Page 1

Operation guide

imag e PRESS C800 Series

Page 2

Copyright

Copyright CANON INC. 2014

No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval

system, or translated into any language or computer language in any form or by any means,

electronic, mechanical, magnetic, optical, chemical, manual or otherwise, without the prior

written permission of Canon Inc.

Edition 2014-10

US

Page 3

Contents

Contents

Chapter 1

Preface................................................................................................................................. 7

Disclaimers........................................................................................................................................................8

Trademarks....................................................................................................................................................... 9

Notes for the reader....................................................................................................................................... 11

Installation precautions..................................................................................................................................12

Handling precautions..................................................................................................................................... 16

Information in this operation guide.............................................................................................................. 18

Chapter 2

Explore the print system..................................................................................................19

What can this print system do for you?........................................................................................................20

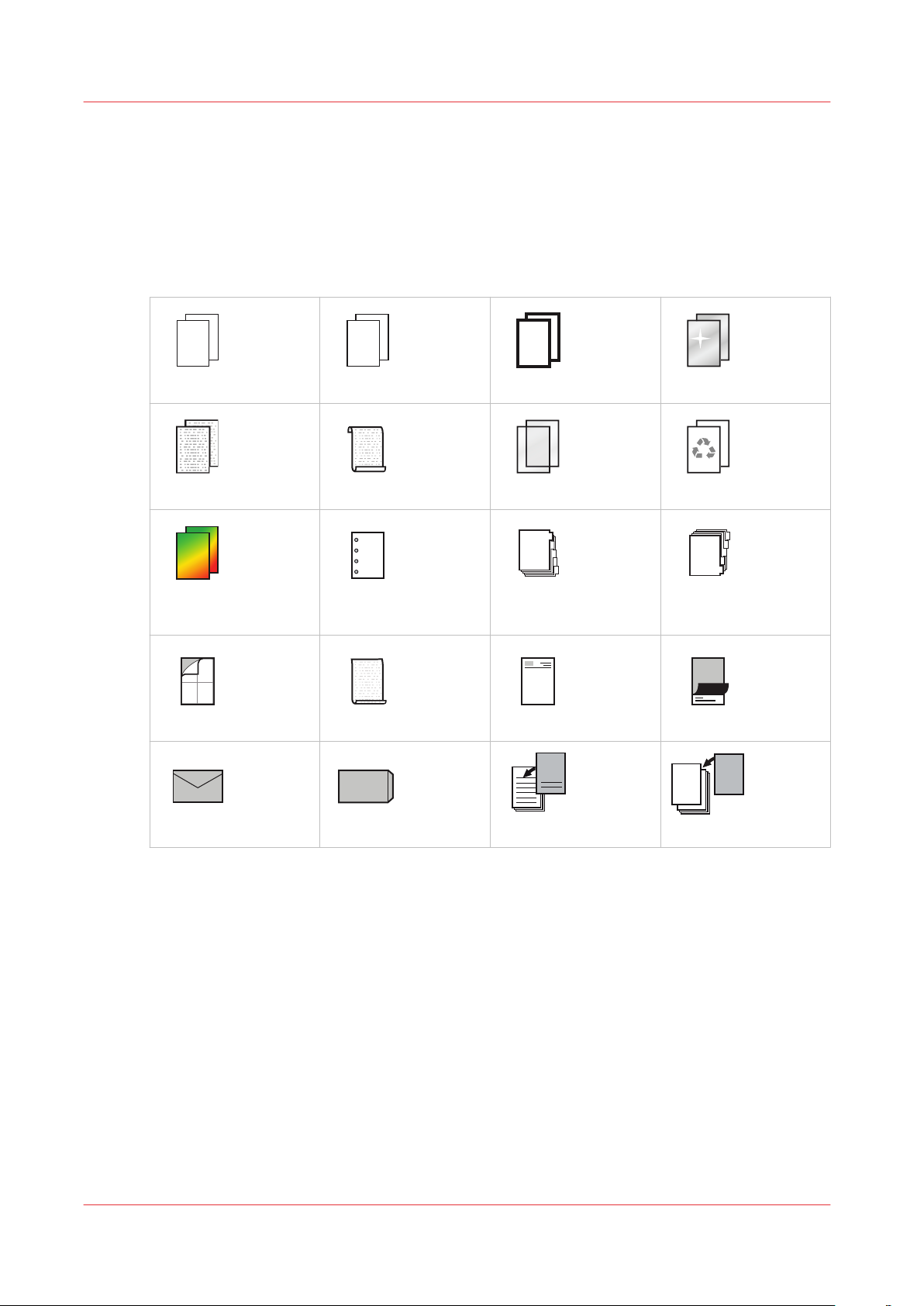

What output can you create.......................................................................................................................... 21

Media for your output..............................................................................................................................21

Finishing for your output.........................................................................................................................23

Color reproduction for your output........................................................................................................ 26

PRISMAsync operating concept....................................................................................................................28

Main hardware parts...................................................................................................................................... 32

Overview of licenses...................................................................................................................................... 35

Control panel.................................................................................................................................................. 36

Paper Input......................................................................................................................................................38

Paper module .......................................................................................................................................... 38

Bulk paper module...................................................................................................................................39

Inserter...................................................................................................................................................... 40

Automatic document feeder................................................................................................................... 41

Special feeder...........................................................................................................................................42

Finishing and delivery....................................................................................................................................43

Professional stacker / stapler.................................................................................................................. 43

Standard stacker / stapler........................................................................................................................45

Professional puncher............................................................................................................................... 46

Folder........................................................................................................................................................ 47

Output tray................................................................................................................................................48

Chapter 3

Prepare the jobs................................................................................................................ 49

Prepare print jobs........................................................................................................................................... 50

Prepare print jobs with the printer driver.............................................................................................. 50

Prepare print jobs with PRISMAprepare................................................................................................ 52

Print a file from a USB drive................................................................................................................... 54

Prepare copy and scan jobs...........................................................................................................................55

Copy jobs.................................................................................................................................................. 55

Scan jobs.................................................................................................................................................. 57

Use the automatic document feeder to copy or scan........................................................................... 59

Use the glass plate to copy or scan........................................................................................................61

Make a copy..............................................................................................................................................63

Make a scan.............................................................................................................................................. 64

Use templates for recurring jobs............................................................................................................ 66

Copy subsets (combined copying)......................................................................................................... 67

Scan subsets (combined scanning)........................................................................................................68

imagePRESS C800 Series

3

Page 4

Contents

Chapter 4

Plan the jobs......................................................................................................................69

Set up your print production preferences.................................................................................................... 70

Automated workflows............................................................................................................................. 70

Workflow profiles ....................................................................................................................................73

Select a workflow profile.........................................................................................................................79

Select an accounting mode.....................................................................................................................80

Change or disable the warning time...................................................................................................... 82

Change the system language..................................................................................................................83

Use of shorter job names........................................................................................................................ 84

Adjust the readability of the control panel ........................................................................................... 85

Use the remote monitor.......................................................................................................................... 86

Transaction printing.................................................................................................................................87

Print in transaction printing mode..........................................................................................................90

Use the DocBox.............................................................................................................................................. 91

DocBox......................................................................................................................................................91

Change a DocBox job.............................................................................................................................. 92

Combine DocBox jobs............................................................................................................................. 93

Lock DocBox job settings........................................................................................................................ 94

Print DocBox jobs.....................................................................................................................................95

Load and assign media.................................................................................................................................. 96

Add temporary media to the media catalog..........................................................................................96

Assign media to a paper tray.................................................................................................................. 97

Manage the jobs in the queue.......................................................................................................................99

Job management in the queues............................................................................................................. 99

View the jobs in the queues.................................................................................................................. 102

Bundle jobs.............................................................................................................................................103

Add extra sheets to a job.......................................................................................................................105

Change job settings............................................................................................................................... 106

Use page programming........................................................................................................................ 107

Print a waiting job ................................................................................................................................. 109

Print a scheduled job immediately....................................................................................................... 110

Move a scheduled job to the list of waiting jobs.................................................................................111

Reprint a job........................................................................................................................................... 112

Send a job to another printer................................................................................................................113

Remove print jobs..................................................................................................................................114

Chapter 5

Print the jobs................................................................................................................... 115

Proofing.........................................................................................................................................................116

Proof and test prints.............................................................................................................................. 116

Make a proof...........................................................................................................................................118

Print a job ticket......................................................................................................................................119

Keep the system printing.............................................................................................................................120

System monitoring................................................................................................................................ 120

Schedule................................................................................................................................................. 122

Load media for the scheduled jobs...................................................................................................... 125

Check the filling level of the toner cartridge........................................................................................127

Check the filling level of the staple cartridge.......................................................................................128

Check the filling level of the waste toner container............................................................................ 129

Handle media................................................................................................................................................130

Check and prepare media before loading............................................................................................130

Check and prepare envelopes before loading..................................................................................... 132

Check and prepare transparencies before loading............................................................................. 134

Load media into the internal paper trays.............................................................................................135

Load media into the paper module...................................................................................................... 137

Load media into the bulk paper module.............................................................................................. 141

Load media into the special feeder...................................................................................................... 145

4

imagePRESS C800 Series

Page 5

Contents

Load media into the inserter................................................................................................................. 147

Load envelopes into the internal paper trays...................................................................................... 149

Load tab paper into the internal paper trays....................................................................................... 152

Stop printing................................................................................................................................................. 154

Remove printed output from the stacker/stapler.......................................................................................155

Store the printed output.............................................................................................................................. 158

Chapter 6

Keep the image quality high..........................................................................................159

Calibration.....................................................................................................................................................160

About calibration....................................................................................................................................160

Calibrate the printer............................................................................................................................... 162

Calibrate the media family.................................................................................................................... 163

Calibrate for maximum print quality.................................................................................................... 165

Adjust the color quality................................................................................................................................166

About image and color adjustments.................................................................................................... 166

Adjust CMYK curves for a single job....................................................................................................167

Adjust CMYK curves for all jobs........................................................................................................... 169

Automatic color mismatch correction..................................................................................................171

Register the color tones for the ACCT function...................................................................................172

Correct the color tones with the ACCT function..................................................................................173

Create a trapping preset........................................................................................................................ 174

Adjust the print quality for media............................................................................................................... 175

About print quality for media................................................................................................................175

Correct curled output media................................................................................................................. 176

Perform a media registration................................................................................................................ 177

Correct skewed and rotated images.....................................................................................................179

Chapter 7

Maintain the print system..............................................................................................181

System configuration and maintenance.................................................................................................... 182

Consumables................................................................................................................................................ 185

Use the power modes.................................................................................................................................. 189

Turn on the print system....................................................................................................................... 189

Turn off the print system.......................................................................................................................190

Restart the print system........................................................................................................................ 191

Use the energy save modes..................................................................................................................192

Refill toner and staples................................................................................................................................ 193

Replace a toner cartridge...................................................................................................................... 193

Replace the waste toner container....................................................................................................... 196

Replace in the professional stacker / stapler the staple cartridge in the staple unit........................ 199

Replace in the professional stacker / stapler the staple cartridge in the saddle-stitch unit.............201

Replace in the standard stacker / stapler the staple cartridge in the staple unit.............................. 204

Replace in the standard stacker /stapler the staple cartridge in the saddle-stitch unit....................207

Remove the staple waste...................................................................................................................... 209

Remove in the professional stacker /stapler the punch waste ..........................................................211

Remove in the standard stacker / stapler the punch waste................................................................213

Keep the print system clean........................................................................................................................ 214

Cleaning tasks and procedures.............................................................................................................214

Clean the control panel..........................................................................................................................215

Clean the glass plate area..................................................................................................................... 216

Clean the automatic document feeder scanning area........................................................................ 217

Clean the scanning sensors.................................................................................................................. 219

Clean the automatic document feeder rollers..................................................................................... 220

Clean the inside of the print module.................................................................................................... 221

Clean the corona assembly wires.........................................................................................................222

Clean the main unit rollers.................................................................................................................... 223

Refresh the fixing belt............................................................................................................................224

Enable Remote Service................................................................................................................................ 225

imagePRESS C800 Series

5

Page 6

Contents

Read the counters.........................................................................................................................................226

Chapter 8

Help.................................................................................................................................. 227

Access the print module parts.....................................................................................................................228

Problem Solving........................................................................................................................................... 230

Optimize the scan quality of the print system........................................................................................... 232

Fix "density not within required range" error............................................................................................ 233

Chapter 9

References....................................................................................................................... 235

Job settings...................................................................................................................................................236

Copy job settings................................................................................................................................... 236

Scan job settings....................................................................................................................................240

Print job settings.................................................................................................................................... 242

Output settings, values and icons........................................................................................................ 246

Zoom function.............................................................................................................................................. 250

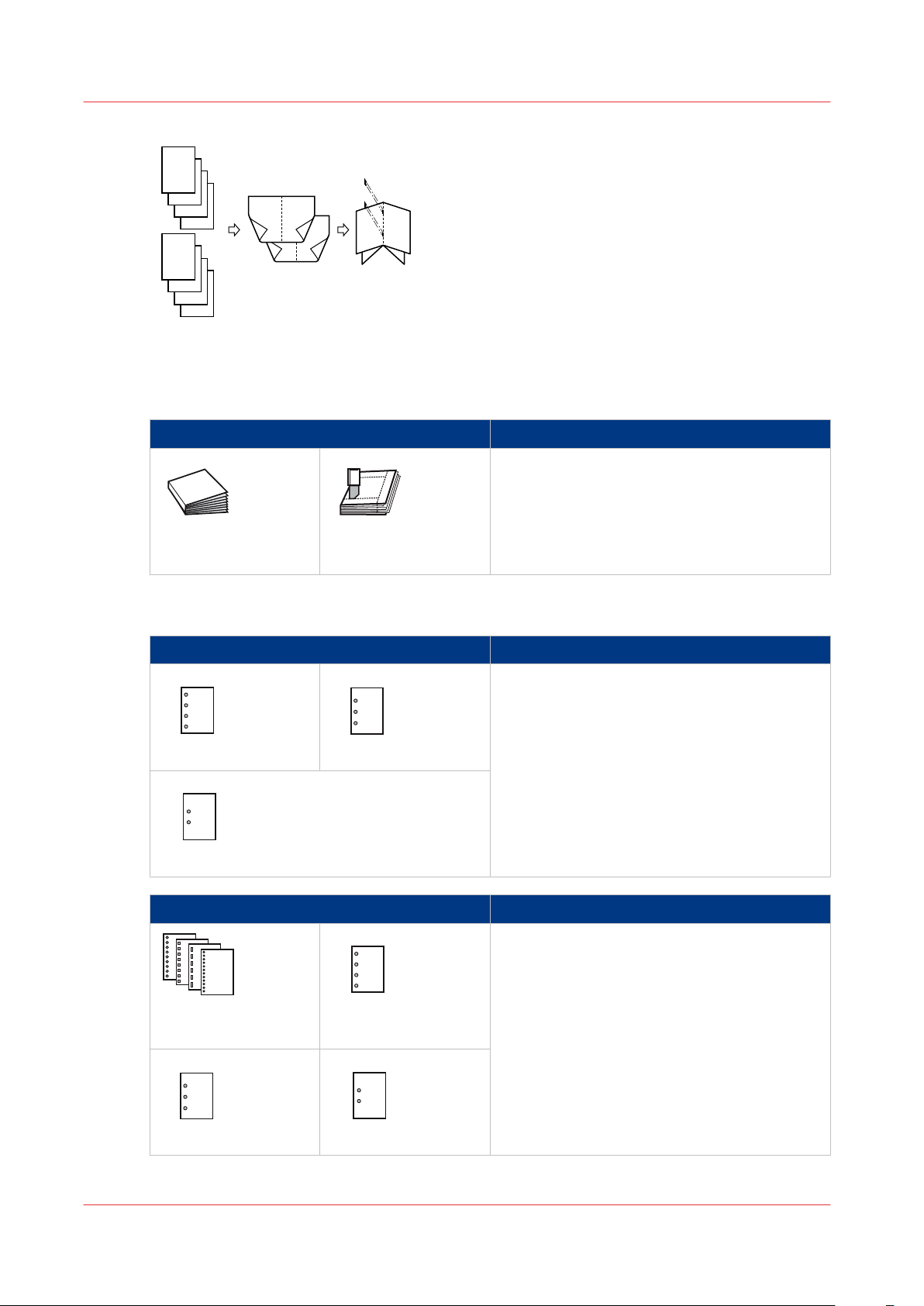

Feed direction............................................................................................................................................... 251

Feed direction for stapling.................................................................................................................... 251

Feed direction for punching.................................................................................................................. 256

Feed direction for folding...................................................................................................................... 257

Feed direction for the inserter...............................................................................................................259

Feed instruction for envelopes............................................................................................................. 261

Feed instruction for tab paper...............................................................................................................263

Status indicators...........................................................................................................................................264

Job status indicators..............................................................................................................................264

Paper tray indicators..............................................................................................................................265

More PRISMAsync color information......................................................................................................... 266

System specifications.................................................................................................................................. 268

Print system specifications....................................................................................................................268

Paper input specifications..................................................................................................................... 270

Finishing and delivery specifications .................................................................................................. 274

Remote monitor specifications............................................................................................................. 288

Media specifications.....................................................................................................................................289

Supported media types for paper input optionals.............................................................................. 289

Supported media sizes by paper input optional................................................................................. 291

Supported envelope types by paper input optional........................................................................... 292

Settings Editor.............................................................................................................................................. 293

Settings Editor specifications................................................................................................................293

Settings Editor media attributes........................................................................................................... 294

Settings Editor settings and information............................................................................................. 295

Index.................................................................................................................................305

6

imagePRESS C800 Series

Page 7

Chapter 1 Preface

Page 8

Disclaimers

Disclaimers

The information in this document is subject to change without notice.

CANON INC. MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS MATERIAL, EITHER

EXPRESS OR IMPLIED, EXCEPT AS PROVIDED HEREIN, INCLUDING WITHOUT LIMITATION,

THEREOF, WARRANTIES AS TO MARKETABILITY, MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE OF USE OR NON-INFRINGEMENT. CANON INC. SHALL NOT BE LIABLE

FOR ANY DIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OF ANY NATURE, OR LOSSES

OR EXPENSES RESULTING FROM THE USE OF THIS MATERIAL.

To view the manual in PDF format, Adobe Reader/Adobe Acrobat Reader is required. If Adobe

Reader/Adobe Acrobat Reader is not installed on your system, please download it from the

Adobe Systems Incorporated website.

Chapter 1 - Preface

8

imagePRESS C800 Series

Page 9

Trademarks

Océ, Océ PRISMA, Océ PRISMAsync, Océ PRISMAprepare and Océ PRISMAaccess are registered

trademarks of Océ.

PANTONE® Colors displayed in the software application or in the user documentation may not

match PANTONE-identified standards. Consult current PANTONE Color Publications for accurate

color. PANTONE® and other Pantone, Inc. trademarks are the property of Pantone, Inc. ©

Pantone, Inc., 2007

Pantone, Inc. is the copyright owner of color data and/or software which are licensed to (insert

name of your company) to distribute for use only in combination with (insert appropriate name of

Licensed Materials). PANTONE Color Data and/or Software shall not be copied onto another disk

or into memory unless as part of the execution of (insert appropriate name of Licensed

Materials).

Xerox is a registered trademark of Xerox Corporation.

This product contains the Universal Font Scaling Technology or UFST® under license from

Monotype Imaging, Inc. UFST® is a trademark of Monotype Imaging, Inc. registered in the United

States Patent and Trademark Office and may be registered in certain jurisdictions.

UFST: Copyright © 1989 - 1996, 1997, 2003, 2004, 2008, all rights reserved, by Monotype Imaging

Inc.

Trademarks

Apple, AppleTalk, EtherTalk, LocalTalk, Mac, Macintosh, Mac OS, and Safari are trademarks of

Apple Inc., registered in the U.S. and other countries.

Microsoft, Windows, Windows Vista, Windows Server, Internet Explorer, Excel and PowerPoint

are either registered trademarks or trademarks of Microsoft Corporation in the United States

and/or other countries.

Portions of this software are copyright © 2007 The FreeType Project (www.freetype.org). All

rights reserved.

Copyright (C) 1999, 2000, 2002 Aladdin Enterprises. All rights reserved.

Java and all Java based trademarks and logos are trademarks or registered trademarks of Oracle

and/or its affiliates.

Adobe, PostScript, and the PostScript logo are either registered trademarks or trademarks of

Adobe Systems Incorporated in the United States and/or other countries.

Copyright © 2007 -08 Adobe Systems Incorporated. All rights reserved.

Protected by U.S. Patents 5,737,599; 5,781,785; 5,819,301; 5,929,866; 5,943,063; 6,073,148;

6,515,763; 6,639,593; 6,754,382; 7,046,403; 7,213,269; 7,242,415; Patents pending in the U.S. and

other countries.

imagePRESS C800 Series

Chapter 1 - Preface

9

Page 10

Trademarks

All instances of the name PostScript in the text are references to the PostScript language as

defined by Adobe Systems Incorporated unless otherwise stated. The name PostScript also is

used as a product trademark for Adobe Systems' implementation of the PostScript language

interpreter.

Except as otherwise stated, any reference to a "PostScript printing device," "PostScript display

device," or similar item refers to a printing device, display device or item (respectively) that

contains PostScript technology created or licensed by Adobe Systems Incorporated and not to

devices or items that purport to be merely compatible with the PostScript language.

Adobe, the Adobe logo, PostScript, the PostScript logo, and PostScript 3 are either registered

trademarks or trademarks of Adobe Systems Incorporated in the United States and/or other

countries.

Linux is a registered trademark of Linus Torvalds. Microsoft and Windows are either registered

trademarks or trademarks of Microsoft Corporation in the United States and/or other countries.

All other trademarks are the property of their respective owners.

The PDF logo is a trademark or registered trademark of Adobe Systems Incorporated in the

United States and other countries.

Copyright © 2008 Adobe Systems Incorporated. All rights reserved.

Protected by U.S. Patents 6,185,684; 6,205,549; 7,213,269; 7,272,628; 7,278,168; Patents pending in

the U.S. and other countries.

All instances of the name PostScript in the text are references to the PostScript language as

defined by Adobe Systems Incorporated unless otherwise stated. The name PostScript also is

used as a product trademark for Adobe Systems' implementation of the PostScript language

interpreter.

Except as otherwise stated, any reference to a "PostScript printing device," "PostScript display

device," or similar item refers to a printing device, display device or item (respectively) that

contains PostScript technology created or licensed by Adobe Systems Incorporated and not to

devices or items that purport to be merely compatible with the PostScript language.

Adobe, the Adobe logo, PostScript, the PostScript Logo, and PostScript 3 are either registered

trademarks or trademarks of Adobe Systems Incorporated in the United States and/or other

countries.

All other trademarks are the property of their respective owners.

Other product and company names herein may be the trademarks of their respective owners.

Chapter 1 - Preface

10

imagePRESS C800 Series

Page 11

Notes for the reader

Introduction

This manual helps you to use the imagePRESS C800 Series. The manual contains a description of

the product and guidelines to use and operate the imagePRESS C800 Series.

Definition

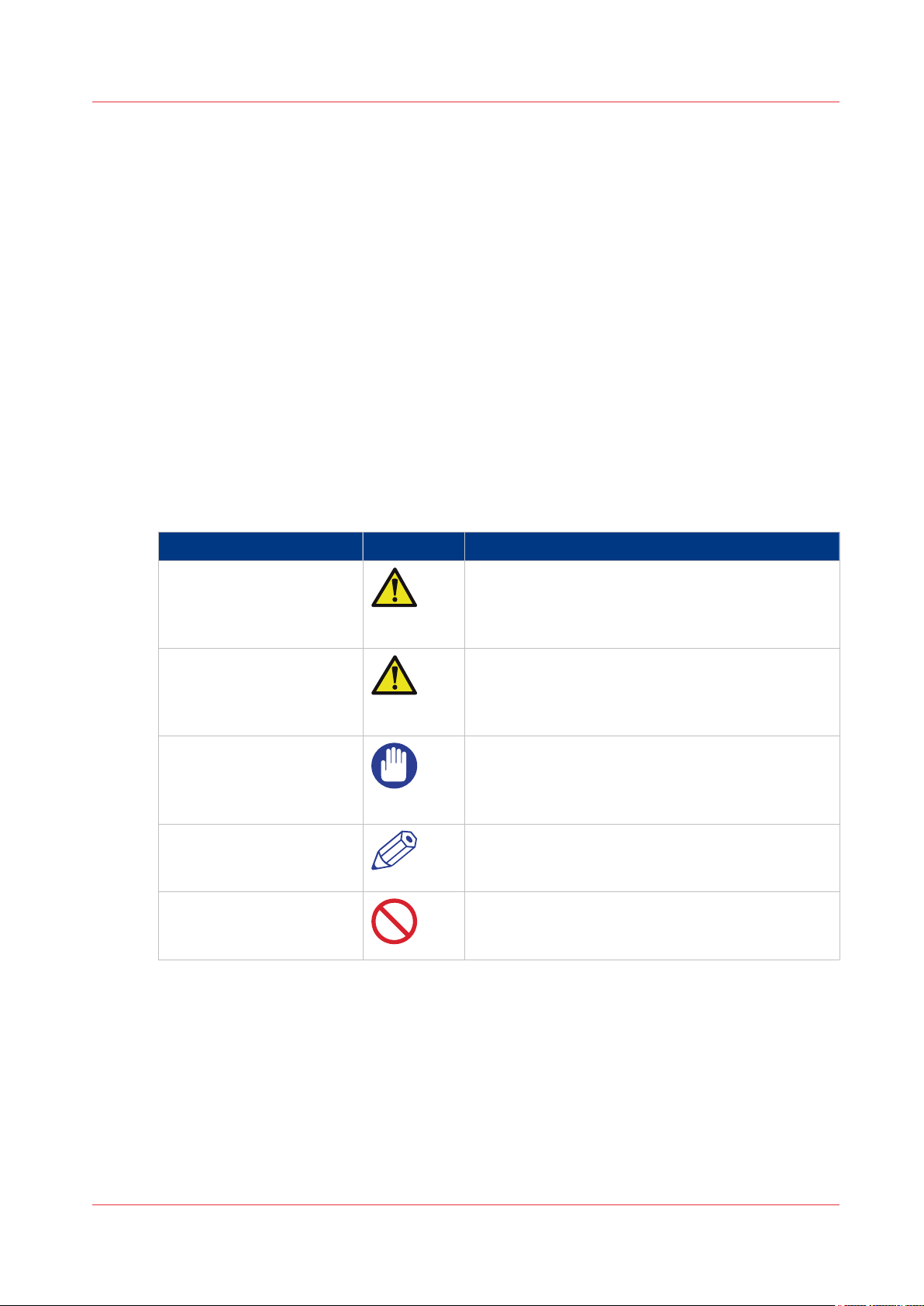

Attention-Getters

Parts of this manual require your special attention. These parts can provide the following:

• Additional general information, for example, information that is useful when you perform a

task.

• Information to prevent personal injuries or property damage.

Symbols used in this manual

The following symbols are used in this manual to explain procedures, restrictions, handling

precautions, and instructions that should be observed for safety.

Overview of the attention-getters

Word Icon Indicates

Notes for the reader

WARNING

CAUTION

IMPORTANT

NOTE

- Indicates an operation that must not be performed.

Indicates a warning concerning operations that may

lead to death or injury to persons if not performed

correctly. To use the machine safely, always pay attention to these warnings.

Indicates a caution concerning operations that may

lead to injury to persons if not performed correctly.

To use the machine safely, always pay attention to

these cautions.

Indicates operational requirements and restrictions.

Be sure to read these items carefully to operate the

machine correctly and to avoid damaging the machine or property.

Indicates a clarification of an operation or contains

additional explanations for a procedure. Reading

these notes is highly recommended.

Read these items carefully and make sure not to

perform the described operations.

imagePRESS C800 Series

Chapter 1 - Preface

11

Page 12

Installation precautions

Installation precautions

Avoid installing the machine in the following locations

•

Avoid locations subject to temperature and humidity extremes, whether low or high.

For example, avoid installing the machine near water faucets, hot water heaters, humidifiers,

air conditioners, heaters, or stoves.

•

Avoid installing the machine in direct sunlight.

If this is unavoidable, use curtains to shade the machine. Be sure that the curtains do not block

the machine's ventilation slots or louvers, or interfere with the electrical cord or power supply.

•

Avoid poorly ventilated locations.

This machine generates a slight amount of ozone etc. during normal use. Although sensitivity

to ozone etc. may vary, this amount is not harmful. Ozone etc. may be more noticeable during

extended use or long production runs, especially in poorly ventilated rooms. It is

recommended that the room be appropriately ventilated, sufficient to maintain a comfortable

working environment, in areas of machine operation. In addition, do not install this machine

where it exhausts directly onto a person.

•

Avoid locations where a considerable amount of dust accumulates.

•

Avoid locations where ammonia gas is emitted.

Chapter 1 - Preface

12

imagePRESS C800 Series

Page 13

Installation precautions

•

Avoid locations near volatile or flammable materials, such as alcohol or paint thinner.

•

Avoid locations that are subject to vibration.

For example, avoid installing the machine on unstable floors or stands.

•

Avoid exposing the machine to rapid changes in temperature.

If the room in which the machine is installed is cold but rapidly heated, water droplets

(condensation) may form inside the machine. This may result in a noticeable degradation in

the quality of the copied image, the inability to properly scan an original, or the copies having

no printed image at all.

•

Avoid installing the machine near computers or other precision electronic equipment.

Electrical interference and vibrations generated by the machine during printing can adversely

affect the operation of such equipment.

•

Avoid installing the machine near televisions, radios, or similar electronic equipment.

The machine might interfere with sound and picture signal reception. Insert the power plug

into a dedicated power outlet, and maintain as much space as possible between the machine

and other electronic equipment.

•

Contact an authorized Canon dealer if communication is unavailable.

Depending on your locale or your telephone connection, you may be unable to perform data

communication. In this case, contact your local authorized Canon dealer.

•

Do not remove the machine's leveling feet.

imagePRESS C800 Series

Chapter 1 - Preface

13

Page 14

Installation precautions

Do not remove the machine's leveling feet after the machine has been installed.

If you put weight on the front of the machine while the drawers are pulled out, the machine

may fall forward. To prevent this from happening, make sure that the machine's leveling feet

are in place.

•

Avoid installing the machine at high altitudes of about 3,000 meters above sea level, or

higher.

Machines with a hard disk may not operate properly when used at high altitudes of about 3,000

meters above sea level, or higher.

Select a safe power supply

•

Plug the machine into an outlet that is 208 V AC 20 A or greater.

•

Make sure that the power supply for the machine is safe, and has a steady voltage.

•

Do not connect other electrical equipment to the same power outlet to which the machine is

connected.

•

Do not connect the power cord to a multiplug power strip, as this may cause a fire or

electrical shock.

•

The power cord may become damaged if it is stepped on, affixed with staples, or if heavy

objects are placed on it. Continued use of a damaged power cord can lead to an accident, such

as a fire or electrical shock.

•

The power cord should not be taut, as this may lead to a loose connection and cause

overheating, which could result in a fire.

•

If excessive stress is applied to the connection part of the power cord, it may damage the

power cord or the wires inside the machine may disconnect. This could result in a fire. Avoid

the following situations:

• Connecting and disconnecting the power cord frequently.

• Tripping over the power cord.

• The power cord is bent near the connection part, and continuous stress is being applied to

the power outlet or the connection part.

• Applying excessive force on the power plug.

Moving the machine

If you intend to move the machine, even to a location on the same floor of your building, contact

your local authorized Canon dealer beforehand. Do not attempt to move the machine yourself.

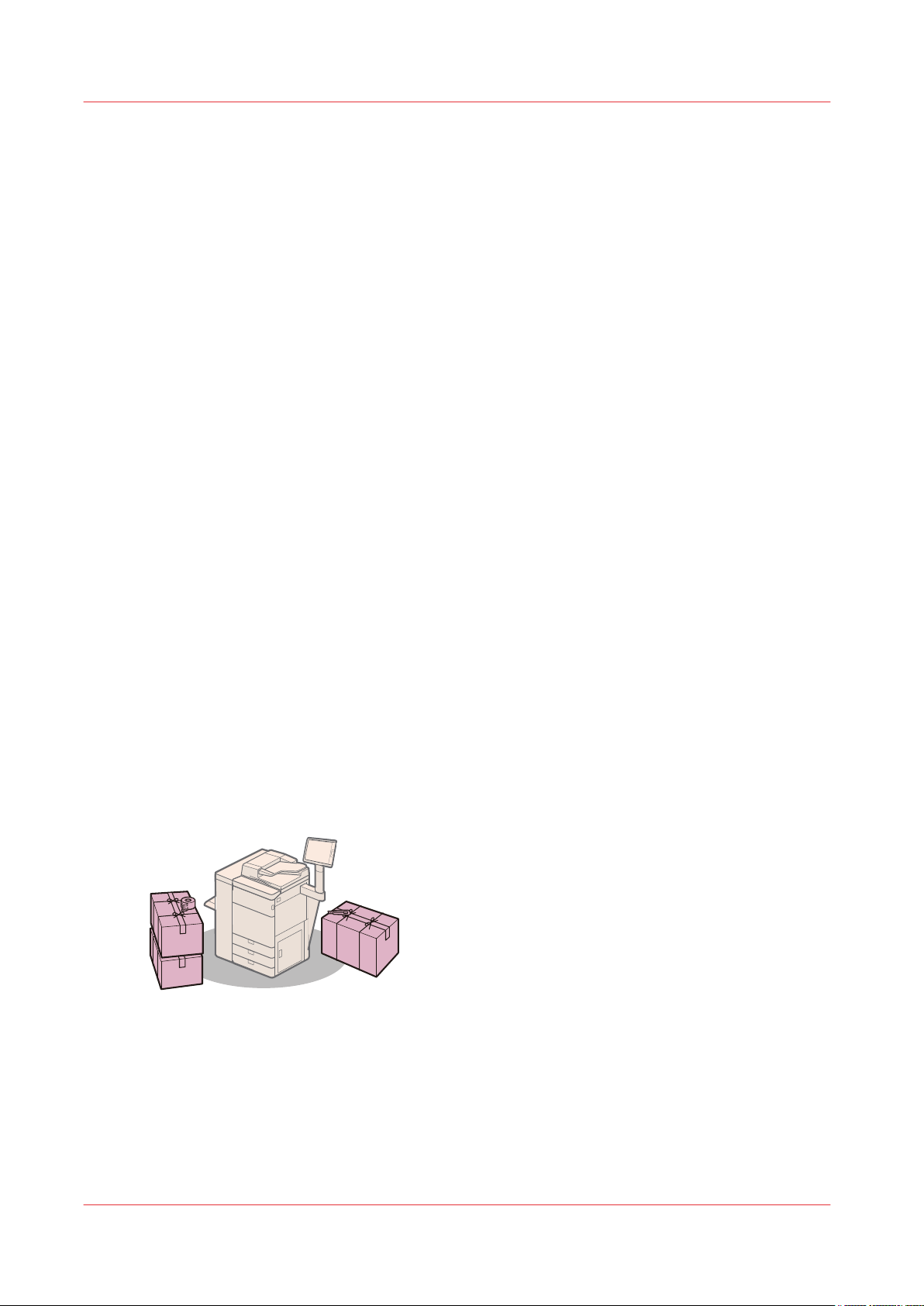

Provide Adequate Installation Space

Provide enough space on each side of the machine for unrestricted operation.

When the Output Tray-A1, Duplex Color Image Reader Unit-H1, and control panel are attached:

Chapter 1 - Preface

14

imagePRESS C800 Series

Page 15

100 mm /4” *1

1,952 mm / 76 7/8”

1,524 mm / 60”

800 mm / 31 1/2” *2

6,445 mm / 253 3/4”

1,765 mm / 69 1/2”

Installation precautions

*1 Make sure to provide at least 800 mm / 31 1/2" of space if you attach one or more of the

following: Paper Folding Unit-F1, Professional Puncher-C1, Document Insertion Unit-M1 or MultiDrawer Paper Deck-A1..

When the Two-Knife Booklet Trimmer-A1, Booklet Trimmer-D1, Saddle Finisher-AM2, Paper

Folding Unit-F1, Perfect Binder-D1, Professional Puncher Integration Unit-A1, Professional

Puncher-C1, Document Insertion Unit-M1, Duplex Color Image Reader Unit-H1, control panel,

and Multi-Drawer Paper Deck-A1. are attached:

*2 Make sure you provide at least 100 mm / 4" of space if none of the Paper Folding Unit-F1,

Professional Puncher-C1, Document Insertion Unit-M1, or Multi-Drawer Paper Deck-A1. are

attached.

imagePRESS C800 Series

Chapter 1 - Preface

15

Page 16

Handling precautions

Handling precautions

Do not attempt to disassemble or modify the machine.

Some parts inside the machine are subject to high voltages and temperatures. Take adequate

precautions when inspecting the inside of the machine. Do not carry out any inspections that are

not described in the manuals for this machine.

Be careful not to spill liquid or drop any foreign objects, such as paper clips or staples inside the

machine. If a foreign object comes into contact with electrical parts inside the machine, it might

cause a short circuit and result in a fire or electrical shock.

Chapter 1 - Preface

16

If there is smoke, or unusual noise, immediately turn the main power switch OFF, disconnect the

power cord from the power outlet, and then call your local authorized Canon dealer. Using the

machine in this state may cause a fire or electrical shock. Also, avoid placing objects around the

power plug so that the machine can be disconnected whenever necessary.

Do not turn the main power switch OFF or open the front covers while the machine is in

operation. This may result in paper jams.

Do not use flammable sprays, such as spray glue, near the machine. There is a danger of

ignition.

imagePRESS C800 Series

Page 17

Handling precautions

This machine generates a slight amount of ozone etc. during normal use. Although sensitivity to

ozone etc. may vary, this amount is not harmful. Ozone etc. may be more noticeable during

extended use or long production runs, especially in poorly ventilated rooms. It is recommended

that the room be appropriately ventilated, sufficient to maintain a comfortable working

environment, in areas of machine operation.

For safety reasons, press the sleep button

when it will not be used for a long period of time,

such as overnight. As an added safety measure, turn OFF the main power switch, and disconnect

the power cord when the machine will not be used for an extended period of time, such as

during consecutive holidays.

Use a USB cable that is shorter than 3 meters / 9' 10" inch.

Paper that has just been output from the machine may be hot. Be careful when removing or

aligning paper from the output tray. Touching paper right after it is output may result in lowtemperature burns.

imagePRESS C800 Series

Chapter 1 - Preface

17

Page 18

Information in this operation guide

Information in this operation guide

Read this operation guide to learn what this product can do for you, how to operate and maintain

the print system and how to use it in a safe way.

The guide begins with basic information on the print system parts, the concept workflow and an

overview of useful functions (Chapter 2).

In the next chapters you can find instructions that detail how to prepare, submit, plan and print

jobs in (Chapter 3, 4 and 5). Please read the media handling instructions carefully.

To keep the image quality high, it is important to read the calibration information and the

instructions detailing how to adjust the color and media quality (Chapter 6).

Maintenance instructions teach you how to keep the print system clean and the performance high

(Chapter 7).

When you encounter problems, you can find some useful solutions for common problems

(Chapter 8).

The reference chapter provides you with topics and detailed information and specifications about

your product and the product supplies (Chapter 9).

Other product information

On the downloads site downloads.oce.com you can find the following product information:

• Separate operation guides for the print system and system accessories

• Separate reference guides for the product

• Separate safety guides for the print system and system accessories

• Third party software overview

Guides on the use of optionals

This operation guide includes the functions and descriptions of the following finishing optionals:

• Document Insertion Unit-M1

• Professional Puncher-C1 and Professional Puncher Integration Unit-A1

• Paper Folding Unit-F1

• Finisher-AM1 / Saddle Finisher-AM2

• Puncher Unit-BS1

• Staple Finisher-T1 / Booklet Finisher-T1

• External 2/3 Hole Puncher-C1

The following optionals have their own operation guides:

• Perfect Binder-D1

• High Capacity Stacker-G1

• Booklet Trimmer-D1

• Two-Knife Booklet Trimmer-A1

Chapter 1 - Preface

18

imagePRESS C800 Series

Page 19

Chapter 2 Explore the print system

Page 20

What can this print system do for you?

What can this print system do for you?

The imagePRESS C800 Series is an easy-to-use multitasking print system that offers many useful

functions.

•

There is one central control panel, the single point of control, which simplifies the print

process.

•

The workflow concept places the operator at the control panel in a central position. The print

operator can manage colors, jobs and schedules, and last-minute job changes from the control

panel.

•

The workflow concept supports efficient task splitting to make the best use of staff resources

and expertise.

•

The central media catalog is available across the whole print workflow. This ensures first-timeright output.

•

The intelligent color management helps you: without an expert color knowledge, you can

reproduce a high and consistent color quality.

•

The input and finishing optionals support many different media types and finishing options.

The print system can staple, fold, trim or punch the printed output in various ways. You can

print professional looking, high quality output, such as stapled booklets and books with glued,

preprinted covers.

•

You can use the print system in two modes: document printing and transaction printing.

This operation guide helps you to meet business demands when you prepare, plan and print your

jobs with the print system.

Chapter 2 - Explore the print system

20

imagePRESS C800 Series

Page 21

What output can you create

Media for your output

Media catalog for media selection

PRISMAsync controls the media definition centrally with the media catalogue. The controller's

media-based workflow PRISMAsync results in less mistakes.

page 28 (See )

When you prepare a job, you can select media from the media catalog. The media catalog stores

attributes for all media that are key to the print quality, such as size, weight, media type, color,

media family and surface. (See

A media family is a group of media that has the same specifications and uses the same color

output profile. (See

After the job submission, use the schedule to see which media the job requires and when to

assign these media to paper trays.

Temporary media

Color reproduction for your output

Settings Editor media attributes

What output can you create

PRISMAsync operating concept

on page 294)

on page 26)

on

During the job preparation you can also temporarily specify media for a job. Temporary media

are not part of the media catalog. When the job is printed on temporary media, you can find these

temporary media in the media section of the System view on the control panel. When you want

to use these media more often, you can add the temporary media to the media catalog. In the

Settings Editor you can define the attributes for these new media.

The temporary media remains available in the System view as long as there are jobs in the queue

that use these temporary media, or these temporary media are assigned to a paper tray.

Media and image quality

Media has a big influence on the image quality and the productivity of a print system. The

performance of a print system, the print quality and the consumption of consumables depend on

media factors, such as:

• Media type

• Media weight

• Surface

• Moisture content

• Smoothness

To ensure optimal output quality and performance, media must comply with the paper

specifications of your print system. Store the media in a dry environment away from direct

sunlight. Before you load the media into the paper trays, it is important to check the media

sheets.

For information detailing how to check and prepare media, see:

Check and prepare media before loading

Check and prepare envelopes before loading

Check and prepare transparencies before loading

imagePRESS C800 Series

on page 130

on page 132

on page 134

Chapter 2 - Explore the print system

21

Page 22

5

4

3

2

1

1

2

3

4

5

Media for your output

Types of media for the paper trays

The paper trays of your print system can handle a variety of media types and sizes, including

uncoated, offset coated, plain, recycled, thin, satinated, tabs, textured paper, digital coated media,

preprinted media and offset coated media. You can use envelopes, tab paper and transparencies

in most paper trays. For covers, insert sheets and separator sheets between sets, you can use the

inserter.

The following table shows the types of media that paper trays support.

Thin Plain Heavy

Textured

Color

Vellum

Prepunched

Transparencies *1 Recycled

Forward-order tab paper

Labels *1 *2

Envelope type a *1

Bond

Envelope type b *1

Letterhead Carbonless

Preprinted covers *3 Insert sheets *3

Coated

Reverse-order tab paper

*1 Not supported by the inserter

*2 Not supported by the internal paper trays

*3 The inserter supports insert sheets. Make sure that the media you use for the inserter have the

insert sheet definition in the media catalog. (See

Settings Editor media attributes

on page 294)

For more information on media specifications, see:

Consumables

Paper input specifications

Supported media types for paper input optionals

Chapter 2 - Explore the print system

22

on page 185

on page 270

on page 289

imagePRESS C800 Series

Page 23

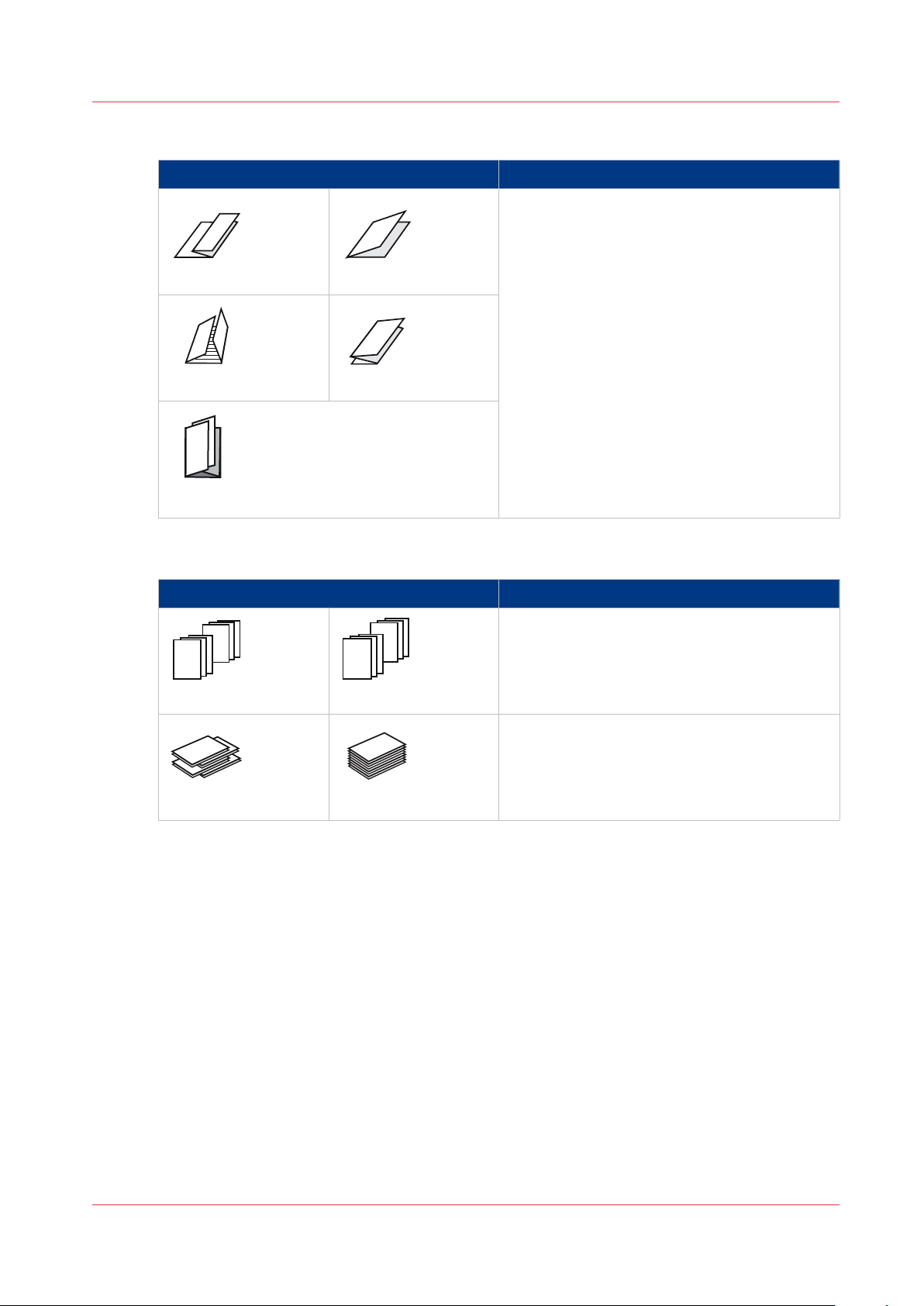

Finishing for your output

If your print system has finishing options, you can select staple, punch, trim, booklet and book

options in the printer driver, the PRISMA software, and the control panel.

NOTE

The control panel shows the finishing options that are available on your print system.

Below you find an overview of the finishing options the print system supports.

Stapling

Stapling options Finishing optional

Finishing for your output

Stacker/stapler

Corner stapling

The feed direction of originals is important for stapled copies.

page 251 (See )

Booklet making

Booklet options Finishing optionals

Saddle-stitched booklet

Saddle-stitched booklet, leading-edge trimmed

Saddle-stitched booklet, trimmed at three

sides

2-side stapling

Feed direction for stapling

Stacker/stapler

Saddle-stitch unit

Stacker/stapler

Saddle-stitch unit

Booklet trimmer

Stacker/stapler

Saddle-stitch unit

Booklet trimmer

Two-knife booklet trimmer

on

imagePRESS C800 Series

Chapter 2 - Explore the print system

23

Page 24

6

5

4

3

3

4

3

2

1

8

7

6

5

8

7

2

1

6

8

1

Finishing for your output

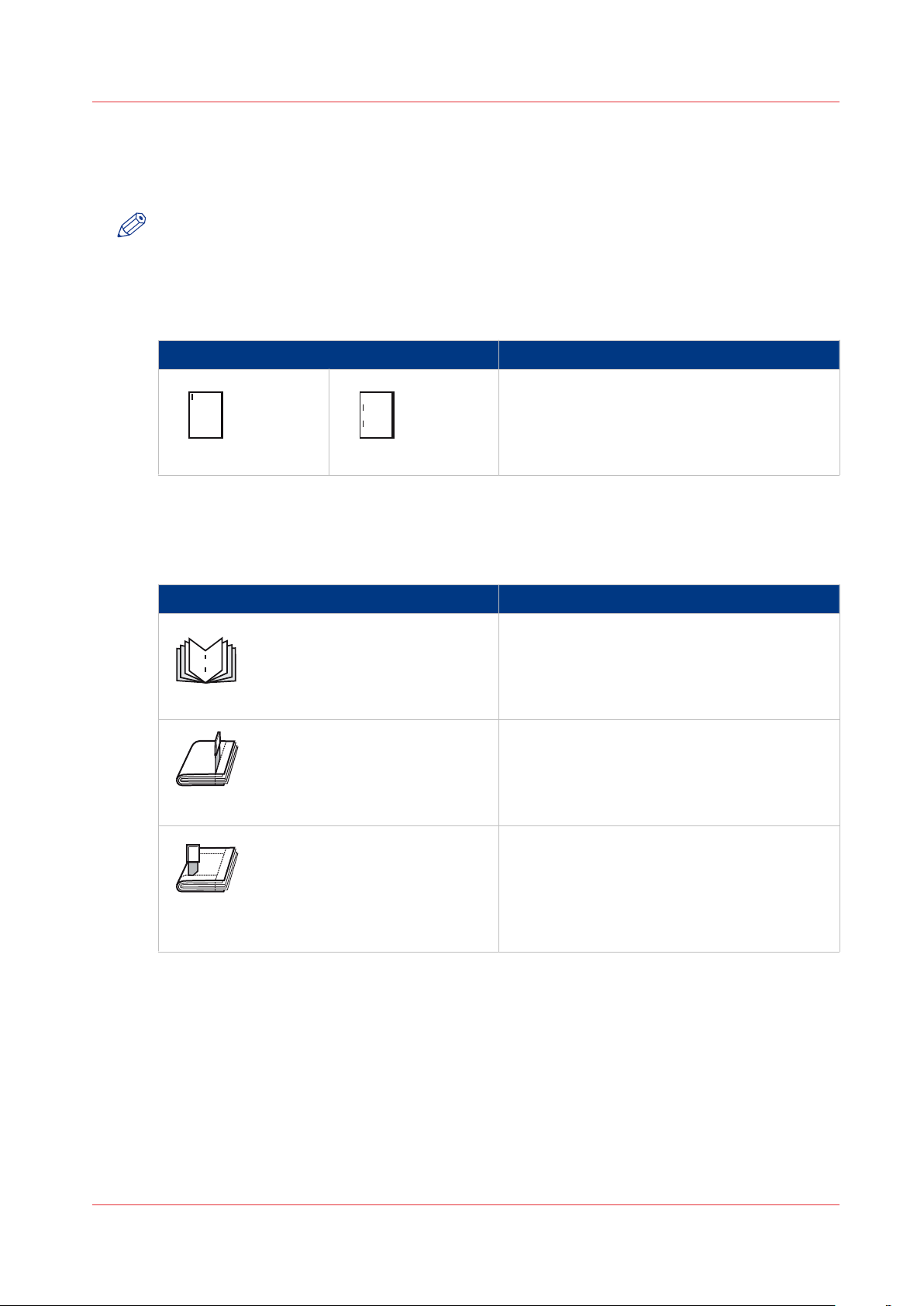

[2] Print and page order of booklets

Perfect binding

Perfect binding options Finishing optional

Perfect binder

Punching

Perfect bound book Perfect bound book,

trimmed at three sides

Punch options Finishing optionals

Stacker/stapler

Punch unit

4-holes punching

3-holes punching

2-holes punching

Professional punching options Finishing optionals

Professional puncher

Die sets

Punching with various

4-holes punching

punch patterns

3-holes punching

24

Chapter 2 - Explore the print system

2-holes punching

imagePRESS C800 Series

Page 25

Folding

1

2

3

1

2

3

2

2

2

1

1

1

Finishing for your output

Folding options Finishing optional

Folder

Z-fold Half-fold

Tri-fold in

Parallel fold

Stacking and sorting

Stacking and sorting Finishing optionals

Sort by set

Offset stacked Stacked

Tri-fold out

Stacker/stapler

High capacity stacker

Sort by page

Stacker/stapler

High capacity stacker

For more information on finishing specifications and options, see:

Main hardware parts

Print job settings

Finishing and delivery

Finishing and delivery specifications

Output settings values and icons

imagePRESS C800 Series

on page 32

on page 242

on page 43

on page 274

on page 246

Chapter 2 - Explore the print system

25

Page 26

Color reproduction for your output

Color reproduction for your output

PRISMAsync color reproduction

The color management of PRISMAsync controls the reproduction of colors and handles the

conversion of input colors (RGB, CMYK, spot colors) to printed colors on paper. PRISMAsync has

two instruments for easy color management across the entire workflow, color presets and media

families, so that the operator does not need to perform color management tasks on a job-by-job

basis.

Color experts can use more color management functions with the advanced color management

license.

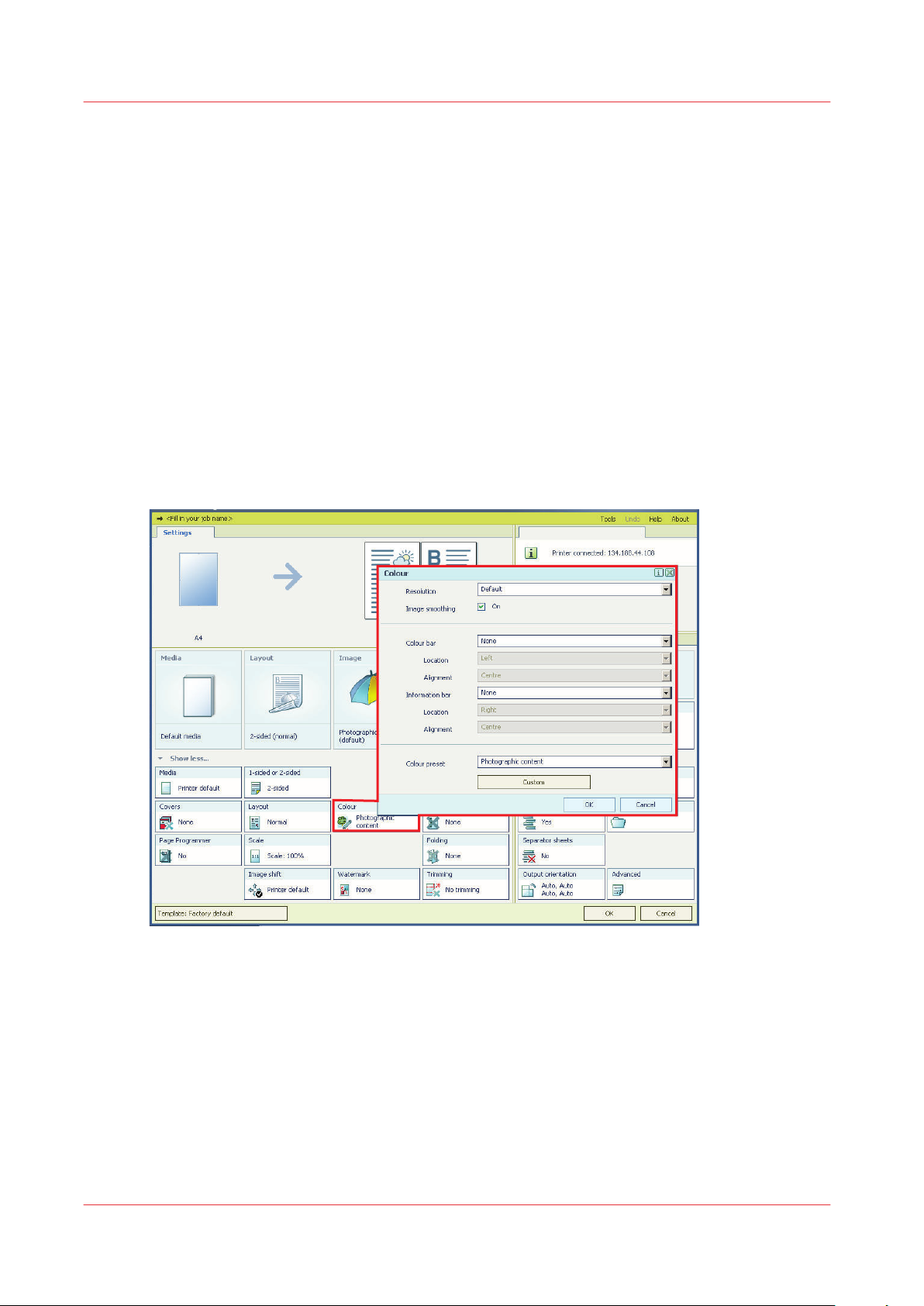

Color Presets

The PRISMAsync color presets simplify the complexity of color management. You can select an

appropriate color preset when you prepare a print job with a printer driver or PRISMA software.

An automated workflow or a hotfolder can also link a color preset to a job. The use of color

presets saves time and does not require an in-depth knowledge on color.

[3] The color settings in the printer driver

PRISMAsync includes the following default color presets:

•

Office documents

This color preset is optimal for color reproduction of text and graphic lines in office documents.

PRISMAsync converts the colors to more saturated colors for the printed output.

•

Photographic content

This color preset is optimal for the reproduction of photographs, pictures, and images.

Create new color presets in the Settings Editor. (See

Chapter 2 - Explore the print system

26

System configuration

on page 182)

imagePRESS C800 Series

Page 27

Media Families

A media family is a set of media that has comparable specifications, such as surface, color and

substrate type. A media family defines the color output profiles for the media. Each media family

has three different output profiles, for the halftone screens Normal, Fine, and Error-diffusion.

When you have more than one halftone screen in a single job or page, PRISMAsync automatically

applies the related output profiles for optimal color management in the job.

When you add new media to the media catalog, you specify the media family.

Advanced color management

The Advanced color management license offers the following color features:

•

Device simulation, to simulate or proof other print engines or offset presses with your print

system.

•

Device Link support, to import Device Link profiles for special CMYK conversions.

•

Named color profile import and export, to extend the functionality of spot color libraries.

•

Information bars, to print extra metadata on printed output. There is one default information

bar, but you can compose other information bars. Information bar selection is possible in the

printer driver, PRISMAprepare, and via automated workflows or hotfolders.

•

Color control bars, to print extra color patches for control of color output via FOGRA

verification. Using a color bar you can check the ink density, dot grain and contrast. Use default

or compose custom color bars. The color bar selection is available in the printer driver,

PRISMAprepare, and via automated workflows or hotfolders.

•

Color mappings, to convert RGB, CMYK to a specific color, for example, your corporate color.

Color mappings are useful to map colors in the input file to a fixed color of a spot color library.

•

Leave out separations, to exclude specific spot colors from printing. You can exclude layers for

printing when you map the colors of these layers to a spot color with the value “None”.

Color reproduction for your output

For more PRISMAsync color information, see

Calibration

Daily printer calibration is very important to maintain high quality color reproduction. Media

family calibration is important to maintain consistent color reproduction levels for all the media

you use. The control panel indicates when printer calibration is needed. (See

page 160)

More PRISMAsync color information

About calibration

on page 266.

on

imagePRESS C800 Series

Chapter 2 - Explore the print system

27

Page 28

PRISMAsync operating concept

PRISMAsync operating concept

PRISMAsync makes print, copy and scan jobs intuitive and productive. This fully integrated

controller supports the setup of the workflow, prepress and job routing. The following concepts

support your way of working.

•

Task-based workflow

The task-based workflow structures the tasks for the staff involved with the print system.

•

Print operator is in the central position of the workflow

The control panel is the central information point for the print operator. The print operator is

responsible for the job planning and the print production, but can also perform last-minute job

changes and color management from the control panel.

•

Media-based workflow

The media catalog is an integrated, central catalog with predefined media that meet the print

system specifications.

•

Two print modes

There are two printing modes: the document printing mode and the optional transaction

printing mode (via IPDS or PCL6). A system reboot is not necessary to switch between the

printing modes.

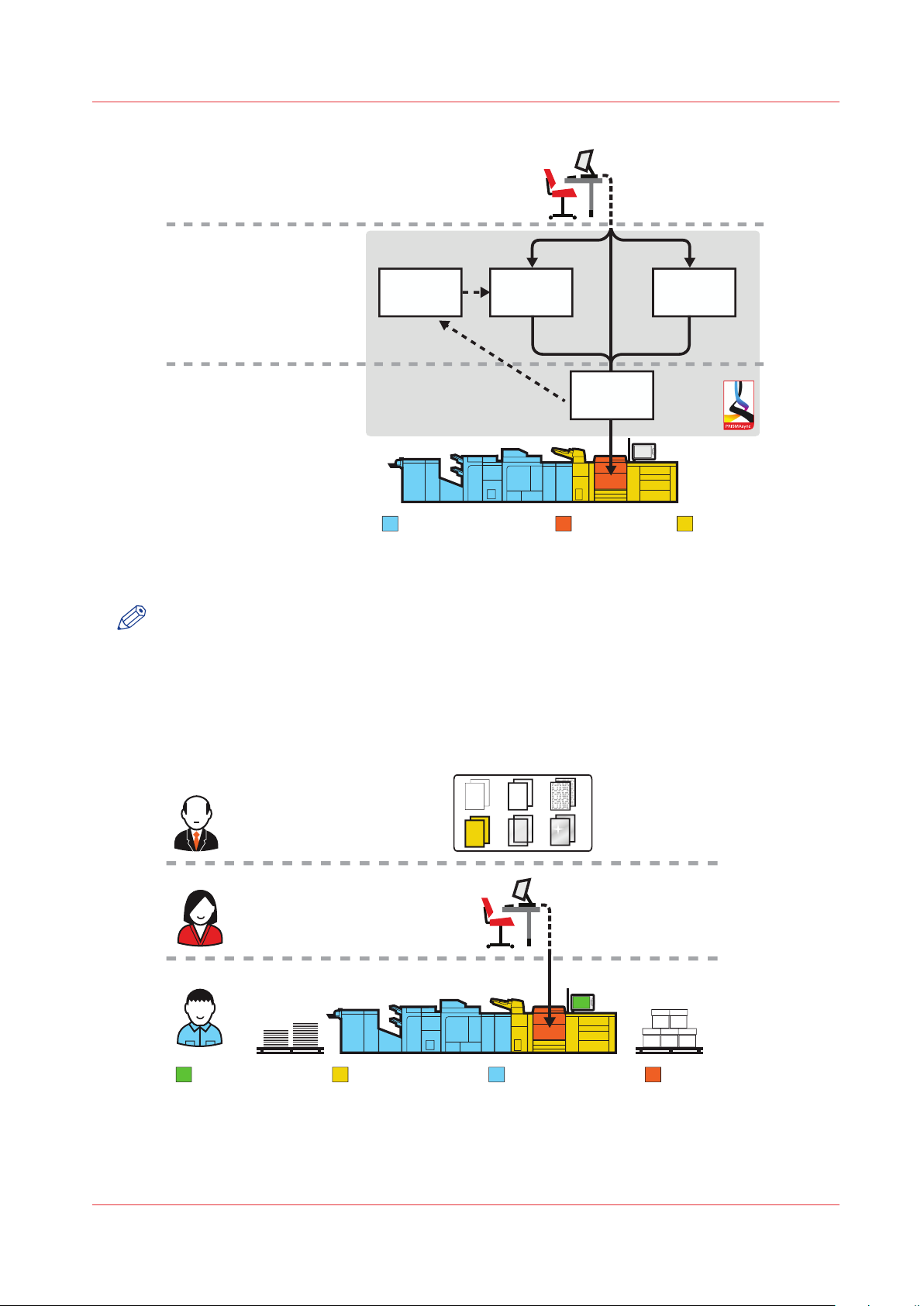

Document printing workflow

The document printing workflow describes the route from the job preparation to the finishing and

delivery of the printed output. The document printing workflow has three phases:

1.

Job preparation

Prepress staff defines the print document and job settings, and submits the print job to the

PRISMAsync controller. The prepress staff uses PRISMA software, a printer driver, automated

workflows or hotfolders to prepare and submit the jobs.

2.

Job planning

Print jobs arrive in one of the following PRISMAsync job locations: a DocBox , the list of

waiting jobs or the list of scheduled jobs. The active workflow profile determines how

toPRISMAsync route the jobs. The print operator is responsible for the job planning.

3.

Print job production

The print system prints and finishes jobs according to the job sequence in the list of

scheduled jobs. The print operator enables the system to keep running.

Chapter 2 - Explore the print system

28

imagePRESS C800 Series

Page 29

DocBox

Scheduled

jobs

Finishing and delivery Printing Media loading

Waiting

jobs

Printed

jobs

Job preparation

Print production

Job planning

Finishing and delivery Refilling toner and

staples

Media loading

Print operator

Prepress

Job planning

Media and color expert

PRISMAsync operating concept

Staff roles and tasks

[4] Job workflow for document printing mode

NOTE

Transaction printing

See

on page 87 for the workflow in the transaction printing mode.

The task-based workflow structures the tasks in the print environment. There are task splits

between job preparation, job planning, and print production.

imagePRESS C800 Series

[5] Task-based workflow

The prepress staff know the quality requirements of the jobs and the way to submit the jobs.

Chapter 2 - Explore the print system

29

Page 30

Print operator loads and assigns the media in the paper trays.

Prepress staff select the required media from

the media catalog.

The media and color expert defines the

media and color settings once in the media

catalog.

PRISMAsync operating concept

The print operators can concentrate on the job planning and the print production. Therefore, the

print operator does the following tasks:

• Starts up the print system.

• Prints the jobs and prepares copy and scan jobs.

• Makes proof prints.

• Performs last-minute job changes.

• Makes sure that all consumables needed for the jobs are available during the day.

• Carries out maintenance routines, such as a daily calibration procedure or a media registration.

Trained operators are allowed to carry out specific maintenance tasks for operators. For example,

correction procedures to clean machine parts or to improve the image quality.

Expert tasks, such as media catalog management and advanced color management, belong to

the role of the system administrator and the key operator.

The key operator is also responsible for mechanical maintenance tasks and maintenance

procedures via the control panel (local key operator settings). (See

maintenance

on page 182 )

NOTE

This guide is based on the roles and tasks as described above. However, you may work in a print

environment that has different needs. For example, in small organizations operators can do

prepress tasks as well as print operator tasks.

System configuration and

Media-based workflow

The media catalog is the backbone of the media-based workflow. The media catalog contains the

media that the print system supports.

The prepress staff select the media for the job from the media catalog. The control panel shows

the print operator the media the job needs.

[6] Media-based workflow

During the initial configuration of the print system, the media catalog is filled with media and

media attributes. Media belong to a media family, which ensures optimal color output settings.

(See

Color reproduction for your output

page 294)

When you work with the media catalog, you can take advantage of the following benefits:

Chapter 2 - Explore the print system

30

on page 26 and

Settings Editor media attributes

imagePRESS C800 Series

on

Page 31

PRISMAsync operating concept

• The media in the media catalog store print quality attributes that the entire print system uses.

Each time you select the media from the media catalog, the print system automatically applies

the same media quality settings.

• The control panel, the printer driver and the PRISMA software access the same media catalog.

• You can use the media catalog for copy jobs.

Define the media attributes with the Settings Editor. (See

System configuration

on page 182)

imagePRESS C800 Series

Chapter 2 - Explore the print system

31

Page 32

1

7

2

3

8

11

6

9

5

13

12

2021 1819

7

2

1

4

3

10

8

6

16

1415

9

17

Main hardware parts

Main hardware parts

The print system can be given different configurations to match various print environments. Your

print system has basic hardware parts extended with optionals. In the table below you can find

descriptions of the main parts.

NOTE

• This manual uses functional names for the print system parts. However, sometimes you may

need the commercial name, for example, if you want to order an optional. In this case, use the

table with the commercial names.

• The availability of optionals differs per country.

[7] Base print system with bulk paper module

[8] Example of a print system extended with several input and output optionals:

Description main hardware parts

1 PRISMAsync controller steers the performance, workflow, image quality and colour

quality of the print system.

2 Control panel, which is the central information point for the print operator.

3 Operator attention light, to display the status of the print system from a distance.

4 Automatic document feeder, to copy and scan originals.

5 Cover, only needed for a print-only system.

6 Toner compartment cover, to access the toner cartridges.

7 Internal paper trays, to hold media.

Chapter 2 - Explore the print system

32

8 Print module, where the print process takes place.

imagePRESS C800 Series

4

Page 33

Main hardware parts

Description main hardware parts

9 Waste toner compartment, to access the waste toner container.

10 Paper module, to hold media.

11 Bulk paper module, to hold media.

12 Special feeder, to manually feed special media, envelopes and tab paper.

13 Output tray, to collect the printed output.

14 Inserter, to feed (preprinted) covers and insert sheets.

15 Professional puncher, to punch holes in the printed output.

16 Perfect binder, to create perfect-bound and trimmed books.

17 High capacity stacker, to stack large piles of output.

18 Folder, to fold the output in various ways.

19 Stacker/stapler, to staple and stack the printed output. A saddle-stitch unit creates sad-

dle-stitched booklets. A punch unit punches printed output.

20 Booklet trimmer, to trim the leading edge of booklets.

21 Two-knife trimmer, to trim the top and bottom-edges of booklets.

Commercial names of paper input optionals

Optional Commercial name

Automatic document feeder Duplex Color Image Reader Unit-H1

Printer cover Printer Cover-F1

Special feeder Stack Bypass-B1

Paper module Multi-Drawer Paper Deck-A1.

Bulk paper module POD Deck Lite-B1

Inserter Document Insertion Unit-M1

For more information, see

Paper input specifications

Commercial names of finishing optionals

Optional Commercial name

Output tray Output Tray-A1

Professional puncher Professional Puncher-C1

Perfect binder Perfect Binder-D1

High capacity stacker High Capacity Stacker-G1

on page 270.

Folder Paper Folding Unit-F1

Stacker / stapler Professional stacker / stapler:

Booklet trimmer Booklet Trimmer-D1

imagePRESS C800 Series

Finisher-AM1 or Saddle Finisher-AM2

Standard stacker / stapler:

Staple Finisher-T1 or Booklet Finisher-T1

Chapter 2 - Explore the print system

4

33

Page 34

Main hardware parts

Optional Commercial name

Two-knife booklet trimmer Two-Knife Booklet Trimmer-A1

For more information, see

Finishing modules specifications

on page 274.

Chapter 2 - Explore the print system

34

imagePRESS C800 Series

Page 35

Overview of licenses

The following licenses are available to increase the functionality and productivity of the print

system.

License Commercial name More information

Overview of licenses

Schedule Scheduler-D1 See

Scan functionality Scanning-C1 See

DocBox DocBox-E1 See

Page programming Page Programming-B1 See

Automated workflows

Hotfolders

E-Schredding E-Shredding-D1 See

PCL6 for transaction printing PCL6 TP-D1 See

IPDS for transaction printing IPDS-D1 See

PDF support for IPDS PDF for IPDS-D1 See

DPlink DP Link-E1 Enables integration with Xe-

Remote Service Remote Service-F1 See

Multiple queue-B1 See

Schedule

Scan jobs

DocBox

on page 122

on page 57

on page 91

Page Programming

page 244

Hotfolders

and

Automated workflows

page 70

on page 70

Removal of printed jobs

on page 100

Transaction printing

page 87

Transaction printing

page 87

Transaction printing

page 87

rox ©systems

Enable Remote Service

page 225

on

on

on

on

on

on

Remote Manager Remote Manager-B1 See

queues

Advanced color management Advanced Color Management-B1See

ment

Asian font sets Fontset Simplified Chinese-D1

Fontset Traditional Chinese-D1

Fontset Japanese-D1

Fontset Korean-D1

Job management in the

on page 101

Advanced color manage-

on page 27

imagePRESS C800 Series

Chapter 2 - Explore the print system

35

Page 36

1

10

2

3

4

5

7

8

9

6

Control panel

Control panel

The control panel is the central point used to operate the print system and to manage print jobs,

copy jobs and scan jobs. The control panel provides you full system control.

The following table describes the main parts of the control panel and their functions.

Description control panel

1 Sleep button , to put the print system into the sleep mode or to wake the print sys-

tem from the sleep mode.

2 Stop button , to stop the printing process, after a set, or as soon as possible.

3 Paper tray button , to access paper tray functions and overviews, such as:

• An overview of the media and filling levels of the paper trays

• Open a paper tray

• Assign media to a paper tray or disable media

• Start a media registration for selected media

4 USB port, to:

• Print from a USB drive

• Scan to a USB drive

• Attach the Eye-One spectrophotometer

5 [Schedule] button, to access the schedule.

6 [Jobs] button, to access:

• The copy and print job function

• The DocBox folders

• The list of scheduled jobs

• The list of waiting jobs

• The list of printed jobs

• The list of scanned documents

7 [Trays] button, to access paper tray functions and overviews (see the paper tray but-

ton (3)).

4

Chapter 2 - Explore the print system

36

imagePRESS C800 Series

Page 37

Control panel

Description control panel

8 [System] button, to access system functions, features and overviews, such as:

• Maintenance information on supplies and finishers

• Maintenance procedures and system shut down

• Control panel adjustments

• Local key operator settings

• Media catalog and temporary media

• Color adjustments and calibration procedures

• Transaction printing settings

9 Dashboard, to display information, such as:

• Color bar, to indicate the system status with a color

• Progress of the print process

• Scheduled operation tasks

• Warnings and errors

• Status indicators of toner cartridges, staple cartridges and waste containers

• Calibration notifications

You can also view the dashboard remotely with the remote monitor. (See

monitor specifications

on page 288)

10 Status LED, to indicate the system status with a color. (See

page 120)

Remote

System monitoring

on

imagePRESS C800 Series

Chapter 2 - Explore the print system

37

Page 38

1

2

3

Paper Input

Paper Input

Paper module

The print module has three internal paper trays with a total capacity of 1,650 sheets. (See

the print module parts

The paper module (Multi-Drawer Paper Deck-A1.) increases the input capacity of the print system.

Each paper tray can hold up to 2,000 sheets (80 g/m² / 22 lb bond or 64 g/m² / 17 lb bond).

[9] Paper module (Multi-Drawer Paper Deck-A1.)

on page 228)

Access

Description paper module

1 Front cover, to access the paper path when a paper jam occurs.

2 Tray buttons, to open a paper tray.

3 Paper trays, to hold the media.

See

Paper input specifications

on page 270 for specifications.

Chapter 2 - Explore the print system

38

imagePRESS C800 Series

Page 39

Bulk paper module

1 2

3

4

Bulk paper module

The print module has three internal paper trays with a total capacity of 1,650 sheets. (See

the print module parts

You can extend the input capacity of the print system with a bulk paper module (POD Deck LiteB1). This bulk paper module can hold up to 3,500 sheets (80 g/m² / 22 lb bond).

[10] Bulk paper module (POD Deck Lite-B1)

on page 228)

Access

Description bulk paper module

1 Release button, to move the bulk paper module.

2 Button, to open the paper tray.

3 Paper tray, to hold the media.

4 POD Deck Lite Attachment Kit-A1, to connect the bulk paper module to the system and

to access the paper path when a paper jam occurs.

See

Paper input specifications

on page 270 for specifications.

imagePRESS C800 Series

Chapter 2 - Explore the print system

39

Page 40

1

2

3

4

5

Inserter

Inserter