Page 1

Page 2

THE CANON imagePRESS C7000VP DIGITAL PRESS

It’s built for today’s work – and tomorrow’s growth.

Canon’s significant annual investment in Research and

Development has helped make the Canon brand synonymous with ultra-high-quality digital imaging. With the

imagePRESS C7000VP digital press, Canon, once again,

has revolutionized the color marketplace. As the next

generation in digital printing technology, the Canon

imagePRESS C7000VP digital press redefines expectations of image quality, productivity, and versatility.

This powerful production engine was built for high-quality,

on-demand printing and value-added services, such as

variable data printing. The imagePRESS C7000VP digital

press produces output that rivals offset image quality

while maintaining superior color consistency and production reliability.

With true 1200 x 1200 dpi color and black-and-white output at a consistent speed of 70 pages per minute (letter),

regardless of weight, the imagePRESS C7000VP digital

press is ideal for:

• Commercial printers looking to expand their services

and revenue opportunities while offering customers

uncompromised print quality;

• Quick printers and digital printers that want to

increase production volume by offering enhanced

image quality on a greater variety of paper stocks;

and,

• In-plant facilities that need to maintain control over

color printing costs, quality, and turnaround time.

Page 3

It’s all about your workflow

and applications

Canon recognizes the need to bring to market more than just a superior digital press. That’s

why we offer imagePRESS Workflow Solutions, a suite of hardware and software solu-

tions to help printers grow their digital print businesses. Canon is committed to integrating

with industry standards such as JDF and PPML to offer and support the latest in workflow

technology, from creative and submission throughout the entire workflow to finishing and

distribution.

As you look to the future, you may want to build more automation into your process, imple-

ment a Web-to-print solution, or expand your variable data printing capabilities. imagePRESS

Workflow Solutions can help you grow and evolve in your business and take advantage of

existing and new technologies to benefit all print environments. The imagePRESS Workflow

Solutions program will deliver, connect, and simplify your workflow.

Deliver – Canon will deliver a complete

solution and fill in the missing pieces to

existing workflows.

Connect – Many environments have already

made large investments in their workflow

and they need Canon to connect into their

existing workflow.

Simplify – The final goal is to deliver a solution

that builds efficiency within the workflow and

to simplify your production processes.

Page 4

IMAGE QUALITY

Ultra-high-quality printing–

nothing less than you’d expect

CANON’S COMMITMENT TO QUALITY, A TRADITION YOU

CAN DEPEND ON

Incorporated into the imagePRESS C7000VP digital press is

Canon’s unique understanding of photography, color science,

color imaging, and workflow. The result is an ultra-high-quality,

high-speed digital press that fully integrates with the way profes-

sionals work and profit in the dynamic world of digital printing.

A DIFFERENCE IN QUALITY YOU CAN SEE—AND FEEL

The imagePRESS C7000VP digital press features revolutionary

technologies you won’t find in any other color device. At the

core of the imagePRESS system are its print engine and toner

technology. These ensure outstanding image quality, reliable

and consistent color, and detailed, sharp images on gloss,

matte, and specialty stocks to produce output that looks and

feels like offset printing.

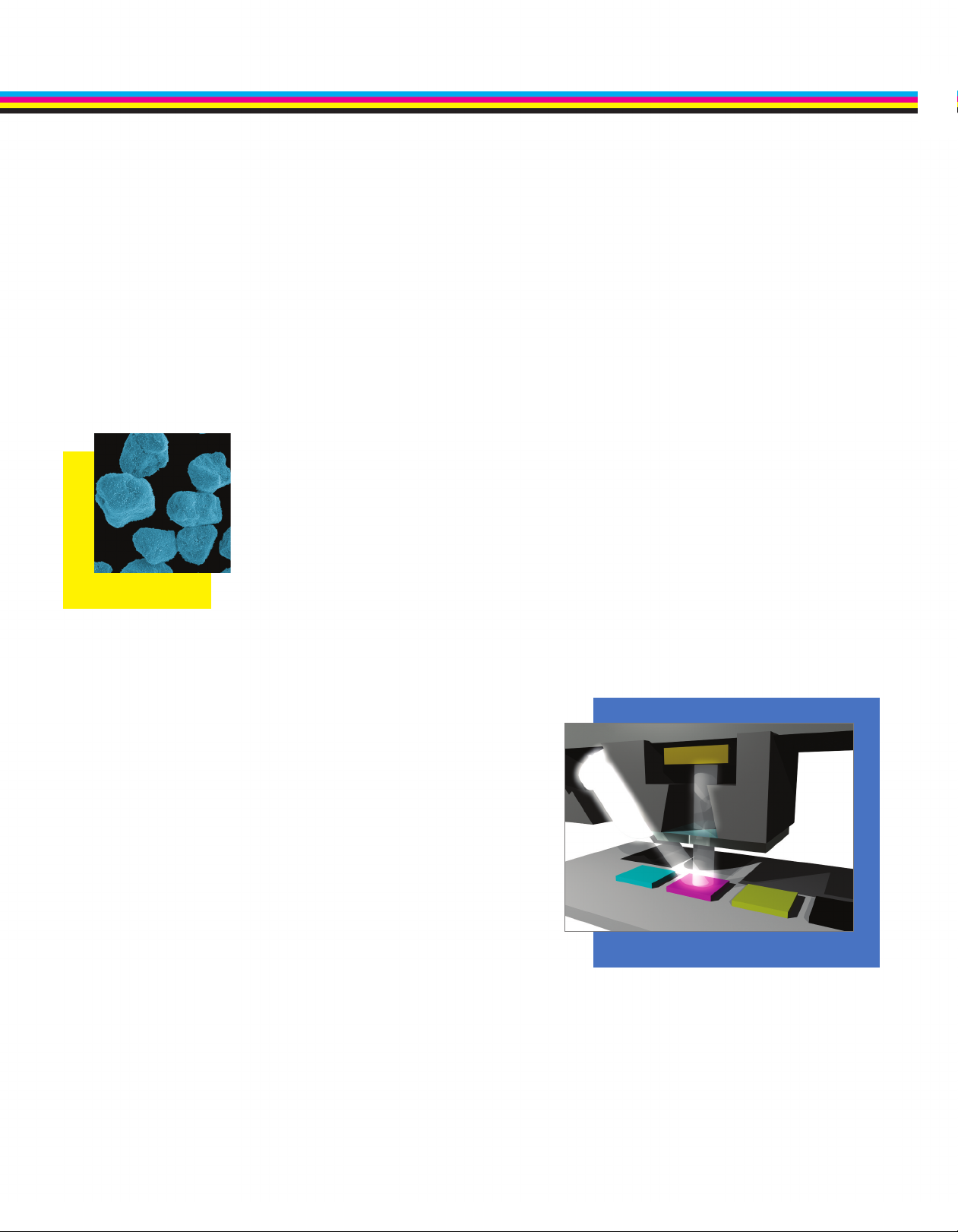

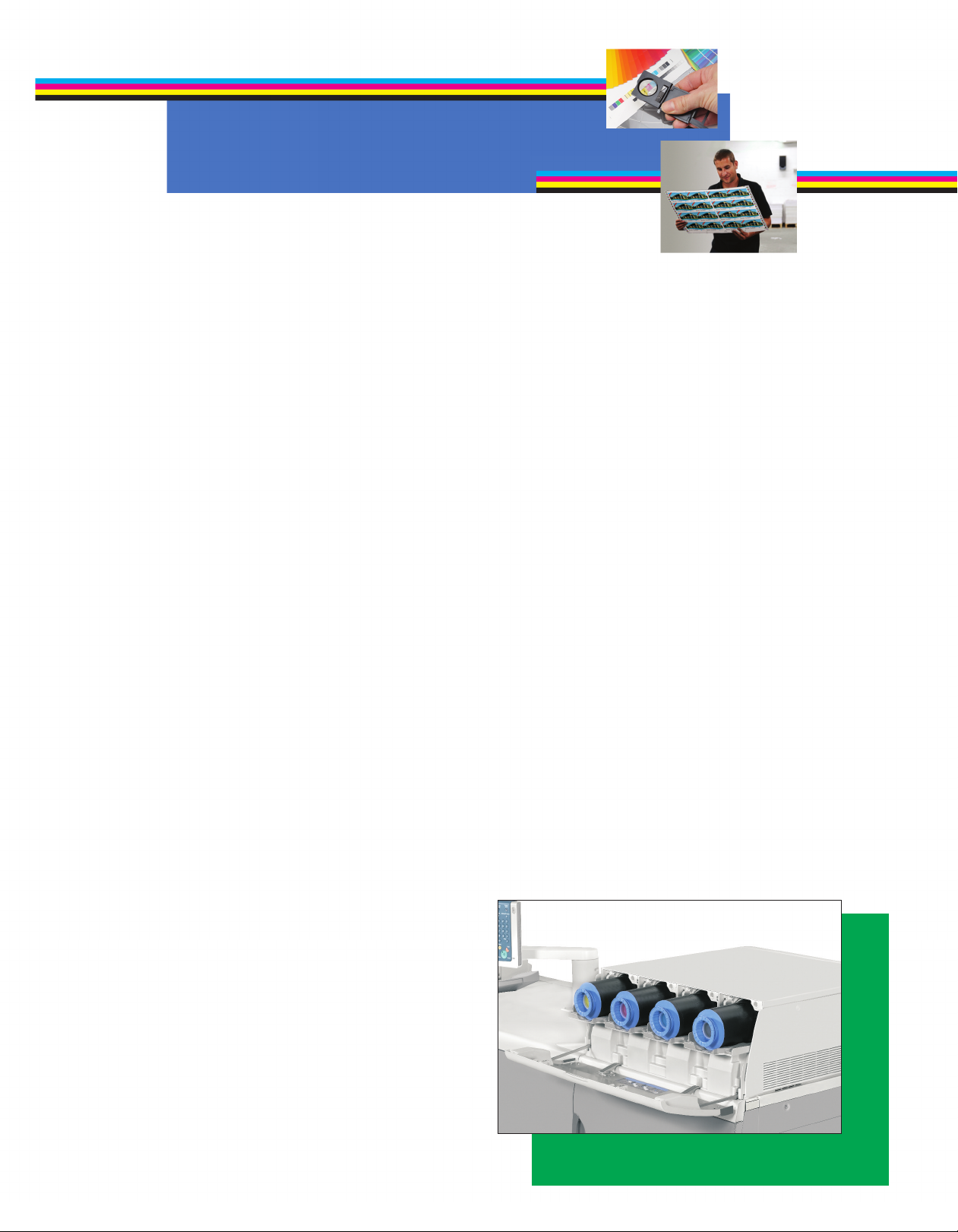

“OPTIMIZED” TONER TECHNOLOGY FOR A SMOOTHER,

FLATTER FINISH

Forget what you think you know about toner-based printing.

Canon’s V Toner is oil-free and utilizes exceptionally small

particles (averaging 5.5 microns) containing micro-dispersed

wax so the toner fixes evenly and lays flat, resulting in sharp,

vivid, dense images and a smooth finish that looks and feels

like offset printing. There are no 3-D or raised toner effects,

which means you won’t be able to tell where the toner

begins and ends on the page.

HIGH-RESOLUTION IMAGING

With true 1200 x 1200 dpi resolution, you get finer image

quality, higher quality characters, smoother corners, and

highly clean gradient transitions. You also get 256 levels

of grayscale for unparalleled color depth, better mid-tones,

and detailed images.

Page 5

GLOSS OPTIMIZATION—A REFLECTION OF QUALITY

Canon’s unique combination of toner, imaging process,

fusing technologies, and media library work together to

ensure that the gloss of the image matches that of the

paper and remains consistent across the page. Since

there are no tell-tale deviations usu ally associated with

digital printing, the result is undeniably superior.

V Toner

CONSISTENCY YOU CAN COUNT ON—PAGE AFTER PAGE,

JOB AFTER JOB, DAY AFTER DAY

Delivering consistent print quality and color matching through-

out a print run, especially on reprint orders, is critically impor-

tant. But it’s sometimes easier said than done, especially when

you’re working with color images, a variety of paper types, and

varying environmental conditions. Built-in Automatic Press

Calibration sets the proper color densities without operator

intervention, while Canon’s Advanced Developer technology

maintains a constant supply of fresh developer to ensure color

consistency from side to side, page to page, and job to job.

Real-Time Calibration measures color density levels in real-

time and automatically makes any necessary adjustments to

ensure that the first print matches the last, and every one

in-between.

ULTRA-HIGH IMAGE QUALITY ON A WIDE RANGE OF

PAPER STOCKS

The imagePRESS C7000VP digital press uses an Advanced

Image Transfer Belt (AITB). Similar to the blanket on an offset

press, the AITB flexible design accepts the image from the

drum then transfers all four colors to the page in a single

pass. The result? Better solids, not only on plain and coated

stocks, but also on specialty papers.

Automatic Press Calibration

Page 6

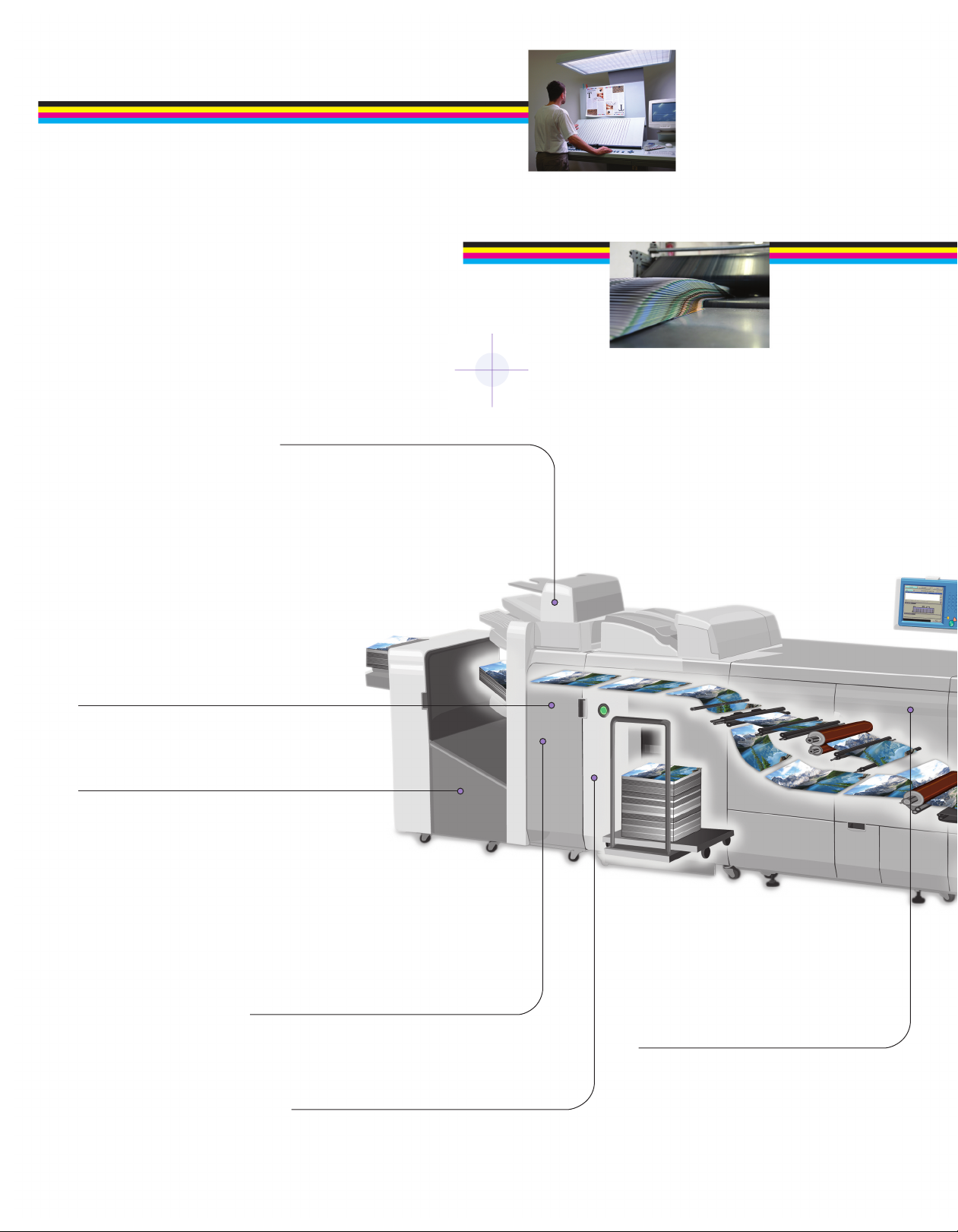

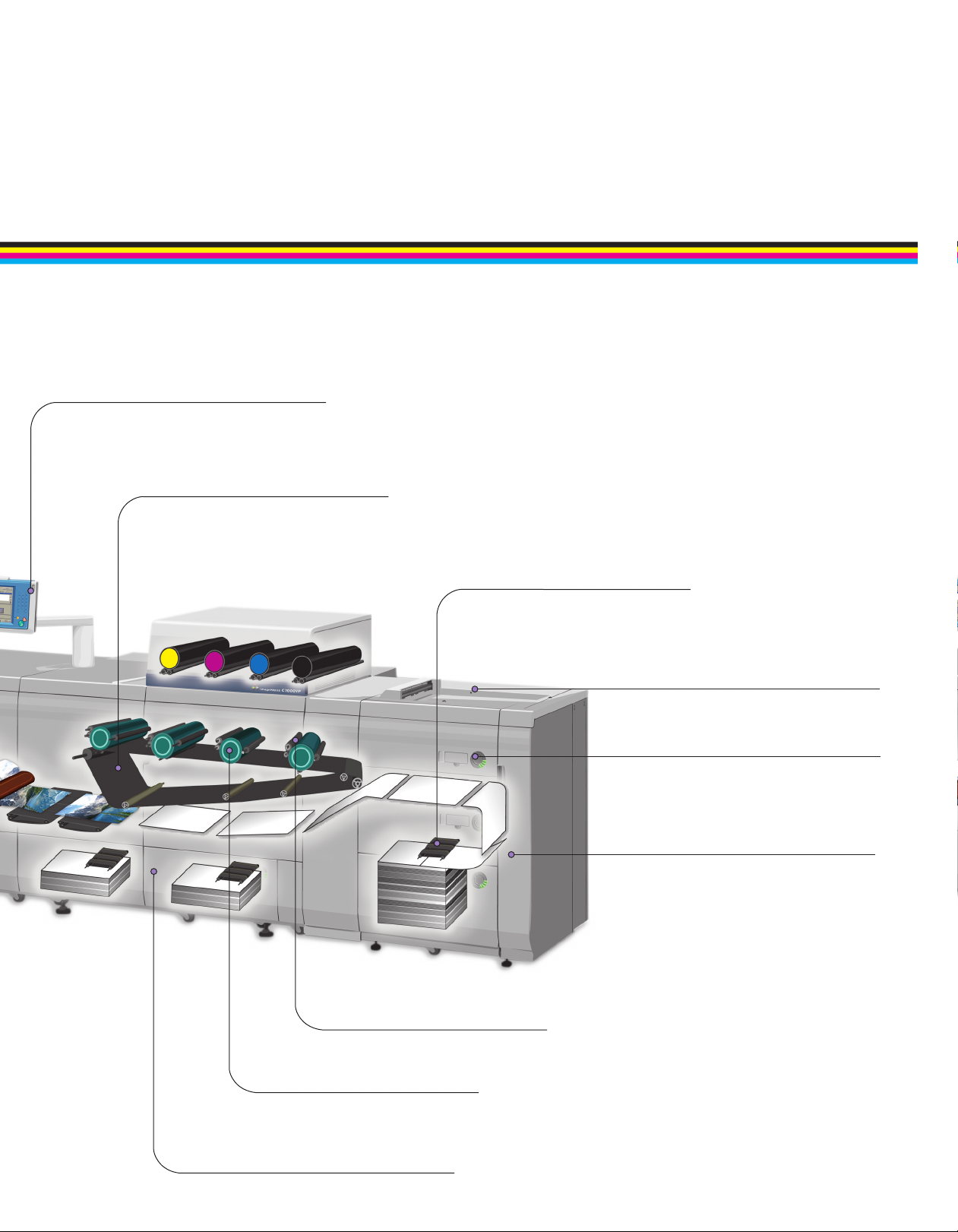

TAKE THE imagePRESS C7000VP DIGITAL PRESS TOUR

Canon’s investment resulted in better image

quality, productivity, and versatility.

The Document Inserter* allows users

to insert preprinted cover sheets into a

saddle-stitched job.

The Puncher Unit* provides accurate

two- and three-hole punch capabilities,

with no set limits.

The Booklet Trimmer* attaches to the

Saddle Finisher and evenly trims booklets

up to 80 pages.** The output tray holds

up to 30 saddle-stitched booklets.

The Saddle Finisher creates saddle-stitched

booklets up to 80 pages (20 sheets) in

length. The Saddle Finisher and Plain Finisher

provide corner- and double-sided staples up

to 100 sheets** and stack on two trays for

an output capacity of 5,000 sheets.**

The High-Capacity Stacker offset and straight

stacks up to 5,000 sheets* on a removable dolly,

making transition to off-line finishing easier.

Dual Fusing allows the press to maintain

maximum output speed while ensuring that

gloss remains consistent across the page.

Page 7

The Press Console is designed to improve

operability and give you access to features

such as the Media Library.

Advanced Image Transfer Belt (AITB)

transfers all four colors to the page in a

single pass for a better impression on a

wider range of specialty, coated, and

uncoated stocks.

Advanced Feeding Technologies are

designed to ensure reliable and accurate

paper feeding.

The Escape Tray is where multifeed

sheets from the POD Decks are routed,

without stopping the press.

Tray Indicators illuminate to tell you how

much paper is left.

Twin Red Laser Imaging produces

precise, clear, higher-resolution images.

The E Drum was engineered for

optimum image transfer and durability.

Standard Paper Capacity is 2,000 sheets.**

1,000 sheets of paper fit in each of the two

standard trays. Both trays hold any supported stock.

The POD Decks hold any supported stock

in any tray, up to 13" x 19.2". Each POD

Deck has three trays, with a total capacity

of 4,000 sheets;** add a second POD Deck

to increase capacity to 10,000 sheets.**

*Optional accessory for Finisher/Saddle Finisher

**20 lb. Bond (75gsm)

Page 8

PRODUCTIVITY

RELIABILITY AND PRODUCTIVITY:

HAT YOU NEED IN THE PRESSROOM

W

The imagePRESS C7000VP digital press features advanced

productivity and reliability via technologies that keep jobs

moving with little or no effort.

MAINTAIN PRINT SPEED, REGARDLESS OF PAPER WEIGHT

While most other digital printing systems are forced to slow

down on heavier stocks, the imagePRESS C7000VP digital

press maintains print speed, regardless of paper weight,

on letter, ledger, 12" x 18", and 13" x 19" sheets. This ability

ensures maximum press throughput and simplifies job

scheduling, no matter which stock is required.

LET IT RUN UNATTENDED WITHOUT MISSING A BEAT

With enhanced productivity and reliability technologies, the

Canon imagePRESS C7000VP digital press can virtually run

by itself. In fact, with a few simple steps taken in advance,

operators can let the press run any job without intervention.

So while the press does its job, operators can prepare for

the next one.

DESIGNED TO MINIMIZE DOWNTIME AND MAXIMIZE

PRODUCTIVITY

When press time is interrupted, it costs time and money.

That’s why Canon designed the imagePRESS C7000VP

digital press with automated features so downtime is

minimized and production maximized!

“On-The-Fly” paper and toner replacements let you main-

tain productivity without stopping the press. You can refill

paper trays, replace the toner bottles, and replace the waste

toner bottles without stopping or pausing the press.

Multifeed detection is a brilliant way to prevent paper jams

and keep the press operating efficiently. If two or more

sheets are detected entering the press from the POD deck

at the same time, they’re diverted to the escape tray on

top of the POD deck, without ever stopping the press.

Toner Station

Page 9

PRINTING THAT WATCHES YOUR FRONT AND BACK

The imagePRESS C7000VP digital press maximizes produc-

tivity with automatic duplexing/perfecting on all support-

ed stocks. With the press’s precision front-to-back registra-

tion technology, you can be confident that all four sides of

an image line up. The highly accurate built-in registration

technology helps prevent images from being misaligned,

giving you a professional result even on 110 lb. Cover

2

(300 g/m

INTELLIGENT REGISTRATION TECHNOLOGIES THAT GIVE

IT TO YOU STRAIGHT

) and 13" x 19.2" sheets.

If registration is one of your major concerns, the Canon

imagePRESS C7000VP digital press will come as a big relief.

It provides In-Track Registration and Timing Sensors that

address skewing, positioning, and timing issues. This helps

ensure that the image is placed in the same location on

every sheet of paper and enters the press straight, centered,

and on time — every time.

Press Console

ADVANCED FEEDING TECHNOLOGIES THAT SATISFY

YOUR APPETITE FOR EFFICIENCY

All trays in the press are equipped with technologies

that facilitate accurate and reliable feeding into the

press. More like a press than a printer, Canon’s

Suction Feeding technology picks up the top sheet

with air, not rollers, for greater stability as the sheet

is fed into the press. Enhanced Air Assist and Air

Separation Technologies help minimize paper friction

and keep sheets separated to prevent double-feeding

and the need for operator intervention.

Page 10

VERSATILITY

MORE INNOVATIVE FEATURES AND PAPER STOCK CHOICES

ENHANCE QUALITY, EFFICIENCY, AND PERFORMANCE

Enhanced paper-handling capabilities of the imagePRESS C7000VP

digital press give operators all the flexibility and versatility they need

to meet the challenges of on-demand digital printing.

PRINT ON THE PAPER STOCK YOUR CUSTOMERS WANT

Why limit paper stock options when you can offer your

customers the right stock for the job with the Canon

imagePRESS C7000VP digital press? It handles a variety of

paper weights, types, and sizes and accepts sheets as small

as 7.2" x 7.2" to as large as 13" x 19.2" (and even custom

sizes) and 17 lb. Bond to 110 lb. Cover in weight. This digital

press gives you consistent, high-quality imaging on coated,

uncoated, and specialty stocks.

A MEDIA LIBRARY THAT SETS PARAMETERS FOR QUALITY

AND EFFICIENCY

Maintaining quality output and operational efficiencies when

you’re running a variety of stocks can be challenging. But the

imagePRESS C7000VP Media Library makes it simple. Just

enter the properties of each paper you run into the Media

Library. This lets you create, edit, manage, and select stocks

from one central location. Once the details of the paper are

entered, they’re stored so you can easily select the appropri-

ate stock for the job and help ensure optimal performance

and quality.

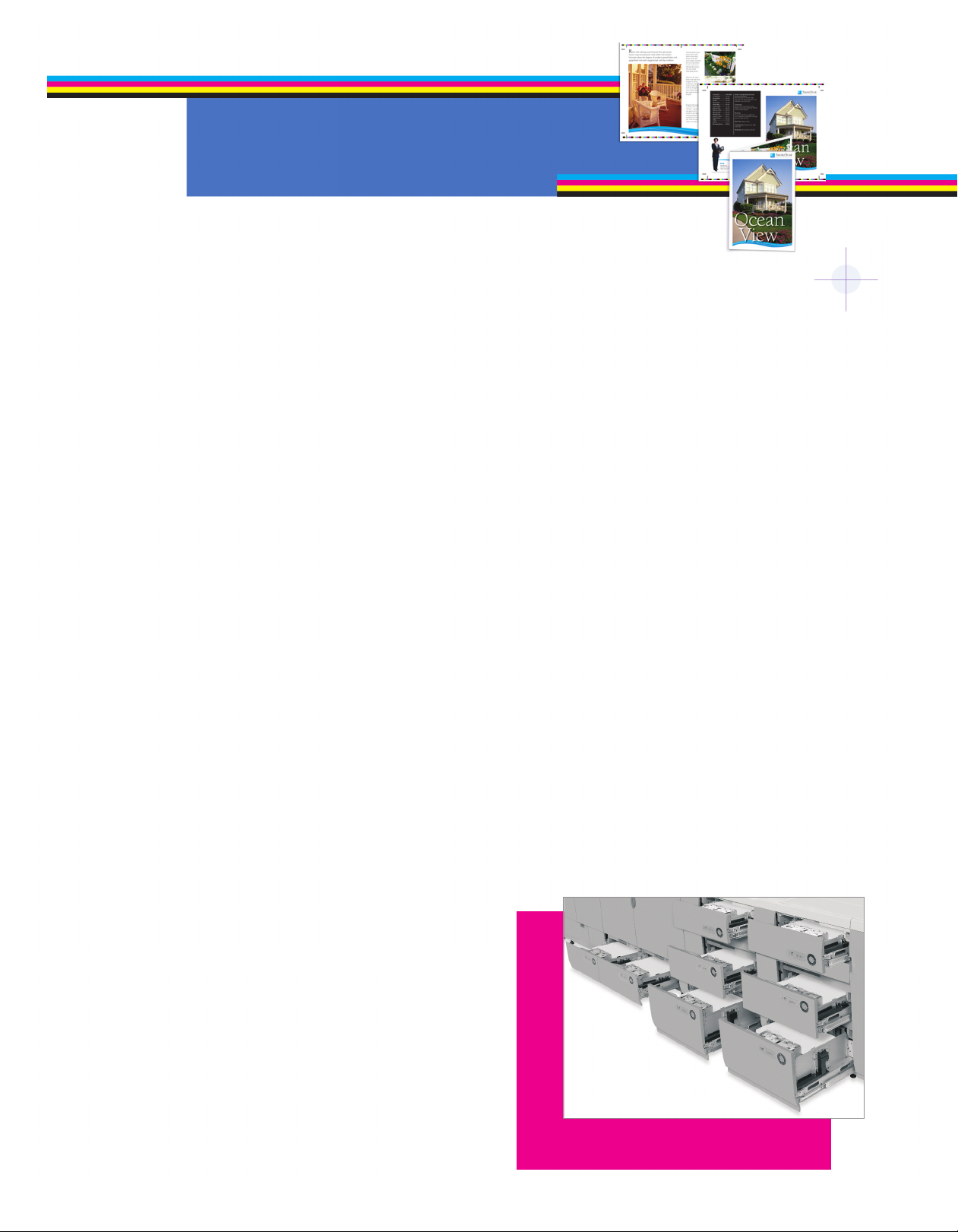

TRAYS THAT TAKE A WIDE VARIETY OF STOCKS AND SIZES

In addition to two standard trays, the imagePRESS C7000VP

digital press has an optional POD Deck that holds any sup-

ported stock in any tray. The POD Deck has three trays—two

trays hold 1,000 sheets* each and the third tray holds 2,000

sheets.* Combine two POD Decks with the two standard

1,000-sheet* trays and the capacity increases to 10,000

sheets.* For environments where space is a concern, the

3,500-sheet* Paper Deck is an economical alternative. With

greater capacity, versatility to meet your needs, support for

more types of stocks, and less time needed for setup, the

imagePRESS C7000VP digital press is more than a high-

performance machine, it’s a productivity tool, too.

*20 lb. Bond (75gsm)

POD Decks and Standard Trays

Page 11

FRONT-END PROCESSING POWER

TO

DRIVE PRODUCTION AND PROFITS!

The imagePRESS C7000VP digital press features

advanced workflow options to keep jobs moving.

The imagePRESS C7000VP digital press has one of the most

extensive lists of controller options to give users the right

level of power and functionality to fit their production environment.

CANON CONTROLLER

When the Canon imagePRESS C7000VP digital press is

configured with this print controller, networked users can

access document/image manipulation features, paper source,

and finishing modes directly from their desktop. Ideal for

environments requiring basic-level graphic processing, this

controller offers a host of capabilities such as Secured Print,

Print-to-Mailbox, and Edit & Preview.

CREO COLOR SERVER: imagePRESS CR SERVER A7000,

POWERED BY CREO COLOR SERVER TECHNOLOGY

The newest digital front end for the imagePRESS C7000VP

digital press, the imagePRESS CR Server A7000 offers

another workflow choice for users. Built on unique Creo Color

Server architecture, the controller offers robust color controls,

make-ready features, and VDP capabilities for every level

user—especially commercial printers. A standard variable data

composition engine, called Easy VDP Creator, also allows

users to access a template-driven VDP solution integrated with

their controller. Hybrid workflow connectivity is made simple

with built-in JDF/JMF support for many commercial prepress

environments. Available with the optional Process Power Pack,

productivity and automation is further enhanced with the

Parallel RIP and Photo Touch-up Software features.

: COLOR UFR II/PCL/PS PRINTER KIT

EFI®SERVERS: imagePRESS SERVER A2100 AND A3100,

POWERED BY EFI FIERY

For those familiar with the popular Fiery-based workflow,

Canon offers two high-performance controller solutions. The

imagePRESS Server A3100 is the most powerful and high-

est performing Fiery-based controller for the imagePRESS

C7000VP digital press. It comes fully loaded with standard

features such as the Graphic Arts Package, Premium Edition,

Impose, and Compose to maximize uptime and drive productivity.

The Canon imagePRESS Server A2100 is another high-

performance controller for the imagePRESS C7000VP digital

press. It’s best suited for corporate in-plants and print service

providers who need a more economical choice without

sacrificing important functionality. This model comes loaded

with standard features, such as the Graphic Arts Package and

Impose, and is configurable with optional packages such as

Compose and the Graphic Arts Package, Premium Edition.

Workflow integration is available with both controllers

through Fiery’s standalone JDF Connector for high-end

environments looking for connectivity to solutions such as

EFI Digital StoreFront

also standard for environments looking to maximize their

investment by offering personalized communications.

®

®

. Support for popular VDP formats is

Page 12

Specifications

®

ADF (Duplex Automatic Document Feeder)-R1

ARKING ENGINE

M

echnology: Laser Electrostatic Transfer System

T

Resolution: Up to 1200 x 1200 dpi

alftones: 256-Level Grayscale

H

Print Speed

implex: 70 ppm (Letter)*

S

Duplex/Perfect: 64 ipm (Letter)*

aximum Paper Size: 13" x 19.2"

M

5 ppm (11" x 17")*

3

31 ppm (13" x 19")*

35 ipm (11" x 17")*

1 ipm (13" x 19")*

3

Paper Feeding

tandard: 2,000 Sheets (20 lb. Bond)

S

Maximum: 10,000 Sheets (20 lb. Bond)

cceptable Paper Weight: 17 lb. Bond to 110 lb. Cover

A

uplexing/Perfecting: Automatic Duplex/Perfect Any

D

ith Optional 2 POD Decks

w

2

(64 to 300 g/m

upported Stock

S

) (All Trays)

Power Source: 3-Phase 208V/30A

imensions (H x W x D): Approx. 52.4" x 101.8" x 44.7"

D

Weight: Approx. 2,645 lb. (1,200kg)

INPUT ACCESSORIES

POD Deck-A1

Paper Capacity: 4,000 Sheets (1,000 x 2 + 2,000)

aximum Paper Size: 13" x 19.2"

M

aper Weight: 17 lb. Bond to 110 lb. Cover

P

20 lb. Bond)

(

(64 to 300 g/m

2

)

Dimensions (H x W x D): Approx. 43.1" x 38.9" x 31.2"

Weight: Approx. 551 lb. (250kg)

Power Source: 208V/15A

Secondary POD Deck-A1

Paper Capacity: 4,000 Sheets (1,000 x 2 + 2,000)

(20 lb. Bond)

Maximum Paper Size: 13" x 19.2"

Paper Weight: 17 lb. Bond to 110 lb. Cover

(64 to 300 g/m

2

)

Dimensions (H x W x D): Approx. 43.1" x 31.9" x 31.2"

Weight: Approx. 507 lb. (230kg)

Power Source: From POD Deck- A1

Paper Deck-AC1

Paper Capacity: 3,500 Sheets (20 lb. Bond)

Paper Size: Letter, Letter-R, Legal, 11" x 17",

Paper Weight: 17 lb. Bond to 110 lb. Cover

12" x 18", 13" x 19"

(64 to 300 g/m

2

)

Dimensions (H x W x D): Approx. 22.4" x 23.7" x 24.4"

Weight: Approx. 112 lb. (51kg)

Power Source: From Marking Engine

Stack Bypass- A1

Paper Capacity: 100 Sheets (20 lb. Bond)

Minimum Paper Size: 5.5" x 7.2"

Maximum Paper Size: 13" x 19.2"

Paper Weight: 17 lb. Bond to 140 lb. Index

(64 to 256 g/m

2

)

Color Image Reader-H1

Image Sensor: CCD

Document Size: Statement to 11" x 17"

Resolution: 600 x 600 dpi, 256 Gradations

Dimensions (H x W x D): Approx. 4.1" x 28.8" x 23.4"

Weight: Approx. 38.5 lb. (17.5kg)

Power Source: From Marking Engine

CANON, IMAGEPRESS, and the GENUINE logo are registered trademarks of Canon Inc. in the United States and may also be

registered trademarks or trademarks in other countries. IMAGEANYWARE is a trademark of Canon. All referenced product names

and other marks are trademarks of their respective owners and are hereby acknowledged. Specifications and availability subject

to change without notice.

©2009 Canon U.S.A., Inc. All rights reserved.

Federal Law prohibits copying of certain documents. Violators may be

subject to penalties. We suggest that you check with your own legal counsel.

Canon U.S.A., Inc. and Canon Canada, Inc. intend to cooperate with Law

Enforcement Agencies in connection with claims of unauthorized copying.

1009-C7000VP-PDF-CR

D

ray Capacity: 100 Sheets (20 lb. Bond)

T

Scanning Speed: Up to 80 ipm (300 dpi)

cceptable Original Size: Statement to 11" x 17"

A

cceptable Paper Weight: 13 lb. Bond to 80 lb. Cover

A

p to 50 ipm (600 dpi)

U

50 to 216 g/m

(

Dimensions (H x W x D): Approx. 5.6" x 25.4" x 22.4"

Weight: Approx. 47.3 lb. (21.5kg)

ower Source: From Marking Engine

P

FINISHING ACCESSORIES

rofessional Puncher-B1

P

Original Size: LTR, LTR-Tab Paper

aper Weight: 20 lb. Bond to 80 lb. Cover

P

Die Set Patterns: Loose Leaf 3-Hole/5-Hole, Velo

75 to 216 g/m

(

Bind 11-Hole, Plastic Comb 19-Hole,

Twin Loop 21-Hole/32-Hole,

ProClick 32-Hole, Color Coil 44-Hole

Size: 22” x 31.5” x 40.9”**

Power Supply: 120V, 60Hz

wo Knife Booklet Trimmer-A1

T

riginal Size: LTR, 11” x 17”, 12 x 18”, Legal

O

Acceptable Paper Weight: 17 lb. Bond to 110 lb. Cover

64 to 300 g/m

(

Number of Sheets:

0 Sheets/80 Pages (20 lb. Bond up to 80 g/m

2

5 Sheets/60 Pages (80 up to 105 g/m

1

0 Sheets/40 Pages (105 up to 128 g/m

1

5 Sheets/20 Pages (128 up to 216 g/m

Cover Sheet can be up to 110 lb. Cover (300 g/m

Trimming Width: 2mm-15mm (0.08” x 0.59”)

Power Supply: 120V, 60Hz

High-Capacity Stacker-C1

Offset Stack Capacity: 5,000 Sheets (20 lb. Bond)

Top Tray Capacity: 1,000 Sheets (20 lb. Bond)

Maximum Paper Size: 13" x 19.2"

Acceptable Paper Weight: 17 lb. Bond to 110 lb. Cover

(64 to 300 g/m

Number of Units

Connected at Once: Up to 2

Dimensions (H x W x D): Approx. 48.8" x 33.9" x 30.1"

Weight: Approx. 440 lb. (200kg)

Power Source: 115V/15A (Second Stacker

Receives Power from First Stacker)

Perfect Binder-B1

Cutting Method: Stack Rotation 3-Direction or

1-Direction Cut

Finished Book Size(After

3-Direction Cutting): 5.4" x 7.99" to 8.5" x 11.69"

Book Thickness: 10 to 200 Sheets (20 lb. Bond)

(up to 25mm)

Warm-Up Time: 440 Seconds

Trim Range (Adjustable in 0.5mm Increments)

Side: .26” to 1.95”

Top and Bottom: .26” to 1.56”

Dimensions (H x W x D): Approx. 53.5" x 36.3" x 31.1"

Weight: Approx. 697 lb. (316kg)

Power Source: 208V/15A

Finisher- AB1/Saddle Finisher- AB2

Number of Trays: 2 - 3

Tray Capacity

Top Tray: 3,000 Sheets (20 lb. Bond)

Lower Tray: 2,000 Sheets (20 lb. Bond)

Saddle-Stitch Tray: 30 Booklets or Limitless

Staple Positions: Corner Stapling, Double Stapling

Acceptable Paper Weight

Finisher: 17 lb. Bond to 110 lb. Cover

(64 to 300 g/m

2

)

2

)

2

)

2

28 lb. Bond)

–

2

32 lb. Bond)

–

2

– 80 lb. Cover)

2

)

2

)

addle Finisher: 17 lb. Bond to 110 lb. Cover

S

64 to 300 g/m

(

2

)

Inside Sheets: 17 lb. Bond to 200 g/m²

over Sheet: 17 lb. Bond to 110 lb.Cover

C

64 to 300 g/m

(

2

)

Acceptable Paper Size

tapling: Executive, Letter-R, Letter,

S

egal, 11" x 17"

L

Sheet Stacking: Up to 13" x 19.2"

Saddle Finisher: Letter-R, Legal, 11" x 17", 12" x 18"

ax. Stapling Capacity: Up to 100 Sheets

M

Saddle-Stitching (Number of Sheets)

lain Paper: 64 to 80 g/m²: 2 to 20 Sheets

P

oated Paper: 80 to 81.4 g/m²: 2 to 15 Sheets

C

1 to 105 g/m²: 2 to 15 Sheets

8

106 to 200 g/m²: 2 to 5 Sheets

1.5 to 105 g/m²: 2 to 10 Sheets

8

06 to 200 g/m²: 2 to 5 Sheets

1

Dimensions (H x W x D): Approx. 46.5" x 31.5" x 31.2"

inisher: Approx. 278 lb. (126kg)

F

Saddle Finisher: Approx. 392 lb. (178kg)

ower Source: 208V/15A

P

Booklet Trimmer-C1

argin Trimming: Open-end Only

M

rim Amount: 0.08" to 0.78"

T

rim Thickness: 40 Sheets

T

2

)

2

)

Waste Tray Capacity: 1,500 Sheets of Trimmed Strip

Acceptable Paper Weight: 17 lb. Bond to 110 lb. Cover

utput Tray Capacity: 30 Booklets

O

64 to 300 g/m

(

2

)

Dimensions (H x W x D): Approx. 40.9" x 62" x 30.3"

Weight: Approx. 335 lb. (152kg)

Puncher Unit-V1 (Option for Finisher/Saddle Finisher)

Punch Method: Press Punch System

Max. Paper Weight: 17 lb. Bond to 110 lb. Index

(64 to 200 g/m

2

)

Paper Sizes

2-Hole: Legal, Letter-R

3-Hole: 11" x 17", Letter, Executive

Punch Speed: Up to 70 ppm (Depends on

Speed of Marking Engine)

Document Insertion Unit-C1 (Option for Finisher/Saddle Finisher)

Number of Trays: 2

Capacity

Upper Tray: 200 Sheets

Lower Tray: 200 Sheets

Acceptable Paper Weight: 17 lb. Bond to 110 lb. Cover

Acceptable Paper Size

Upper Tray: 7.2” x 7.2” to 11.6” x 13”

Lower Tray: 7.2: x 7.2” to 13” x 19.2”

Dimensions (H x W x D): Approx. 8.4" x 24.6" x 26.3"

Weight: Approx. 37.5 lb. (17kg)

*Regardless of paper weight

**Size includes Professional Puncher Integration Unit-A1

1-800-OK-CANON

www.usa.canon.com

Canon U.S.A., Inc.

One Canon Plaza

Lake Success, NY 11042

Loading...

Loading...