Canon imagePRESS C7000VP Series Trouble Shooting Information

Trouble Shooting Information for C7000VP series

Page 1

Rev. 2.0

2010/09/17

imagePRESS C7000VP Series

Trouble Shooting Information

Trouble Shooting Information for C7000VP series

Page 2

Rev. 2.0

2010/09/17

Table of Contents

1 Error Code ····································································································································· 5

1.1 E000-0102 ·········································································································································· 5

1.2 E007-0001 ·········································································································································· 6

1.3 E012-1080 ·········································································································································· 7

1.4 E014-0100 ·········································································································································· 7

1.5 E016 Photosensitive drum cleaner motor lock ···································································· 8

1.6 E018 ······················································································································································ 9

1.7 E061-0181 ········································································································································ 11

1.8 E062-0300 ········································································································································ 11

1.9 E065-0201 ········································································································································ 12

1.10 E077-0001 ····································································································································· 13

1.11 E078-0001 ····································································································································· 13

1.12 E202-0001 ····································································································································· 14

1.13 E260-2000, E260-0002, E227-0001 ···················································································· 15

1.14 E260-2004 Power Supply Error (ITB Driver PCB right 13V) ···································· 15

1.15 E512-8011 ····································································································································· 16

1.16 E514-8001 only at first power-on in the morning ························································· 18

1.17 E578 ·················································································································································· 18

1.18 E590-8003 ····································································································································· 19

1.19 E747-051B ····································································································································· 19

1.20 E750-0002 ····································································································································· 20

1.21 E750-2012 ····································································································································· 20

1.22 E804-0001 ····································································································································· 21

1.23 E805-0404 ····································································································································· 23

1.24 E805-0701 ····································································································································· 24

1.25 E822-0903 ····································································································································· 25

1.26 E020 ·················································································································································· 26

1.27 E194 and Color Registration Failure ···················································································· 31

1.28 E842-0211 -> New item ········································································································· 42

1.29 E750-2012 at installation -> New item ·········································································· 43

1.30 E805-Y701 -> Additional contents ···················································································· 45

2 Operational Failure ················································································································· 47

2.1 Message prompting for toner supply ····················································································· 47

2.2 Message ‘Check: Punch waste tray’ ··················································································· 48

2.3 Cannot print in spite of ‘Printing’ indication ···································································· 49

2.4 Unavailable RUI although same IP address has been specified ·································· 49

2.5 Directory server name does not appear as SMB directory under browse ············· 50

2.6 ‘Invalid user data’ displays on browser when connecting to RUI ····························· 51

2.7 When importing paper database via RUI, parameters are not carried over ············ 52

2.8 Full adjustment for auto gradation cannot be completed·············································· 52

2.9 Noise from around developing drive assembly/Cracked developing drive gear ··· 53

2.10 Although Tray A is designated as delivery outlet, paper is delivered to Tray B.58

2.11 The red warning light blinks and print operation is not accepted -> New item58

2.12 Noise occurred at operating the refresh roller -> New item ····································· 59

2.13 The magenta developing assembly is not activated -> New item ··························· 60

2.14 Breakage of the splatter prevention sheet at the end of the developing assembly -> New

item 60

Trouble Shooting Information for C7000VP series

Page 3

Rev. 2.0

2010/09/17

3 Image Quality ····························································································································· 62

3.1 Y Tiger / BK Tiger ························································································································ 62

3.2 Uneven gloss area appears at end of output images: Silicon oil is depleted ········· 64

3.3 Soiled back side due to toner at secondary transfer external roller ························ 66

3.4 Soiled back side cases reported from field ········································································· 66

3.5 Magenta fogging throughout page /E020-02b1 during continuous printing job ···· 67

3.6 Color displacement in main scanning direction ································································· 68

3.7 Uneven density due to toner-coating failure of sleeve ·················································· 69

3.8 Trace of delivery reversing roller (uneven gloss) on 1st side of duplex in continuous printing

70

3.9 Glossy Lines equivalent to A4R or LTRR width ································································ 71

3.10 Dirt of pin hole (ring mark) ······································································································ 72

3.11 Trace of bypass decurler belt (uneven gloss) on 1st side of duplex in continuous printing

73

3.12 Wax mark in tandem feeding mode ······················································································· 74

3.13 White spots appear at 68mm intervals ··············································································· 76

3.14 3.7mm Pitch Banding ················································································································· 77

3.15 Density difference on image between front side and rear side ································ 78

3.16 Boomerang ····································································································································· 78

3.17 Hue variation ································································································································· 79

3.18 Uneven image with approx. 60mm pitch in main scanning direction ······················· 79

3.19 Sleeve ghost (shadow image) ································································································· 80

3.20 Streaks due to uneven gloss on the coated paper (sub scanning) ························· 81

3.21 Starter overflow ··························································································································· 82

3.22 Hue variation - 2 ························································································································· 83

3.23 Soiled back side of image (toner overflow from the secondary transfer cleaner) -> New

item 84

3.24 2mm-pitch banding -> New item ·························································································· 85

3.25 Uneven gloss on image (entire surface) -> New item ·············································· 85

3.26 Uneven gloss on image (unevenness at the center in vertical direction) -> New item

86

3.27 Soiled front side of image (fault in ITB cleaning) -> New item ································ 87

3.28 Color displacement in sub scanning direction -> New item·································· 90

3.29 Distorted toner image due to wax -> New item ························································ 91

3.30 Scratches on images of coated paper -> New item ·············································· 93

4 Jam Code ····································································································································· 94

4.1 010E/0209/020A Jam Code: Spring at cross feeding assembly breaks ················· 94

4.2 012A JAM ········································································································································· 95

4.3 1145 Jam with A4R paper: Timing Belt of Saddle Assembly in Saddle Finisher-AB2 slips off

96

4.4 0114 JAM·········································································································································· 97

4.5 Pick-up failure, multi feed (how to adjust the pick-up air flow) ································· 98

-> New item················································································································································ 98

5 Specification-related issues ····························································································· 104

5.1 Description on fixing roller refresh operation and its execution timing ················· 104

5.2 Specifications for staple capacity of Finisher-AB1/AB2 ············································ 105

5.3 Number of sheets and size specification for saddle stitching ··································· 105

5.4 When uploading DC Controller data with SST, ‘SramDCON’ does not appear on SST

screen ························································································································································· 106

5.5 Description of features of Function Expansion PCB on DC Controller PCB 1-2106

Trouble Shooting Information for C7000VP series

Page 4

Rev. 2.0

2010/09/17

6 Adjustment Items ··················································································································· 107

6.1 Adjustments under [Registering/Editing Custom Paper Types] ······························ 107

6.2 Adjusting the Level of Curl Correction of a Custom Paper Type···························· 118

6.3 Shading correction in the main scanning direction ························································ 119

7 Reference ··································································································································· 120

7.1 Table indicating Fixing Temperature Shift ········································································· 120

7.2 Addition of ‘CP-PRINT’ ·········································································································· 122

8 Operations for Sublog (iPRC7000VP) ········································································· 123

8.1 What is Sublog? ···························································································································· 123

8.2 What is RB-SRAM UNIT? ········································································································· 123

8.3 How to obtain RB-SRAM UNIT ····························································································· 123

8.4 Points to note when collecting Sublog ··············································································· 124

8.5 When RB- SRAM UNIT Is Not Equipped ············································································ 124

8.6 How to Collect Sublog ··············································································································· 124

8.7 Information Required at Log Collection ·············································································· 127

8.8 Points to Note ······························································································································ 127

8.9 Reference Information ··············································································································· 128

Trouble Shooting Information for C7000VP series

Page 5

Rev. 2.0

2010/09/17

UL (Sub station)

KTM00460/ KTZ00003/ CWR00003

EU/O (Sub station)

KTQ00429/ KUF00004

CN (Sub station)

KTT00031/ KUJ00001

1 Error Code

1.1 E000-0102

Description

Since the fixing belt did not separate from the fixing roller during warm-up rotation after

power-on, the error code ‘E000-0102’ was indicated.

- E000-0102 can be displayed when the fixing roller main thermistor detection temperature

does not reach 10 deg. C within 100 sec during warm-up.

Note:

When E000/E001/E002/E003/E004/E013/E717/E719 has been indicated, take the appropriate

remedial action, and turn the main power switch ON; then execute the following service mode:

COPIER > Function > CLEAR > ERR. After this, turn the main power switch OFF/ON to clear

the error code. At this time, be sure to switch on the pick-up/delivery option before the main

power of this machine. Otherwise, this machine will fail to recognize the option.

Cause

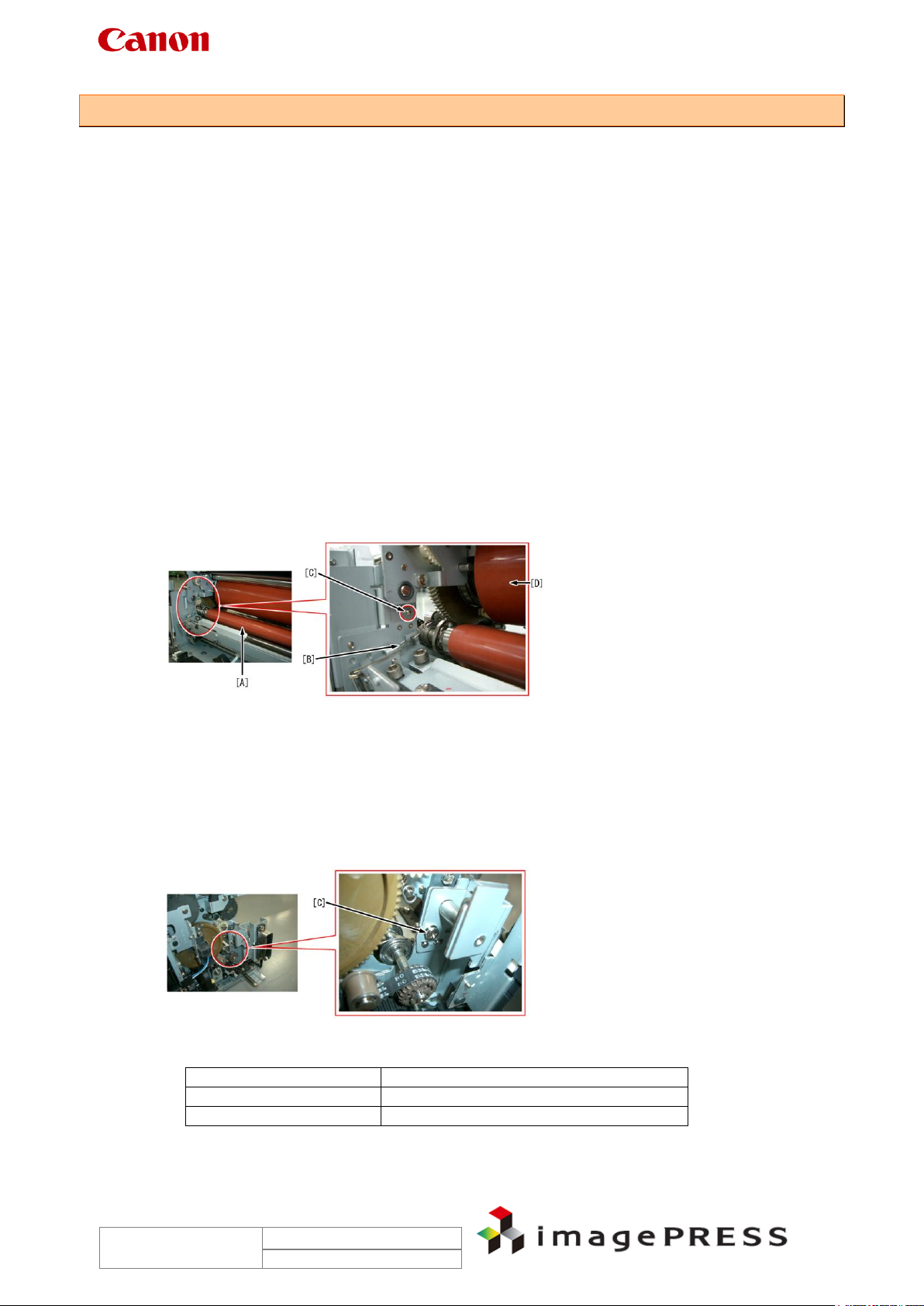

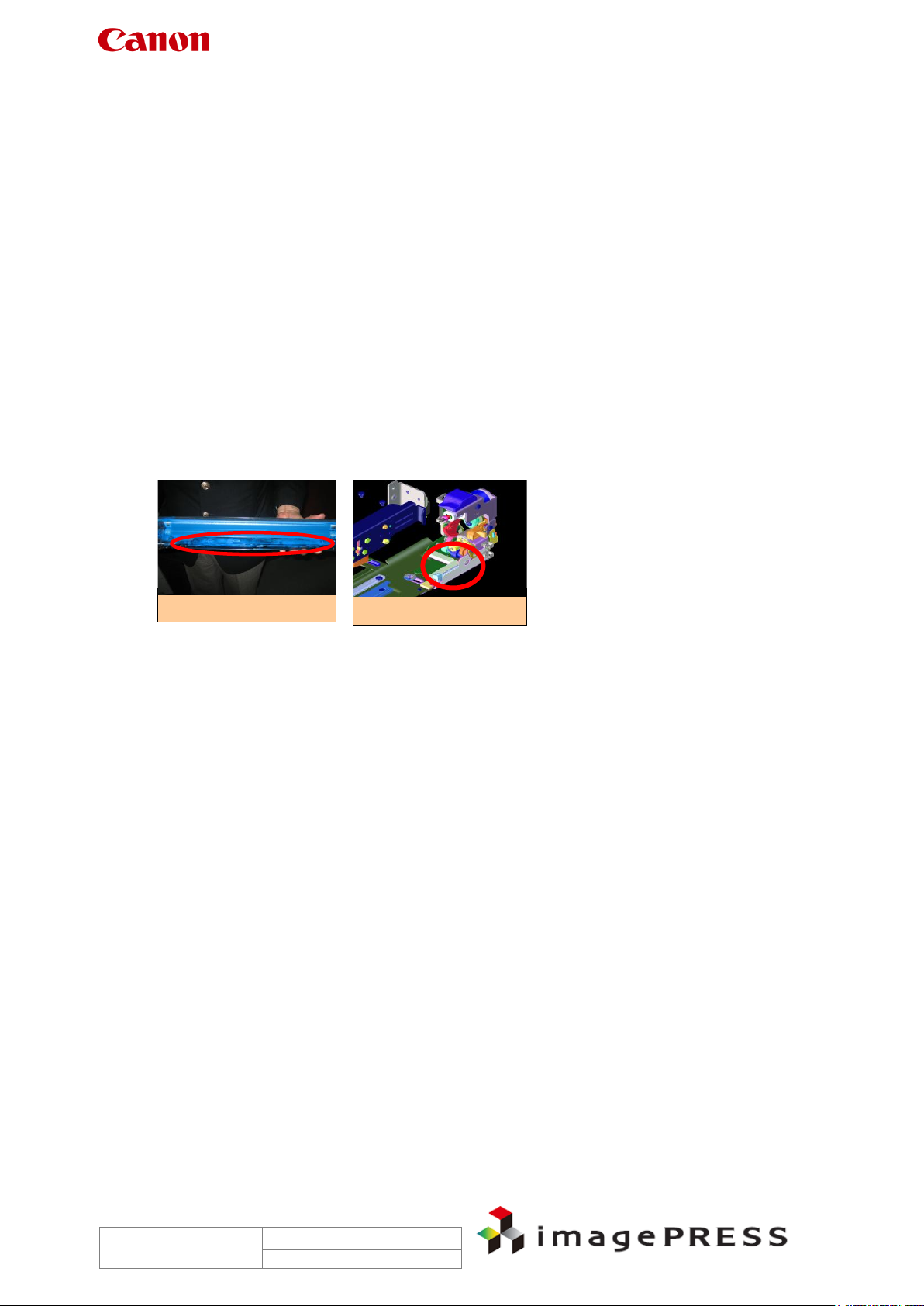

Since the roller fixing spring [B], which retains the end of the fixing belt [A], contacted to the

screw [C], and thereby was deformed, the fixing belt failed to separate from the fixing roller [D].

This caused the fixing belt to deprive temperature of the fixing roller, as a result the fixing roller

failed to reach the appropriate temperature within the specified period of time, resulting in the

error code.

Field Remedy

1. Check to see if the roller fixed spring [B] (rear) has been deformed; if so, replace it.

2. If the spring has not been deformed, move the fixing belt up and down while pushing it

slightly toward the rear, and then check to see if the roller fixed spring contacts the

screw [C].

3. If the spring contacts the screw, change its type from double sems screw M4x8 to

M4x6.

Reference:

The following are the starting serial numbers having the double sems screw M4x6.

FC6-2048 Roller Fixed Spring

XB2-8400-609 Screw, W/Washer, M4x6

Trouble Shooting Information for C7000VP series

Page 6

Rev. 2.0

2010/09/17

Model

Starting Serial Number

C7000VP (120V)

KTM00348

C6000 (120V)

KTZ00001

C6000VP (120V)

CWR00001

C7000VP (230V EU)

KTQ00397

C6000 (230V EU)

KUF00001

C6000VP (230V EU)

DQF00019

C7000VP (230V CN)

KTT00020

1.2 E007-0001

Description

When the main power switch of this machine was turned on, the error code ‘E007-0001’ was

indicated. This was because the tracking detection arm adjusting plate of the first fixing

assembly was fixed at an improper position, and thus the tracking detection arm that detects

the position of the pressure belt failed to track the edge of the belt.

- E007-0001 can be displayed when the pressure belt of the first fixing assembly has been

displaced completely.

Cause

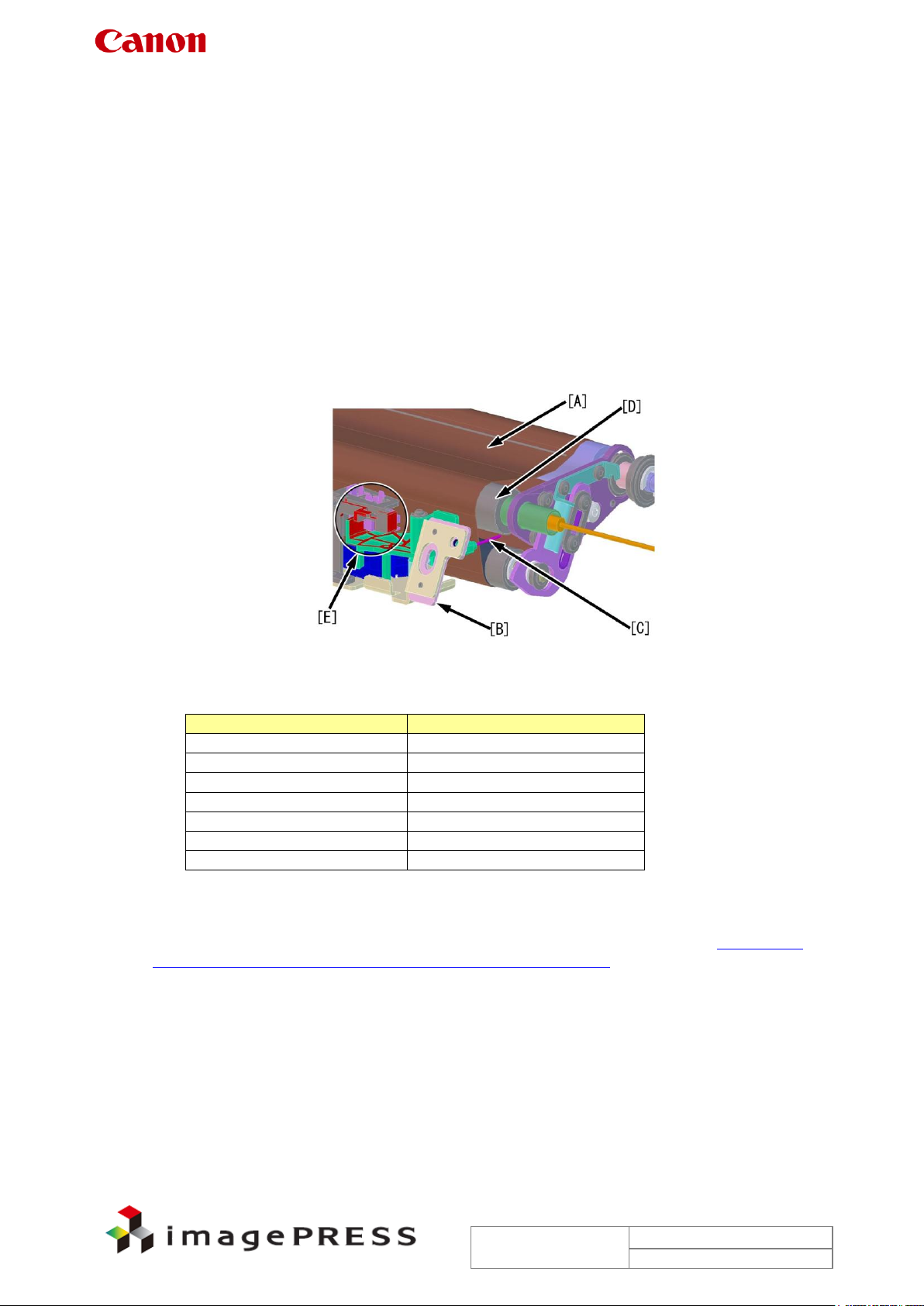

Since the tracking detection adjusting plate [B] that contacts the pressure belt [A] was disposed

at a slightly higher position, the tracking detection arm [C] contacted the separation roller [D],

and thus failed to track the belt edge. This caused the sensor flag to block off the light from the

primary fixing pressure belt position sensors [E] (PS301 and PS302) simultaneously, causing

the error code.

To deal with this, the accuracy of position adjustment of the tracking detection arm adjustment

plate was improved from the machines having the following serial numbers.

Field Remedy

When the same symptom occurs with a machine having a serial number earlier than the above,

adjust the position of the tracking detection arm adjusting plate in reference to Appendix 1

‘Tracking Detection Arm Adjusting Plate Adjustment Procedure.’

Note:

The screw securing the tracking detection arm adjusting plate is fixed with a (red) bonding

material and generally is not removed. When the adjustment is finished, be sure to fix it with a

bonding material.

Trouble Shooting Information for C7000VP series

Page 7

Rev. 2.0

2010/09/17

FC6-0361-000

Separation Drive Shaft

FC6-0314-000

Belt Tension Roller

FU5-3197-000

20T Pulley

XF2-1305-280

Timing Belt

XG9-0286-000

Ball Bearing

FU6-0343-000

19T Gear

FIRST FIXING ASSEMBLY, LOWER

(Extracts from Parts Catalog FIGURE 816)

Transmission Shaft

Ball Bearing

20T Pulley

Timing Belt

19T Gear

Belt Tension Roller

Transmission Shaft

FC6-0361

1.3 E012-1080

Cause

There are some reported instances from the field where E012-0180 occurred because the

primary transfer roller was omitted to pressurize at the time of installation. This caused

insufficient tension to be applied to the ITB belt and a rotational failure of the belt.

1.4 E014-0100

Description

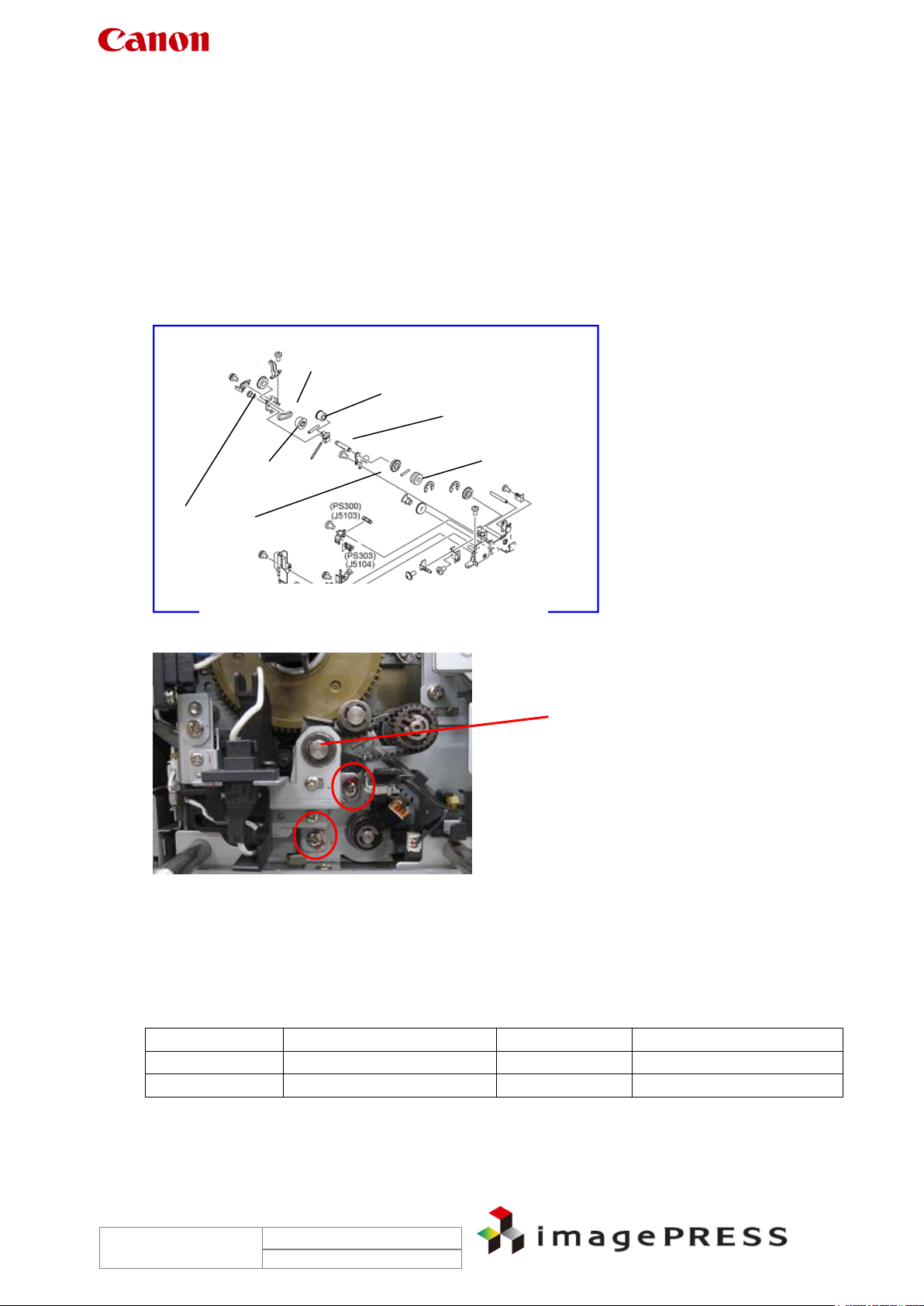

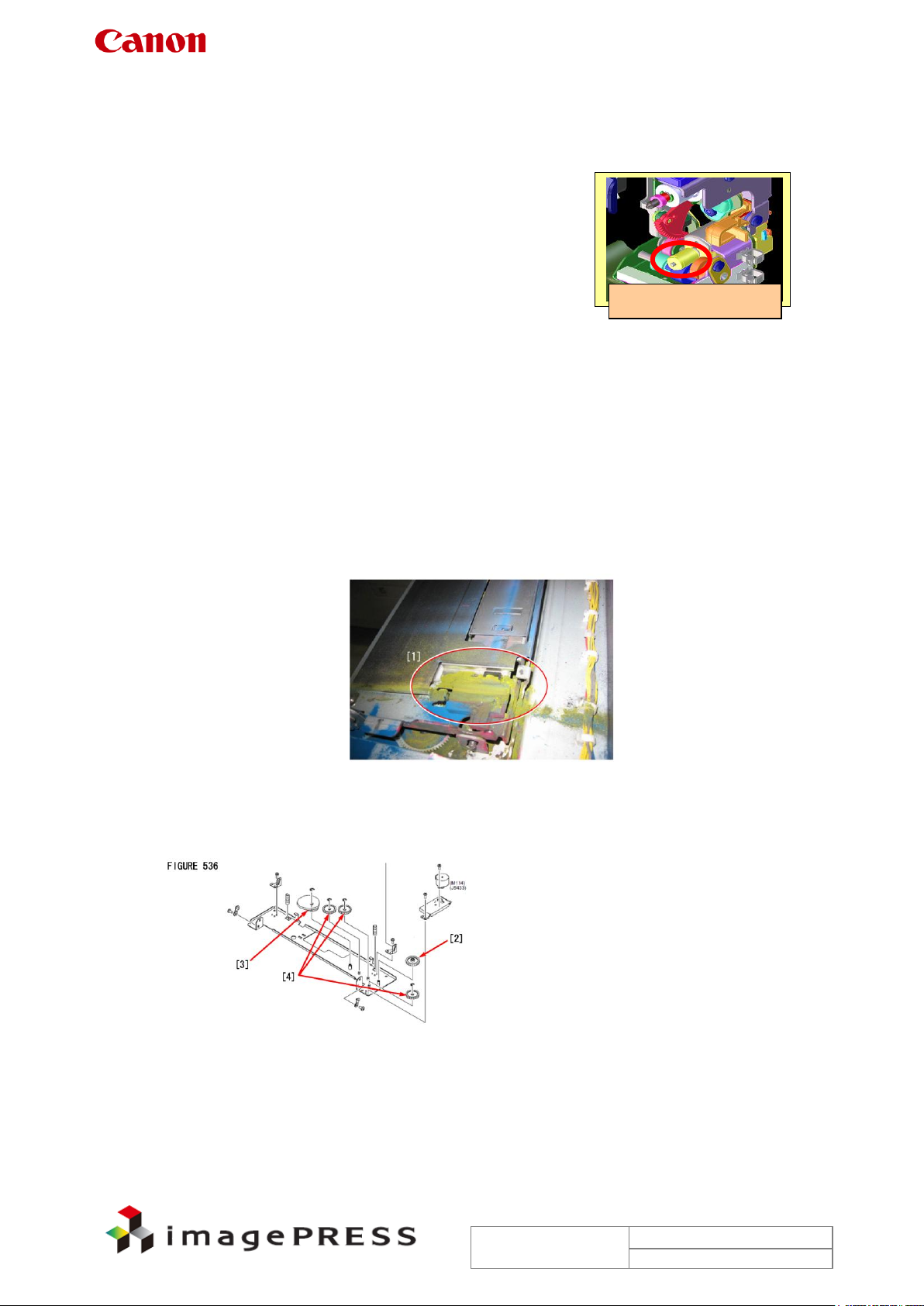

There are some cases where E014-0100 occurred because the transmission shaft, which is

used in the transmission drive unit in the first fixing assembly lower, was chipped.

- E014-0100 indicates an error of the fixing drive motor (M300) in the first fixing assembly.

Field Remedy

When a similar symptom occurs, inspect the shaft and replace it with a new one if chipping is

confirmed.

Note: Do NOT loosen 2 screws (which fix the transmission drive unit, red circle in the picture)

because the shaft and the gears can be replaced without removing the screws. Be aware of red

marking on them.

Trouble Shooting Information for C7000VP series

Page 8

Rev. 2.0

2010/09/17

No. Part Number

Part Name

1

New

FL3-0541

Waste toner joint assembly

Addition of an agitating spring

1.5 E016 Photosensitive drum cleaner motor lock

Description

There are some cases where the feed screw of photosensitive drum cleaner locks and causes

E016-0x00.

Cause

If outputting high volume of low duty image, waste toner may clog at the waste toner joint

assembly.

Measure for factory

An agitating spring is added to break down the waste toner accumulated at the waste toner joint

assembly. Bringing waste toner feed screw into contact with the agitating spring and moving it

up and down can prevent clog prevented at the joint assembly.

Trouble Shooting Information for C7000VP series

Page 9

Rev. 2.0

2010/09/17

Shutter lever slide area

Developing rail assembly

1.6 E018

< Case 1 > E018-0x11

Description

There are cases where E018-0213 was caused by malfunction of the drum patch shutter or a

soiled patch sensor, or malfunction of the patch detect cleaning motor.

Cause

When continuously printing high-density image (solid image), scattering toner may accumulate

around the drum patch sensor shutter, and may burrow into minute clearance between the

shutter lever slider and the guide. Accordingly, this will make the movement of the shutter lever

dull and fail to detect the patch, resulting in an error of the drum patch sensor shutter drive

motor.

Field Remedy

1. Clean the shutter lever slider and the guide, with lint-free paper moistened with alcohol.

2. Remove the drum patch sensor cleaning motor from the developing rail assembly. Clean

3. Replace the motor with a new one. After installing, turn the main power switch OFF/ON.

4. If the symptom still occurs, replace the developing rail assembly with a new one.

the attachment area of the rail if it is soiled with toner.

FL2-6138 Patch Detect Cleaning Motor

FM2-2109 Developing Rail Assembly

< Case 2 > E018-0x13 keeps displaying after power-OFF/ON to

clear 070A Jam Code or E733-0001

Description

There are some cases where E018 displayed after power-OFF/ON to clear 070A Jam code or

E733-0001.

- 070A can be displayed when the registration paper feeder assembly does not transfer paper

in time for the start of paper-feeding operation. (Related sensor: pre-feed sensor 3 PS141)

- E733-0001 can be displayed when communication with the printer (DC controller PCB 1-1)

is not established at startup.

- E018 can be displayed when a shutter operation error occurs.

Reference:

When turning off the main power switch, be sure to turn off all the optional equipment as well as

the main engine. When turning on, turn on the optional equipment first, and then the main

engine.

Trouble Shooting Information for C7000VP series

Page 10

Rev. 2.0

2010/09/17

Rotate the gear by hand

Field Remedy

In order to deal with this malfunction, the DC controller software has been updated to Ver.12.04.

When the same symptom occurs, check the software version, if it is earlier than Ver.12.04,

upgrade to Ver.12.04 or higher.

As a difference case, the warm gear at the rear side

may get onto the engaging gear. In such a case,

rotate the warm gear in counter clockwise to ease

this state.

< Case 3 > E018-0102

Description

There are some reported instances from the field where the machine was restored from

E018-0102 after cleaning the edge registration detect assembly. When the same symptom

occurs, go through the following steps in sequence.

- E018-0102 is displayed when the edge registration patch sensor causes shutter-related

error.

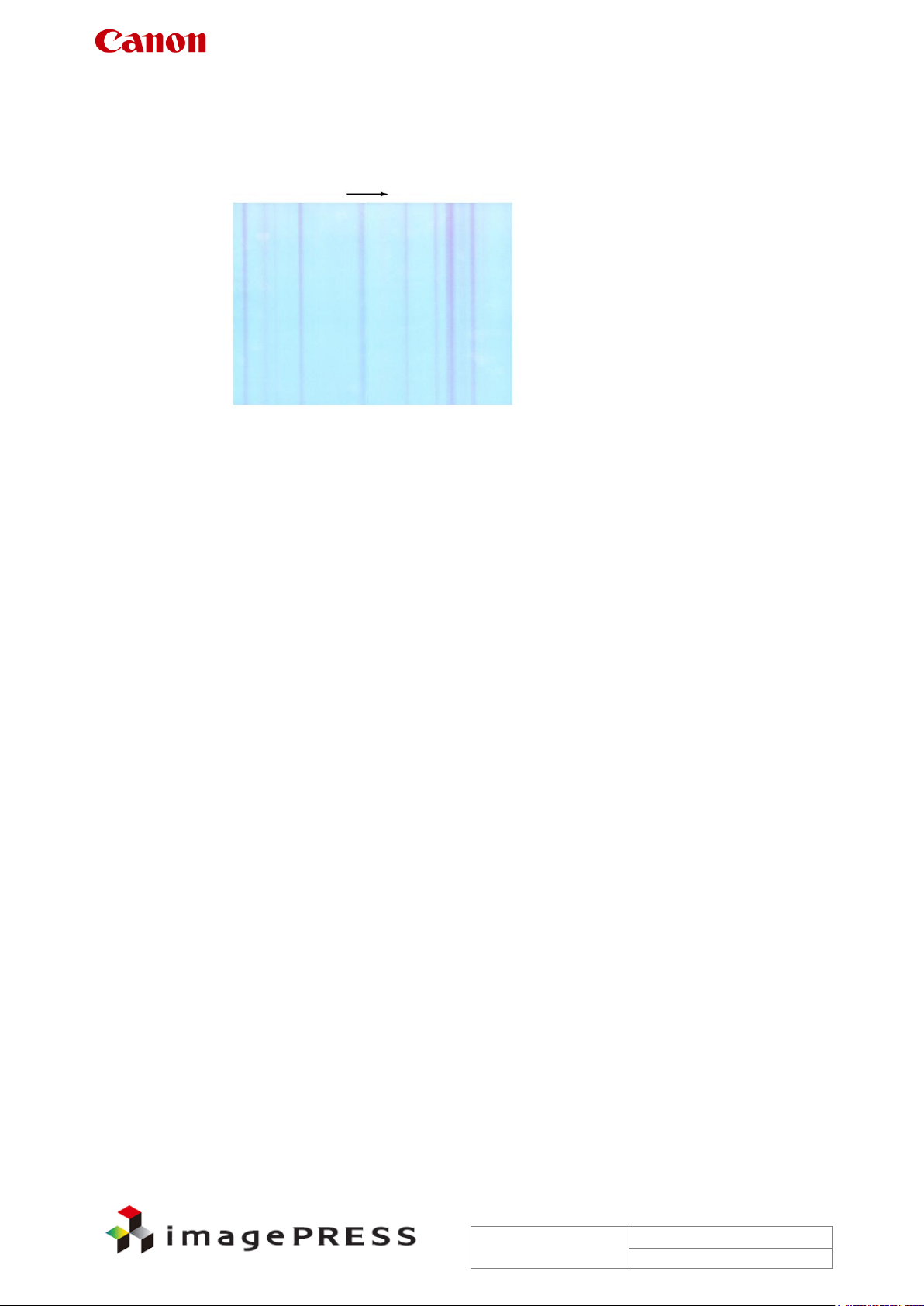

Field Remedy

1. If the side scraper (FL2-2025) in the edge registration detect assembly has been soiled like

[1]; clean it, then turn the main power switch OFF/ON.

If the symptom still occurs, clean or replace the 30T/63T gear [2] (FU6-0381), the 60T gear

[3] (FU6-0382) and the 60T gears [4] (FU6-0383, 3 pc) that drive the shutter, then turn the

main power switch OFF/ON.

4. If the symptom still occurs, replace the edge registration detect sensor with a new one.

FU6-0381 30T/63T Gear

FU6-0382 60T Gear

FU6-0383 60T Gear

FM2-2156 Edge Registration Detect Assembly

Trouble Shooting Information for C7000VP series

Page 11

Rev. 2.0

2010/09/17

1.7 E061-0181

Description

There are some reported instances from the field that E061-0181 was solved by replacing the

P-kit drawer assembly (FM2-2079) with a new one, not by replacing the primary corona

assembly. In this field case, service mode COPIER > Display > V00 showed 905V and VFF

showed 802V.

Reference:

The difference in voltage between V00 and VFF normally falls in the range between 400V and

500V.

- E061-0181 is a low laser power error, and can be displayed when the difference in voltage

between VD and VL at the maximum potential control laser power output is 200V or lower.

The meaning of the second digit of detail code is as follows: 1= yellow, 2=magenta, 3= cyan,

and 4= black.

Cause

Since the spring terminal of the H.V. cable to which grid bias is applied was deformed,

unexpected amount of electrical charge was carried, causing the error code.

Field Remedy

Perform the following Steps 1 though 5, which the service manual describes, if the symptom still

recurs, perform Step 6.

1. Clean the dust-proof glass.

2. Re-fit the drum unit.

Note:

Be sure to connect the connectors of the potential sensor and the pre-exposure lamp.

5. In service mode > COPIER > Display > DPOT, check the values of V00-Y (M/C/K)

through VFF-Y (M/C/K). If those values are nearly same, the laser does not go on. In

this case, check the connection of the video cable.

6. Re-fit the primary corona assembly.

7. Replace the following parts.

Potential sensor

Laser scanner unit

Primary corona assembly

8. Check the spring terminal of the H.V. cable of a trouble P-kit for deformation or

disconnection; if there is a problem, replace the drawer connector with a new one.

FM2-2079 P-Kit Drawer Assembly

FM3-4189 Primary Corona Assembly

FM2-9295 Potential Measuring Assembly

FM2-4887 Scanner Assembly

1.8 E062-0300

There are some reported instances from the field where E062-0300 occurred because of a not

securely fitted connector of the Process Unit Driver PCB.

Trouble Shooting Information for C7000VP series

Page 12

Rev. 2.0

2010/09/17

1.9 E065-0201

Description

Since the magenta drum reached the end of life, the primary corona high voltage leakage

occurred at an end portion of the drum, consequently causing either the error code ‘E065-0201’

or blurred band-like image at random in the main scanning direction.

- E065-0x01 can be displayed when the primary corona high voltage leakage has been

detected for 300msec (100msc x 3 times) continuously 200msec after output of the primary

corona high voltage starts. (Y = 1, M = 2, C = 3, and Bk = 4)

Field Remedy

1. In service mode > COPIER > Counter > DRBL-1 > PT-DR-M, check the counter reading; if

it is in the order of 580000 or higher, replace the magenta drum with a new one.

Bk = PT-DRM, Y = PT-DR-Y, C = PT-DR-C

If the symptom still occurs, go through the following steps.

9. Turn the main power switch OFF/ON.

10. Refit all the connectors of the primary corona assembly, and UN137 through UN140

connectors of the HV1 PCB. (Make sure of no uplift connectors.).

11. Replace the primary corona assembly with a new one.

12. Replace the HV1 PCB with a new one.

FM3-4189 Primary Corona Assembly

FM2-7705 Dev. Primary H.V. PCB Assembly

Trouble Shooting Information for C7000VP series

Page 13

Rev. 2.0

2010/09/17

1.10 E077-0001

Description

There are some reported instances from the field where, during initial rotation after clearing a

jam at the main station and closing the front cover, the error code ‘E077-0001’ was displayed.

- E077-0001 displays when engagement/disengagement of the secondary transfer external

roller cannot be completed within 5 sec.

Cause

Since the lever (B-E1) on the Registration Paper feeder assembly (at the main station) is not

securely locked, engagement/disengagement of the secondary transfer external roller cannot

be completed normally.

Field Remedy

1. If the same error code appears when the front cover is closed after work, check to see if the

lever (B-E1) is shifted to the locking position; if not, shift it again. If the lever is in the locking

position, go to Step2.

Note:

If the lever is locked at the wrong position, the lower portion of the cover may not be fitted

completely although the upper portion does so. After the front cover is closed, be sure to

make sure that both upper and lower portions fit completely to the main body.

13. Refit the connector of the secondary transfer pressure release motor (M184).

14. If the symptom still occurs, replace the secondary transfer pressure release motor with

a new one.

FK2-3124 Stepping DC Motor

1.11 E078-0001

Description

There are some reported instances from the field where E078-0001 was displayed because the

ITB cleaner motor did not rotate. When the same symptom occurs, perform the following field

remedy.

- E078-0001 can be displayed when the phase lock signal is not detected for 500msec

(100msec x 5 times) continuously even if 2 sec or more have passed since the start of the ITB

cleaner motor.

Field Remedy

1. Re-fit the connector at J5229S or J5229P on the ITB cleaner motor.

15. Re-fit the connectors at J1340 and J1337 on the I.T.B. Driver PCB Assembly (L).

16. If the symptom still occurs, replace the ITB cleaner motor with a new one.

Reference:

The connector at J1046 on the DC Controller PCB 1-1 is also related to the aforementioned

error code.

FK2-2725 Brushless Motor

FM2-7690 I.T.B. Driver PCB Assembly, L

Trouble Shooting Information for C7000VP series

Page 14

Rev. 2.0

2010/09/17

1.12 E202-0001

Description

There are some reported instances from the field where, upon installation of the cooling fan for

DADF-R1, a harness extending from the fan was pinched and the fuse on the Interface PCB

had an open-circuit, causing the error code E202-0001.

- E202-0001 can be displayed when an error is found during the forward trip of the HP search.

The possible cause of this error is a fault in the scanner HP sensor, the scanner motor or the

reader controller PCB.

Field Remedy

1. When the same symptom occurs, check if the harness of the cooling fan (front/rear) has

been pinched.

2. If the harness has been pinched, suspect removal of harness covering and replace the fan

with a new one. Refer to Appendix 2 ‘Fan installation procedure’.

3. If the symptom still occurs, suspect an open-circuit of fuse on the Interface PCB and

replace the PCB with a new one.

FL2-3427 Front Fan

FL2-3426 Rear Fan

FM2-4662 Interface PCB Assembly

Trouble Shooting Information for C7000VP series

Page 15

Rev. 2.0

2010/09/17

1.13 E260-2000, E260-0002, E227-0001

Description

At the time of installation, there are some cases where multiple error codes such as E260-2000,

E260-0002, or E227-0001 occurred after the operation as follows. For the purpose of toner

supply, the setting of ‘AINR-OFF’ was changed to ‘1’ with the front door open and then the door

switch tool was inserted into the door switch unit. The error code was indicated, so the front

door was closed, however, even the fan did not run.

The following events were confirmed.

a. The fan was running with the front door open.

b. With the front door open, 24V output was confirmed at 24V power supply1 but no output was

at 24V power supply2. However, after opening the front door of the sub station and closing the

main station’s door, 24V output was confirmed.

- E260-2000: 5V, 13V power supply error.

- E260-0002: When activation of 24V-2 cannot be detected even when 1 sec elapsed after the

relay and remote signal was turned on.

- E227-0001: When activation of 24V-1 cannot be detected even when 1 sec elapsed after the

relay and remote signal was turned on.

Cause

The connectors in the 24V power supply 2 were not fitted securely.

Field Remedy

1. Interchange the 24V power supply 1 [1] and 2 [2], and observe that the error code will be

changed to ‘E260-0001’.

17. If the error code is changed, open the original 24V power supply 2 box and refit the

connectors [3] inside.

18. If the symptom still recurs, replace the 24V power supply 2 with a new one.

FK2-2711 24V DC power supply assembly

1.14 E260-2004 Power Supply Error (ITB Driver PCB right 13V)

Description

There are some reported instances from the field where the error was fixed by cutting the

tie-wrap of the harness between J1032 on the DC-CON and ITB driver PCB (right).

Trouble Shooting Information for C7000VP series

Page 16

Rev. 2.0

2010/09/17

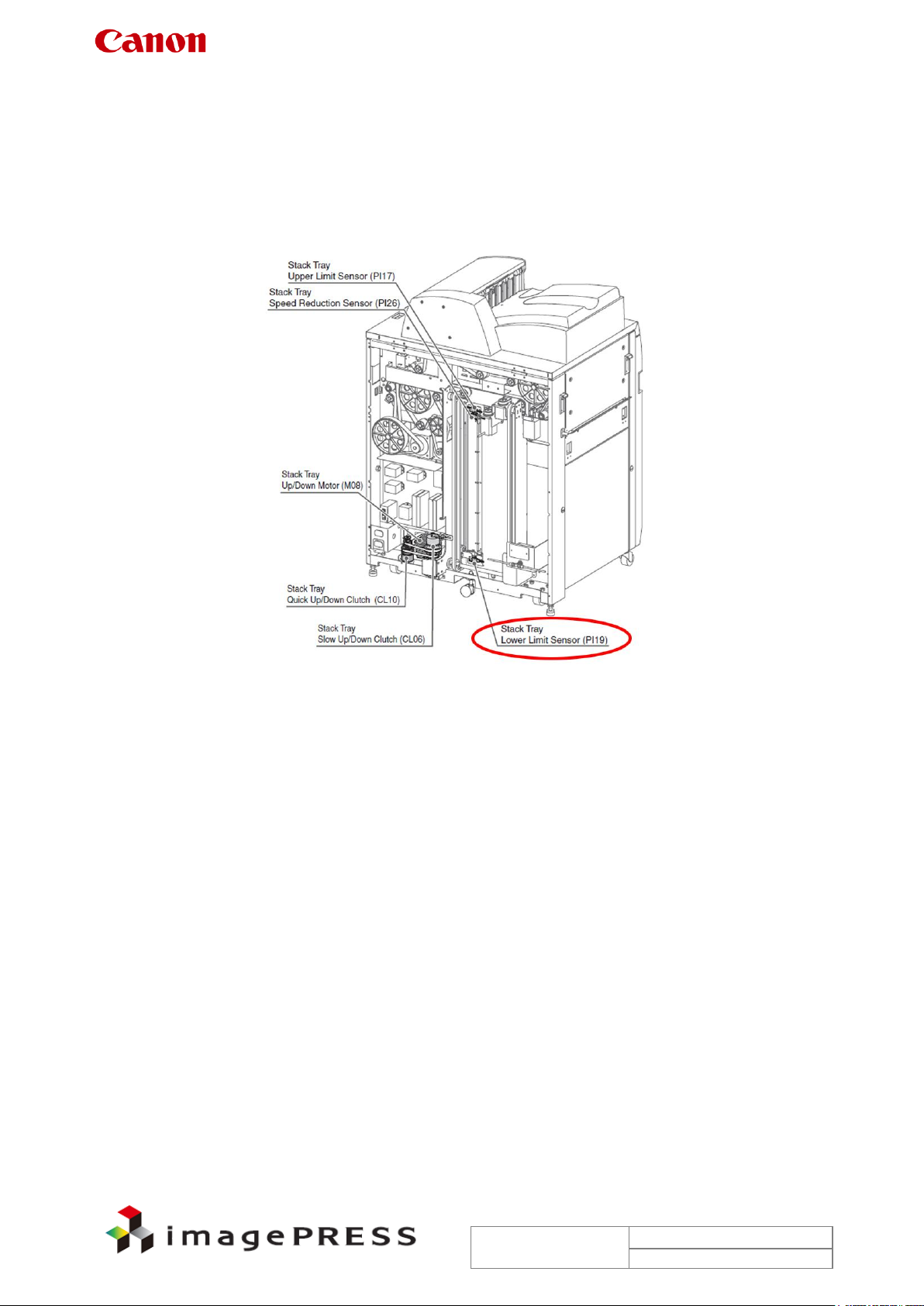

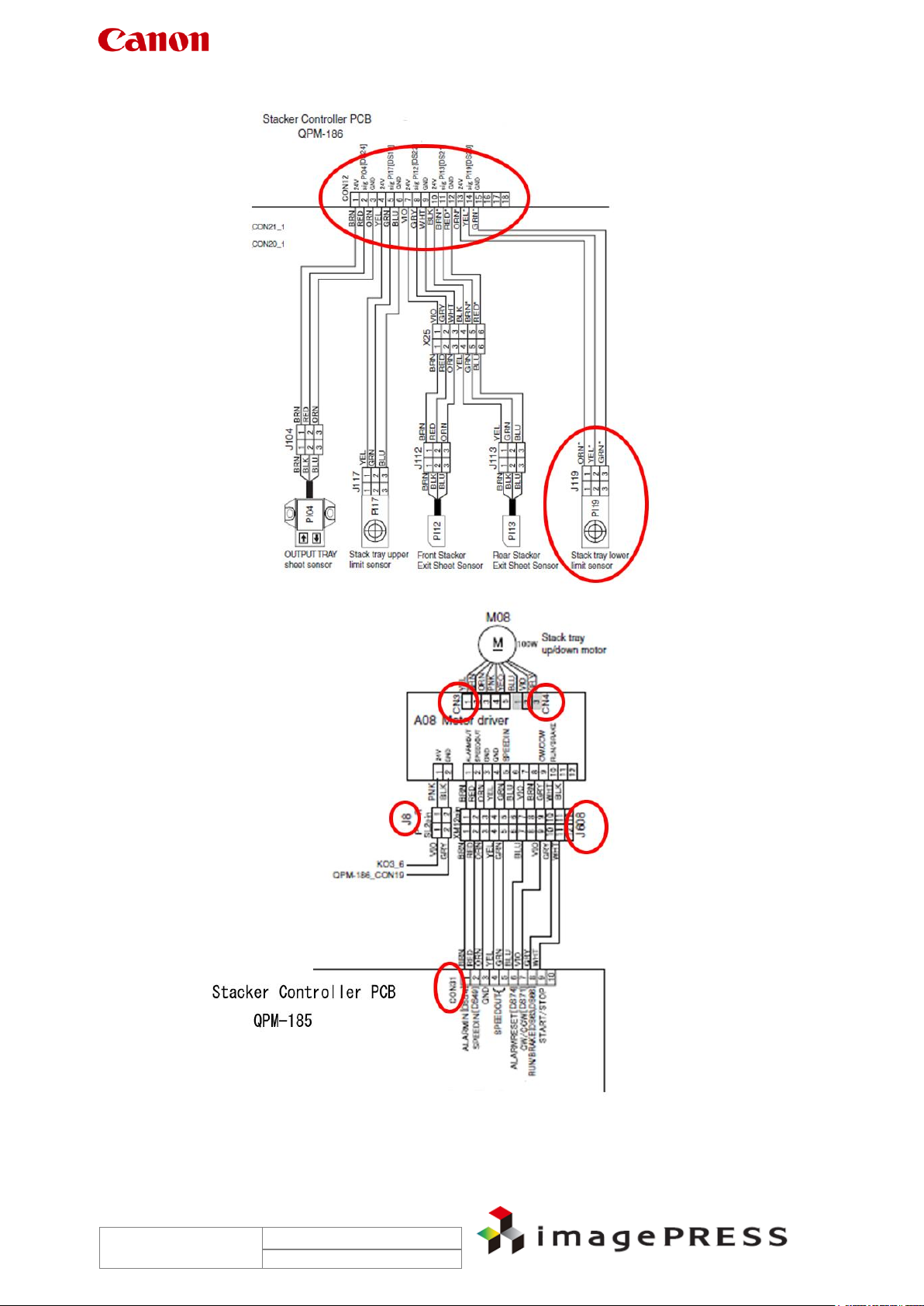

1.15 E512-8011

Description

When the front cover open button was pushed after the stacking operation has been completed,

the stack tray overran the lower limit position, resulting in E512-8011.

- E521-8011: Stack Tray Up/Down Motor Alarm

Cause

The stack tray lower limit sensor (PI19) was faulty.

Field Remedy

1. Refit the connectors described below:

Connector J119 of the stack tray lower limit sensor (PI19) and CON12 of the stacker

controller PCB (QPM-186)

Stack tray up/down motor (M08) and CN3/CN4 on the motor driver A08.

CON31 of the stacker controller PCB (QPM-186)

J8 and J608 which connect the motor driver A08 and the stacker controller PCB

(QPM-186)

1. Replace the stack tray lower limit sensor (PI19) with a new one

2. When the symptom still recurs, check whether the chain or the warm gear is moving

smoothly. If no problem is found, replace the following parts in order:

Stack tray up/down motor (M08)

Motor Driver A08

Stacker controller PCB (QPM-186)

FC3-1716 SENSOR (PI19)

FC3-4548 MOTOR (M08)

FC3-2666 MOTOR DRIVER (A08)

FC3-3100 P.C.B (QPM186)

Trouble Shooting Information for C7000VP series

Page 17

Rev. 2.0

2010/09/17

Trouble Shooting Information for C7000VP series

Page 18

Rev. 2.0

2010/09/17

Weight of paper

# of sheets applicable (Small size / Large size)

64g to 80g

100sh / 50sh

Over 80g to 81.4g

80sh / 50sh

Over 81.4g to 105g:

60sh / 30sh

Over 105g to 200g:

20sh / 10sh

Over 200g to 300g:

Cover and back cover only

1.16 E514-8001 only at first power-on in the morning

Due to slight weight difference observed when comparing the shifting load of assist plate, the

rail assembly in the photograph below was disassembled and cleaned, and grease was also

reapplied.

1.17 E578

Description

When copying 50 sheets of coated paper of 128g in weight in 2-point staple mode, an error of

paper folding position for saddle stitching occurred and the error code E578 was displayed.

- E578 can be displayed when the feed belt HP sensor does not go ON or OFF within 5 sec

after the feed belt shift motor operation starts. (Knurling error)

Cause

This machine stapled more than the specified number of sheets at a time.

Field Remedy

Before making copies, check paper type and the number of sheets to be stapled at a time.

Reference:

The following describes the specifications for stapling.

Note:

- Thickness of stack has to be less than 11mm for small size, and less than 5.5mm for large

size.

- Length of paper in feeding direction has to be as follows.

For large size: 216.1mm to 482.7mm (e.g. 13x19, 12x18, SRA3, A3, B4, A4R, B5R,

LDR, LGL, LTRR, EXER)

For small size: shorter then 216mm (e.g. A4, B5, A5R, LTR, EXE, STMTR)

Trouble Shooting Information for C7000VP series

Page 19

Rev. 2.0

2010/09/17

1.18 E590-8003

Description

The punch motor brake control varies depending on the type of connected punch unit. If the

dipswitch setting does not match the punch unit connected, the error code ‘E590-8003’

appears.

- E590-8003 can be displayed when a punch motor brake error occurs.

Field Remedy

1. Check the type of connected punch unit.

2. If the connected punch unit is Punch Unit-V1, turn on Bit2 of DIP SW 381 on the optional

switch PCB on the finisher.

Reference:

Regarding other punch units set the appropriate Bit(s) of DIP SW381 as follows:

Punch Unit-U1 (2-hole): turn Bit1 ON

Punch Unit-V1 (2/3-hole): turn Bit2 ON

Punch Unit-W1 (4-hole: FRANCE): turn Bit 1 and 2 ON

Punch Unit-X1 (4-hole: SWEDEN): turn Bit3 ON

1.19 E747-051B

Description

Since the S-B PCB was faulty, the error code ‘E747-051B’ was indicated when copies or

printouts were output after this machine had started up. When the same symptom occurs, go

through the following steps in sequence.

- E747-051B can be displayed when an error occurs in the main controller PCB (MAIN-M).

Field Remedy

1. Turn the main power switch OFF and then ON.

2. If the symptom still occurs, turn the main power switch OFF and clean the terminals of the

following boards, which are piggybacked on the main controller PCB, with lint-free paper

moistened with alcohol; then re-fit the boards.

RO-B PCB

O-B PCB (when an EFI controller is connected) or GU-Short PCB (when an EFI

controller is not connected)

S-B PCB

ZJ-A PCB (piggybacked on the S-B PCB)

LAN-BAR-B PCB

RB-A PCB (w/REOS function, included in the PDL option)

1. If the symptom still occurs, replace the S-B PCB with a new one.

2. If the symptom still occurs, replace the main controller PCB (MAIN-M) with a new one.

3. If the symptom still occurs, replace all the boards listed in Step 2 except the S-B PCB

by new ones.

FM2-7813 Main Controller PCB Assembly, M

FM2-9076 S-B PCB Assembly

Trouble Shooting Information for C7000VP series

Page 20

Rev. 2.0

2010/09/17

1.20 E750-0002

Description

There are some reported instances from the field where, when the machine was relocated the

necessary work was done according to the procedure ‘Relocating the Machine.’ At this time,

however, not the drawer connector mount but each connector was detached from the backside

of the sub station. This caused an error in plugging each connector at the new installation place,

ultimately leading to the error code E750-0002.

- E750-0002 can be displayed when the model name informed by the main controller does

not match with that stored in the DC controller (i.e., same series but different model).

Cause

Communication error occurred between the DC controller software and the main controller

software because the connectors were plugged mistakenly.

Field Remedy

Although it's difficult to identify a connector plugged to the wrong jack from the error code, when

the same error occurs at time of relocation of this machine or service work for the drawer

connector mount, check to see if each connectors are connected to the correct jack.

Note:

When detaching/re-attaching the drawer connector to connect the main station and sub station

during installation or relocation, be sure to work not by the connector but by the drawer

connector mount to prevent errors in plugging connectors.

1.21 E750-2012

Description

There are some reported instances from the field where, at time of replacement of the fixing

intermediate assembly (FM2-9291) the two short connectors for identifying the destination

failed to be reattached, resulting in the error code E750-2012.

- E750-2012 can be displayed when the combination of the DC controller software and the

fixing assembly is not correct.

Field Remedy

When replacing the fixing intermediate assembly, be sure to follow the cautions described in

Appendix 3 ‘Points to Note When Replacing Primary/Secondary Fixing Intermediate Unit.’

Trouble Shooting Information for C7000VP series

Page 21

Rev. 2.0

2010/09/17

J1035

Controller Box Panel

Mount Ass'y

J10

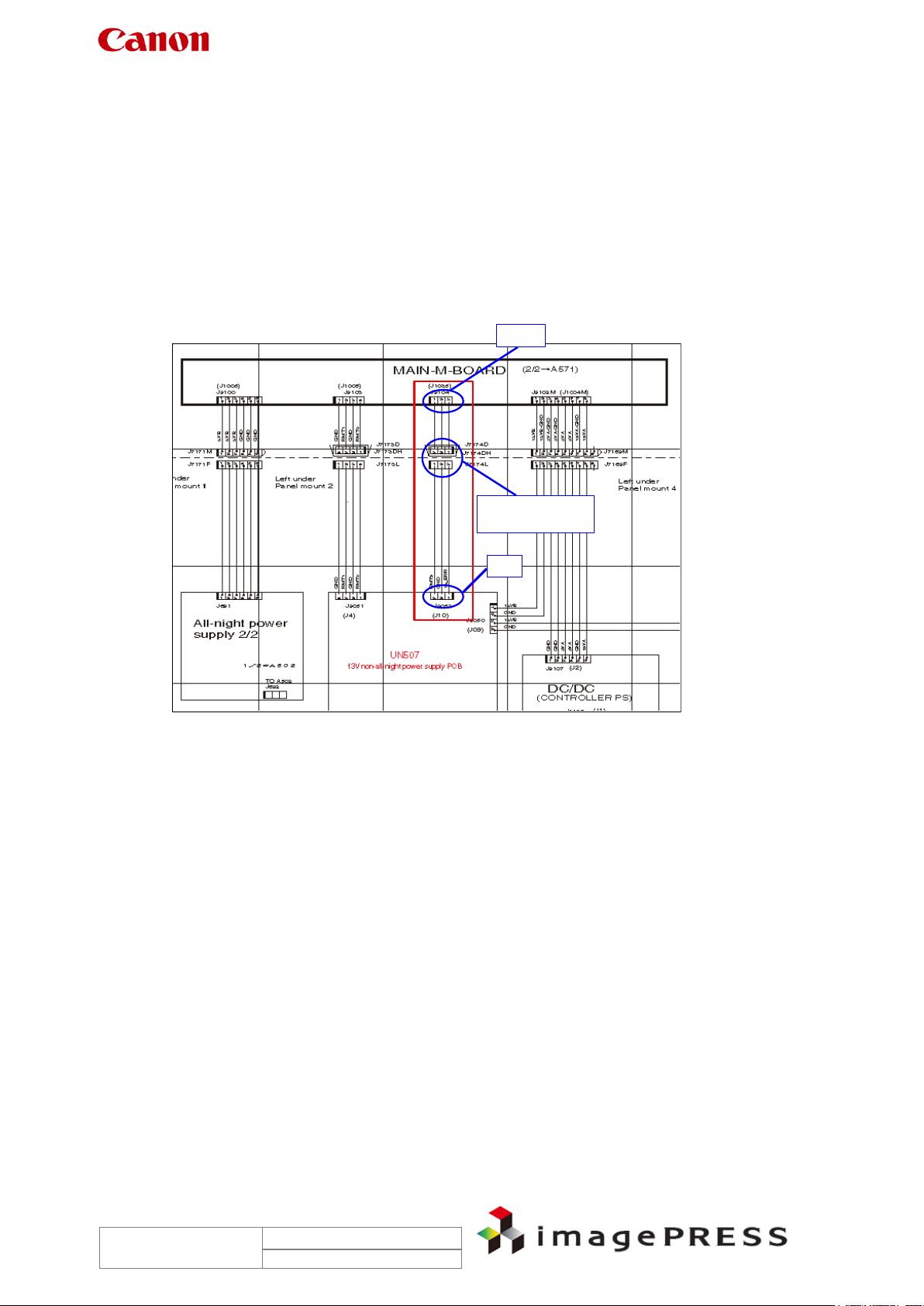

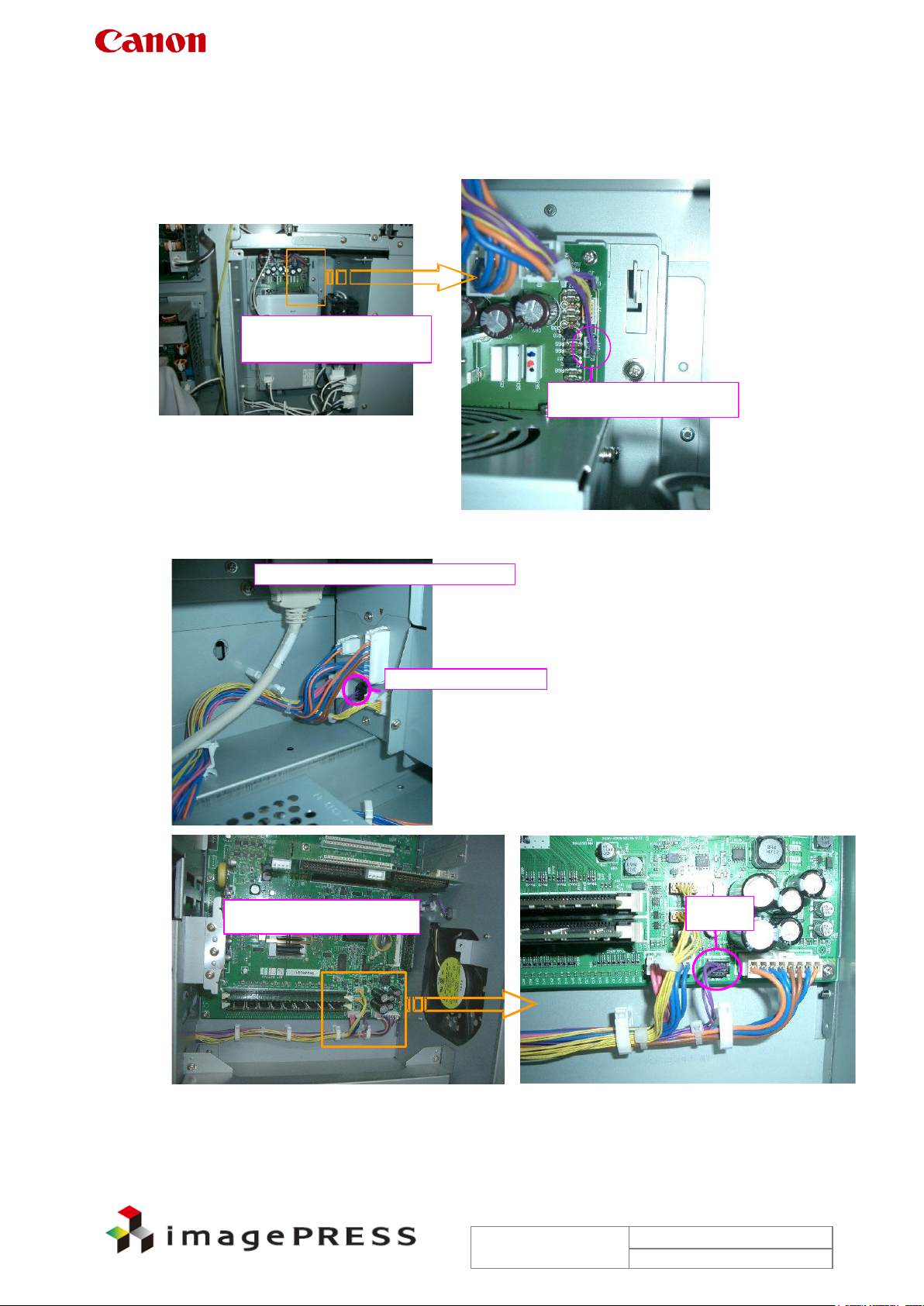

1.22 E804-0001

Description

‘E804-0001’ is an error code that is displayed when a power supply fan error is detected. The

fan related to this code is FM508 mounted in the power unit station.

Cause

The lead wire of the 3-pin connector of FM508 or 3-pin connector ‘J1035’ on the MAIN-M board

contacts the flame plate of the power unit station because of a cause such as wire pinching.

Reference:

The wire is routed from J1035 of the controller BOX via the relay connector to FM508 by

harness connection.

Trouble Shooting Information for C7000VP series

Page 22

Rev. 2.0

2010/09/17

MAIN CONTROLLER BOX Panel Mount

relay area of J10-J1035

J1035

Main controller PCB (M)

DC Power Supply Ass'y,

13V UN507

J10 Upper side is 1P

Field Remedy

1. Check the wire routing with reference to the pictures below.

2. If there is a problem with the wire routing, modify it.

3. If there is no problem with the wire routing, replace the DC power supply assembly (13V

non-all night power supply) or the main controller PCB (M) with a new one.

FK2-2712 DC Power Supply Assembly (13V)

FM2-7813 Main controller PCB Assembly, M

Trouble Shooting Information for C7000VP series

Page 23

Rev. 2.0

2010/09/17

1.23 E805-0404

Description

There are some reported instances from the field where the machine was restored from the

error code E805-0404 after replacement of the fixing/feeder driver assembly (FM2-2260).

- E805-0404 can be displayed when the pre-fixing feed rear left fan (FM137) error occurs.

FM137 is used to attract paper to the pre-fixing feed belt.

Note:

When this error code occurs, after taking the appropriate remedy, turn the main power switch

ON and then execute the following service mode: service mode > COPIER > Function >

CLEAR > ERR. After that, turn the main power switch OFF/ON so that the error code will be

cleared. Be sure to turn the switch of the pick-up/delivery optional equipment ON first, and then

the main engine. Otherwise, the machine fails to recognize the optional equipment.

Reference:

The error codes that require the error clear operation are as follows: E000, E001, E002, E003,

E004, E013, E717, and E719.

Field Remedy

1. Re-fit J1557 connector of the fixing/feeder driver PCB.

2. Re-fit the connectors J5449, J7405, and J7400 between the fan FM137 and J1557 of the

fixing/feeder driver PCB.

3. If the symptom still occurs, replace the fixing/feeder driver PCB with a now one.

FM2-2260 Fixing/feeder Driver PCB Assembly

Trouble Shooting Information for C7000VP series

Page 24

Rev. 2.0

2010/09/17

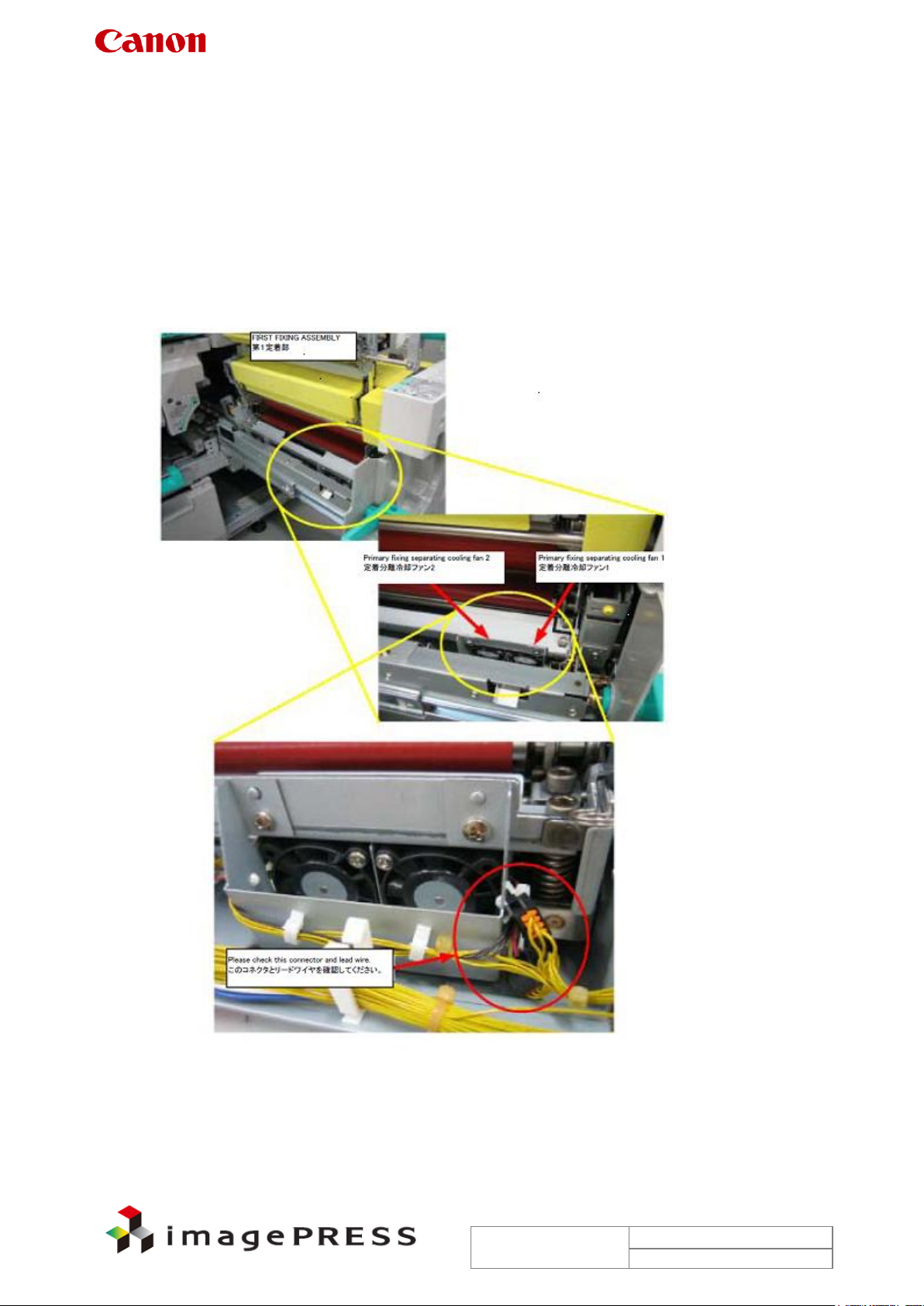

1.24 E805-0701

Description

There are some reported instances from the field where the error code ‘E805-0701’ was

indicated during a continuous copy job because the primary fixing separating cooling fan 1 had

wire pinching.

- E805-0701 can be displayed when an error occurs with the primary fixing separating cooling

fan 1. This error code is detected when the phase unlock state is detected for 2 sec

continuously 10 sec after the fan is turned on.

Field Remedy

1. Check the lead wire of connector on the primary fixing separating cooling fan 1 has NOT

been pinched.

4. If the lead wire has been pinched, repair it. If not, re-fit the connector.

5. If the symptom still occurs, re-fit J4372 and J4360 connectors of the primary fixing

internal driver PCB, J4080 and J4400 connectors of the fixing heater driver PCB 1, and

J1003 connector of the DC controller PCB.

6. If the symptom still occurs, replace the fan with a new one.

FK2-3148 Fan

Trouble Shooting Information for C7000VP series

Page 25

Rev. 2.0

2010/09/17

1.25 E822-0903

Description

There are some reported instances from the field where the error code ‘E822-0903’ was

indicated because a communication error occurred between the fixing duplex feed PCB and the

DC controller PCB 1-2 on the main station due to poor contact of the fixing duplexing drawer.

- E822-0903 can be displayed when the tandem guide lower cooling fan (FM358) causes an

error (sub station).

Field Remedy

1. Service mode > COPIER > Function > PART-CHK > FAN > enter '84' using the numeric

keys > OK > FAN-ON > check the operation of the fan. If the fan has no problem, it will

rotate for 10 sec at full speed.

2. If the fan does not rotate, re-fit the connector of the fan (FM358) to correct such a problem

as poor contact.

3. If the symptom still occurs, re-fit the fixing duplexing drawer connectors (fitted on the front

and back sides).

4. If the symptom still occurs, re-fit J4106 and J4070 connectors of the fixing duplex feed PCB,

and J1072 connector of the DC controller PCB 1-2.

5. If the symptom still occurs, replace the fan (FM358), the fixing duplex feed PCB, the DC

controller PCB 1-2 with new ones in this order.

FK2-3100 FAN

FM2-7700 Fixing Duplex Feed PCB Assembly

FM2-7686 DC Controller PCB 1-2 Assembly

Trouble Shooting Information for C7000VP series

Page 26

Rev. 2.0

2010/09/17

1.26 E020

E020-0x81

Error Description: Lower limit error in light intensity on drum base (reflecting light intensity from

the drum surface)

* COPIER > Display > DENS > P-B-P-Y/M/C/K is less than 150.

Cause of occurrence (Highly possible): Soil on the ATR sensor [*1]

Cause of occurrence (Low possible): Faulty pressure for developing assembly

Broken wire of ATR sensor

Damaged ATR sensor

Malfunction of ATR patch detection shutter

E020-0x82

Error Description: Lower limit error in current passed to the sensor while the patch sensor LED

is off

* COPIER > Display > DENS > P-D-P-Y/M/C/K is 30 or less.

Cause of occurrence (Highly possible): Broken wire of ATR sensor

Damaged ATR sensor

E020-0x84

Error Description: Fault at sampling drum base

* A difference between the values in service mode > COPIER > Display > DENS >

P-B-P-Y/M/C/K and P-D-P-Y/M/C/K is 30 or less.

Cause of occurrence (Highly possible): Soil on the ATR sensor [*1]

Cause of occurrence (Low possible): Faulty pressure for developing assembly

Broken wire of ATR sensor

Damaged ATR sensor

Malfunction of ATR patch detection shutter

E020-0x85

Error Description: Fault at sampling 1 in patch image

* A difference between the values in service mode > COPIER > Display > DENS >

DENS-S-Y/M/C/K and P-D-P-Y/M/C/K is 30 or less.

Cause of occurrence (Highly possible): Soil on the ATR sensor [*1]

Cause of occurrence (Low possible): Image density is too high.

Faulty pressure for developing assembly

Broken wire of ATR sensor

Damaged ATR sensor

Malfunction of ATR patch detection shutter

E020-0x86

Error Description: Fault at sampling 2 in patch image

* A difference between the values in service mode > COPIER > Display > DENS >

DENS-S-Y/M/C/K and P-B-P-Y/M/C/K is 30 or less.

Cause of occurrence (Highly possible): Image density is too low. [*2]

Cause of occurrence (Low possible): Soil on the ATR sensor

Faulty pressure for developing assembly

Broken wire of ATR sensor

Damaged ATR sensor

Malfunction of ATR patch detection shutter

Trouble Shooting Information for C7000VP series

Page 27

Rev. 2.0

2010/09/17

E020-0x87

Error Description: Upper limit error 2 in current passed to the sensor while the patch sensor

LED is off

* COPIER > Display > DENS > P-D-P-Y/M/C/K is 930 or more.

Cause of occurrence (Highly possible): Damaged ATR sensor

E020-0xC2

Error Description: Error in variation of sampling value in patch image

* When variation of sampling Sig values is 400 or more.

Cause of occurrence (Highly possible): Tiger stripe

Cause of occurrence (Low possible): Scratches on drum

E020-0x90

Error Description: Lower limit error in ATR patch image density

Cause of occurrence (Highly possible): Soil on the ATR sensor [*1]

Cause of occurrence (Low possible): Image density is too high.

Faulty pressure for developing assembly

Broken wire of ATR sensor

Damaged ATR sensor

Malfunction of ATR patch detection shutter

E020-0x91

Error Description: Upper limit error in ATR patch image density

* COPIER > Display > DENS > DENS-S-Y/M/C/K is more than 880.

Cause of occurrence (Highly possible): Image density is too low. [*2]

Cause of occurrence (Low possible): Soil on the ATR sensor

Faulty pressure for developing assembly

Broken wire of ATR sensor

Damaged ATR sensor

Malfunction of ATR patch detection shutter

E020-0x92

Error Description: Lower limit error in developer density

* COPIER > Display > DENS > DENS-S-Y/M/C/K is –4% or less 3 consecutive times.

Cause of occurrence (Highly possible): Image density is too low. [*2]

Cause of occurrence (Low possible): Soil on the ATR sensor

Faulty pressure for developing assembly

Broken wire of ATR sensor

Damaged ATR sensor

Malfunction of ATR patch detection shutter

E020-0x93

Error Description: Upper limit error in developer density

* COPIER > Display > DENS > DENS-S-Y/M/C/K is +4% or more 3 consecutive times.

Cause of occurrence (Highly possible): Soil on the ATR sensor [*1]

Cause of occurrence (Low possible): Image density is too high.

Faulty pressure for developing assembly

Broken wire of ATR sensor

Damaged ATR sensor

Malfunction of ATR patch detection shutter

Trouble Shooting Information for C7000VP series

Page 28

Rev. 2.0

2010/09/17

E020-0xB0

Error Description: Lower limit error in signal value of toner density sensor

* While printing, COPIER > Display > DENS > SGLL-Y/M/C/K is 64 or less for Y and 48 or less

for M/C/K for 5 prints continuously (T/D ratio is too high).

Cause of occurrence (Highly possible): Abnormal toner supply [*3]

Cause of occurrence (Low possible): Short circuit of harness for ATR sensor

Occurrence of Tiger stripe

E020-0xB1

Error Description: Upper limit error in signal value of toner density sensor

* While printing, COPIER > Display > DENS > SGLL-Y/M/C/K is 192 or more for Y and 126 or

more for M/C/K for 5 prints continuously (T/D ratio is too low).

Cause of occurrence (Highly possible): Disconnected connector of toner density sensor (or

poor contact)

Cause of occurrence (Low possible): Faulty sub hopper (no toner)

Damaged toner density sensor

Trouble Shooting Information for C7000VP series

Page 29

Rev. 2.0

2010/09/17

*1 Soil on the ATR sensor

Field Remedy

1. Clean the ATR sensor with alcohol.

Note: Wipe the sensor in one direction more than 3 times. Do NOT wipe it back-and-forth.

7. Replace the ATR sensor with a new one.

In addition, for the purpose of preventing any future occurrence, follow the steps below.

a. Service mode(Level 2) > COPIER > Adjust > DENS > HLMT-PTY/M/C/K,

Settings: If the current value is 4, change it to 9.

Note:

Density might decrease as a negative effect. Therefore, execute the above setting value

change only if soil on the sensor occurred at less than 250K intervals of periodic cleaning

maintenance for ATR sensor.

Or

b. Shorten the interval of cleaning maintenance.

If the current value is 9, change it to 10.

*2 Image density is too low

As possible causes of low image density, soiled primary charging assembly, faulty laser, soiled

dust-proof glass, faulty drum, faulty developing, and etc. are conceivable. However, faulty

developing is the most likely. For this reason, check the area around the developing assembly

first.

Field Remedy

1. Check the area around the developing assembly.

Are there occurrences of Tiger stripe?

Are there occurrences of developer overflow?

If these symptoms have occurred, replace the developer after taking actions such as

cleaning.

1. If there is no abnormality found at the step 1, output PG5 of the corresponding color

with density settings ‘80’ and ‘255’. Check the density and unevenness.

Trouble Shooting Information for C7000VP series

Page 30

Rev. 2.0

2010/09/17

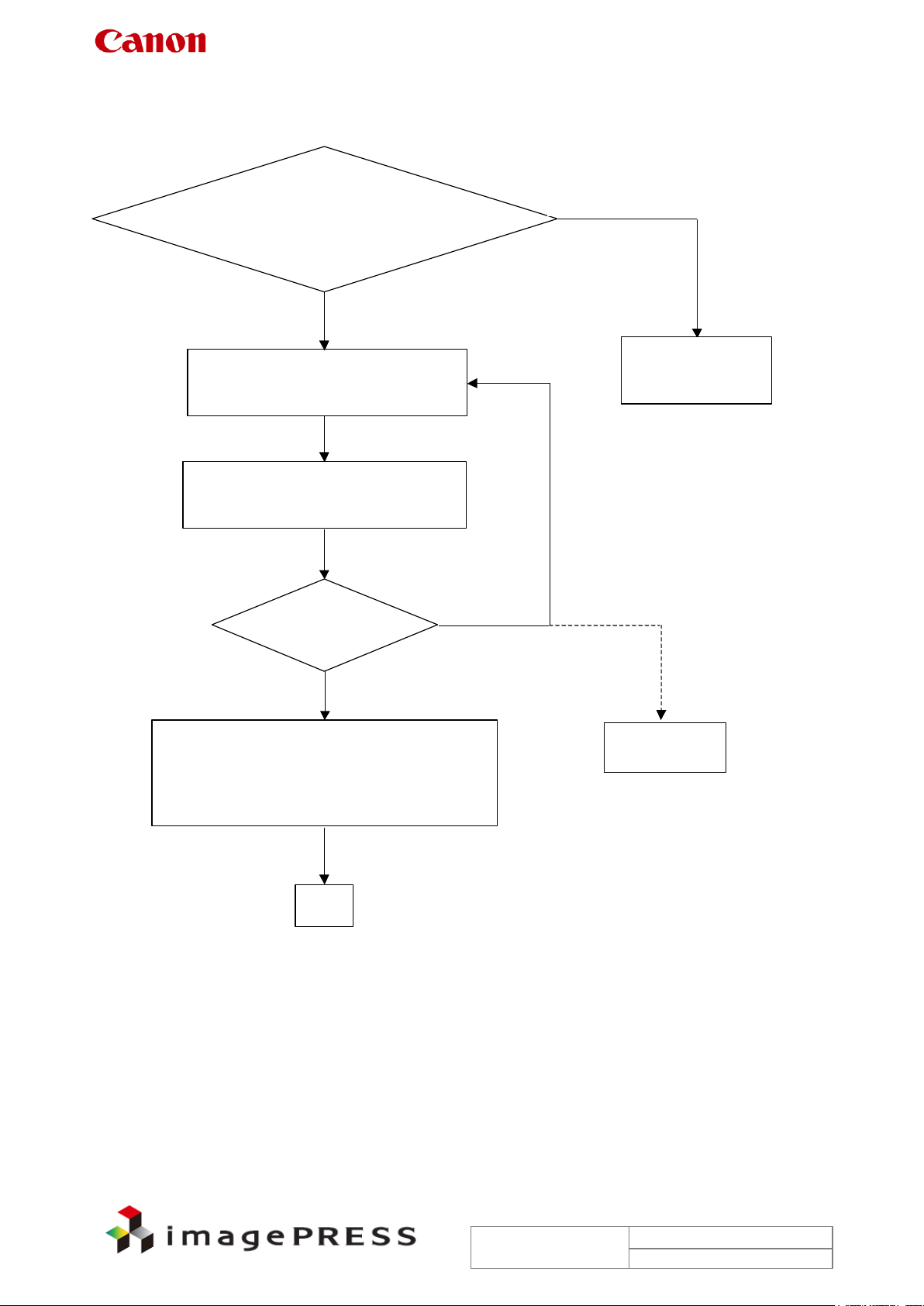

No

Yes

No

No improvement even after

repeating the left loop 3 times

・Feed 100 sheets of A3/LDR size or larger

for PG10

(200 sheets for A4/LTR)

Service mode

COPIER > Display > DENS > DENS-YMCK

Y +1or more

M/C/K +2 or more

Check

・Any occurrence of developer

overflow?

・Any occurrence of Tiger stripe?

Yes

・Replace developer

・Clean in the machine

Execute the above.

Replace

developing

assembly

- Service mode

COPIER > Adjust > DENS > HLMT-TY/M/C/K

Settings: If it is 4 at this point, change it to 9.

If it is 9 at this point, change it to 10.

Note: Density might decrease as a negative effect.

Finish

*3 Abnormal toner supply

Loading...

Loading...