Canon BJC-8500 Service Manual

QY8-1356-000

REVISION 0

COPYRIGHT 1999 CANON INC. CANON BJC-8500 0399 AB 0.30-0 PRINTED IN JAPAN (IMPRIME AU JAPON)

MAR. 1999

0399 AB 0.30-0

Target Readers

This manual is published by Canon Inc. for qualified persons and contains the necessary technical

information for technical theory, installation, maintenance, and repair of products. This manual covers

all localities where the products are sold. For this reason, it may contain information that does not

apply to your locality.

Revisions

This manual may include technical inaccuracies or typographical errors due to improvements or

changes in the products. When amendments are made to the content of this manual, Canon will issue

technical information as the need arises. In the event of major alterations to the content of this manual

over a long or short period, Canon will publish a revised version of the manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with the local law.

Trademarks

The product names and company names appearing in this manual are the registered trademarks or

trademarks of the individual companies.

Copyright

This manual is copyrighted and all rights reserved. Under the copyright laws, this manual may not be

copied, reproduced, or translated into other languages, in whole or in part, without the express written

consent of Canon Inc. except in the case of internal business use.

Copyright 1999 by Canon Inc.

CANON INC.

BJ Products Quality Support Dept.

16-1, Shimonoge 3-chome, Takatsu-ku, Kawasaki, Kanagawa 213, Japan

This manual was produced on an Apple Macintosh Power Mac 7300/180 personal computer and Apple

LaserWriter II NTX-J laser beam printer; final pages were printed on Agfa SelectSet Avantra 25.

A YANO 640MO drive system NJ640MO with MITSUBISHI MO disk cartridge MR230M1 were used for

storing large volumes of page layout and graphic data for this manual.

All graphics were produced with MACROMEDIA FREEHAND 7.0J.

All documents and all page layouts were created with QuarkXPress 3.3J.

I

I. ABOUT THIS MANUAL

This manual is divided into five parts containing the information required for servicing the BJC8500 printer.

Part 1: Safety and Precautions

This part contains information on how to service the unit safely. It is very important, and

must be read.

Part 2: Product Specifications

This part outlines the product and its specifications.

Part 3: Operating Instructions

This part explains how to operate the unit properly, how to set it up properly, and how to

use the service mode.

Part 4: Technical Reference

This part outlines the unit operation giving a technically.

Part 5: Maintenance

This part explains maintenance of the unit. It includes details of disassembly/assembly,

adjustments required when assembling, troubleshooting procedures, and wiring/circuit

diagrams, etc.

This manual does not contain complete information required for

disassembling and assembling the BJC-8500 printer. Please also refer to the

separate Parts Catalog.

This printer prints various ink and plain paper ink optimizer (except in the

draft mode when plain paper, envelope or thick paper is selected). This plain

paper ink optimizer is an almost transparent, colorless liquid.

For convenience, this manual sometimes refers to the plain paper ink

optimizer simply as "ink optimizer" and the combination of ink and plain

paper ink optimizer as "ink."

This manual also refers to the BJ cartridge and print head (head) as the one

and same thing.

II. TABLE OF CONTENTS

Page

Part 1: SAFETY AND PRECAUTIONS

1 - 1 1. PERSONAL SAFETY PRECAUTIONS

1 - 1 1.1 Moving Sections of the Printer

1 - 2 1.2 Ink Stains

1 - 2 1.2.1 Ink path

1 - 3 1.2.2 Ink mist

1 - 4 1.3 Electrically Live Sections of the Printer

1 - 5 2. MACHINE PRECAUTIONS

1 - 5 2.1 Handling BJ Cartridges

1 - 5 2.1.1 Unpacking BJ cartridges

1 - 6 2.1.2 Protecting BJ cartridges

1 - 7 2.1.3 Turing the printer ON/OFF

1 - 7 2.1.4 When not using the printer

1 - 7 2.1.5 Ink electroconductivity

1 - 8 2.2 Handling the Ink Tanks

1 - 8 2.2.1 Unpacking the ink tanks

1 - 8 2.2.2 Protecting the ink tanks

1 - 9 2.3 Handling the Printer

1 - 9 2.3.1 Spurs

1 - 9 2.3.2 Encoder

1 -10 2.3.3 Paper feed roller unit

1 -10 2.3.4 Purge motor

1 -11 2.3.5 Precautions to prevent damage from static electricity

1 -12 2.3.6 Ink leakage/ink dry-up precautions

1 -12 2.3.7 Precautions when carrying the printer

1 -13 3. PRECAUTIONS FOR SERVICE

1 -13 3.1 Precautions Concerning Memory Data

1 -14 3.2 Special Settings

1 -15 3.3 Precautions to Prevent Damage from Static Electricity

1 -16 3.4 Precautions for Disassembly/Assembly

1 -16 3.4.1 Disassembly prohibited parts

1 -16 3.4.2 Precautions for disassembly/assembly

1 -17 3.5 Self-diagnostic Functions

Part 2:

PRODUCT SPECIFICATIONS

2 - 1 1. PRODUCT OUTLINE

2 - 1 1.1 Product Outline

2 - 2 1.2 Features

2 - 3 1.3 BJ Cartridges

2 - 3 1.3.1 Black BJ cartridge [BC-80]

2 - 3 1.3.2 Color BJ cartridge [BC-81]

2 - 4 1.3.3 Photo BJ cartridge [BC-82 Photo]

2 - 5 1.3.4 Relationship between BJ cartridges and printing mode

2 - 6 1.4 BJ Cartridge Container SB-80

2 - 7 1.5 Consumables

2 - 7 1.5.1 BJ cartridge

2 - 7 1.5.2 Ink tank

2 - 8 2. SPECIFICATIONS

2 - 8 2.1 General Specifications

2 -11 2.2 Paper Specifications

2 -11 2.2.1 Paper types

II

Page

2 -12 2.2.2 Printing area

2 -13 2.3 Interface Specifications

2 -13 2.3.1 Parallel interface

2 -19 2.3.2 Serial interface

Part 3: OPERATING INSTRUCTIONS

3 - 1 1. PRINTER SETUP

3 - 1 1.1 Unpacking

3 - 3 1.2 Installation Space

3 - 4 1.3 Installation Procedure

3 - 4 1.3.1 Connecting the interface cable

3 - 4 1.3.2 Connecting the power supply

3 - 5 1.3.3 Installing BJ cartridges

3 - 8 1.3.4 Replacing ink tanks

3 - 9 1.3.5 BJ cartridge container SB-80

3 -10 1.4 Turning the Printer ON/OFF

3 -10 1.4.1 Turning the printer on

3 -10 1.4.2 Turning the printer off

3 -11 1.5 Paper Settings

3 -13 1.6 Names and Functions of Parts

3 -15 2. TRANSPORTING THE PRINTER

3 -15 2.1 Transporting the Printer

3 -16 2.2 Capping Lock/Unlock

3 -17 3. PRINTER SERVICING FUNCTIONS

3 -17 3.1 Error Indications

3 -17 3.1.1 Operator call

3 -18 3.1.2 Service call

3 -18 3.2 Warning Display

3 -19 3.3 Function Settings

3 -19 3.3.1 Maintenance settable items

3 -21 3.3.2 Custom setting

3 -23 3.4 Control Buttons

3 -23 3.4.1 Cleaning the BJ cartridges

3 -24 3.4.2 Service mode

3 -25 3.5 Self Test Print (Nozzle Check Pattern)

3 -27 3.6 EEPROM

3 -27 3.6.1 Continued use of EEPROM memory data

3 -27 3.6.2 Resetting the EEPROM

3 -28 3.6.3 EEPROM list print

3 -29 3.6.4 Destination setting

Part 4: TECHNICAL REFERENCE

4 - 1 1. OVERVIEW

4 - 1 1.1 Printer Block Diagram

4 - 2 1.2 Initial Flowchart

4 - 5 1.3 Power OFF Operation Flow

4 - 6 1.4 Print Signal Flow

4 - 7 1.5 BJ Cartridge Drive

4 - 7 1.5.1 Printing drive control

4 - 8 2. FIRMWARE

4 - 8 2.1 Interface

4 - 8 2.1.1 Nibble mode

4 - 9 2.1.2 ECP mode

III

Page

4 -10 2.2 Printing Modes

4 -11 2.2.1 P-POP (Plain Paper Optimized Printing) mode

4 -11 2.2.2 Draft mode (Print Quality: High Speed)

4 -11 2.2.3 Photo printing mode

4 -11 2.2.4 Carriage speed

4 -12 2.2.5 Advanced settings

4 -14 2.3 Optimum Printing Control

4 -14 2.3.1 Power monitor

4 -14 2.3.2 Ink-smear control

4 -15 3. PRINTER MECHANISM

4 -15 3.1 Overview of the Mechanical System

4 -16 3.1.1 Mechanical system configuration

4 -17 3.2 BJ Cartridge

4 -17 3.2.1 BJ cartridge structure

4 -18 3.2.2 BJ head unit structure

4 -19 3.2.3 Nozzle arrangement

4 -20 3.2.4 Signal contact part

4 -22 3.2.5 BJ cartridge drive circuit

4 -23 3.2.6 BJ cartridge detection

4 -24 3.3 Purge Unit

4 -24 3.3.1 Purge unit functions

4 -26 3.3.2 Purge unit structure

4 -28 3.4 Carriage Unit

4 -28 3.4.1 Carriage unit functions

4 -29 3.4.2 Carriage unit structure

4 -30 3.5 Paper Feed Section/Sheet Feeder Unit/Cassette Units

4 -30 3.5.1 Paper feed/sheet feeder/cassette functions

4 -32 3.5.2 Sheet feeder unit structure

4 -33 3.5.3 Cassette unit structure

4 -34 3.5.4 Flapper unit structure

4 -35 3.5.5 Path of fan air flow

4 -36 4. PRINTER ELECTRICAL SYSTEM

4 -36 4.1 Overview

4 -37 4.2 Logic Section

4 -37 4.2.1 Logic section block diagram

4 -38 4.2.2 Logic section components

4 -41 4.3 Power Supply Section

4 -41 4.3.1 Block diagram of power supply section

4 -41 4.3.2 Power supply section structure

4 -43 5. DETECTION FUNCTIONS

4 -43 5.1 Sensor Functions

4 -45 5.2 Other Detection Functions

4 -45 5.2.1 Waste ink level detection

4 -45 5.2.2 BJ cartridge sensor

4 -46 5.2.3 Ink-out detection

4 -48 5.2.4 No ink tank detection

Part 5: MAINTENANCE

5 - 1 1. MAINTENANCE

5 - 1 1.1 Periodically-replaced Parts

5 - 1 1.2 Worn Parts

5 - 1 1.3 Consumables

5 - 1 1.4 Periodic Maintenance

IV

Page

5 - 2 2. SERVICE TOOLS

5 - 2 2.1 List of Tools

5 - 3 3. APPLYING GREASE

5 - 6 4. DISASSEMBLY/ASSEMBLY

5 - 6 4.1 About Disassembly/Assembly

5 - 6 4.2 Precautions for Disassembly/Assembly

5 - 6 4.2.1 Unlocking the carriage

5 - 7 4.2.2 Disassembly prohibited parts

5 - 8 4.2.3 Purge unit tubes

5 - 8 4.2.4 Screw fastening of idle pulley ass'y

5 - 9 4.3 Logic Board Replacement

5 - 9 4.3.1 Except for EEPROM replacement

5 - 9 4.3.2 EEPROM replacement

5 -10 4.4 Waste Ink Absorber Replacement

5 -11 5. ADJUSTMENT

5 -11 5.1 Adjustment Locations

5 -11 5.1.1 EEPROM (IC501) and waste ink absorber

5 -11 5.1.2 Adjusting the printing position of BJ cartridges

5 -11 5.1.3 Carriage belt tension adjustment

5 -12 6. TROUBLESHOOTING

5 -12 6.1 Overview of Troubleshooting

5 -12 6.1.1 Definition

5 -12 6.1.2 Precautions for troubleshooting

5 -13 6.2 Error Condition Diagnosis

5 -13 6.2.1 Diagnosis flowchart

5 -16 6.2.2 Error recovery

5 -32 7. CONNECTOR POSITION & SIGNAL ASSIGNMENT

5 -32 7.1 Logic Board

5 -38 7.2 Carriage Board

5 -42 7.3 Panel Board

5 -42 7.4 Carriage Driver Board

5 -43 7.5 Upper Cassette Board

5 -44 7.6 Lower Cassette Board 1

5 -45 7.7 Lower Cassette Board 2

5 -46 7.8 Fan Board

5 -47 7.9 Power Supply Unit

5 -48 8. CIRCUIT DIAGRAMS

5 -48 8.1 Parts Layout

5 -48 8.1.1 Logic board

5 -50 8.1.2 Carriage board

5 -51 8.1.3 Panel board

5 -53 8.2 Circuit Diagrams

5 -53 8.2.1 Logic board

5 -65 8.2.2 Carriage board

5 -68 8.2.3 Carriage driver board

5 -69 8.2.4 Ink sensor/Fan board

5 -70 8.2.5 Panel board

5 -71 8.2.6 Upper cassette board

5 -72 8.2.7 Lower cassette board

V

III. ILLUSTRATION INDEX

Page

Part 1: SAFETY AND PRECAUTIONS

1 - 1 Figure 1 - 1 Moving Sections of the Printer

1 - 2 Figure 1 - 2 Ink Path

1 - 3 Figure 1 - 3 BC-80, BC-81, and BC-82 Photo

1 - 3 Figure 1 - 4 Ink Mist

1 - 4 Figure 1 - 5 Power Supply Unit

1 - 5 Figure 1 - 6 Removing the Protective Cap

1 - 6 Figure 1 - 7 BJ Cartridges

1 - 8 Figure 1 - 8 Removing the Ink Tank Protective Cap

1 - 8 Figure 1 - 9 Ink Outlets

1 - 9 Figure 1 -10 Spurs

1 - 9 Figure 1 -11 Encoder Film and Carriage Board

1 -10 Figure 1 -12 Paper Feed Roller

1 -10 Figure 1 -13 Purge Motor

1 -11 Figure 1 -14 Contact Sections

1 -12 Figure 1 -15 Capping

1 -12 Figure 1 -16 Precautions when Carrying the Printer

1 -15 Figure 1 -17 Electronic System

1 -16 Figure 1 -18 Disassembly Prohibited Parts

1 -16 Figure 1 -19 How to Release Plastic Hooks

Part 2: PRODUCT SPECIFICATIONS

2 - 1 Figure 2 - 1 External View of Printer

2 - 3 Figure 2 - 2 Black BJ Cartridge [BC-80]

2 - 3 Figure 2 - 3 Color BJ Cartridge [BC-81]

2 - 4 Figure 2 - 4 Photo BJ Cartridge [BC-82 Photo]

2 - 4 Figure 2 - 5 Path of Ink Tank and BJ Cartridge (Front View)

2 - 6 Figure 2 - 6 BJ Cartridge Container [SB-80]

2 - 7 Figure 2 - 7 Ink Tanks

2 -12 Figure 2 - 8 Printing Area

2 -18 Figure 2 - 9 Compatibility Mode Timing Chart

2 -18 Figure 2 -10 Nibble Mode Timing Chart

2 -18 Figure 2 -11 ECP Mode Timing Chart

Part 3: OPERATING INSTRUCTIONS

3 - 1 Figure 3 - 1 Packing (1)

3 - 2 Figure 3 - 2 Packing (2): Lower Cassette

3 - 3 Figure 3 - 3 Installation Space

3 - 4 Figure 3 - 4 Connecting the Interface Cable

3 - 4 Figure 3 - 5 Connecting the Power Supply

3 - 5 Figure 3 - 6 Removing the Protective Cap

3 - 5 Figure 3 - 7 Installing BJ Cartridges

3 - 6 Figure 3 - 8 Checking the Position of the Print Head (1)

3 - 7 Figure 3 - 9 Checking the Position of the Print Head (2)

3 - 8 Figure 3 -10 Replacing Ink Tanks

3 - 8 Figure 3 -11 How to Remove the Ink Tank Protective Cap

3 - 9 Figure 3 -12 BJ Cartridge Container SB-80

3 -10 Figure 3 -13 Precautions When Turning the Printer OFF

3 -11 Figure 3 -14 Paper Settings

3 -13 Figure 3 -15 Names and Functions of Parts (1)

3 -14 Figure 3 -16 Names and Functions of Parts (2)

VI

Page

3 -15 Figure 3 -17 Transporting the Printer

3 -16 Figure 3 -18 Capping Lock

3 -16 Figure 3 -19 Capping Lock/Unlock

3 -17 Figure 3 -20 Control Panel

3 -18 Figure 3 -21 BJ Cartridges do not Match Warning (Sample)

3 -19 Figure 3 -22 Windows 95/98 Printer Driver Maintenance Sheet (Sample)

3 -20 Figure 3 -23 Macintosh Printer Driver Utility Sheet (Sample)

3 -22 Figure 3 -24 Special Settings (Sample)

3 -25 Figure 3 -25 Nozzle Check Pattern (Sample using Black BJ cartridge BC-80+ Color

BJ cartridge BC-81)

3 -26 Figure 3 -26 Nozzle Check Pattern (Sample using Color BJ cartridge BC-81+ Photo

BJ cartridge BC-82 Photo)

3 -28 Figure 3 -27 EEPROM List Print (Sample)

Part 4: TECHNICAL REFERENCE

4 - 1 Figure 4 - 1 Printer Block Diagram

4 - 2 Figure 4 - 2 Initial Flowchart (1)

4 - 3 Figure 4 - 3 Initial Flowchart (2)

4 - 4 Figure 4 - 4 Initial Flowchart (3)

4 - 5 Figure 4 - 5 Power OFF Operation Flow

4 - 6 Figure 4 - 6 Print Signal Flow

4 - 7 Figure 4 - 7 Printing Drive Control

4 - 8 Figure 4 - 8 Interface Timing (Nibble Mode)

4 - 9 Figure 4 - 9 Interface Timing (ECP Mode)

4 -11 Figure 4 -10 Ink Layering with the Ink Optimizer

4 -12 Figure 4 -11 Main Sheet (Sample)

4 -13 Figure 4 -12 Advanced Detailed Setting (Sample)

4 -14 Figure 4 -13 Custom Setting

4 -15 Figure 4 -14 Printer Mechanism

4 -17 Figure 4 -15 BJ Cartridge Structure

4 -18 Figure 4 -16 Exploded View of BJ Head Unit

4 -19 Figure 4 -17 Nozzle Arrangement

4 -20 Figure 4 -18 BJ Cartridge I/O Signals

4 -22 Figure 4 -19 BJ Cartridge Drive Circuit Block Diagram

4 -22 Figure 4 -20 Head Temperature Sensor

4 -22 Figure 4 -21 Rank Wiring Diagram

4 -24 Figure 4 -22 Purge Unit

4 -27 Figure 4 -23 Purge Unit

4 -28 Figure 4 -24 Carriage Unit

4 -29 Figure 4 -25 Structure of Encoder Film and Encoder Head

4 -30 Figure 4 -26 Pick-up Path from Sheet Feeder Unit/Manual Feed Slot

4 -30 Figure 4 -27 Pick-up Path from Upper Cassette/Lower Cassette Units

4 -31 Figure 4 -28 Paper Feed Section

4 -31 Figure 4 -29 Platen Ribs

4 -32 Figure 4 -30 Structure of Sheet Feeder Unit

4 -33 Figure 4 -31 Cassette Body and Claws

4 -33 Figure 4 -32 Structure of Cassette Unit

4 -33 Figure 4 -33 Mechanical Clutch of Upper Cassette

4 -34 Figure 4 -34 Structure of Flapper Unit

4 -35 Figure 4 -35 Path of Fan Air Flow

4 -36 Figure 4 -36 Printer Electrical Section

4 -37 Figure 4 -37 Logic Board Block Diagram

4 -37 Figure 4 -38 Printer Block Diagram

VII

Page

4 -41 Figure 4 -39 Block Diagram of Power Supply Section

4 -42 Figure 4 -40 Output Connectors

4 -43 Figure 4 -41 Sensor Locations

4 -46 Figure 4 -42 Principle of Ink-out Detection

4 -47 Figure 4 -43 Ink Sensor and Anti-reflection Sheet

4 -48 Figure 4 -44 Principle of No Ink Tank Detection

Part 5: MAINTENANCE

5 - 3 Figure 5 - 1 Grease Application Sections (1)

5 - 4 Figure 5 - 2 Grease Application Sections (2)

5 - 5 Figure 5 - 3 Grease Application Sections (3)

5 - 6 Figure 5 - 4 Unlocking the Carriage

5 - 7 Figure 5 - 5 BJ Cartridge Contact Section on Carriage Unit

5 - 7 Figure 5 - 6 Disassembly Prohibited Locations

5 - 8 Figure 5 - 7 Purge Unit Tubes

5 - 8 Figure 5 - 8 Screw Fastening of Idle Pulley Ass'y

5 - 9 Figure 5 - 9 EEPROM

5 -10 Figure 5 -10 Waste Ink Absorber

5 -32 Figure 5 -11 Logic Board

5 -38 Figure 5 -12 Carriage Board

5 -42 Figure 5 -13 Panel Board

5 -42 Figure 5 -14 Carriage Driver Board

5 -43 Figure 5 -15 Upper Cassette Board

5 -44 Figure 5 -16 Lower Cassette Board 1

5 -45 Figure 5 -17 Lower Cassette Board 2

5 -46 Figure 5 -18 Fan Board

5 -47 Figure 5 -19 Power Supply Unit

5 -48 Figure 5 -20 Logic Board Front Surface

5 -49 Figure 5 -21 Logic Board Rear Surface

5 -50 Figure 5 -22 Carriage Board Front Surface

5 -50 Figure 5 -23 Carriage Board Rear Surface

5 -51 Figure 5 -24 Panel Board Front Surface

VIII

IV. TABLE INDEX

Page

Part 2: PRODUCT SPECIFICATIONS

2 - 5 TABLE 2- 1 CARTRIDGE AND PRINTING MODES

2 -11 TABLE 2- 2 PAPER SPECIFICATIONS

Part 3: OPERATING INSTRUCTIONS

3 -11 TABLE 3- 1 PRINTER PAPER SETTINGS

3 -17 TABLE 3- 2 OPERATOR CALL

3 -18 TABLE 3- 3 SERVICE CALL

3 -24 TABLE 3- 4 SERVICE MODE

Part 4: TECHNICAL REFERENCE

4 -10 TABLE 4- 1 PRINTER DOT PITCH NUMBER OF PASSES, NUMBER OF

EJECTION NOZZLES

4 -12 TABLE 4- 2 CARRIAGE SPEED

4 -12 TABLE 4- 3 MAIN AUTO PALETTE DEFAULTS (Windows 95/98)

4 -20 TABLE 4- 4 INK TYPE EJECTED FROM BJ CARTRIDGES

4 -21 TABLE 4- 5 BJ CARTRIDGE I/O SIGNALS

4 -23 TABLE 4- 6 HEAD ID AND RANKOUT OUTPUT LEVEL

4 -25 TABLE 4- 7 CLEANING EXECUTION CONDITIONS, CLEANING TIME AND INK

SUCTION AMOUNTS

Part 5: MAINTENANCE

5 - 1 TABLE 5- 1 PERIODICALLY-REPLACED PARTS

IX

Part 1

SAFETY AND PRECAUTIONS

Page

1 - 1 1. PERSONAL SAFETY PRECAUTIONS

1 - 1 1.1 Moving Sections of the printer

1 - 2 1.2 Ink Stains

1 - 4 1.3 Electrically Live Sections of the Printer

1 - 5 2. MACHINE PRECAUTIONS

1 - 5 2.1 Handling BJ Cartridges

1 - 8 2.2 Handling the Ink Tanks

1 - 9 2.3 Handling the Printer

1 -13 3. PRECAUTIONS FOR SERVICE

1 -13 3.1 Precautions Concerning Memory Data

1 -14 3.2 Special Settings

1 -15 3.3 Precautions to Prevent Damage from Static Electricity

1 -16 3.4 Precautions for Disassembly/Assembly

1 -17 3.5 Self-diagnostic Functions

1. PERSONAL SAFETY PRECAUTIONS

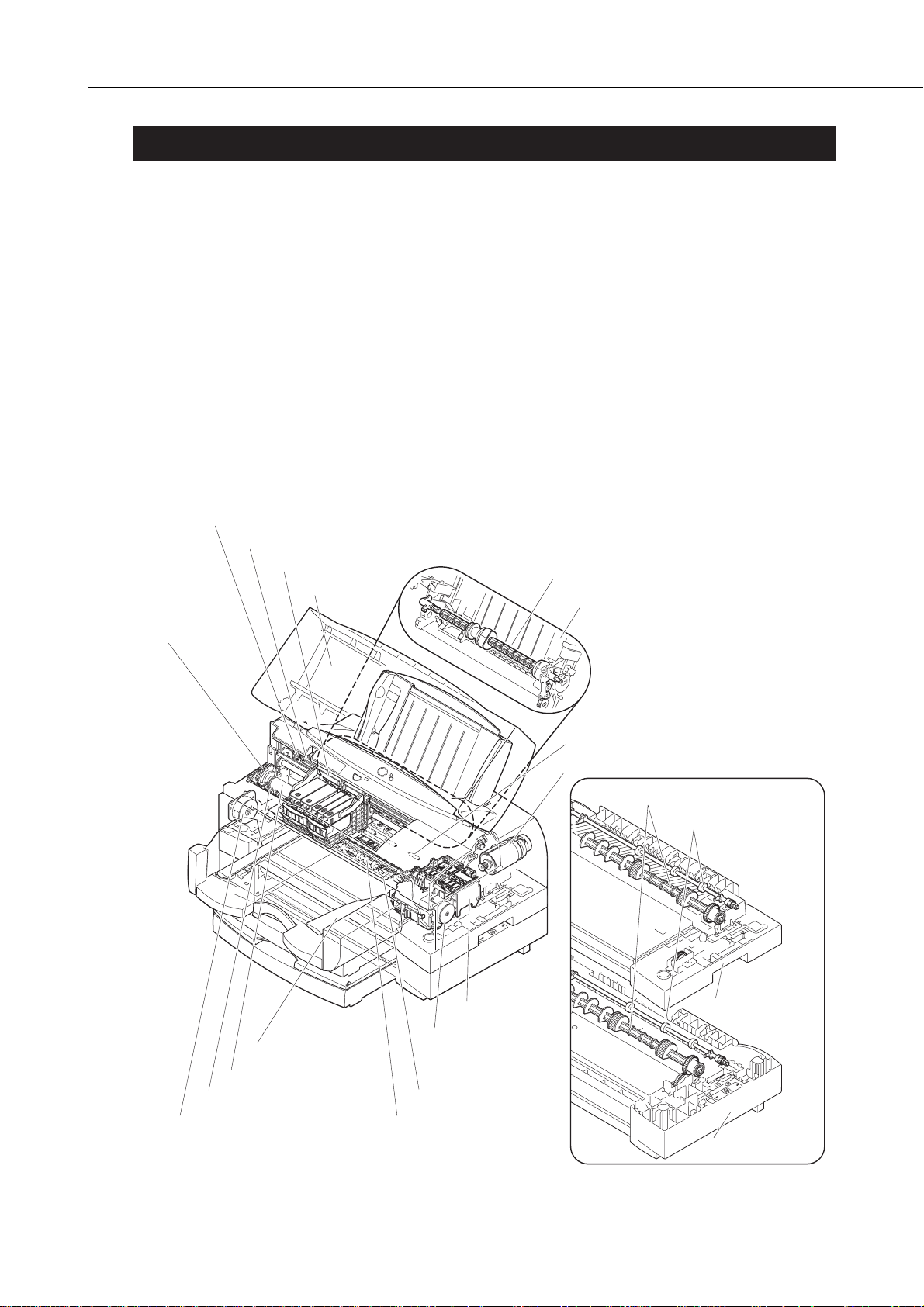

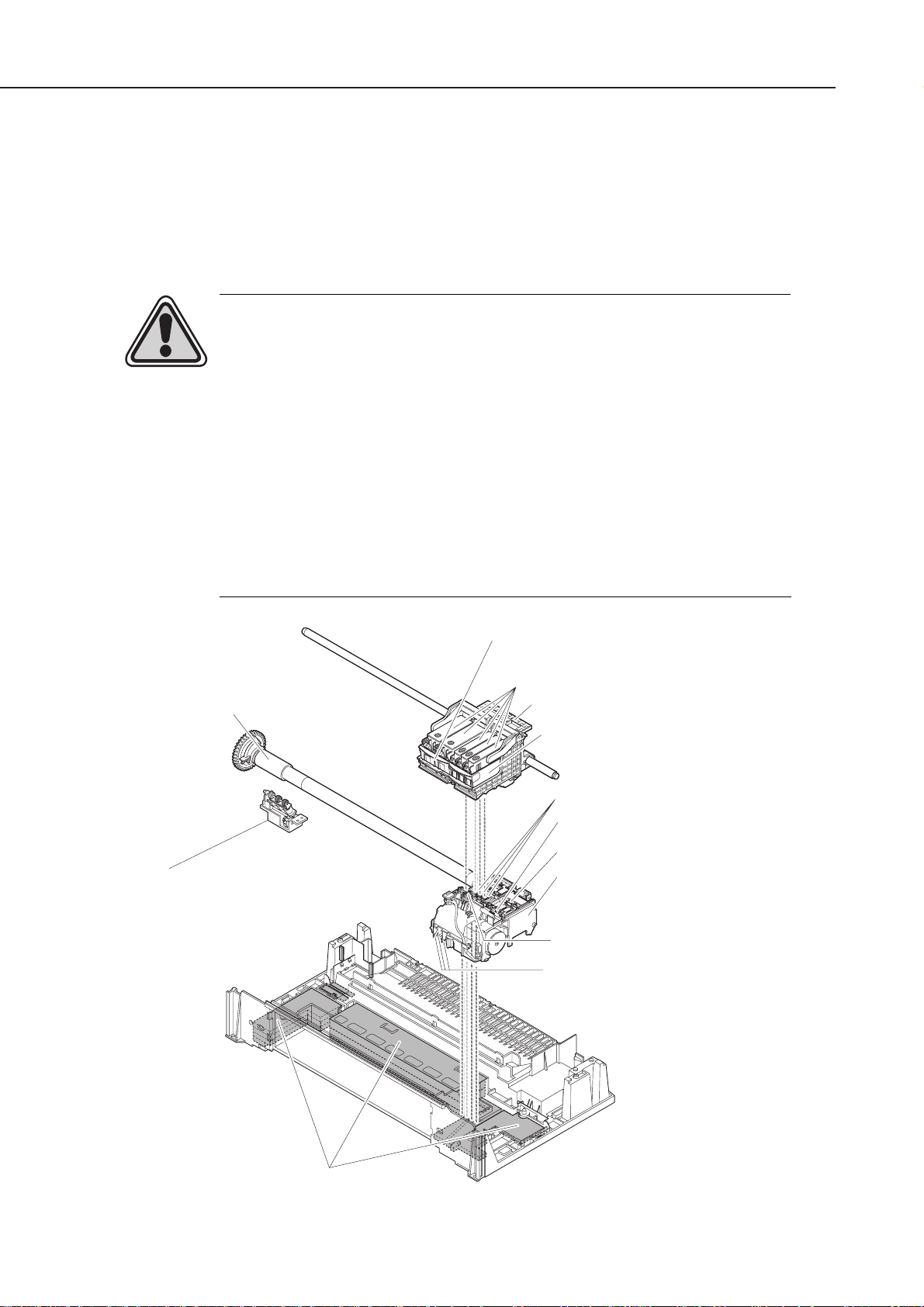

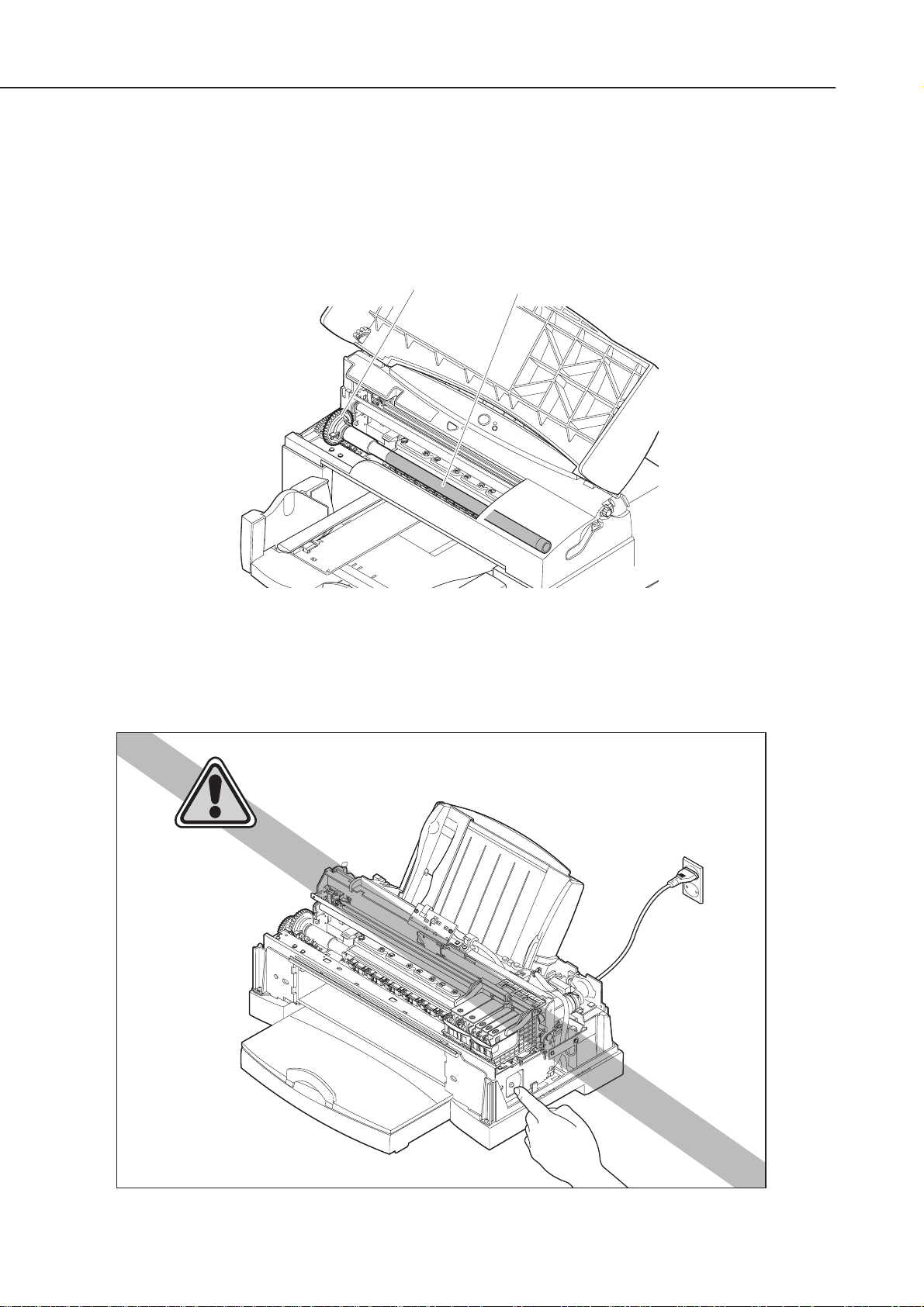

1.1 Moving Sections of the Printer

Be careful not to let your hands or fingers, hair, clothes, accessories, etc., become

caught in any moving sections of the printer. The moving sections of the printer are

driven by the carriage motor, paper feed motor, or the purge motor.

Moving sections driven by the carriage motor:

Carriage belt, idle pulley, carriage, etc.

Moving sections driven by the paper feed motor:

Paper feed rollers, pinch roller, cleaning unit, eject roller, spur unit, transmission

gear, flapper unit, etc.

Moving sections driven by the purge motor:

Purge unit, pick-up roller of the sheet feeder unit, pick-up rollers in the upper and

lower cassettes, paper feed roller, etc.

During operation close the top cover (except when checking operation), and take care

not to touch the above moving parts. Also note that the spurs are made of metal and

have sharp edges. Avoid touching these inadvertently with bare hands.

1-1

BJC-8500

Part 1: Safety and Precautions

Figure 1-1 Moving Sections of the Printer

Transmission

Gear

Idle Pulley

Carriage Belt

Carriage Belt

Top Cover

Pick-up Roller

Sheet Feeder Unit

Flapper Unit

Paper Feed Roller

Cleaning Unit

Paper Feed Motor

Purge Motor

Spur Unit

Eject Roller

Purge Unit

Pinch Roller

Carriage Motor

Pick-up Rollers

Paper Feed Rollers

Upper Cassette

Lower Cassette

1.2 Ink Stains

1.2.1 Ink path

Be careful not to touch the ink path on the printer, or get ink stains on your hands or

fingers, clothing, printer while it is operating and on the work table.

The ink path is comprised of the nozzle section of BJ cartridges, suction caps, waste

ink tubes, wiper section, wiper cleaner, maintenance jet section, wiper unit, wiper

unit transfer pad and waste ink absorber.

CAUTION

The ink and plain paper ink optimizer are not substances harmful to the

human body. They do, however, contain organic solvents (Ink: isopropyl

alcohol 67-63-0, glycerin 56-81-5, Plain Paper Ink optimizer: ethleneglycol

111-46-6, glycerin 56-81-5). Be careful not to get any ink in your mouth

or eyes. Also, keep ink and plain paper ink optimizer out of the reach of

small children.

If you do get any into your eyes, wash it out immediately with plenty of water.

If you inadvertently swallow a large amount of ink, consult a doctor

immediately.

Since ink contains dyes, if it gets on your clothes, etc., it will not come out

even through washing.

Part 1: Safety and Precautions

BJC-8500

1-2

Figure 1-2 Ink Path

Cleaning Unit Transfer Pad

Cleaning Unit

(exclusively for Black BJ cartridge BC-80)

Black BJ Cartridge BC-80 or

Photo BJ Cartridge BC-82 Photo

Ink Tanks

Carriage

Color BJ Cartridge BC-81

Suction Caps

Wiper Cleaner

Wiper Unit

Purge Unit

Maintenance Jet Section

Waste Ink Tubes

Waste InkAbsorber

The ink path includes the filters of the Black BJ cartridge [BC-80], Color BJ cartridge

[BC-81] and Photo BJ cartridge [BC-82 photo], and each ink outlet of the ink tanks.

Take care of the ink path when handling BJ cartridges and ink tanks.

Never unnecessarily remove ink tanks from BJ cartridges. When an ink tank is

removed from a BJ cartridge, air can enter the ink path and may adversely affect

printing. If an ink tank is removed from a BJ cartridge, carry out cleaning. (Cleaning

is automatically carried out when the ink tank is attached after a no ink tank error is

detected. For details, see

"Part 4: TABLE 4-7 CLEANING EXECUTION CONDITIONS,

CLEANING TIME AND INK SUCTION AMOUNTS." (page 4-25)

)

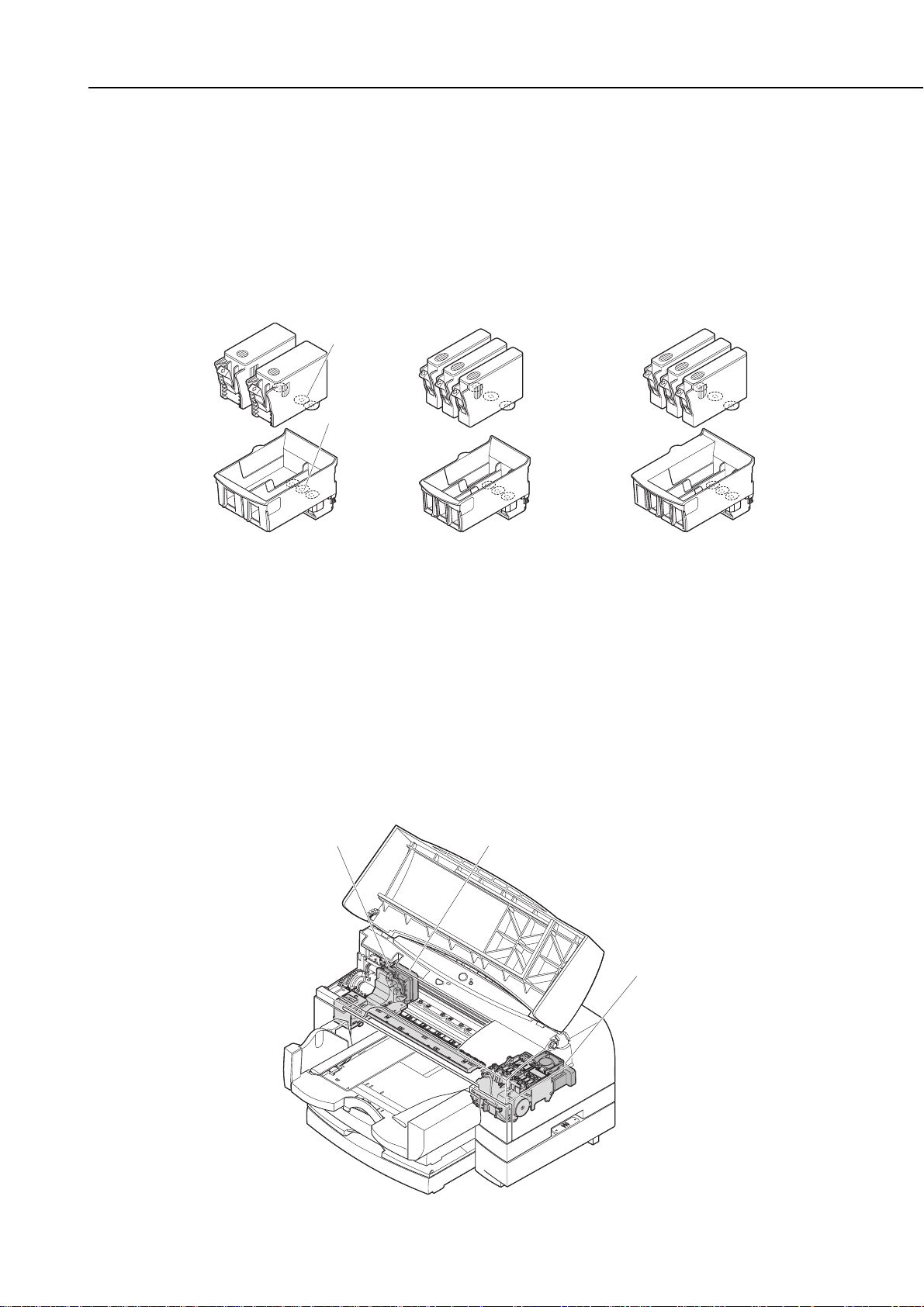

1.2.2 Ink mist

With the BJ cartridges used on this printer, minute ink droplets rise up and bounce

back from the paper during printing as "ink mist." This printer generates a much

larger amount of ink mist than conventional Canon printers. As a countermeasure,

two fans, A and B, are provided to create an air path to draw the ink mist behind fan

B into the ink mist absorber. Fan A pulls in air, while fan B sucks in this blown air.

When servicing or disassembling this printer, wear gloves. Hands, fingers or clothes

may become soiled by this ink mist. If necessary, wipe off ink mist using a soft cloth

moistened with water.

1-3

BJC-8500

Part 1: Safety and Precautions

Figure 1-4 Ink Mist

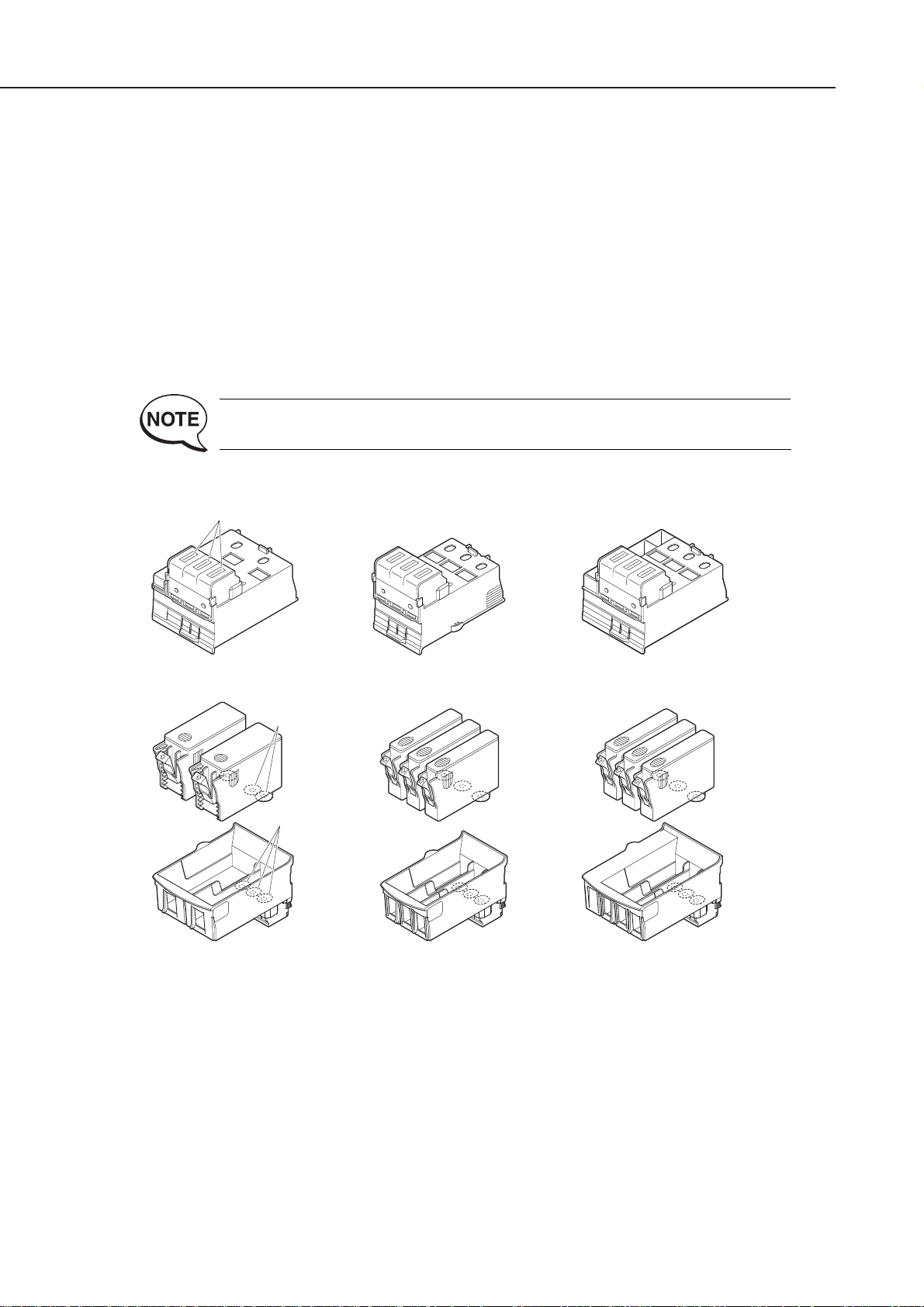

Figure 1-3 BC-80, BC-81, and BC-82 Photo

Ink Outlet

Filter

Black BJ Cartridge

BC-80

Color BJ Cartridge

BC-81

Photo BJ Cartridge

BC-82 Photo

Fan B

Ink Mist Absorber

Fan A

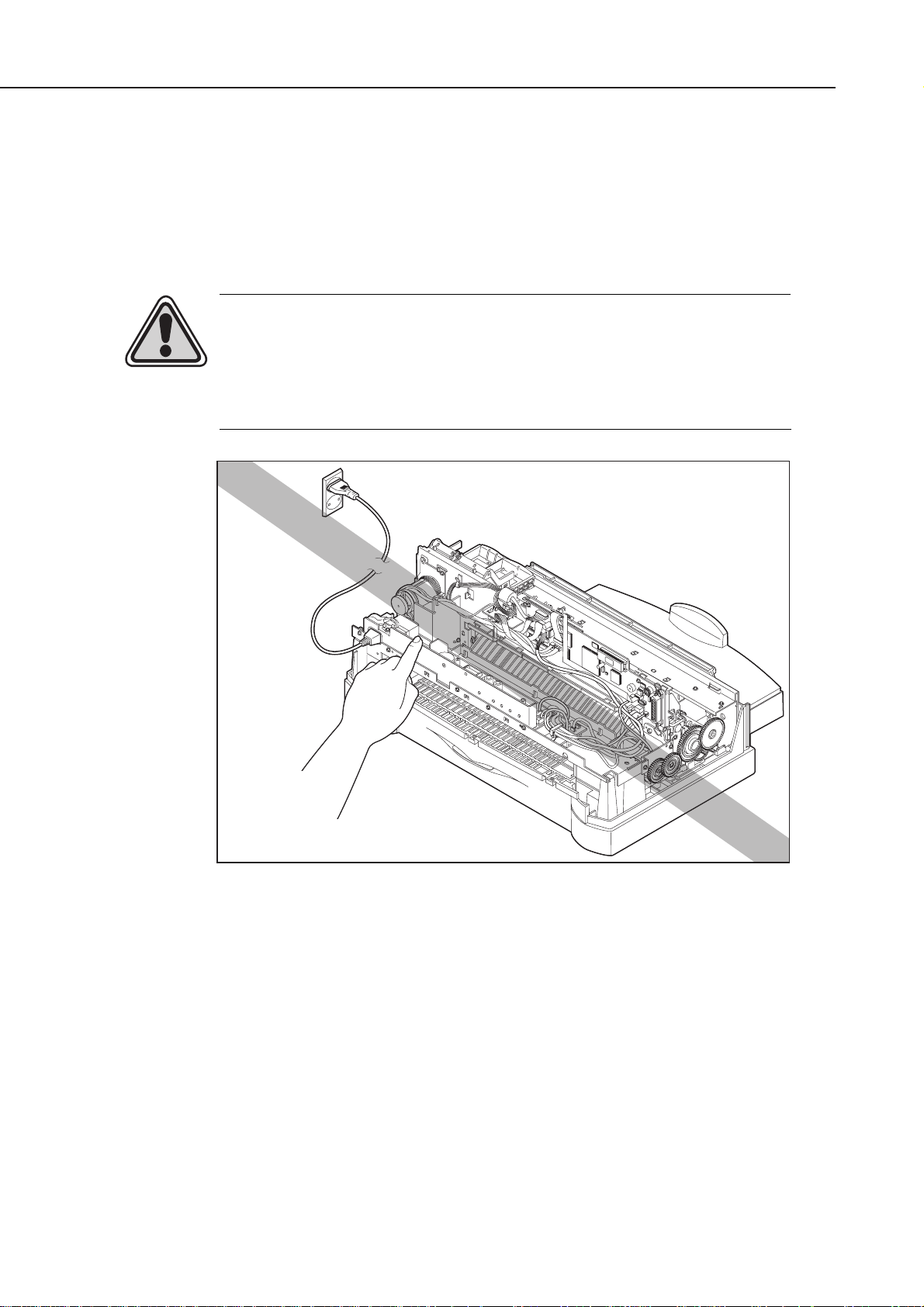

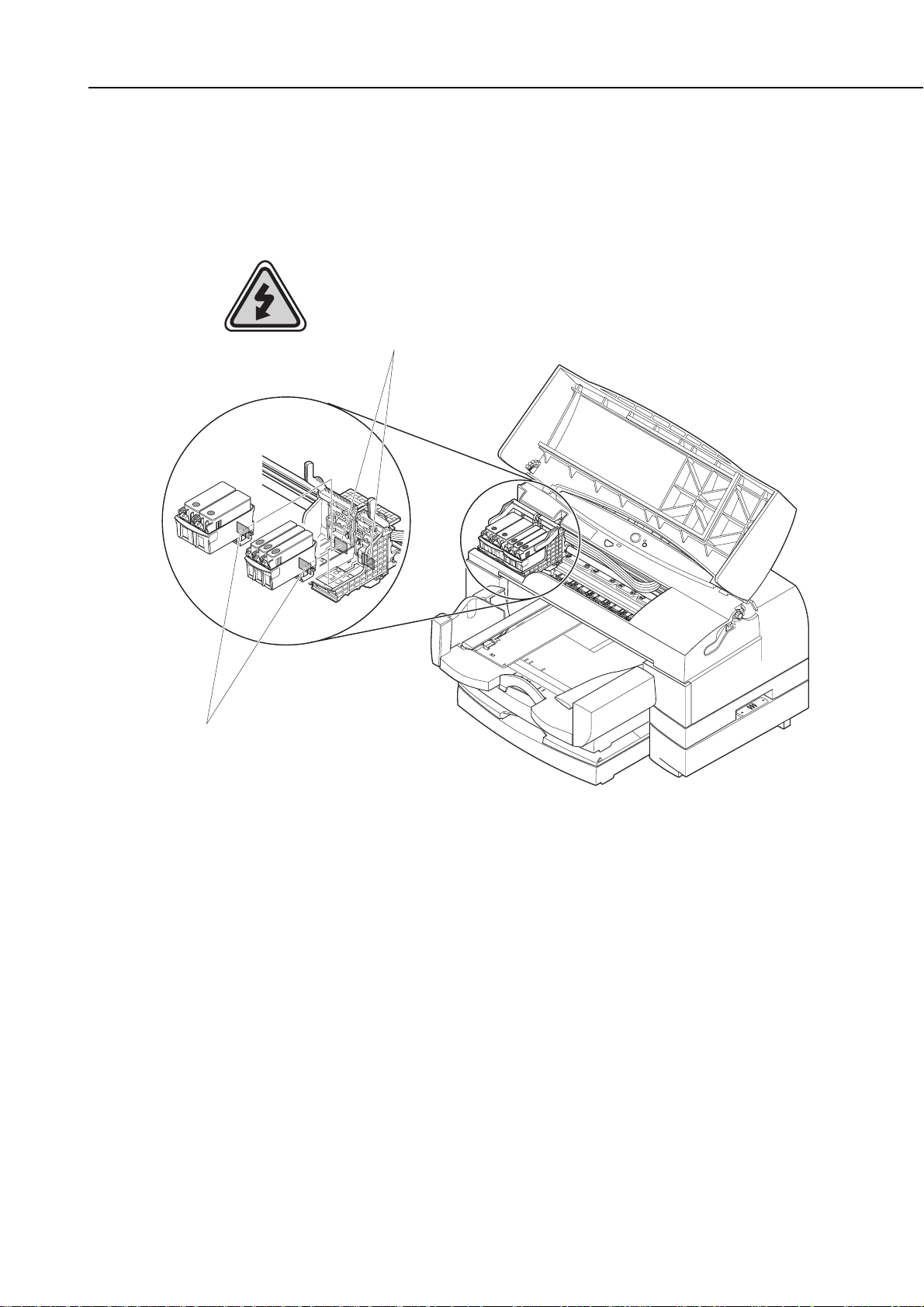

1.3 Electrically Live Sections of the Printer

All electrical sections of the printer supplied with AC power are electrically live when

the power cord is connected whether the printer is turned ON or OFF using the

POWER

button.

Be careful of electric shock when checking printer operation with the covers removed

during servicing. For this reason, be sure to unplug the power cord from the power

outlet during servicing.

CAUTION

As the AC main voltage is supplied to the primary side of the power supply

unit, there is always the danger of an electric shock.

Always unplug the AC power cord before disassembling for service.

Part 1: Safety and Precautions

BJC-8500

1-4

Figure 1-5 Power Supply Unit

2. MACHINE PRECAUTIONS

2.1 Handling BJ Cartridges

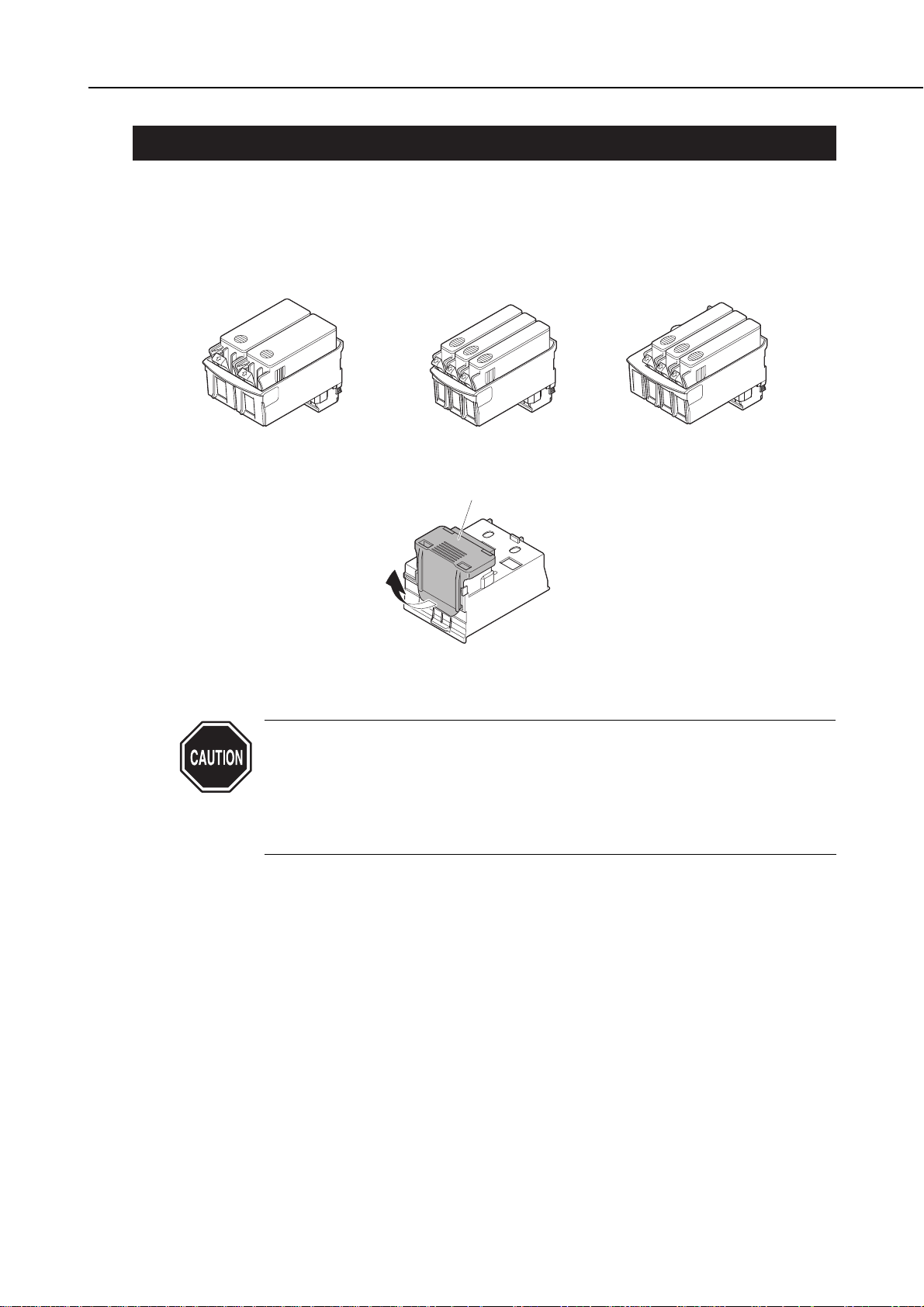

2.1.1 Unpacking BJ cartridges

Do not unpack the BJ cartridges until they are ready to be used. Before installing the

BJ cartridge in the printer, gently remove the cap protecting the nozzles as shown in

Figure 1-6 Removing the Protective Cap

.

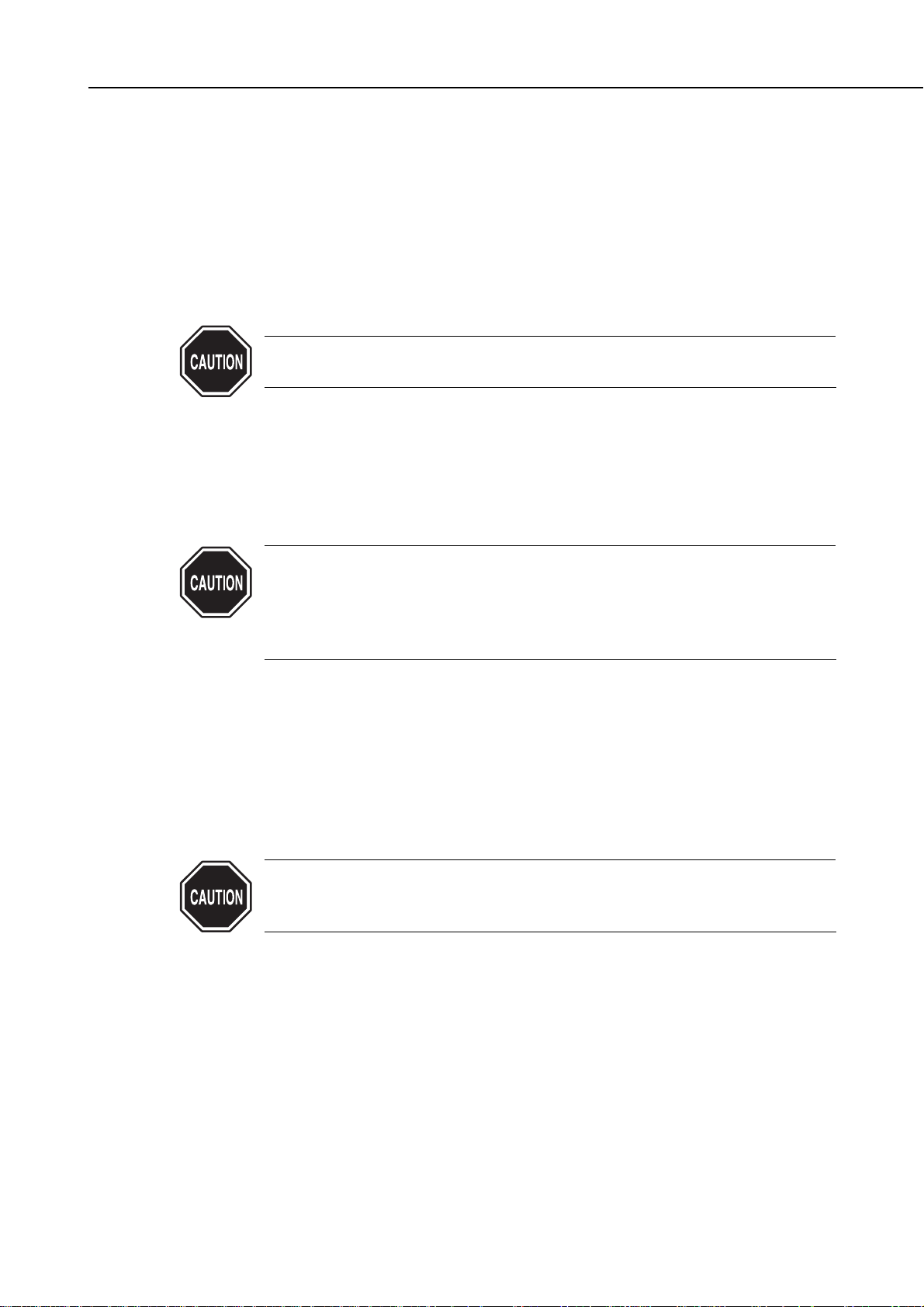

Never re-use a protective cap once it has been removed. Re-using a

protective cap may cause defective printing. Also, be sure to use BJ

cartridge container SB-80 for storing BJ cartridges. If the protective cap is

re-attached to the BJ cartridge, the film or tape on the cap may form an

ink path with other inks. This, in turn, may cause inks of different colors

to mix or cause the nozzles to clog.

1-5

BJC-8500

Part 1: Safety and Precautions

Figure 1-6 Removing the Protective Cap

Black BJ Cartridge

BC-80

Color BJ Cartridge

BC-81

Protective Cap

Photo BJ Cartridge

BC-82 Photo

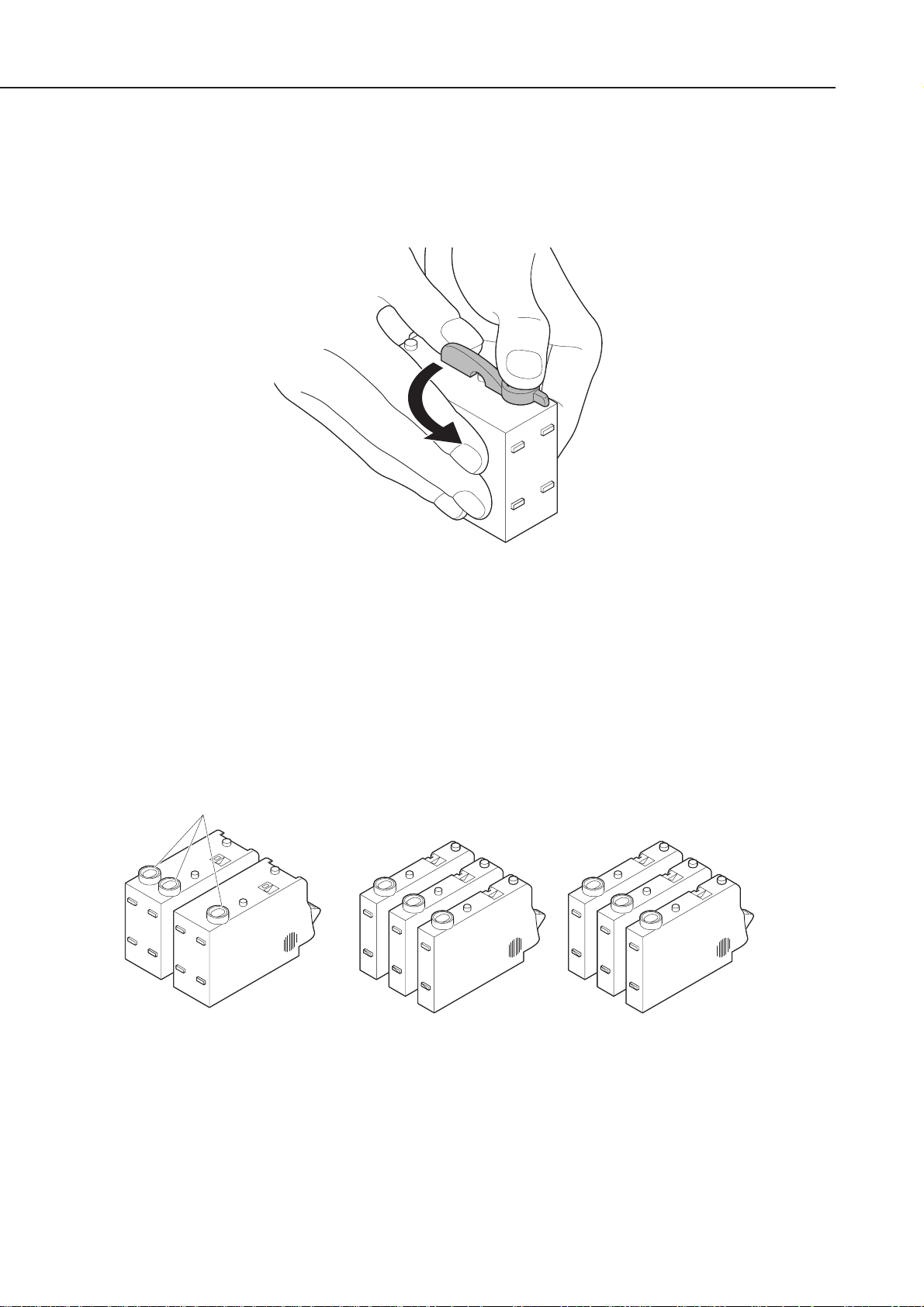

2.1.2 Protecting BJ cartridges

To prevent clogging of the nozzles due to foreign matter, never touch the nozzle

section of the BJ cartridge, filters, and ink outlets on the ink tanks, or wipe off foreign

matter or clogged ink with tissue paper or the like.

Once you have removed the protective cap from a BJ cartridge, either install the BJ

cartridge in the printer or store it in the cartridge container (SB-80) to prevent

clogging of the nozzles due to ink drying or foreign matter.

Do not re-attach a protective cap once it has been removed.

Also, never leave a BJ cartridge exposed with the ink tank removed. (Doing so may

allow the ink outlets to dry and cause defective printing.)

Do not disassemble or assemble BJ cartridges, and do not wash the heads with water

as this may cause the nozzles to clog.

Clogging of the nozzles causes defective printing. If cleaning does not

restore proper printing, you must replace the BJ cartridge.

Part 1: Safety and Precautions

BJC-8500

1-6

Figure 1-7 BJ Cartridges

Nozzle Section

Black BJ Cartridge

BC-80

Ink Outlets

Filters

Color BJ Cartridge

BC-81

Photo BJ Cartridge

BC-82 Photo

2.1.3 Turning the printer ON/OFF

When the power is switched OFF with the

POWER

button, the printer automatically

caps the nozzle section of the BJ cartridge to protect it and prevent ink leakage.

If you unplug the power cord before the printer is turned OFF with

POWER

button,

the printer may stop without capping the nozzles, depending on the position of the

carriage. If this happens, reconnect the power cord, start up the printer as usual,

turn the power OFF with the

POWER

button, make sure that the carriage returns to

the home position and that the nozzles are capped before disconnecting the power

cord.

If the nozzle section is not capped, ink may leak or dry, causing the

nozzles on the BJ cartridges to clog.

2.1.4 When not using the printer

Keep the Color BJ cartridge BC-81 installed in the printer even when the printer is

not in use to ensure the quality of the BJ cartridge. Install either the Black BJ

cartridge BC-80 or Photo BJ cartridge BC-82 photo in the printer, and store the other

in BJ cartridge container SB-80.

If the BJ cartridge is removed from the printer and left unprotected,

foreign matter may stick or dry ink may clog the nozzles, making it

impossible to use the BJ cartridge.

Ink may also leak from the caps if cleaning is not performed after the BJ

cartridge is removed and the printer is carried or transported.

2.1.5 Ink electroconductivity

The ink in the BJ cartridge is electrically conductive. If it leaks onto a mechanical

section, wipe it up with a damp paper towel or the like. If it leaks onto an electrical

circuit, wipe it up completely with tissue paper or the like. If ink leaks onto the logic

board or into the power supply unit and gets into the electrical components and PCB,

and is difficult to clean, replace the logic board or other electrical components with

new ones.

If the power cord is connected to the printer with ink leaked, this may

damage the electrical section. Never switch the power on if there has been

a leak.

1-7

BJC-8500

Part 1: Safety and Precautions

2.2 Handling the Ink Tanks

2.2.1 Unpacking the ink tanks

Do not unpack the ink tank from its package until it is ready to be used. Before

installing the ink tank in the BJ cartridge, unpack the ink tank and remove the

protective cap protecting the ink outlets.

2.2.2 Protecting the ink tanks

To prevent poor ink suction due to foreign matter on the joints with the BJ cartridge,

never touch the ink outlets of the ink tank with your hands or fingers. After removing

the protective cap from the ink tank, immediately install the ink tank in the BJ

cartridge to prevent the nozzles from clogging due to ink drying. Do not remove ink

tanks from BJ cartridges unless replacing them. (When not using an ink tank, place

them, installed in the BJ cartridge, in BJ cartridge container SB-80.

Part 1: Safety and Precautions

BJC-8500

1-8

Figure 1-8 Removing the Ink Tank Protective Cap

Figure 1-9 Ink Outlets

Ink Outlets

2.3 Handling the Printer

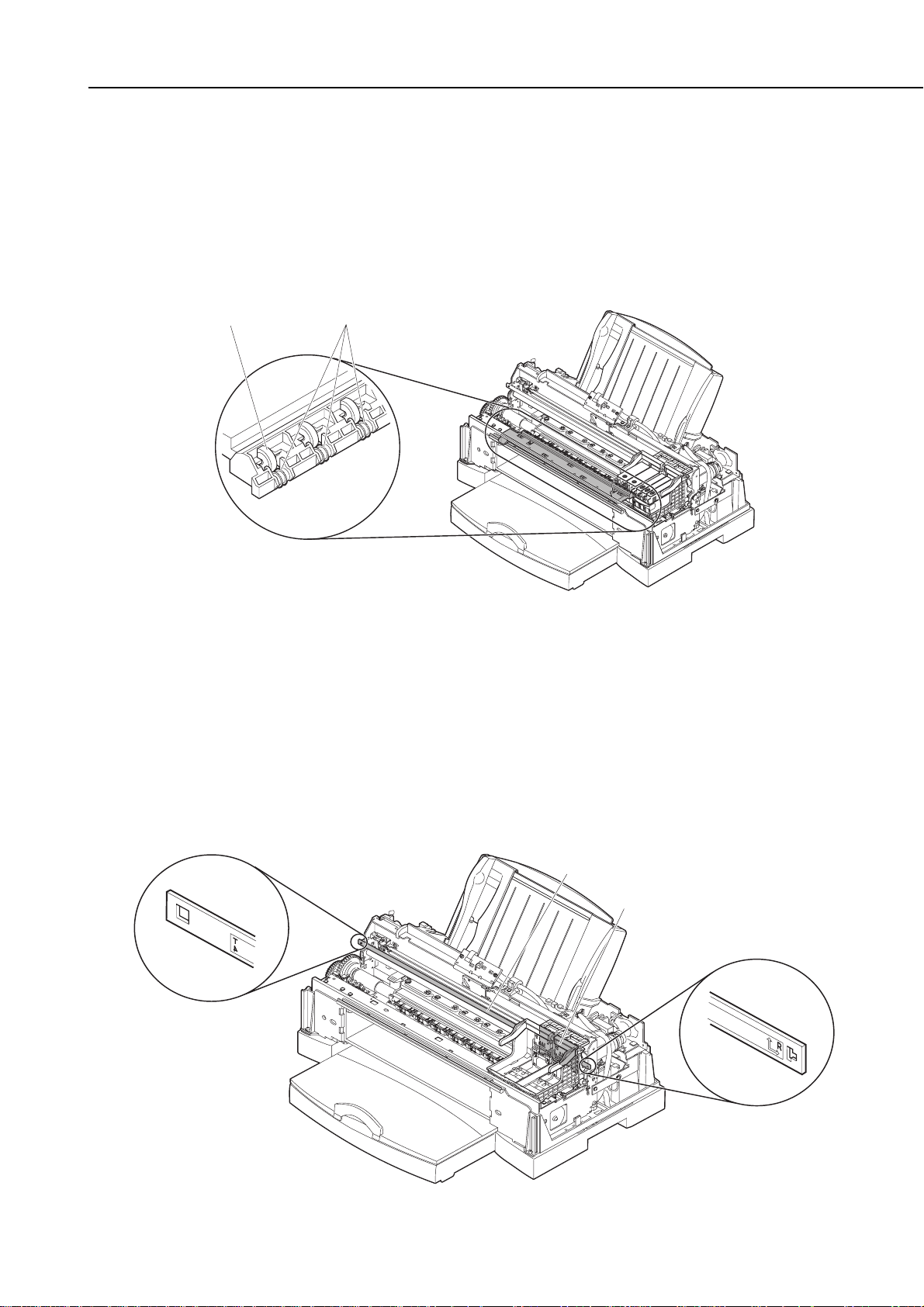

2.3.1 Spurs

Metal spurs are used for feeding and outputting paper after printing. The tips of the

spurs are also sharp and pointed. They are small and easily deformed. Take care not

to deform them. Take care to prevent injury when handling them.

If the tips of the spurs become deformed or worn, and their surface contact area with

the paper increases, a minute line of dots may appear on the paper. If this happens,

replace the spurs. (refer to

"Part 5: 1.1 Periodically-replaced Parts" (page 5-1)

)

2.3.2 Encoder

The BJ cartridge used on this printer generates a lot of ink mist as described in

"Part

1: 1.2.2 Ink mist" (page 1-3)

. So, the encoder film and encoder head may become coated

with ink mist.

To clean the encoder film, wipe with lint-free paper or a dry cloth. Do not wipe with a

wet cloth. Replace the encoder film if wiping does not clean it. When replacing the

encoder film, make sure that it is installed facing the correct way. (The top of the

encoder film is marked as shown in

Figure 1-11 Encoder Film and Carriage Board

.)

Do not wipe off ink mist on the encoder head. Replace with a new head (mounted on

the carriage board.) (refer to

"Part 5: 1.1 Periodically-replaced Parts" (page 5-1)

)

1-9

BJC-8500

Part 1: Safety and Precautions

Figure 1-11 Encoder Film and Carriage Board

Figure 1-10 Spurs

SpursSpur Cleaner

Encoder Film

Carriage Board

2.3.3 Paper feed roller unit

The surface of the paper feed roller is blast-finished to ensure a maximum resolution

of 1200 × 1200 dpi. Take care not to scratch the surface of this roller.

The drive gear used on the paper feed roller is also finished to high precision to feed

the paper in small increments for 1/1200 inch feeding. Take special care not to leave

any knock marks on this gear.

2.3.4 Purge motor

The purge motor is very hot immediately after repeated printing or cleaning. Take

care not to touch the purge motor directly with bare hands after these operations.

Part 1: Safety and Precautions

BJC-8500

1-10

Figure 1-12 Paper Feed Roller

Figure 1-13 Purge Motor

Drive Gear

Paper Feed Roller

Danger! High Temperature!

2.3.5 Precautions to prevent damage from static electricity

The electrical charge accumulated on a person when clothes rub can damage electric

elements or change their electrical characteristics. Never touch the contact section on

carriage top or the contact section on BJ cartridges.

1-11

BJC-8500

Part 1: Safety and Precautions

Figure 1-14 Contact Sections

Attention! Static Electricity!

Contact Section on Carriage Top

Contact Section on BJ Cartridges

2.3.6 Ink leakage/ink dry-up precautions

Always turn the printer OFF by the

POWER

button with the BJ cartridges installed.

The following operation is automatically carried out when powering OFF with the

POWER

button.

Capping

The head cap covers and secures the nozzle section to prevent the nozzles on the BJ

cartridge from drying. If the power cord is unplugged from the power outlet by

mistake without turning the printer OFF by the

POWER

button, reconnect the power

cord to the power outlet, turn the power ON, then OFF again, by the

POWER

button,

and make sure that the nozzles are capped before unplugging the power cord.

If the power is turned OFF with the BJ cartridge removed or the power is turned

OFF after unplugging the power cord from the power outlet, the nozzles are not

capped. This may cause ink to leak or dry up.

If the power cannot be turned ON due to printer trouble, manually lock

the nozzle cap. For details, see

"Part 3: 2.2 Capping Lock/Unlock" (page 3-16)

.

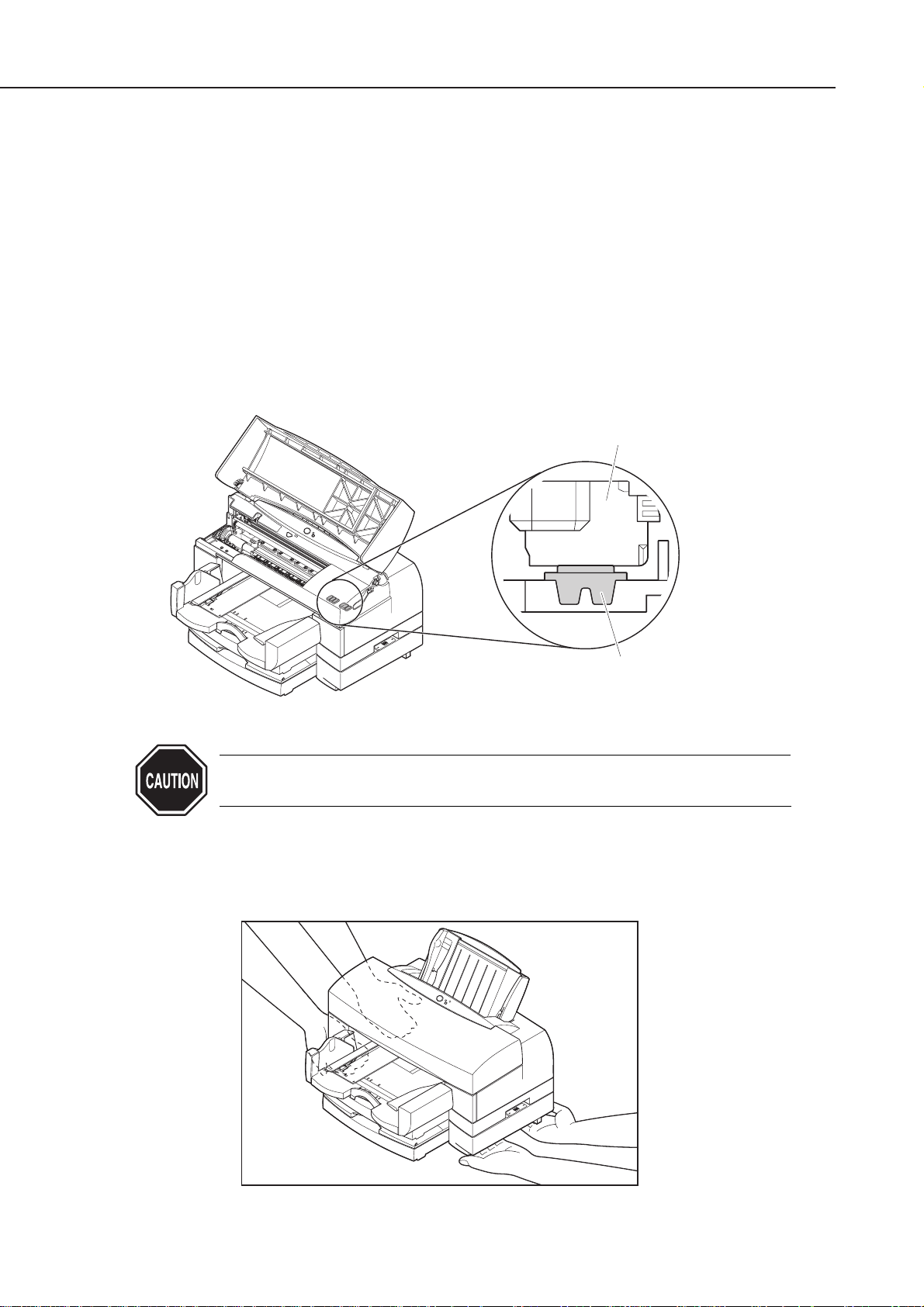

2.3.7 Precautions when carrying the printer

The printer weighs 25 kg. It should be carried by two personnel, holding it on both

sides as shown in

Figure 1-16 Precautions when Carrying the Printer

.

Part 1: Safety and Precautions

BJC-8500

1-12

Figure 1-15 Capping

Figure 1-16 Precautions when Carrying the Printer

BJ Cartridge

Head Cap

(enlarged view of indicated section)

3. PRECAUTIONS FOR SERVICE

3.1 Precautions Concerning Memory Data

This printer counts the number of BJ cartridge attachments/removals, number of

sheets fed, waste ink amount, head position adjustment values, and cleaning count,

and stores this data in the EEPROM on the logic board.

Observe the following precautions during servicing.

1) Before servicing:

Check the EEPROM with a test print in the service mode. For details, see

"Part 3: 3.4.2

Service mode" (page 3-24)

.

2) When replacing the logic board:

If the EEPROM is not defective, remove the EEPROM from its socket and attach it to

the new logic board. All data settings stored to EEPROM can be used on the new logic

board as they are. To check the EEPROM data settings, make a test printout.

If the EEPROM is not attached to the new logic board, the amount of waste ink in the

waste ink absorber will not match the waste ink amount (stored in EEPROM), and ink

may leak without the waste ink error being displayed.

3) EEPROM defect (replacement of EEPROM or logic board):

When you replace the EEPROM, also replace all of the waste ink absorbers with new

ones.

If you do not replace the waste ink absorbers, the amount of waste ink in the waste

ink absorber will not match the waste ink amount (stored in EEPROM), and ink may

leak without the waste ink error being displayed.

The data in a replacement EEPROM is not defined. So, the EEPROM cannot be used

as it is. Initialize the EEPROM when you replace the waste ink absorbers. (For

details, see

"Part 3: 3.4.2 Service mode" (page 3-24)

). Then make a test printout, and

make sure that the EEPROM data has been defined.

For details on how to handle the EEPROM, see

"Part 3: 3.6 EEPROM" (page 3-27)

.

4) After replacing a full waste ink absorber:

After you have replaced the waste ink absorber, reset the total waste ink amount by

clearing the EEPROM's waste ink level (for details, see

"Part 3: 3.4.2 Service mode" (page

3-24)

). Then make a test printout, and make sure that the waste ink amount has

been reset to zero. (For details, see

"Part 3: 3.6.3 EEPROM list print" (page 3-28)

)

5) If

the total waste ink amount is reset to zero, or the EEPROM is initialized by

mistake:

Take care when you clear or initialize the EEPROM. Data settings stored in EEPROM

cannot be restored once the EEPROM is cleared. If you have cleared EEPROM by

mistake, carry out the same process and settings for a defective EEPROM described in

3) above.

After the EEPROM is reset, the data it held cannot be printed out with a

test printout. If you want to check the stored data, be sure to execute a

test printout before resetting the EEPROM. Data in EEPROM also cannot

be rewritten via computer.

When the EEPROM is initialized, all data that was held in EEPROM is lost.

When you return the printer after servicing, reset the various function

settings (e.g. head position adjustment values) that were set by the user.

1-13

BJC-8500

Part 1: Safety and Precautions

When the printer is turned OFF, the printer updates the waste ink amount

in EEPROM. To prevent ink leakage when the waste ink amount exceeds

the capacity of the waste ink absorber, the printer stops printing and

displays a "waste ink full" error. If this happens, remedy the error by

following the instructions in

"Part 5: 6.2.2 Error recovery 5. Waste Ink Warning

/ Waste Ink Full Error" (page 5-21)

.

For details on checking the EEPROM data with a test printout, see

"Part 3:

3.6.3 EEPROM list print" (page 3-28)

.

When you clear EPPROM data, you can choose either to "clear the waste

ink amount" or to "initialize EEPROM." For details, see

"Part 3: 3.6.2

Resetting the EEPROM" (page 3-27).

3.2 Special Settings

The printer driver has a special settings dialog box. This dialog box is only for servicing

and dealing with claims on the market. It is not disclosed to the user.

(1) Operation Procedure

In Windows:

• Select the [Custom Setting] button in Maintenance on the printer driver. You can

select the "Set printer to ECP mode" and "Pause page" setup items. ➝ not

disclosed to the user

• If you select the [Custom Setting] button with the [Shift] key held down, you can

select all five setup items in (2) below.

On a Macintosh:

• Select the [Settings] button in Utility on the printer driver. You can select the

"Pause Between Pages" setup item.➝ not disclosed to the user

• If you select the [Settings] button with the [Shift] key held down, you can select four

setup items (excluding "Set printer to ECP mode") in (2) below.

(2) Setup Items (underline indicates default ON= , OFF= )

• Set printer to ECP mode (OFF/ON)

Sets the printer interface to ECP.

• Pause Page (OFF/ON)

When pages containing high-density images are printed continuously, the preceding

page may become smudged by the following page if you do not allow enough time for

it to dry. In such circumstances, set whether or not to pause before outputting

pages.

• Cleaning after cartridge replacement (OFF/ON)

To prevent ink consumption, set not to perform cleaning when the head (BJ

cartridge) is replaced.

• Economy Cleaning (OFF/ON)

To prevent ink consumption, set not to perform cleaning at the first software ON

after a hardware ON and not to perform timer cleaning.

• Display low ink warning (OFF/ON)

Set not to display low ink warning (Disabling "ink-out" detection) to prevent the ink

sensors from malfunctioning.

Part 1: Safety and Precautions

BJC-8500

1-14

Loading...

Loading...