Canon Inner Finisher-A1, Inner Finisher Additional Tray-A1 Service Manual

654321

Inner Finisher-A1

Inner Finisher Additional Tray-A1

Service Manual

0

0

b

b

Application

This manual has been issued by Canon Inc. for qualied persons to learn technical theory,

installation, maintenance, and repair of products. This manual covers all localities where the

products are sold. For this reason, there may be information in this manual that does not

apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements

or changes in products. When changes occur in applicable products or in the contents of this

manual, Canon will release technical information as the need arises. In the event of major

changes in the contents of this manual over a long or short period, Canon will issue a new

edition of this manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks

of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may

not be copied, reproduced or translated into another language, in whole or in part, without the

written consent of Canon Inc.

(C) CANON INC. 2009

Caution

Use of this manual should be strictly supervised to avoid disclosure of condential

information.

0

0

c

c

Explanation of Symbols

The following symbols are used throughout this Service Manual.

Symbols Explanation Symbols Explanation

Check.

Remove the claw.

Check visually. Insert the claw.

Check the noise. Use the bundled part.

Disconnect the connector.

Push the part.

Connect the connector. Plug the power cable.

Remove the cable/wire

from the cable guide or wire

saddle.

Turn on the power.

Set the cable/wire to the

cable guide or wire saddle.

Remove the screw.

Tighten the screw.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specic functions and the

relationship between electrical and mechanical systems with reference to the timing of

operation.

In the diagrams, represents the path of mechanical drive; where a signal name

accompanies the symbol, the arrow indicates the direction of the electric

signal.

The expression "turn on the power" means ipping on the power switch, closing the

front door, and closing the delivery unit door, which results in supplying the machine with

power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is

"High", while '0' is used to indicate "Low". (The voltage value, however, differs from

circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked

in the eld. Therefore, the operations of the microprocessors used in the machines

are not discussed: they are explained in terms of from sensors to the input of the DC

controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product

improvement or other purposes, and major changes will be communicated in the form of

Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service

Manual and all relevant Service Information bulletins and be able to identify and isolate faults

in the machine.

0

0

d

d

0

0

e

e

Contents

0 Safety Precautions

Notes Before it Works Serving ---------------------------------------------0-2

1 Produt Outline

Features -------------------------------------------------------------------------1-2

Specications ------------------------------------------------------------------1-3

Names of Parts ----------------------------------------------------------------1-4

External View 1 --------------------------------------------------------------------- 1-4

External View 2 --------------------------------------------------------------------- 1-4

External View 3 --------------------------------------------------------------------- 1-5

Cross Section ----------------------------------------------------------------------- 1-5

2 Technology

Basic Conguration -----------------------------------------------------------2-2

Outline of basic operation -------------------------------------------------------- 2-2

Non-sort operation-------------------------------------------------------------------------- 2-2

Offset operation ----------------------------------------------------------------------------- 2-2

Stapling operation -------------------------------------------------------------------------- 2-3

Servicing Work -----------------------------------------------------------------2-5

Scheduled Servicing -------------------------------------------------------------- 2-5

Customer maintenance ----------------------------------------------------------- 2-5

Cleaning the offset roller ------------------------------------------------------------------ 2-5

Version Upgrade ------------------------------------------------------------------- 2-5

3 Periodic Servicing

Periodic Service Works ------------------------------------------------------3-2

4 Parts Replacement and Cleaning Procedure

List of Parts ---------------------------------------------------------------------4-2

Motors/Switches/Solenoids ------------------------------------------------------ 4-2

Sensors1 ----------------------------------------------------------------------------- 4-2

Sensors2 ----------------------------------------------------------------------------- 4-3

PCBs ---------------------------------------------------------------------------------- 4-3

Main Units -----------------------------------------------------------------------4-4

Removing the Upper Unit -------------------------------------------------------- 4-4

Removing the Gripper Unit ------------------------------------------------------ 4-7

Consumable Parts Requiring Periodic Replacement and Cleaning

Points ----------------------------------------------------------------------------4-8

Removing the Stapler Unit ------------------------------------------------------- 4-8

Removing the Offset Roller ------------------------------------------------------ 4-9

Removing the Shutter Unit -----------------------------------------------------4-10

Removing the Paper retainer (front/rear) -----------------------------------4-11

Removing the Solenoid ---------------------------------------------------- 4-13

Removing the Paper Lever Drive Solenoid---------------------------------4-13

Removing the Staple Solenoid ------------------------------------------------4-15

Removing the Motors ------------------------------------------------------ 4-18

Removing the Shift Roller Release Motor ----------------------------------4-18

Removing the Shift Motor -------------------------------------------------------4-19

Removing the Feed Motor ------------------------------------------------------ 4-21

Removing the Gripper Open/Close Motor ----------------------------------4-22

Removing the STP Move Motor/Gripper Unit Move Motor ------------- 4-22

Removing the Entrance Roller Release /Stopper HP Motor ----------- 4-25

Removing the Additional Tray Lift Motor ------------------------------------4-26

Removing the Tray Lift Motor -------------------------------------------------- 4-27

Removing the Switches --------------------------------------------------- 4-30

Removing the Front Cover Switch --------------------------------------------4-30

Removing the Staple Safety Switch ------------------------------------------4-31

Removing the PCB --------------------------------------------------------- 4-34

Removing the Additional Tray PCB -------------------------------------------4-34

Removing the Finisher Controller PCB --------------------------------------4-35

Removing the Flexible Cable Broadcast PCB ----------------------------- 4-37

Others -------------------------------------------------------------------------- 4-38

Stapler Cradle Installation Procedure ----------------------------------------4-38

5 Installation(Inner Finisher-A1)

Making Pre-installation Checks --------------------------------------------5-2

0

0

f

f

Cautions at the Installation ------------------------------------------------------ 5-2

Kontrollen vor der Installation (German/Deutsch) --------------------5-2

Vorsichtshinweise zur Installation ---------------------------------------------- 5-2

Checking Bundled Components -------------------------------------------5-3

How to Utilize This Installation Procedure ------------------------------ 5-4

When Using the Contained Parts (Bundled Components

in the Shipping Carton) ----------------------------------------------------------- 5-4

Symbols in the Illustration ------------------------------------------------------- 5-4

Installation Procedure --------------------------------------------------------5-5

Installation Procedure ------------------------------------------------------------- 5-5

6 Installation(Addtional Tray-A1)

Making Pre-installation Checks --------------------------------------------6-2

Cautions at the Time of Installation -------------------------------------------- 6-2

Checking Bundled Components -------------------------------------------6-3

How to Utilize This Installation Procedure ------------------------------ 6-4

When Using the Contained Parts(Bundled Components in the Shipping

Carton) -------------------------------------------------------------------------------- 6-4

Symbols in the Illustration ------------------------------------------------------- 6-4

Installation Procedure --------------------------------------------------------6-5

Preparation to install in the host machine ----------------------------------- 6-5

Connecting to Connected Equipment ----------------------------------------- 6-6

7 Appendix

Service Tools -------------------------------------------------------------------7-2

Solvents and Oils ------------------------------------------------------------------ 7-2

Special Tools ------------------------------------------------------------------------ 7-2

General Circuit Diagram -----------------------------------------------------7-3

Safety Precautions

Notes Before it Works Serving

■

0

0

0-2

0-2

Safety Precautions > Notes Before it Works Serving

Safety Precautions > Notes Before it Works Serving

Notes Before it Works Serving

Caution:

At servicing, be sure to turn off the power source according to the specied steps and

disconnect the power plug.

Caution:

Do not turn off the power switch when downloading is under way.

Turning off the main power switch while downloading is under way can disable the

machine.

1

1

Produt Outline

Produt Outline

Names of Parts

Specications

Names of Parts

■

■

■

1

1

1-2

1-2

Produt Outline > Features

Produt Outline > Features

Features

A variety of nishing functions

2 delivery tray + Multi stapling

Large tray capacity (500 sheets+)

Utilize the inner room of the system

•

•

1

1

1-3

1-3

Produt Outline > Specications

Produt Outline > Specications

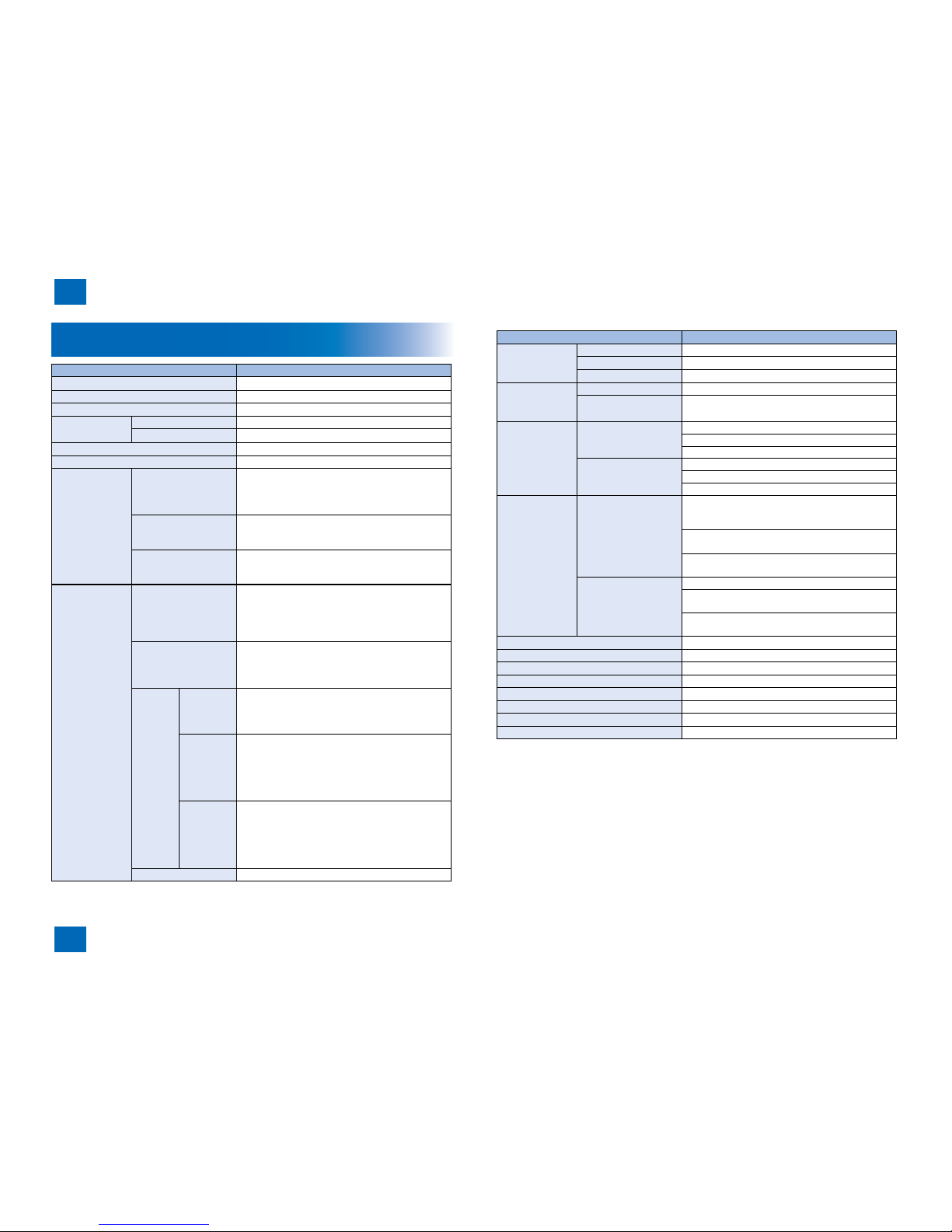

Specications

Item Specications

Stacking method

Stacking tray descending method

Paper ejection

Face-down ejection

Stacking alignment

Center alignment

Stackable paper

size

Feeding direction

139.7mm - 457mm

Cross-feeding direction

100.0mm - 320mm

Paper weight

52-256g/m2 (Japanese post card supported))

Number of tray

1 (+additional option tray)

Finishing modes Non-sort stacking

A3/A4/A4R/A5/A5R/B4/B5/B5R/Japanese Post

Card/EXE/LDR/LGL/LTR/LTR-R/STMT/STMT-R

8K/16K/16K-R

SRA3(320X450)/A3+(305X457)

Bunch offset stacking

A3/A4/A4R/B4/B5

LDR/LGL/LTR/LTR-R

8K/16K

Staple stacking

A3/A4/A4R/B4/B5

LDR/LGL/LTR/LTR-R

8K/16K

Stacking capacity Processing tray

S size: 50 sheets or Less

Length in feeding direction: 139.7mm-215.9mm

L size: 30 sheets or Less

Length in feeding direction: more than 215.9mm-

457.0mm

Standard tray (lower

tray) only

S size: 62.5mm high or less (62.5mm is equivalent

to 500 sheets+/-.)

L size: 62.5mm high or less (62.5mm is equivalent to

500 sheets+/-.)

When the

Additional

Tray-A1 is

installed

Additional

Tray-A1

(Upper tray))

S size: 12.5mm high or less (12.5mm is equivalent

to 100 sheets+/-.)

L size: 12.5mm high or less (12.5mm is equivalent to

100 sheets+/-.)

Standard

tray

(lower tray)/

Random

stacking

S size: 25.0mm high or less (25.0mm is equivalent

to 200 sheets+/-.)

L size: 25.0mm high or less (25.0mm is equivalent to

200 sheets+/-.)

Standard

tray

(lower tray)/

Cascade

stacking

S size: 62.5mm high or less (62.5mm is equivalent

to 500 sheets+/-.)

L size: 62.5mm high or less (62.5mm is equivalent to

500 sheets+/-.)

Stapled stack

Above-mentioned heights or within 30 books

Item Specications

Capable size for

alignment

Non-sort stacking

Width: 100mm-320mm

Bunch offset stacking

Width: 210mm-297mm

Staple stacking

Width: 210mm-297mm

Paper detection Processing tray

Available

Standard tray/Additional

Tray-A1

Available

Capable size for

stapling

Single corner stapling

(front or rear

A3/B4/A4/A4R/B5

LDR/LGL/LTR/LTR-R

8K/16K

Double stapling

(sidestitching)

A3/B4/A4/A4R/B5

LDR/LGL/LTR/LTR-R

8K/16K

Number of paper

stapled

Small size

(A4/B5/LTR/16K)

Plain paper (52-81.4g/m2) : 50 sheets (Max: 2

sheets x Cover paper (256g/m2) + 48 sheets x

bookblock (81.4g/m2))

Plain paper (more than 81.4g/m2-105.0g/m2): 30

sheets

Thick paper (more than 105.0g/m2 - 256g/m2: 2

sheets

Large size

(A3/B4/A4R/LDR/LGL/

LTR-R/8K)

Plain paper(52-81.4g/ 30m2) : 30 sheets

Plain paper (more than 81.4g/m2-105.0g/m2): 20

sheets

Thick paper (more than 105.0g/m2 - 256g/m2: 2

sheets

Staple replenishment

Exclusive staple cartridge (5000 staples)

Staple

Exclusive staple

Staple run-out detection

Available

Manual stapling

Unavailable

Control panel

Not exsisting

Power supply

Supplied by the host machine

Dimensions

424.2mm×552.1mm×228.5mm(W×D×H)

Mass

Approx. 9.8Kg

T-1-1T-1-1

1

1

1-4

1-4

Produt Outline > Names of Parts > External View 2

Produt Outline > Names of Parts > External View 2

Names of Parts

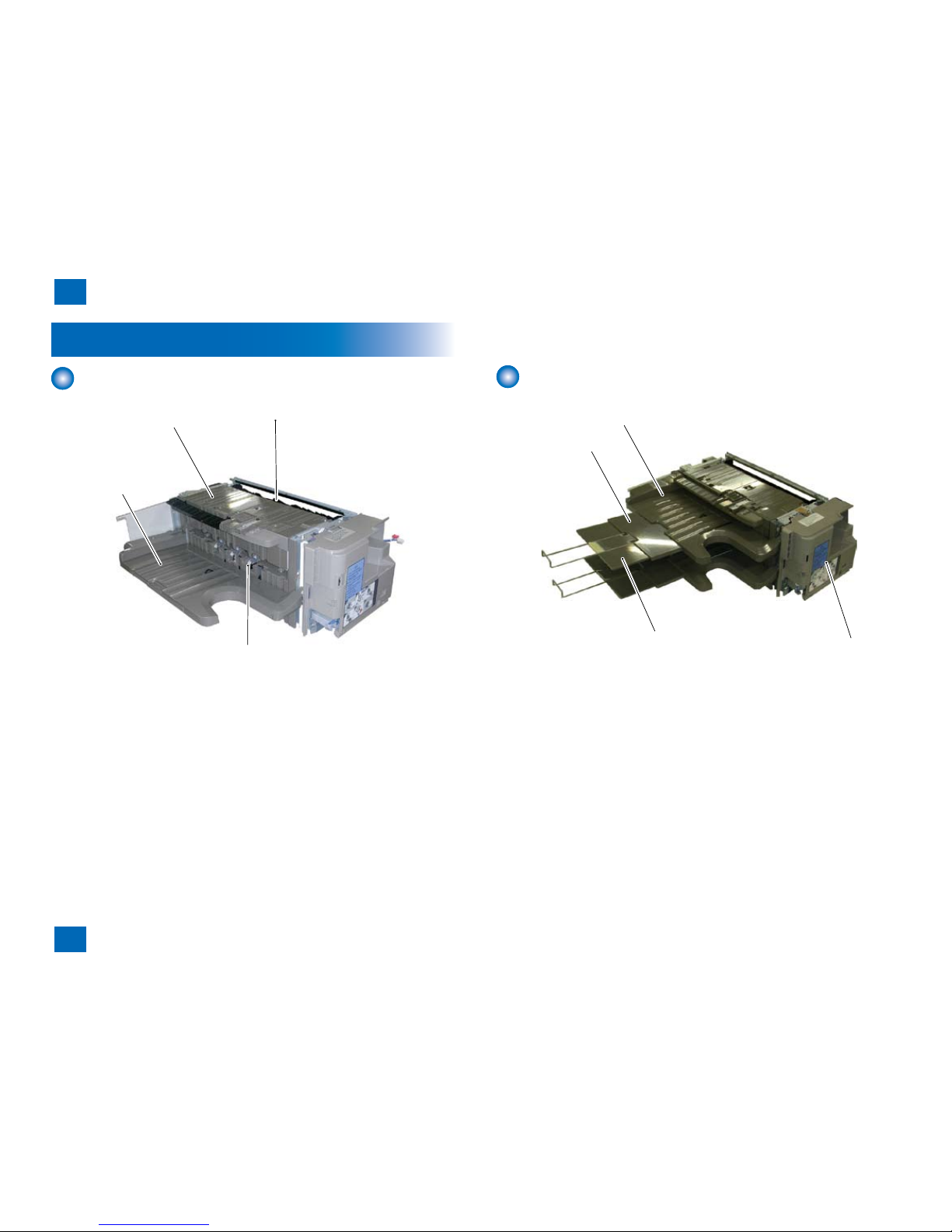

External View 1

Tray paper holdig arm

Upper guide part

Stack tray

Switchback guide

F-1-1F-1-1

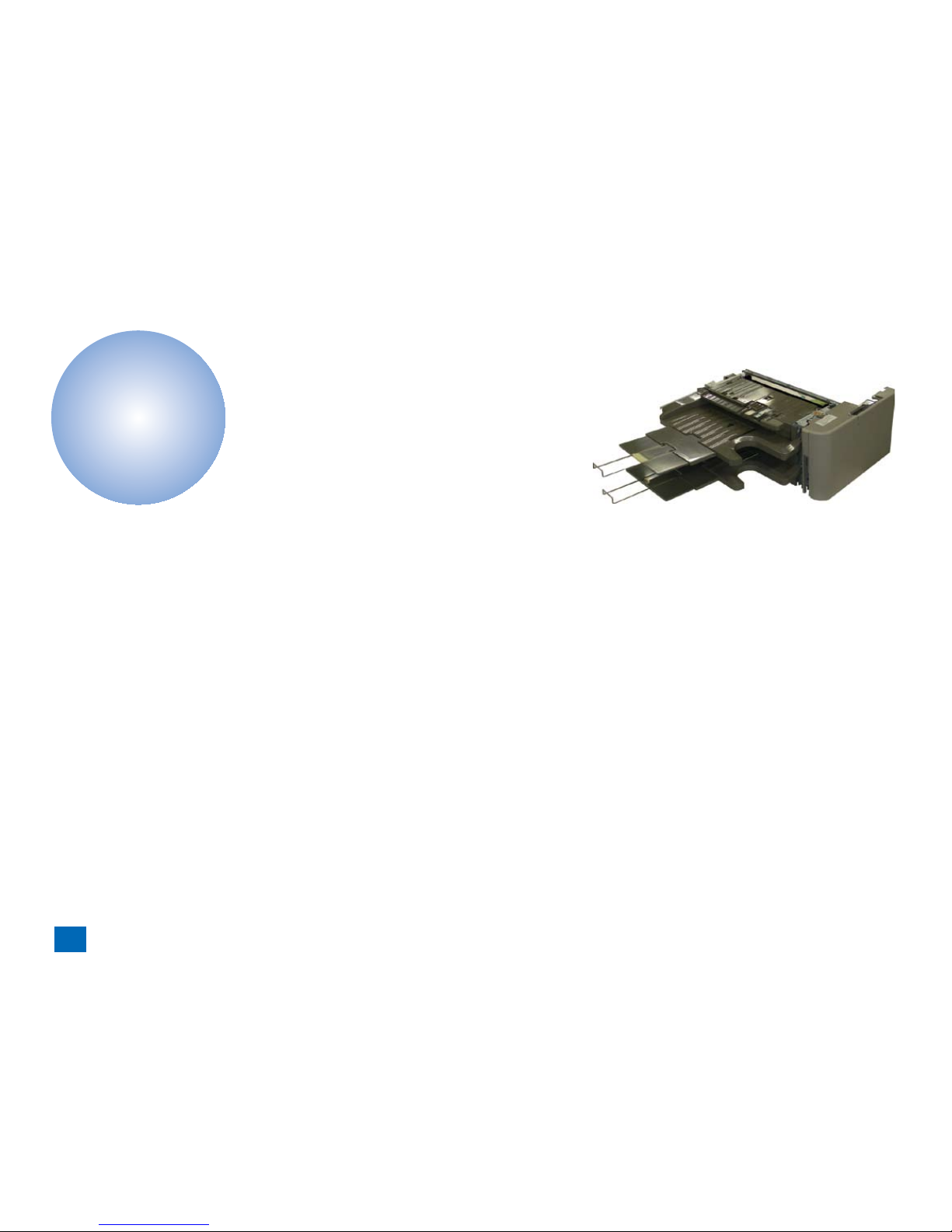

External View 2

Stapler

Additional Tray-A1

Stack extension tray 2

Stack extension tray 1

F-1-2F-1-2

1

1

1-5

1-5

Produt Outline > Names of Parts > Cross Section

Produt Outline > Names of Parts > Cross Section

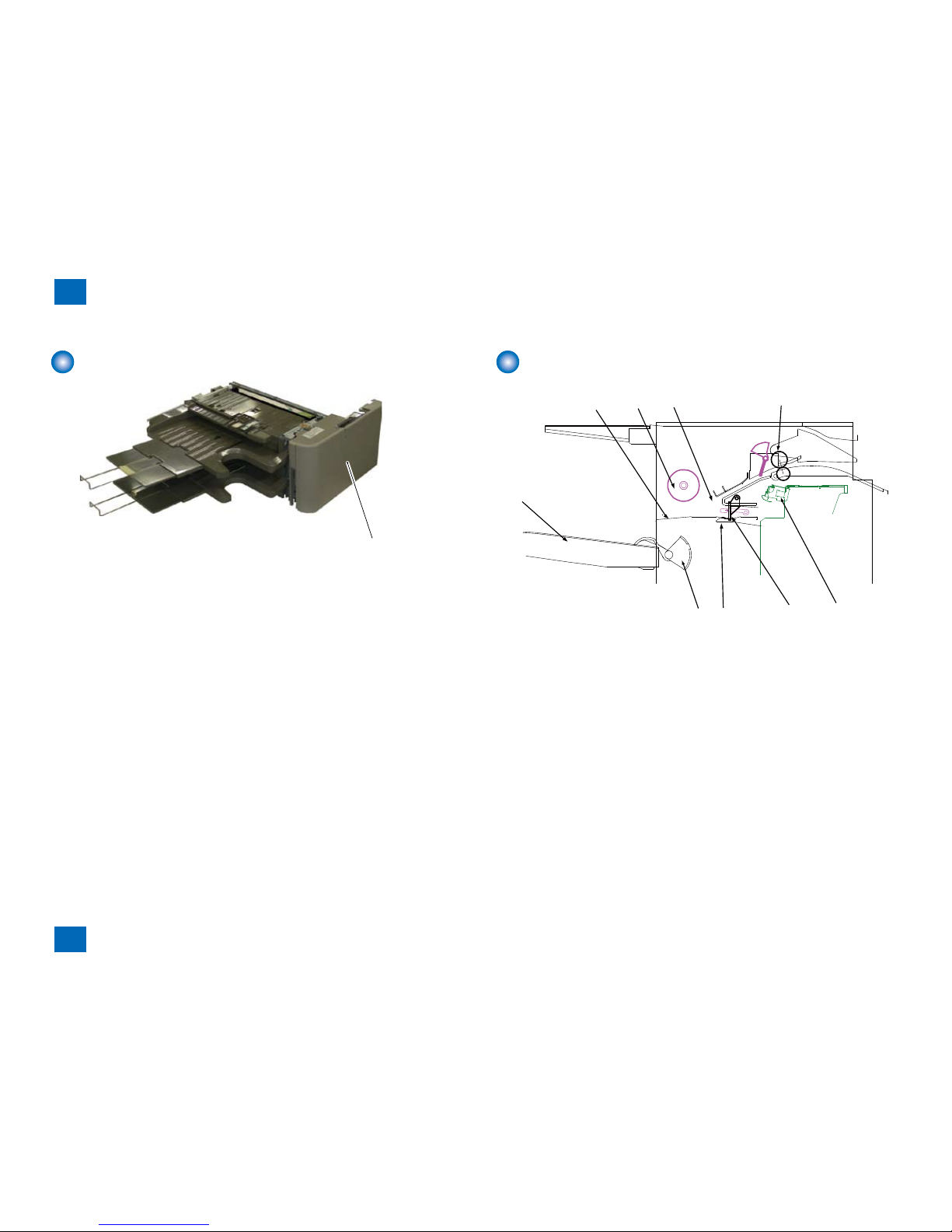

External View 3

Finisher front cover

F-1-3F-1-3

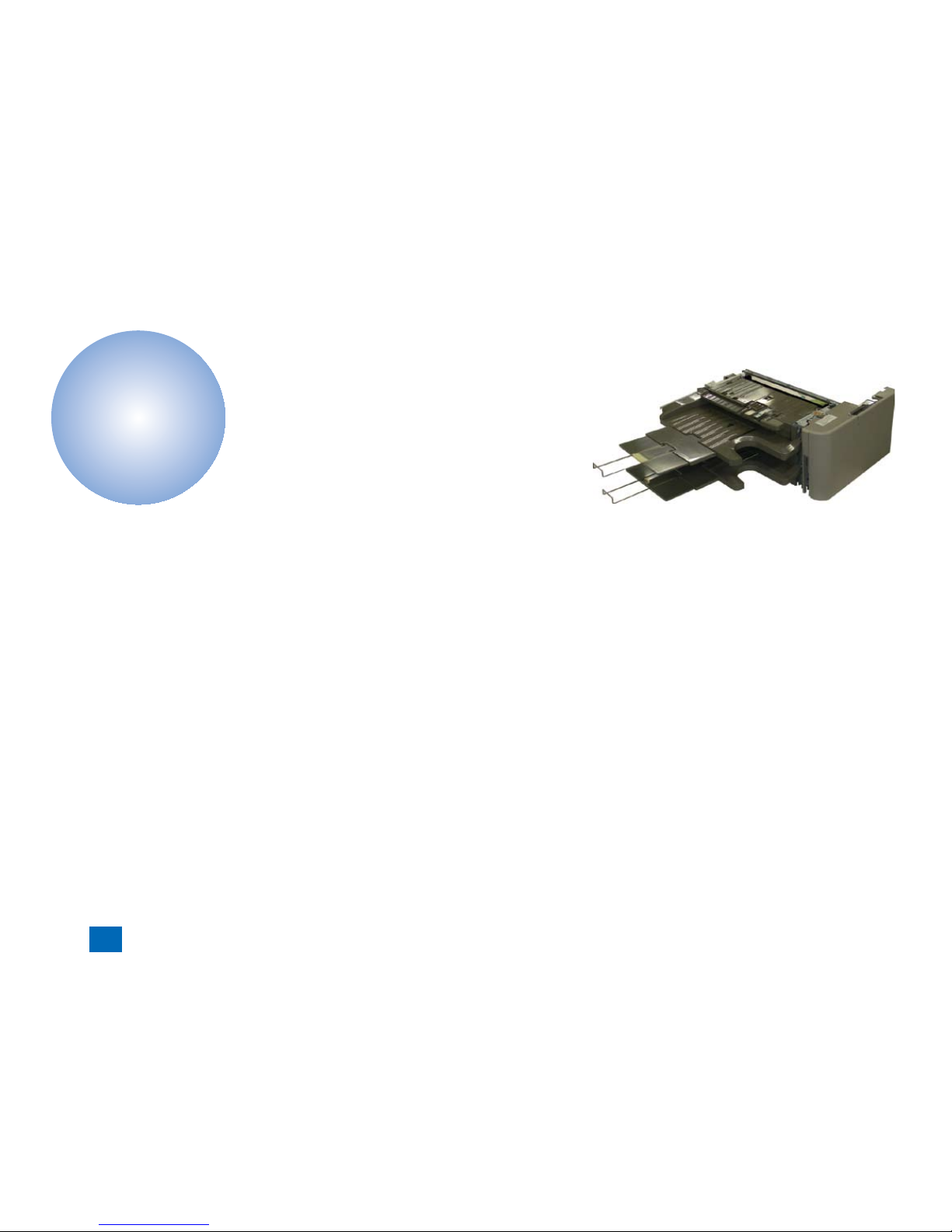

Cross Section

[1]

[6]

[5]

[4]

[3]

[2]

[9]

[8]

[7]

[1] Stack tray [6] Stapler

[2] Processing tray [7] Stapler

[3] Shift roller [8] Gripper

[4] Switchback part [9] Stack height detection lever

[5] Entrance roller

F-1-4F-1-4

2

2

Technology

Technology

Basic Conguration

Work of Service

■

■

2

2

2-2

2-2

Technology > Basic Conguration > Outline of basic operation > Offset operation

Technology > Basic Conguration > Outline of basic operation > Offset operation

Basic Conguration

Outline of basic operation

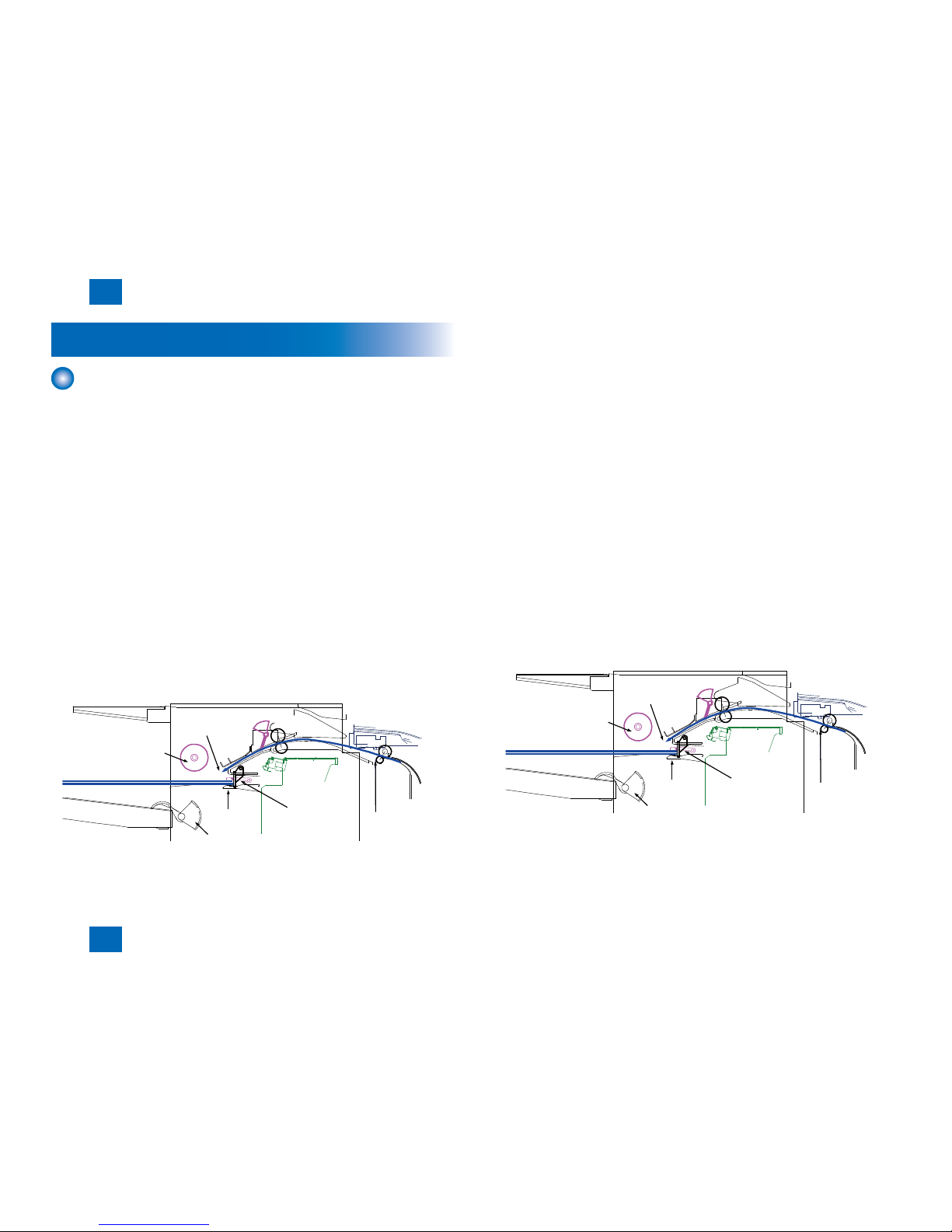

Non-sort operation

1.Outline

Ejected paper from the host machine is aligned and stacked on the processing tray. Paper

stack is then ejected on the stack tray. The paper stack is placed at the center in cross

feeding direction.

2.Details

Outline of operation

1)Ejected paper from the host machine is conveyed into the nisher.

2)Before paper trailing edge passes by the entrance roller, the shift roller goes down to press

the paper. After the trailing edge passes by the entrance roller, the shift roller stops turning.

3)The gripper opens and the shift roller reverses to transport the paper stack to the aligning

plate.

4)The shift roller goes up to release the paper stack and the gripper closes to grip the stack.

5)The above steps repeat themselves up until the number of the paper on the processing

tray becomes 10 (1 for the envelope) or the operation complete signal is issued whichever

comes rst.

6)Gripper starts to eject the paper stack on the stack tray.

7)Stack height detection lever moves up to evacuate itself and moves down again to detect

the stacking height when the stack ejection has completed.

Switchback part

Shift roller

Entrance roller

Stapler

Gripper

Trailing edge

aligning plate

Stack tray

Processing tray

Stack height detetion lever

Ejection roller

of the host machine

[Non-sort stacking operation]

■

•

F-2-1F-2-1

Offset operation

1.Outline

Stacking the ejected paper from the host machine onto the processing tray. Every paper

stack consisting of 10sheets of paper is offset and ejected on the stack tray.

2.Details

Outline of operation

1)1)through 5) are the same operation as "Non-sort".

6)The shift roller moves to the center or rear-end position and align the paper stack to locate

it at specied shift position.

7)The shift roller goes up to release the paper stack and the gripper closes to grip the stack.

8)The shift roller returns to its idle position and the above steps repeats themselves till the

last paper.

9)Gripper starts to eject the paper stack on the stack tray.

10)Stack height detection lever moves up to evacuate itself and moves down again to detect

the stacking height when the stack ejection has completed.。

Alignment position

Center shift: No offsetting (Non-sort position)

Rear-end shift: From the center reference position to the rear-end position;

178.5mm

Switchback part

Shift roller

Entrance roller

Stapler

Gripper

Trailing edge

aligning plate

Stack tray

Processing tray

Stack height detetion lever

Ejection roller

of the host machine

[Offset stacking]

■

•

•

F-2-2F-2-2

2

2

2-3

2-3

Technology > Basic Conguration > Outline of basic operation > Stapling operation

Technology > Basic Conguration > Outline of basic operation > Stapling operation

Stapling operation

1.Outline

Stacking the ejected paper from the host machine onto the processing tray. Stapling and

ejecting the paper stack on the stack tray.

2.Details

Outline of operation

"Angle stapling at 1 front corner", "Angle stapling at 1 rear corner" and "Double stapling (side

stitching)"

1)1) through 7) are the same operation as the offset operation.

2)Gripper conveys the paper stack to the stapling position with holding the stack.

"The operation 9) and 10) are applicable only to the front/ rear corner stapling."

9)After stapling the paper stack, the gripper starts to eject the stack on the stack tray.

10)At the same time, the stacking height detection lever moves up. The detection lever

moves down when the paper stack has ejected on the stack tray to detect the paper.

"The operation 9)' through 18) are applicable only to the double stapling (side stitching)."

9)The shift roller moves down and gives higher pressure to the paper stack. Gripper then

opens and evacuates itself to the connecting position with the stapler.

Stack tray

Shift roller

Higher nip pressure

Stapler

Gripper

Gripper evacuates

itself to the connecting position

Stack height detetion lever

[Gripper evacuating operation]

■

•

F-2-3F-2-3

Gripper opens

Shift roller nip

Gripper evacuating

and connecting to the stapler

connecting mechanism-1

connecting mechanism-2

Gripper unit rail

Shift roller nip

[Gripper evacuating operation (Top view)]

10)When the gripper closes, the connecting lever moves downward to connect the stapler

and the gripper to each other, so the stapler can travel back and forth.

11)Stapler unit travels to its rst stapling position to execute stapling.

12)Stapler unit travels to its second stapling position to execute stapling.

Stapling (first)

Stapling (second)

The stapler unit and the gripper unit move with connecting

to each other and execute the stapling operation.

F-2-4F-2-4

F-2-5F-2-5

2

2

2-4

2-4

Technology > Basic Conguration > Outline of basic operation > Stapling operation

Technology > Basic Conguration > Outline of basic operation > Stapling operation

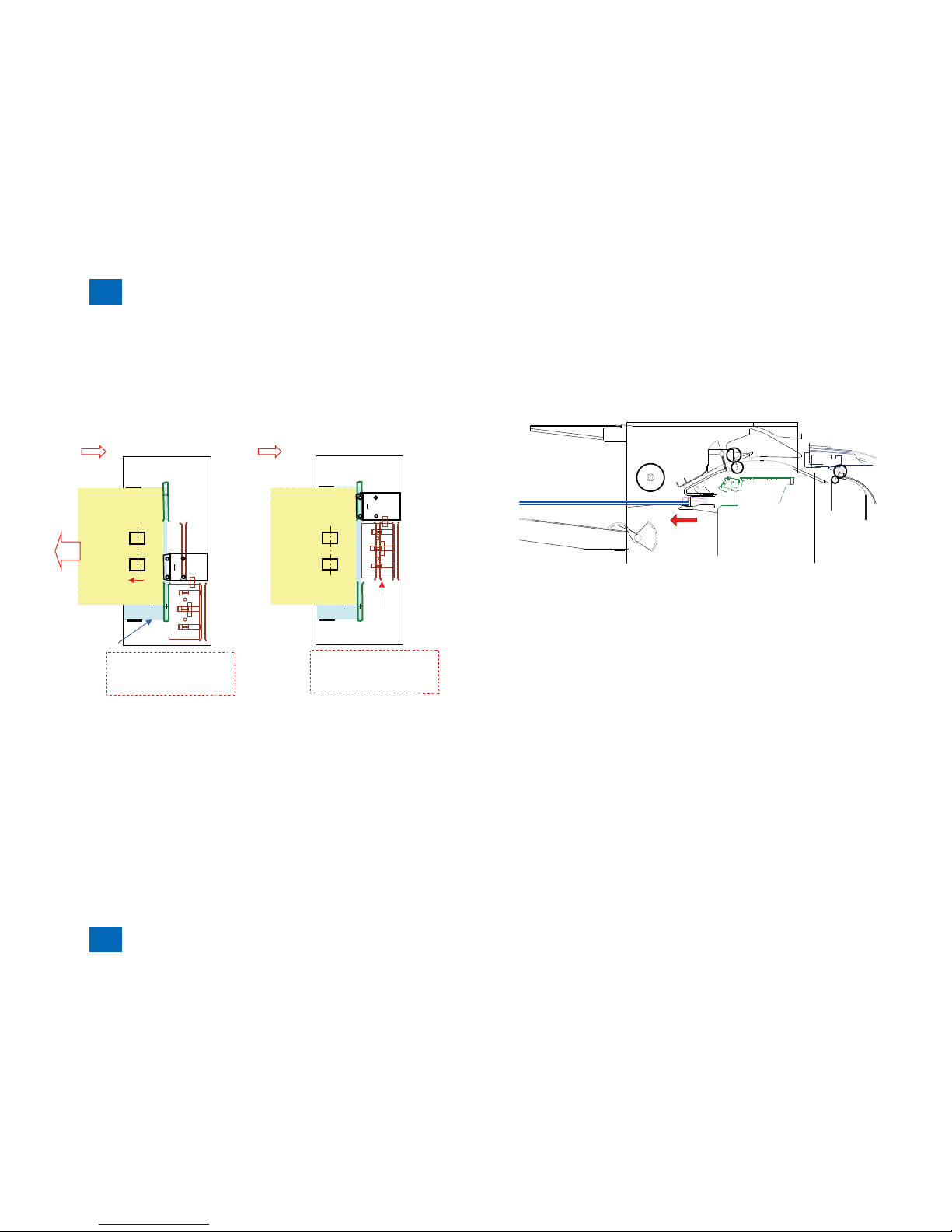

13)The shift roller starts up to convey the paper stack in the delivering direction and stops

after the shift roller evacuates the trailing edge of the paper stack inside the path guide.

14)While the shift roller conveys the paper stack, the stapler starts to move to the position

where the gripper had connected to the stapler at step 10)

Conveying the paper stack with

the shift roller

The paper guide

The stapler and the gripper move to the

original position where the gripper had

connected to the stapler at step 10)

Gripper opens to release the connection

The stapler and the gripper move

Conveying

direction

Returning to

the connecting

position

After the stapling operation, the shift

roller rotates to convey the paper stack

until the trailing edge of the stack gets

into the paper guide.

15)When the gripper opens, the connecting lever moves upward to release the connection to

the stapler.

16)Gripper moves to the position where there is the paper stack evacuated in the path guide

and closes.

F-2-6F-2-6

17)The gripper starts to deliver the paper stack.

18)At the same time, the stacking height detection lever moves up. The detection lever

moves down when the paper stack has ejected on the stack tray to detect the paper.

Stapler

Gripper delivers the paper stack

Stack tray

[Paper stack delivery]

F-2-7F-2-7

2

2

2-5

2-5

Technology > Servicing Work > Version Upgrade

Technology > Servicing Work > Version Upgrade

Servicing Work

Scheduled Servicing

When the endurance time of a part expires soon, replace and/or clean it as required.

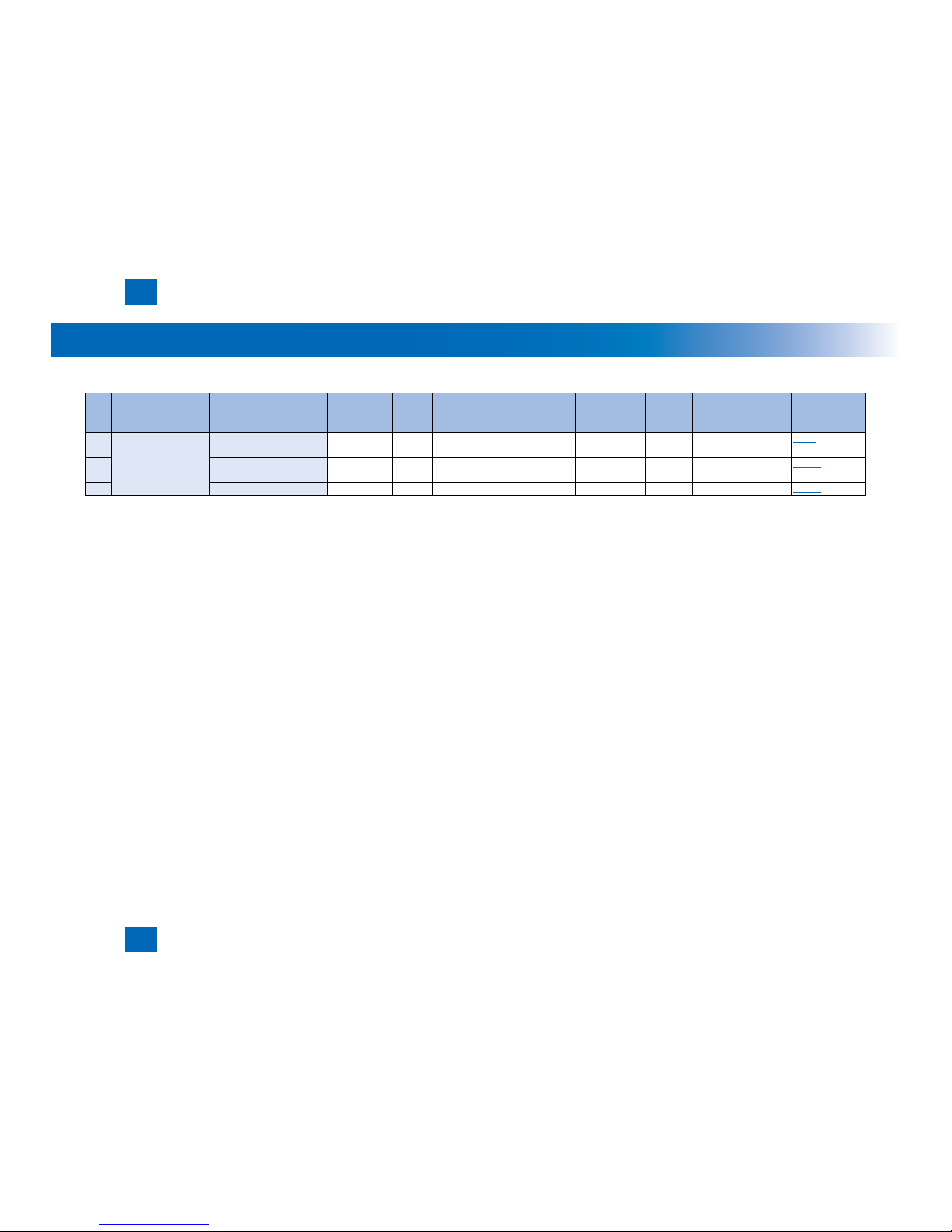

Item Part name Expected

service life

Qty Operation remarks Reference

Periodically

replaced

parts

none

Consumable

parts

Stapler 500,000 sheets 1 Replacement p. 4-8

Offset Roller 1,000,000

sheets

2 Replacement p. 4-9

Shutter unit 1,000,000

sheets

1 Replacement Static eliminator

at the exit part

p. 4-10

Paper

retainer(Front)

1,000,000

sheets

1 Replacement Static eliminator

at the entrance

p. 4-11

Paper

retainer(Rear)

1,000,000

sheets

1 Replacement Static eliminator

at the entrance

p. 4-11

Periodically

serviced

parts

none

T-2-1T-2-1

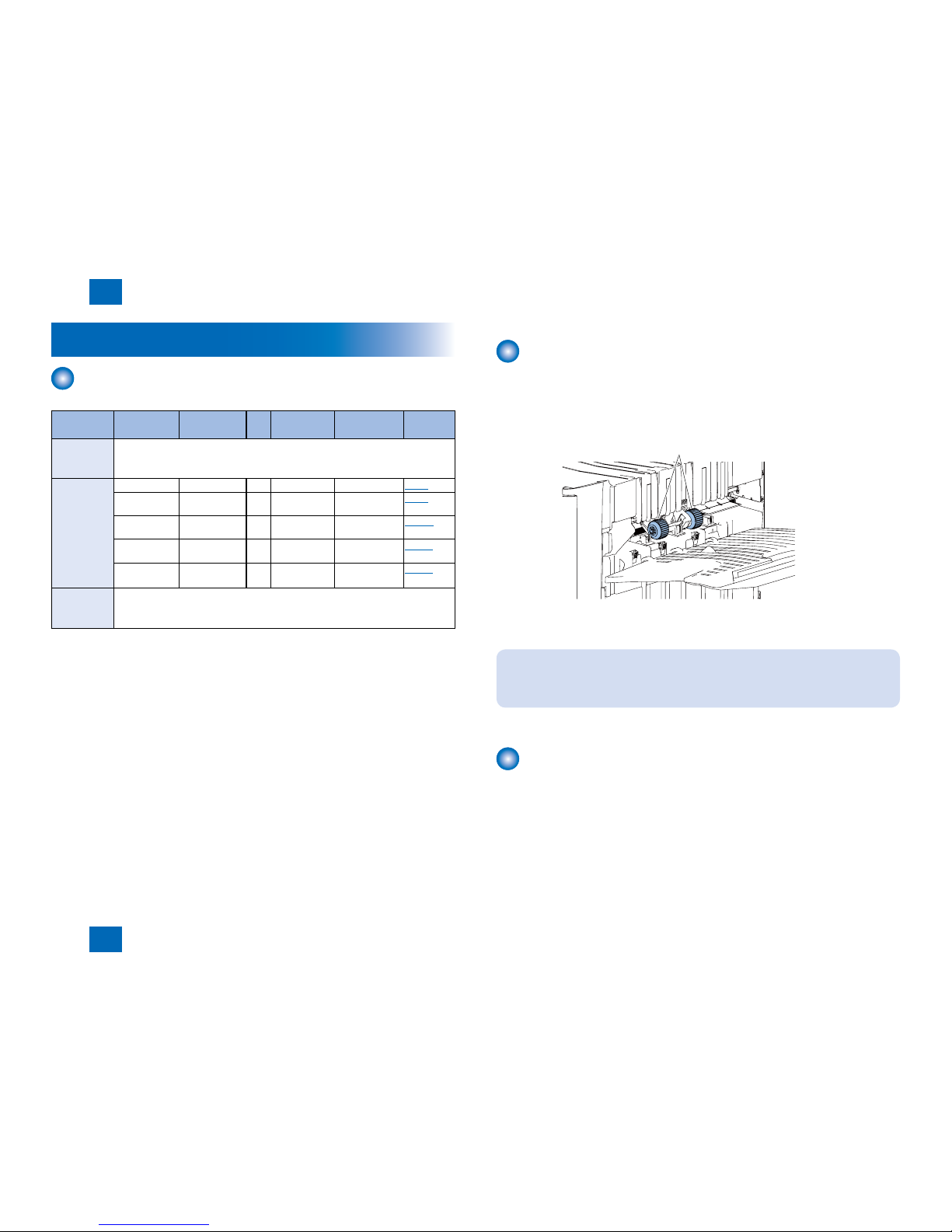

Customer maintenance

Cleaning the offset roller

Details

Offset roller should be cleaned once a month to maintain the accuracy of the stacking

alignment as foreign articles like dust are likely to stick to the roller.

[1]

Instruction

1) With holding up the roller a little, rub off paper dusts, etc. by a moist cloth.

MEMO:

If the optional tray is installed, it is easier to clean the rollers just after delivering a paper

onto the optional tray since the optional tray gets descended lower than the rollers.

Version Upgrade

Upgrade the rmware of the nisher controller according to the upgrade procedure

described in the service manual of the host machine.

This nisher does not support upgrading via downloader PCB (FY9-2034).

■

•

•

F-2-8F-2-8

3

3

Periodic Servicing

Periodic

Servicing

Periodic Service Works

■

3

3

3-2

3-2

Periodic Servicing > Periodic Service Works

Periodic Servicing > Periodic Service Works

Periodic Service Works

PR:Replacement (Periodically replaced parts) CR:Replacement (consumable parts) CL:Cleaning LU:Lubrication AD:Adjustment CH:Maintenance

As of Jule 2009

No. Category Part name Part number Qty Interval Remarks Adjusted/

not

adjusted

Counter Reference

1 Stapler Stapler FM4-2710 1 CR/500,000 sheets None FIN-STPR p. 4-8

2 Processing tray Offset Roller 4A3-1121 2 CR/1,000,000 sheets None OFST-RL p. 4-9

3 Shutter unit FL3-4298 1 CR/1,000,000 sheets None DL-STC p. 4-10

4 Paper retainer(Front) FL3-4304 1 CR/1,000,000 sheets None ENT-STC p. 4-11

5 Paper retainer(Rear) FL3-4305 1 CR/1,000,000 sheets None ENT-STC p. 4-11

T-3-1T-3-1

4

4

Parts Replacement and Cleaning Procedure

Parts

Replacement

and Cleaning

Procedure

List of Parts

Main Units

Consumable Parts

Requiring Periodic

Replacement and

Cleaning Points

Solenoids

Motors

Switches

■

■

■

■

■

■

PCBs

Others

■

■

4

4

4-2

4-2

Parts Replacement and Cleaning Procedure > List of Parts > Sensors1

Parts Replacement and Cleaning Procedure > List of Parts > Sensors1

List of Parts

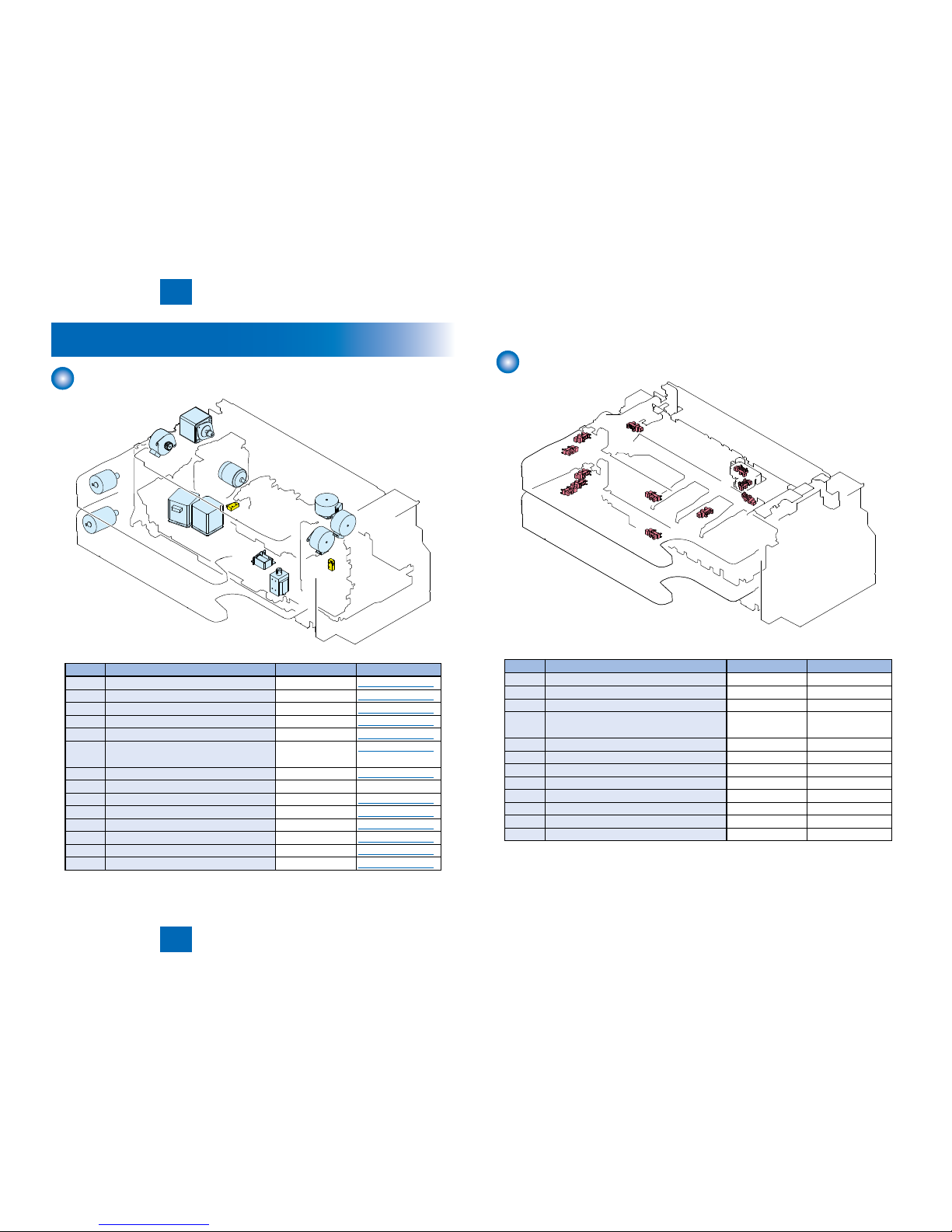

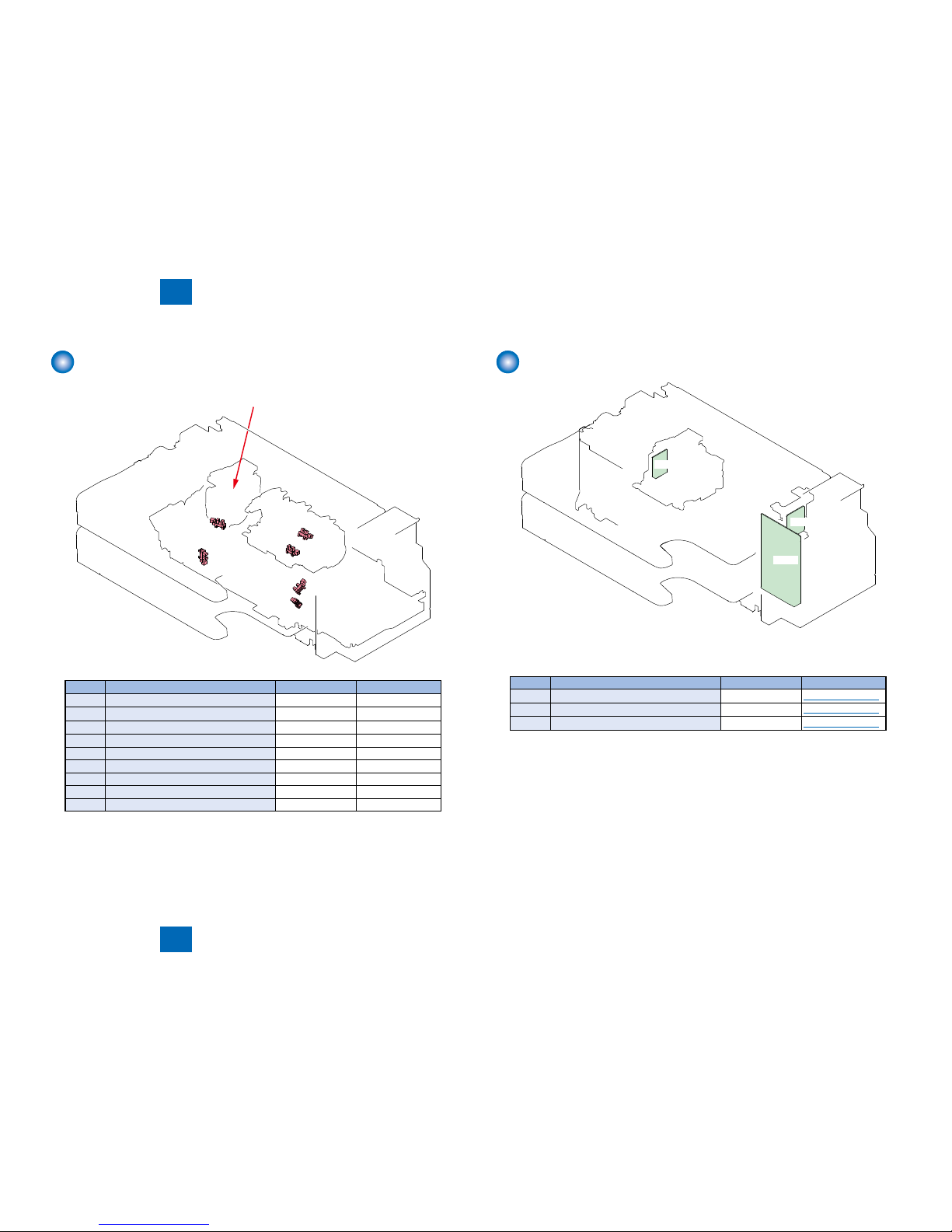

Motors/Switches/Solenoids

M12

M6

M3

M10

M4

M5

M7

M1

M2

M11

SW2

SW1

SOL2

SOL1

No. Part name Part number Reference

M1 STP move motor

FK2-8750 Refer to page 4-22

M2 Gripper unit move motor

FK2-8750 Refer to page 4-22

M3 Feed motor

FK2-8751 Refer to page 4-21

M4 Shift motor

FK2-8753 Refer to page 4-19

M5 Shift roller release motor

FK2-8752 Refer to page 4-18

M6 Entrance roller release /stopper HP

motor

FK2-8752 Refer to page 4-25

M7 Gripper open/close motor

FK2-8752 Refer to page 4-22

M10 Stapler motor

- -

M11 Tray lift motor

FK2-8754 Refer to page 4-27

M12 Additional Tray lift motor

FK2-8754 Refer to page 4-26

SW1 Front cover switch

FM4-2136 Refer to page 4-30

SW2 Stapler safety switch

FM4-2152 Refer to page 4-31

SOL1 Paper lever drive solenoid

FL3-4299 Refer to page 4-13

SOL2 Stapler solenoid

FK2-8762 Refer to page 4-15

F-4-1F-4-1

T-4-1T-4-1

Sensors1

S5

S1

S2

S3

S17

S16

S14

S15

S6

S21

S23

S22

No. Part name Part number Reference

S1 Entrance sensor

WG8-5836

S2 Shift roller HP sensor

WG8-5836

S3 Shift roller release sensor

WG8-5836

S5 Entrance roller release /stopper HP

sensor

WG8-5836

S6 Processing tray sensor

WG8-5836

S14 Stack tray clock sensor

WG8-5836

S15 Stack tray paper sensor

WG8-5836

S16 Stack tray middle sensor

WG8-5836

S17 Stack tray lower limit sensor

WG8-5836

S21 Additional tray upper/Lower limit sensor

WG8-5836

S22 Additional tray paper sensor

WG8-5836

S23 Additional tray clock sensor

WG8-5836

T-4-2T-4-2

4

4

4-3

4-3

Parts Replacement and Cleaning Procedure > List of Parts > PCBs

Parts Replacement and Cleaning Procedure > List of Parts > PCBs

Sensors2

S10

S20

S19

S18

S7

S12

S11

S9

S13

No. Part name Part number Reference

S7 Gripper unit HP sensor

WG8-5836

S9 Gripper stapler connection sensor

WG8-5836

S10 Stapler move HP sensor

WG8-5836

S11 Paper surface sensor1

WG8-5836

S12 Paper surface sensor2

WG8-5836

S13 Gripper arm sensor

WG8-5836

S18 Stapler HP sensor

-

S19 Stapler edging sensor

-

S20 Stapler sensor

-

T-4-3T-4-3

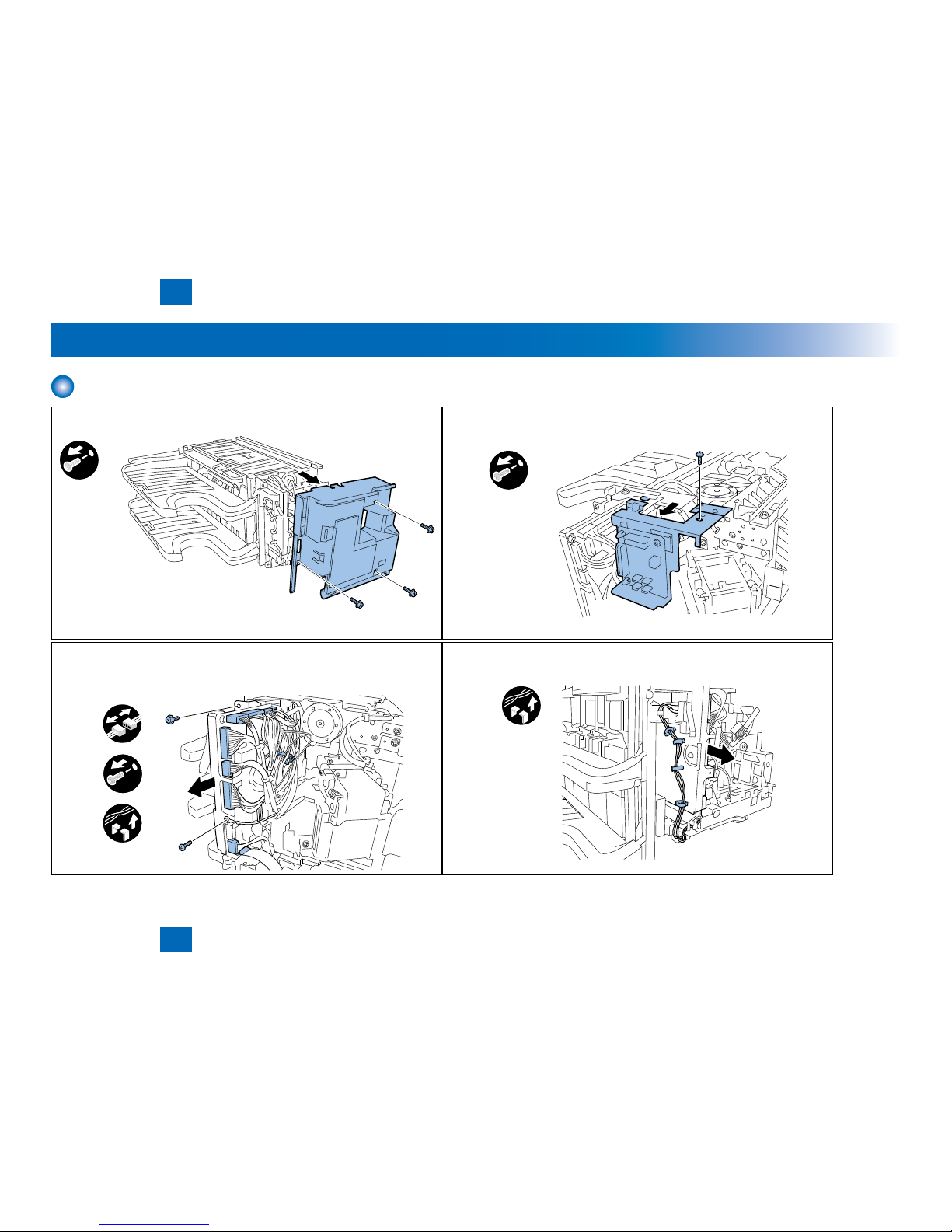

PCBs

[PCB2]

[PCB1]

[PCB3]

No. Part name Part number Reference

PCB1 Finisher controller PCB

FM4-2124 Refer to page 4-35

PCB2 Flexible cable broadcast PCB

FM4-2125 Refer to page 4-37

PCB3 Additional tray PCB

FM4-2126 Refer to page 4-34

T-4-4T-4-4

4

4

4-4

4-4

Parts Replacement and Cleaning Procedure > Main Units > Removing the Upper Unit

Parts Replacement and Cleaning Procedure > Main Units > Removing the Upper Unit

Main Units

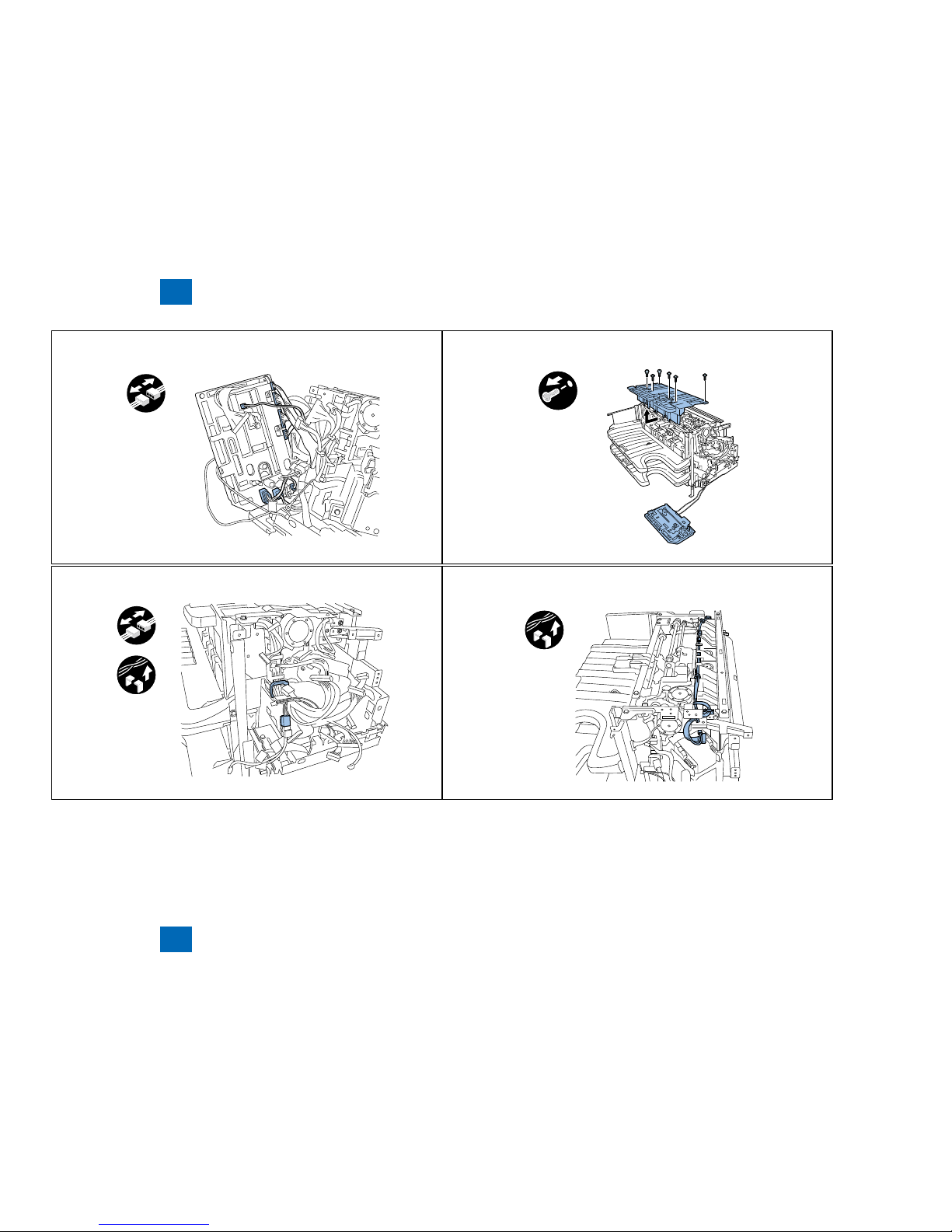

Removing the Upper Unit

1) Remove three screws and then the inner cover.

x3

F-4-2F-4-2

2) Remove the additional tray PCB along with the mount (only when the additional tray is

installed).

x1

F-4-3F-4-3

3) Disconnect one exible cable and eight connectors.

4) Remove one wire saddle.

5) Remove two screws, and then pull out the nisher controller PCB along with the mount.

x2

x9

x1

F-4-4F-4-4

6) Remove four wire saddles and the harness from the harness guide, and then pull out the

nisher controller PCB along with the mount.

x4

F-4-5F-4-5

4

4

4-5

4-5

Parts Replacement and Cleaning Procedure > Main Units > Removing the Upper Unit

Parts Replacement and Cleaning Procedure > Main Units > Removing the Upper Unit

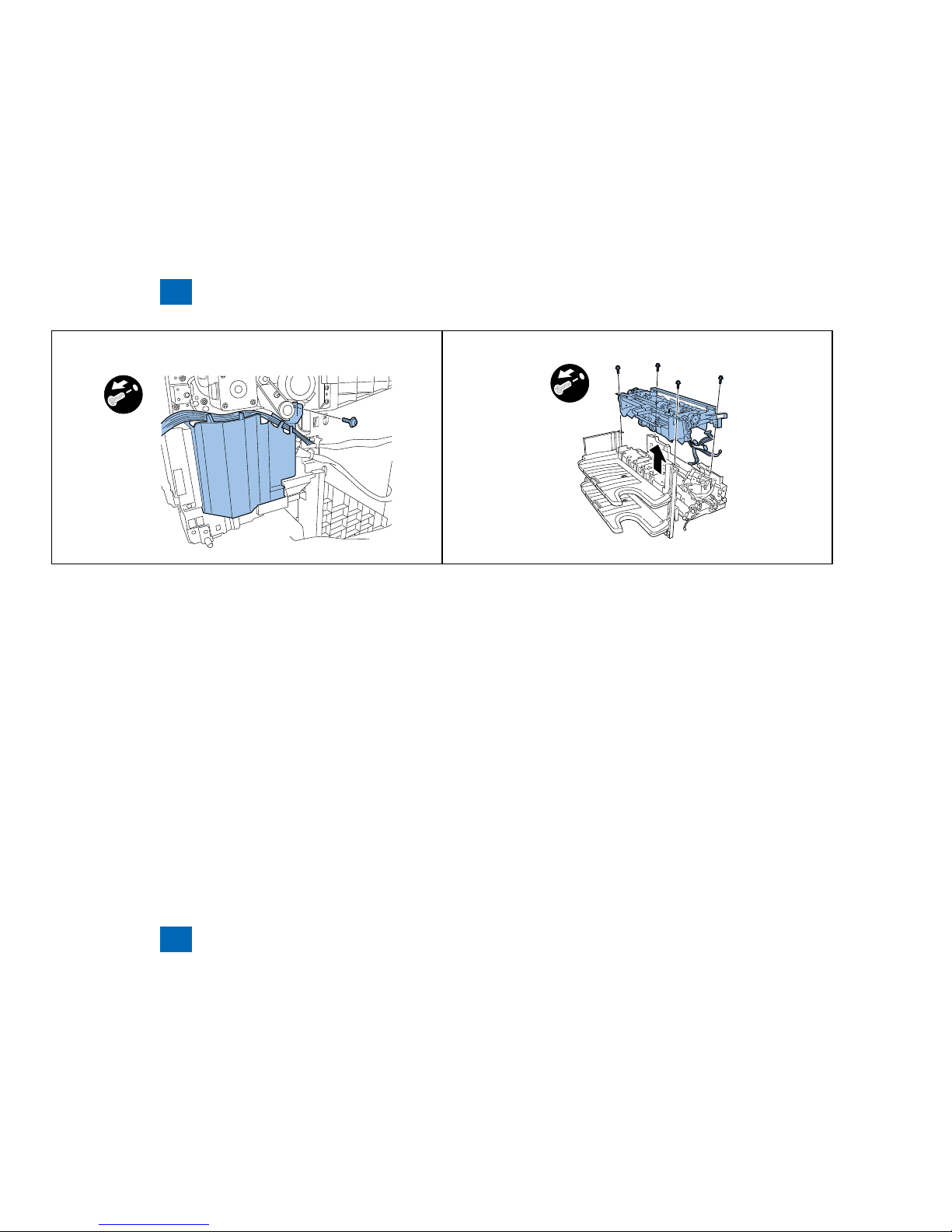

7) Disconnect eight connectors.

x8

F-4-6F-4-6

8) Place the nisher controller PCB as shown, remove six screws and then the upper guide.

x6

F-4-7F-4-7

9) Remove one wire saddle, one connector, and then the harness leading to the upper guide from

the harness guide.

x1

x1

F-4-8F-4-8

10) Remove ve wire saddles, two edge saddles, and then the additional tray harness rearward

(only when the additional tray is installed).

x7

F-4-9F-4-9

4

4

4-6

4-6

Parts Replacement and Cleaning Procedure > Main Units > Removing the Upper Unit

Parts Replacement and Cleaning Procedure > Main Units > Removing the Upper Unit

11)Remove the harness from the harness guide.

12) Remove one screw and then the cover.

x1

F-4-10F-4-10

13) Remove four screws and then the upper unit.

x4

F-4-11F-4-11

Loading...

Loading...