Page 1

-

Operating

Information

Page 2

Copyright

Copyright 2011 by Canon Inc. All rights reserved.

No part of this publication may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording, or by any information

storage or retrieval system without the prior written permission of Canon Inc.

© 2011, Océ

All rights reserved. No part of this work may be reproduced, copied, adapted, or transmitted

in any form or by any means without written permission from Océ.

Océ makes no representation or warranties with respect to the contents hereof and specifically disclaims any implied warranties of merchantability or fitness for any particular purpose.

Furthermore, Océ reserves the right to revise this publication and to make changes from

time to time in the content hereof without obligation to notify any person of such revision

or changes.

Edition: 07-2011

Page 3

Contents

Contents

Chapter 1

Preface.................................................................................................................9

Trademarks...............................................................................................10

Copyright...................................................................................................11

Notes for the reader.................................................................................12

Abbreviations used in this manual.........................................................14

Available documentation.........................................................................15

Chapter 2

Main parts..........................................................................................................17

Overview of the machine configuration.................................................18

The main unit............................................................................................22

The paper modules..................................................................................26

The tab feeder (optional).........................................................................31

The special feeder (optional)...................................................................33

The automatic document feeder - ADF (optional).................................35

The color scanner (optional)...................................................................37

The operator panel...................................................................................38

The operator attention light....................................................................42

Finishing options......................................................................................44

The stacker/stapler, optional inserter and optional integrated punch

unit.............................................................................................................45

The puncher..............................................................................................56

Chapter 3

Operating concept............................................................................................59

Operating concept....................................................................................60

Access the Settings Editor ......................................................................64

Maintain the 'Media catalog' ..................................................................66

Maintain the 'Media families' .................................................................68

Maintain the 'Color pre-sets' ..................................................................70

Maintain the 'Input profiles' ...................................................................72

Maintain the 'Output profiles' ................................................................73

Maintain the 'Spot colors' ......................................................................74

Prepare print jobs with PRISMAprepare ...............................................75

Prepare print jobs with the printer driver...............................................77

Manage production printing...................................................................80

Chapter 4

Operator panel views.......................................................................................83

The dashboard..........................................................................................84

3

Page 4

Contents

The 'Schedule' view.................................................................................86

The 'Jobs' view.........................................................................................88

The 'Trays' view.......................................................................................90

The 'System' view....................................................................................91

Chapter 5

Power information............................................................................................93

The power buttons and power modes...................................................94

Turn on the controller..............................................................................96

Turn on the printer...................................................................................98

Turn off the printer...................................................................................99

Use the Sleep mode...............................................................................100

Chapter 6

Print jobs..........................................................................................................101

General information...............................................................................102

Introduction to the print function....................................................102

Description of the print job settings...............................................104

Contradiction handling....................................................................119

Manage print jobs..................................................................................120

Print an urgent job immediately.....................................................120

Give priority to a print job...............................................................121

Print a scheduled job later...............................................................122

Reprint a job......................................................................................123

Print a job ticket................................................................................125

Make a proof.....................................................................................126

Stop the printer.................................................................................127

Delete print jobs...............................................................................129

Schedule a waiting job for printing................................................131

Select more than one job for printing............................................132

Print a file from a USB drive............................................................133

Media handling.......................................................................................134

Introduction to the 'Schedule' view................................................134

Load the media using the 'Schedule' view....................................138

Description of the 'Trays' view........................................................140

Load the media using the 'Trays' view...........................................143

Introduction to the 'Media' section.................................................145

Introduction to the media handling................................................147

Add temporary media to the 'Media catalog' ...............................149

Correct skewed and rotated images...............................................150

Perform a media registration..........................................................152

Change the job settings before printing...............................................154

Change the number of sets.............................................................154

Check the first set.............................................................................155

Change the use of separator sheets...............................................157

4

Page 5

Contents

Stack the prints with an offset.........................................................158

Combine jobs....................................................................................160

Change the output settings before printing.........................................162

Change '2-sided' into '1-sided' and vice versa...............................162

Change the binding edge.................................................................163

Select a different media for a job....................................................164

Change the settings for covers........................................................165

Shift the image roughly to create binding space...........................166

Shift the image precisely to create binding space or correct the lay-

out......................................................................................................167

Change the print delivery settings..................................................169

Change the finishing method..........................................................171

Chapter 7

Copy jobs.........................................................................................................173

General information...............................................................................174

Introduction to the copy function....................................................174

Description of the copy job settings...............................................176

Feed originals to the ADF (optional)...............................................193

Feed originals to the SADF (optional).............................................196

Put originals on the glass plate.......................................................198

Clean the glass plate........................................................................200

Copy your documents............................................................................202

Make a copy......................................................................................202

Combine subsets into 1 document.................................................203

Access other functions during a copy job or scan job..................204

The zoom behavior...........................................................................205

Create and use custom copy templates.........................................208

Rename a copy job...........................................................................209

Copy non-standard size originals....................................................210

Scan now and print later (postponed copying).............................211

Finish the output...............................................................................212

Adjust the image to improve the copy and scan quality..............213

Chapter 8

Scan jobs.........................................................................................................215

Introduction to the scan function..........................................................216

Description of the scan job settings.....................................................218

Scan to file..............................................................................................225

Scan to USB............................................................................................226

Combine subsets into one file...............................................................227

Chapter 9

Paper, toner, and staples...............................................................................231

Paper........................................................................................................232

Load the media into the paper tray.................................................232

5

Page 6

Contents

Adjust the paper tray to hold a different media size.....................240

Load the media into the bulk media module (optional)................245

Adjust the media size for the bulk media module (optional)........252

Adjust the outer size change plate of the bulk paper module (option-

al).......................................................................................................261

Load the media into the special feeder (optional).........................268

Load tabs via the tab feeder (optional)...........................................272

Adjust the media size of the tab feeder (optional).........................279

Load the required media into the selected tray.............................282

Check the status of the punch waste box.......................................289

Removing the punch waste.............................................................290

Toner.......................................................................................................293

Check the status of the toner reservoir and waste toner container.293

Replacing the toner cartridge..........................................................295

Replacing the waste toner container..............................................301

Staples.....................................................................................................304

Check the status of the staple cartridges........................................304

Replacing the staple cartridge in the stapler unit..........................306

Replacing the staple cartridge in the saddle stitcher unit.............310

Chapter 10

Adapt printer settings to your needs............................................................315

System settings (access through the operator panel)........................316

Introduction to the 'Setup' section..................................................316

Work with the workflow profiles.....................................................318

Change the warning time................................................................322

Disable the warning time.................................................................323

Truncate the job name.....................................................................324

Adjust the brightness and contrast of the operator panel............325

Access Settings Editor settings via the operator panel.................326

Automated workflows (access through the Settings Editor)..............329

Introduction to automated workflows............................................329

Add an automated workflow...........................................................331

Edit an automated workflow...........................................................332

Delete an automated workflow.......................................................333

Restore the factory default workflow..............................................334

Hotfolders................................................................................................335

Introduction to hotfolders................................................................335

Activate the hotfolder function........................................................336

Create a hotfolder.............................................................................337

Create a shared network folder on a workstation..........................338

Create a hotfolder default ticket ('default_ticket.jdf').....................340

Chapter 11

Maintenance and calibration.........................................................................341

6

Page 7

Contents

Maintenance...........................................................................................342

Introduction to the 'Maintenance' section......................................342

Reset the day counters.....................................................................344

Find the meter readings (counters).................................................345

'Auto color mismatch correction' ...................................................346

Clean the automatic document feeder rollers................................347

Clean the roller (main unit)..............................................................348

Clean the wire...................................................................................349

Handle paper jams...........................................................................350

'Refresh the fixing roller' ................................................................351

Engine maintenance (trained operators)........................................353

Calibration...............................................................................................354

Introduction to printer calibration...................................................354

Calibrate the printer - '1. Shading correction' ...............................355

Calibrate the printer - '2. Auto gradation adjustment' .................357

Calibrate the controller - '3. Media family calibration' .................359

Adjust the CMYK calibration curve manually................................361

Chapter 12

Specifications..................................................................................................363

Specifications.........................................................................................364

Chapter 13

Third-Party Software......................................................................................383

Third Party Software..............................................................................384

The Software Subjected to the Other Conditions................................386

FPU Emulation code ..............................................................................387

Library for SDE Compiler ......................................................................389

7

Page 8

Contents

8

Page 9

Chapter 1 Preface

Page 10

Trademarks

Trademarks

List of trademarks

Océ, Océ PRISMA, Océ PRISMAsync, Océ PRISMAprepare and Océ PRISMAaccess

are registered trademarks of Océ.

Canon and imagePRESS are registered trademarks of Canon Corporation.

Adobe, Acrobat, Reader and Distiller are registered trademarks of Adobe Systems Incorporated.

PostScript 3® is a registered trademark of Adobe Systems Incorporated.

Microsoft, Windows , Windows NT, Windows 98, Windows 2000, Windows XP,

Windows Server 2003 are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other countries.

Products in this publication are referred to by their general trade names. In most, if not

all cases, these designations are claimed as trademarks or registered trademarks of their

respective companies.

PANTONE® Colors displayed in the software application or in the user documentation

may not match PANTONE-identified standards. Consult current PANTONE Color

Publications for accurate color. PANTONE® and other Pantone, Inc. trademarks are

the property of Pantone, Inc. © Pantone, Inc., 2007

Pantone, Inc. is the copyright owner of color data and/or software which are licensed to

(insert name of your company) to distribute for use only in combination with (insert

appropriate name of Licensed Materials). PANTONE Color Data and/or Software shall

not be copied onto another disk or into memory unless as part of the execution of (insert

appropriate name of Licensed Materials).

This product contains the Universal Font Scaling Technology or UFST® under license

from Monotype Imaging, Inc. UFST® is a trademark of Monotype Imaging, Inc. registered in the United States Patent and Trademark Office and may be registered in certain

jurisdictions.

Copyright © 1989 - 1996, 1997, 2003, 2004, 2008, all rights reserved, by Monotype

Imaging Inc.

Chapter 1 - Preface10

Page 11

Copyright

This product includes software and/or software modules that are licensed by Canon Inc.

or its licensors from third parties. Use and distribution of this software and/or software

modules are subject to conditions (a) through (d) below.

(a)

Copyright (C) 1999, 2000, 2002 Aladdin Enterprises. All rights reserved.

(b)

Copyright © Unpublished Work of Novell, Inc.

All Rights Reserved

(c)

Copyright©1992,1993

The Regents of the University of California. All rights reserved.

This code is derived from software contributed to Berkeley by Ralph Campbell.

(d)

•

1/4 University of California, Berkeley

Copyright (c) 1990 The Regents of the University of California.

All rights reserved.

•

2/4 David M. Gay at AT&T

The author of this software is David M. Gay.

Copyright (c) 1991 by AT&T.

•

3/4 Sun Microsystems

Copyright (C) 1993 by Sun Microsystems, Inc. All rights reserved.

•

4/4 Cygnus Solutions

Copyright (c) 1994, 1997 Cygnus Solutions.

All rights reserved.

Copyright

Chapter 1 - Preface 11

Page 12

Notes for the reader

Notes for the reader

Introduction

This manual helps you to use the imagePRESS C7010VPS/C6010VPS/C6010S. The

manual contains a description of the product and guidelines to use and operate the

imagePRESS C7010VPS/C6010VPS/C6010S.

Definition

Attention-Getters

Parts of this manual require your special attention. These parts can provide the following:

•

Additional general information, for example, information that is useful when you

perform a task.

•

Information to prevent personal injuries or property damage.

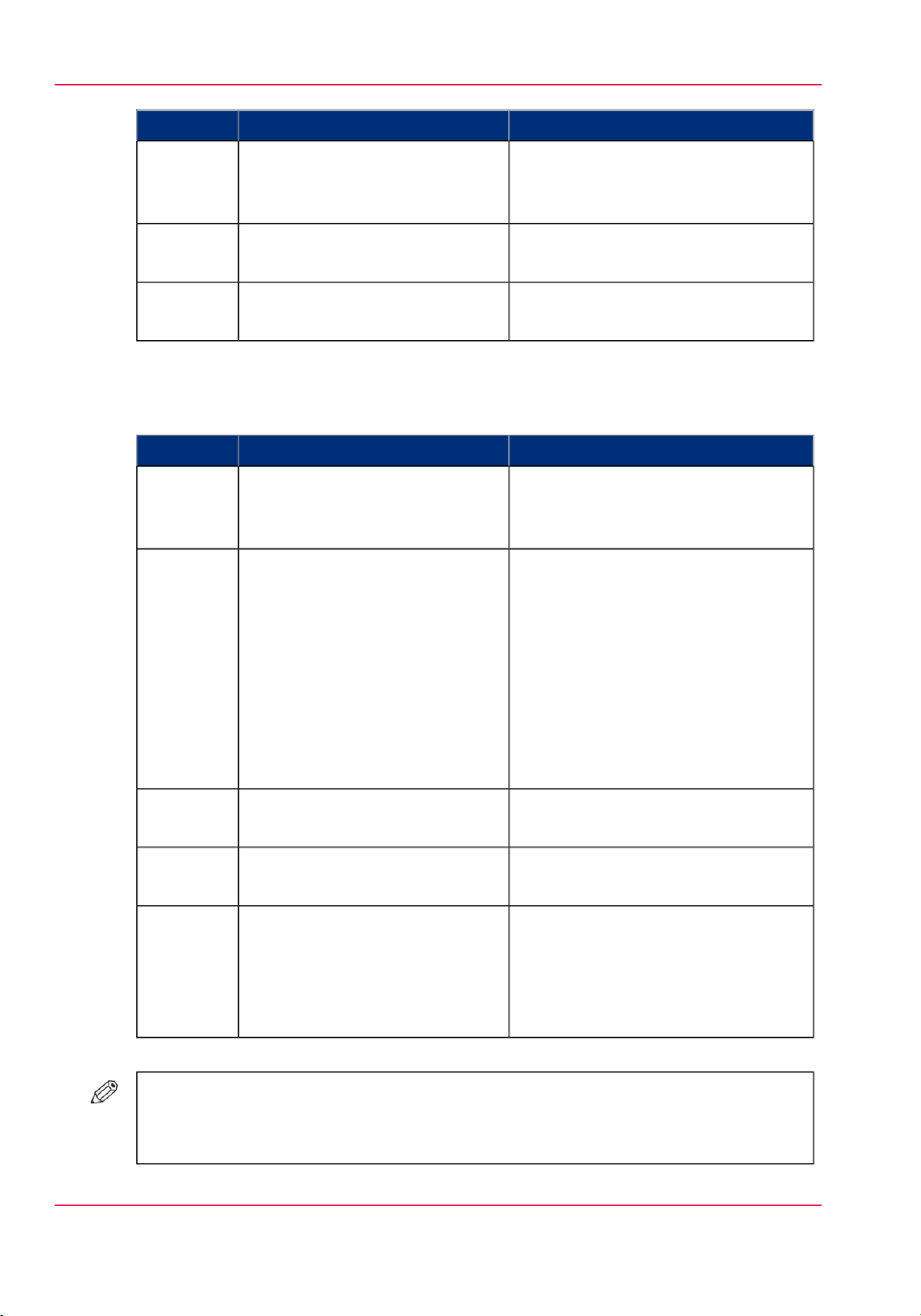

Symbols used in this manual

The following symbols are used in this manual to explain procedures, restrictions, handling

precautions, and instructions that should be observed for safety.

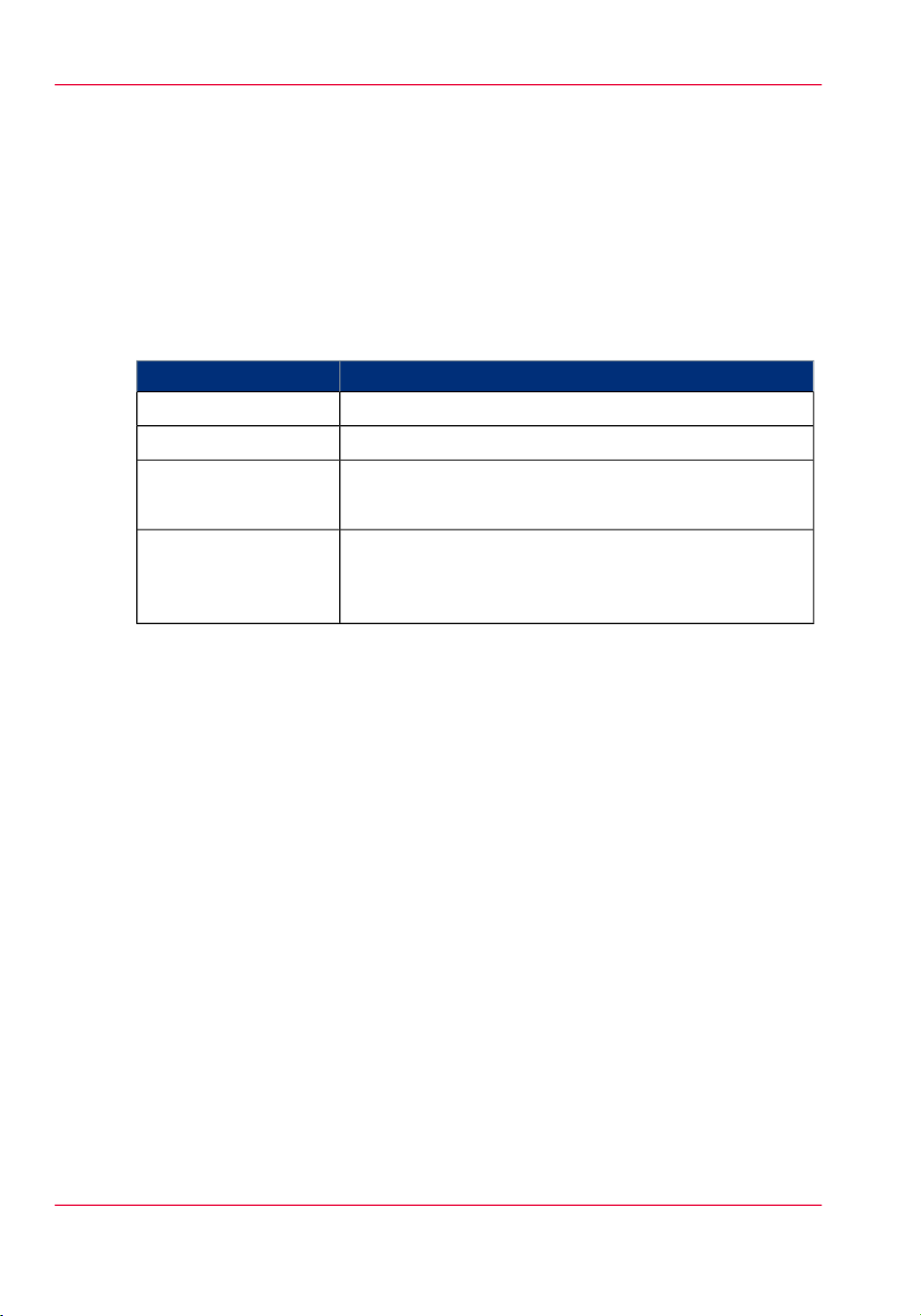

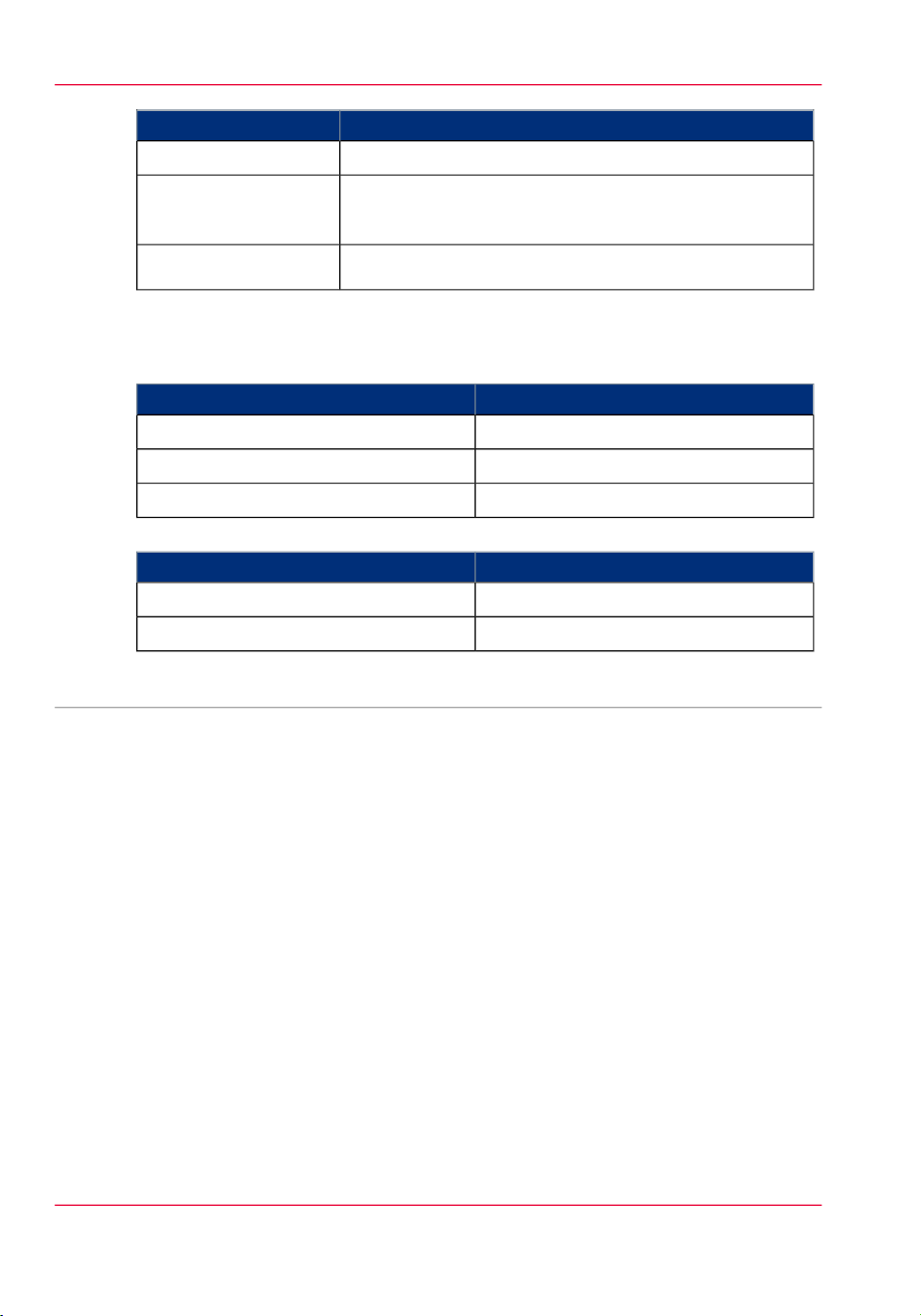

Overview of the attention-getters#

WARNING

CAUTION

IMPORTANT

NOTE

IndicatesIconWord

Indicates a warning concerning operations

that may lead to death or injury to persons if

not performed correctly. To use the machine

safely, always pay attention to these warnings.

Indicates a caution concerning operations that

may lead to injury to persons if not performed

correctly. To use the machine safely, always

pay attention to these cautions.

Indicates operational requirements and restrictions. Be sure to read these items carefully to

operate the machine correctly and to avoid

damaging the machine or property.

Indicates a clarification of an operation or

contains additional explanations for a procedure. Reading these notes is highly recommended.

Chapter 1 - Preface12

Page 13

Notes for the reader

IndicatesIconWord

Indicates an operation that must not be performed. Read these items carefully and make

sure not to perform the described operations.

Chapter 1 - Preface 13

Page 14

Abbreviations used in this manual

Abbreviations used in this manual

#

Microsoft Windows 2000:

Microsoft Windows 2000 Professional:

Microsoft Windows 2000 Server:

Microsoft Windows Server 2003:

Microsoft Windows XP:

Microsoft Windows XP Professional:

Microsoft Windows Vista operating system:

Microsoft Windows 7 operating system:

Microsoft Windows Server 2008:

Microsoft Windows operating system:

Novell NetWare:

Apple Macintosh:

Apple Mac:

Windows 2000

Windows 2000 Professional

Windows 2000 Server

Windows Server 2003

Windows XP

Windows XP Professional

Windows Vista

Windows 7

Windows Server 2008

Windows

NetWare

Macintosh

Mac

Chapter 1 - Preface14

Page 15

Available documentation

For the imagePRESS C7010VPS/C6010VPS/C6010S the following information is

available.

•

Operating information

•

Operating information for finishers

•

Operator's Maintenance Manual (English only)

•

Safety Instructions for the printer

•

Safety Information for the controller

•

Material Safety Data Sheets.

Available documentation

Chapter 1 - Preface 15

Page 16

Available documentation

Chapter 1 - Preface16

Page 17

Chapter 2 Main parts

Page 18

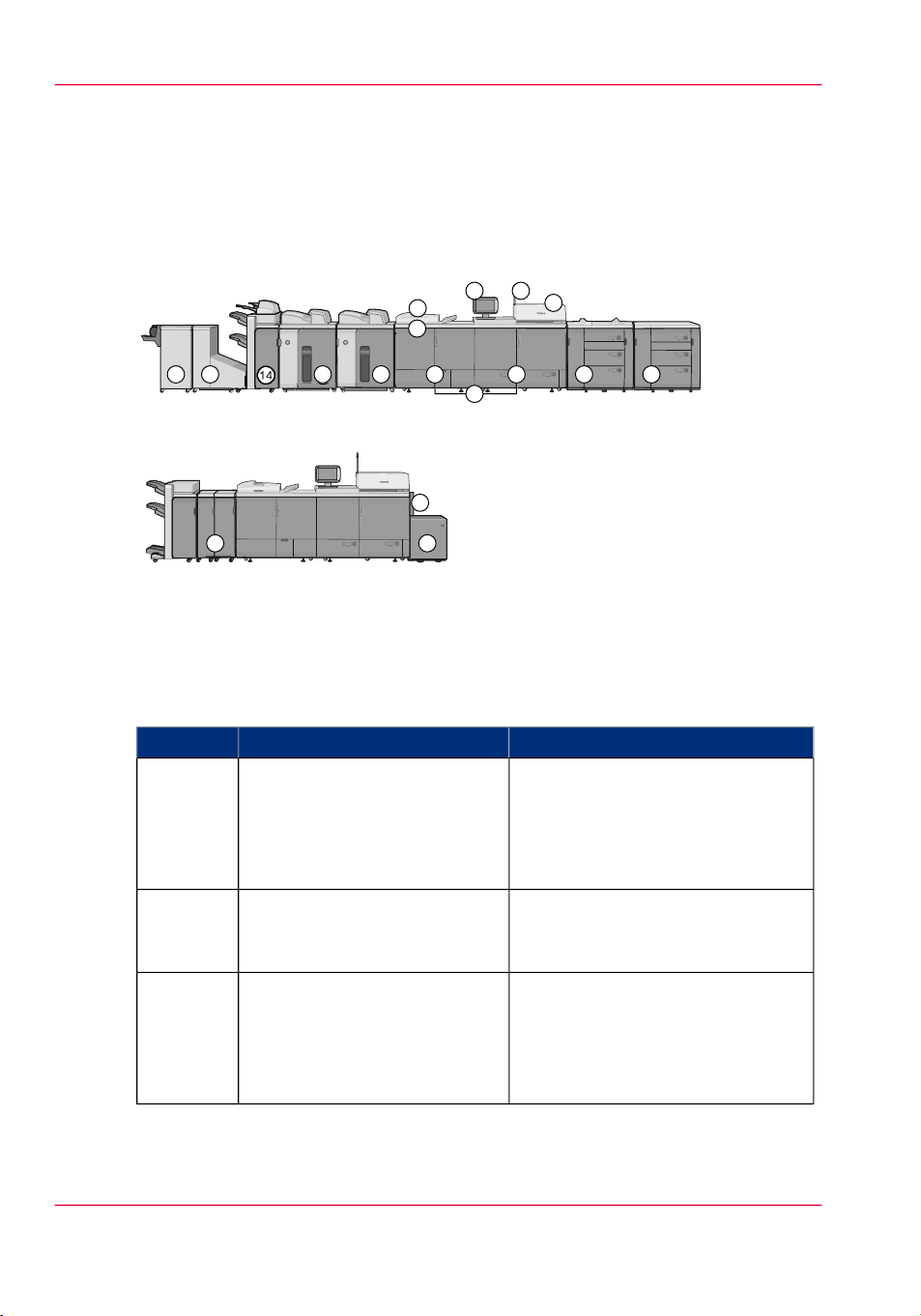

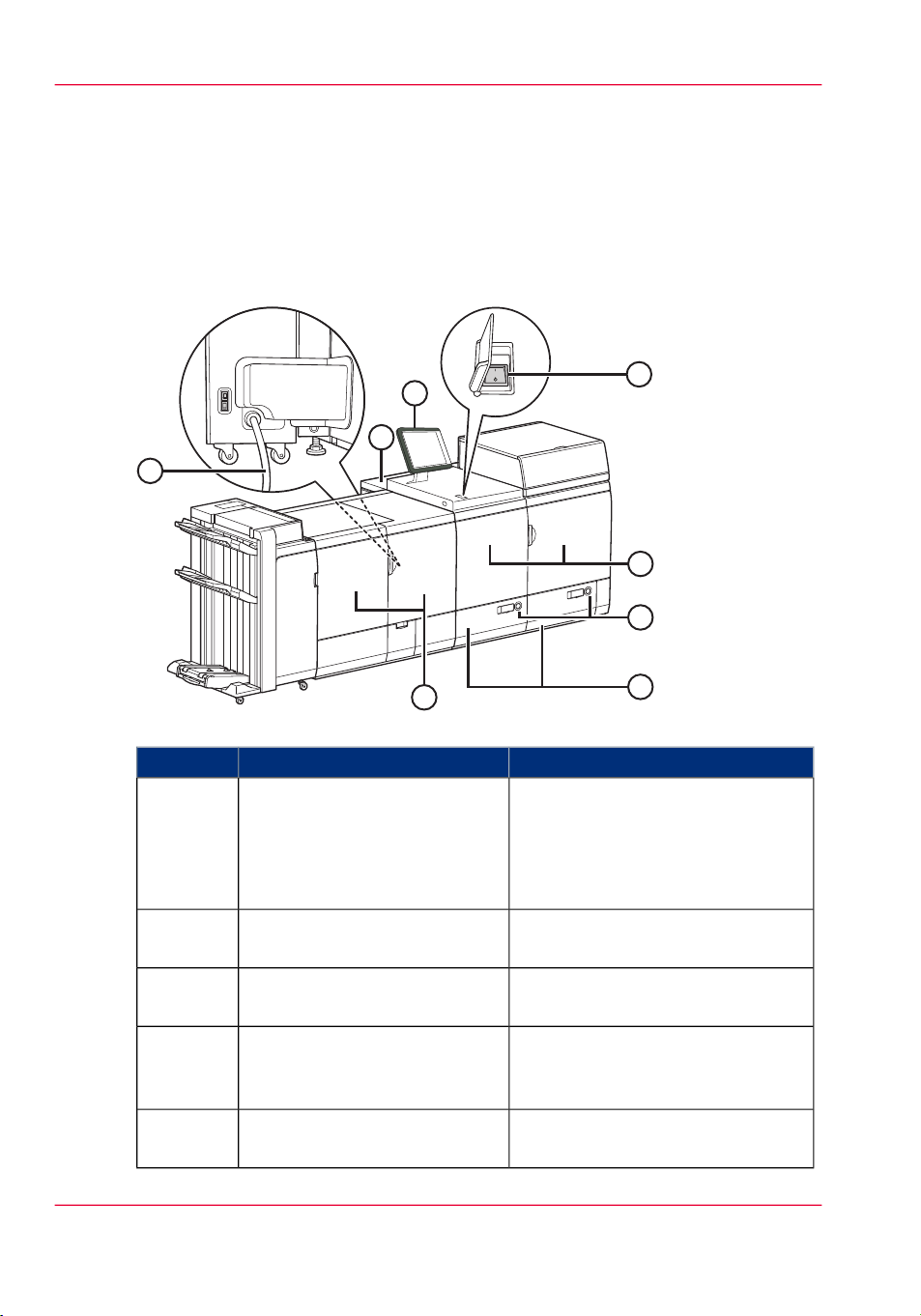

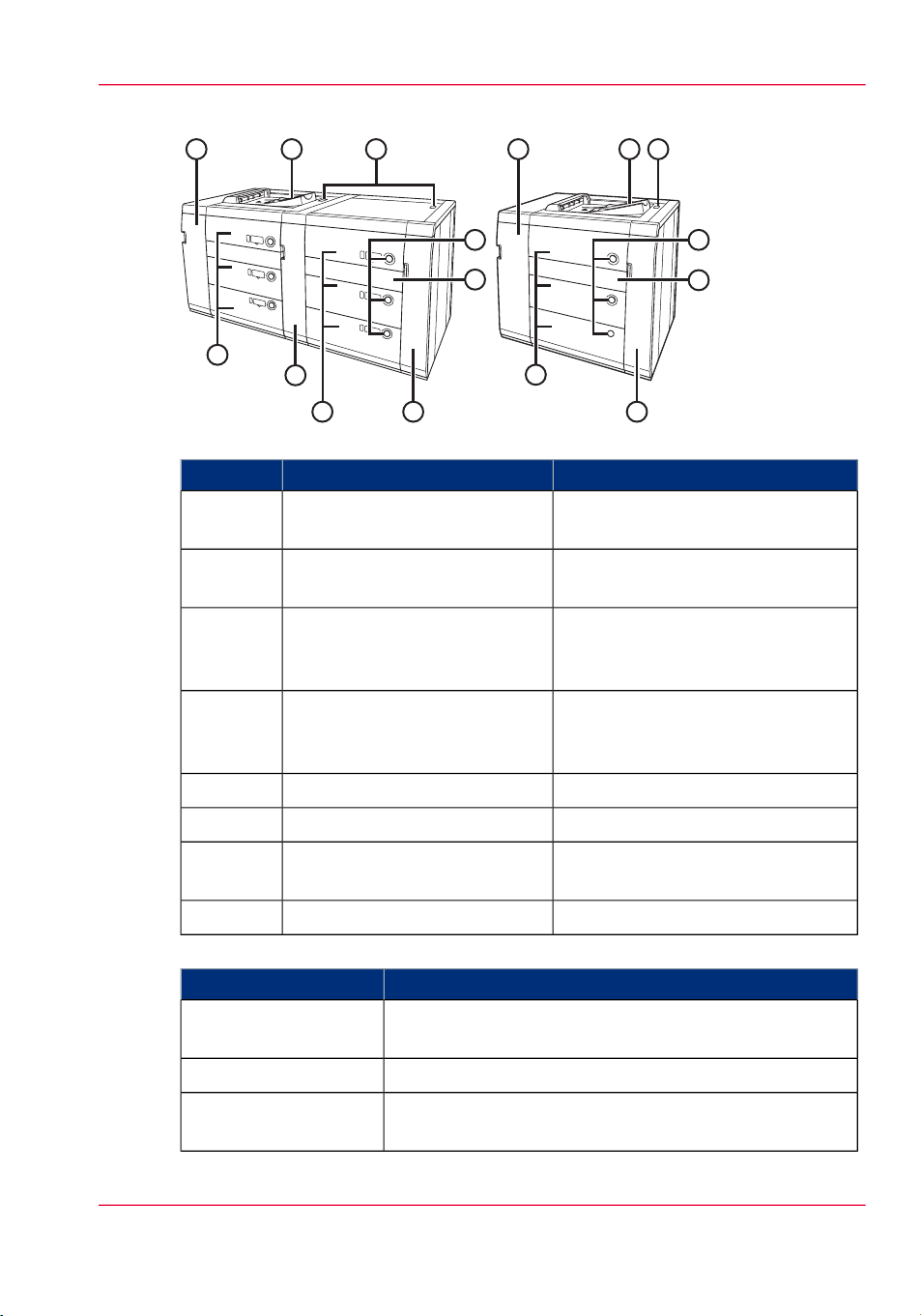

1 2

3

4

7

5

6

8 9 10

13 13

14

15

16

11

12

17

Overview of the machine configuration

Overview of the machine configuration

Introduction

The following figures display two example configurations.

[6] Mass production configuration

[7] Space saving configuration

The next section describes all available modules and options.

Main unit

#

FunctionComponent

Operator panel1

The operator panel helps you with

your daily work, for example the

scheduling of the jobs. Furthermore,

the operator panel helps you to solve

errors.

Operator attention light2

The operator attention light enables

you to check the status of the system

from a distance.

3

Color scanner and original cover

(Color Image Reader-H1 and

Platen Cover Type-K)

Optional

The color scanner is used to copy and

scan black & white and colored

originals. The original cover holds

down the original to the glass plate

of the color scanner.

Chapter 2 - Main parts18

Page 19

Overview of the machine configuration

FunctionComponent

4

Automatic Document Feeder

(Feeder DADF-R1)

Optional

The automatic document feeder is

used to copy and scan sets of 1-sided

and 2-sided documents.

Main unit5

The main unit contains the components that print the media. Access to

the main unit is only required when

a paper jam occurs or when maintenance is required.

The main unit consists of the following main parts.

•

Imaging unit (right-side)

(Marking unit)

•

Fusing unit (left-side)

(Fixing unit)

•

Power supply unit

Integrated paper trays6

The engine module contains paper

trays that contain the media that will

be printed.

Gives access to the toner bottles.Toner compartment cover7

Waste toner tray8

Gives access to the waste toner container.

#

NOTE

The spectrophotometer for calibration is not illustrated.

Optional paper modules

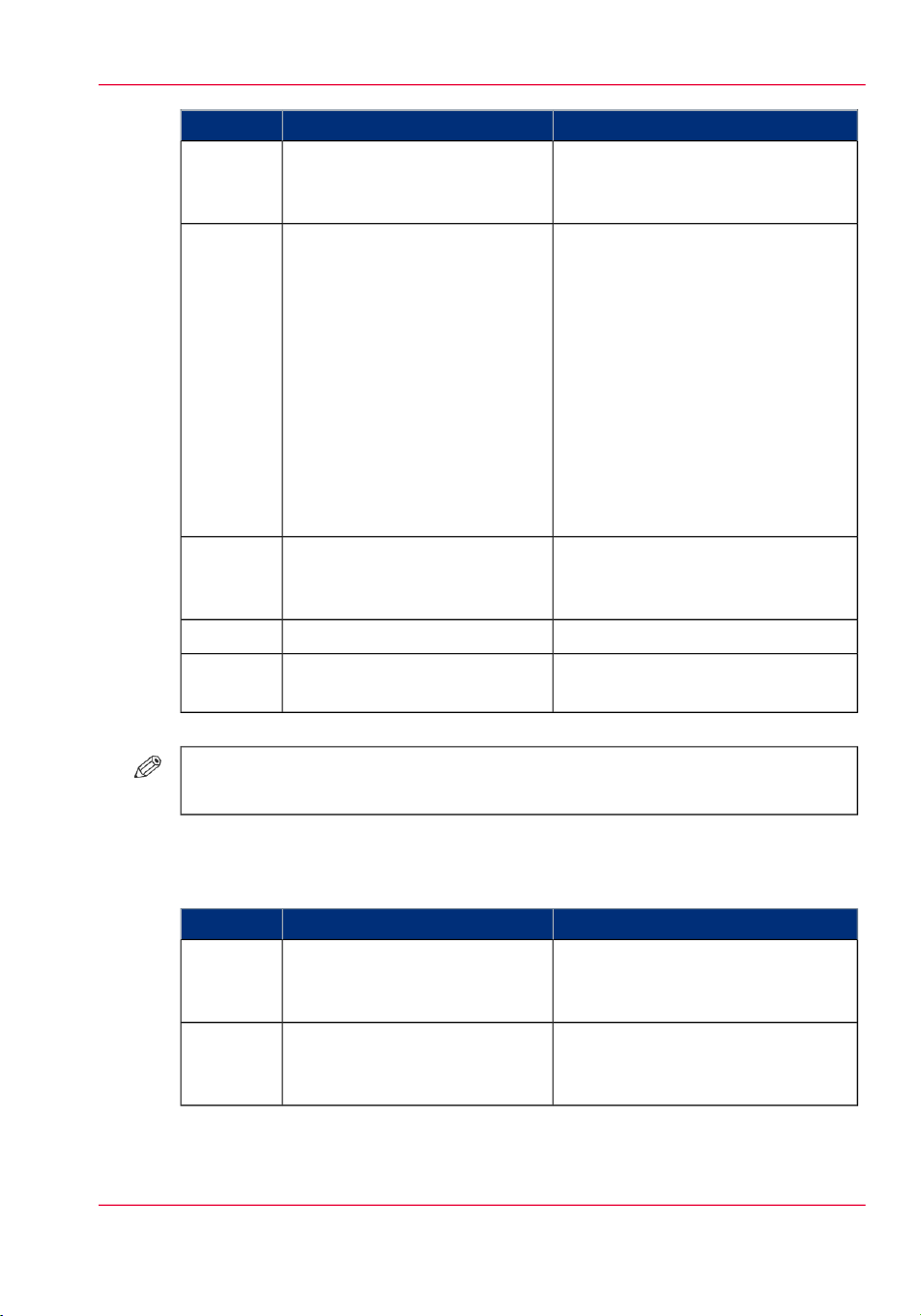

Input options#

9

Left-hand paper module

(POD Deck-A1)

10

Right-hand paper module

(Secondary POD-Deck-A1)

FunctionComponent

The additional paper module has

paper trays that contain the media

that will be printed.

You can add a secondary paper

module to increase the media input

capacity.

Chapter 2 - Main parts 19

Page 20

Overview of the machine configuration

11

Bulk paper module

(Paper Deck-AC1)

FunctionComponent

The bulk paper module contains the

media that will be printed. The bulk

paper module contains 1 media type.

12

Special feeder

(Stack Bypass-A1)

-

Tab feeder

(Tab Feeding Attachment-C1)

Optional finishing equipment

Output options#

13

Stacker

(High Capacity Stacker-C1)

Optional, maximum 2.

14

Stacker/stapler, optional inserter

and optional integrated punch

unit

(Finisher-AJ1 or

Saddle Finisher-AJ2 with

Document Insertion Unit-C1

and

Puncher Unit-BC1/BD1)

The special feeder is used to feed

media manually.

The tab feeder is used to load tab

paper into the paper trays.

FunctionComponent

The stacker adds output capacity to

your system. The stacker cannot staple the jobs.

The stacker/stapler offers the following functionality.

•

Stack prints

•

Staple prints

•

Create stapled booklets

•

Punch prints

With the optional inserter you can

add preprinted covers to the booklet

and sets.

15

16

17

Trimmer

(Booklet Trimmer-D1)

Two-knife trimmer

(Two-Knife Trimmer-A1)

Puncher

(Professional Puncher-B1 and

Professional Puncher Integration

Unit-A1)

The trimmer trims the long edge of

a booklet.

The two-knife trimmer trims the

short edges of a booklet.

The Professional Puncher-B1

punches several types of holes. The

Professional Puncher Integration

Unit-A1 reverses the paper punched

by the Professional Puncher-B1.

#

NOTE

Please refer to the operating information that comes with the optional finish equipment.

Chapter 2 - Main parts20

Page 21

•The operator panel, on page 38

•The operator attention light, on page 42

•The color scanner (optional), on page 37

•The automatic document feeder - ADF (optional), on page 35

•The main unit, on page 22

•The paper modules, on page 26

•The tab feeder (optional), on page 31

Overview of the machine configuration

Chapter 2 - Main parts 21

Page 22

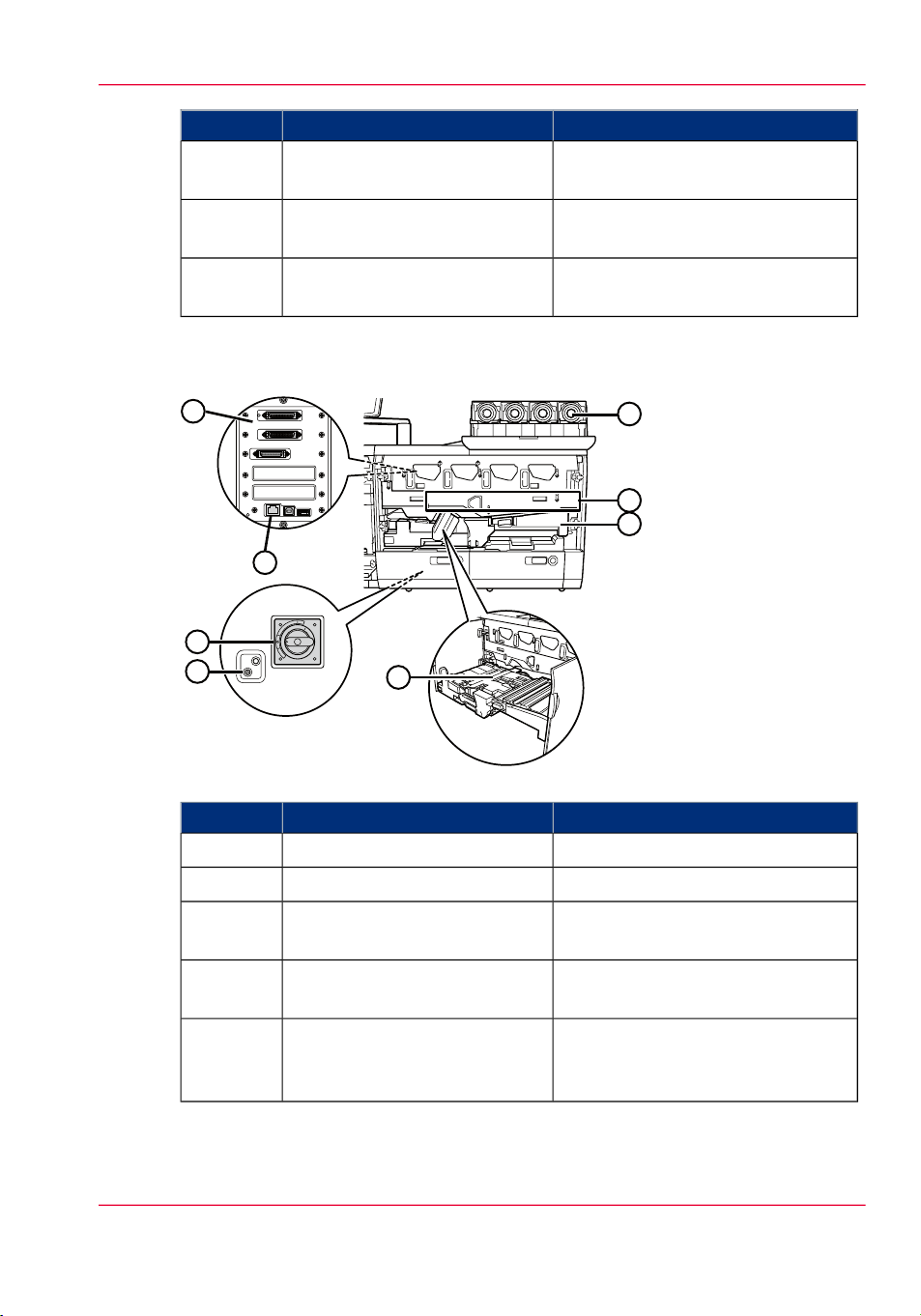

4

7

8

3

6

5

2

1

The main unit

The main unit

Introduction

This section describes and shows the main parts of the main unit.

External view

#

FunctionComponent

Operator panel1

The operator panel helps you with

your daily work, for example the

scheduling of the jobs. Furthermore,

the operator panel helps you to solve

errors.

2

Main power switch of the main

unit

3

Imaging unit

(Marking unit)

Open buttons4

Press to the "I" side to turn the power

ON.

Gives access to the imaging unit to

clear paper jams.

Press to open the paper tray when

you need to load paper or check for

a paper jam.

Integrated paper trays5

Chapter 2 - Main parts22

Contain the media that will be

printed.

Page 23

8

6

7

1

2

3

4

5

The main unit

FunctionComponent

6

Fusing unit

(Fixing unit)

Gives access to the fusing unit to

clear paper jams.

Power cord7

Power supply unit8

Internal view: the imaging unit (marking unit)

Supplies the power from AC outlet

to the main unit and ADF.

Provides the power to the imaging

unit and fusing unit.

Main parts of the imaging unit (marking unit)#

FunctionComponent

Gives access to the toner bottles.Toner unit1

Transfers the toner to the paper.Intermediate transfer belt2

Feeding unit3

Receives paper and can be opened to

remove jammed paper.

Skew correction roller4

Compensates paper skewing or dispersion of side edge.

Test button5

Located on the back side of the

power supply unit. Press this button

to periodically test the circuit breaker.

Chapter 2 - Main parts 23

Page 24

3

1

4

2

5

The main unit

FunctionComponent

Breaker6

Located on the back side of the

power supply unit. Detects excess

current or leakage current.

LAN Port7

Data ports8

Internal view: the fusing unit (fixing unit)

Located on the side of the power

supply unit. This port supports 100/

10BASE-T.

The LAN port is the communication

port to the PRISMAsync controller.

The USB ports are not used.

Use these ports to connect the printer

to the PRISMAsync controller.

Main parts of the fusing unit (fixing unit)#

FunctionComponent

Primary fixing assembly1

Fixes toner that has transferred to

paper. Pull out the primary fixing

unit to clear a paper jam inside the

assembly

Secondary fixing assembly2

Fixes toner securely for some paper

types. Pull out the secondary fixing

unit to clear a paper jam inside the

Waste toner container tray3

assembly.

Pull out this tray to replace waste

toner container.

Chapter 2 - Main parts24

Page 25

The main unit

FunctionComponent

Reverse unit4

Reverses paper and returns it to the

marking engine for two-sided printing. Pull out the delivery/reverse unit

to clear a paper jam inside the unit.

Decurler unit5

•Overview of the machine configuration, on page 18

Corrects the paper curl caused by

heat. Pull out this unit to clear a paper jam inside the unit.

Chapter 2 - Main parts 25

Page 26

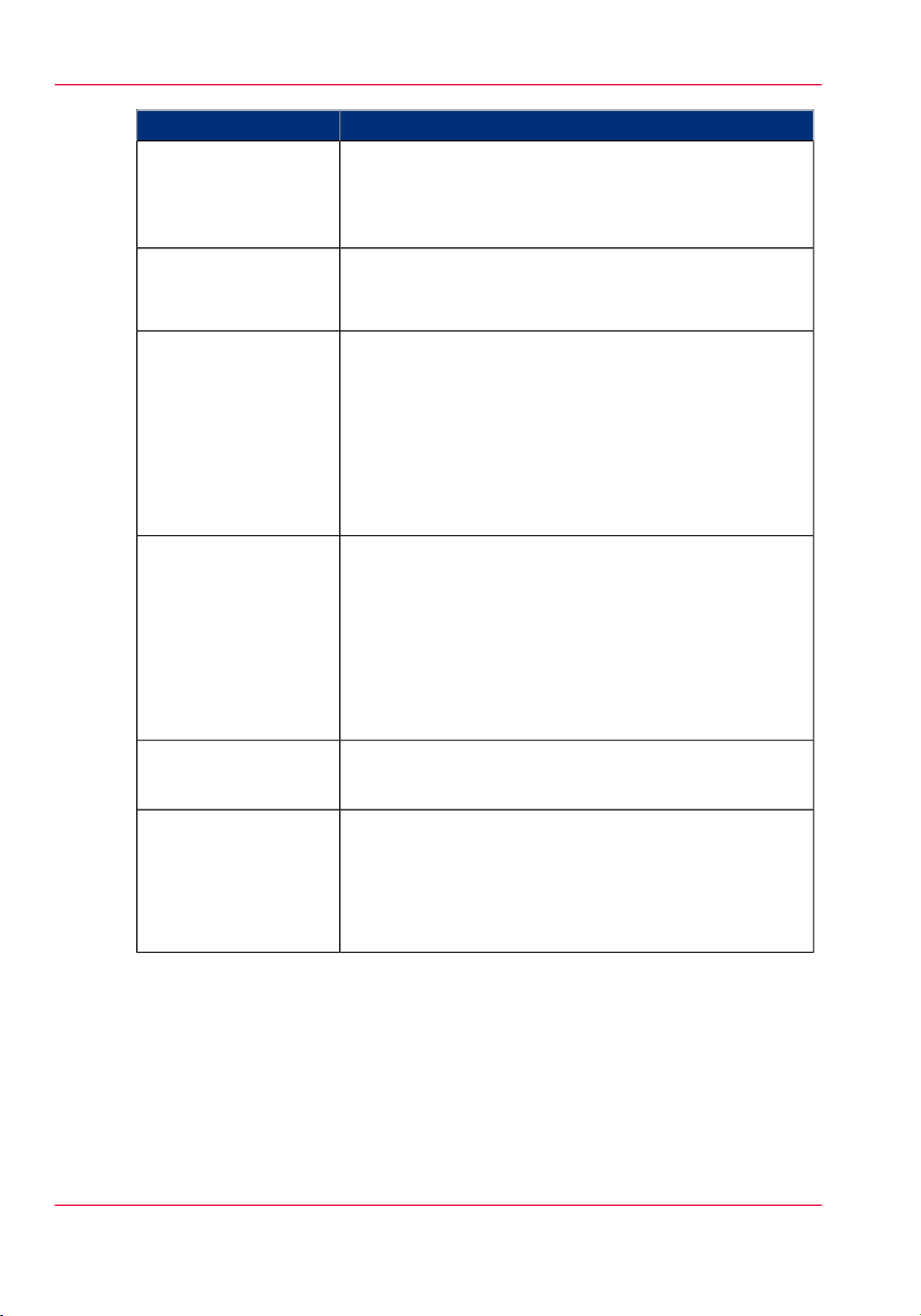

The paper modules

The paper modules

Introduction

This section describes the parts and specifications of the available paper modules.

Integrated paper trays

The printer contains 2 integrated paper trays.

#

Paper feed technology

Features

ValueSpecification

2 x 1000 sheets (80 g/m² / 22 lb Bond)Capacity

60 - 325 g/m² / 16 lb. Bond - 120 lb CoverPaper weight

•

Suction feed

•

Air separation

•

Paper level detection (visual)

•

Automatic tray opening

•

Double sheet detection

External paper modules

Optionally, you can extend the printer with up to 2 external paper modules.

Chapter 2 - Main parts26

Page 27

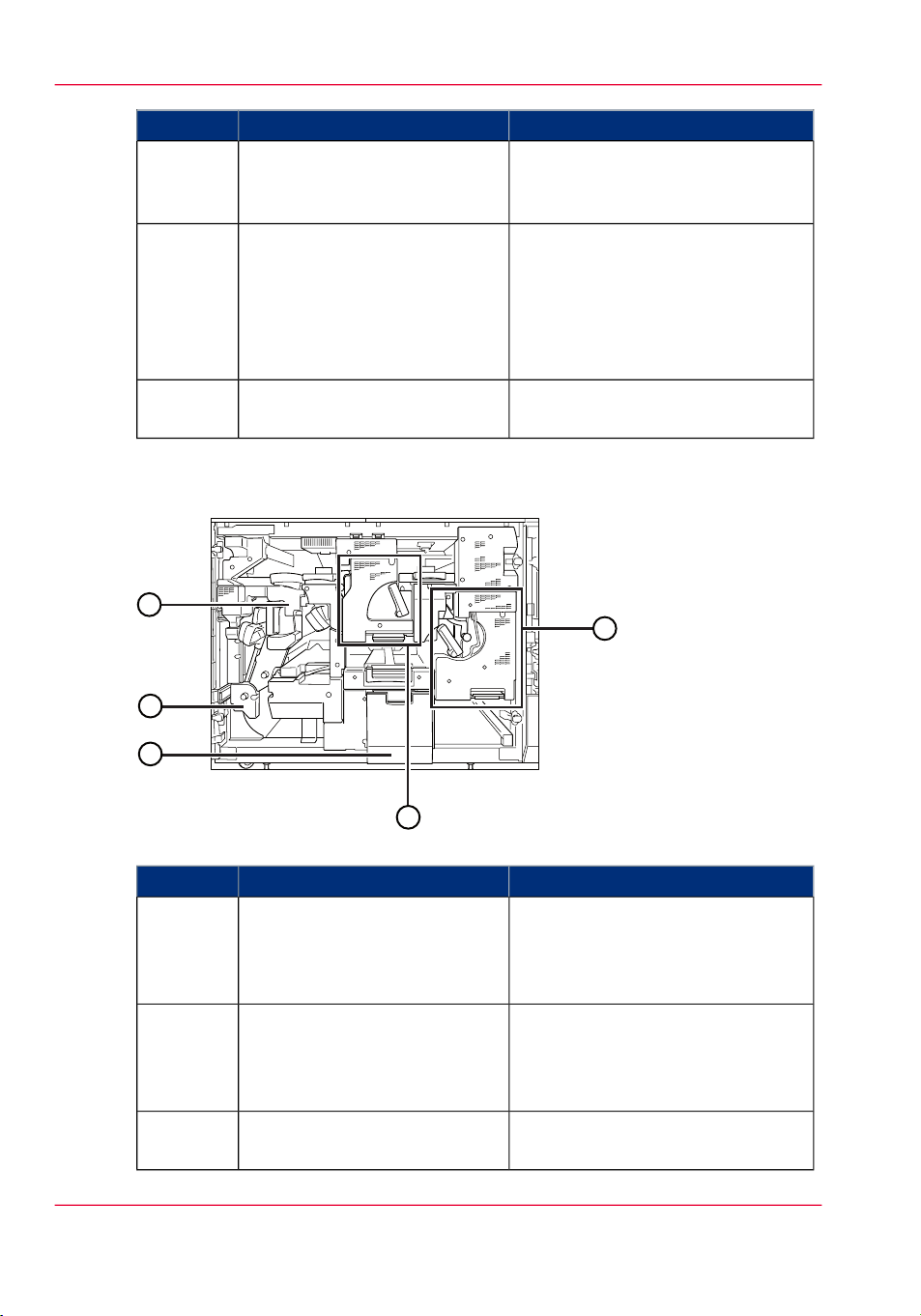

1 2 3

4

5

6

7

8

7

1 2 3

4

5

6

7

Parts of the paper module#

Front Cover (Buffer Pass)1

The paper modules

FunctionComponent

Open this cover to remove jammed

paper

#

3

Description

ity

Escape tray2

Main power switch

(POD Deck-A1 and

Secondary POD-Deck-A1)

Open button4

Paper trays7

ValueSpecification

Optional 3-tray paper module; up to 2 paper modules can

be installed

2 x 1000 sheets, 1 x 2000 sheets (80 g/m² / 22 lb. Bond)Paper trays

8000 sheets (2 paper modules)Maximum paper capac-

Receives detected double sheets to

avoid paper jams

Press to the "I" side to turn ON the

paper module

Press to open the paper tray when

you need to load paper or check for

a paper jam

Gives access to jammed paperHorizontal pass cover5

Gives access to jammed paperFront right cover6

Contains the media that will be

printed

Gives access to jammed paperTandem pass cover8

Chapter 2 - Main parts 27

Page 28

The paper modules

Dimensions (WxDxH)

ValueSpecification

Left-hand paper module: 982 x 792 x 1095 mm / 38.66"

x 31.18" x 43.11"

Right-hand paper module: 811 x 792 x 1095 mm / 32" x

31.18" x 43.11"

Weight

Power requirement

Power consumption

Paper feed technology

250 kg / 551 lbs

480 kg / 1058 lb for tandem of first and second paper

module

EUR:

POD Deck-A1: 220-240 V AC, 50/60 Hz, 6 A

Secondary POD Deck-A1: From POD Deck-A1 (200-240

V AC, 50/60 Hz, 2.8 A)

US:

POD Deck-A1: 200-208 V AC, 50/60 Hz, 6 A

Secondary POD Deck-A1: From POD Deck-A1 (200-240

V AC, 50/60 Hz, 2.8 A)

EUR:

POD Deck-A1 only: 850 W maximum

POD Deck-A1 + Secondary POD Deck-A1: 1500 W

maximum

US:

POD Deck-A1 only: 750 W maximum

POD Deck-A1 + Secondary POD Deck-A1: 1380 W

maximum

•

Suction feed

•

Air separation

Features

Bulk paper module

Optionally, you can extend the printer with a bulk paper module with a capacity of 3,500

sheets.

Chapter 2 - Main parts28

•

Paper level detection (visual)

•

Automatic tray opening

•

Escape tray

For automatic shoot out of sheets in case of double-sheet

feeding

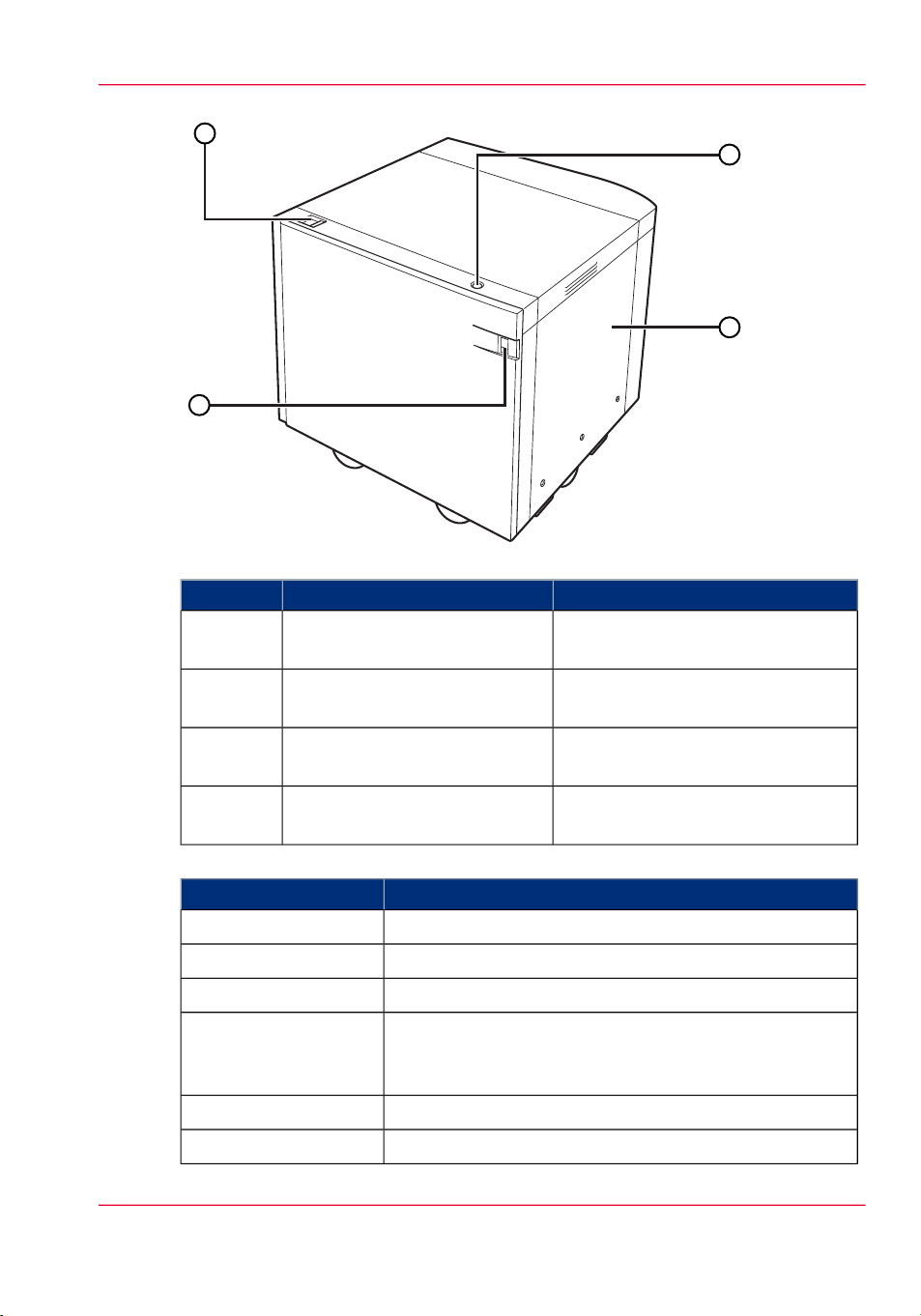

Page 29

1

2

3

4

Parts of the bulk paper module#

Release button1

The paper modules

FunctionComponent

Detaches the bulk paper module

from the main unit when pressed.

Open button2

Opens the paper tray to load media

or check for a paper jam.

Paper tray3

Contains the media that will be

printed

Paper supply indicator4

Enables you to check the amount of

paper remaining in the paper tray.

#

ValueSpecification

Optional single-tray paper moduleDescription

1 x 3500 sheets (80 g/m² / 22 lb. Bond)Paper trays

64 - 300 g/m² / 17 lb. Bond - 110 lb. CoverPaper weight

Paper size

A4, A4R, A3, SRA3, B5, B4, LTR, LTRR, LGL, Ledger,

12" x 18" / 304.8 x 457.2 mm, 13" x 19" / 330.2 x 482.6

No custom sizes supported

601 x 621 x 570 mm / 23.66" x 24.45" x 22.44"Dimensions (WxDxH)

51 kg / 112 lbsWeight

Chapter 2 - Main parts 29

Page 30

The paper modules

Paper feed technology

Total capacity

Total capacity including the external paper modules#

Total capacity including the bulk paper module#

ValueSpecification

From main enginePower consumption

•

Friction feed

•

Air separation

•

Automatic tray openingFeatures

Total number of sheetsPaper modules

2,000 sheetsInternal paper trays only

6,000 sheetsWith 1 external paper module

10,000 sheetsWith 2 external paper modules

Total number of sheetsPaper modules

2,000 sheetsInternal paper trays only

•Overview of the machine configuration, on page 18

5,500 sheetsWith 1 external bulk paper module

Chapter 2 - Main parts30

Page 31

The tab feeder (optional)

34

1

2

Introduction

The tab feeder is needed to feed tabs via a paper tray.

Tab feeder

The tab feeder (optional)

Parts of the tab feeder#

FunctionComponent

Paper holder1

The paper holder constrains the tab

paper downwards.

Handle2

Grip this handle to install the tab

feeding attachment in the paper trays.

Location fix frame3

Embed the location fix frame in the

hole of the lifter to fix the tab feeding

attachment to the paper deck.

Paper size change screw4

Specifications of the tab feeder#

ValueItem

Description

Needed for reliable tab feeding. One kit is needed per paper

Use this screw to change the tab paper size to A4 or LTR.

tray to support tab feeding

Option for

The paper modules of the main unit and the optional POD

Deck-A1/Secondary POD Deck-A1

Chapter 2 - Main parts 31

Page 32

The tab feeder (optional)

•Overview of the machine configuration, on page 18

•Load tabs via the tab feeder (optional), on page 272

Chapter 2 - Main parts32

Page 33

The special feeder (optional)

1

2

Introduction

You can use the special feeder to feed media to print on manually.

The special feeder (optional)

The special feeder (optional)

Parts of the special feeder#

Slide guides1

Auxiliary tray2

#

ity

Paper size

FunctionComponent

Enables you to match the size of the

paper.

Enables you to guide paper with large

sizes.

ValueSpecification

100 sheets (80 g/m² / 22 lb. Bond)Maximum paper capac-

64 - 256 g/m² / 17 lb. Bond - 95 lb. CoverPaper weight

A3R, A4R, A4, B4R, B5R, B5, A5R, SRA3, 11×17, LGLS,

LTRL, LTRS, STMTS, 12×18, 13×19, Exec

Custom sizes: 139.7 x 182 mm - 330.2 x 487.7 mm / 5.5"

x 7.17" - 13" x 19.2"

Chapter 2 - Main parts 33

Page 34

The special feeder (optional)

NOTE

•

Feed coated paper one sheet at a time. Loading several sheets together may cause

paper jams.

•

Not available in combination with external paper module.

ValueSpecification

Chapter 2 - Main parts34

Page 35

1

2 3

6 5 4

(7)

The automatic document feeder - ADF (optional)

The automatic document feeder - ADF (optional)

Introduction

This section describes the part of the Automatic Document Feeder (ADF).

The automatic document feeder (ADF)

#

FunctionComponent

Open this cover to clear a paper jam.Feeder cover1

Original set indicator2

Original supply tray3

Lights when originals are placed in

the original supply tray.

Place originals face up here for automatic document feeding.

Original output tray4

Receives scanned originals in the order that they are fed.

Chapter 2 - Main parts 35

Page 36

The automatic document feeder - ADF (optional)

SADF tray5

FunctionComponent

Single Automatic Document Feeder

Tray. To feed heavy or lightweight

originals one by one, face down.

Slide guides6

Adjust the slide guides to match the

width of the original.

Helps to close the ADF.ADF Access Handle7

Chapter 2 - Main parts36

Page 37

The color scanner (optional)

1

Introduction

You can use the color scanner to scan bound originals (such as books and magazines),

heavy or lightweight originals, and transparencies. If the color scanner is attached, the

optional ADF or Platen Cover Type K is required.

#

IMPORTANT

When you use the glass plate to copy or scan thick originals, such as books or magazines, do not press down hard on the feeder or glass plate cover.

Color scanner (optional)

The color scanner (optional)

#

FunctionComponent

Glass plate1

Scan bound originals (such as books

and magazines), heavy or lightweight

originals, and transparencies.

Chapter 2 - Main parts 37

Page 38

1

10

2

3

4

5

7

8

9

6

The operator panel

The operator panel

Introduction

The operator panel helps you to carry out print jobs, copy jobs and scan jobs. This section

describes the main components of the operator panel.

#

IMPORTANT

You can clean the screen of the operator panel with a 50% mix of water and isopropyl

alcohol (K2). Use a lint-free cloth. Always put the cleaner onto the cloth and not directly on the screen.

Illustration

[18] The operator panel

The components of the operator panel

The components of the operator panel#

Sleep mode key1

Stop key2

Chapter 2 - Main parts38

FunctionComponent

Depending on whether the printer is currently

active or in the sleep mode:

•

Put the machine into the sleep mode, or

•

Wake up the machine from the sleep

mode.

•

Shut down the printer and controller.

Stop the printer.

•

After a set, or

•

As soon as possible

Page 39

The operator panel

FunctionComponent

Paper tray key3

Get immediate and always access to the 'Trays'

section on the operator panel to do the following, for example:

•

Check the content of all paper trays.

•

Load a new media type into a paper tray.

•

Change the media type which is available

in one of the paper trays.

USB port4

Use the USB port to:

•

Connect the spectrophotometer and calibrate the printer and controller.

•

Print a file from an USB drive

•

Scan to a USB drive

'Schedule' button5

Access the 'Schedule' view to manage the jobs

in the schedule.

'Jobs' button6

Access all functions to print, copy and scan

your documents.

•

Manage or change the settings of jobs in

the lists of 'Waiting jobs', 'Scheduled jobs'

and 'Printed jobs'.

•

Carry out copy jobs and scan jobs.

'Trays' button7

Access the 'Trays' view on the operator panel

to do the following, for example:

•

Check the content of all paper trays.

•

Load a new media type into a paper tray,

or

•

Change the media type which is available

in one of the paper trays.

Chapter 2 - Main parts 39

Page 40

The operator panel

FunctionComponent

'System' button8

Access 'System' view to do the following, for

example:

•

Check the status of the toner, staples and

other supplies.

•

Read the counters.

•

Start maintenance.

•

Set up the preferred workflows.

•

Change a number of default system settings.

•

Adjust the brightness and contrast of the

LCD panel.

•

Shut down the printer.

•

View the content of the Media catalogue

or add temporary media to the Media catalogue.

•

Start maintenance, calibration and media

registration

Dashboard9

The dashboard displays information about the

system status such as:

•

Information about the current printing

process.

•

Information about operator intervention

that is required soon.

•

Information about errors.

•

Information about the status of the toner

reservoir and staple cartridges.

•

Continue the job when the status is 'On

hold'.

Chapter 2 - Main parts40

Page 41

The operator panel

FunctionComponent

Status LED10

Displays the status of the system.

•

Red

The machine has stopped, for example

because a required media type is not available or an error has occurred. Operator

attention is required now.

•

Orange

The machine will stop soon, for example

because more paper is required. Operator

attention is required soon.

The orange light illuminates when the

machine reaches the warning time. The

warning time is a time you can set to determine when the orange light must illuminate. You can set the warning time in the

'System' view of the operator panel.

•

Green

The machine is busy printing. The machine can print longer than the set warning

time. Operator attention is not required.

•Stop the printer, on page 127

•Introduction to the Schedule view, on page 134

•Overview of the machine configuration, on page 18

•The operator attention light, on page 42

•

No color.

The machine is idle. There are no jobs

scheduled for printing.

Chapter 2 - Main parts 41

Page 42

The operator attention light

The operator attention light

Introduction

The operator attention light on top of the printer helps you to monitor the status of the

printer from a distance. The colors of the lights match the printer status that the dashboard

displays.

Illustration

[19] The operator attention light

Status colors

The status colors of the operator attention light#

Red

Chapter 2 - Main parts42

DescriptionColor

The machine has stopped, for example because a required

media type is not available or an error has occurred.

Operator attention is required now.

Page 43

Orange

The operator attention light

DescriptionColor

The machine will stop soon, for example because more

paper is required.

Operator attention is required soon.

The orange light illuminates when the machine reaches the

warning time. The warning time is a time you can set to

determine when the orange light must illuminate. You can

set the warning time in the 'System' section of the operator

panel.

By factory default, the warning time is set to 10 minutes.

So 10 minutes before operator attention is required, the

orange light will illuminate.

Green

The machine is busy printing. The machine can print

longer than the set warning time.

Operator attention is not required.

All lights off

The machine is idle. There are no jobs scheduled for

printing.

•Overview of the machine configuration, on page 18

Chapter 2 - Main parts 43

Page 44

Finishing options

Finishing options

The following optional finishing options are described in separate manuals.

•

High Capacity Stacker-C1

•

Booklet Trimmer-D1

•

Two-Knife Booklet Trimmer-A1

•

Perfect Binder-B1

The Finisher-AJ1/Saddle Finisher-AJ2/Puncher Unit-BC1/BD1/Document Insertion

Unit-C1 is described in this manual.

Chapter 2 - Main parts44

Page 45

(I side)

( side)

1

2

3

2

3

4

5

6 6

7

7

8

The stacker/stapler, optional inserter and optional integrated punch unit

The stacker/stapler, optional inserter and optional integrated

punch unit

Introduction

With the Finisher-AJ1 and Saddle Finisher-AJ2 you can stack and staple prints. With

the Saddle Finisher-AJ2 you can also saddle stitch booklets. With the optional Puncher

Unit-BC1/BD1/BB1 you can punch holes in your prints.

#

IMPORTANT

You cannot attach the optional Finisher-AJ1 and Saddle Finisher-AJ2 to the machine

at the same time.

External view

[20] The Saddle Finisher-AJ2 with inserter (left side) and Finisher-AJ1 (right side)

Main parts#

Main power switch1

Top cover2

FunctionComponent

Press to the "I" side to turn on the

stacker/stapler.

Open the top cover to clear a paper

jam inside the unit.

Chapter 2 - Main parts 45

Page 46

The stacker/stapler, optional inserter and optional integrated punch unit

FunctionComponent

Front cover3

Open the front cover to replace the

staple cartridge, remove jammed paper, or clear a staple jam in the stapler

unit and saddle stitcher unit.

4

Receives saddle stitched booklets.Booklet tray

Saddle Finisher-AJ2 only

5

Auxiliary booklet tray

Saddle Finisher-AJ2 only

Pull out the auxiliary booklet tray to

receive large size booklets.

Receives finished documents.Lower tray6

Receives finished documentsUpper tray7

Inserter8

The inserter is used to feed cover

sheets for printed documents and

booklets. The inserter is also an option for the Finisher-AJ1.

Chapter 2 - Main parts46

Page 47

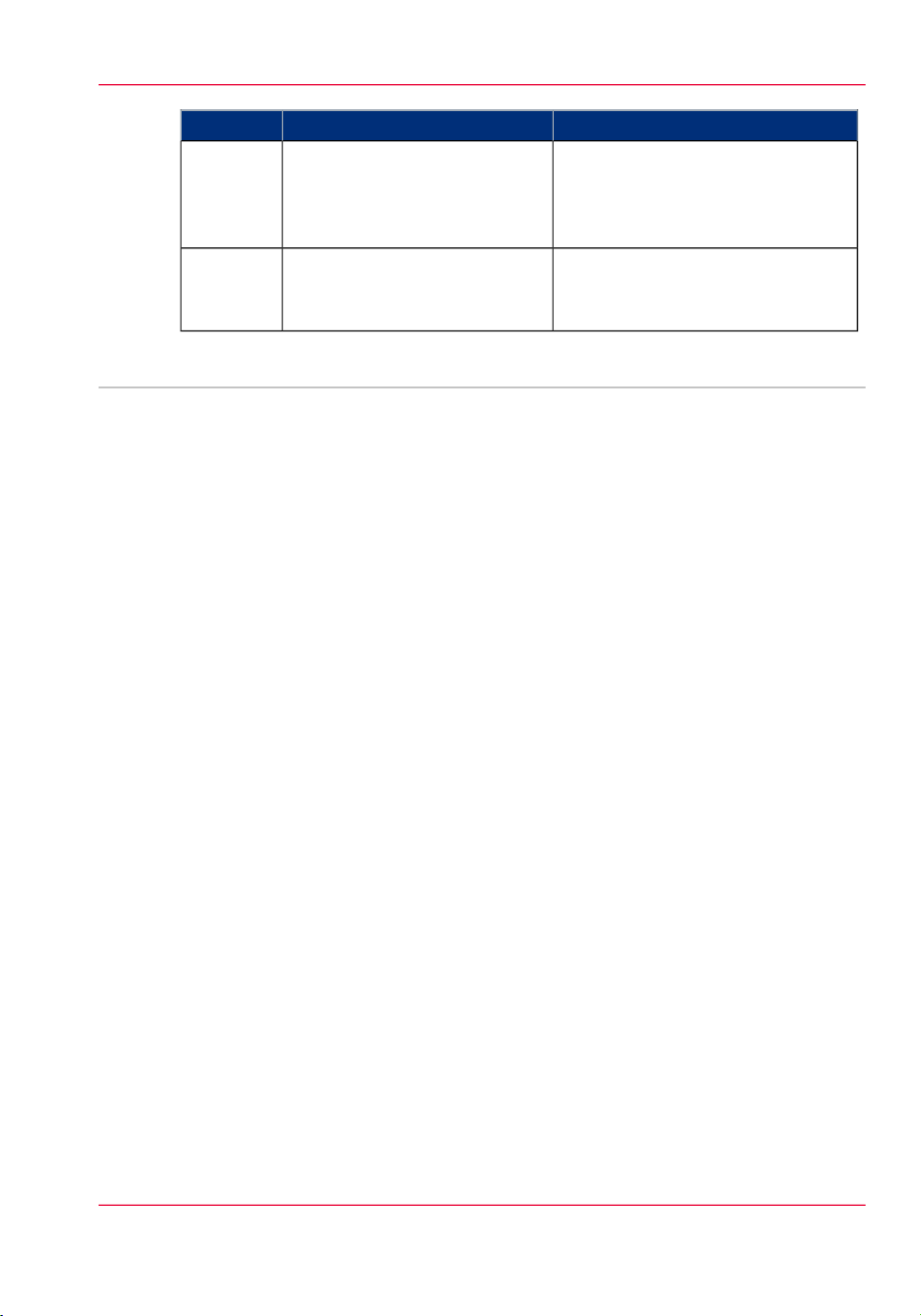

Internal view

12

The stacker/stapler, optional inserter and optional integrated punch unit

[21] The finisher module

Main parts#

Punch waste tray1

Staple waste tray2

FunctionComponent

Pull out the punch waste tray to remove punch waste.

Pull out the staple waste tray to discard the staple waste.

Chapter 2 - Main parts 47

Page 48

The stacker/stapler, optional inserter and optional integrated punch unit

Finishing options

#

IMPORTANT

•

Do not place anything other than output paper in the trays of the finisher, as doing

so may damage the trays.

•

Do not place anything under the trays of the finisher, as doing so may damage

the trays.

[22]

#

NOTE

•

If the finishing is used, the output trays move downward as the stack of paper that

is output increases in quantity and thickness. Once an output tray has reached its

stacking limit, subsequent prints are automatically delivered to the next available

tray. If all of the available trays have reached their stacking limits, printing stops

temporarily. Remove all of the output paper from the trays. The trays move upward

and printing resumes.

•

If the optional Booklet Trimmer-D1 is attached to the Saddle Finisher-AJ2, you

cannot output stapled paper to the booklet.

#

CAUTION

Do not place your hands in the part of the tray where stapling is performed (near

the rollers) when a finisher is attached, as this may result in personal injury.

Chapter 2 - Main parts48

Page 49

The stacker/stapler, optional inserter and optional integrated punch unit

[23]

Stapling

#

IMPORTANT

•

During stapling, the output trays move downward as the stack of paper that is

output increases in quantity and thickness. Once an output tray has reached its

stacking limit, or after 100 sets of prints have been output, printing and stapling

stop temporarily. Remove all of the stapled prints from the output tray, and

printing and stapling resume.

•

You can corner and double staple A3, B4, A4, A4R, and B5 paper.

•

You can corner and double staple 11" x 17", LGL, LTR, LTRR and EXEC paper.

•

You cannot staple vellums, transparencies, or labels.

•

Do not pull copies or prints out of the output area while they are being stapled.

Remove the copies or prints after they are output to one of the output trays.

#

NOTE

•

If you want to staple more than 50 sheets (80 g/m² /22 lb Bond) of A3, B4, or

A4R paper, or 100 sheets (80 g/m² / 22 lb Bond) of A4 or B5 paper, the

copies/prints are only offset but not stapled. In addition, when selecting coated

or heavy paper, you may not be able to use stapling even if the number of sheets,

including sheet insertions or job separators, is below the set limit of a finisher.

•

If you want to staple more than 50 sheets (80 g/m² / 22 lb Bond) of 11"x 17",

LGL or LTRR paper, or 100 sheets (80 g/m² / 22 lb Bond) of LTR or EXEC paper,

the copies/prints are only offset but not stapled. In addition, when selecting coated

or heavy paper, you may not be able to use stapling even if the number of sheets,

including sheet insertions or job separators, is below the set limit of a finisher.

•

If the machine stops while stapling because almost all of the staples have been used

the staple cartridge must be replaced.

•

Saddle stitching (booklets)

Chapter 2 - Main parts 49

Page 50

Cross Section Cross Section

The stacker/stapler, optional inserter and optional integrated punch unit

#

IMPORTANT

•

Saddle stitching (booklets) is available only if the Saddle Finisher-AJ2 is attached.

•

The maximum number of sheets that can be saddle stitched differs depending on

the paper weight and type.

- When using plain paper (80 g/m² / 22 lb Bond), 25 sheets of paper (100 pages)

can be saddle stitched at once.

- When using coated paper (80 g/m² / 22 lb Bond), 15 sheets of paper (60 pages)

can be saddle stitched at once.

•

The paper sizes that can be saddle stitched are: 330.2 mm x 482.6 mm, 320 mm

x 450 mm (SRA3), 304.8 mm x 457.2 mm, A3, B4, A4R, and irregular size (210

mm x 279.4 mm to 330.2 mm x 487.7 mm).

The paper sizes that can be saddle stitched are: 13" x 19", 12.60" x 17.72", 12" x

18", 11" x 17", LGL, LTRR, and irregular size (8 1/4" x 11" to 13" x 19 13/64").

•

The accuracy of folds created with saddle stitching may vary, depending on the

paper type and the number of sheets.

•

Saddle pressing

Saddle press enables you to compress a saddle stitched booklet spine.

[24]

#

IMPORTANT

Saddle press is automatically used when you select booklet.

#

NOTE

To make sure that saddle pressing is effective, you must saddle stitch more than nine

sheets of paper (including one cover sheet).

•

Punching

Chapter 2 - Main parts50

Page 51

80 mm

Puncher Unit-BC1 (2 holes)

80 mm 80 mm 80 mm

Puncher Unit-BC1 (4 holes)

The stacker/stapler, optional inserter and optional integrated punch unit

#

IMPORTANT

•

Punching is available only if the Puncher Unit-BB1/BC1/BD1 or Professional

Puncher-B1 is attached.

•

Only the following paper size can be hole punched:

A3, B4, A4, A4R, B5, or B5R / 11" x 17", LGL, LTR, LTRR, or EXEC

•

When the Puncher Unit-BC1 is attached, only A3 or A4 paper can be punched

in four holes.

•

If only the optional Puncher Unit-BB1 is attached, the machine automatically

selects how many holes to punch depending on the selected paper size.

- Two holes in case of LGL and LTRR

- Three holes in case of 11" x 17", LTR and EXEC

•

Holes cannot be punched in paper heavier than 201 g/m² / 54 lb Bond, vellums,

transparencies, labels, or prepunched paper.

•

Paper that is fed from the optional Document Insertion Unit-C1 cannot be hole

punched.

#

NOTE

The distance between the punch holes is shown in the illustration below

[25]

[26]

Chapter 2 - Main parts 51

Page 52

21 mm 70 mm 21 mm

Puncher Unit-BD1

4 1/4"

(108 mm)

4 1/4"

(108 mm)

2 3/4"

(70 mm)

Three Holes Two Holes

5

4

3

2

1

1

The paper is saddle folded

with a m

aximum of 5 sheets

seipoCslanigirO

The stacker/stapler, optional inserter and optional integrated punch unit

[27]

Chapter 2 - Main parts52

[28] Puncher Unit-BB1

•

Folding

Folding folds multiple sheets in 2-folds.

[29]

Page 53

The stacker/stapler, optional inserter and optional integrated punch unit

#

IMPORTANT

•

Saddle folding is available only if the Saddle Finisher-AJ2 is attached.

•

The paper is saddle folded with a maximum of 5 sheets (80 g/m²), and then output.

•

The sizes of paper that can be used with saddle folding are:

- 330.2 mm x 482.6 mm, 320 mm x 450 mm (SRA3), 304.8 mm x 457.2 mm,

A3, B4, A4R, and irregular size paper (210 mm x 279.4 mm to 330.2 mm x 487.7

mm).

•

- 13" x 19", 12.60" x 17.72", 12" x 18”, 11" x 17", LGL, LTRT and irregular size

paper (8 1/4" x 11" to 13" x 19 13/64").

#

NOTE

The following are paper sizes that can be output to the output trays of the machine.

However, some paper sizes may not be output, depending on the set functions.

Input options#

Booklet trayLower trayUpper trayPaper size

A3

-A4

A4R

--A4R

Custom size

139.7 mm x

182 mm to

)²)¹

330.2 mm x

487.7 mm

)¹ Only the custom size (182 mm x 182 mm to 330.2 mm x 487.7 mm) can be output.

)² Only the custom size (210 mm x 279.4 mm to 330.2 mm x 487.7 mm) can be output.

Input options#

Booklet trayLower trayUpper trayPaper size

11" x 17"

-LGL

Chapter 2 - Main parts 53

Page 54

The stacker/stapler, optional inserter and optional integrated punch unit

LTR

Custom size

139.7 mm x

182 mm to

330.2 mm x

487.7 mm

)¹ Only the custom size (7 1/8" x 7 1/8" to 13" x 19 13/64" (182 mm x 182 mm to 330.2

mm x 487.7 mm)) can be output.

)² Only the custom size (8 1/4" x 11" to 13" x 19 13/64" (210 mm x 279.4 mm to 330.2

mm x 487.7 mm)) can be output.

#

NOTE

The Booklet Tray can only be used when the Saddle Finisher-AJ2 is attached.

Booklet trayLower trayUpper trayPaper size

--LTRR

-EXEC

)²)¹

Optional accessories

[56] Staple-N1: a case that holds staples for stapling

Chapter 2 - Main parts54

Page 55

The stacker/stapler, optional inserter and optional integrated punch unit

[57] Staple-P2: a case that holds staples for saddle stitching

•Removing the punch waste, on page 290

•Replacing the staple cartridge in the stapler unit, on page 306

Chapter 2 - Main parts 55

Page 56

( I side)

( side)

a

b

The puncher

The puncher

Introduction

The Professional Puncher Integration Unit-A1 reverses the paper punched by the Professional Puncher-B1.

#

IMPORTANT

Always keep the main power switch of the Professional Puncher-B1 inside the front

cover turned to the "I" side. In this case, the main power switch of the Professional

Puncher-B1 works with the main power switch of the Professional Puncher Integration

Unit-A1 automatically.

[58] Power switch of Professional Puncher-B1

#

IMPORTANT

Illustration

[59] Professional Puncher Integration Unit-A1

If the main power switch of the Professional Puncher-B1 is turned to the "O" side,

turn it to the "I" side before turning ON the main power switch of the Professional

Puncher Integration Unit-A1.

Chapter 2 - Main parts56

Page 57

The puncher

#

FunctionComponent

Open this cover to clear a paper jam.Front cover1

Main power switch2

Press to the "I" side to turn ON the

Professional Puncher Integration

Unit-A1.

Chapter 2 - Main parts 57

Page 58

The puncher

Chapter 2 - Main parts58

Page 59

Chapter 3 Operating concept

Page 60

Operating concept

Operating concept

Introduction

To maximize efficient and productive printing, the operating concept of the system, is

based on the following principles.

•

Document preparation / job submission and production printing are clearly separated

steps in the workflow.

•

Media definition is done by choosing from a media catalog instead of selecting trays.

•

Operation is intuitive and convenient at all workflow steps.

•

The workflow is entirely integrated because all components work together seamlessly.

Chapter 3 - Operating concept60

Page 61

Illustration

1

2

3

5

6

7

8

4

Operating concept

[60] The components of the complete system

Chapter 3 - Operating concept 61

Page 62

Operating concept

Components overview

#

Settings Editor1

Main taskComponent

Define initial and default system settings

•

Set default print and workflow settings

•

Define default color management settings like

color pre-sets

•

Maintain the media catalog

•

Set scan settings

2

Printer driver

Available via any application, e.g. Adobe Acrobat, Microsoft Word.

3

PRISMAprepare

Optional software

Document preparation and job submission

•

Document preparation for production printing

•

Define settings per print job

•

Send print jobs to the printer

Document preparation and job submission

•

Document preparation with full preview for

production printing

•

Define settings per page for complex print jobs

•

Send print jobs to the printer

•

Send print jobs to the PostScript printers in

the network

4

PRISMAaccess

Optional software

Workflow management for production environments

•

Easy integration in PDF workflow

•

Job submission via web

•

Acceptance and preparation of incoming jobs

•

Link to PRISMAprepare

•

Link to all production printers

•

Link to PRISMAarchive or your local reprint

archive

5

PRISMAsync controller

Process print jobs

•

Rip print jobs

Remote Monitor6

Monitor production printing remotely

•

Monitor remotely when operator intervention

is needed

Chapter 3 - Operating concept62

Page 63

Operating concept

Main taskComponent

Operator panel7

Manage production printing from the 'Schedule'

view

•

Monitor your print and copy jobs

•

Load and assign media to the media trays

Manage jobs from the 'Jobs' view

•

Schedule print and copy jobs

•

Change job properties if required

•

Define and handle copy jobs

•

Define and handle scan jobs

Manage media from the 'Trays' view

•

Change the media that is currently assigned to

a paper tray

•

Assign the media to the paper tray

Manage the system from the 'System' view

•

Calibrate the system

•

Perform maintenance tasks

•

Set default workflow and printer settings

•

View the media catalog, add temporary media

and perform media registration

•

8

imagePRESS

C7010VPS/C6010VPS/C6010S

Production printing

•

Finishing

Chapter 3 - Operating concept 63

Page 64

Access the Settings Editor

Access the Settings Editor

Introduction

The Settings Editor is a web-based application and therefore accessible via an Internet

browser. The Settings Editor enables you to manage settings or to display information in

the following areas.

•

'Media'

•

'color'

•

'Preferences'

•

'Workflow'

•

'Configuration'

•

'Support'

Before you begin

Make sure you have the following information.

•

The IP address or hostname of the controller.

•

The key operator password to change all settings except for the settings in the 'Configuration' tab.

•

The administrator password to change all settings including the settings in the 'Configuration' tab.

Access the Settings Editor

Open the Internet browser.

1.

At the address bar, enter the IP address or host name of the controller.

2.

Chapter 3 - Operating concept64

Page 65

The Settings Editor appears.

Access the Settings Editor

Result

You can now use the Settings Editor to make changes in the above listed areas.

Chapter 3 - Operating concept 65

Page 66

Maintain the 'Media catalog'

Maintain the 'Media catalog'

Introduction

The 'Media catalog' is a list of media with pre-defined characteristics including the 'Media

family'.

See ‘Maintain the 'Media families' ’ on page 68.

Before you begin

Make sure you have the following information.

•

Key operator or system administrator password

Maintain the 'Media catalog'

From the navigation bar, select the 'Media' tab.

1.

From the 'Media' tab, select 'Media'.

2.

The 'Media catalog' window appears.

[62] The 'Media catalog' window

From the toolbar, select the required option to maintain the 'Media catalog'.

3.

Chapter 3 - Operating concept66

Page 67

Maintain the 'Media catalog'

#

NOTE

When you add, change or import new media, make sure that you enter the correct

values for the following options.

•

'Weight'

•

'Media family'

•

'Media type'

The correct values are required for optimal print quality.

[63] The 'Add new media' window

Chapter 3 - Operating concept 67

Page 68

Maintain the 'Media families'

Maintain the 'Media families'

Introduction

The 'Media family' is a group of media that uses the same output profile. The controller

provides by default the media families coated and uncoated. An expert can create a new

media family for a specific group of media. A media family refers to 1 of the following

halftones.

•

'Normal'

•

'Fine'

•

'Error diffusion'

Before you begin

Make sure you have the following information.

•

Key operator password

Maintain the 'Media families'

From the navigation bar, select the 'Media' tab.

1.

From the 'Media' tab, select 'Media family'.

2.

The 'Media families' window appears.

[64] The 'Media families' window

Chapter 3 - Operating concept68

Page 69

Maintain the 'Media families'

From the toolbar, select the required option to maintain the 'Media families'.

3.

[65] The 'Add media family' window

Chapter 3 - Operating concept 69

Page 70

Maintain the 'Color pre-sets'

Maintain the 'Color pre-sets'

Introduction

A color pre-set is a collection of color and quality settings that matches a specific document

type, workflow or color application. The color pre-sets enable users to select the correct

settings easily without in-depth knowledge about color management.

The controller provides the following color pre-sets to start printing immediately.

•

'Office documents' to print the Microsoft Office documents.

The Microsoft Office documents use the RGB color space.

•

'Photographic content' to print documents from photo editing or layout applications.

These documents use the CMYK color space.

A color expert can create more color pre-sets. The color pre-sets appear in the printer

driver and in PRISMAprepare (optional software).

Maintain the 'Color pre-sets'

From the navigation bar, select the 'color' tab.

1.

From the 'color' tab, select 'Color pre-sets'.

2.

The 'Color pre-sets' window appears.

[66] The 'Color pre-sets' window

Chapter 3 - Operating concept70

Page 71

Maintain the 'Color pre-sets'

From the toolbar, select the required option to maintain the 'Color pre-sets'.

3.

[67] The 'Add color pre-set' window

Chapter 3 - Operating concept 71

Page 72

Maintain the 'Input profiles'

Maintain the 'Input profiles'

Introduction

An input profile defines a reference color workspace for the color data of the objects in

the document. An input profile is used to define colors in a device independent way.

Maintain the 'Input profiles'

From the navigation bar, select the 'color' tab.

1.

From the 'color' tab, select 'Input profiles'.

2.

The 'Input profiles' window appears.

[68] The 'Input profiles' window

From the toolbar, select the required option to maintain the input profiles.

3.

Chapter 3 - Operating concept72

Page 73

Maintain the 'Output profiles'

Introduction

An output profile defines a reference color workspace for the color data of the objects in

the document. An output profile is used to define colors in a device independent way.

Maintain the 'Output profiles'

From the navigation bar, select the 'color' tab.

1.

From the 'color' tab, select 'Output profiles'.

2.

The 'Output profiles' window appears.

Maintain the 'Output profiles'

[69] The 'Output profiles' window

From the toolbar, select the required option to maintain the output profiles.

3.

Chapter 3 - Operating concept 73

Page 74

Maintain the 'Spot colors'

Maintain the 'Spot colors'

Introduction

Spot colors are used to standardize colors to make sure that colors match regardless of

the equipment used to produce the color.

Maintain the 'Spot colors'

From the navigation bar, select the 'color' tab.

1.

From the 'color' tab, select 'Spot colors'.

2.

The 'Spot colors' window appears.

[70] The 'Spot colors' window

From the toolbar, select the required option to maintain the spot colors.

3.

Chapter 3 - Operating concept74

Page 75

Prepare print jobs with PRISMAprepare

Prepare print jobs with PRISMAprepare

Introduction

Océ PRISMAprepare allows you to prepare the print job completely on page level. You

can preview the result per page. PRISMAprepare is an optional application.

This procedure describes the most important settings for daily use.

Prepare print jobs with PRISMAprepare

Prepare the document.

1.

[71] Lay out preparation with PRISMAprepare

Use the media catalog to define the media.

2.

Chapter 3 - Operating concept 75

Page 76

Prepare print jobs with PRISMAprepare

With PRISMAprepare you can export the media catalogue to PRISMAsync controllers

of the black & white and color systems.

[72] The media catalog in PRISMAprepare

Select the required color pre-set or define customized color settings for optimal print

3.

quality.

•

Select 'Office documents' to print the Microsoft Office documents. The Microsoft

Office documents use the RGB color space.

•

Select 'Photographic content' to print documents from photo editing or layout applications. These documents use the CMYK color space.

Define the required finishing options.

4.

#

NOTE

Please refer to the online help of PRISMAprepare for detailed information.

Chapter 3 - Operating concept76

Page 77

Prepare print jobs with the printer driver

Prepare print jobs with the printer driver

Introduction

The printer driver enables you to prepare the print job completely. The printer driver

appears in all applications running in the Microsoft Windows or Apple Mac OS operating

systems.

This procedure describes the most important settings for daily use.

Prepare print jobs with the printer driver

Use the media catalog to select the media to print on.

1.

[73] The media catalog in the printer driver

Select the required color pre-set or define customized color settings for optimal print

2.

quality.

•

Select 'Office documents' to print Microsoft Office documents. Microsoft Office

documents use the RGB color space.

Chapter 3 - Operating concept 77

Page 78

Prepare print jobs with the printer driver

•

Select 'Photographic content' to print documents from photo editing or layout applications. These documents use the CMYK or RGB color space.

[74] The color pre-sets in the printer driver

Chapter 3 - Operating concept78

Page 79

Define the required finishing options.

3.

Prepare print jobs with the printer driver

[75] The finishing options in the printer driver

#

NOTE

Click the white question mark to open the online help of the printer driver for detailed

information.

Chapter 3 - Operating concept 79

Page 80

Manage production printing

Manage production printing

Introduction

The operating panel of the printer enables you to manage production printing. You

manage all print jobs from the 'Schedule' tab. The Remote Monitor enables you to

monitor the system status from a distance via an internet browser.

Manage production printing

Press the 'Schedule' button at the lower left of the operator panel to access the 'Schedule'

1.

view.

[76] The 'Schedule' view

Monitor operator intervention remotely

Open the Internet Browser.

1.

At the address bar, enter 'http://printername/remoteinfo'.

2.

Chapter 3 - Operating concept80

Page 81

The Remote Monitor displays a fixed time line of 30 minutes.

[77] The remote monitor

Manage production printing

Chapter 3 - Operating concept 81

Page 82

Manage production printing

Chapter 3 - Operating concept82

Page 83

Chapter 4 Operator panel views

Page 84

32

1

4

32

1

4

The dashboard

The dashboard

Introduction

The dashboard is the upper part of the operator panel. The dashboard is always visible,

irrespective of the current view. The dashboard shows the following.

•

The status of the system.

•

The status of the supplies.

•

The status of the finishers.

•

The current process.

•

Instructions for the operator.

•

The 'Continue' button after you stopped the printer.

Illustration

The following illustration shows the dashboard while the machine is busy. The vertical

status bar is green. No action is required.

[78] The dashboard - No action is required

The following illustration shows the dashboard while the machine is busy. The vertical