Canon BJC-8200 Service Manual

QY8-1369-000

REVISION 0

COPYRIGHT 1999 CANON INC. CANON BJC-8200 1199 SE 0.28-0 PRINTED IN JAPAN (IMPRIME AU JAPON)

NOV. 1999

1199 SE 0.28-0

Target Readers

This manual is published by Canon Inc. for qualified persons and contains the necessary technical

information for technical theory, installation, maintenance, and repair of products. This manual covers

all localities where the products are sold. For this reason, it may contain information that does not

apply to your locality.

Revisions

This manual may include technical inaccuracies or typographical errors due to improvements or

changes in the products. When amendments are made to the content of this manual, Canon will issue

technical information as the need arises. In the event of major alterations to the content of this manual

over a long or short period, Canon will publish a revised version of the manual.

The following paragraphs do not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names appearing in this manual are the registered trademarks or

trademarks of the individual companies.

Copyright

This manual is copyrighted and all rights reserved. Under the copyright laws, this manual may not be

copied, reproduced, or translated into other languages, in whole or in part, without the express written

consent of Canon Inc. except in the case of internal business use.

Copyright 1999 by Canon Inc.

CANON INC.

BJ Products Quality Support Dept.

16-1, Shimonoge 3-chome, Takatsu-ku, Kawasaki-shi, Kanagawa 213, Japan

This manual was produced on an Apple Macintosh Power Mac 9600/233 personal computer and Apple

LaserWriter II NTX-J laser beam printer; final pages were printed on Varityper 5300 with 4000-J RIP.

A Canon mo-5001S Magneto-Optical Storage Subsystem with mo-502M Magneto-Optical Storage Disk

Cartridge and mo-IF2 interface kit were used for storing large volumes of page layout and graphic data

for this manual.

All graphics were produced with MACROMEDIA FREEHAND 7.0J.

All documents and all page layouts were created with QuarkXPress 3.3J.

I

PRODUCT

SPECIFICATION

MAINTENANCEOPERATIONTROUBLE

SHOOTING

REFERENCE

I. ABOUT THIS MANUAL

This manual is divided into five parts containing the information required for servicing the

BJC-8200 printer.

Part 1: PRODUCT SPECIFICATIONS

This part outlines the product and its specifications.

Part 2: MAINTENANCE

This part explains maintenance of the unit. It includes precautions and details for

disassembly and assembly, and adjustments required when assembling.

Part 3: OPERATION

This part explains how to operate the unit properly, and how to use the service mode.

Part 4: TROUBLESHOOTING

This part explains how to resolve problems of the unit, and contains information on

how to locate and replace serviceable units and parts. It is divided into two sections:

"Troubleshooting by Errors" and "Troubleshooting by Symptoms."

Part 5: REFERENCE

This part outlines the unit operation giving technical information on hardware, and

contains block diagrams, pin assignments, and wiring/circuit diagrams.

This manual does not contain complete information required for

disassembling and assembling the BJC-8200 printer. Please also refer to the

separate Parts Catalog.

REF

II. TABLE OF CONTENTS

Page

Part 1: PRODUCT SPECIFICATIONS

1 - 1 1. PRODUCT OUTLINE

1 - 1 1.1 Product Outline

1 - 2 1.2 Features

1 - 3 2. SPECIFICATIONS

1 - 3 2.1 Main Unit Specifications

1 - 3 2.1.1 Main unit specifications

1 - 3 2.1.2 Product life

1 - 4 2.2 Paper Specifications

1 - 4 2.2.1 Paper sizes

1 - 4 2.2.2 Paper measurement

1 - 4 2.2.3 Printable area

1 - 4 2.3 BJ Cartridge

1 - 6 2.4 Interface Specifications

1 - 6 2.4.1 Parallel interface

1 - 6 2.4.2 Serial (USB) interface

1 - 7 2.5 Printer Driver

1 - 7 2.6 Scanner Cartridge IS-52 (Optional)

1 - 8 3. NAMES OF PARTS AND THEIR FUNCTIONS

1 - 8 3.1 Names of Parts and Their Functions

Part 2: MAINTENANCE

2 - 1 1. PERIODICAL REPLACEMENT/MAINTENANCE

2 - 1 1.1 Parts for Periodic Replacement

2 - 1 1.2 List of Periodic Maintenance

2 - 2 2. DISASSEMBLY AND REASSEMBLY

2 - 2 2.1 List of Tools

2 - 3 2.2 Operation Precautions

2 - 3 2.2.1 Ink paths

2 - 4 2.2.2 Ink mist

2 - 4 2.2.3 Precautions for damage due to static electricity

2 - 5 2.2.4 Precautions for transporting the printer

2 - 5 2.2.5 Precautions on spur tip deformation

2 - 6 2.3 Precautions for Disassembling and Reassembling the Printer

2 - 6 2.3.1 Unlocking the carriage

2 - 6 2.3.2 Removing/installing self tap screws

2 - 7 2.3.3 Adjustable bushings supporting the carriage shaft

2 - 7 2.3.4 Feed gear

2 - 8 2.4 Grease Application

2 - 9 2.5 Adjustment/Setting Procedures

2 - 9 2.5.1 Adjustments (Timing, adjustment, time, tool)

2 - 9 2.5.2 Cleaning the pick-up roller

2 -10 2.5.3 Print head position adjustment

2 -11 2.5.4 Setting the EEPROM

2 -12 3. OPERATION CHECK AFTER DISASSEMBLING/REASSEMBLING

2 -12 3.1 Confirmation Methods

2 -13 4. TRANSPORTING THE PRINTER

2 -13 4.1 Transporting the Printer

Page

Part 3: OPERATION

3 - 1 1. FUNCTIONS RELATED TO PRINTER OPERATION

3 - 1 1.1 Error Display

3 - 3 1.2 Descriptions of Error Indications

II

Page

3 - 4 1.3 BJ Status Monitor

3 - 4 1.3.1 Main functions of the BJ status monitor

3 - 4 1.3.2 Items displayed on the BJ status monitor

3 - 5 1.4 Function Settings

3 - 5 1.4.1 Function settings using the printer driver

3 - 6 1.5 Off-line Operation

3 - 6 1.5.1 Cleaning operation

3 - 6 1.5.2 Nozzle check pattern printing

3 - 7 1.5.3 Replacing the cartridge/ink tank

3 - 8 2. SERVICE MODE

3 - 8 2.1 Service Mode Operations

3 - 9 2.2 Service Test Print

3 -10 2.3 Printing EEPROM Information

3 -11 2.4 Resetting the EEPROM

3 -11 2.5 Setting the Waste Ink Counter

3 -12 2.6 Setting the Model

3 -12 2.7 Adjusting the Head Position

3 -13 2.8 Roller Cleaning

Part 4: TROUBLESHOOTING

4 - 1 1. TROUBLESHOOTING BY DISPLAYED ERRORS

4 - 1 1.1 Initial Flowchart

4 - 4 1.2 Error List (Indicator/Beeper/Error Code)

4 - 5 1.3 Troubleshooting by Errors

4 -14 2. TROUBLESHOOTING BY SYMPTOMS

4 -14 2.1 Troubleshooting by Symptoms

Part 5: REFERENCE

5 - 1 1. TECHNICAL REFERENCE

5 - 1 1.1 Functions of the Paper Feed Unit

5 - 2 1.2 Carriage Function

5 - 3 1.3 Purge Unit Functions

5 - 4 1.4 BJ Cartridge

5 - 5 1.5 Detection With Sensors

5 - 6 2. CONNECTOR POSITIONS AND PIN ASSIGNMENT

5 - 6 2.1 Logic Board

5 -10 2.2 Carriage Board

5 -13 2.3 BJ Cartridge

5 -14 2.4 Scanner Cartridge

5 -15 2.5 AC Adapter

5 -15 2.6 DC Power Cable

5 -16 2.7 Carriage Motor

5 -16 2.8 Paper Feed Motor

5 -16 2.9 Purge Motor

5 -17 2.10Ink Sensor

5 -17 2.11Paper Thickness Sensor

5 -17 2.12Purge Sensor

5 -18 3. CIRCUIT DIAGRAM

5 -18 3.1 Parts Layout

5 -18 3.1.1 Logic board

5 -20 3.1.2 Carriage board

5 -21 3.2 Circuit Diagrams

III

III. ILLUSTRATION INDEX

Page

Part 1: PRODUCT SPECIFICATIONS

1 - 1 Figure 1- 1 Printer Appearance

1 - 5 Figure 1- 2 Printable Area

1 - 8 Figure 1- 3 Names of Parts and Their Functions

Part 2: MAINTENANCE

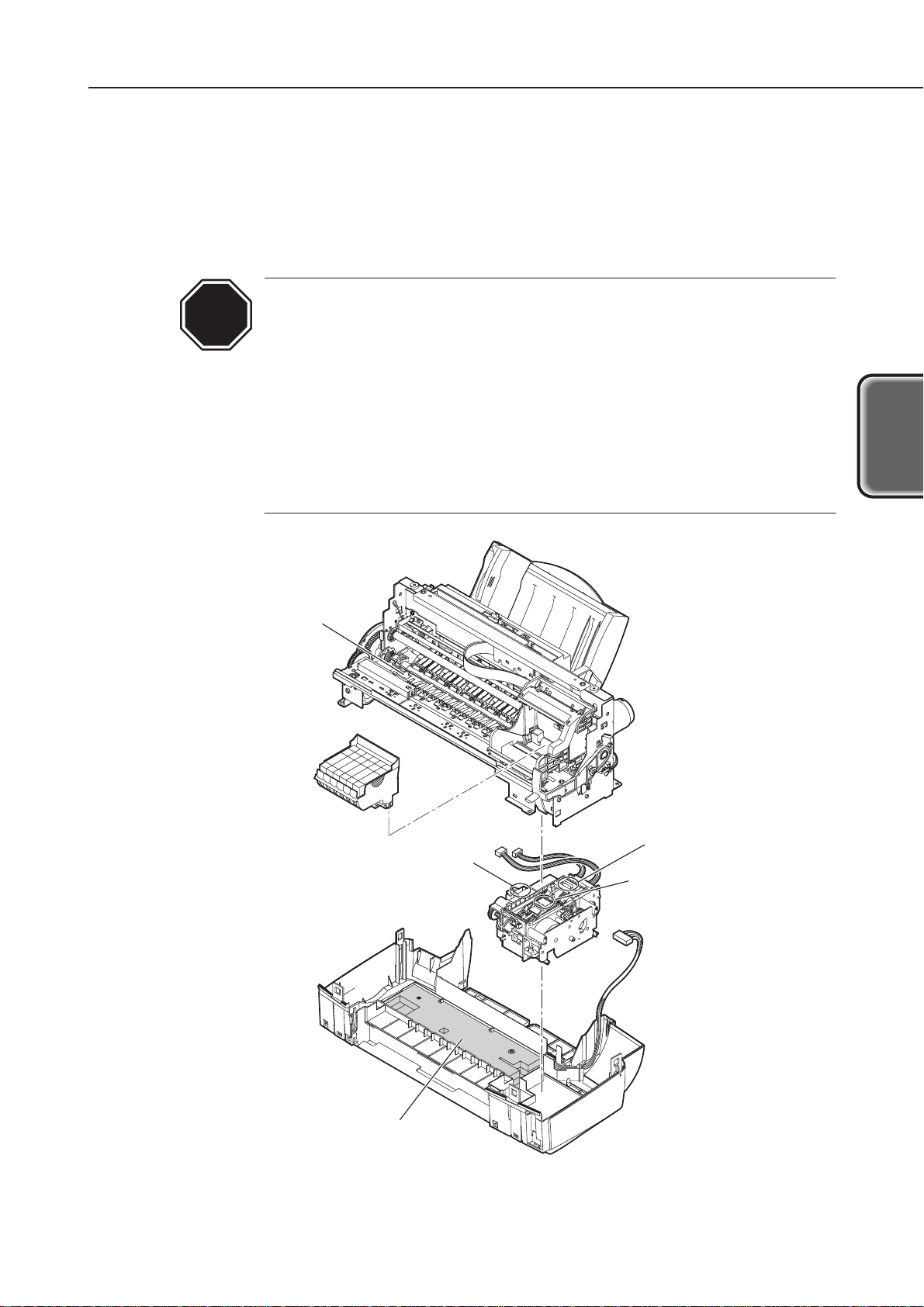

2 - 3 Figure 2- 1 Ink Paths

2- 4 Figure 2- 2 Ink Mist

2 - 5 Figure 2- 3 Capping Position

2 - 5 Figure 2- 4 Spur Unit

2 - 6 Figure 2- 5 Unlocking the Carriage

2 - 7 Figure 2- 6 Adjustable Bushings Supporting the Carriage Shaft

2 - 7 Figure 2- 7 Precautions on Feed Gears

2 - 8 Figure 2- 8 Grease Points

2 -10 Figure 2- 9 Print Position Adjustment Pattern

Part 3: OPERATIONS

3 - 1 Figure 3- 1 Operation Panel

3 - 4 Figure 3- 2 BJ Status Monitor (Sample)

3 - 5 Figure 3- 3 Printer Driver Utility (Sample)

3 - 7 Figure 3- 4 Nozzle Check Pattern Print

3 - 9 Figure 3- 5 Service Test Print (Sample)

3 -10 Figure 3- 6 EEPROM Information Print (Sample)

3 -11 Figure 3- 7 A Guide to Determine the Amount of Waste Ink Absorbed (Sample)

3 -13 Figure 3- 8 Head Position Adjustment Pattern (Sample)

Part 5: REFERENCE

5 - 1 Figure 5- 1 Paper Feed Path

5 - 2 Figure 5- 2 Carriage Unit

5 - 3 Figure 5- 3 Purge Unit

5 - 4 Figure 5- 4 BJ Cartridge

5 - 5 Figure 5- 5 Sensor Position

5 - 6 Figure 5- 6 Logic Board

5 - 6 Figure 5- 7 Block Diagram

5 -10 Figure 5- 8 Carriage Board

5 -13 Figure 5- 9 BJ Cartridge

5 -14 Figure 5- 10 Scanner Cartridge

5 -15 Figure 5- 11 AC Adapter

5 -15 Figure 5- 12 DC Power Cable

5 -16 Figure 5- 13 Carriage Motor

5 -16 Figure 5- 14 Paper Feed Motor

5 -16 Figure 5- 15 Purge Motor

5 -17 Figure 5- 16 Ink Sensor

5 -17 Figure 5- 17 Paper Thickness Sensor

5 -17 Figure 5- 18 Purge Sensor

5 -18 Figure 5- 19 Logic Board (Top View)

5 -19 Figure 5- 20 Logic Board (Bottom View)

5 -20 Figure 5- 21 Carriage Board

IV

IV. TABLE INDEX

Page

Part 3: OPERATION

3 - 2 TABLE3- 1 ERROR DISPLAY

Part 4: TROUBLESHOOTING

4 - 4 TABLE4- 1 ERROR DISPLAY

Part 5: APPENDIX

5 - 3 TABLE5- 1 AMOUNTS OF INK USED DURING CLEANING (GUIDE)

V

VI

This page intentionally left blank

Page

1 - 1 1. PRODUCT OUTLINE

1 - 1 1.1 Product Outline

1 - 2 1.2 Features

1 - 3 2. SPECIFICATIONS

1 - 3 2.1 Main Unit Specifications

1 - 4 2.2 Paper Specifications

1 - 4 2.3 BJ Cartridge

1 - 6 2.4 Interface Specifications

1 - 7 2.5 Printer Driver

1 - 7 2.6 Scanner Cartridge IS-52 (Optional)

1 - 8 3. NAMES OF PARTS AND THEIR FUNCTIONS

1 - 8 3.1 Names of Parts and Their Functions

Part 1

PRODUCT

SPECIFICATIONS

1. PRODUCT OUTLINE

1.1 Product Outline

This printer, with ultra small 4-pl ink droplets and new light-and-dark ink system,

delivers graininess-free, photographic-quality, high-resolution images.

In addition, the support of a high-resolution scanner cartridge and adapter for direct

connection to digital cameras, as optional equipment, and the USB interface as

standard equipment, prove this printer a highly value-added product.

This printer is intended to increase the market share where photo-realistic output is

demanded, targeting users who need excellent photographic quality printing.

1-1

BJC-8200

Part 1: PRODUCT SPECIFICATIONS

PRODUCT

SPECIFICATION

Figure 1-1 Printer Appearance

Operation Panel

Paper

Paper Guide

Front Cover

Paper Output Tray

Auto Sheet Feeder

Parallel Interface Connector

Paper Thickness Lever

BC-50

BJ Cartridge

Optional Scanner

IS-52

Scanner Cartridge

USB Interface Connector

Cartridge Container

(Supplied with Scanner Cartridge)

1.2 Features

1) Highest resolution photo imaging without any graininess. (4-pl ink droplets; new

light-and-dark ink with light ink density of 1/6.)

2) Optionally available 600 dpi scanner cartridge.

3) Both IEEE1284-compatible, 8-bit parallel interface and USB interface, as standard

equipment.

4) Individually replaceable ink tanks for each color for reduced running costs.

5) Ink-low detection using both optical and dot-counting systems and translucent ink

tanks allow visual checking of the ink level.

6) A mechanism to allow manual correction of print position misalignment of each

color, as well as in bi-directional printing.

7) A function to notify of the optimum head gap setting of the paper thickness lever.

Part 1: PRODUCT SPECIFICATIONS

BJC-8200

1-2

2. SPECIFICATIONS

2.1 Main Unit Specifications

2.1.1 Main unit specifications

Type Desktop serial printer

Paper feeding method Automatic and manual feeding

Resolution 1200dpi x 1200dpi (maximum resolution)

Throughput Draft Standard High

(Reference values) Bk (PC Magazine) 3.15 2.24 0.37

ppm Color (A4 Full Page) 2.0 1.4 0.26

Color (New Pattern) 2.0 1.4 0.26

Printing direction 1-pass/bidirectional

2-pass/unidirectional

4-pass/bidirectional

4-pass/unidirectional

8-pass/bidirectional

Automatically switched over by driver, corresponding to

selected media and print quality.

Printing width 203.2 mm

Line feed speed 161ms/line (for 256/1200-inch feed)

Interface IEEE 1284-compatible 8-bit parallel interface

(Compatible/nibble/ECP)

USB (without hub function)

ASF capacity Up to 10 mm (Approx. 100 sheets of 75 g/m2paper)

Detection functions Cover open Yes

BJ cartridge installed Yes

Scanner cartridge installed Yes

Cartridge correctly installed Yes

Ink-out Yes

Paper-detection Yes

Waste ink full Yes

Paper width detection No

Acoustic noise during Approx. 37 dB(A) (For 8-pass printing with a sheet feeder

operation full of paper) (Sound pressure level: compliant with

ISO9296)

Environmental conditions Operation Temperature: 5 to 35°C

Humidity: 10-90% RH (No condensation)

Standby Storage: 0-35°C

Humidity: 10-90% RH (No condensation)

Power supply Voltage/frequency Power consumption At standby

AC100-120V 50/60Hz 23W (max.) 8W

AC200-240V 50/60Hz 23W (max.) 8W

External dimension 450 mm (W) x 327 mm (D) x 204 mm (H)

Weight Approx. 5.9 Kg (Excluding BJ cartridge)

Certification Electromagnetic radiance: VCCI, FCC, IC, CE Mark, EMC

(Taiwan), C-tick

Electrical safety: Electrical Safety Regulations, UL, C-UL,

CB Report, CE Mark, FIMCO, GS,

GCIB, SISIR, AS, Electrical Safety

Regulations of Korea

Environmental regulations: Blue Angel, Energy Star

Optional parts Scanner cartridge (See Page 1-7)

2.1.2 Product life

Product life is either of the following periods, whichever is shortest.

(1) From the start of use until 15,000 sheets has been fed.

(2) From the start of use until 5 years lapses.

1-3

BJC-8200

Part 1: PRODUCT SPECIFICATIONS

PRODUCT

SPECIFICATION

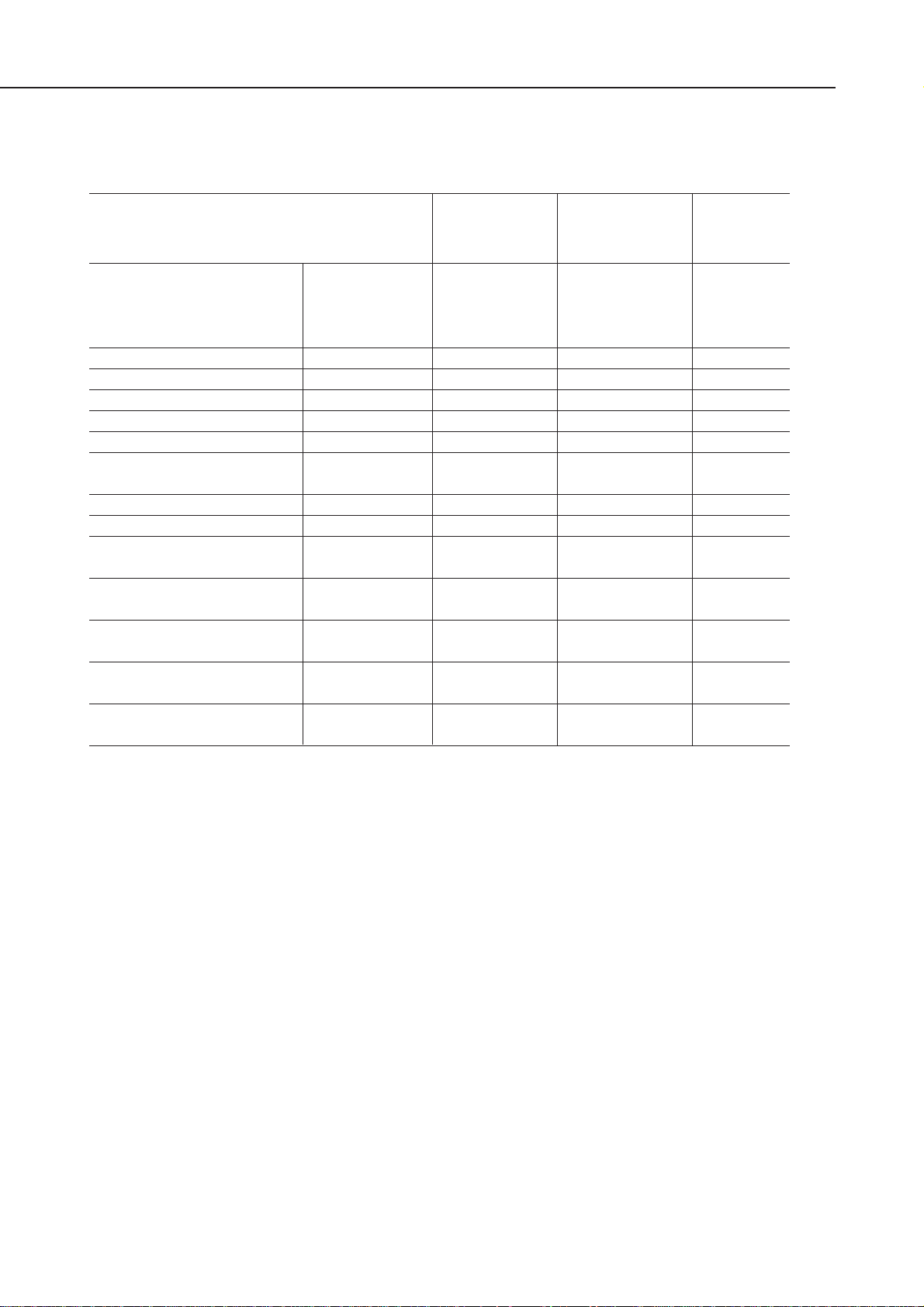

2.2 Paper Specifications

2.2.1 Paper sizes

Canon recommends the following papers:

Paper type Size Stacked in the Paper

ASF thickness

lever

position

Plain paper Measurement: A4/B5/A5/ 10 mm or less Up

64-90 g/m

2

LTR/LGL (Approx. 100

sheets of

75-g/m2paper)

Color BJ paper LC-301 A4/B5 75 sheets Up

High-resolution paper HR-101 A4/B5/LTR 80 sheets Up

Glossy photo paper GP-301 A4/LTR 10 sheets* Up

Glossy photo film HG-201 A4/LTR 1 sheet Up

OHP film CF-102 A4/LTR 10 sheets** Up

BJ cloth FS-101 (L)356 x 1 sheet Down

(W)251 mm

Banner paper BP-101 A4/LTR 1 sheet Down

T-shirt transfer TR-201 A4/LTR 1 sheet Up

Glossy photo card FM-101 (L)216 x 1 sheet*** Up

(W)119 mm

Envelope COM#10 (L)105 x 10 sheets or less Down

(W)241 mm

DL (L)110 x 10 sheets or less Down

(W)220 mm

Photo paper pro PR-101 A4/LTR 1 sheet* Up

Thick paper Measurement: A4/LTR Manual feed Down

91-500 g/m

2

only

* Always use GP-301/PR-101 with the cleaning plate underneath it.

** Always use OHP film with a sheet of plain paper beneath it.

*** Always use glossy photo paper with the associated auxiliary sheet beneath it.

2.2.2 Paper measurement

Automatically-fed paper 64-90 g/m

2

Manually-fed paper 64-500 g/m2(up to 0.6 mm)

2.2.3 Printable area

Refer to Figure 1-2 Printable Area.

2.3 BJ Cartridge

Construction 6 color integrated head, with separately-replaceble ink tanks for

each color

Print head 256 x 6 nozzles (Placed in line for each color)

Ink color BK, C, M, Y, Photo-C, Photo-M

Ink tank 6 separate tanks (One tank for each color)

Weight Approx. 80 g (excluding ink tanks)

Cartridge life

5000 sheets (7.5%-duty print pattern) or 2 years in box/1 year out of box.

Print capacity Approx. 240 sheets/tank (7.5%-duty print pattern)

Note) The BJ head, available as a consumable part, does not include ink tanks.

Part 1: PRODUCT SPECIFICATIONS

BJC-8200

1-4

1-5

BJC-8200

Part 1: PRODUCT SPECIFICATIONS

PRODUCT

SPECIFICATION

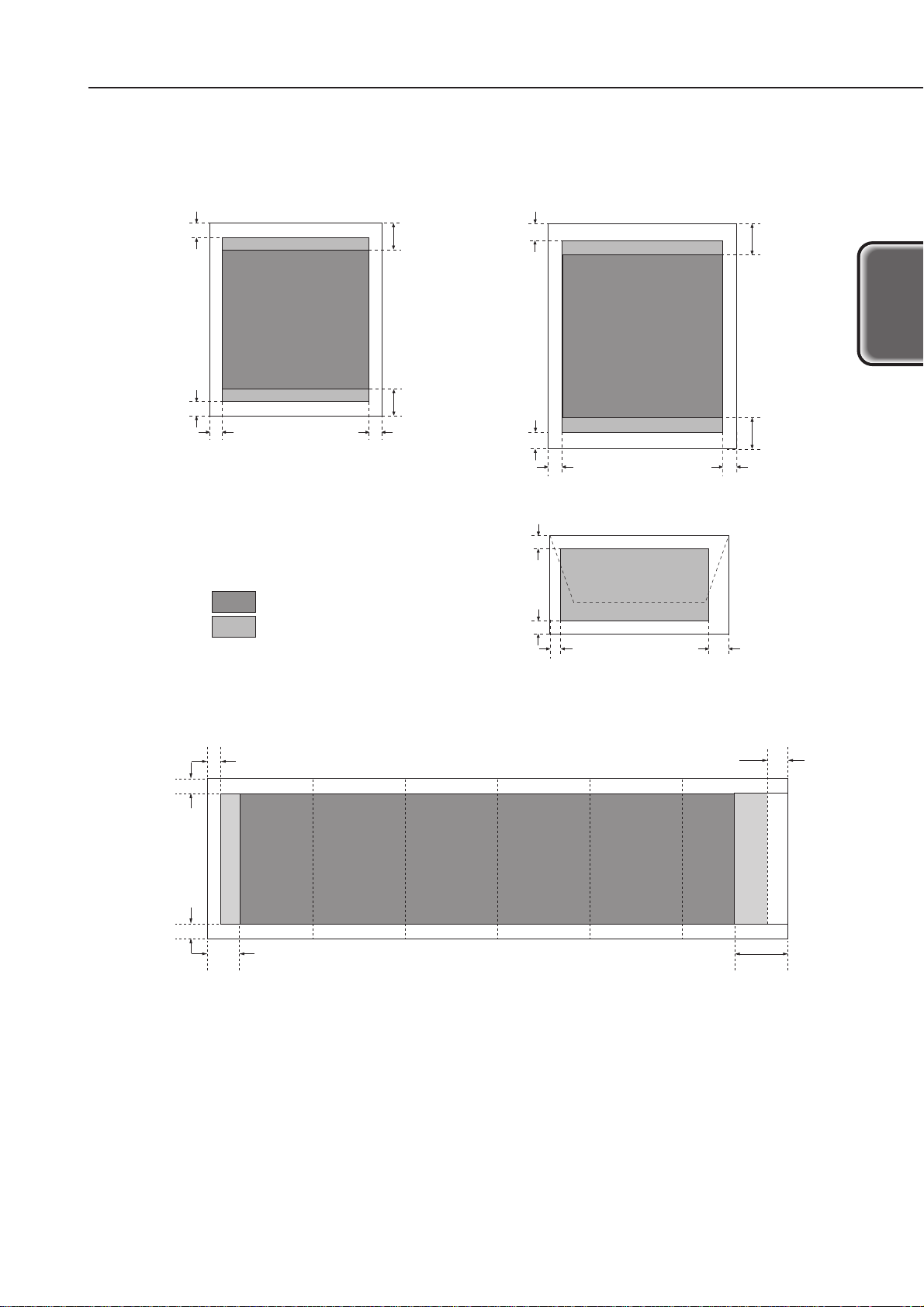

Figure 1-2 Printable Area

3.0mm

5.0mm

A4/A5/B5 Size

3.4mm

3.4mm

:Recommended printing area

:Printable area

28.0mm

20.0mm

Letter (LTR)/Legal (LGL) Size

3.0mm

5.0mm

6.4mm 6.4mm

Envelope

3.0mm

5.0mm

6.4mm

COM#10: 30.4mm

DL : 9.4mm

28.0mm

20.0mm

3.4mm

3.4mm

Banner Paper

3.0mm

5.0mm

123456

28.0mm

*: For 6-page printing

20.0mm

2.4 Interface Specifications

2.4.1 Parallel interface

1) Interface type

IEEE 1284 compatible parallel interface

2) Data transfer:

8-bit parallel transfer method (Compatible/nibble/ECP mode supported)

3) Signal voltage levels

Input: "Low" level: 0.0V to +0.8V

"High" level: +2.4V to +5.0V

Output: "Low" level: 0.0V to +0.8V

"High" level: +2.4V to +5.25V

4) Input/Output

Each signal pulled up with +5V

5) Interface cable

Twisted-pair double shielded cable

Material: AWG No. 28 or higher (AWG: American Wire Gauge)

Length: Up to 2.0 m.

6) Interface connector:

Printer-side Amphenol 57-40360 (or equivalent)

Cable-side Amphenol 57-30360 (or equivalent)

7) Input/Output signal and pin arrangements

Refer to

Part 5: 2. CONNECTOR POSITIONS AND PIN ASSIGNMENT

(Page 5-6) for

details.

2.4.2 Serial (USB) interface

1) Interface type

USB Interface (Universal Serial Bus; USB Specification Release 1.0)

2) Data transfer:

Control transfer method

Bulk transfer method

3) Signal voltage level

Input:

Input difference sensitivity: +0.2V (Max)

Common-mode difference: +0.8V to +2.5V

Output:

Static output high: +2.8V to +3.6V

Static output low: 0.0V to +0.3V

4) Input/Output

Each signal pulled up with 3.3V

5) Interface cable

Cable Twisted pair shielded cable, up to 2.0 m

Full-speed mode must be supported.

Material: AWG No. 28 or higher (AWG: American Wire Gauge)

6) Interface connector

Printer-side USB standard, Series B receptacle

Cable-side USB standard, Series B plug

7) Input/Output signal and pin arrangements

Refer to

Part 5:2. CONNECTOR POSITIONS AND PIN ASSIGNMENT

(Page 5-6) for

details.

Part 1: PRODUCT SPECIFICATIONS

BJC-8200

1-6

2.5 Printer Driver

The drivers that can be used for this printer:

1) For Windows:

Raster driver (For Win3.1/95/98)

Raster driver (For Win NT4.0/(5.0))

2) For Macintosh:

Macintosh driver for USB I/F

Serial I/F drivers are not available.

2.6 Scanner Cartridge IS-52 (Optional)

Type Cartridge replacement type color scanner

Light source 3 LED's for RGB

Resolution 600x600, 300x300, 200x200, 150x150, and 75x75 dpi

Paper width 208.2mm

Scannable band width Up to 10.8mm

Paper thickness Up to 0.25mm

Operation environment OS: Win98/95/NT4.0, Mac OS 8.1 or later

I/F: Parallel (IEEE1284-compliant)/USB

Memory: 8MB (16MB or more recommended.)

Unused Disk space: (50MB at least)

Life span 1200 sheets (A4 paper)

1-7

BJC-8200

Part 1: PRODUCT SPECIFICATIONS

PRODUCT

SPECIFICATION

3. NAMES OF PARTS AND THEIR FUNCTIONS

3.1 Names of Parts and Their Functions

The following shows the names of the printer parts and their major functions:

Part 1: PRODUCT SPECIFICATIONS

BJC-8200

1-8

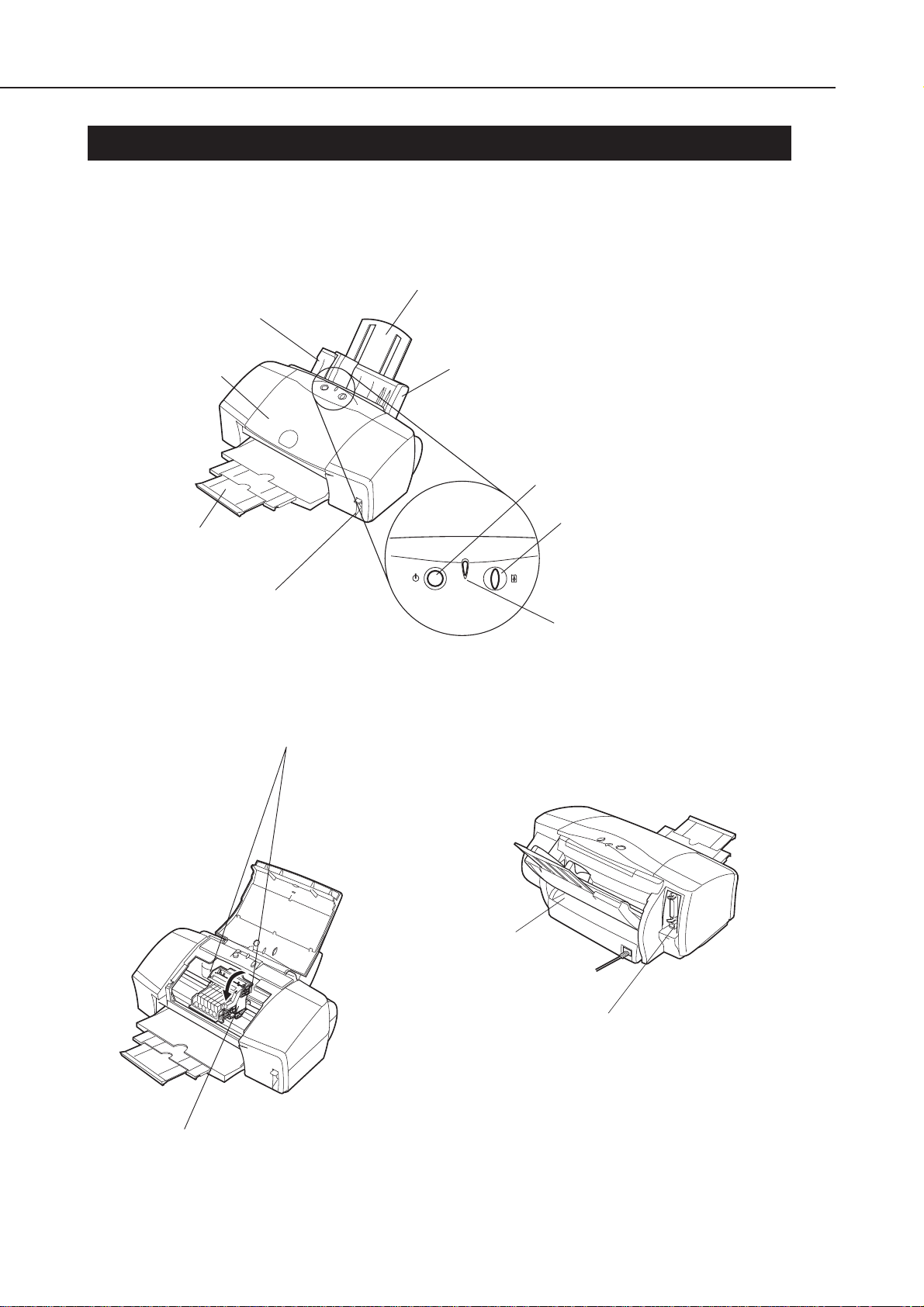

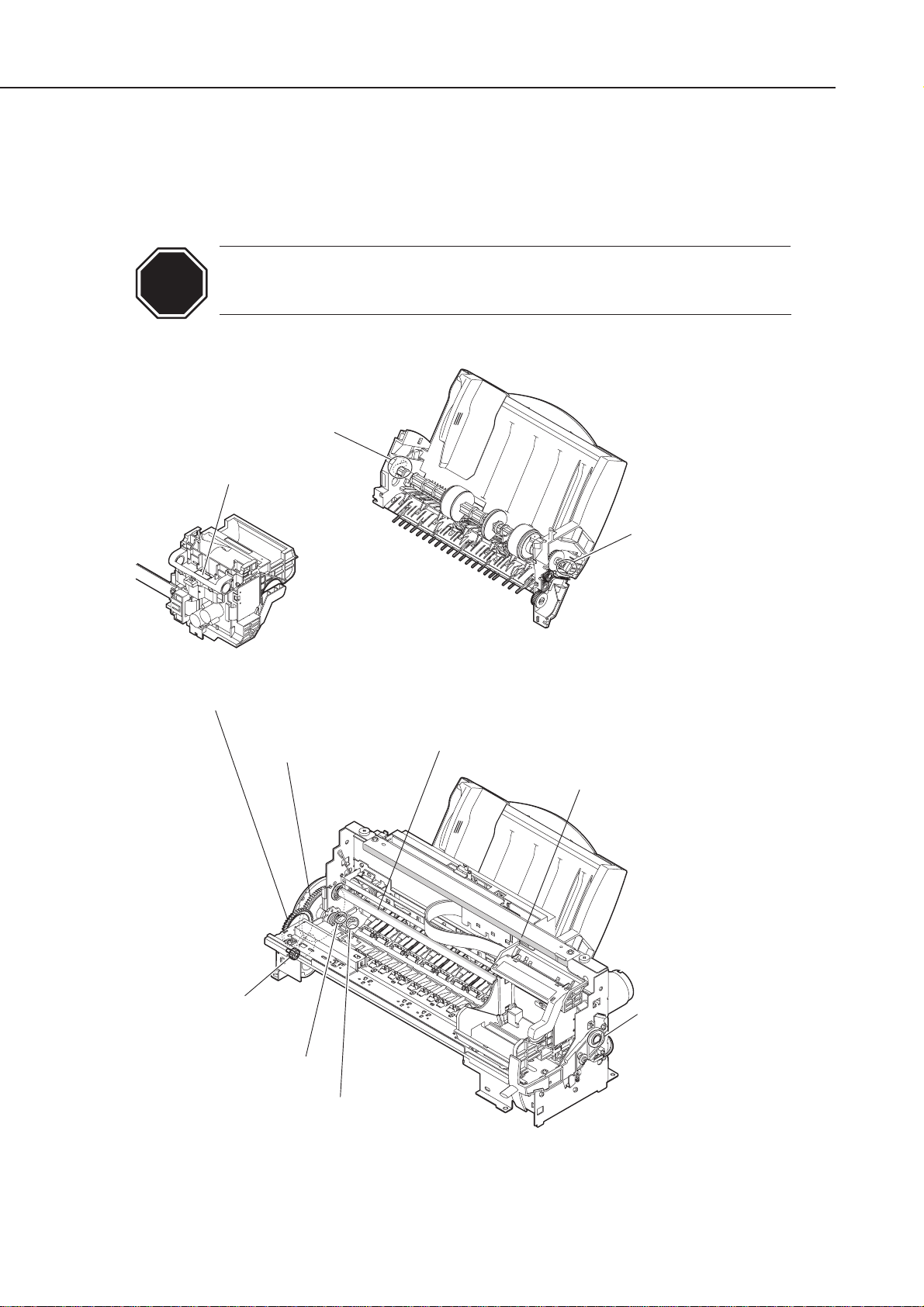

Figure 1-3 Names of Parts and Their Functions

Paper Guide

Lightly press this guide against

the left side of paper sheets to

align them.

Front Cover

Open this cover when

replacing the BJ cartridge or

clearing paper-jams.

Paper Output Tray

Allows smooth ejection

of paper and reduces

paper friction.

Paper Support

Extend this paper rest to support

larger sized paper.

Auto Sheet Feeder (ASF)

Set paper here. You can set multiple sheets;

each sheet is fed one by one.

POWER Button

Press this button to power on or

off the printer.

RESUME Button

After correcting a problem,

press this button to make the

printer ready.

Paper Thickness Lev er

Allows you to adjust the gap

between the print head and paper

surface by raising this lever up

and down.

The illustration shows the lever

in the "Up" position.

Cartridge Lock Lever

Use this lever to secure the BJ

cartridge in the carriage.

Raise it to remove the BJ cartridge.

Operation Panel

Manual Paper Feed Slot

To feed paper manually,

insert paper here.

Interface Connector

Connects to the interface cable

from the computer.

Two types of connector interfaces are provided:

USB and parallel.

Indicator

Not lit when powered off.

When lit in green, the printer

is ready to print.

When lit or blinking in orange,

an error has occurred and the

printer cannot print.

Carriage

Either BJ cartridge or optional Scanner cartridge

is installed.

Page

2 - 1 1. PERIODICAL REPLACEMENT/MAINTENANCE

2 - 1 1.1 Parts for Periodic Replacement

2 - 1 1.2 List of Periodic Maintenance

2 - 2 2. DISASSEMBLY AND REASSEMBLY

2 - 2 2.1 List of Tools

2 - 3 2.2 Operation Precautions

2 - 6 2.3 Precautions for Disassembling and Reassembling the Printer

2 - 8 2.4 Grease Application

2 - 9 2.5 Adjustment/Setting Procedures

2 -12 3. OPERATION CHECK AFTER DISASSEMBLING/REASSEMBLING

2 -12 3.1 Confirmation Methods

2 -13 4. TRANSPORTING THE PRINTER

2 -13 4.1 Transporting the Printer

Part 2

MAINTENANCE

1. PERIODICAL REPLACEMENT/MAINTENANCE

1.1 Parts for Periodic Replacement

Level Parts for periodical replacement

User None

Service personnel None

Level Consumable

User BJ cartridge (Ink tanks not included)

Ink tank (Black)

Ink tank (Cyan)

Ink tank (Magenta)

Ink tank (Yellow)

Ink tank (Photo cyan)

Ink tank (Photo magenta)

Service personnel None

1.2 List of Periodic Maintenance

Level Location

User None

Service personnel None

2-1

BJC-8200

Part 2: MAINTENANCE

MAINTENANCE

2. DISASSEMBLY AND REASSEMBLY

2.1 List of Tools

The following are the tools necessary for disassembly and reassembly:

Ordinary tools Note

Philips screwdriver For removing and replacing screws

Blade screwdriver For removing plastic parts

Long-nose pliers For removing and replacing springs

Tweezers For removing and installing flexible cables

Flat brush For applying grease (one per grease type)

Multimeter For troubleshooting

Special tools (part No.) Note

Grease MOLYKOTE PG-641 To be applied to specified locations (See Page 2-8)

(CK-0562-000)

Grease EU-1 To be applied to the portion of the guide shaft which the

(QY9-0037-000) carriage slides over.

Part 2: MAINTENANCE

BJC-8200

2-2

2.2 Operation Precautions

2.2.1 Ink paths

Be careful not to touch the ink paths. Ink on hands could stain the printer, work

table, or clothes. The ink paths include the BJ cartridge ink tank outlet, the BJ

cartridge ink filters and nozzles, the maintenance jet receiving section, the head caps,

the wipers, and the waste ink absorber.

The ink is not harmful to the human body, but contains some organic

solvents.

Black, cyan, magenta, photo cyan, and photo magenta ink contain

glycerin 56-81-5, isopropyl alcohol 67-63-0, ethylene glycol 107-21-1, and

di-ethylene glycol 111-46-6 respectively. Yellow ink contains glycerin 5681-5 and isopropyl alcohol 67-63-0.

Be careful not to get the ink into your mouth or eyes. If the ink gets into

your eyes, wash with plenty of water and consult a doctor. In case a large

amount of ink has been swallowed, consult a doctor immediately. The ink

contains dyes. If clothing is stained with the ink, the ink may not be

removed completely.

2-3

BJC-8200

Part 2: MAINTENANCE

MAINTENANCE

Figure 2-1 Ink Paths

CAUTION

Maintenance

Jet Receiving

Section

BJ Cartridge

Maintenance

Jet Receiving

Section

Wiper

Head Cap

Waste Ink Absorber

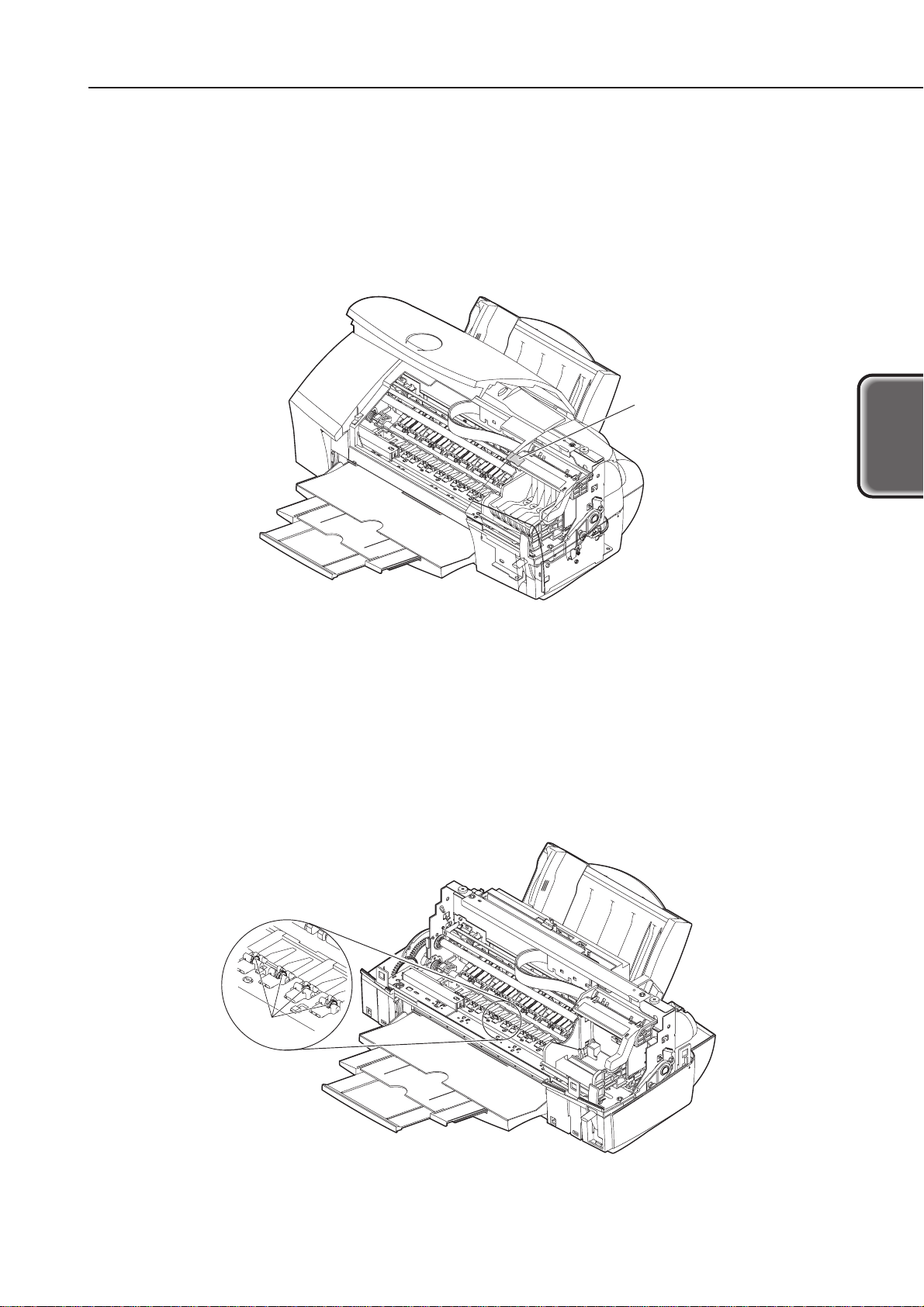

2.2.2 Ink mist

The BJ cartridge ejects ink onto the paper during printing. After the printer is used for

a long period or used heavily, the ink mist bouncing back from the paper could

accumulate and soil the front cover, platen, and the area around the operation panel,

purge unit, and paper output tray.

Carefully wipe off the ink mist with a soft dampened cloth so that hands or clothing

will not be stained by soiled parts during servicing.

Also, be careful not to smudge the pick roller when removing the upper cover.

2.2.3 Precautions for damage due to static electricity

Static electricity can be generated by clothing rubbing against each other and may

accumulate in the body. If you touch electrical elements, the discharge of static

electricity could damage them, or change their electrical characteristics. For this

reason, avoid touching the ink sensor contacts or the printer's BJ cartridge contacts.

Part 2: MAINTENANCE

BJC-8200

2-4

Figure 2-2 Ink Mist

Upper Cover

Front Cover

Around Operation Panel

Platen

Around Purge unit

Paper Output Tray

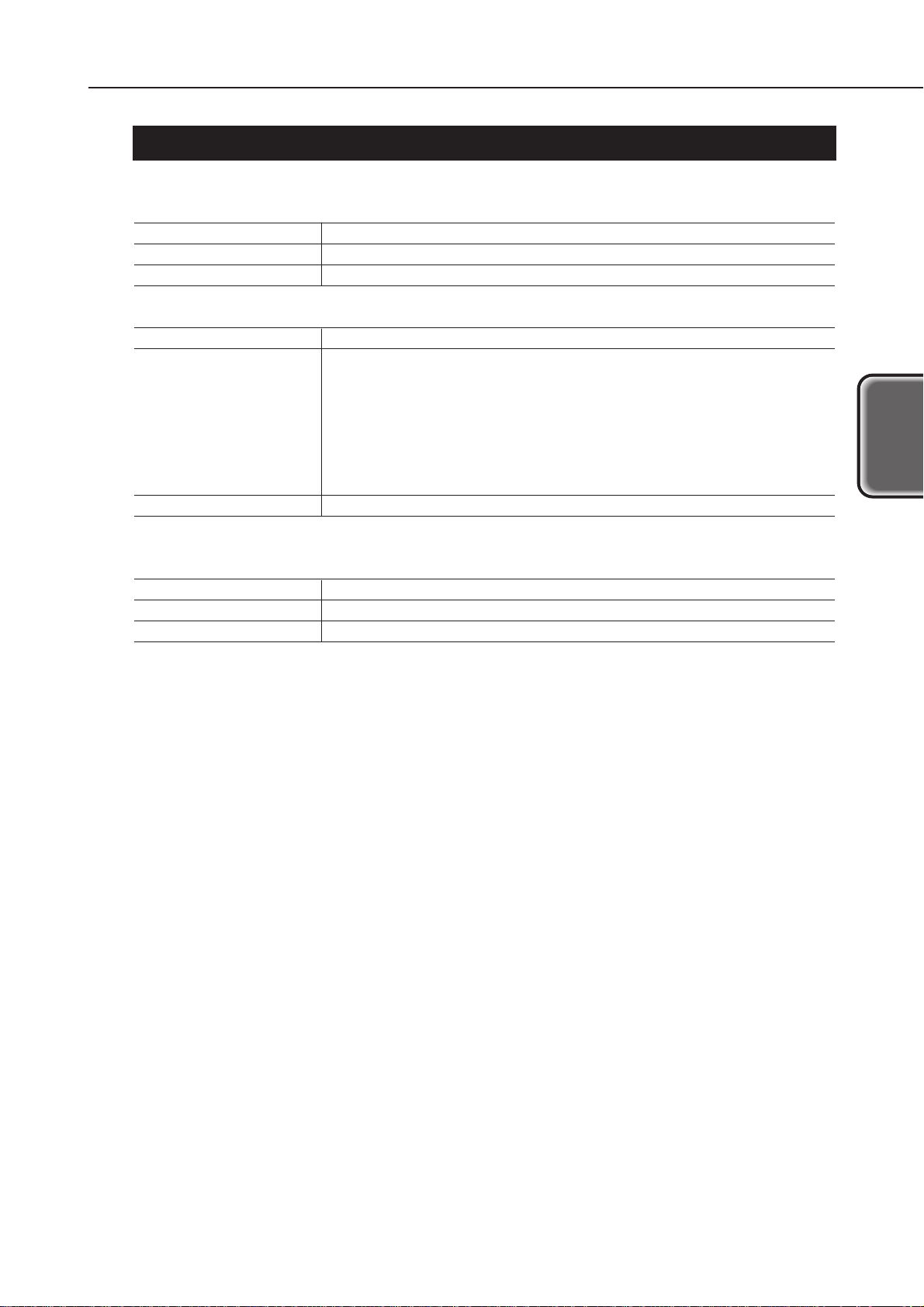

2.2.4 Precautions for transporting the printer

When turned off by the

POWER

button, the BJ cartridge is capped and the carriage is

locked in place at the capping position by the lock arm. When the printer cannot be

powered off by the

POWER

button for transportation, etc., move the carriage to the

capping position by hand and secure it with tape before transporting the printer.

Remove the ink tanks and keep them in a vinyl bag while the printer is being

transported.

2.2.5 Precautions on spur tip deformation

Take care not to bend the tips of the spurs. The tips of the spurs make contact with

printed paper and are contaminated with ink, but due to their small surface contact

area, the tips, cleaned by the spur cleaners, will not stain the printed paper. However,

if the tips are bent and their contact surface area increases, they collect more ink and

are not easily cleaned by the spur cleaners, and thereby stain the printed paper by

making dotted lines on it.

2-5

BJC-8200

Part 2: MAINTENANCE

MAINTENANCE

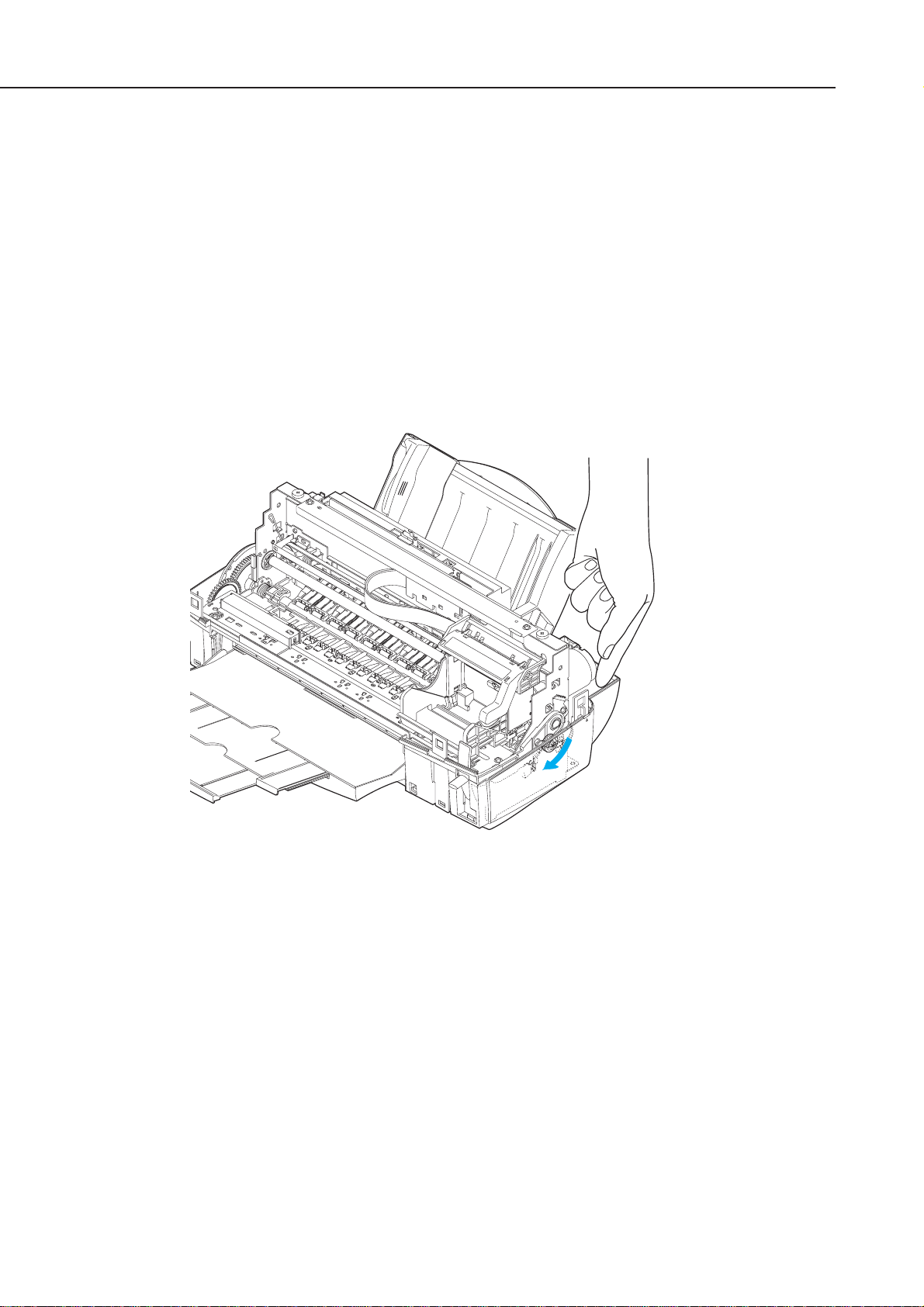

Figure 2-3 Capping Position

Figure 2-4 Spur Unit

Emergency Fixing Tape

Spurs

2.3 Precautions for Disassembling and Reassembling the Printer

Note the following when disassembling or reassembling the printer. When

disassembling or reassembling the printer, refer to the parts catalog. The numbers in

the parts catalog illustrations indicate the disassembly sequence.

2.3.1 Unlocking the carriage

When the printer is shipped from the factory (or when the cartridge is installed and

the power has been turned off normally), the carriage is locked in the capping position

to secure the cartridge during transportation.

When the printer is powered on properly, the carriage is unlocked automatically. If the

printer cannot be powered on normally, it will be necessary to manually unlock the

carriage. This can be done by turning the gear of the purge unit in the direction of the

arrow by finger, as shown in Figure 2-5 Unlocking the Carriage.

2.3.2 Removing/installing self tap screws

The printer unit is secured to the lower case with tap screws. Once the tap screws

have been removed, pieces of the molding remain attached to the screw threads.

Reinstalling the tap screws in this condition can damage the screw threads. To

prevent this, when reinstalling screws, remove the remains in advance or, where

possible, use new screws. Also, blow away any remains on the mold before reinstalling

the tap screws.

Part 2: MAINTENANCE

BJC-8200

2-6

Figure 2-5 Unlocking the Carriage

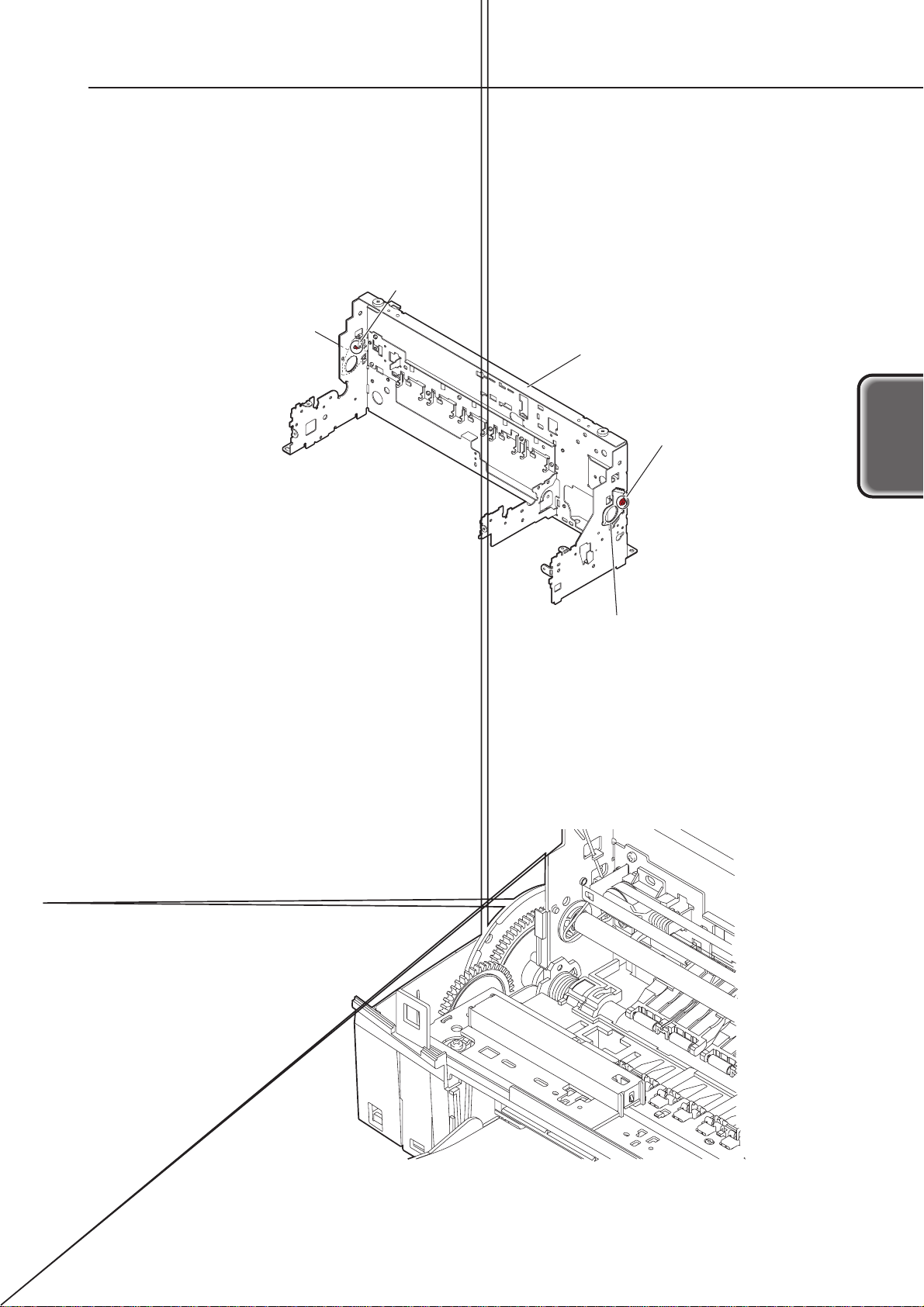

2.3.3 Adjustable bushings supporting the carriage shaft

The adjustable bushings supporting the carriage shaft are adjusted and secured to

the printer frame so that the ideal gap, or head gap, between the BJ cartridge nozzle

and platen is maintained for best print quality.

The fixing screws are painted red to protect against careless removal. Do not loosen

the fixing screws.

2.3.4 Feed gear

Be careful not to touch the gears in the paper feed unit, especially the feed roller gear,

during disassembling or reassembly. Although covered, even slight damage to it could

affect paper feeding when printing at high resolution.

2-7

BJC-8200

Part 2: MAINTENANCE

MAINTENANCE

Figure 2-6 Adjustable Bushings Supporting the Carriage Shaft

Figure 2-7 Precautions on Feed Gears

Fixing Screw

Adjustable Bushing

Supporting the Carriage

Shaft

Printer Frame

Fixing Screw

Adjustable Bushing

Supporting the Carriage

Shaft

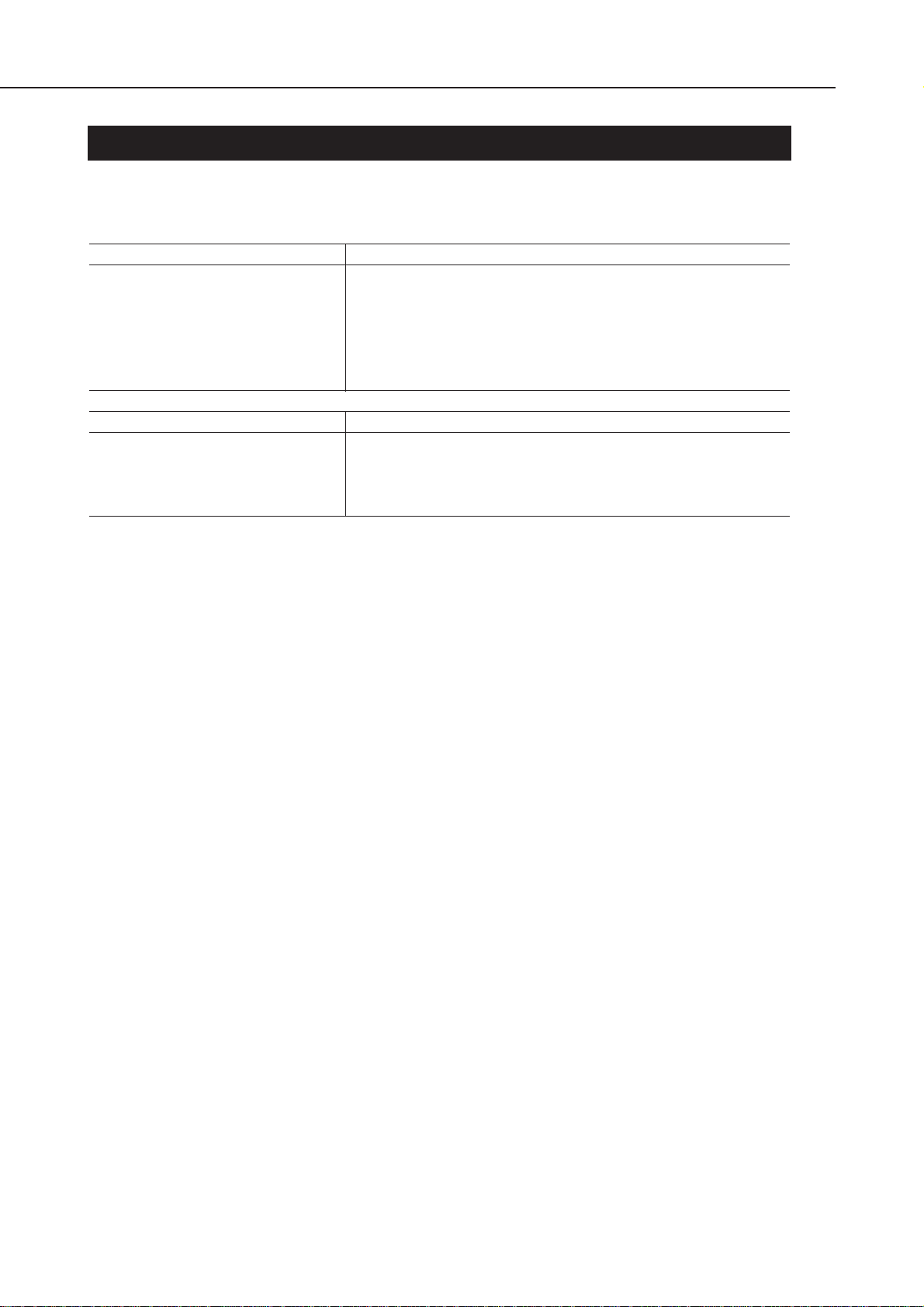

2.4 Grease Application

Apply greases at the points shown below.

Apply a thin film of grease using the flat brush. For the grease (EU-1) for the grease

pad, do not use a brush but apply directly. For printer disassembly and reassembly

procedures, refer to the parts catalog.

When applying greases, be careful to not get any on the wiper, cap, or

encoder film. If grease is applied to them, wipe them clean immediately.

Part 2: MAINTENANCE

BJC-8200

2-8

Figure 2-8 Grease Points

CAUTION

Cam Sliding Surface

Approx. 24 mg (Molykote PG-641 )

Grease Pad

Approx. 35 mg (EU-1)

Eject Roller Gear Teeth (apply to all teeth evenly)

Approx. 60 mg (Molykote PG-641 )

Feed Roller Gear Teeth

(apply to all teeth evenly)

Approx. 96 mg (Molykote PG-641)

Cam Sliding Surface

Approx. 24 mg

(Molykote PG-641 )

Guide Shaft Sliding Surface

(apply the proper amount of grease so as not to drip)

Approx. 90 mg (EU-1)

Guide Frame Underside (apply

a thin coat of grease over the entire surface)

Approx. 48 mg (Molykote PG-641)

LF Gear Teeth (apply to all teeth evenly)

Approx. 72 mg (Molykote PG-641 )

Feed Roller Sliding Surface

Approx. 24 mg (Molykote PG-641)

Feed Roller Sliding Surface

Approx. 12 mg (Molykote PG-641)

Paper Thickness Lev er

Approx. 12 mg

(Molykote PG-641)

Loading...

Loading...