imageRUNNER ADVANCE

Consumable Parts and Cleaning Parts

Adjustment

Error Code

List of User Mode

Service Mode

List of Parts

Features/Specications

Version upgrade

Appendix

C2030/C2025/C2020 Series

Service Manual Digest Rev.1

1

2

3

4

5

6

7

8

9

Application

This manual has been issued by Canon Inc. for qualied persons to learn technical theory,

installation, maintenance, and repair of products. This manual covers all localities where the

products are sold. For this reason, there may be information in this manual that does not

apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements

or changes in products. When changes occur in applicable products or in the contents of this

manual, Canon will release technical information as the need arises. In the event of major

changes in the contents of this manual over a long or short period, Canon will issue a new

edition of this manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks

of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may

not be copied, reproduced or translated into another language, in whole or in part, without the

consent of Canon Inc.

© CANON INC. 2010

0-2

Caution

Use of this manual should be strictly supervised to avoid disclosure of condential

information.

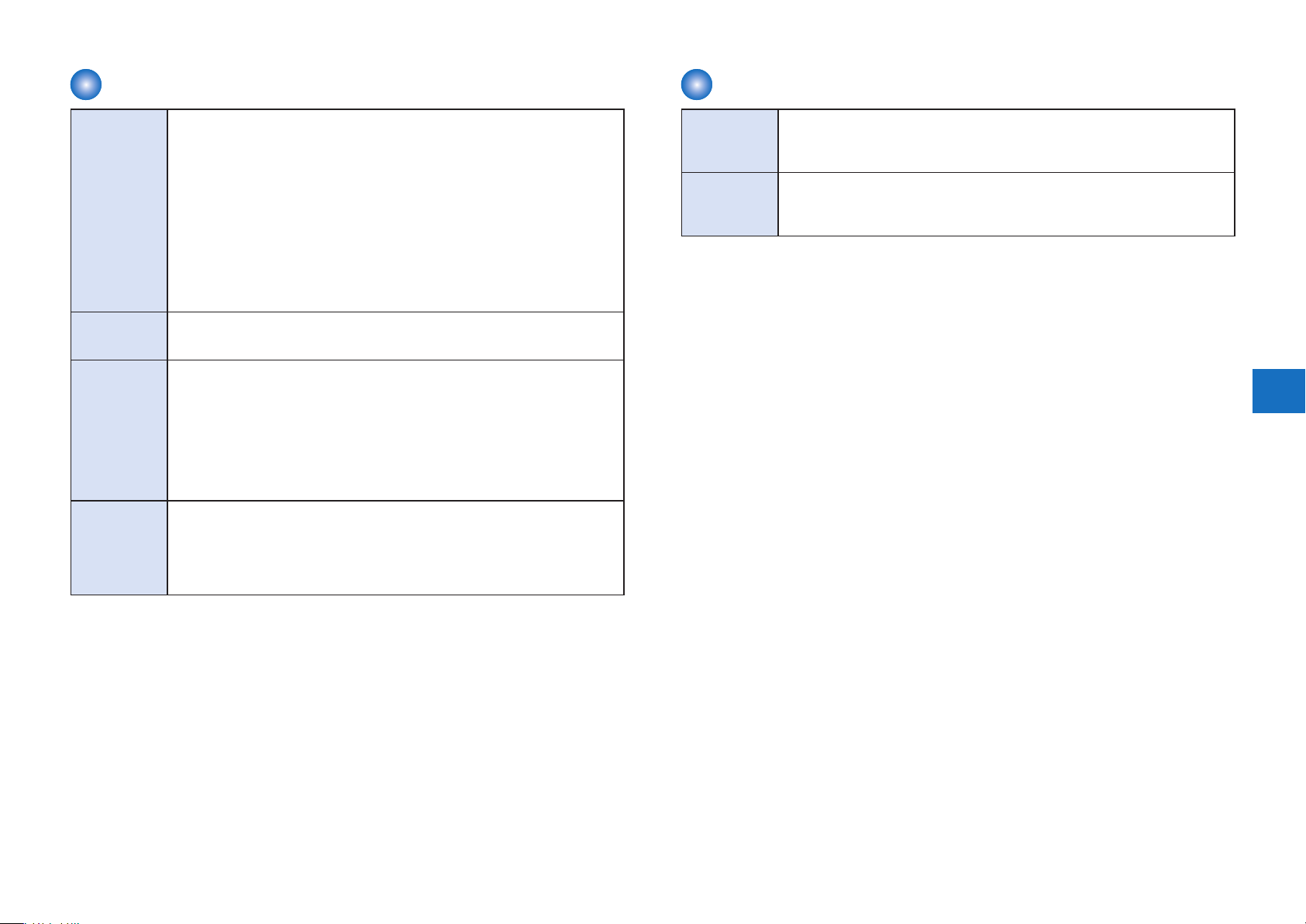

Explanation of Symbols

The following symbols are used throughout this Service Manual.

Symbols Explanation Symbols Explanation

Check. Remove the claw.

F-0-1

Check visually. Insert the claw.

F-0-3 F-0-4

Check the noise. Use the bundled part.

F-0-5 F-0-6

Disconnect the connector.

F-0-7 F-0-8

Connect the connector. Plug the power cable.

F-0-9 F-0-10

Remove the cable/wire

from the cable guide or wire

saddle.

F-0-11 F-0-12

Set the cable/wire to the

cable guide or wire saddle.

F-0-13

Remove the screw.

F-0-2

Push the part.

Turn on the power.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specic functions and the

relationship between electrical and mechanical systems with reference to the timing of

operation.

In the diagrams, represents the path of mechanical drive; where a signal name

accompanies the symbol, the arrow indicates the direction of the electric

signal.

The expression "turn on the power" means ipping on the power switch, closing the

front door, and closing the delivery unit door, which results in supplying the machine with

power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is

"High", while '0' is used to indicate "Low". (The voltage value, however, differs from

circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked

in the eld. Therefore, the operations of the microprocessors used in the machines

are not discussed: they are explained in terms of from sensors to the input of the DC

controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product

improvement or other purposes, and major changes will be communicated in the form of

Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service

Manual and all relevant Service Information bulletins and be able to identify and isolate faults

in the machine.

F-0-14

Tighten the screw.

F-0-15

0-3

Contents

Consumable Parts and Cleaning Parts

Consumable Parts and Cleaning Parts ----------------------------------1-2

Drum Unit ------------------------------------------------------------------------------------- 1-3

Cleaning Parts -----------------------------------------------------------------1-4

Adjustment

Main Controller ----------------------------------------------------------------2-2

HDD ----------------------------------------------------------------------------------- 2-2

Main controller PCB 1 ------------------------------------------------------------ 2-2

Main controller PCB 2 ------------------------------------------------------------ 2-3

DC controller PCB ----------------------------------------------------------------- 2-3

Error Code

Overview ------------------------------------------------------------------------3-2

Outline -------------------------------------------------------------------------------- 3-2

Outline ----------------------------------------------------------------------------------------- 3-2

Location code -------------------------------------------------------------------------------- 3-2

Location code -------------------------------------------------------------------------------- 3-2

Points to Note When Clearing MN-CON ---------------------------------------------- 3-3

Points to Note When Clearing HDD---------------------------------------------------- 3-3

Error Code ----------------------------------------------------------------------3-4

Error Code Details ----------------------------------------------------------------- 3-4

Jam Code --------------------------------------------------------------------- 3-73

image RUNNER ADVANCE C2030/C2025/C2020 -----------------------3-73

Color Image Reader Unit-D1/D2 ----------------------------------------------3-74

Inner Finisher-C1 -----------------------------------------------------------------3-75

Alarm Code ------------------------------------------------------------------- 3-77

Alarm Code -------------------------------------------------------------------------3-77

List of User Mode

List of User Mode -------------------------------------------------------------4-2

Preferences ------------------------------------------------------------------------- 4-2

Paper Settings ------------------------------------------------------------------------------- 4-2

Display Settings ----------------------------------------------------------------------------- 4-2

Timer/Energy Settings --------------------------------------------------------------------- 4-3

Network --------------------------------------------------------------------------------------- 4-4

External Interface -------------------------------------------------------------------------- 4-11

Accessibility ---------------------------------------------------------------------------------4-11

Adjustment/Maintenance --------------------------------------------------------4-12

Adjust Image Quality ---------------------------------------------------------------------- 4-12

Maintenance --------------------------------------------------------------------------------4-12

Function Settings -----------------------------------------------------------------4-13

Common -------------------------------------------------------------------------------------4-13

Copy ------------------------------------------------------------------------------------------4-16

Printer -----------------------------------------------------------------------------------------4-17

Send ------------------------------------------------------------------------------------------4-17

Receive/Forward ---------------------------------------------------------------------------4-21

Store/Access Files -------------------------------------------------------------------------4-22

Encrypted Secure Print

Set Destination --------------------------------------------------------------------4-23

Set Destination -----------------------------------------------------------------------------4-23

Management Settings -----------------------------------------------------------4-24

User Management ------------------------------------------------------------------------- 4-24

Device Management ----------------------------------------------------------------------4-25

License/Other -------------------------------------------------------------------------------4-28

Data Management ------------------------------------------------------------------------- 4-28

*1 ------------------------------------------------------------------------------------------------------------------4-22

Service Mode

Overview ------------------------------------------------------------------------5-2

Service Mode Menu --------------------------------------------------------------- 5-2

Service mode item explanations ----------------------------------------------- 5-2

I/O information enhancement --------------------------------------------------- 5-3

Display of Error Code/Alarm Code description ----------------------------- 5-3

COPIER > OPTION > BODY, Item Segmentation ------------------------- 5-4

Security features ------------------------------------------------------------------- 5-4

Related service modes -------------------------------------------------------------------- 5-4

Switching Screen (Level 1 < - > 2) -------------------------------------------- 5-5

Language switch ------------------------------------------------------------------- 5-6

0-1

Back-up of service mode --------------------------------------------------------- 5-6

COPIER -------------------------------------------------------------------------5-7

DISPLAY ----------------------------------------------------------------------------- 5-7

VERSION ------------------------------------------------------------------------------------- 5-7

USER -----------------------------------------------------------------------------------------5-23

ACC-STS ------------------------------------------------------------------------------------5-23

ANALOG -------------------------------------------------------------------------------------5-25

HV-STS ---------------------------------------------------------------------------------------5-25

CCD -------------------------------------------------------------------------------------------5-27

DPOT -----------------------------------------------------------------------------------------5-28

DENS -----------------------------------------------------------------------------------------5-29

MISC ------------------------------------------------------------------------------------------5-32

HT-C ------------------------------------------------------------------------------------------5-33

IO -------------------------------------------------------------------------------------5-39

Main Device (DCON > P001 to P016) ------------------------------------------------5-39

Color Image Reader Unit (RCON > P001) ------------------------------------------5-43

Color Image Reader Unit-D2 (FEEDER > P001) ----------------------------------5-43

Inner Finisher-C1(SORTER>P001 to P012) ----------------------------------------5-43

ADJUST -----------------------------------------------------------------------------5-45

ADJ-XY ---------------------------------------------------------------------------------------5-45

CCD -------------------------------------------------------------------------------------------5-46

IMG-REG ------------------------------------------------------------------------------------5-55

DENS -----------------------------------------------------------------------------------------5-56

BLANK ----------------------------------------------------------------------------------------5-60

V-CONT --------------------------------------------------------------------------------------5-61

PASCAL --------------------------------------------------------------------------------------5-64

COLOR ---------------------------------------------------------------------------------------5-65

HV-PRI ---------------------------------------------------------------------------------------5-70

HV-TR ----------------------------------------------------------------------------------------5-73

FEED-ADJ -----------------------------------------------------------------------------------5-87

MISC ------------------------------------------------------------------------------------------5-90

FUNCTION -------------------------------------------------------------------------5-92

INSTALL --------------------------------------------------------------------------------------5-92

CCD -------------------------------------------------------------------------------------------5-94

CLEANING ----------------------------------------------------------------------------------5-95

PANEL ----------------------------------------------------------------------------------------5-96

PART-CHK ----------------------------------------------------------------------------------5-96

CLEAR ---------------------------------------------------------------------------------------5-97

MISC-R ------------------------------------------------------------------------------------- 5-100

MISC-P ------------------------------------------------------------------------------------- 5-101

SYSTEM ----------------------------------------------------------------------------------- 5-102

DBG-LOG ---------------------------------------------------------------------------------- 5-103

OPTION --------------------------------------------------------------------------- 5-105

FNC-SW ----------------------------------------------------------------------------------- 5-105

DSPLY-SW -------------------------------------------------------------------------------- 5-113

IMAG-FIX ---------------------------------------------------------------------------------- 5-117

IMG-TR ------------------------------------------------------------------------------------- 5-119

IMG-DEV ----------------------------------------------------------------------------------- 5-120

IMG-LSR ----------------------------------------------------------------------------------- 5-121

IMG-RDR ----------------------------------------------------------------------------------5-122

IMG-MCON -------------------------------------------------------------------------------- 5-123

IMG-SPD ----------------------------------------------------------------------------------- 5-128

CLEANING -------------------------------------------------------------------------------- 5-129

ENV-SET ----------------------------------------------------------------------------------- 5-129

FEED-SW ---------------------------------------------------------------------------------- 5-130

NETWORK -------------------------------------------------------------------------------- 5-130

CUSTOM ---------------------------------------------------------------------------------- 5-137

USER --------------------------------------------------------------------------------------- 5-138

CST ----------------------------------------------------------------------------------------- 5-149

ACC ----------------------------------------------------------------------------------------- 5-151

INT-FACE ---------------------------------------------------------------------------------- 5-154

LCNS-TR ---------------------------------------------------------------------------------- 5-154

TEST ------------------------------------------------------------------------------- 5-164

PG ------------------------------------------------------------------------------------------- 5-164

NETWORK -------------------------------------------------------------------------------- 5-166

COUNTER ------------------------------------------------------------------------ 5-168

TOTAL -------------------------------------------------------------------------------------- 5-168

PICK-UP -----------------------------------------------------------------------------------5-168

FEEDER -----------------------------------------------------------------------------------5-168

JAM ----------------------------------------------------------------------------------------- 5-169

MISC ---------------------------------------------------------------------------------------- 5-169

JOB ------------------------------------------------------------------------------------------ 5-170

DRBL-1 ------------------------------------------------------------------------------------- 5-170

DRBL-2 ------------------------------------------------------------------------------------- 5-172

T-CNTR ------------------------------------------------------------------------------------5-173

V-CNTR ------------------------------------------------------------------------------------ 5-174

0-2

V2-CNTR ---------------------------------------------------------------------------------- 5-174

LF -------------------------------------------------------------------------------------------- 5-174

FEEDER --------------------------------------------------------------------- 5-175

DISPLAY -------------------------------------------------------------------------- 5-175

ADJUST --------------------------------------------------------------------------- 5-175

FUNCTION ----------------------------------------------------------------------- 5-176

SORTER -------------------------------------------------------------------- 5-178

ADJUST --------------------------------------------------------------------------- 5-178

FUNCTION -------------------------------------------------------------------------------- 5-178

OPTION --------------------------------------------------------------------------- 5-179

BOARD ---------------------------------------------------------------------- 5-180

OPTION --------------------------------------------------------------------------- 5-180

Improved Upgrading Operability -------------------------------------------------------- 7-5

Applying New Connectors ---------------------------------------------------------------- 7-5

Realization of Breaker-less Machine -------------------------------------------------- 7-6

Specications ------------------------------------------------------------------7-8

Specications ----------------------------------------------------------------------- 7-8

Weight and Size -------------------------------------------------------------------- 7-9

Productivity (Print Speed) -------------------------------------------------------- 7-9

Paper Type -------------------------------------------------------------------------- 7-9

Pickup ----------------------------------------------------------------------------------------7-10

Parts Name ------------------------------------------------------------------- 7-11

External View ---------------------------------------------------------------------- 7-11

Cross Section View ---------------------------------------------------------------7-12

List of Parts

List of Parts ---------------------------------------------------------------------6-2

List of Cover ------------------------------------------------------------------------- 6-2

List of Main Unit -------------------------------------------------------------------- 6-5

Unit Layout ----------------------------------------------------------------------------------- 6-5

Solenoid --------------------------------------------------------------------------------------- 6-9

Motor ------------------------------------------------------------------------------------------6-12

Fan --------------------------------------------------------------------------------------------6-15

Sensor ----------------------------------------------------------------------------------------6-16

Heater / Other ------------------------------------------------------------------------------6-21

Switch -----------------------------------------------------------------------------------------6-22

PCBs ------------------------------------------------------------------------------------------6-25

Conector ----------------------------------------------------------------------------6-30

Features/Specications

Product Lineup -----------------------------------------------------------------7-2

Host Machine ----------------------------------------------------------------------- 7-2

Model Type ----------------------------------------------------------------------------------- 7-2

Options ------------------------------------------------------------------------------- 7-3

Pickup/Delivery/Image Reading System Options ---------------------------------- 7-3

Function Expansion System Options -------------------------------------------------- 7-4

Features -------------------------------------------------------------------------7-5

Product Features ------------------------------------------------------------------- 7-5

Service Features ------------------------------------------------------------------- 7-5

Version upgrade

Version upgrade ---------------------------------------------------------------8-2

Overview ----------------------------------------------------------------------------- 8-2

Overview of Version Upgrade ----------------------------------------------------------- 8-2

Download mode ----------------------------------------------------------------------------- 8-3

Writing System Software ------------------------------------------------------------------ 8-3

System Software Conguration --------------------------------------------------------- 8-3

Note on download process --------------------------------------------------------------- 8-4

Version Upgrade via SST -------------------------------------------------------- 8-4

Overview -------------------------------------------------------------------------------------- 8-4

Registering System Software ------------------------------------------------------------ 8-5

Connection ----------------------------------------------------------------------------------- 8-6

Downloading System Software (Assist mode) -------------------------------------- 8-8

Downloading System Software (in single mode) ----------------------------------- 8-9

Formatting HDD ----------------------------------------------------------------------------8-11

Backup ---------------------------------------------------------------------------------------8-12

Version Upgrade using USB Memory Storage Device ------------------ 8-15

Relation between SST and USB memory storage device -----------------------8-15

Registering System Software ----------------------------------------------------------- 8-16

Connection ----------------------------------------------------------------------------------8-20

Upgrading System Software ------------------------------------------------------------8-21

Selecting System Software--------------------------------------------------------------8-22

Downloading/ Writing System Software (Automatic) -----------------------------8-23

Formatting FLASH PCB or HDD ------------------------------------------------------- 8-25

0-3

Backup/ Restore ---------------------------------------------------------------------------8-27

Other menus --------------------------------------------------------------------------------8-27

Version Upgrade via CDS ------------------------------------------------------8-28

Overview -------------------------------------------------------------------------------------8-28

Preparation ----------------------------------------------------------------------------------8-28

a. UGW-linked Download and Update (Full-remote Update) -------------------8-33

b. UGW-linked Download (Remote Distribution Update) ------------------------ 8-33

c. Manual Download and Update (On-site Update from Service Mode) -----8-35

Deleting Firmware Distribution Schedule --------------------------------------------8-40

Updating Downloaded Firmware (Applying Firmware) ---------------------------8-41

Deleting Downloaded Firmware--------------------------------------------------------8-42

Troubleshooting on Firmware Installation -------------------------------------------8-43

Information required for Reports -------------------------------------------------------8-45

Debug Logs ---------------------------------------------------------------------------------8-45

Error Messages ----------------------------------------------------------------------------8-47

Error Codes ---------------------------------------------------------------------------------8-52

Appendix

General Timing Chart --------------------------------------------------------9-2

General Timing Chart ------------------------------------------------------------- 9-2

A4 single-sided 2 prints full color ------------------------------------------------------- 9-2

A4 single-sided 2 prints Bk color-------------------------------------------------------- 9-3

General Circuit Diagram Signal Input/Output List --------------------1-IV

General Circuit Diagram -----------------------------------------------------1-7

General Circuit Diagram(1/14) -------------------------------------------------- 1-7

General Circuit Diagram(2/14) -------------------------------------------------- 1-8

General Circuit Diagram(3/14) -------------------------------------------------- 1-9

General Circuit Diagram(4/14) -------------------------------------------------1-10

General Circuit Diagram(5/14) ------------------------------------------------- 1-11

General Circuit Diagram(6/14) -------------------------------------------------1-12

General Circuit Diagram(7/14) -------------------------------------------------1-13

General Circuit Diagram(8/14) -------------------------------------------------1-14

General Circuit Diagram(9/14) -------------------------------------------------1-15

General Circuit Diagram(10/14) -----------------------------------------------1-16

General Circuit Diagram(11/14) -----------------------------------------------1-17

General Circuit Diagram(12/14) -----------------------------------------------1-18

General Circuit Diagram(13/14) -----------------------------------------------1-19

General Circuit Diagram(14/14) -----------------------------------------------1-20

Backup Data ------------------------------------------------------------------ 1-22

Detail of HDD partition ----------------------------------------------------- 1-24

Soft counter specications ------------------------------------------------ 9-25

Soft counter specications ------------------------------------------------------9-25

Controller Self Diagnosis -------------------------------------------------- 9-30

Introduction -------------------------------------------------------------------------9-30

Boot System Error Diagnosis Tool -----------------------------------------------------9-30

Controller System Error Diagnosis Tool ----------------------------------------------9-30

Overview ----------------------------------------------------------------------------9-30

Boot System Error Diagnosis Tool -----------------------------------------------------9-30

Controller System Error Diagnosis Tool ----------------------------------------------9-31

Layout Drawing -------------------------------------------------------------------- 9-32

Basic Flowchart -------------------------------------------------------------------9-34

Basic Check Items -------------------------------------------------------------------------9-34

Prerequisite -------------------------------------------------------------------------9-35

Operation ---------------------------------------------------------------------------9-35

Boot System Error Diagnosis --------------------------------------------------9-36

Boot Method --------------------------------------------------------------------------------9-36

Diagnosis Time -----------------------------------------------------------------------------9-36

Error Diagnosis -----------------------------------------------------------------------------9-37

Controller System Error Diagnosis -------------------------------------------9-38

Boot Method --------------------------------------------------------------------------------9-38

Diagnosis Time ----------------------------------------------------------------------------9-38

Restrictions -------------------------------------------------------------------------9-41

<Boot System Error Diagnosis> -------------------------------------------------------9-41

<Controller System Error Diagnosis>-------------------------------------------------9-41

0-4

Consumable Parts and Cleaning

1

Parts

Consumable Parts and Cleaning Parts

■

Cleaning Parts

■

1

Consumable Parts and Cleaning PartsConsumable Parts and Cleaning Parts

Consumable Parts and Cleaning Parts

Consumable Parts and Cleaning Parts

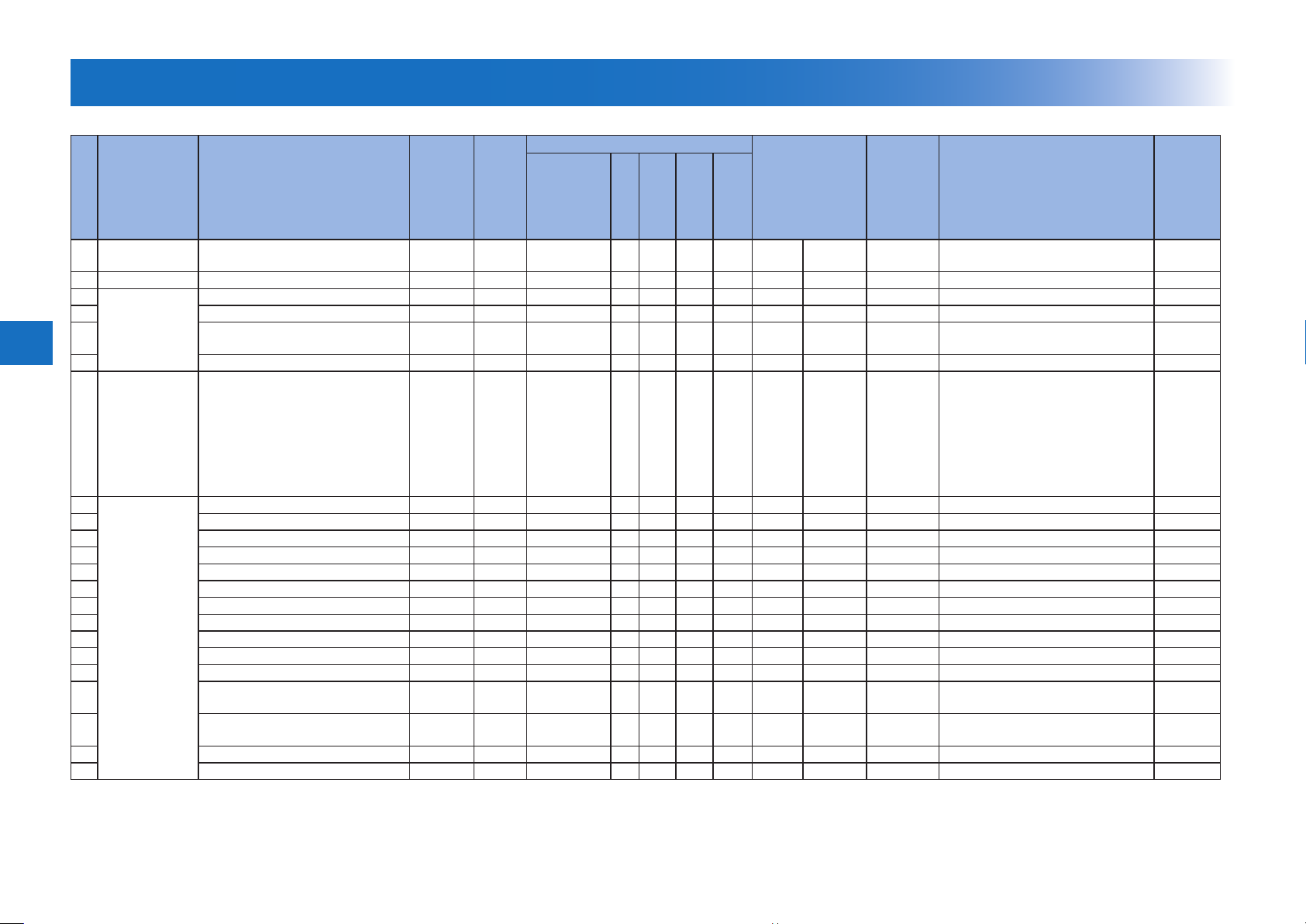

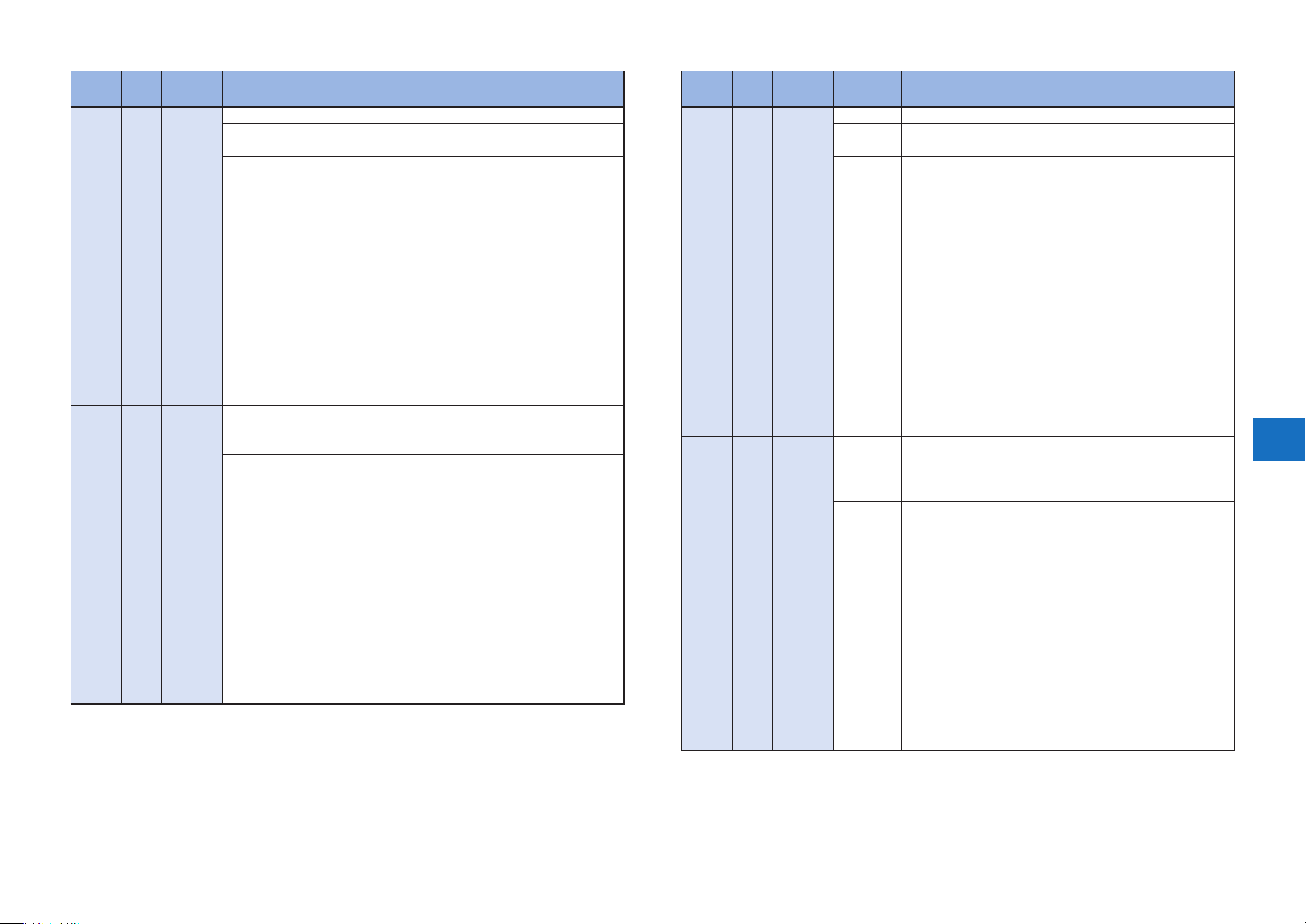

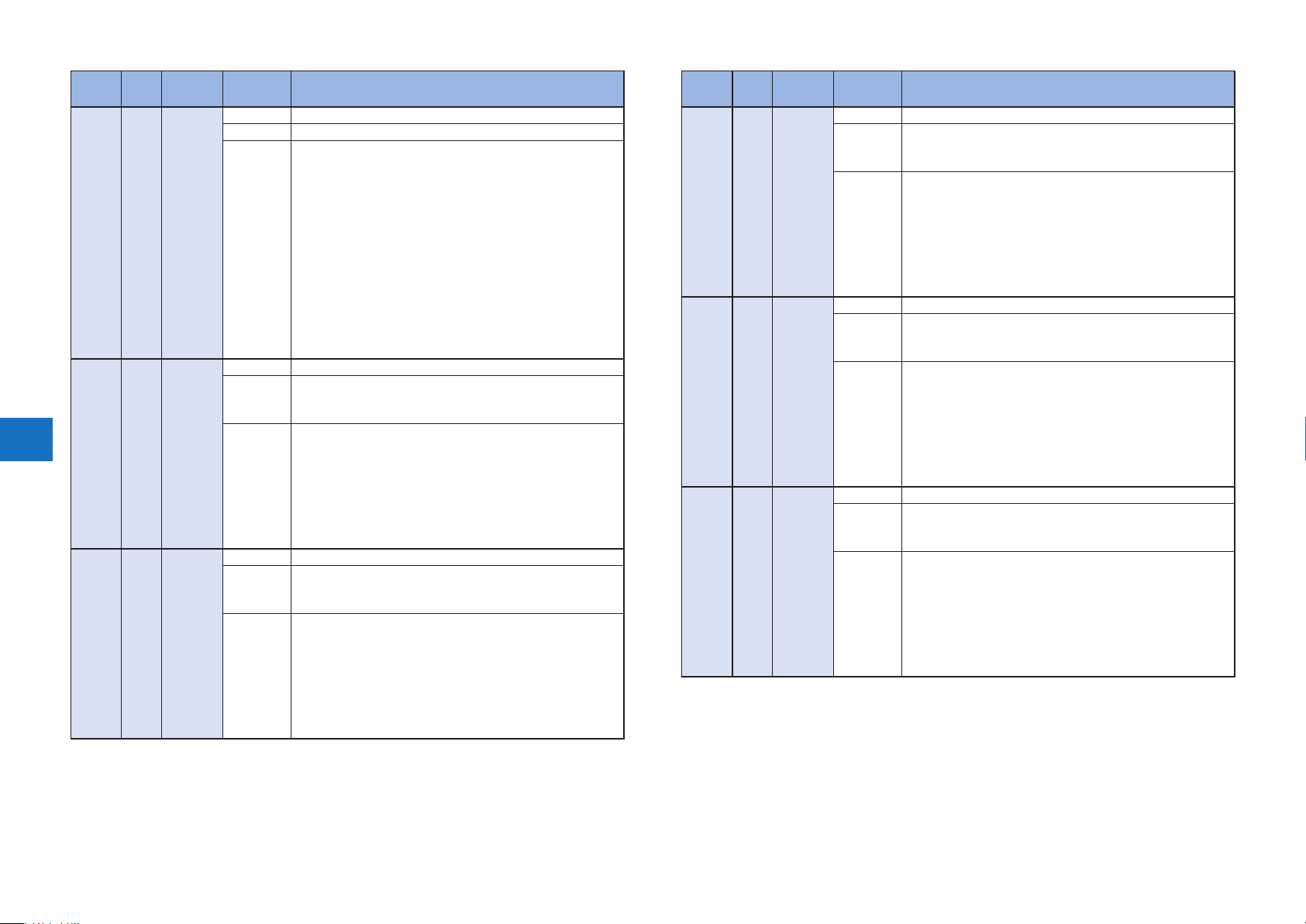

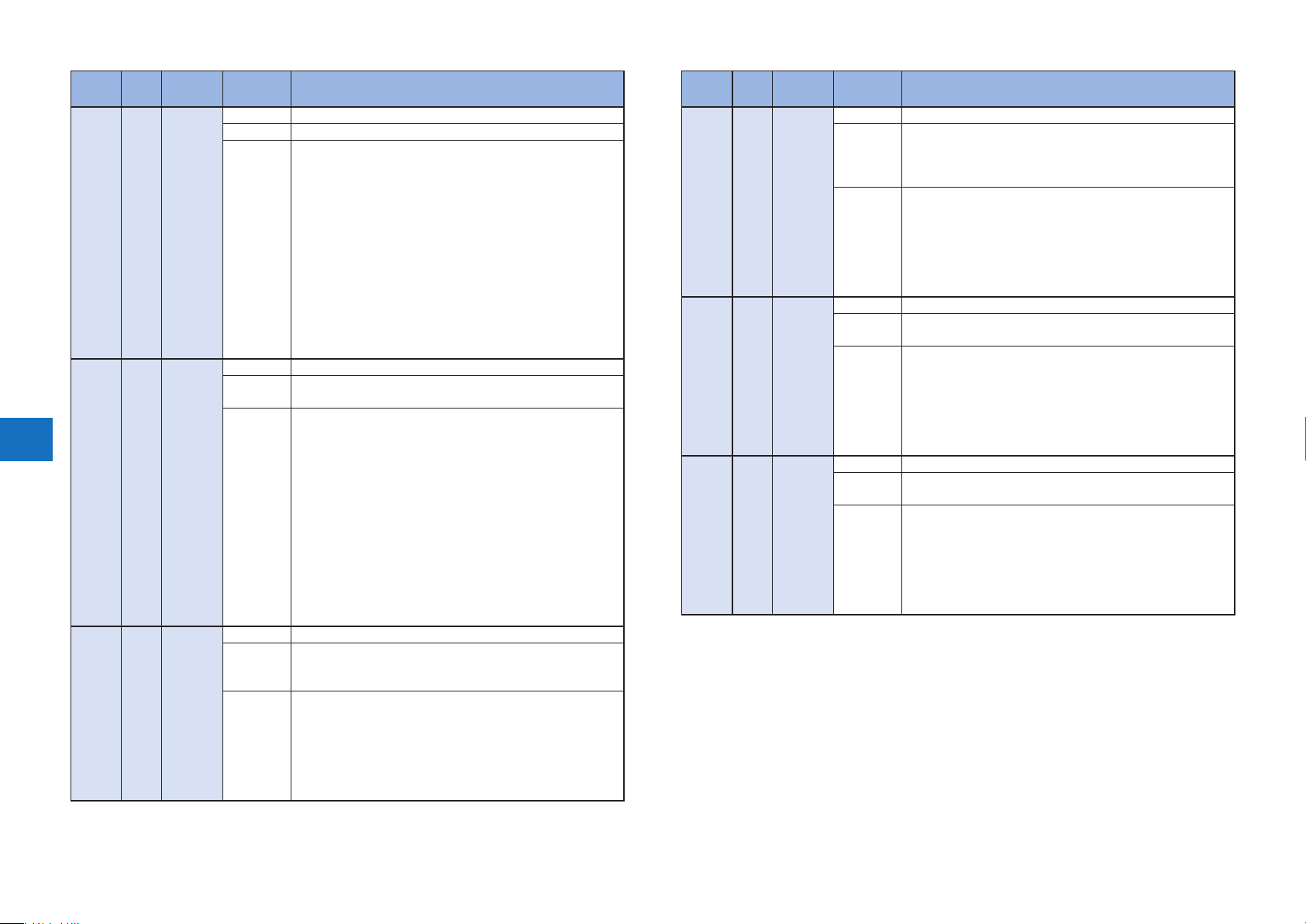

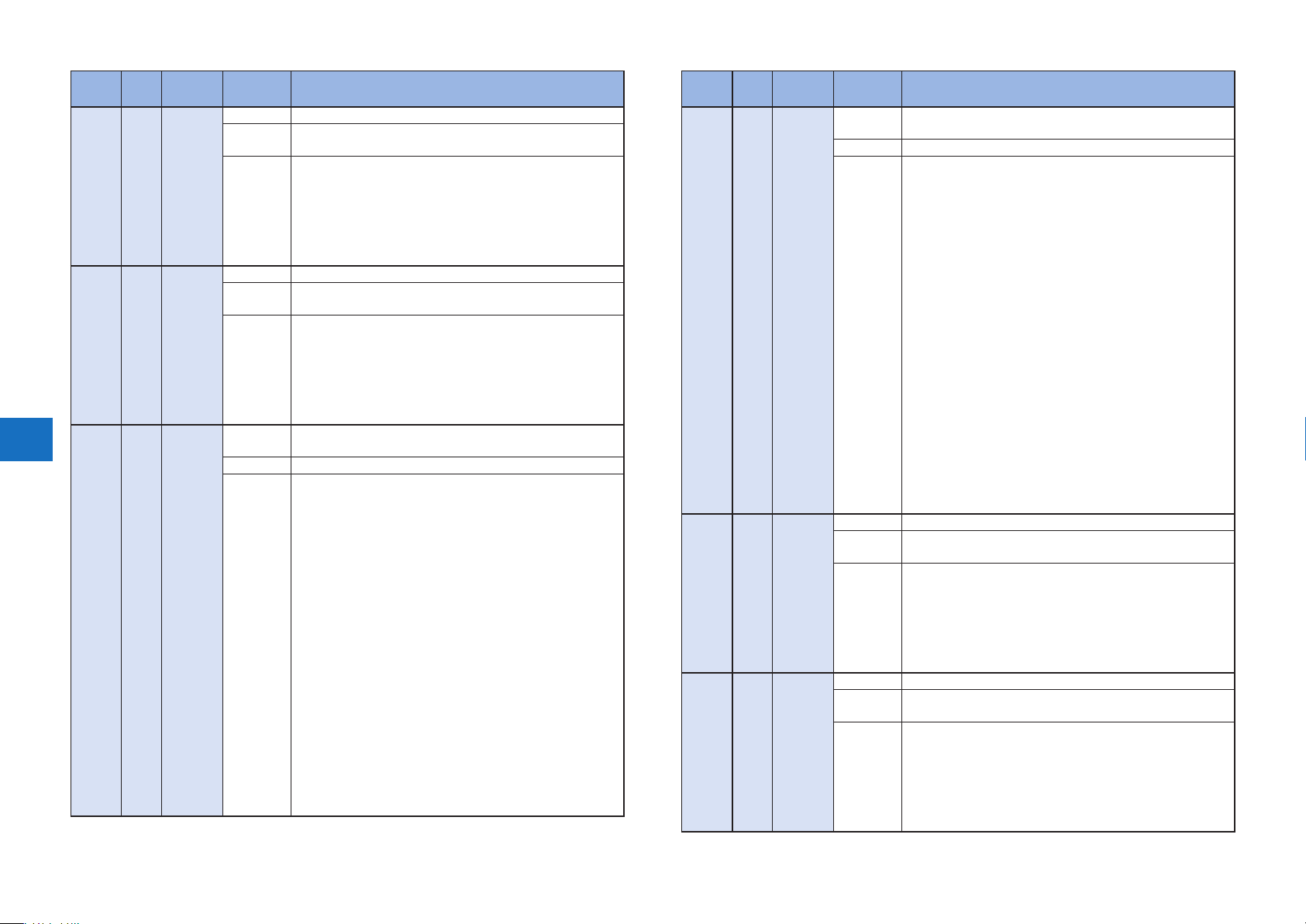

●: Replacement (Consumable parts) Δ: Cleaning ■: Inspection

Interval

No. Category Part Name Part No Number

1 Body Dust-blocking glass - 1 Δ - - -

2 Fixing Systemt Fixing Assembly FM4-6226 1 ● - FX-UNIT 3

4 Registration Patch Sensor FK2-7316 1 Δ - - -

Image Formation

1

5

6 Pre-Secondary Transfer Outer Guide - 1 Δ - - -

Consumable Parts and Cleaning Parts

7 -

8

9 Pre-Registration Guide - 1 Δ - - 10 Merging Roller 1 ■ - - 11 Duplex Feed Upper Roller - 1 ■ - - 12 Duplex Feed Lower Roller - 1 ■ - - 13 Cassette 1 Pickup Roller RM1-6175 1 ● DRBL-1 C1-PU-RL 14 Cassette 1 Separation Roller RM1-6176 1 ● DRBL-1 C1-SP-RL 15 Cassette 2 Feed Roller FC6-7083 1 ● DRBL-1 C2-FD-RL 16 Cassette 2 Separation Roller FC6-6661 1 ● - C2-SP-RL 17 Cassette 2 Vertical Path roller FC6-6661 1 ■ - - 18 Pickup Assembly Idler Gear FU3-0280 1 ● - - - China only

19

20

21 Second Delivery roller - 1 ■ - - 22 Third Delivery Roller - 1 ■ - - -

System

Pickup Feed

System

ITB Unit FM3-8240 1 ● DRBL-1 TR-BLT -

Secondary Transfer Outer Rolelr RM1-7928 1

Waste Toner Container FM3-8137 1

Registration Roller - 1 Δ - - -

Multi-purpose Tray Pickup Roller RM1-6177 1

Multi-purpose Tray Separation Roller RM1-6178 1

At installation 50K 150K 500K Other

■ ● DRBL-1

● - WST-TNR -

● DRBL-1

● DRBL-1

Counter

2TR-

ROLL

MP-PU-

RL

MP-SP-

PD

Adjustment

(Yes/No)

-

-

-

Remark Reference

Cleaning with Dust-blocking glass

Cleaning tool

Plain paper, Intermittent printing of 2

sheets per job, Bk color, image ratio at

5%

60k sheets

If service engineer removes the waste

toner from the Waste Toner Container,

the Waste Toner Container can be

reused.

T-1-1

1-2

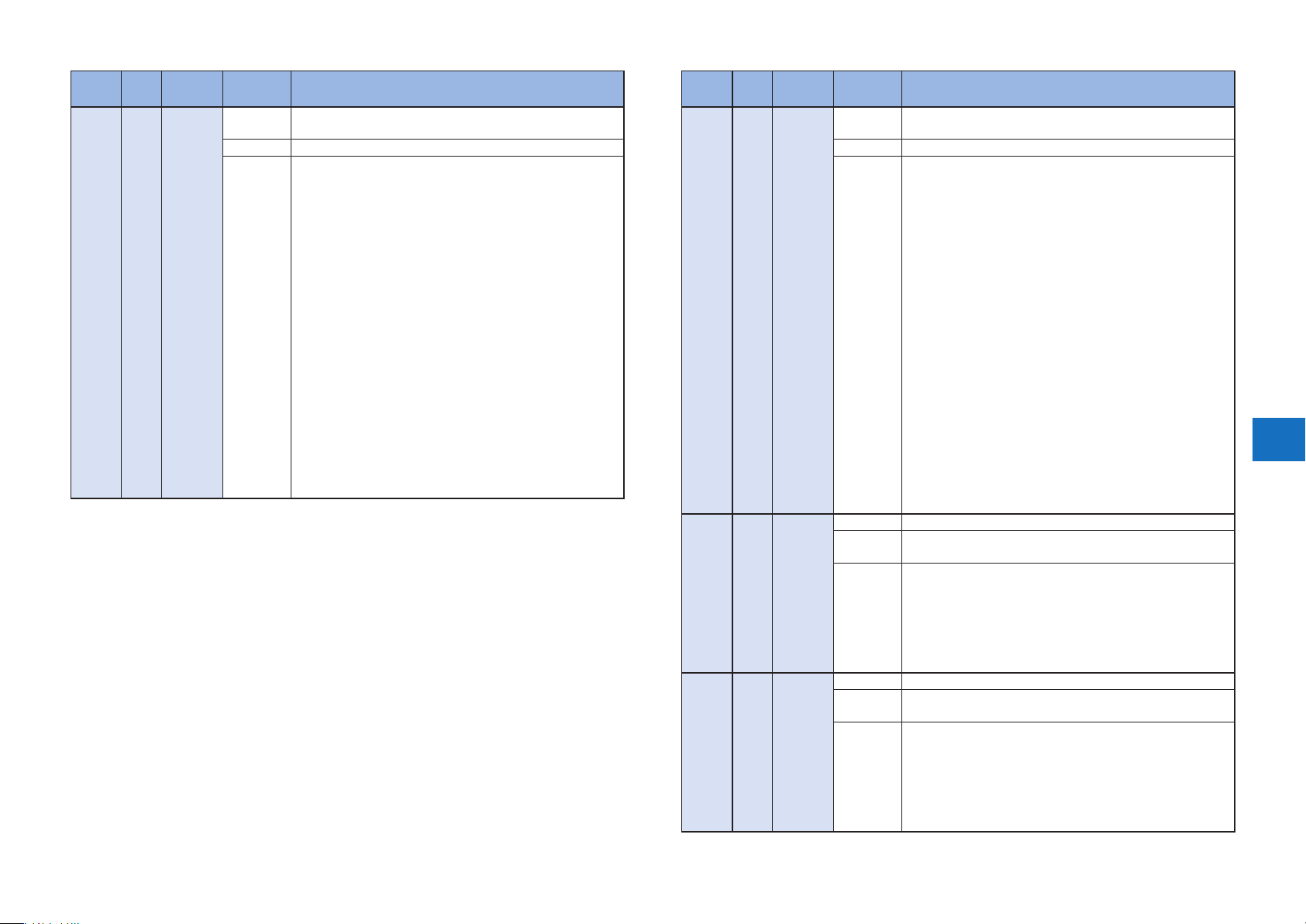

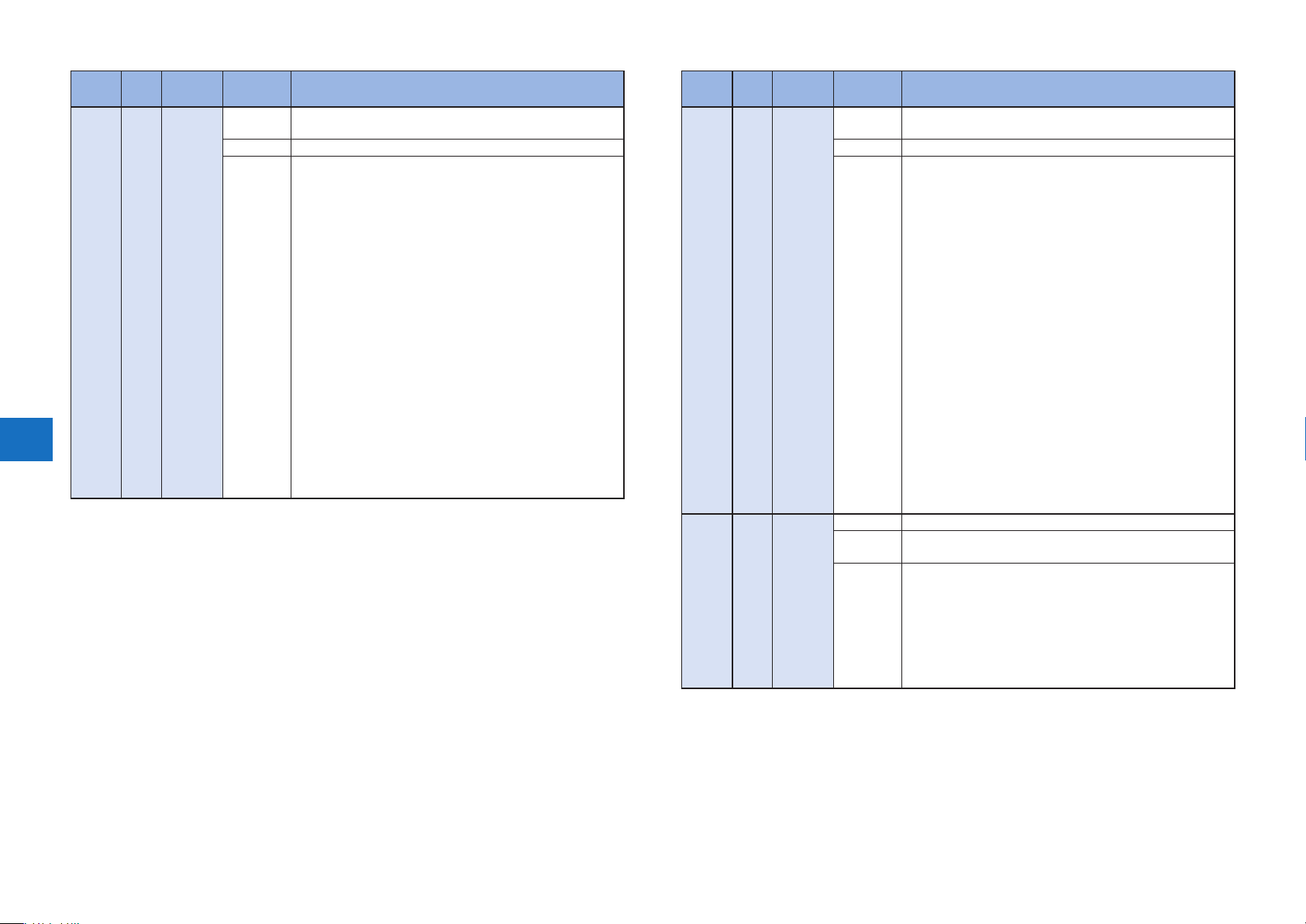

■Drum Unit

Model Drum Life

Bk YMC

iR ADVANCE C2020 USA 43k 36k

Europe 43k 36k

Other area 43k 36k

iR ADVANCE C2025 Other area 49k 41k

iR ADVANCE C2030 USA 60k 51k

Europe 60k 51k

Other area 55k 46k

T-1-2

1

Consumable Parts and Cleaning PartsConsumable Parts and Cleaning Parts

1-3

Cleaning Parts

Consumable Parts and Cleaning Parts

1

Consumable Parts and Cleaning Parts

[1] Pre-Secondary Transfer Outer Guide

[2] Pre-registration Guide

[3] Registration Roller

[4] Dust-blocking Glass

[5] Registration Patch Sensor

[1]

[5]

[2]

[3]

1-4

[4]

[4]

[4]

[4]

Adjustment

2

Main Controller

■

2

AdjustmentAdjustment

Main Controller

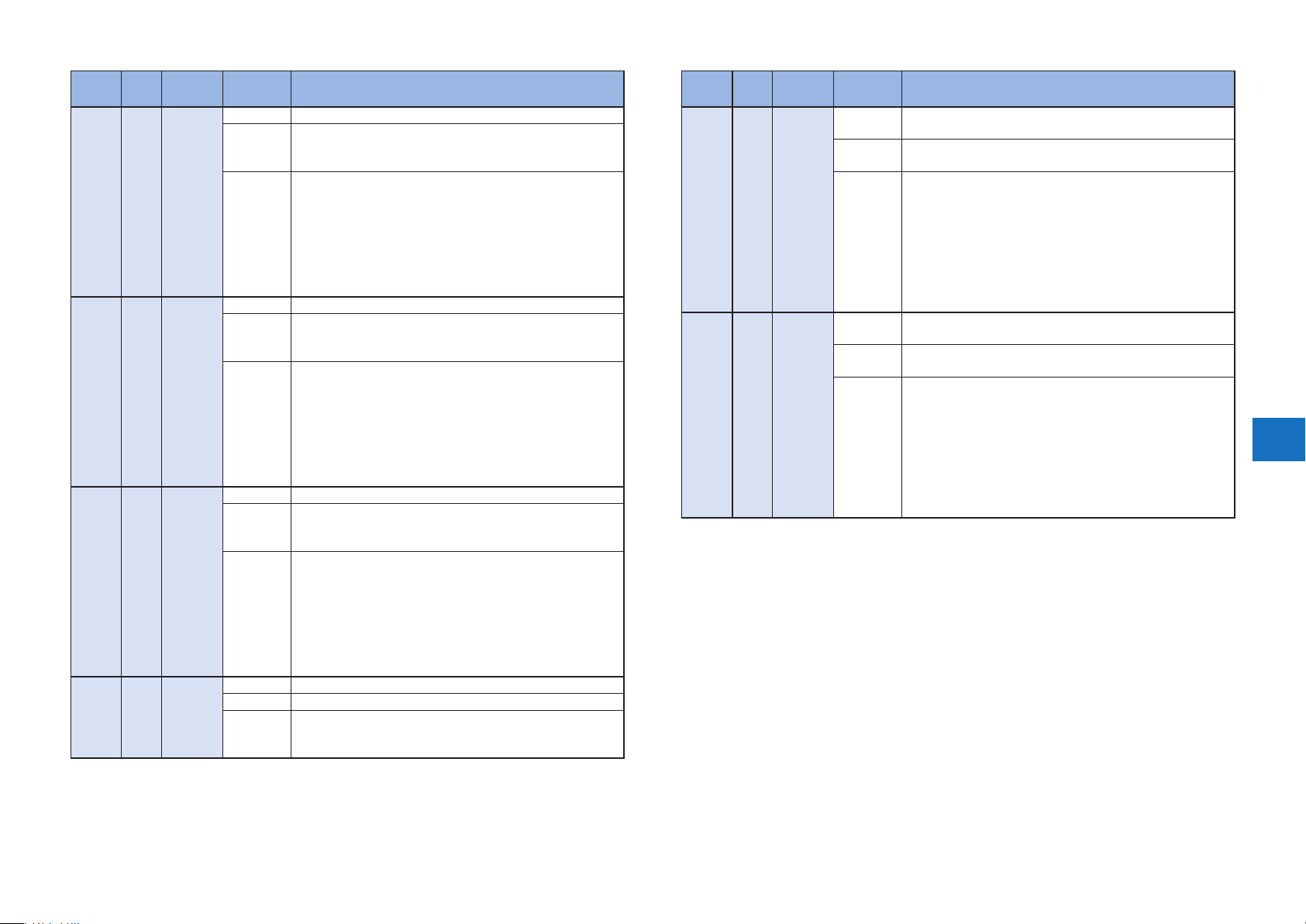

Main controller PCB 1

Adjustment

2

Adjustment

HDD

Before

Replacing

Aftter Replacing 1) HDD format

Points to Note

when Using the

HDD

1) Backup of the set/registered data

Use the Remote UI.

Management Settings > Data Management > Import/Export

Target data:

• Address List

• Forwarding Settings

• Settings/Registration

• Web Access Favorites

• Printer Settings

• Paper Information

2) Printing the set/registered data

Use the service mode.

(Lv.1) COPIER > FUNCTION > MISC-P > USER-PRT

List of the set/registered data which cannot be backed up is printed."

1-1) Start with the safe mode. (While pressing 2 and 8 keys simultaneously,

turn ON the main power switch.)

1-2) Use SST to format all partitions.

2) Downloading system software

2-1) Use SST to download the system software (System, LANG, RUI and

others).

3) Initializing the key, certicate and CA certicate

(Lv.2) COPIER > FUNCTION > CLEAR > CA-KEY

4) Turning OFF and ON the main power switch

5) Restoring the backup data

Use the Remote UI.

Management Settings > Data Management > Import/Export

6) Resetting/registering the data

While referring to the list of set/registered data which was printed before

replacement, reset/register the data.

7) When the user generates and adds the encryption key, certicate and/or CA

certicate, request the user to generate them again.

When using the HDD of the other machine (different serial number), be sure to

format the HDD after the installation. If the HDD is not formatted, the operation

cannot be guaranteed.

T-2-1

Operation at

Replacement

Prohibited

Operation

Transferring the parts from old PCB to new PCB

• DDR2-SDRAM (2 pc.)

• Flash PCB

• TPM PCB

Resetting/registering the data is not necessary after Main Controller PCB 1 is

replaced.

Do not transfer the following parts to another model (which has a different serial

number).

If you fail to do so, the Main Body does not activate normally and this might cause

to fail the restoration.

• Main Controller PCB 1 (with Flash PCB installed)

• Flash PCB

T-2-2

2-2

Main controller PCB 2

DC controller PCB

Before

Replacing

Replacement Transferring the parts from old PCB to new PCB

Aftter Replacing 1) After installing the parts, turn ON the main power switch.

Prohibited

Operation

1) Backup of the set/registered data

Use the Remote UI.

Management Settings > Data Management > Import/Export

Target data:

• Forwarding Settings

• Settings/Registration

• Web Access Favorites

• Printer Settings

• Paper Information

2) Printing the set/registered data

Use the service mode.

(Lv.1) COPIER > FUNCTION > MISC-P > USER-PRT

List of the set/registered data which cannot be backed up is printed

• DDR2-SDRAM (1 pc.)

• Memory PCB

2) Restoring the backup data

Use the Remote UI.

Management Settings > Data Management > Import/Export

3) Resetting/registering the data

While referring to the list of set/registered data which was printed out before

replacement, reset/register the data.

4) When the user generates and adds the encryption key, certicate and/or CA

certicate, request the user to generate them again.

Do not transfer the following parts to another model (which has a different serial

number).

If you fail to do so, the Main Body does not activate normally and this might cause

to fail the restoration.

• Main Controller PCB 2 (with Memory PCB installed)

• Memory PCB

T-2-3

Before

Replacing

Aftter Replacing Turn ON the main power supply and restore the DC Controller PCB SRAM.

Execute the following Service Mode to backup the DC Controller PCB SRAM.

Execute COPIER > FUNCTION > SYSTEM > DSRAMBUP (LEVEL2).

After “ACTIVE” is displayed for approx. 2 minutes, “OK!” is displayed.

After the above execution is completed, turn OFF the main power supply.

Execute COPIER > FUNCTION > SYSTEM > DSRAMRES (LEVEL2).

After the above execution, “ACTIVE” is displayed for approx. 2 minutes, then “OK!”

is displayed. Restoration is completed now.

T-2-4

2

AdjustmentAdjustment

2-3

Error Code

3

Overview

■

Error Code

■

Jam Code

■

Alarm Code

■

3

Error CodeError Code

Overview

Outline

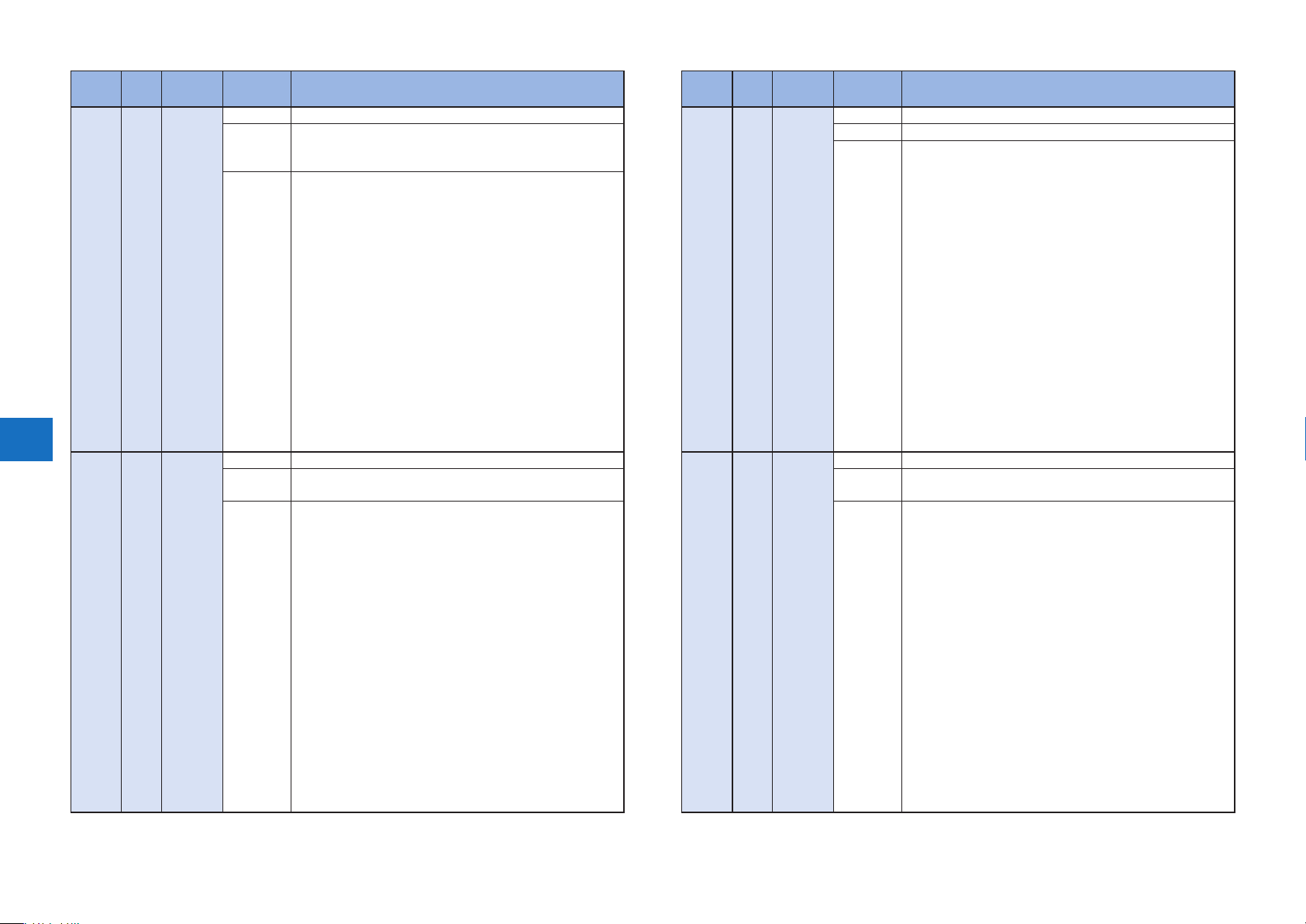

■Outline

This chapter describes various codes which are displayed when a failure occurs on the

product. These are classied into 3 codes as follows.

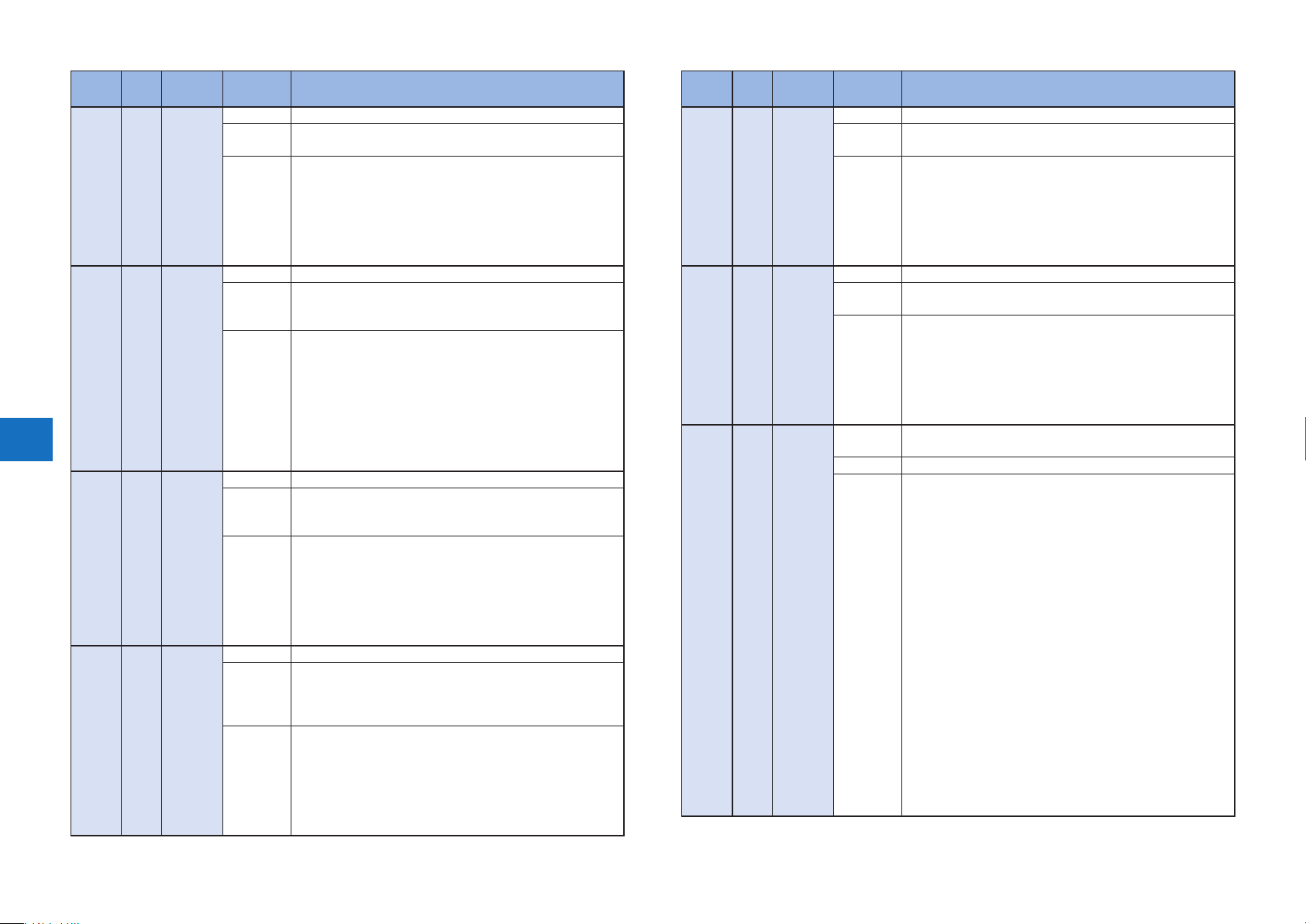

Code type Explanation

Error code This code is displayed when an error occurs on the machine.

Jam code This code is displayed when a jam occurs inside the machine.

Alarm code This code is displayed when a function of the machine is malfunctioned.

Error Code

• Error code notation

An error code is shown in 7-digit [E000XXX] on the display on the operation panel. However,

[000] in 2 to 4 digit is not used. Thus, an error code is described as [EXXX] using 5 to 7 digit

in the service manual. (e.g.: E012 = E000012)

T-3-1

■Location code

When jam occurs, pickup location is indicated with the following pickup position code.

Pickup position Pickup position code

At Finisher jam/At error avoidance jam/At ADF jam without pickup

operation (at SEND, Inbox, etc.)

Cassette 2 02

Cassette 3 (Cassette Feeding Unit-AF1) 03

Cassette 4 (Cassette Feeding Unit-AF1) 04

Multi-purpose Tray 05

00

T-3-3

3

Error Code

■Location code

Error code, jam code, and alarm code include the location information.

Location information is displayed as 2-digit numbers as follows.

Device JAM ERR ALARM

imageRUNNER ADVANCE C2030/C2025/C2020 00 Main Controller = 00

Printer engine = 05

Cassette Feeding Unit-AF1 00 05 -

Color Image Reader Unit - D1(Reader+DADF) 01 04 02

Inner Finisher-C1 02 05 -

3-2

Others of

listed below

T-3-2

■Points to Note When Clearing MN-CON

• Execution of clearing MN-COM deletes all data in Address Book, Forwarding Settings,

Settings/Registration (Preferences), Adjustment/Maintenance, Function Settings, Set

Destination, Management Settings, TPM Settings, etc. Before execution of this operation,

ask user to back up the data and get approval for this operation.

• When clearing MN-CON while any login application other than Default Authentication is,

error such as not displayed login screen occurred. In this case, access SMS once and

switch login application to Default Authentication to recover to the normal status.

■Points to Note When Clearing HDD

As a remedy for error codes (E602-XXXX, E611-0000), HDD partition is selected and the

target partition may be cleared.

When clearing partition, be sure to check which data will be deleted by referring Detail of

HDD partition and explain to the user before starting work.

3

Error CodeError Code

3-3

Error Code

3

Error Code

Error Code

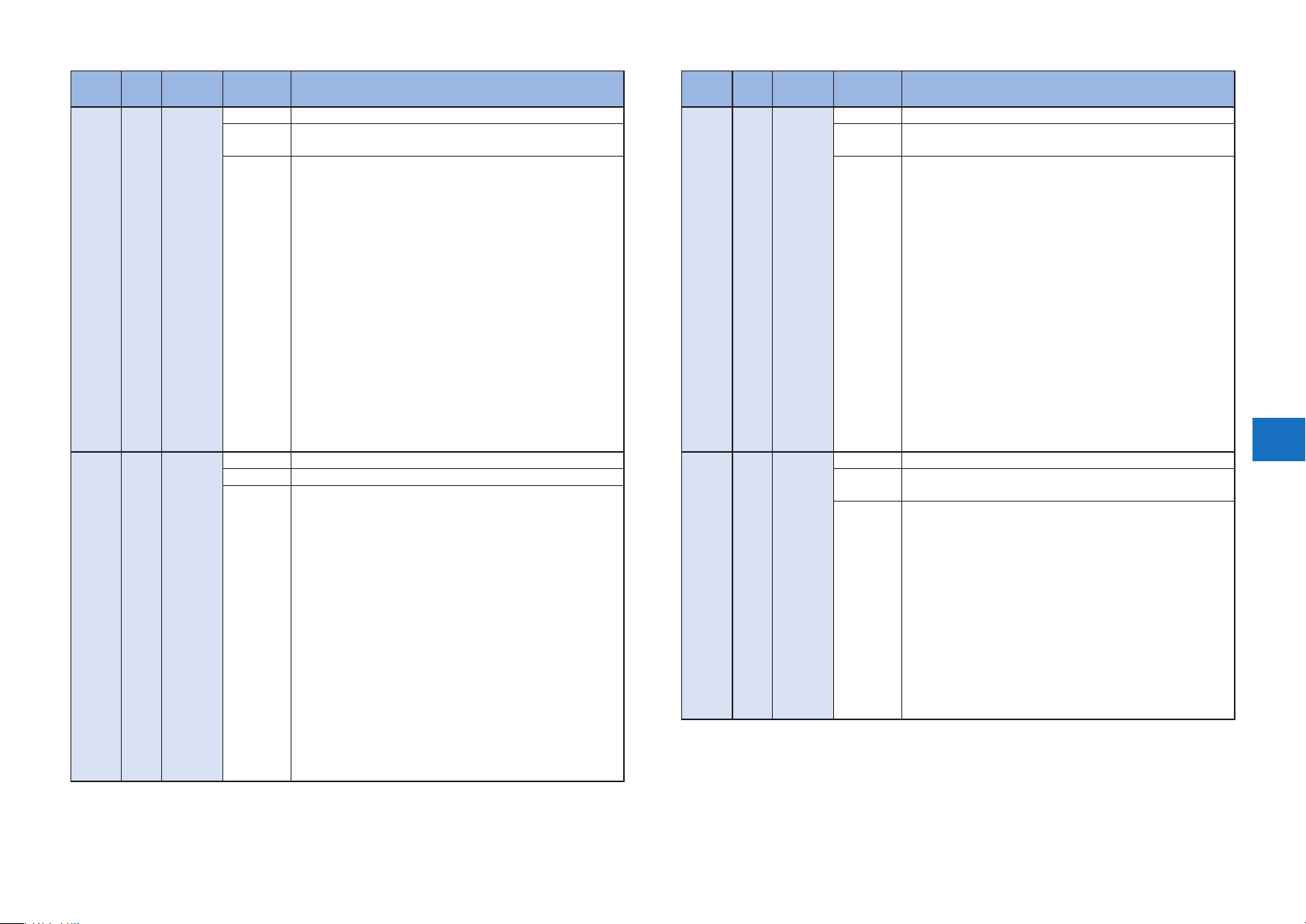

Error Code Details

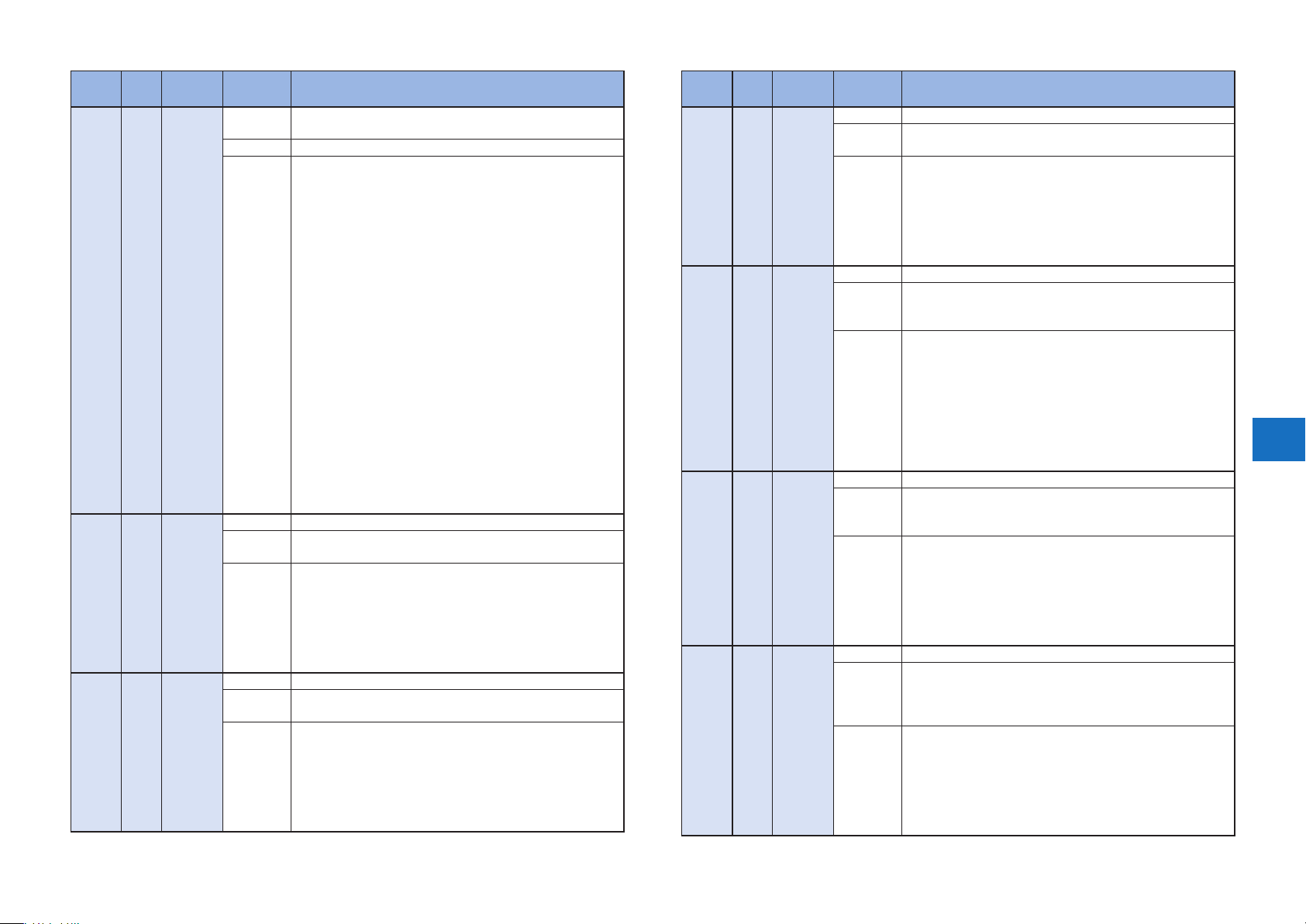

E Code Detail

E001 0001 05 Title Main Thermistor high temperature detection

E001 0002 05 Title Center Thermistor high temperature detection

Location Item Description

Code

Detection Main Thermistor 2 detected a temperature of 230 deg C or

higher for 0.1 sec or longer.

Remedy Fixing Assembly error, Fixing temperature detection error

1. Check failure between the DC Controller PCB (UN09/

J12) and the Fixing Assembly (UN37/J123,UN13/J13)

(trapped cable, open circuit, connector disconnection).

-> Replace the part in the case of trapped cable/open circuit

2. Disconnect the connector of DC Controller PCB (UN09/

J12) and start the host machine to check the reading value

of the following: service mode > COPIER > DISPLAY >

ANALOG > FIX-C

=> When the value is 40 deg C or higher

3-1. Replace the DC Controller PCB (UN09)

=> When the value is lower than 40 deg C

3-2. Replace the Fixing Assembly

Detection Main Thermistor 1 detected a temperature of 283 deg C or

higher for 0.1 sec or longer.

Remedy Fixing Assembly error, Fixing temperature detection error

1. Check failure between the DC Controller PCB (UN09/

J12) and the Fixing Assembly (UN37/ J123, UN13/ J13)

(trapped cable, open circuit, connector disconnection).

-> Replace the part in the case of trapped cable/open circuit

2. Disconnect the connector of DC Controller PCB (UN09/

J12) and start the host machine to check the reading value

of the following: service mode > COPIER > DISPLAY >

ANALOG > FIX-E

=> When the value is 40 deg C or higher

3-1. Replace the DC Controller PCB (UN09)

=> When the value is lower than 40 deg C

3-2. Replace the Fixing Assembly

E Code Detail

Location Item Description

Code

E001 0003 05 Title Edge Thermistor high temperature detection

Detection Sub Thermistor 1 detected a temperature of 283 deg C or

higher for 0.1 sec or longer.

Remedy Fixing Assembly error, Fixing temperature detection error

1. Check failure between the DC Controller PCB (UN09/

J12) and the Fixing Assembly (UN37/ J123, UN13/ J13)

(trapped cable, open circuit, connector disconnection).

-> Replace the part in the case of trapped cable/open circuit

2. Disconnect the connector of DC Controller PCB (UN09/

J12) and start the host machine to check the reading value

of the following: service mode > COPIER > DISPLAY >

ANALOG > FIX-E2

=> When the value is 40 deg C or higher

3-1. Replace the DC Controller PCB (UN09)

=> When the value is lower than 40 deg C

3-2. Replace the Fixing Assembly

E001 0004 05 Title Edge Thermistor high temperature detection

Detection Sub Thermistor 2 detected a temperature of 283 deg C or

higher for 0.1 sec or longer.

Remedy Fixing Assembly error, Fixing temperature detection error

1. Check failure between the DC Controller PCB (UN09/

J12) and the Fixing Assembly (UN37/ J123, UN13/ J13)

(trapped cable, open circuit, connector disconnection).

-> Replace the part in the case of trapped cable/open circuit

2. Disconnect the connector of DC Controller PCB (UN09/

J12) and start the host machine to check the reading value

of the following: service mode > COPIER > DISPLAY >

ANALOG > FIX-E3

=> When the value is 40 deg C or higher

3-1. Replace the DC Controller PCB (UN09)

=> When the value is lower than 40 deg C

3-2. Replace the Fixing Assembly

3-4

E Code Detail

Location Item Description

Code

E001 0005 05 Title Center Thermistor high temperature detection

Detection Main Thermistor 1 hardware signal is continued for 1 sec or

longer.

Remedy Fixing Assembly error, Fixing temperature detection error

1. Check failure between the DC Controller PCB (UN09/

J12) and the Fixing Assembly (UN37/ J123, UN13/ J13)

(trapped cable, open circuit, connector disconnection).

-> Replace the part in the case of trapped cable/open circuit

2. Disconnect the connector of DC Controller PCB (UN09/

J12) and start the host machine to check the reading value

of the following: service mode > COPIER > DISPLAY >

ANALOG > FIX-E

=> When the value is 40 deg C or higher

3-1. Replace the DC Controller PCB (UN09)

=> When the value is lower than 40 deg C

3-2. Replace the Fixing Assembly

E001 0006 05 Title Edge Thermistor high temperature detection

Detection Sub Thermistor 1 hardware error detection signal is

continued for 1 sec or longer.

Remedy Fixing Assembly error, Fixing temperature detection error

1. Check failure between the DC Controller PCB (UN09/

J12) and the Fixing Assembly (UN37/ J123, UN13/ J13)

(trapped cable, open circuit, connector disconnection).

-> Replace the part in the case of trapped cable/open circuit

2. Disconnect the connector of DC Controller PCB (UN09/

J12) and start the host machine to check the reading value

of the following: service mode > COPIER > DISPLAY >

ANALOG > FIX-E2

=> When the value is 40 deg C or higher

3-1. Replace the DC Controller PCB (UN09)

=> When the value is lower than 40 deg C

3-2. Replace the Fixing Assembly

E Code Detail

Location Item Description

Code

E001 0007 05 Title Edge Thermistor high temperature detection

Detection Sub Thermistor 2 hardware error detection signal is

continued for 1 sec or longer.

Remedy Fixing Assembly error, Fixing temperature detection error

1. Check failure between the DC Controller PCB (UN09/

J12) and the Fixing Assembly (UN37/ J123, UN13/ J13)

(trapped cable, open circuit, connector disconnection).

-> Replace the part in the case of trapped cable/open circuit

2. Disconnect the connector of DC Controller PCB (UN09/

J12) and start the host machine to check the reading value

of the following: service mode > COPIER > DISPLAY >

ANALOG > FIX-C

Check the reading value of the following: service mode >

COPIER > DISPLAY > ANALOG > FIX-E3

=> When the value is 40 deg C or higher

3-1. Replace the DC Controller PCB (UN09)

=> When the value is lower than 40 deg C

3-2. Replace the Fixing Assembly

E001 0008 05 Title Displacement detection

Detection The temperature difference between the Sub Thermistor 1

(TH3) and the Sub Thermistor 2 (TH4) remained 45 deg C

or more for 1 second or more.

Remedy Fixing Assembly error, Fixing temperature detection error

1. Check failure between the DC Controller PCB (UN09/

J12) and the Fixing Assembly (UN37/ J123, UN13/ J13)

(trapped cable, open circuit, connector disconnection).

-> Replace the part in the case of trapped cable/open circuit

2. Disconnect the connector of DC Controller PCB (UN09/

J12) and start the host machine to check the reading value

of the following: service mode > COPIER > DISPLAY >

ANALOG > FIX-E2,FIX-E3

=> When the value of either one is 40 deg C or higher

3-1. Replace the DC Controller PCB (UN09)

=> When the both values are lower than 40 deg C

3-2. Replace the Fixing Assembly

3

Error CodeError Code

3-5

Error Code

3

Error Code

E Code Detail

Location Item Description

Code

E002 0006 05 Title Detection of abnormal temperature increase

Detection Fixing Assembly error, Fixing temperature detection error

Remedy 1. Check the location for voltage of the Fixing Assembly

-> Replace with a correct Fixing Assembly for the location in

the case of mismatching.

2. Check the location for voltage of the AC Driver PCB

(UN14)

-> Replace with a correct AC Driver PCB (UN14) for the

location in the case of mismatching.

3. Check failure between the AC Driver PCB (UN14/J103)

and the Fixing Assembly (UN37/J123, UN13/J13). (trapped

cable, open circuit, connector disconnection)

-> Replace the part in the case of trapped cable/open circuit

4. Replace the AC Driver PCB (UN14)

5. Replace the Fixing Assembly

6. Replace the DC Controller PCB (UN09)

E003 0001 05 Title Thermistor open circuit detection

Detection In the period from initial rotation to printing, Main Thermistor

1 detected a temperature of 22 deg C or lower for more

than 5 seconds.

Remedy Fixing Assembly error, Fixing temperature detection error

1. Check failure between the DC Controller PCB (UN09/

J12) and the Fixing Assembly (UN37/ J123, UN13/ J13)

(trapped cable, open circuit, connector disconnection).

-> Replace the part in the case of trapped cable/open circuit

2. Replace the Fixing Assembly

3. Replace the DC Controller PCB (UN09)

E003 0002 05 Title Thermistor open circuit detection

Detection In the period from initial rotation to printing, Main Thermistor

2 detected a temperature of 40 deg C or lower for more

than 3 seconds.

Remedy Fixing Assembly error, Fixing temperature detection error

1. Check failure between the DC Controller PCB (UN09/

J12) and the Fixing Assembly (UN37/ J123, UN13/ J13)

(trapped cable, open circuit, connector disconnection).

-> Replace the part in the case of trapped cable/open circuit

2. Replace the Fixing Assembly

3. Replace the DC Controller PCB (UN09)

E Code Detail

Location Item Description

Code

E003 0003 05 Title Thermistor open circuit detection

Detection In the period from initial rotation to printing, Sub Thermistor

1 detected a temperature of 40 deg C or lower for more

than 3 seconds.

Remedy Fixing Assembly error, Fixing temperature detection error

1. Check failure between the DC Controller PCB (UN09/

J12) and the Fixing Assembly (UN37/ J123, UN13/ J13)

(trapped cable, open circuit, connector disconnection).

-> Replace the part in the case of trapped cable/open circuit

2. Replace the Fixing Assembly

3. Replace the DC Controller PCB (UN09)

E003 0004 05 Title Thermistor open circuit detection

Detection In the period from initial rotation to printing, Sub Thermistor

2 detected a temperature of 40 deg C or lower for more

than 3 seconds.

Remedy Fixing Assembly error, Fixing temperature detection error

1. Check failure between the DC Controller PCB (UN09/

J12) and the Fixing Assembly (UN37/ J123, UN13/ J13)

(trapped cable, open circuit, connector disconnection).

-> Replace the part in the case of trapped cable/open circuit

2. Replace the Fixing Assembly

3. Replace the DC Controller PCB (UN09)

E003 0005 05 Title Main Thermistor 2 low temperature detection at printing

Detection In the period from printing to last rotation, Main Thermistor 1

detected a temperature of 70 deg C or lower for more than

5 seconds.

Remedy Fixing Assembly error, Fixing temperature detection error

1. Check failure between the DC Controller PCB (UN09/

J12) and the Fixing Assembly (UN37/ J123, UN13/ J13)

(trapped cable, open circuit, connector disconnection).

-> Replace the part in the case of trapped cable/open circuit

2. Replace the Fixing Assembly

3. Replace the DC Controller PCB (UN09)

3-6

E Code Detail

Location Item Description

Code

E003 0006 05 Title Center Thermistor low temperature detection at printing

Detection In the period from printing to last rotation, Main Thermistor 2

detected a temperature of 80 deg C or lower for more than

1 second.

Remedy Fixing Assembly error, Fixing temperature detection error

1. Check failure between the DC Controller PCB (UN09/

J12) and the Fixing Assembly (UN37/ J123, UN13/ J13)

(trapped cable, open circuit, connector disconnection).

-> Replace the part in the case of trapped cable/open circuit

2. Replace the Fixing Assembly

3. Replace the DC Controller PCB (UN09)

E003 0007 05 Title Edge Thermistor low temperature detection at printing

Detection In the period from printing to last rotation, Sub Thermistor 1

detected a temperature of 80 deg C or lower for more than

1 second.

Remedy Fixing Assembly error, Fixing temperature detection error

1. Check failure between the DC Controller PCB (UN09/

J12) and the Fixing Assembly (UN37/ J123, UN13/ J13)

(trapped cable, open circuit, connector disconnection).

-> Replace the part in the case of trapped cable/open circuit

2. Replace the Fixing Assembly

3. Replace the DC Controller PCB (UN09)

E003 0008 05 Title Edge Thermistor low temperature detection at printing

Detection In the period from printing to last rotation, Sub Thermistor 2

detected a temperature of 80 deg C or lower for more than

1 second.

Remedy Fixing Assembly error, Fixing temperature detection error

1. Check failure between the DC Controller PCB (UN09/

J12) and the Fixing Assembly (UN37/ J123, UN13/ J13)

(trapped cable, open circuit, connector disconnection).

-> Replace the part in the case of trapped cable/open circuit

2. Replace the Fixing Assembly

3. Replace the DC Controller PCB (UN09)

E004 0001 05 Title Fixing Relay PCB welding detection error

Detection Zero cross interruption although relay is not ON.

Remedy Electrical trouble with abnormal xing safety circuit relay

Replace the AC Driver PCB (UN14)

E Code Detail

Location Item Description

Code

E004 0005 05 Title Failure in electrical current detection circuit (abnormal small

current)

Detection Failure in electrical current detection circuit (Less than the

specied range of current value)

Remedy Electrical trouble with abnormal xing current detection

circuit

1. Check failure between the AC Driver PCB (UN14/ J122)

and the DC Controller PCB (UN09/ J10). (trapped cable,

open circuit, connector disconnection) -> Replace the part

in the case of trapped cable/open circuit

2. Replace the AC Driver PCB (UN14)

3. Replace the DC Controller PCB (UN09)

E004 0006 05 Title Failure in electrical current detection circuit (abnormal large

current)

Detection Failure in electrical current detection circuit (More than the

specied range of current value)

Remedy Electrical trouble with abnormal xing current detection

circuit

1. Check failure between the AC Driver PCB (UN14/ J122)

and the DC Controller PCB (UN09/ J10). (trapped cable,

open circuit, connector disconnection) -> Replace the part

in the case of trapped cable/open circuit

2. Replace the AC Driver PCB (UN14)

3. Replace the DC Controller PCB (UN09)

3

Error CodeError Code

3-7

Error Code

3

Error Code

E Code Detail

Location Item Description

Code

E009 0000 05 Title Fixing Film Unit engagement / disengagement error

Detection There is no change in the result of detection by the Fixing

Pressure Release Sensor even after ve seconds elapsed

after counterclockwise rotation of the Fixing Motor started.

Remedy Possible cause is overload or rotation failure of the motor

due to an electrical trouble

1. Check if the Fixing Assembly is installed.

2. Remove and reinstall the Fixing Assembly

3. Check the gear

4. Replace the Fixing Assembly

5. Check the harness/connector between the DC Controller

PCB (UN09/ J210) and the Fixing Motor (M17).

6. Check the harness/connector between the DC Controller

PCB (UN09/ J12) and the Fixing Pressure Release Sensor

(PS24)

6. Check conduction of FU1153 in the AC Driver PCB

(UN14)

=> Replace the AC Driver PCB (UN14) in the case of

disconnection.

7. Replace the Fixing Motor (M17)

8. Replace the DC Controller PCB (UN09)

E010 0001 05 Title ITB Motor startup error

Detection Within a specied period of time from the startup, the speed

fails to be OK.

Remedy Possible cause is overload or rotation failure of the motor

due to an electrical trouble

1. Check the Main Drive Unit (turn the unit by hand to see if

it rotates)

Replace the Main Drive Unit when the unit failed to rotate

When the unit rotates

2. Check failure of the harness between the ITB Motor (M02/

J6027) and the DC Controller PCB (UN09/ J210W) (trapped

cable, open circuit, connector disconnection)

3. Check conduction of the fuse (FU4) in the DC Controller

PCB (UN09)

When the fuse is not blown out

4-1. Replace the ITB Motor (M02)

5-1. Replace the DC Controller PCB (UN09)

6-1. Replace the Main Drive Unit

When the fuse is blown out

4-2. Replace the DC Controller PCB (UN09)

E Code Detail

Location Item Description

Code

E010 0002 05 Title ITB Motor speed error

Detection ITB Motor speed error

Remedy Possible cause is overload or rotation failure of the motor

due to an electrical trouble

1. Check the Main Drive Unit (turn the unit by hand to see if

it rotates)

Replace the Main Drive Unit when the unit failed to rotate

When the unit rotates

2. Check failure of the harness between the ITB Motor (M02/

J6027) and the DC Controller PCB (UN09/ J210W) (trapped

cable, open circuit, connector disconnection)

3. Check conduction of the fuse (FU4) in the DC Controller

PCB (UN09)

When the fuse is not blown out

4-1. Replace the ITB Motor (M02)

5-1. Replace the DC Controller PCB (UN09)

6-1. Replace the Main Drive Unit

When the fuse is blown out

4-2. Replace the DC Controller PCB (UN09)

E010 0003 05 Title ITB Motor lock detection

Detection Within a specied period of time from the startup, signal is

not received.

Remedy Possible cause is overload or rotation failure of the motor

due to an electrical trouble

1. Check the Main Drive Unit (turn the unit by hand to see if

it rotates)

Replace the Main Drive Unit when the unit failed to rotate

When the unit rotates

2. Check failure of the harness between the ITB Motor (M02/

J6027) and the DC Controller PCB (UN09/ J210W) (trapped

cable, open circuit, connector disconnection)

3. Check conduction of the fuse (FU4) in the DC Controller

PCB (UN09)

When the fuse is not blown out

4-1. Replace the ITB Motor (M02)

5-1. Replace the DC Controller PCB (UN09)

6-1. Replace the Main Drive Unit

When the fuse is blown out

4-2. Replace the DC Controller PCB (UN09)

3-8

E Code Detail

Location Item Description

Code

E012 0001 05 Title CL Drum Motor speed error

Detection Within a specied period of time from the startup, the speed

fails to be OK.

Remedy Possible cause is overload or rotation failure of the motor

due to an electrical trouble

1. Check the Main Drive Unit (turn the unit by hand to see if

it rotates)

Replace the Main Drive Unit when the unit failed to rotate

When the unit rotates

2. Check failure of the harness between the Motor (M04/

J6025) and the DC Controller PCB (UN09/ J210W)

(trapped cable, open circuit, connector disconnection)

3. Check conduction of the fuse (FU7) in the DC Controller

PCB (UN09)

When the fuse is not blown out

4-1. Replace the Drum Motor (M04)

5-1. Replace the DC Controller PCB (UN09)

When the fuse is blown out

4-2. Replace the DC Controller PCB (UN09)

E012 0002 05 Title CL Drum Motor speed error

Detection CL Drum Motor speed error

Remedy Possible cause is overload or rotation failure of the motor

due to an electrical trouble

1. Check the Main Drive Unit (turn the unit by hand to see if

it rotates)

Replace the Main Drive Unit when the unit failed to rotate

When the unit rotates

2. Check failure of the harness between the Motor (M04/

J6025) and the DC Controller PCB (UN09/ J210W)

(trapped cable, open circuit, connector disconnection)

3. Check conduction of the fuse (FU7) in the DC Controller

PCB (UN09)

When the fuse is not blown out

4-1. Replace the Drum Motor (M04)

5-1. Replace the DC Controller PCB (UN09)

When the fuse is blown out

4-2. Replace the DC Controller PCB (UN09)

E Code Detail

Location Item Description

Code

E012 0003 05 Title CL Drum Motor lock detection

Detection Within a specied period of time from the startup, the speed

fails to be OK.

Remedy Possible cause is overload or rotation failure of the motor

due to an electrical trouble

1. Check the Main Drive Unit (turn the unit by hand to see if

it rotates)

Replace the Main Drive Unit when the unit failed to rotate

When the unit rotates

2. Check failure of the harness between the Motor (M04/

J6025) and the DC Controller PCB (UN09/ J210W)

(trapped cable, open circuit, connector disconnection)

3. Check conduction of the fuse (FU7) in the DC Controller

PCB (UN09)

When the fuse is not blown out

4-1. Replace the Drum Motor (M04)

5-1. Replace the DC Controller PCB (UN09)

When the fuse is blown out

4-2. Replace the DC Controller PCB (UN09)

E014 0001 05 Title Fixing Motor startup error

Detection Within a specied period of time from the startup, the speed

fails to be OK.

Remedy Possible cause is overload or rotation failure of the motor

due to an electrical trouble

1. Check if the Fixing Assembly is installed.

2. Remove and reinstall the Fixing Assembly

3. Check the gear

4. Replace the Fixing Assembly

5. Check the harness/connector between the DC Controller

PCB (UN09/ J210) and the Fixing Motor (M17).

6. Check conduction of FU1153 in the AC Driver PCB

(UN14)

=>Replace the AC Driver when the fuse is blown out

7. Replace the Fixing Motor (M17)

8. Replace the DC Controller PCB (UN09)

3

Error CodeError Code

3-9

Error Code

3

Error Code

E Code Detail

Location Item Description

Code

E014 0002 05 Title Fixing Motor speed error

Detection Fixing Motor speed error

Remedy Possible cause is overload or rotation failure of the motor

due to an electrical trouble

1. Check if the Fixing Assembly is installed.

2. Remove and reinstall the Fixing Assembly

3. Check the gear

4. Replace the Fixing Assembly

5. Check the harness/connector between the DC Controller

PCB (UN09/ J210) and the Fixing Motor (M17).

6. Check conduction of FU1153 in the AC Driver PCB

(UN14)

=>Replace the AC Driver when the fuse is blown out

7. Replace the Fixing Motor (M17)

8. Replace the DC Controller PCB (UN09)

E014 0003 05 Title Fixing Motor lock detection

Detection Within a specied period of time from the startup, signal is

not received.

Remedy Possible cause is overload or rotation failure of the motor

due to an electrical trouble

1. Check if the Fixing Assembly is installed.

2. Remove and reinstall the Fixing Assembly

3. Check the gear

4. Replace the Fixing Assembly

5. Check the harness/connector between the DC Controller

PCB (UN09/ J210) and the Fixing Motor (M17).

6. Check conduction of FU1153 in the AC Driver PCB

(UN14)

=>Replace the AC Driver when the fuse is blown out

7. Replace the Fixing Motor (M17)

8. Replace the DC Controller PCB (UN09)

E020 0020 05 Title ATR Sensor (Y) error or toner supply error

Detection Error in detected delta T/D ratio

At Y inductance initialization, the average inductance

reference value is equal to or lower than the specied value

Remedy 1. Check if the Drum Unit (Y) is installed.

2. Check the Drum Unit Relay PCB (Y) (UN26)

3. Check the Drum Unit Memory PCB (Y) (UN30)

4. Check the harness/connector between the DC Controller

PCB (UN09/ J25) and the Drum Unit Relay PCB (Y) (UN26).

5. Replace the Drum Unit (Y).

6. Replace the DC Controller PCB (UN09)

E Code Detail

Location Item Description

Code

E020 0030 05 Title ATR Sensor (Y) error or toner supply error

Detection Error in detected delta T/D ratio

At Y inductance initialization, the average inductance

reference value is equal to or higher than the specied

value

Remedy 1. Check if the Drum Unit (Y) is installed.

2. Check the Drum Unit Relay PCB (Y) (UN26)

3. Check the Drum Unit Memory PCB (Y) (UN30)

4. Check the harness/connector between the DC Controller

PCB (UN09/ J25) and the Drum Unit Relay PCB (Y) (UN26).

5. Replace the Drum Unit (Y).

6. Replace the DC Controller PCB (UN09)

E020 0040 05 Title ATR Sensor (Y) error or toner supply error

Detection Unable to adjust the control voltage at Y inductance

initialization

Remedy 1. Check if the Drum Unit (Y) is installed.

2. Check the Drum Unit Relay PCB (Y) (UN26)

3. Check the Drum Unit Memory PCB (Y) (UN30)

4. Check the harness/connector between the DC Controller

PCB (UN09/ J25) and the Drum Unit Relay PCB (Y) (UN26).

5. Replace the Drum Unit (Y).

6. Replace the DC Controller PCB (UN09)

E020 0041 05 Title ATR Sensor (Y) error or toner supply error

Detection Unable to adjust the control voltage at Y inductance

initialization

Remedy 1. Check if the Drum Unit (Y) is installed.

2. Check the Drum Unit Relay PCB (Y) (UN26)

3. Check the Drum Unit Memory PCB (Y) (UN30)

4. Check the harness/connector between the DC Controller

PCB (UN09/ J25) and the Drum Unit Relay PCB (Y) (UN26).

5. Replace the Drum Unit (Y).

6. Replace the DC Controller PCB (UN09)

3-10

E Code Detail

Location Item Description

Code

E020 0050 05 Title ATR patch failed to be created correctly or Patch Sensor

error

Detection High density for the target at patch detection (+200)

Remedy 1. Clean the scanner’s window.

2. Use your hand to check if the shutter of the Registration

Patch Sensor Unit can be open.

3. Check if the window of the Patch Sensor (UN43/ UN44)

is soiled.

4. Check scar on the ITB.

5. Check movement of the Registration Shutter Solenoid

(SL02).COPIER > FUNCTION > PART-CHK > SL to move

SL02

6. Check the harness/connector between the DC Controller

PCB (UN09/J12) and the Patch Sensors (UN43/J4007,

UN44, J4006).

7.Replace the Drum Unit (Y)

8.Replace the Registration Patch Sensor Unit

9 Replace the ITB Unit.

10. Check conduction of the fuses (FU5, FU8) in the DC

Controller PCB (UN09).

11. Replace the Primary Transfer High Voltage PCB (UN04)

12. Replace the Developing High Voltage PCB (UN07)

13. Replace the Primary Charging High Voltage PCB (UN06)

14. Replace the Auxiliary High Voltage PCB (UN08)

15. Replace the Replace the DC Controller PCB (UN09)

E Code Detail

Location Item Description

Code

E020 0060 05 Title ATR patch failed to be created correctly or Patch Sensor

error

Detection High density for the target at patch detection(-200)

Remedy 1. Check the patch shape.

2. Clean the high voltage contact point with dry wiping or air

blower.

3. Check the harness/connector between the DC Controller

(UN09) and the High Voltage PCB.

Between the DC Controller PCB (UN09/ J21) and the

Primary Charging High Voltage PCB (UN06/ J441, J442)

Between the DC Controller PCB (UN09/ J21, J22) and the

Developing High Voltage PCB (UN07/ J451, J452)

Between the DC Controller PCB (UN09/ J19) and the

Auxiliary High Voltage PCB (UN08/J461, J462)

Between the DC Controller PCB (J205) and the Primary

Transfer High Voltage PCB (UN04/J1001)

4. Replace the Drum Unit (Y)

5. Replace the Registration Patch Sensor Unit

6. Replace the ITB Unit.

7. Check conduction of the fuses (FU5, FU8) in the DC

Controller PCB (UN09).

8. Replace the Primary Transfer High Voltage PCB (UN04)

9. Replace the Developing High Voltage PCB (UN07)

10. Replace the Primary Charging High Voltage PCB (UN06)

11. Replace the Auxiliary High Voltage PCB (UN08)

12. Replace the DC Controller PCB (UN09)

E020 0090 05 Title ATR Sensor (Y) error or toner supply error

Detection The average value of detected inductance sampling value

is equal to or lower than the specied value (0x0F)

Remedy 1. Check if the Drum Unit (Y) is installed.

2. Check the Drum Unit Relay PCB (Y) (UN26)

3. Check the Drum Unit Memory PCB (Y) (UN30)

4. Check the harness/connector between the DC Controller

PCB (UN09/ J25) and the Drum Unit Relay PCB (Y) (UN26).

5. Replace the Drum Unit (Y).

6. Replace the DC Controller PCB (UN09)

E020 0091 05 Title ATR Sensor (Y) error or toner supply error

Detection The average value of detected inductance sampling value

is equal to or higher than the specied value (0xE0)

Remedy 1. Check if the Drum Unit (Y) is installed.

2. Check the Drum Unit Relay PCB (Y) (UN26)

3. Check the Drum Unit Memory PCB (Y) (UN30)

4. Check the harness/connector between the DC Controller

PCB (UN09/ J25) and the Drum Unit Relay PCB (Y) (UN26).

5. Replace the Drum Unit (Y).

6. Replace the DC Controller PCB (UN09)

3

Error CodeError Code

3-11

Error Code

3

Error Code

E Code Detail

Location Item Description

Code

E020 00B0 05 Title ATR Sensor (Y) error or toner supply error

Detection T/D ratio detected by the ATR Sensor (Y) (UN39) is equal to

or higher than the specied value (high density)

Remedy 1. Check if the Drum Unit (Y) is installed.

2. Check the Drum Unit Relay PCB (Y) (UN26)

3. Check the Drum Unit Memory PCB (Y) (UN30)

4. Check the harness/connector between the DC Controller

PCB (UN09/ J25) and the Drum Unit Relay PCB (Y) (UN26).

5. Replace the Drum Unit (Y).

6. Replace the DC Controller PCB (UN09)

E020 00B1 05 Title ATR Sensor (Y) error or toner supply error

Detection Error in detected delta T/D ratio

T/D ratio detected by the ATR Sensor (Y) (UN39) is equal to

or lower than the specied value (light density)

Remedy Possible cause: overload with the motor or motor failure

1. Check conduction with FU2 on the DC Controller PCB

(UN09)

2. Check the harness/connector between the DC Controller

PCB (UN09/ J23) and PS06.

3. Replace the DC Controller PCB (UN09)

4. Check the Hopper Unit (Y)

5. Replace the Hopper Unit (Y).

E020 0120 05 Title ATR Sensor (M) error or toner supply error

Detection Error in detected delta T/D ratio

At M inductance initialization, the average inductance

reference value is equal to or lower than the specied value

Remedy 1. Check if the Drum Unit (M) is installed.

2. Check the Drum Unit Relay PCB (M) (UN27).

3. Check the Drum Unit Memory PCB (M) (UN31).

4. Check the harness/connector between the DC Controller

PCB (UN09/ J25) and the Drum Unit Relay PCB (M) (UN27).

5. Replace the Drum Unit (M).

6. Replace the DC Controller PCB (UN09)

E020 0130 05 Title ATR Sensor (M) error or toner supply error

Detection Error in detected delta T/D ratio

At M inductance initialization, the average inductance

reference value is equal to or higher than the specied

value

Remedy 1. Check if the Drum Unit (M) is installed.

2. Check the Drum Unit Relay PCB (M) (UN27).

3. Check the Drum Unit Memory PCB (M) (UN31).

4. Check the harness/connector between the DC Controller

PCB (UN09/ J25) and the Drum Unit Relay PCB (M) (UN27).

5. Replace the Drum Unit (M).

6. Replace the DC Controller PCB (UN09)

E Code Detail

Location Item Description

Code

E020 0140 05 Title ATR Sensor (M) error or toner supply error

Detection Unable to adjust the control voltage at M inductance

initialization

Remedy 1. Check if the Drum Unit (M) is installed.

2. Check the Drum Unit Relay PCB (M) (UN27).

3. Check the Drum Unit Memory PCB (M) (UN31).

4. Check the harness/connector between the DC Controller

PCB (UN09/ J25) and the Drum Unit Relay PCB (M) (UN27).

5. Replace the Drum Unit (M).

6. Replace the DC Controller PCB (UN09)

E020 0141 05 Title ATR Sensor (M) error or toner supply error

Detection Unable to adjust the control voltage at M inductance

initialization

Remedy 1. Check if the Drum Unit (M) is installed.

2. Check the Drum Unit Relay PCB (M) (UN27).

3. Check the Drum Unit Memory PCB (M) (UN31).

4. Check the harness/connector between the DC Controller

PCB (UN09/ J25) and the Drum Unit Relay PCB (M) (UN27).

5. Replace the Drum Unit (M).

6. Replace the DC Controller PCB (UN09)

E020 0150 05 Title ATR patch failed to be created correctly or Patch Sensor

error

Detection High density for the target at patch detection

Remedy 1. Clean the scanner’s window.

2. Use your hand to check if the shutter of the Registration

Patch Sensor Unit can be open.

3. Check if the window of the Patch Sensor (UN43/ UN44)

is soiled.

4. Check scar on the ITB.

5. Check movement of the Registration Shutter Solenoid

(SL02).COPIER > FUNCTION > PART-CHK > SL to move

SL02

6. Check the harness/connector between the DC Controller

PCB (UN09/J12) and the Patch Sensors (UN43/J4007,

UN44, J4006).

7.Replace the Drum Unit (M)

8.Replace the Registration Patch Sensor Unit

9 Replace the ITB Unit.

10. Check conduction of the fuses (FU5, FU8) in the DC

Controller PCB (UN09).

11. Replace the Primary Transfer High Voltage PCB (UN04)

12. Replace the Developing High Voltage PCB (UN07)

13. Replace the Primary Charging High Voltage PCB (UN06)

14. Replace the Auxiliary High Voltage PCB (UN08)

15. Replace the Replace the DC Controller PCB (UN09)

3-12

E Code Detail

Location Item Description

Code

E020 0160 05 Title ATR patch failed to be created correctly or Patch Sensor

error

Detection High density for the target at patch detection

Remedy 1. Check the patch shape.

2. Clean the high voltage contact point with dry wiping or air

blower.

3. Check the harness/connector between the DC Controller

(UN09) and the High Voltage PCB.

Between the DC Controller PCB (UN09/ J21) and the

Primary Charging High Voltage PCB (UN06/ J441, J442)

Between the DC Controller PCB (UN09/ J21, J22) and the

Developing High Voltage PCB (UN07/ J451, J452)

Between the DC Controller PCB (UN09/ J19) and the

Auxiliary High Voltage PCB (UN08/J461, J462)

Between the DC Controller PCB (J205) and the Primary

Transfer High Voltage PCB (UN04/J1001)

4. Replace the Drum Unit (M)

5. Replace the Registration Patch Sensor Unit

6. Replace the ITB Unit.

7. Check conduction of the fuses (FU5, FU8) in the DC

Controller PCB (UN09).

8. Replace the Primary Transfer High Voltage PCB (UN04)

9. Replace the Developing High Voltage PCB (UN07)

10. Replace the Primary Charging High Voltage PCB (UN06)

11. Replace the Auxiliary High Voltage PCB (UN08)

12. Replace the DC Controller PCB (UN09)

E020 0190 05 Title ATR Sensor (M) error or toner supply error

Detection The average value of detected inductance sampling value

is equal to or lower than the specied value (0x0F)

Remedy 1. Check if the Drum Unit (M) is installed.

2. Check the Drum Unit Relay PCB (M) (UN27).

3. Check the Drum Unit Memory PCB (M) (UN31).

4. Check the harness/connector between the DC Controller

PCB (UN09/ J25) and the Drum Unit Relay PCB (M) (UN27).

5. Replace the Drum Unit (M).

6. Replace the DC Controller PCB (UN09)

E020 0191 05 Title ATR Sensor (M) error or toner supply error

Detection The average value of detected inductance sampling value

is equal to or higher than the specied value (0x0F)

Remedy 1. Check if the Drum Unit (M) is installed.

2. Check the Drum Unit Relay PCB (M) (UN27).

3. Check the Drum Unit Memory PCB (M) (UN31).

4. Check the harness/connector between the DC Controller

PCB (UN09/ J25) and the Drum Unit Relay PCB (M) (UN27).

5. Replace the Drum Unit (M).

6. Replace the DC Controller PCB (UN09)

E Code Detail

Location Item Description

Code

E020 01B0 05 Title ATR Sensor (M) error or toner supply error

Detection The T/D ratio detected by the ATR Sensor (M) (UN40) is

equal to or higher than the specied value (high density)

Remedy 1. Check if the Drum Unit (M) is installed.

2. Check the Drum Unit Relay PCB (M) (UN27).

3. Check the Drum Unit Memory PCB (M) (UN31).

4. Check the harness/connector between the DC Controller

PCB (UN09/ J25) and the Drum Unit Relay PCB (M) (UN27).