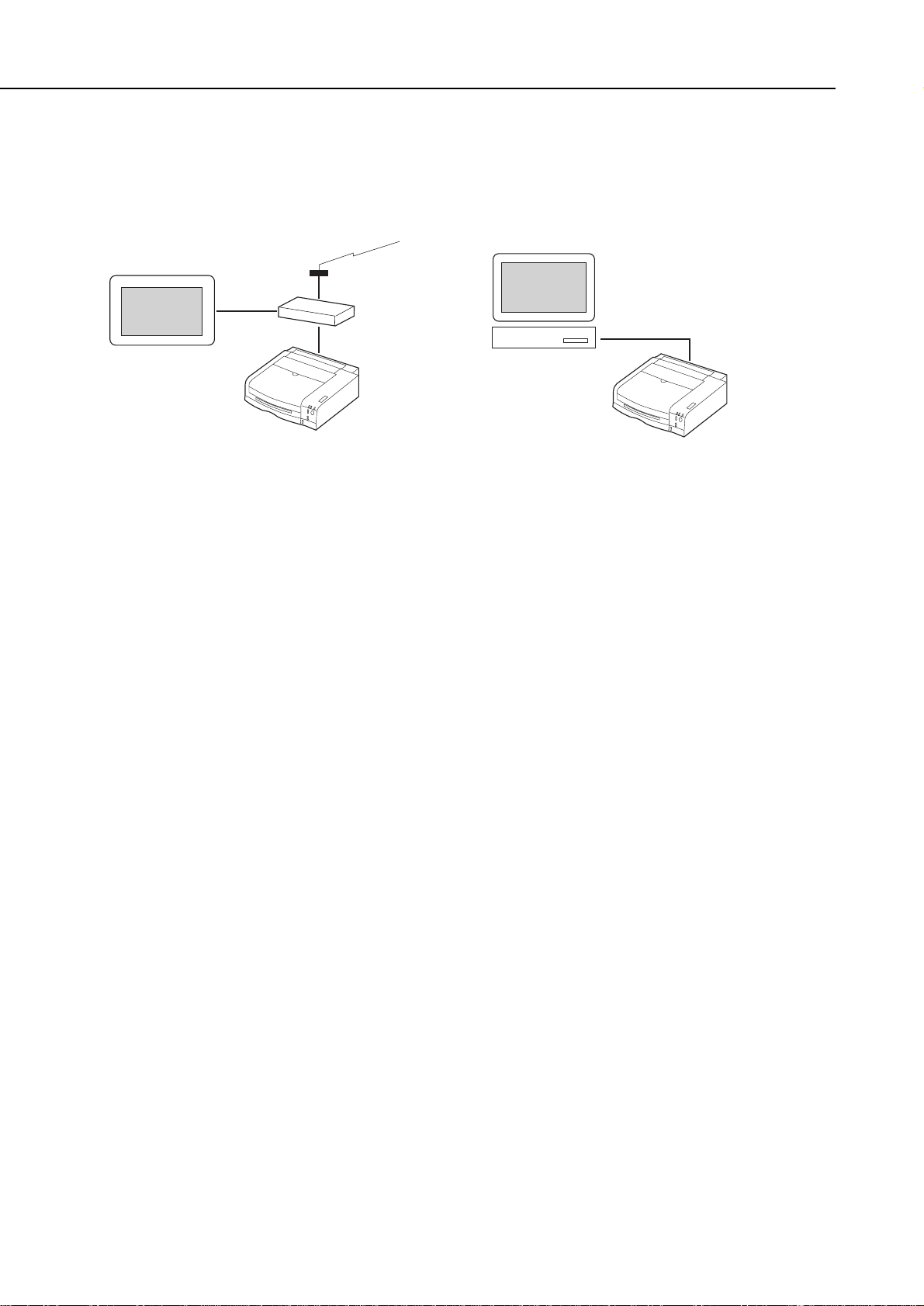

1.2 Features

1) The printer is connected to the TV via the STB to enable images from the Internet to

be printed. It can also be used as a PC printer.

2) By using a paper cassette and the operation panel on the front of the printer, frontend operation is easy.

3) The printer uses three types of BJ cartridges: Black, color, and photo color.

The black and color cartridges use large-capacity ink cartridges to make ink cartridge

replacement less frequent.

Black BJ cartridge BC-10 (optional): 128-nozzle head with detachable ink cartridge

Color BJ cartridge BC-11e: 136-nozzle head (64-nozzles for Bk and 24

nozzles each for Y, M, and C) with detachable

ink tank and ink-drop modulation technology

Photo Color BJ cartridge BC-12e (optional):

136-nozzle head (64-nozzles for Bk and 24

nozzles each for Y, M, and C) with detachable

ink cartridge and ink-drop modulation

technology

Ink Cartridge BCI-10 Black: For BC-10 Black

Ink Cartridge BCI-17 Black: For BC-10 large-capacity Black

Ink Cartridge BCI-11 Black: For BC-11e Black

Ink Cartridge BCI-11 Color: For BC-11e Color (YMC integrated)

Ink Cartridge BCI-18 Black: For BC-11e large-capacity Black

Ink Cartridge BCI-18 Color: For BC-11e large-capacity Color (YMC integrated)

Ink Cartridge BCI-12 Black: For BC-12e Photo Black

Ink Cartridge BCI-12 Color: For BC-12e Photo Color (YMC integrated)

4) The remaining ink amount is calculated with the dot counter. An

INK-LOW

indicator

is also provided.

5) Bitmap fonts for the Internet are built-in for high-quality and quick text output.

Part 1: Product Outline

LR1

1-2

With a STB (set top box).

TV

Modem

Internet

STB

LR1

With a personal computer.

Personal computer

LR1

Figure 1-2 Possible System Configurations

Page 18

2. SPECIFICATIONS

2.1 Printer Specifications

2.1.1 Printer specifications

1-3

LR1

Part 1: Product Outline

Product

Outline

Type

Paper Feed System

Resolution

Throughput

(Reference only)

Printing Direction

Max. Print Width

Line Feed Speed

Interface

Cassette Capacity

Manual Feed Tray

Capacity

Detection Function

Operating Noise

Ambient Conditions

Power Source

External

Dimensions

Weight

Certification

Desk-top serial color printer, non-PC printer for STB

Automatic feed (cassette)/Manual feed (manual feed tray)

360 × 720 dpi (Max. resolution)

* Catalog specification.

Unidirectional (automatically selected according to the print data)

203 mm

Approx. 136 ms/line: 9.03 mm (128/360 inch) carriage return

USB and IEEE 1284-standard, 8-bit parallel (Compatible/Nibble)

Plain paper: 5 mm max. (Approx. 50 sheets at 75 g/m2)

1 sheet

Cartridge cover-open detection: Provided

BJ cartridge detection: Provided

BJ cartridge identification: Provided

Ink-low detection sensor: Provided

Waste ink capacity detection: Provided

Paper width detection: None

Approx. 45 dB (A): Sound pressure level conforms to ISO 9296.

During operation: Temperature 5°C-35°C (41°F-95°F)

Humidity 10%-90% RH (No condensation)

During non-operation: Temperature 0°C-35°C (32°F-95°F)

Humidity 5%-95% RH (No condensation)

Power voltage/frequency: 100-240 VAC 50/60 Hz

Power consumption: During printing: Approx. 30 W

During standby: Approx. 2 W

Soft power off: Approx. 2 W

Approx. 365mm W × 364mm D × 110 mm H

Approx. 4.0 kg (excluding BJ cartridge)

Radio wave interference: FCC, SISPR 22, CE Mark

Electrical safety: UL, CSA, IEC, GS, FIMKO, SEMCO, AS/NZS,

CCIB, SISIR,

EI, NEMKO, Korean Electric Commerce

Environmental: Energy Star, Blue Angel

BC-10 Black Cartridge

Black Text (PC Magazine)

New monochrome pattern (E)

BC-11e Color Cartridge

New color pattern (E)

BC-12e Photo Cartridge

Full Address Printing

High-speed

3.5 ppm

4.1 ppm *

1.9 ppm *

-

High-quality

-

1.0 ppm

0.3ppm

0.1 ppm *

Standard

3.2 ppm

3.9 ppm *

1.6 ppm *

-

Page 19

2.1.2 Printer life

The printer’s life shall be until any of the following conditions is attained:

(1) A total of 12,000 sheets are printed with the1,500-character standard pattern in

black ink

(2) A total of 6,000 sheets are printed with the color printing standard pattern at 7.5%

duty per color

(3) A total of 2,000 sheets are printed with photographic standard patterns

(4) Five years of operation elapses

2.2 Paper Specifications

2.2.1 Paper sizes and weights

(1) Paper sizes

A4, B5, A5, letter, envelope (Com #10/DL-size)

(2) Weight

64-105 g/m2for cassette feeding

2.2.2 Paper types and handling

* Paper dedicated to BJ printers.

Note 1: The printing side of the paper is stacked face-down in the cassette.

Note 2: Only A4 or letter-size paper can be fed from the paper cassette.

Part 1: Product Outline

LR1

1-4

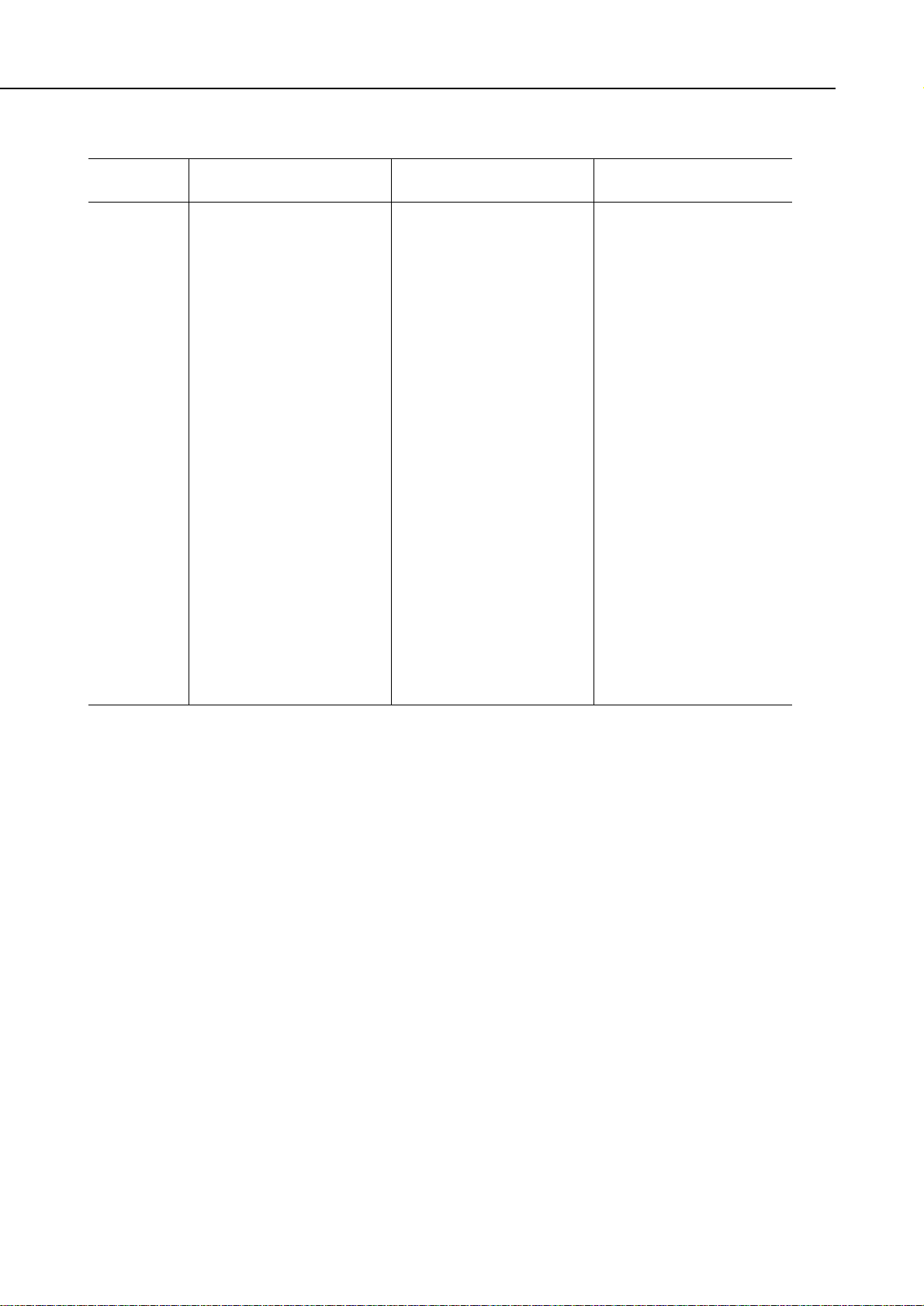

Type

Plain paper

Plain paper

for Color BJ

High-quality

paper

Photo glossy

paper

Glossy film

Transparency

film

Back print

film

Banner

T-shirt

transfer

Photo glossy

card

Envelope

Size

A4/LTR

A4/B5/LTR/A5

A4/LTR

A4/LTR

A4/LTR

A4/LTR

A4/LTR

A4/LTR

A4/LTR

A4/LTR

120 mm × 216 mm

241 mm × 105 mm

220 mm × 110 mm

LC-301*

HR-101*

GP-301*

HG-101*

CF-102*

BF-102*

BP-101*

TR-201*

FM-101*

Com #10

DL-size

Feed method

Cassette

Manual

Cassette

Manual

Cassette

Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

Capacity

Approx. 5 mm or less

(Approx. 50 sheets of 75 g/m

2

weight)

1 sheet

Approx. 5 mm or less

(Approx. 50 sheets of 75 g/m

2

weight)

1 sheet

Approx. 5 mm or less

(Approx. 40 sheets)

1 sheet

1 sheet

1 sheet

1 sheet

1 sheet

1 sheet

1 sheet

1 sheet

1 sheet

1 sheet

Page 20

2.2.3 Printable area

1-5

LR1

Part 1: Product Outline

Product

Outline

:Recommended printing area.

: Possible printing area.

3.0mm

7.0mm

3.4mm: A4/A5/B5/Postcard

6.4mm: LTR

3.4mm: A4/A5/B5/Postcard

6.3mm: LTR

22mm

A4/A5/B5/Letter/Postcard Size

3.0mm

7.0mm

6.4mm

Envelopes

22mm

22mm

22mm

(COM#10: 31.4mm)

(DL size: 10.4mm)

Figure 1-3 Printable Area

Page 21

2.3 BJ Cartridge Specifications

*1 : The number of sheets per ink cartridge

*2 : 1,500-character standard pattern.

*3 : 7.5% duty per color (using standard pattern).

*4 : Average 16.7% duty per color.

*5 : 7.5% duty per color (calculated values by ink volume used).

Part 1: Product Outline

LR1

1-6

Construction

Head

Ink colors

Ink

cartridge

Weight

Service Life

Printable

Sheets*

1

Black BJ Cartridge

BC-10

Detachable ink cartridge

128 nozzles

(Vertical array)

Bk (128 nozzles × 1)

Bk

BCI-10 Black

BCI-17 Black

(large-capacity)

26 g

(with BCI-10 installed)

Approx. 3,000 sheets*

2

Approx. 170 sheets

(BCI-10)*

2

Approx. 270 sheets

(BCI-17)*

2

Color BJ Cartridge

BC-11e

Detachable ink cartridge

136 nozzles

(Vertical array)

Bk (64 nozzles × 1)

C, M, Y (24 nozzles × 3)

Bk, C, M, Y

BCI-11 Black

BCI-11 Color

BCI-18 Black

(large-capacity)

BCI-18 Color

(large-capacity)

29 g

(with BCI-11 installed)

Approx. 2,000 sheets*

3

Color : Approx. 30 sheets

(BCI-11)*

3

Black : Approx. 25

sheets (BCI-11)*

3

Color : Approx. 50 sheets

(BCI-18)*

3

Black : Approx. 40

sheets (BCI-18)*

3

Photo BJ Cartridge

BC-12e

Detachable ink cartridge

136 nozzles

(Vertical array)

Bk (64 nozzles × 1)

C, M, Y (24 nozzles × 3)

Photo Bk, Photo C,

Photo M, Y

BCI-12 Black (Photo)

BCI-12 Color (Photo)

29 g

(with BCI-12 installed)

Approx. 200 sheets*

4

Approx. 20 sheets*

5

Page 22

2.4 Interface Specifications

2.4.1 Parallel interface

1) Interface type

IEEE 1284 parallel interface

2) Data transfer method

8-bit parallel transfer (Compatibility mode and nibble mode supported)

3) Signal level

Input

“Low” level: 0.0 V to +0.8 V

“High” level: +2.0 V to +5.0 V

Output

“Low” level: 0.0 V to +0.4 V

“High” level: +2.4 V to +5.5 V

4) Input/Output

+5 V pull-up for all signals

5) Interface cable

Cable: Twisted-pair, double-shielded cable, 2.0 m or shorter

Must conform to IEEE 1284.

Wire material: AWG (American Wire Gauge) No. 28 or higher

6) Interface connector

On printer: Amphenol 57-40360 or equivalent

On cable: Amphenol 57-30360 or equivalent

7) I/O signal and pin array

For details, see

“Part 5: CONNECTOR LOCATION AND PIN ARRAY” on page 5-13

.

2.4.2 Serial interface

1) Interface type

USB (Universal Serial Bus conforming to USB Specification Revision 1.0)

2) Data transfer method

Control transfer

Bulk transfer

3) Signal level

-Data, +Data

Difference input sensitivity: +0.2 V (Min.)

“H” level output voltage: +2.8 V to +3.6 V

“L” level output voltage: +0.0 V to +0.3 V

Vcc

“H” level input voltage: +2.0 V to +5.5 V

“L” level input voltage: +0.0 V to +0.8 V

4) Input/Output

3.3 V pull-up for +Data signal

5) Interface cable

Cable: Twisted-pair, shielded cable, 5.0 m or shorter

Must conform to USB.

Wire material: AWG (American Wire Gauge) No. 28 or higher

6) Interface connector

On printer: USB with series-B receptacle

On cable: USB with series-B plug

7) I/O signal and pin array

For details, see

“Part 5: CONNECTOR LOCATION AND PIN ARRAY” on page 5-13

.

1-7

LR1

Part 1: Product Outline

Product

Outline

Page 23

2.5 Printer Drivers

The compatibility between printer drivers and interface ports is shown below.

●●: Compatible, ▲▲: Compatible under certain conditions, ✕: Incompatible

* For USB, compatibility is assured only with personal computers preinstalled with

Windows 98.

Part 1: Product Outline

LR1

1-8

Windows 95/98

Windows NT4.0

Windows 2000

Macintosh

Printer Driver

Parallel I/F

●●

✕

✕

✕

USB I/

▲▲*

✕

✕

✕

Page 24

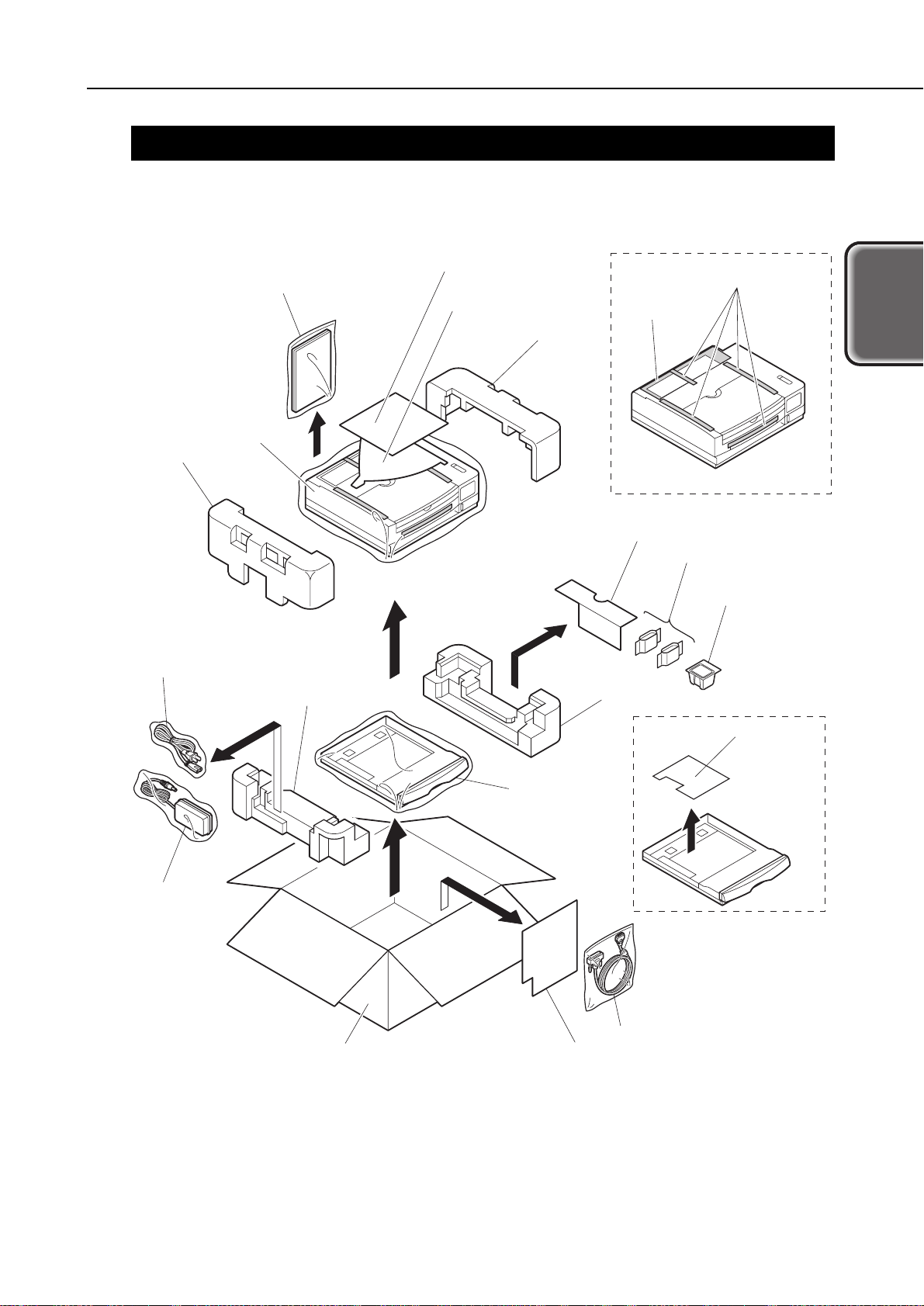

3. PACKING

After opening the package, make sure all the items below have been included.

1-9

LR1

Part 1: Product Outline

Product

Outline

Box

BJ cartridge

Packing

Packing

Packing

Packing

Ink cartridges

Packing for accessories

Packing for accessories

Power cord

Paper cassette

Cassette

protective

packing

AC adapter

Printer

Quick sheet

Interface cable

Manuals

Tape

Quick guide

Protective

sheet

Figure 1-4 Packing

Page 25

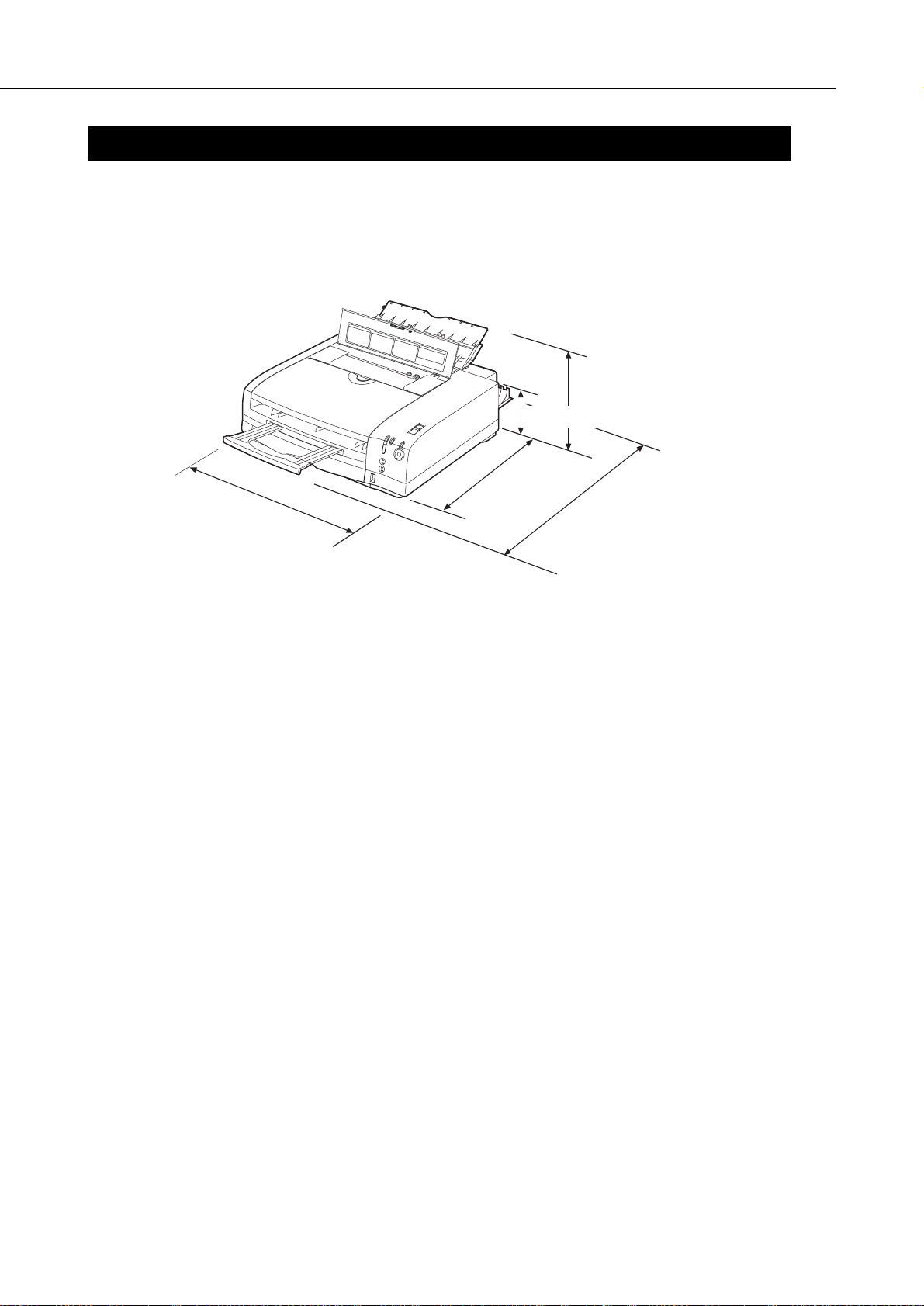

4. INSTALLATION

For installation details, see the User’s Manual.

4.1 Installation Location

For optimum use, place the printer where there is enough space. The printer’s external

dimensions are shown below.

4.2 Installation Procedure

To prevent an electric potential difference between the computer and printer, first

connect the interface cable, then connect the AC plug into an AC power outlet.

4.2.1 Connecting the centronics interface cable

1) Make sure the printer and computer’s power is off.

2) Connect the interface cable to the printer’s interface connector. Lock the

connection with the cable’s connector clips.

3) Connect the other end of the interface cable to the computer and lock the

connection.

4.2.2 Connecting the USB interface cable

1) Connect the interface cable to the printer’s interface connector. Lock the

connection with the cable’s connector clips. It is unnecessary to turn off the printer

or computer before connecting cables. The cable can be connected while their

powers are turned on.

2) Connect the other end of the interface cable to the computer and lock the

connection.

4.2.3 Connecting to a power supply

1) Connect the AC plug of the power cable to an AC power outlet and the DC plug of

the AC adapter to the printer.

2) Press the printer’s

POWER

button to turn on the printer. First, all the indicators

on the printer will light. Then the

POWER

indicator will light and the

BUSY

indicator will blink during the initialization operation. After the initialization ends,

the

BUSY

indicator will turn off. If a BJ cartridge has not been installed, the

ERROR

indicator will light and the beeper will sound three times. The carriage will also

move to the cartridge replacement position.

Part 1: Product Outline

LR1

1-10

Approx.365 mm

Approx.185.5 mm

Approx.559.5 mm

Approx.110 mm

Approx.

364 mm

Figure 1-5 Installation Space

Page 26

5. NAMES AND FUNCTION OF PARTS

The names and major functions of parts are shown below.

1-11

LR1

Part 1: Product Outline

Product

Outline

POWER

button

Press to turn on/off the power

and print the test pattern.

Operation panel

POWER

indicator (Green)

OFF: Power is off.

ON: Power is on.

INK-LOW

indicator

Lights when the remaining ink

amount is low.

Cartridge cover

Open this cover when

replacing the BJ cartridge.

• When this cover is opened,

the carriage moves to the

cartridge replacement

position.

• Also, if the cartridge is being

loaded and this cover is left

open for 10 min. or longer,

the carriage returns to the

home position.

• If this cover is opened during

printing, the printing will

stop. Closing the cover will

resume the printing.

Mode switch

If the connected STB has a

mode switching function, it

can be set with this switch.

It cannot be used when a

computer is connected.

Manual-feed tray

Load this tray during manual

paper feeding.

Paper check window

Displays the amount of

paper remaining in the

cassette.

Parallel interface connector

Connector for connection

to a computer.

Paper delivery tray

After printing, the paper is

discharged to this tray.

Paper cassette

Load with plain paper or

HR-101. (only for A4/LTR)

DOT COUNTER RESET

button

After replacing the BJ

cartridge or ink cartridge,

press this button to reset

the ink dot counter.

If the ink dot counter is

not reset, the ink-low

indicator will not be

accurate.

USB interface connector

Connector for connection

to a computer.

Rear cover

This is opened to fix paper jams

or to execute the pick-up roller

cleaning.

RESUME/

CLEAN

LOW INK

BUSY

COLOR

BLACK

POWER

Paper delivery cover

Prevents dust, etc., from

adhering to the discharged

paper.

Power connector

Connector for connection to a

AC adapter.

BUSY

indicator (Green)

OFF: Standby

ON: Printing in progress

or printing data

being received.

Blinks:During

initialization or

cleaning.

Cover is open.

ERROR

indicator (Orange)

OFF: Normal status

Lit or blinking:

An error has occurred and

printing is not possible.

RESUME

button

This cancels user-resolvable

errors. Also, it is used to

execute cleaning, and pick-up

roller cleaning.

Extension tray

Figure 1-6 Parts Names and Major Functions

Page 27

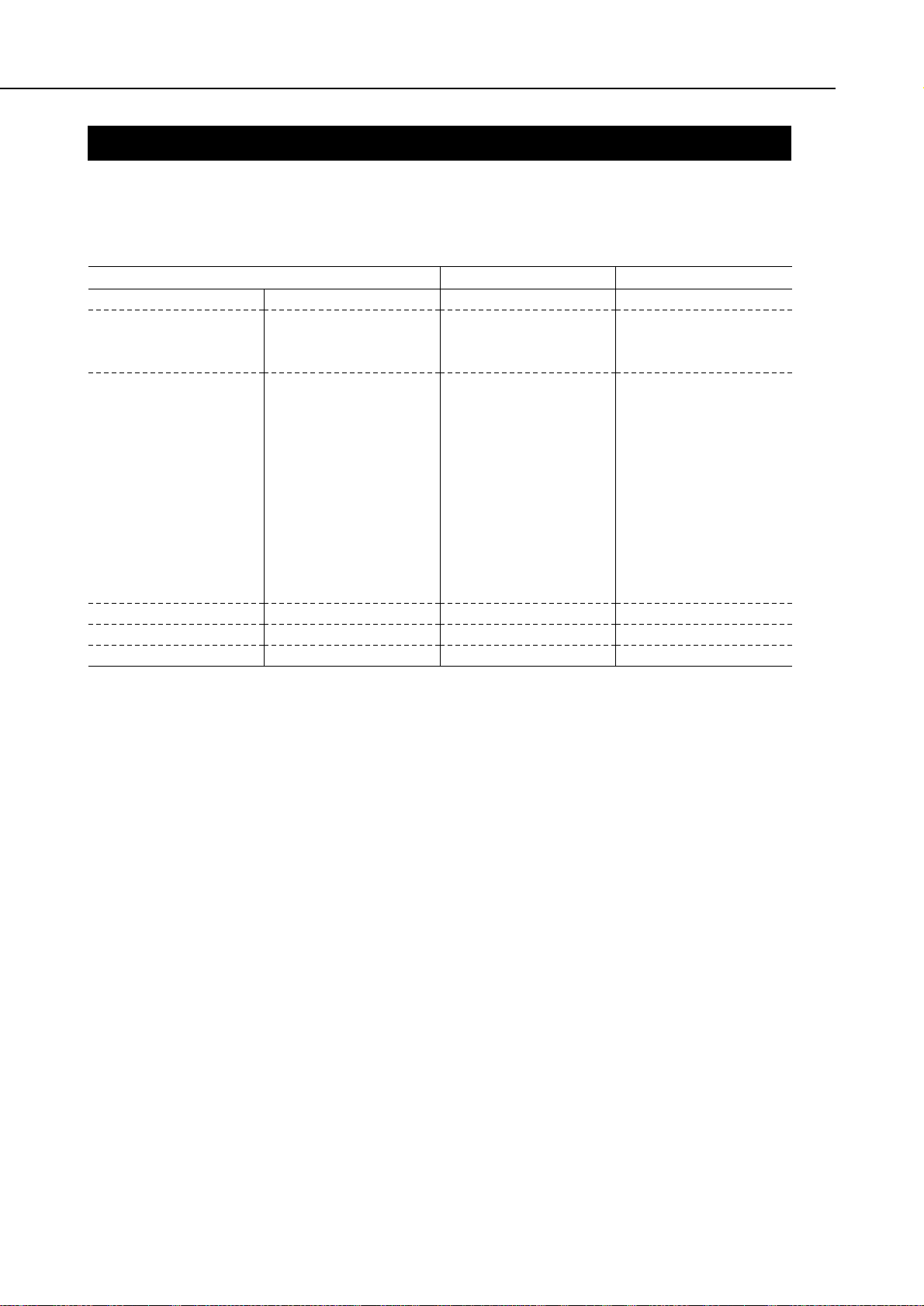

6. PARTS CODE LIST

A list of printer parts, consumables, and optional equipment are listed below.

* Items included with LR1: BC-11e, BCI-18 Bk, BCI-18 Color, AD 360U, power cable,

parallel interface cable.

Part 1: Product Outline

LR1

1-12

Table 1-1 PARTS CODE

Item

Printer

BJ cartridge

Ink cartridge

Cartridge storage box

Universal Adapter

Power cable

Black

Color

Photo

Black

Black (large-capacity)

Black

Color

Black (large-capacity)

Color (large-capacity)

Photo black

Photo color

-

-

-

Designation

LR1*

BC-10

BC-11e

BC-12e Photo

BCI-10Bk

BCI-17Bk

(large-capacity)

BCI-11Bk

BCI-11Color

BCI-18Bk

(large-capacity)

BCI-18Color

(large-capacity)

BCI-12Bk

BCI-12Color

SB-11

AD360U

-

Product Code

Q30-3220

F45-0631

F45-1321

F45-1751

F47-0751

F47-2721

F47-0761

F47-0771

F47-2731

F47-2741

F47-2751

F47-2761

Q70-4120

Q70-3839

Q70-3980

Page 28

Part 2

MAINTENANCE

Page

2 - 1 1. PERIODIC REPLACEMENT PARTS AND MAINTENANCE

2 - 1 1.1 Periodic Replacement Parts

2 - 1 1.2 Consumables

2 - 1 1.3 Periodic Maintenance

2 - 2 2. DISASSEMBLY AND REASSEMBLY

2 - 2 2.1 Tools

2 - 3 2.2 Cautions for Disassembly and Reassembly

2 - 6 2.3 Disassembly and Reassembly

2 - 9 2.4 Applying Grease

2 - 9 2.5 Adjustments and Settings After Disassembly and Reassembly

2 -10 2.6. Spur Cleaner

2 -11 3. OPERATION CHECK AFTER DISASSEMBLY AND ASSEMBLY

2 -11 3.1 Check Procedure

Page 29

Page 30

1.

PERIODIC REPLACEMENT PARTS AND MAINTENANCE

1.1 Periodic Replacement Parts

1.2 Consumables

1.3 Periodic Maintenance

2-1

LR1

Part 2: Maintenance

Maintenance

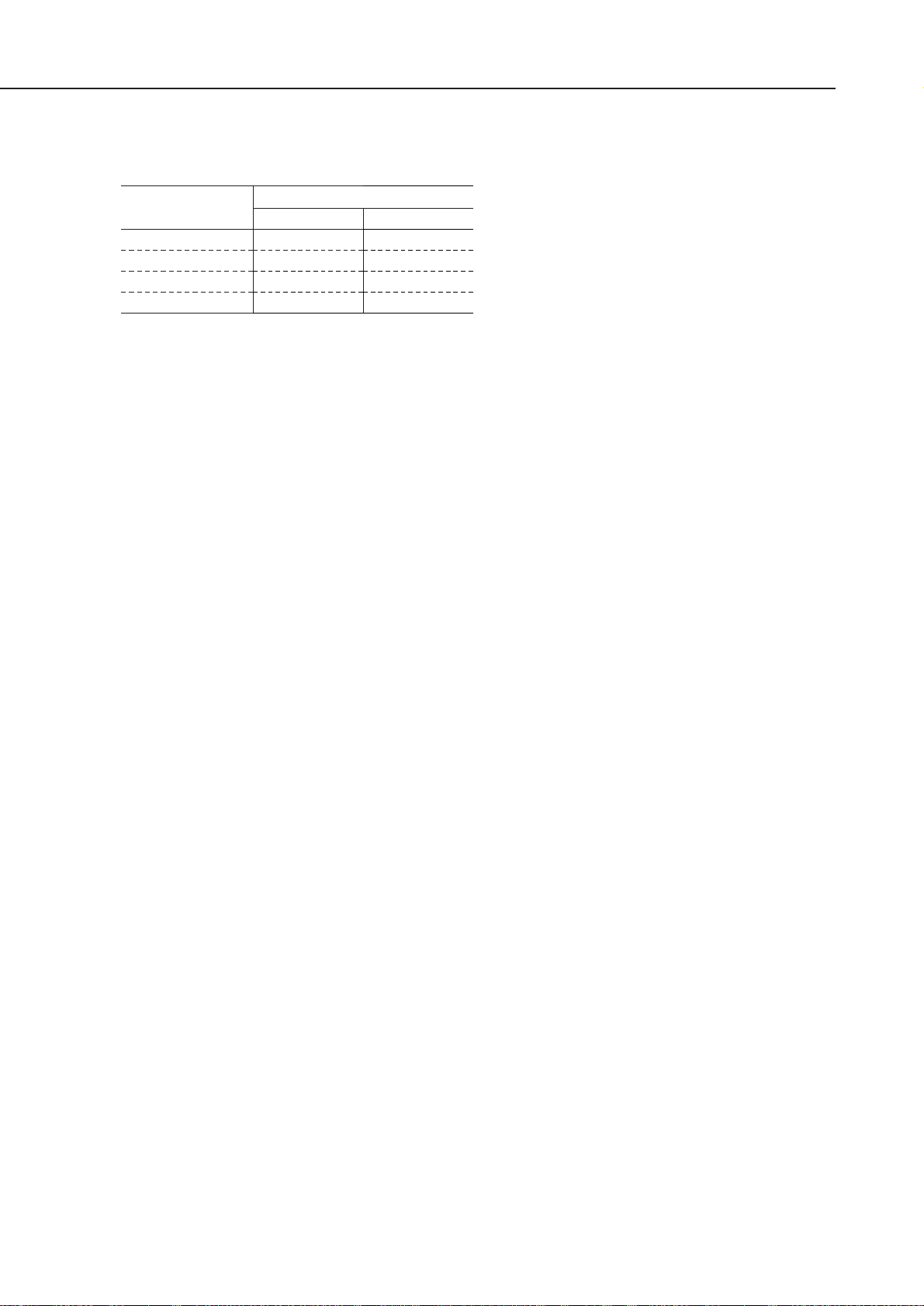

Level

User

Service

personnel

Consumables

None

BJ Cartridge

Ink Cartridge

LargeCapacity

Ink Cartridge

For Black BJ

Cartridge

BC-10

BCI-10

BCI-17

For Color BJ

Cartridge

BC-11e

Bk: BCI-11 Bk

Color: BCI-11 Color

Bk: BCI-18 Bk

Color: BCI-18 Color

For Photo BJ

Cartridge

BC-12e

Bk: BCI-12 Bk

Color: BCI-12 Color

None

Level

User

Service personnel

Replacement Parts

None

None

Level

User

Service personnel

Periodic Inspections

None

None

Page 31

2. DISASSEMBLY AND REASSEMBLY

2.1 Tools

Tools required for disassembly and reassembly are listed below.

Part 2: Maintenance

LR1

2-2

Ordinary Tools

Phillips screwdriver

Blade screwdriver

Needle-nosed pliers

Tweezers

Flat brush

Remarks

For the removal and installation of screws.

For the removal of plastic parts.

For the removal and installation of springs.

For the disconnection and connection of flexible cables, etc.

For applying grease.

Special Tools (Part No.)

Grease MOLYKOTE PG-641

(CK-0562-000)

Spur Cleaner (QY9-0055-000)

Remarks

To be applied on the specified parts (see

page 2-9

).

For cleaning the spurs (see

page 2-10

).

Page 32

2.2 Cautions for Disassembly and Reassembly

2.2.1 Cautions for ink stains (ink path/ink mist)

During servicing, be careful not to touch the ink path and get ink stains on the

printer, work table, and your hands and clothing.

The ink path includes the BJ cartridge’s ink cartridge supply inlet, the BJ cartridge’s

ink filter, the ink nozzles and maintenance jet receptacle, head cap, wiper, and waste

ink absorber.

Although the ink does not contain anything harmful to humans, it does

contain organic solvents.

Black ink: Glycerin 56-81-5, ethylene glycol 107-21-1, isopropyl alcohol

107-21-1

Color ink: Isopropyl alcohol 67-63-0

Photo ink: Glycerin 56-81-5, ethylene glycol 107-21-1, isopropyl alcohol

67-63-0

Be careful not to get the ink in your mouth or eyes.

If ink gets into your eyes, wash with lots of water and see a doctor. If you

consume a large amount of ink orally, see a doctor promptly.

Since the ink contains dyes, it will permanently stain clothing and other

materials.

2-3

LR1

Part 2: Maintenance

Maintenance

Waste ink absorber

Pump

Cap

Wiper

Ink path

Maintenance jet receptacle

Figure 2-1 Ink Path

Page 33

The BJ cartridge ejects ink onto the paper to print. After a long period of time or

heavy-duty use, ink mist created by loose ink droplets and ink bouncing off by the

paper will soil the platen, inside the cartridge cover, and around the purge section.

These soiled parts can soil the paper and your hands and clothing. To prevent this,

use a soft, damp cloth to wipe these parts clean.

When cleaning the purge section, be careful not to touch the cap or wiper

section.

2.2.2 Damage by static electricity

Due to the rubbing of clothing, static electricity can build up within the human body.

Static electricity can damage electrical components or alter the electrical

characteristics of components.

Never touch the contacts on the carriage and the BJ cartridge.

Handle the control board, sensor board or operation panel board with care not to

break them by static electricity.

Part 2: Maintenance

LR1

2-4

Figure 2-2 Parts Exposed to Ink Mist

Platen section

Purge section

Purge section

Check point !

Page 34

2.2.3 Preparation for transportation

While moving or transporting the printer, either leave the BJ cartridge in the printer

or keep it in the storage box. This is to prevent the ink from leaking and the BJ

cartridge’s ink nozzles from drying up.

(1) Carrying the printer

Before carrying the printer while the BJ cartridge is still installed, follow the

procedure below.

1) Turn off the printer by pressing the

POWER

button.

2) Check that the BJ cartridge is at the capping position (right end of printer). If it is

not at the capping position, turn the printer on and off by the

POWER

button so that

the carriage is moved to the capping position.

3) Disconnect the interface cable.

4) Disconnect the AC adapter’s DC plug from the printer.

Disconnect the AC adapter’s AC plug from the power outlet.

If you turn off the power by disconnecting the AC adapter or if you carry or

transport the BJ cartridge without putting it in the storage box, ink may

leak and the nozzles may dry up.

(2) Transporting the printer

Before transporting the printer, follow the procedure below.

1) Follow the procedure above for

“(1) Carrying the printer”

to turn off the printer and

disconnect the interface cable and AC adapter.

2) Pack the printer and AC adapter in their original packaging.

If you do not have the original packaging, use enough shock-absorbing material to

pack the printer.

2-5

LR1

Part 2: Maintenance

Maintenance

Page 35

2.3 Disassembly and Reassembly

Cautions for disassembling and reassembling the printer are stated below.

As for the disassembly procedure, refer to the

Parts Catalog

. The illustrations in the

Parts Catalog

are numbered according to the order of disassembly.

2.3.1 Removing plastic parts

The printer has many plastic parts. When disassembling the printer, be careful not to

break or bend the plastic hooks. For details on disassembly and reassembly, refer to

the

Parts Catalog

.

Some plastic parts contain glass fiber to improve the rigidity for better

precision. Since these parts are less flexible, their plastic hooks are

especially easy to break. During disassembly, do not exert excessive force

on plastic parts with a screwdriver or other instrument.

2.3.2 Removing and installing tap screws

The printer uses tap screws to fasten the upper and bottom cases, the control board

and bottom case, the pick-up unit and bottom case unit, and the chassis platen unit

and bottom case. The removed tap screws will have residue from the mold in which

the internal thread was made. Since the residue may crush the screw threads, clean

off the residue from the tap screws before re-installing or use new tap screws.

2.3.3 Cable positions

Lay the cables connecting the motors, sensors, and control board according to the

stipulated position.

For positioning the cables, refer to the

Parts Catalog

.

2.3.4 Deformation of spur tips

Be careful not to deform the spur tips.

The spur contacts the paper after the printing.

If the spur’s tips are deformed, the contact area with the paper will become larger,

increasing the amount of ink on the paper transferring onto the spur tips which will

soil paper with dotted lines.

Part 2: Maintenance

LR1

2-6

Spurs section

Figure 2-3 Spurs

Page 36

2.3.5 Feed gear cautions

When disassembling or reassembling the printer, do not touch the gears of the at

paper feeding section. Note that even a slight scratch on the gears will cause irregular

paper feeding during high-quality printing.

2.3.6 Installing and removing the upper case unit

Before installing or removing the upper case unit, the paper delivery tray must be

removed.

2-7

LR1

Part 2: Maintenance

Maintenance

Paper feed

gear

Paper feed

double gear

Figure 2-4 Feed Gear Cautions

1

2

Paper delivery tray

Upper case unit

Figure 2-5 Installing and Removing the Upper Case Unit

Page 37

2.3.7 Positioning the MODE switch

The position of the MODE switch on the upper cover must match the switch on the

control board. Otherwise, the cover cannot be attached properly.

2.3.8 Installing and removing the home position sensor

The home position sensor cannot be installed or removed when the carriage is at the

home position. Move the carriage away from the home position before installing or

removing the home position sensor.

Part 2: Maintenance

LR1

2-8

Match the position of the Mode switch

to the position of the control board.

Mode switch

The switch on the control board

Mode switch in

the A position

Mode switch in

the B position

Mode switch

Switch on the control board

Figure 2-6 MODE Switch Positioning

Home position sensor

1

2

Figure 2-7 Installing and Removing the Home Position Sensor

Page 38

2.4 Applying Grease

The places where grease is applied are shown below.

Only one type of grease is to be used: PG-641 (CK-0562).

Use a flat brush to apply grease thinly and evenly.

To disassemble and assemble the printer, refer to the

Parts Catalog

.

When applying grease, be careful not to get any grease on the wiper and

cap.

2.5 Adjustments and Settings After Disassembly and Reassembly

2.5.1 Adjustments

(1) User Level

None.

(2) Service personnel Level

* To clear and set the EEPROM, refer to

“Part 3: 2.1 Service Mode Operations” on page 3-10

.

2-9

LR1

Part 2: Maintenance

Maintenance

Carriage shaft

Carriage guide

Figure 2-8 Applying Grease

Timing

After control board replacement

After printer base unit replacement

Adjustment

EEPROM setting*

EEPROM clear*

Time Required

2 min.

2 min.

Tools Required

None

None

Page 39

2.6. Spur Cleaner

If the tips of spurs become dirty with ink, spur marks can be left on the print images.

In such case, clean the spurs by using the spur cleaner (QY9-0055-000). The spur

cleaner can be used until it loses its intended effect.

2.6.1 Usage

1) Moisten the fabric part of the spur cleaner with approx. 5 cc of water.

Moisten the fabric with water, as shown below, so that the fabric absorbs enough

water from end to end, especially the areas that will contact the spurs.

Be careful not to moisten the fabric with too much water. In case too much water

is used, there is a possibility that water will be squeezed from the spur cleaner

when passing through the paper feed roller, spread inside the printer, and cause

failure.

2) Turn the power on.

3) Set the spur cleaner.

Open the manual feed tray and set the spur cleaner with the fabric-affixed part of

the cleaner face-up and to the top.

The spur cleaner is fed and stops at the print start position.

4) Feed the spur cleaner.

Press the

RESUME

button, and release it after the beeper sounds once. The spur

cleaner is delivered.

5) Repeat procedures 3) and 4) approx. 5 times in case of heavy soiling.

6) Remove the moisture remaining in the paper feeding path.

With a single sheet of plain paper set in the manual feed tray, repeat procedure 4)

several times until the water is completely removed from the paper path.

Part 2: Maintenance

LR1

2-10

Fabric (white-colored)

Spur cleaner

Part moistened with water

Be careful that the water

is absorbed by the fabric

from end to end.

Transparent film

Fabric (white-colored)

Spur cleaner

Figure 2-9 Spur Cleaner

Figure 2-10 Set the Spur Cleaner

Page 40

3. OPERATION CHECK AFTER DISASSEMBLY AND ASSEMBLY

3.1 Check Procedure

After disassembly and reassembly, follow the procedure below to check the printer’s

operation.

1) After repairs

Check that the printer can print out the EEPROM data properly. For the procedure,

see

“Part 3: 2.1 Service Mode Operations” on page 3-10

.

2) After replacing the control board and printer base unit

After replacing the control board and printer base unit, check the following:

After control board replacement The ROM version in the list of EEPROM data

must be the correct one.

In the list of EEPROM data, the total waste ink

amount must be about the same percentage as

in the waste ink absorber.

The nozzle check pattern must be able to be

printed from the printer driver.

After printer base unit replacement In the list of EEPROM data, the total waste ink

amount must be cleared to 0%.

*1: To print out the list of EEPROM settings, see

“Part 3: 2.1 Service Mode Operations” on

page 3-10

.

*2: To set or clear the total waste ink amount, see

“Part 3: 2.1 Service Mode Operations”

on page 3-10

.

2-11

LR1

Part 2: Maintenance

Maintenance

Page 41

Part 2: Maintenance

LR1

2-12

This page intentionally left blank

Page 42

Part 3

OPERATION

Page

3 - 1 1. PRINTER OPERATION FUNCTIONS

3 - 1 1.1 Status Indications

3 - 6 1.2 Operation With a Computer

3 - 7 1.3 Operation From the Printer Itself

3 -11 2. SERVICE-RELATED FUNCTION

3 -11 2.1 Service Mode Operations

3 -12 2.2 Printing the EEPROM Data

3 -13 2.3 Setting the Waste Ink Amount

Page 43

Page 44

1. PRINTER OPERATION FUNCTIONS

The printer’s operation functions include status indications and printer control via a

personal computer or via the printer’s operation panel and operation from the printer

itself.

1.1 Status Indications

The printer has indicators to indicate the printer status.

The printer indicates an error with a green

POWER

indicator, a green

BUSY

indicator,

an orange

ERROR

indicator, and a certain number of beeper sounds.

The remaining ink amount is indicated by the

INK-LOW

indicator.

3-1

LR1

Part 3: Operation

Operation

RESUME/

CLEAN

LOW INK

BUSY

COLOR

BLACK

POWER

INK-LOW

indicator

ERROR

indicator

RESUME

button

POWER

button

POWER

indicator

BUSY

indicator

Figure 3-1 Operation Panel

Page 45

1.1.1 Status indicators

1) Normal Status

Refer to the following

“Table 3-1 STATUS INDICATORS”

.

2) Error Status

2-1) Error display for user-recoverable errors

When a user-resolvable error occurs, the

ERROR

indicator either turns on or blinks

and the beeper sounds a certain number of times. By closing the cartridge cover

and pressing the

RESUME

button, the beeper sounds a certain number of times to

indicate which error has occurred and the error is canceled.

2-2) Error display for user-unrecoverable errors

When a user-unrecoverable error occurs, the

POWER

indicator,

BUSY

indicator, or

ERROR

indicator blinks and the beeper sounds a certain number of times to indicate

which error has occurred.

* The

BUSY

indicator turns on when there is receiving data.

Part 3: Operation

LR1

3-2

Table 3-1 STATUS INDICATORS

Indicator State

Power

(Green)

On

On

On

Off

Busy

(Green)

Off

Blinking

On

Off

Status

During power on.

During initialization and busy, cartridge

replacement, cleaning operation, and cartridge

cover open.

During printing.

During power on and standby.

Error

(Orange)

Off

Off

Off

Off

Status

User-recoverable errors

Paper-feed error

Paper jam error

Cartridge not-loaded error

Cartridge mismatch error

Failed manual feed warning

Cartridge replacement

auto-completion warning

Cartridge overheating warning

Waste ink full warning

User-unrecoverable errors

ROM error

RAM error

No-cartridge error

Home position error

Waste ink full error

Internal temperature sensor error

Automatic correction error

Head overheating error

EEPROM error

Power

On

On

On

On

On

On

On

On

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Busy

Off

Off

Off

Off

Off

Off

Off

Off*

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Error

On

On

On

On

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Beeper Sounds

1

2

3

4

1

3

4

5

1

2

3

4

5

6

7

8

11

Page

Page 4-11

Page 4-11

Page 4-13

Page 4-13

Page 4-10

Page 4-15

Page 4-8

Page 4-5

Page 4-5

Page 4-5

Page 4-13

Page 4-6

Page 4-5

Page 4-5

Page 4-6

Page 4-8

Page 4-5

Page 46

1.1.2 Error description

User-recoverable errors

1) Paper-feed error

The paper is not fed during the paper-feed operation.

2) Paper jam error

The paper cannot be delivered even when the paper delivery operation is executed for

584.2 mm (23 inches).

3) Cartridge not-loaded error

The cartridge is not loaded in the printer.

4) Cartridge mismatch error

The data sent by the personal computer does not match the installed cartridge.

Open the cartridge cover and install the correct cartridge. The error will then be

canceled. Pressing the

POWER

button to turn the printer on/off will also cancel the

error.

5) Failed manual feed warning

The paper cannot be fed manually with the manual feed tray.

6) Cartridge replacement auto-completion warning

The cartridge replacement mode has been disabled by the printer. Closing the

cartridge cover cancels the error.

7) Cartridge overheating warning

The cartridge temperature is high and the cartridge cover is also open.

8) Waste ink full warning

The total waste ink amount recorded in the EEPROM is close to the full capacity

(99% or higher).

User-unrecoverable errors

9) ROM error

The ROM check failed during initialization.

10) RAM error

The RAM check failed during initialization.

11) No-cartridge error

The printer is unable to detect the BJ cartridge at any position except at the

cartridge replacement position.

12) Home position error

The home position sensor is not working (line disconnected).

The carriage’s home position cannot be detected.

13) Waste ink full error

The total waste ink amount recorded in the EEPROM exceeds the full capacity

(100%).

14) Internal temperature sensor error

The temperature sensor (TH1) on the control board has a malfunction (line

disconnected).

15) Automatic correction error

The home position cannot be detected during printing position correction.

16) Head overheating error

The BJ cartridge temperature is abnormal.

17) EEPROM error

An error occurred during the writing to EEPROM.

3-3

LR1

Part 3: Operation

Operation

Page 47

1.1.3 Ink-low indicator

The printer has an

INK-LOW

indicator to display the remaining ink amount.

No lamps lit: Enough ink remains.

One lamp lit: The large-capacity ink cartridges have less than half (equivalent

to the amount in the standard ink cartridge) the full amount of

ink.

The standard-capacity ink cartridges have little ink remaining.

Two lamps lit: The large-capacity ink cartridge has little ink remaining.

After replacing the ink cartridge, reset the dot counter. If the dot counter

is not reset, the remaining ink amount detected will not be correct. To

reset the dot counter, see

“1.3.3 Resetting the dot counter” on page 3-8

.

Part 3: Operation

LR1

3-4

The BCI-18 Color still has ink.

The BCI-18 Color's remaining ink amount

is half or less.

The BCI-11 Color's/BCI-12 Color has little

ink remaining.

BCI-18 Color has little ink remaining.

The BCI-17 Black/BCI-18 Black's

remaining ink amount is less than half.

The BCI-10 Black/BCI-12 Black has little

ink remaining.

BCI-18 Black has little ink remaining.

COLOR

: off

: lit (Green)

BLACK

COLOR

BLACK

COLOR

BLACK

The BCI-17 Black/BCI-18 Black still has

ink.

Page 48

1.1.4 BJ status monitor (Used only when connected to a computer)

The BJ status monitor indicates the printer’s status and printer progress. It can also

cancel the printing.

The BJ status monitor can be used only when it is connected to a personal computer.

It cannot be used when it is connected to a set top box.

(1) BJ status monitor features

1) Displays the printer’s status and printing progress in real-time with diagrams and

messages.

2) When an error occurs, the error type and solutions are displayed.

3) The type of BJ cartridge installed and ink-low warning are displayed as text and

icons.

4) The current printing operation can be canceled.

(2) BJ status monitor display items

1) Printer name

2) Document name

3) Status: When an error occurs, the error code and solutions are displayed.

4) Start date and time

5) Progress

6) Printed page count

7) Printing canceled

8) Installed cartridge: Cartridge type indicated by an icon.

9) Ink-low warning: The remaining amount of ink for each ink cartridge is displayed

as an icon.

3-5

LR1

Part 3: Operation

Operation

Figure 3-2 BJ Status Monitor (Sample)

Page 49

1.2 Operation With a Computer

When the printer is connected to a personal computer, the printer’s functions can be

set with the exclusive printer driver. The exclusive printer driver cannot be used when

the printer is connected to a set top box.

1.2.1 Function settings with the printer driver

The following utility items can be set or executed with the exclusive printer driver.

1) Cleaning

2) Head refreshing

3) Pick-up roller cleaning

To clean the pick-up roller, feed one cleaning sheet in the cassette to the rear of the

printer. This cleans the paper bits adhering to the pick-up roller.

To clean the pick-up roller, open the rear cover. The cleaning sheet will be delivered

from the rear of the printer.

4) Printing the demo pattern

5) Printing the nozzle check pattern

6) Printer power off

7) Automatic power on/off function setting

8) Status monitor startup

Part 3: Operation

LR1

3-6

Figure 3-3 Printer Driver Utilities (Sample)

Page 50

1.3 Operation From the Printer Itself

The printer has a

POWER

button,

RESUME

button, MODE switch, and

DOT COUNTER

RESET

button.

These printer controls enable “offline operation” while the printer is not connected to a

computer or STB.

1.3.1 Cleaning and head refreshing

While the power is on, hold down the

RESUME

button and release after the beeper

sounds the stipulated number of times. The cleaning will then start. Cleaning can

also be executed from the printer driver’s utility while the printer is connected to a

computer.

3-7

LR1

Part 3: Operation

Operation

MODE

switch

POWER

button

DOT COUNTER RESET

buttons

RESUME

button

Figure 3-4 Printer Buttons

Operation

Cleaning

Head refreshing

Beeper Sounds

2 times

3 times

Page 51

1.3.2 Printing the nozzle check pattern

With the printer off, hold down the

POWER

button and release after the beeper

sounds four times. The nozzle check pattern will then start printing. If any printing

defects show up in this printout, excute the BJ cartridge cleaning. If the printing

defect still persists after cleaning the BJ cartridge or refreshing the head five times or

more, replace the BJ cartridge.

If possible, print out the nozzle check pattern with paper fed from the cassette.

If you must feed the paper manually to print out the nozzle check pattern, follow the

procedure below:

1) Without setting any paper in the manual-feed slot, and the paper cassette try to

print out the nozzle check pattern. A paper-feed error will occur.

2) Insert one sheet of paper into the manual-feed slot, then press the

RESUME

button.

The paper-feed error will be canceled and the nozzle check pattern will be printed.

1.3.3 Resetting the dot counter

After replacing the ink cartridge or BJ cartridge with a new cartridge, follow the

procedure below to reset the dot counter.

1) Open the cartridge cover. The cartridge will move to the center.

2) Check that the ink cartridge whose dot counter is to be reset is installed. (The dot

counter reset will be enabled only for the cartridge installed.)

3) When resetting the dot counter for the black ink cartridge, press the

“BLACK”

COUNTER RESET

button. To reset the dot counter for a color ink cartridge, hold

down the

“COLOR”

button and release when the beeper sounds.

After replacing the ink cartridge or BJ cartridge to a new one, be sure to

reset the dot counter. If the dot counter is reset without the ink cartridge

being replaced or if the dot counter is not reset after the cartridge is

replaced, the remaining ink amount detected will not be correct.

Part 3: Operation

LR1

3-8

Figure 3-5 Printing the Nozzle Check Pattern (Sample BC-11e)

24

24

24

64

24

24

24

24

Printed with the first nozzle.

Printed with the 136th nozzle.

Large and small dot printing

Yellow 24 nozzles

Magenta 24 nozzles

Black 64 nozzles

Cyan 24 nozzles

Printed with the 136th nozzle.

Small dot printing

Printed with the first nozzle.

Page 52

1.3.4 Cleaning the pick-up roller

When dust and paper bits adhere to the pick-up roller, the paper feeding becomes less

efficient. In such a case, use a cleaning sheet to clean the pick-up roller as described

below.

Use the exclusive cleaning sheet included in the pack of high-resolution paper.

1) Put the cleaning sheet in the paper cassette.

Peel off the cleaning sheet’s backing. Lay the sheet with the sticky side facing up.

Set the sticky side toward the claw.

2) Open the rear cover.

3) Hold down the

RESUME

button and release it when the beeper sounds once.

The cleaning sheet will be fed into the printer and discharged out the back of the

printer. The error indicator will light.

4) Take out the cleaning sheet and close the rear cover. Press the

RESUME

button.

You can also clean the pick-up roller with the printer driver if the printer

is connected to a personal computer. See

1.2.1 Function settings with the

printer driver on page 3-6

.

1.3.5 Auto power on/off setting

The printer has an auto power on/off feature.

Upon factory shipment, the printer is set as follows:

Auto power on: Enabled

Auto power off: Enabled, 30 min.

To disable the auto power on/off, hold down the

POWER

button and release after the

beeper sounds the stipulated number of times.

To enable the auto power on/off again, set the function back to the factory setting.

With the power off, hold down the

POWER

button and release after the beeper sounds

seven times. The function will then be returned to the factory shipment setting. Note

that this will also return all other items in the function setting table to the factory

shipment setting.

The auto power on/off setting can also be changed with the printer driver’s utility

while the printer is connected to a personal computer.

3-9

LR1

Part 3: Operation

Operation

Setting

Auto power on: Disabled

Auto power off: Disabled

Beeper Sounds

12 times

13 times

Page 53

The function settings upon factory shipment are shown below.

1.3.6 Mode switch

If the STB connected to the printer has a mode selection switch, you can choose the

mode by the

MODE

switch. The

MODE

switch is not used when the printer is

connected to a computer.

Part 3: Operation

LR1

3-10

Paper Selection

LTR

Smoothing

Disable

Font

Roman

Internal

Character Set

USA

Test Scale

Disable

Reduction

1/1

Font Lock

Disable

Character Set

Italic

Top Margin

8.5mm

Auto Power On

Enable

Input/Download

Buffer

64/23KB

Code Page

PC437

Print Mode

HQ

Auto Power Off

Enable (30 min.)

Automatic Line

Feed

CR=CR

Low Ink Alert

Enable

Page 54

2. SERVICE-RELATED FUNCTION

The printer has a service mode to access service settings and to execute a test printout.

2.1 Service Mode Operations

1) Disconnect the cable of AC adapter from the printer power connector. Open the

cartridge cover.

2) While holding down the

COLOR DOT COUNTER RESET

button and the

BLACK DOT

COUNTER RESET

button and insert the AC adapter’s DC plug into the printer.

3) While holding down the

COLOR DOT COUNTER RESET

button and the

BLACK DOT

COUNTER RESET

button, press the

POWER

button and release the buttons after the

beeper sounds once.

4) Press the

COLOR DOT COUNTER RESET

button the number of times indicated below

to select the function to be executed.

Each time you press the button, the beeper will sound and the indicator will change

to orange or green.

5) After making the selection, press the

BLACK DOT COUNTER RESET

button. The

beeper sounds once and the functions will be executed.

The service mode can be set only when the cartridge cover is open. The

cover sensor detects whether the cartridge cover is open or not.

When the cover sensor lever is up, the cover is detected as closed.

When the cover sensor lever is down, the cover is detected as open.

When you take off the upper case or cartridge cover, the cover sensor lever

will be up. In that case, do step 2 above while pushing down the cover

sensor lever.

3-11

LR1

Part 3: Operation

Operation

Times

7

13

14

15

16

Indicator

Busy (Green)

Busy (Green)

Error (Orange)

Busy (Green)

Error (Orange)

Function

EEPROM reset

EEPROM data printout

Waste ink absorber capacity setting: 25%

Waste ink absorber capacity setting: 50%

Waste ink absorber capacity setting: 75%

Page 55

2.2 Printing the EEPROM Data

The EEPROM records various data such as the settings, total page count of each BJ

cartridge, total waste ink absorption amount, and the dot counter for each ink

cartridge. The data in EEPROM serves as a general guide to how much the printer has

been used.

Part 3: Operation

LR1

3-12

ROM version

Ink dot count

B461---------------Black

B462/B467 -------Color

B467us------------Photo

Total page count

(monochrome/color)

Total waste ink

amount count (ng/%)

Figure 3-6 EEPROM Data Printout (sample)

Page 56

2.3 Setting the Waste Ink Amount

The printer detects “waste ink full” based on the total waste ink absorption amount

recorded in the EEPROM. Thus, after you replace the waste ink absorber, you must

also reset the total waste ink absorption amount.

Also, after replacing the control board, you must reset the new control board’s

EEPROM and set the waste ink absorption amount for the waste ink absorber installed

in the printer base unit.

1) After replacing the control board

Before replacing the control board, visually check the waste ink absorption amount in

the waste ink absorber in the printer base unit.

After replacing the control board, set the waste ink absorption amount you found out

visually to the EEPROM.

2) After replacing the printer base unit (waste ink absorber)

After replacing the printer base unit, set 0% as the waste ink absorption amount to

the EEPROM (EEPROM reset).

The EEPROM contains various data such as the settings, total page count for each BJ

cartridge, total waste ink absorption amount, and the dot counter for each ink

cartridge. When the EEPROM is reset, all those data will be reset as well.

3-13

LR1

Part 3: Operation

Operation

0 % 25 %

50 %

75 %

100 %

Waste ink full error

Waste ink

Purge unit side

Ink absorber

Printer Base Unit

Figure 3-7 Waste Ink Absorber (50% of capacity)

Page 57

Part 3: Operation

LR1

3-14

This page intentionally left blank

Page 58

Part 4

TROUBLESHOOTING

Page

Part 4: TROUBLESHOOTING

4 - 1 1. TROUBLESHOOTING ACCORDING TO ERROR DISPLAY

4 - 1 1.1 Initial Flow Chart

4 - 4 1.2 Error List

4 - 5 1.3 Troubleshooting Errors

4 -16 2. TROUBLESHOOTING BY SYMPTOMS

4 -16 2.1 Troubleshooting By Symptoms

Page 59

Page 60

1.

TROUBLESHOOTING ACCORDING TO ERROR DISPLAY

1.1 Initial Flow Chart

4-1

LR1

Part 4: TROUBLESHOOTING

T roubleshooting

Insert the DC jack of the

AC adapter.

• RAM check

• ROM check

Yes

No

END

START

When DC power is supplied

Specity that the printer

enters the service mode

at power on and write it

into the EEPROM.

No

Yes

When the printer is turn

on, the following is

displayed:

• RAM error

• ROM error

: Lights

: Blinking

: OFF

LED Display

Press the

POWER

button

to turn on the printer.

No

Yes

RAM error: 2 beeps

ROM error: 1 beep

START

When the power turns on with the

POWER

button

POWER

indicator

turns on.

• RAM check

• ROM check

• RAM error

• ROM error

BUSY

Indicator start

blinking.

Correct?

Service mode?

Correct?

POWERBUSYERROR

Next

page

Page 61

Part 4: TROUBLESHOOTING

LR1

4-2

No

Yes

Beeper : 6 times

Internal temperature

sensor error

Internal temperature

sensor check.

No

Yes

Execute selected test

printing after

initialization ends.

No

Yes

If 99 to 99.9%:

Waste-ink full warning

If 100% or more:

Waste-ink full error

Waste ink amount check.

No

Yes

Home position error

Initialization of paper feed

motor.

Beeper : 4 times

Carriage moves to home

position.

Cap open

Printing position

correction setting.

Printing position

correction detection.

Yes

No

Automatic correction

error

Beeper: 7 times

Warning

Beeper : 5 times

Correct?

Test printing

selected?

Correct?

Home position

detectable?

Detectable?

Next

page

Previous

page

POWERBUSYERROR

POWERBUSYERROR

POWERBUSYERROR

POWERBUSYERROR

ERROR

Beeper : 5 times

POWERBUSYERROR

Page 62

4-3

LR1

Part 4: TROUBLESHOOTING

T roubleshooting

No

Yes

Beeper : 2 times

No

Yes

Paper jam error

Move carriage to cartridge

replacement position.

Head temperature

adjustment signal setting

Paper delivery operation

Internal temperature

detection

Check printer’s status to

execute cleaning

BUSY

Indicator turns off

Beeper : 3 times

END

Yes

No

Cleaning executed to

match the status

Yes

No

Detect paper by PE

sensor and paper

delivery sensor.

Maintenance jet.

BJ cartridge

installed?

Is cleaning

necessary?

Previous

page

Detected?

Paper delivered?

POWERBUSYERROR

POWERBUSYERROR

Initialize ASF Motor

Page 63

1.2 Error List

Error Status

1) Error display for user-recoverable errors

When a user-resolvable error occurs, the

ERROR

indicator either turns on or blinks

and the beeper sounds a certain number of times. By closing the cartridge cover

and pressing the

RESUME

button, the beeper sounds a certain number of times to

indicate which error has occurred and the error is canceled.

2) Error display for user-unrecoverable errors

When a user-unrecoverable error occurs, the

POWER

indicator,

BUSY

indicator, and

ERROR

indicator blink and the beeper sounds a certain number of times to indicate

which error has occurred.

* The

BUSY

indicator turns on when there is receiving data.

Part 4: TROUBLESHOOTING

LR1

4-4

Table 4-1 ERROR DISPLAY

Status

User-recoverable errors

Paper-feed error

Paper jam error

Cartridge not-loaded error

Cartridge mismatch error

Failed manual feed warning

Cartridge replacement

auto-completion warning

Cartridge overheating warning

Waste ink full warning

User-unrecoverable errors

ROM error

RAM error

No-cartridge error

Home position error

Waste ink full error

Internal temperature sensor error

Automatic correction error

Head overheating error

EEPROM error

Power

On

On

On

On

On

On

On

On

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Busy

Off

Off

Off

Off

Off

Off

Off

Off*

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Error

On

On

On

On

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Beeper Sounds

1

2

3

4

1

3

4

5

1

2

3

4

5

6

7

8

11

Page

Page 4-11

Page 4-11

Page 4-13

Page 4-13

Page 4-10

Page 4-15

Page 4-8

Page 4-5

Page 4-5

Page 4-5

Page 4-13

Page 4-6

Page 4-5

Page 4-5

Page 4-6

Page 4-8

Page 4-5

Page 64

1.3 Troubleshooting Errors <Cause> The contents in ROM could not be read during the

initialization.

<Suspected parts> Control ROM.

<Measure> Replace the ROM or the control board.

<Cause> Reading and writing in RAM cannot be performed

properly.

<Suspected parts> DRAM, MPU, and print controller.

<Measure> Replace the control board.

<Cause> Writing to EEPROM cannot be performed properly.

<Suspected parts> EEPRROM, MPU, and print controller.

<Measure> Replace the control board.

If ROM error or RAM error occurs, the error display might not always be

accurate.

<Cause> Thermistor is abnormal.

<Suspected parts> Thermistor.

<Measure> Replace control board.

<Cause> When the waste-ink amount reaches 99%, a waste-ink

warning is issued.

When it reaches 100%, the waste-ink full error occurs.

<Suspected parts> Waste-ink absorber and control board.

<Measure> 1. Replace printer base unit (replace waste-ink

absorber) and reset the EEPROM.

2. Replace the control board and reset the wasteink amount in the EEPROM.

4-5

LR1

Part 4: TROUBLESHOOTING

T roubleshooting

1. ROM Error

2. RAM Error

3. EEPROM Error

4. Internal

Temperature

Sensor Error

5. Waste-Ink Full

Error/Waste-Ink

Full Warning

Page 65

<Cause> Automatic correction error: The printing correction

cannot be detected

properly.

Home position error: The home position

sensor cannot detect the

carriage.

<Suspected parts> Home position sensor, carriage motor,

paper-feed motor, control board, carriage

ribbon cable, lock arm, and printer base

unit

<Measure>

Part 4: TROUBLESHOOTING

LR1

4-6

6. Automatic

Correction Error

7. Home Position

Error

Remove upper case.

Check the inside of the

printer visually.

Correct?

Yes

Power ON.

Check (visually) operation

of carriage motor and

paper-feed motor.

Correct?

No

• Check for any loose or deformed parts in the carriage section.

• Check if the lock arm is broken or deformed.

• Check for any paper bits or waste particles stuck between parts.

No

Fix the problem or

replace the chassis

platen unit.

Yes

Replace home position

sensor.

Check (visually) operation

of lock arm.

Correct?

Yes

Next

page

• Check the lock arm operation during the initialization.

No

Replace printer base

unit.

Page 66

4-7

LR1

Part 4: TROUBLESHOOTING

T roubleshooting

1-2

3-4

Check the carriage motor

and paper-feed motor.

Replace control board.

Replace chassis platen

unit.

Yes

No

• Before measuring, disconnect the paper-feed motor's connector

from the control board.

Measuring Point NormalValue

Approx. 70.0 Ω

CNLF

Pin No.

2-5

3-4

Paper-feedmotor

Measuring Point NormalValue

Approx. 8.5 Ω

CNCR

Pin No.

Carriage motor

CNCR

4

1

A

Approx.8.5 Ω/

phase

Carriage motor

• Before measuring, disconnect the carriage motor's connector

from the control board.

Previous

page

• Faulty carriage motor.

• Faulty paper-feed motor.

1

2

3

4

A

B

B

Correct?

5

1

Paper-feed motor

CNLF

4

5

3

2

1

Approx. 70.0 Ω

/ phase

B

A

A

B

COM

Page 67

<Cause> The head temperature is abnormally high.

Even after the head's power is turned off, the head

temperature does not go down.

<Suspected parts> There is no ink in the BJ cartridge and ink

cartridge.

Control board

<Measure>

Part 4: TROUBLESHOOTING

LR1

4-8

8. Head

Overheating

Error

9. Cartridge

Overheating

Warning

Leave the printer for

several minutes.

Error displayed?

Yes

Press the

to turn off the power, then

Remove and install the BJ

Press the

to turn on the power.

POWER

leave the printer for

several minutes.

cartridge.

POWER

Error displayed?

Yes

Check connector.

button

button

No

END