Canon BJC-5000 Service Manual

QY8-1359-000

REVISION 0

AUGUST. 1998

COPYRIGHT©1998 CANON INC. CANON BJC-5000 0898 SC 0.55-0 PRINTED IN JAPAN (IMPRIME AU JAPON)

0898 SC 0.55-0

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory,

installation, maintenance, and repair of products. This manual covers all localities where the

products are sold. For this reason, there may be information in this manual that does not apply to

your locality.

Corrections

This manual could include technical inaccuracies or typographical errors due to improvements or

changes in the products. When changes occur in applicable products or in the content of this

manual, Canon will release technical information as the need arises. In the event of major

changes in the contents of this manual over a long or short period, Canon will issue a new editions of

this manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names described in this manual are the registered trademarks of

the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not

be copied, reproduced or translated into another language, in whole or in part, without the written

consent of Canon Inc., except in the case of internal business use.

Copyright © 1998 by Canon Inc.

CANON INC.

BJ Products Technical Support Dept

16-1, Shimonoge 3-chome, Takatsu-ku, Kawasaki-shi, Kanagawa 213, Japan

This manual was produced on an Apple Macintosh™ Power Mac 8500/180 personal computer and

Apple LaserWriter™16/600PS-J laser beam printer; final pages were printed on Varityper™ 5300 with

4000-J RIP. All graphics were produced with MACROMEDIA® FREEHAND® 7.0J.

All documents and all page layouts were created with QuarkXPress™ 3.3J.

I. ABOUT THIS MANUAL

Part 1: Safety and Precautions

This section tells you how to service the unit safely. It is very important, so please

read it.

Part 2: Product Specifications

This section outlines and specification.

Part 3: Operating Instructions

This section explains how to operate the unit properly. Information required about

installation and service made.

Part 4: Technical Reference

This section outlines the way the unit operates so you can understand it technically.

Part 5: Maintenance

This section explains how to maintain the unit. Descriptions of assembly/disassembly,

adjustment for assembly, troubleshooting procedures, and wiring/circuit diagrams

are given.

Procedures for assembly/disassembly are not given in this manual.

See the illustrations in the separate Parts Catalog.

I

This manual is divided into four sections, and contains information required for

servicing the unit.

REF.

II. TABLE OF CONTENTS

Page

1 - 1 1. SAFETY PRECAUTIONS

1 - 1 1.1 Moving Parts

1 - 2 1.2 Ink Stains

1 - 2 1.2.1 Ink path

1 - 3 1.2.2 Ink mist

1 - 4 1.3 BJ Cartridge Heat-Up

1 - 5 2. MACHINE PRECAUTIONS

1 - 5 2.1 Handling BJ Cartridges

1 - 5 2.1.1 Unpacking the BJ cartridge

1 - 5 2.1.2 Preventing clogged nozzles

1 - 6 2.1.3 Power on/off

1 - 6 2.1.4 When not using the printer

1 - 6 2.1.5 Ink electroconductivity

1 - 7 2.2 Handling Ink Cartridges (Color BJ Cartridge)

1 - 7 2.2.1 Unpacking the ink cartridge

1 - 7 2.2.2 Protecting the ink cartridge

1 - 8 2.3 Printer Precautions

1 - 8 2.3.1 Preventing deformation of the spur tip

1 - 8 2.3.2 Static electricity damage prevention

1 - 9 2.3.3 Ink leakage prevention

1 -10 3. MAINTENANCE SERVICE PRECAUTIONS

1 -10 3.1 EEPROM Data Precautions

1 -11 3.2 Static Electricity Precautions

1 -12 3.3 Disassembly and Assembly Precautions

1 -12 3.4 Built-In Self-Diagnosis

Part 1: Safety and Precautions

Part 2: Product Specifications

2 - 1 1. PRODUCT OUTLINE

2 - 1 1.1 Product Outline

2 - 2 1.2 Features

2 - 3 1.3 BJ Cartridge

2 - 3 1.3.1 Color BJ cartridge (BC-21e)

2 - 3 1.3.2 Black BJ cartridge (BC-23)

2 - 4 1.3.3 Black BJ cartridge (BC-20) (reference)

2 - 4 1.3.4 Photo BJ cartridge (BC-22e Photo)

2 - 5 1.4 Dual Cartridge System

2 - 5 1.5 BJ Cartridge Container

2 - 6 1.6 Consumables

2 - 6 1.6.1 BJ cartridge (Black, Color, Photo)

2 - 6 1.6.2 Ink cartridge (BC-21e Color BJ Cartridge only)

2 - 7 2. SPECIFICATIONS

2 - 7 2.1 Printer Specifications

2 - 9 2.2 Paper Specifications

2 - 9 2.2.1 Paper size

2 - 9 2.2.2 Paper type

2 -10 2.2.3 Cut sheet feeder sheet loading capacity

2 -11 2.2.4 Printing area

2 -12 2.3 Interface Specifications

II

Page

3 - 1 1. PRINTER SETUP

3 - 1 1.1 Unpacking and Inspection

3 - 2 1.2 Site Selection

3 - 3 1.3 Setup Procedure

3 - 3 1.3.1 Connecting the interface cable

3 - 3 1.3.2 Connecting the AC power cord

3 - 4 1.3.3 Turning on the printer

3 - 4 1.3.4 Installing the BJ cartridge

3 - 7 1.3.5 Replacing the ink cartridge

3 - 8 1.3.6 BJ cartridge container

3 - 9 1.4 Turning the Printer On/Off

3 - 9 1.4.1 Turning the printer on

3 - 9 1.4.2 Turning the printer off

3 -10 1.5 Paper Settings

3 -11 1.6 Banner Print

3 -12 1.7 Names of Parts and Their Functions

3 -13 2. TRANSPORTING THE PRINTER

3 -13 2.1 Carrying the Printer

3 -13 2.2 Transporting the Printer

3 -14 3. PRINTER SERVICING FUNCTION

3 -14 3.1 Error Indications

3 -16 3.2 Cleaning the BJ Cartridge

3 -17 3.3 Self-Test Printout

3 -18 3.4 Service Mode

3 -20 3.5 Service Mode Print Sample

3 -20 3.5.1 Ripple pattern

3 -20 3.5.2 Service information printing

Part 3: Operating Instructions

Part 4: Technical Reference

4 - 1 1. OVERVIEW

4 - 1 1.1 Printer Block Diagram

4 - 2 1.2 Initialization Sequence Flowchart

4 - 3 1.3 Print Signal Flow

4 - 3 1.3.1 Data between host computer and printer

4 - 3 1.3.2 Print signal flow in the printer

4 - 4 1.4 Print Drive

4 - 4 1.4.1 Print drive control

4 - 6 1.5 Power-Off Sequence Flowchart

4 - 7 2. FIRMWARE

4 - 7 2.1 Interface

4 - 7 2.1.1 Compatible mode

4 - 8 2.1.2 Nibble mode

4 - 9 2.1.3 ECP mode

4 -11 2.2 Printing System

4 -11 2.3 Printing Modes

4 -11 2.3.1 Printing mode

4 -11 2.3.2 Photo print mode

4 -11 2.3.3 Multi-drop print mode

4 -13 2.4 Cartridge Automatic Adjustment Function

4 -13 2.4.1 Automatic correction of head nozzle alignment

4 -13 2.4.2 Automatic density correction of left/right cartridge

4 -14 2.5 Data Separation Function

4 -14 2.6 Ink Smear Control

III

Page

4 -14 2.7 Head Overheating Protection Control

4 -14 2.8 Auto Power-Off

4 -15 3. PRINTER MECHANICAL SYSTEM

4 -15 3.1 Overview

4 -15 3.1.1 Mechanical components

4 -17 3.2 BJ Cartridge

4 -17 3.2.1 Black BJ cartridge structure

4 -18 3.2.2 Color BJ cartridge structure

4 -19 3.2.3 Photo BJ cartridge structure

4 -20 3.2.4 Bubble head unit structure

4 -26 3.3 Purge Unit

4 -26 3.3.1 Purge unit functions

4 -27 3.3.2 Purge unit structure

4 -29 3.4 Carriage

4 -29 3.4.1 Carriage function

4 -30 3.4.2 Carriage structure

4 -32 3.5 Paper Feed/Cut Sheet Feeder

4 -32 3.5.1 Paper feed/cut sheet feeder function

4 -34 3.5.2 Sheet feeder structure

4 -36 4. PRINTER ELECTRICAL SYSTEM

4 -36 4.1 Overview of Printer Electrical System

4 -37 4.2 Logic Section

4 -37 4.2.1 Logic section block diagram

4 -38 4.2.2 Logic section components

4 -41 5. SENSOR FUNCTIONS

4 -41 5.1 Pick-Up Roller Sensor

4 -41 5.2 Paper End Sensor

4 -42 5.3 Home Position Sensor

4 -42 5.4 Purge Sensor

4 -42 5.5 Cover Open Sensor

4 -42 5.6 Printer Temperature Sensor

4 -42 5.7 Head Temperature Sensor

4 -42 5.8 Auto-Alignment Sensor

4 -43 5.9 Waste Ink Amount Detection

Part 5: Maintenance

5 - 1 1. Maintenance

5 - 1 1.1 Parts for Regular Replacement

5 - 1 1.2 Consumables

5 - 1 1.3 Periodic Maintenance

5 - 2 2. SERVICE TOOLS

5 - 2 2.1 List of Tools

5 - 3 3. GREASE APPLICATION

5 - 4 4. DISASSEMBLY AND REASSEMBLY

5 - 4 4.1 Disassembly and Reassembly

5 - 4 4.2 Disassembly and Reassembly Cautions

5 - 4 4.2.1 Fastening screws of idler pulley assembly

5 - 5 4.2.2 Carriage guide frame installation

5 - 6 4.2.3 Unlocking the carriage lock

5 - 6 4.3 Logic Board and Waste Ink Absorber Replacement Cautions

5 - 6 4.3.1 Logic board replacement cautions

5 - 7 4.3.2 Cautions after replacing the waste ink absorber

IV

Page

5 - 8 5. ADJUSTMENTS

5 - 8 5.1 Adjustment Point

5 - 8 5.2 When Adjustment is Required

5 - 8 5.2.1 Tools required for adjustment

5 - 9 5.3 Adjustment Procedure

5 - 9 5.3.1 Preparation

5 -10 5.3.2 Adjustment

5 -12 6. TROUBLESHOOTING

5 -12 6.1 Troubleshooting

5 -12 6.1.1 Overview

5 -12 6.1.2 Troubleshooting cautions

5 -14 6.2 Error Condition Diagnostics

5 -14 6.2.1 Diagnostic flowcharts

5 -17 6.2.2 Error recovery

5 -34 7. LOCATION AND SIGNAL ASSIGNMENT

5 -34 7.1 Logic Board

5 -37 8. CIRCUIT DIAGRAMS

5 -37 8.1 Parts Layout

5 -37 8.1.1 Logic board

5 -39 8.2 Circuit Diagrams

V

III. ILLUSTRATION INDEX

Page

1- 1 Figure 1 - 1 Moving Parts of the Printer

1- 2 Figure 1- 2 Ink Path

1- 3 Figure 1- 3 Ink Path of the BJ Cartridge

1- 3 Figure 1- 4 Ink Mist

1- 4 Figure 1- 5 BJ Cartridge Aluminum Plate

1- 5 Figure 1- 6 Removing the Head Cap and Protective Tape

1- 6 Figure 1- 7 BJ Cartridge

1- 7 Figure 1- 8 Removing the Ink Cartridge Cap

1- 7 Figure 1- 9 Ink Outlets (Ink Cartridge)

1- 8 Figure 1-10 Spurs

1- 8 Figure 1-11 Electrical Contacts of Carriage Ribbon Cable

1- 9 Figure 1-12 Capping Position

1-11 Figure 1-13 Electrical System of Printer

1-12 Figure 1-14 Releasing the Plastic Hooks

2- 1 Figure 2 - 1 Printer Appearance

2- 3 Figure 2- 2 Color BJ Cartridge (BC-21e)

2- 3 Figure 2- 3 Black BJ Cartridge (BC-23)

2- 4 Figure 2- 4 Black BJ Cartridge (BC-20 [reference])

2- 4 Figure 2- 5 Photo BJ Cartridge (BC-22e Photo)

2- 5 Figure 2- 6 BJ Cartridge Container

2- 6 Figure 2- 7 BJ Cartridges

2- 8 Figure 2 - 8 Ink Cartridges

2-11 Figure 2- 9 Printing Area

2-17 Figure 2-10 Timing Chart (Compatible Mode)

2-18 Figure 2-11 Timing Chart (Nibble Mode)

2-18 Figure 2-12 Timing Chart (ECP Mode)

2-19 Figure 2-13 Timing Chart (ECP Mode/Reverse Mode)

3- 1 Figure 3- 1 Unpacking

3- 2 Figure 3- 2 Printer Site Selection Dimensions

3- 3 Figure 3- 3 Connecting the Interface Cable

3- 3 Figure 3- 4 Connecting the AC Power Cord

3- 4 Figure 3- 5 Removing the BJ Cartridge Protectors

3- 5 Figure 3- 6 BJ Cartridge Handling Precautions

3- 5 Figure 3- 7 Installing the BJ Cartridge

3- 7 Figure 3- 8 Removing the Ink Cartridge

3- 7 Figure 3- 9 Removing the Ink Cartridge Cap

3- 8 Figure 3-10 BJ Cartridge Container

3- 9 Figure 3-11 Caution! Do not unplug the AC power cord

without pressing the POWER button first

3-11 Figure 3- 12 Banner Print

3-12 Figure 3-13 Names of Parts and Their Functions

3-13 Figure 3-14 Carriage Capping Position

3-14 Figure 3-15 Control Panel

3-17 Figure 3-16 Self-Test Printout (Sample)

3-20 Figure 3-17 Ripple Pattern Sample

3-20 Figure 3-18 Service Information Printing Sample

4- 1 Figure 4- 1 Printer Block Diagram

4- 2 Figure 4- 2 Initialization Sequence Flowchart

4- 3 Figure 4- 3 Print Signal Flow

4- 4 Figure 4- 4 Printing Sequence (Black BJ Cartridge/Standard Mode)

4- 5 Figure 4- 5 Print Signals

VI

Page

4- 6 Figure 4- 6 Power-Off Sequence Flowchart

4- 7 Figure 4- 7 Interface Timing (Compatible Mode)

4- 8 Figure 4- 8 Interface Timing (Nibble Mode)

4- 9 Figure 4- 9 Interface Timing (ECP Mode)

4-10 Figure 4-10 Timing Chart (ECP Mode/Reverse Mode)

4-15 Figure 4-11 Mechanical System of Printer

4-17 Figure 4-12 Black BJ Cartridge Structure

4-18 Figure 4-13 Color BJ Cartridge Structure

4-19 Figure 4-14 Photo BJ Cartridge Structure

4-20 Figure 4-15 Bubble Jet Nozzles (Partial View)

4-21 Figure 4- 16 Nozzle Arrangement

4-21 Figure 4- 17 Contact Pad

4-23 Figure 4-18 Bubble Jet Head Driver Block Diagram (Black BJ Cartridge)

4-23 Figure 4-19 Bubble Jet Head Driver Block Diagram

(Color/Photo BJ Cartridge) (Multi-Drop)

4-28 Figure 4-20 Purge Unit

4-29 Figure 4- 21 Carriage

4-31 Figure 4-22 Paper Feed Motor Power Switching

4-32 Figure 4-23 Paper Feed

4-33 Figure 4-24 Automatic Printhead and Paper Clearance Adjustment

4-35 Figure 4-25 Paper Separator

4-36 Figure 4-26 Printer Electrical System

4-37 Figure 4-27 Logic Board Block Diagram

4-37 Figure 4-28 Printer Block Diagram

4-40 Figure 4- 29 Motor-Driving Circuit

4-41 Figure 4- 30 Sensors

5- 3 Figure 5- 1 Grease Application Points

5- 4 Figure 5- 2 Idler Pulley Assembly

5- 5 Figure 5- 3 Carriage Guide Frame

5- 6 Figure 5- 4 Unlocking the Carriage Lock

5- 7 Figure 5- 5 Waste Ink Absorber

5- 8 Figure 5- 6 Head Gap Adjustment

5- 9 Figure 5- 7 Adjustment Preparation

5-10 Figure 5- 8 Head Gap Adjustment (1)

5-11 Figure 5- 9 Head Gap Adjustment (2)

5-34 Figure 5- 10 Logic Board

5-37 Figure 5-11 Logic Board (Top View)

5-38 Figure 5-12 Logic Board (Bottom View)

VII

IV. TABLE INDEX

Page

3-10 Table 3-1 Printer Paper Setting

3-14 Table 3-2 Error Indications

3-18 Table 3-3 Service Mode

4-12 Table 4-1 Printing Modes and Driving Method

4-22 Table 4-2 List of BJ Cartridge Signal Contacts

4-25 Table 4-3 Head Installation Status and Signal Detection

4-26 Table 4-4 Ink Consumption During Cleaning (as a Guideline)

4-43 Table 4-5 List of Sensor Functions

5-8 Table 5-1 Tools Required for Head Gap Adjustment

VIII

Page

Part 1

SAFETY AND

PRECAUTIONS

1 - 1 1. SAFETY PRECAUTIONS

1 - 1 1.1 Moving Parts

1 - 2 1.2 Ink Stains

1 - 4 1.3 BJ Cartridge Heat-Up

1 - 5 2. MACHINE PRECAUTIONS

1 - 5 2.1 Handling BJ Cartridges

1 - 7 2.2 Handling Ink Cartridges (Color BJ Cartridge)

1 - 8 2.3 Printer Precautions

1 -10 3. MAINTENANCE SERVICE PRECAUTIONS

1 -10 3.1 EEPROM Data Precautions

1 -11 3.2 Static Electricity Precautions

1 -12 3.3 Disassembly and Assembly Precautions

1 -12 3.4 Built-In Self-Diagnosis

1. SAFETY PRECAUTIONS

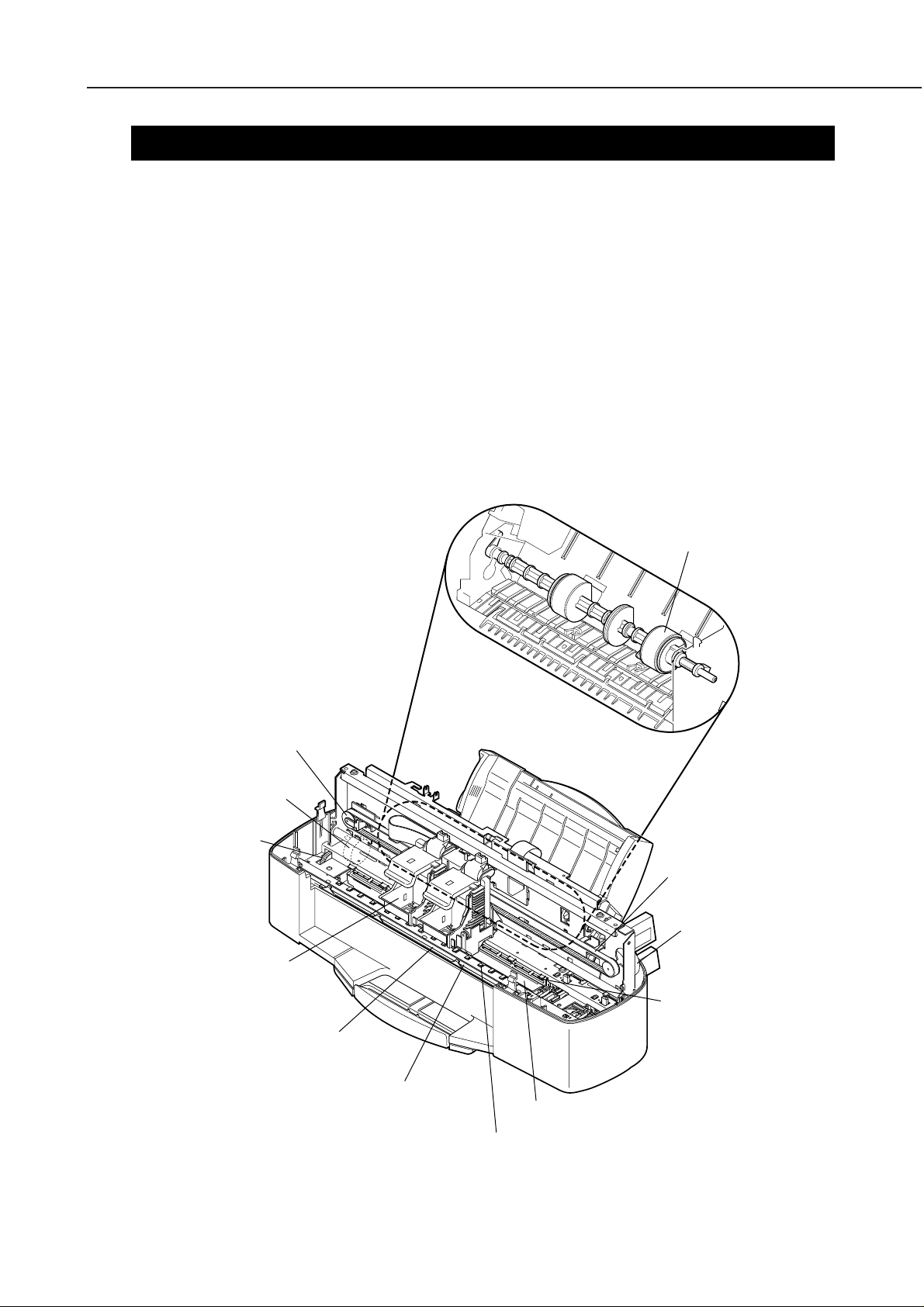

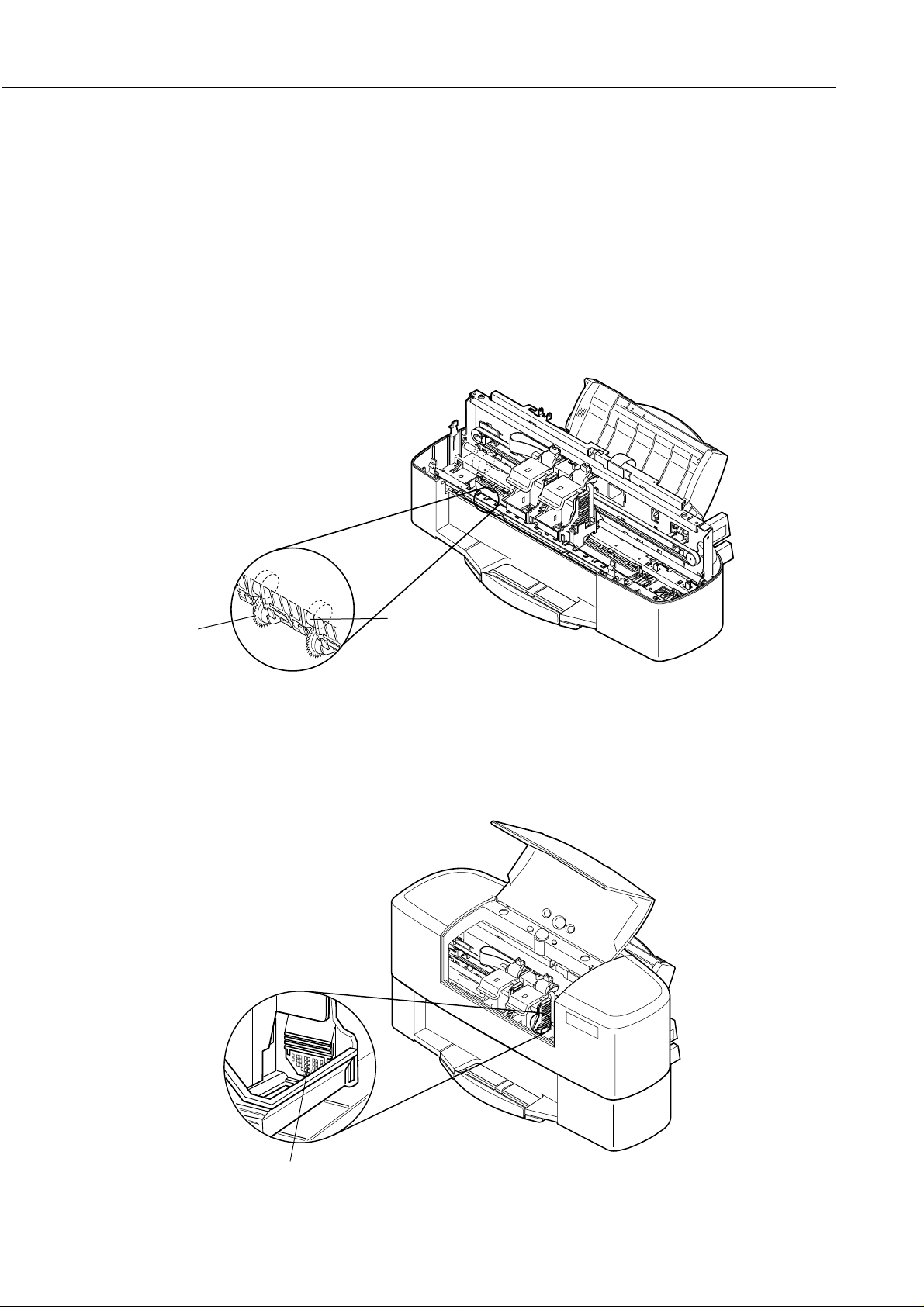

1.1 Moving Parts

Be careful not to get fingers, hair, clothing, or personal accessories caught in the

moving parts of the printer. There are several moving parts, driven by the carriage

motor and by the paper feed motor.

Moving parts driven by the carriage motor:

Carriage belt, idler pulley, and carriage.

Moving parts driven by the paper feed motor:

Feed roller, pressure rollers, spurs, pick-up roller, slow down gear, eject roller, and

transmission roller.

Also note that the spurs are made of metal and have sharp edges. Do not touch the

spurs, especially with bare hands. Serious injury could be caused by touching the

spurs unintentionally.

Part 1: Safety and Precautions

BJC-5000

1-1

Figure 1-1 Moving Parts of the Printer

Idler Pulley

Paper Feed Motor

Slow Down Gear

Carriage

Pick-Up Roller

Carriage Belt

Carriage Motor

Spurs

Eject Roller

Feed Roller

Transmission Roller

Pressure Rollers

Part 1: Safety and Precautions

1.2 Ink Stains

1.2.1 Ink path

Do not touch the ink path during repairs or maintenance to avoid getting ink stains on

the printer, work table, hands, and clothing.

The ink flow path consists of the BJ cartridge nozzles, head cap, head wiper,

maintenance jet receiving section, waste ink tube, and waste ink absorber.

The ink flow path of the color BJ cartridges consists of ink outlets and joint pipes. Do

not touch the ink flow path also, to avoid ink stains.

When the purge unit is removed, waste ink could spill out from the unit’s waste ink

flow path. When repairing or replacing this unit, stop up the waste ink flow path with

a paper towel to prevent the ink from spilling out.

Caution!

Although the ink is non-toxic, it contains organic solvents.

BC-23: Diethylenglycol 111-46-5, glycerin 56-81-5

BC-21e: Isopropyl alcohol 67-63-0, glycerin 56-81-5

BC-22e Photo: Isopropyl alcohol 67-63-0, glycerin 56-81-5, ethylenglycol 107-21-1

BC-20 (reference): Isopropyl alcohol 67-63-0, glycerin 56-81-5, ethylenglycol107-21-1

Never get ink in your eyes and mouth. If any ink should get into your eyes, wash

them out with plenty of water and consult a doctor. If a large quantity of ink is

swallowed accidentally, consult a doctor immediately. Provide the doctor with the

information printed on the BJ cartridge package or label. Since the ink contains

dyes, any ink stain on clothing, etc. shall be permanent.

BJC-5000

Waste Ink Absorber

BJ Cartridge

Carriage

Maintenance Jet

Receiving Section

Head Wiper

Waste Ink Tube

Purge Unit

Figure 1-2 Ink Path

1-2

BJC-5000

Nozzles

Part 1: Safety and Precautions

Black BJ Cartridge Color BJ Cartridge

Joint Pipe

Ink Outlet

Ink Outlet

Nozzles

Joint Pipe

Nozzles

Figure 1-3 Ink Path of the BJ Cartridge

1.2.2 Ink mist

The BJ cartridge ejects ink onto the paper to print. During prolonged or heavy-duty

use of the printer, small amounts of ink mist which splatter off the printing paper

during printing can be deposited on the inside of the

these parts can cause stains on the printing paper, hands, or clothing. Wipe the ink

off these parts periodically with a soft moist cloth.

front cover

and

platen

. Ink on

Platen

Front Cover

Figure 1-4 Ink Mist

1-3

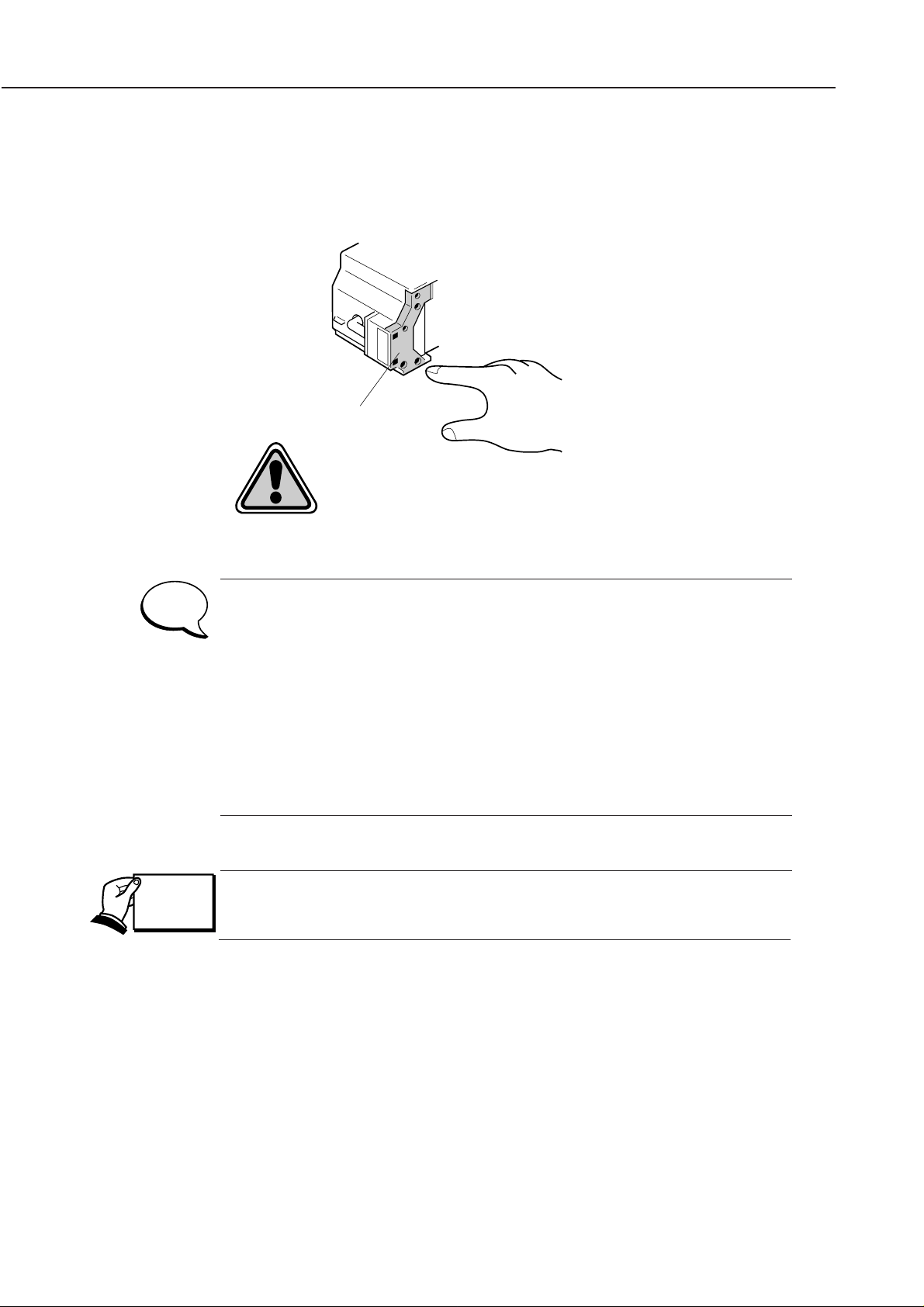

1.3 BJ Cartridge Heat-Up

Do not touch the aluminum plate of the BJ cartridge. This aluminum plate heats up

during printing. It will become very hot during prolonged and continuous printing

sessions or when printing is attempted even after the cartridge has run out of ink.

This printer is provided with a protective mechanism for the overheating of

the BJ cartridge. A head temperature (diode) sensor in the BJ cartridge

detects the temperature levels for activating the protection mechanism.

To prevent the user from touching the hot aluminum plate of the head

when the head temperature becomes high, the carriage will not move to

the cartridge replacement position even when the user opens the

front

cover

. During this time, the printer beeps 5 times and the indicator lights

in orange. If this happens, wait for a while and then either press the

RESUME button

or close the

front cover

once and open it again.

If the head temperature increases further, printing will be stopped due to

the head temperature error.

When the printer stops printing due to a head temperature error, follow the

required troubleshooting procedure in “

Part 5: 6, TROUBLESHOOTING”

(page

5-12).

Part 1: Safety and Precautions

BJC-5000

1-4

Figure 1-5 BJ Cartridge Aluminum Plate

Aluminum Plate

Caution! High Temperature!

NOTE

REF.

BJC-5000

2. MACHINE PRECAUTIONS

2.1 Handling BJ Cartridges

Part 1: Safety and Precautions

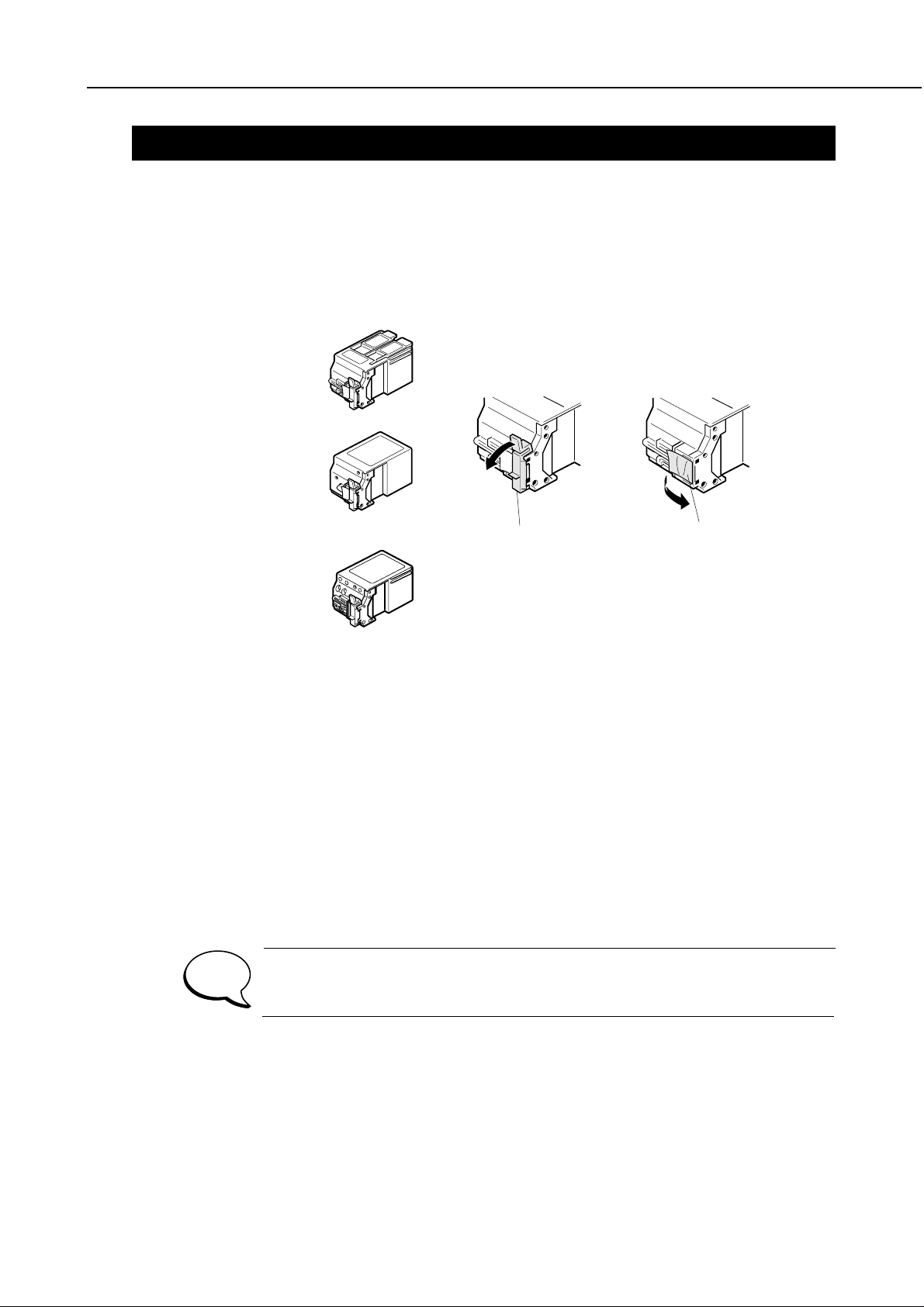

2.1.1 Unpacking the BJ cartridge

Do not unpack the BJ cartridge until it is ready to be used. Before installing the BJ

cartridge in the printer, remove the protective head caps from the nozzles and peel off

the protective tape as shown in the figure below.

Never re-use the removed protective head caps and protective tape. This could cause

printing troubles.

12

Color BJ Cartridge (BC-21e)

Black BJ Cartridge

(BC-23/BC-20 [reference])

Photo BJ Cartridge (BC-22e Photo)

Cap Tape

Figure 1-6 Removing the Head Cap and Protective Tape

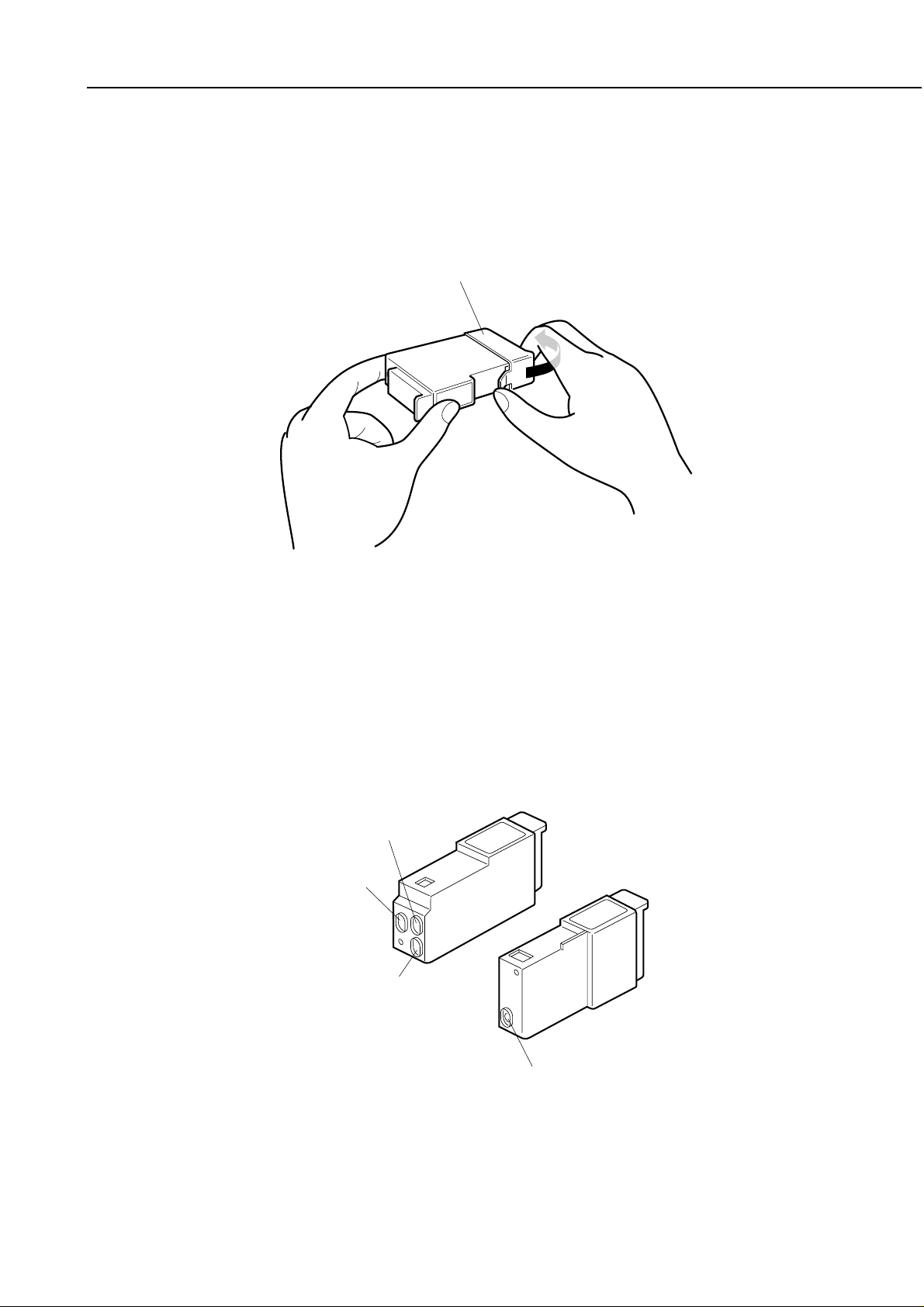

2.1.2 Preventing clogged nozzles

Never touch the nozzles of the BJ cartridge or wipe them with tissue paper. Any

foreign substance could easily clog the nozzles. Also, handle the inner joint pipe of the

color BJ cartridge carefully to avoid clogging it and thus blocking the ink feed.

To prevent clogging the nozzles with foreign substances and dried-out ink, install the

BJ cartridge in the printer after the head cap and protective tape are removed (so that

the printer caps the nozzles). When storing the BJ cartridge, make sure the nozzles of

the cartridge are capped or store the cartridge in the BJ cartridge container. Foreign

substances on the nozzles or dried up ink will result in poor ink suction. Never

disassemble or assemble the BJ cartridge and do not wash it.

NOTE

When the nozzles are clogged, white streaks will appear across the printed

areas periodically. If this problem persists even after cleaning, replace the

BJ cartridge with a new one.

1-5

Part 1: Safety and Precautions

CAUTION

Black BJ Cartridge Color BJ Cartridge

Nozzles

BJC-5000

Joint Pipe

Ink Outlet

Ink Outlet

Nozzles

Joint Pipe

Nozzles

Figure 1-7 BJ Cartridge

2.1.3 Power on/off

When the printer is turned off with the

the nozzles of the BJ cartridge for their protection and to prevent ink leakage.

If the AC power cord of the AC adapter is unplugged unintentionally and the printer is

turned off without pressing the

such cases, plug in the AC power cord of the AC adapter, turn on the power of the

printer, and then press the

CAUTION

If the nozzles are not capped properly, the ink may either dry out and clog

the nozzles or leak out.

POWER button

POWER button

POWER button

, the nozzles may not be capped. In

to turn it off again.

, the printer automatically caps

2.1.4 When not using the printer

Leave the BJ cartridge in the printer or store it in the BJ cartridge container when the

printer is not in use. Also keep the BJ cartridge installed in the printer or store it in

the BJ cartridge container while carrying, transporting, or storing the printer.

If the BJ cartridge is removed from the printer and left lying about,

CAUTION

printing defects may occur when it is used again due to clogging of nozzles

and dried-out ink. If the BJ cartridge is removed to relocate the printer,

ink could leak out from the cap section.

2.1.5 Ink electroconductivity

The ink in the BJ cartridge is electroconductive. If the ink leaks into the printer’s

mechanical parts, use a paper towel to wipe off completely. If the ink leaks into the

printer’s electrical parts, use a tissue paper to wipe off completely. If ink is spilled

under the IC chips on the printed circuit board (PCB) and is difficult to clean, replace

the PCB.

Do not connect the AC power cord when ink has leaked into the electrical

parts. This could damage the circuitry.

1-6

BJC-5000

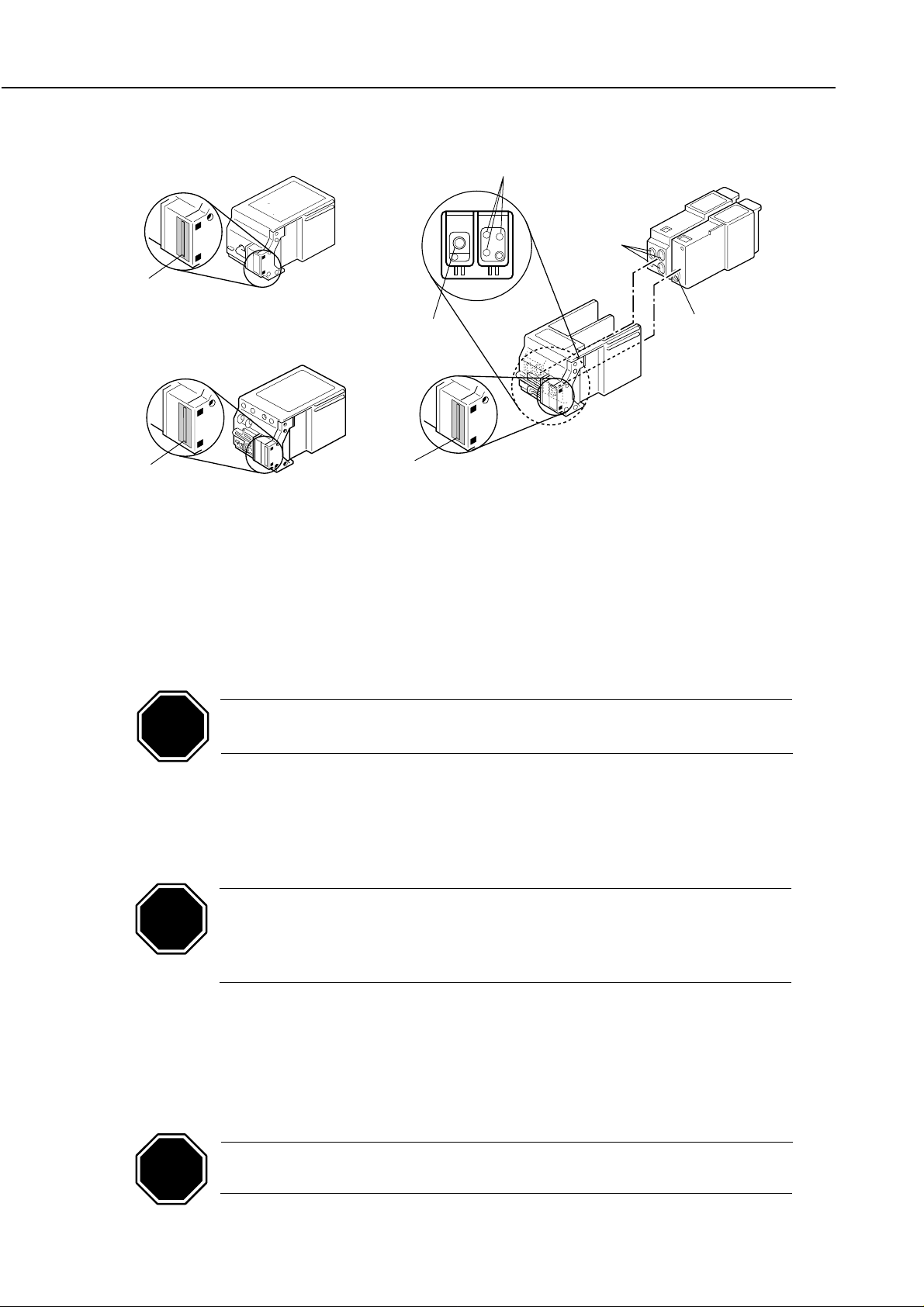

2.2 Handling Ink Cartridges (Color BJ Cartridge)

Part 1: Safety and Precautions

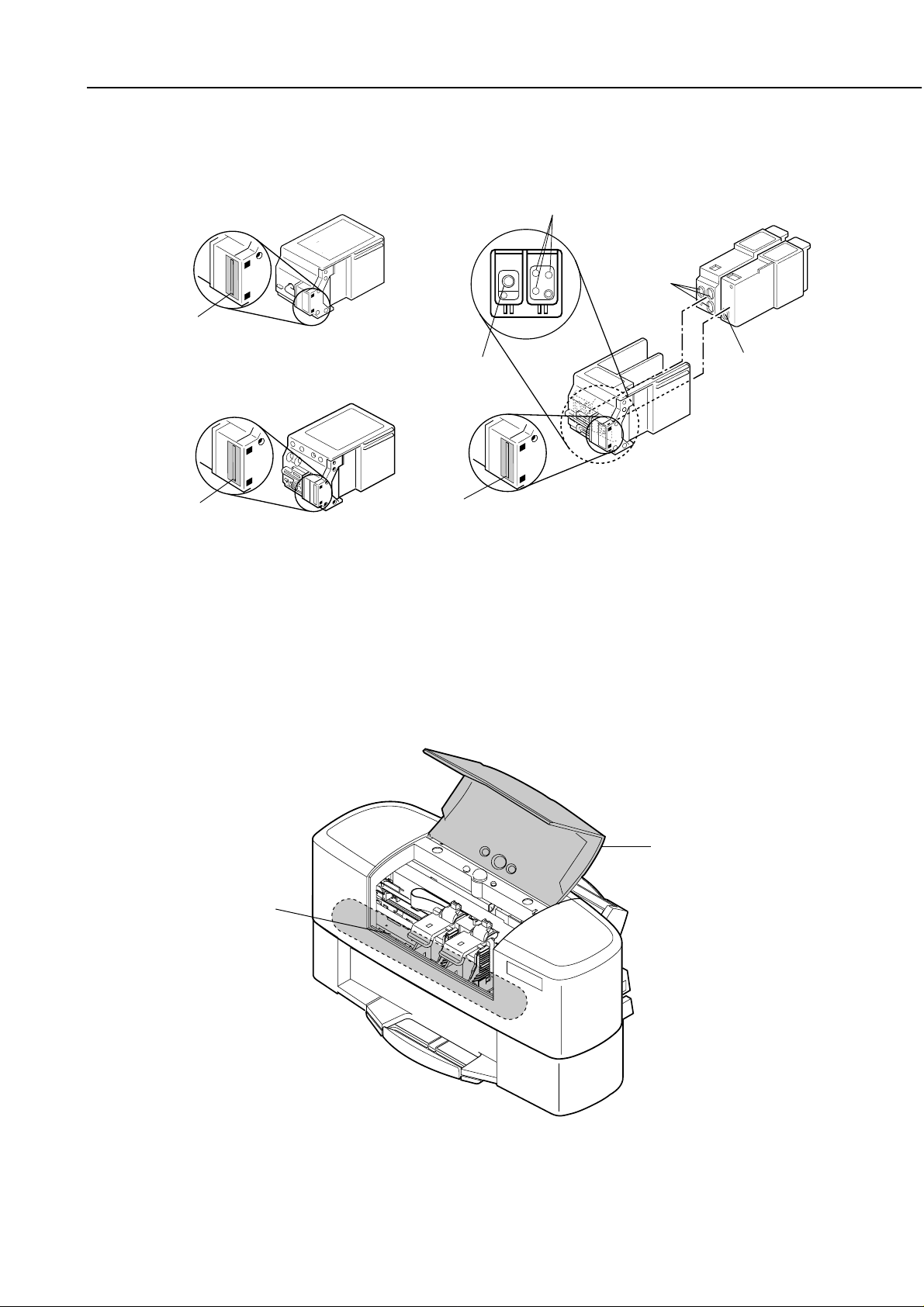

2.2.1 Unpacking the ink cartridge

Do not unpack an ink cartridge until it is ready to be used. Before installing it in the

color BJ cartridge, remove the ink cartridge from its’ package and remove the cap that

covers the ink outlets.

Cap

Figure 1-8 Removing the Ink Cartridge Cap

2.2.2 Protecting the ink cartridge

To prevent poor ink suction due to the attachment of foreign substances to the joint

pipes connected to the BJ cartridge, never touch the ink outlets of the ink cartridge.

After removing the cap from the ink cartridge, immediately install the ink cartridge in

the BJ cartridge to prevent the nozzles from clogging due to dried-out ink. Do not

remove an ink cartridge from the BJ cartridge unless it needs to be replaced.

Color Ink Cartridge

Yellow Ink Outlet

(Joint Pipe Contact)

Magenta Ink Outlet

(Joint Pipe Contact)

Cyan Ink Outlet

(Joint Pipe Contact)

Black Ink Cartridge

Black Ink Outlet

(Joint Pipe Contact)

Figure 1-9 Ink Outlets (Ink Cartridge)

1-7

Part 1: Safety and Precautions

2.3 Printer Precautions

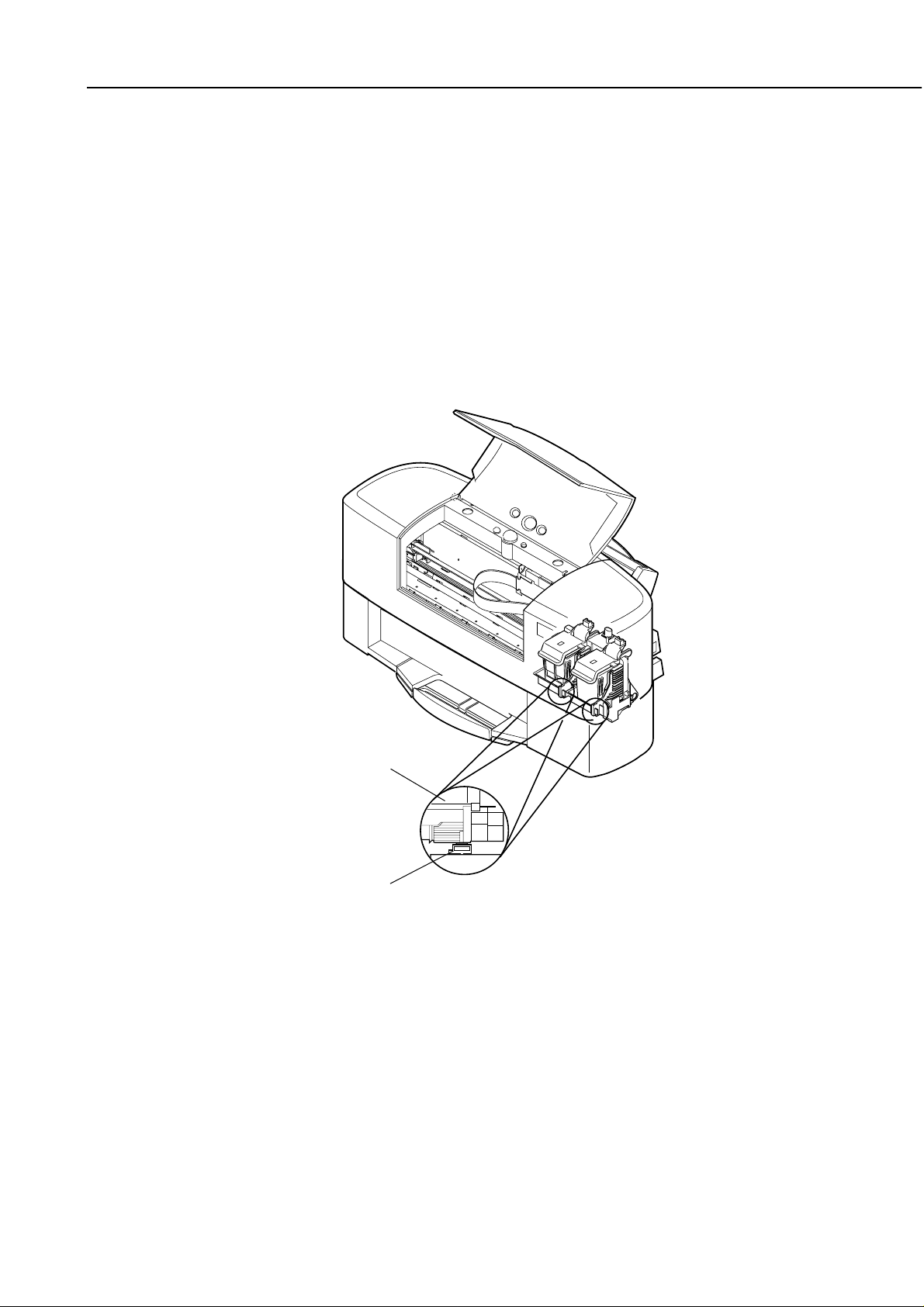

2.3.1 Preventing deformation of the spur tip

Do not touch the tips of the spurs. The spurs transfer and eject the paper after

printing. They have a delicate structure and could be easily deformed. Since the tip

of the spurs have a very small contact surface with the paper, the ink adhering to the

spurs is minimal. The spur cleaner wipes off the adhered ink from the spurs to

prevent smudges on the paper. If the spurs are touched and the tip of the spurs

become deformed, the contact surface with the paper might increase, causing more

ink to adhere to each spur. As a result, should the spur cleaner fail to wipe the ink

from the spurs completely, a dotted-line smear may be printed on the paper or a trace

may be produced. If this happens, replace the spur unit with a new one.

BJC-5000

Spurs

Spur Cleaners

Figure 1-10 Spurs

2.3.2 Static electricity damage prevention

Never touch the electrical contacts to the cartridge of the carriage ribbon cable. Any

static electricity produced by clothing and friction could damage the electrical

components or change their electrical characteristics.

Contact Points

Figure 1-11 Electrical Contacts of Carriage Ribbon Cable

1-8

BJC-5000

Part 1: Safety and Precautions

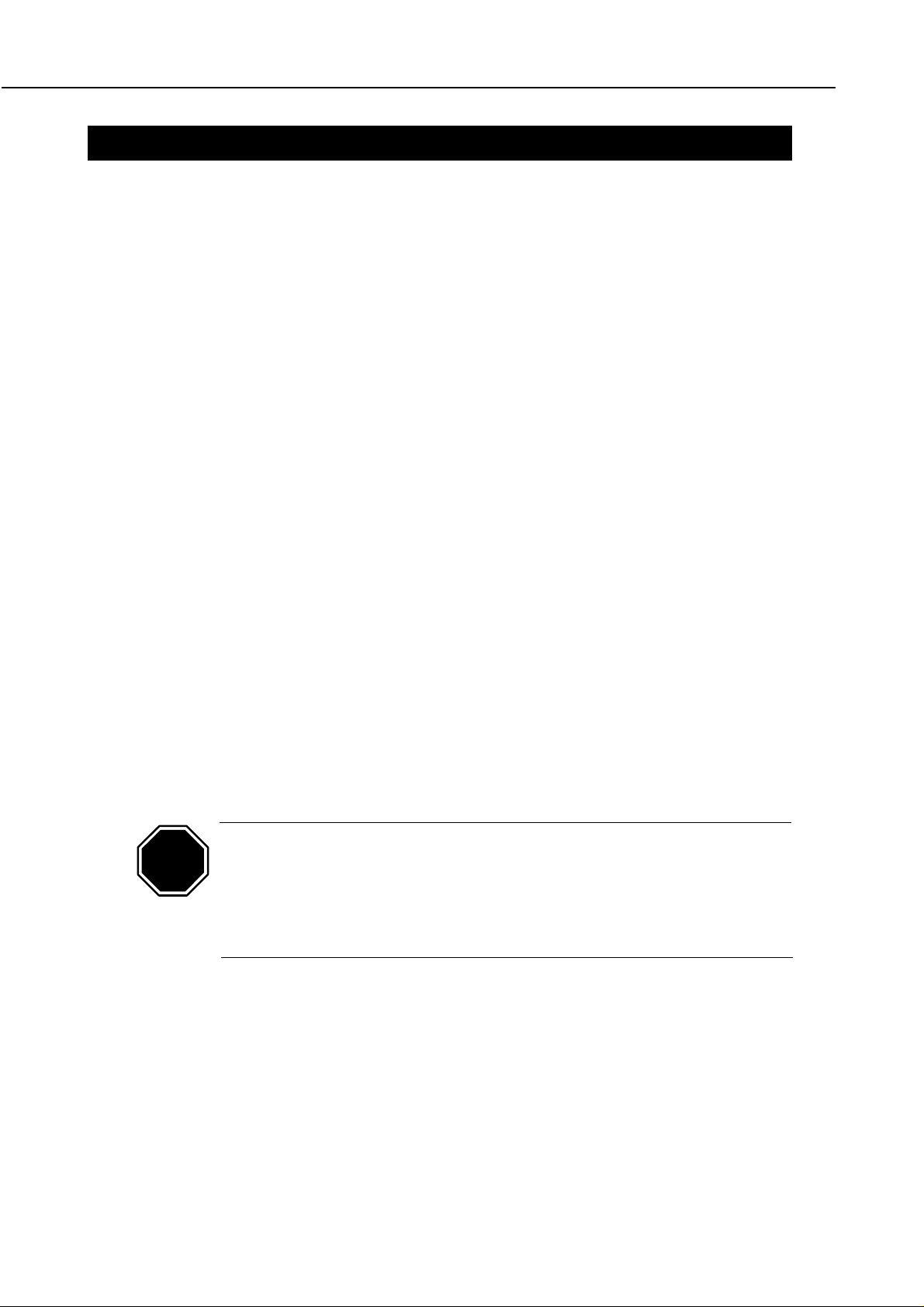

2.3.3 Ink leakage prevention

Transport, pack, or store the printer with the BJ cartridge installed in the printer.

Otherwise, the ink in the purge unit could flow backward and spill out inside the

printer. Before packing the printer, make sure the carriage is at the capping position

(the right end of the carriage shaft).

The nozzles of the BJ cartridge are automatically capped when the printer is turned off

by pressing the

before turning off the printer with the

stopped without capping the nozzles, which could cause ink leaks and ink bonding.

In case this happens, plug in the AC power cord, turn on the printer by pressing the

POWER button

power cord again.

POWER button

, turn it off by pressing the

. Do not unplug the AC power cord of the AC adapter

POWER button

. Otherwise, the printer will be

POWER button

, and then unplug the AC

BJ Cartridge

Head Cap

Figure 1-12 Capping Position

1-9

Part 1: Safety and Precautions

3. MAINTENANCE SERVICE PRECAUTIONS

3.1 EEPROM Data Precautions

This printer keeps track of various function settings, the total number of sheets printed,

and the total waste ink amount. Such information is stored in the EEPROM on the

logic board. Heed the following precautions during maintenance servicing.

1) Before servicing

Check the data stored in the printer with a test print (only for the total number of

sheets printed) and a service information print in the Service Mode. The total

number of sheets printed can provide an idea of how much the printer has been

used.

2) When the logic board (EEPROM) is replaced or if the memory data was unintentionally reset

Check the waste ink absorbers, replace them if necessary, and set the total waste ink

amount counter according to instructions in “

Absorber Replacement Cautions”

0% (clearing the data), 25%, 50%, and 75%. If this task is neglected, a “waste ink

full” error may not occur even when the waste ink amount exceeds the full capacity

and waste ink may start leaking, depending on the waste ink amount already

absorbed by the waste ink absorbers.

The memory data in the replacement logic board (EEPROM) is not defined. After

replacing the logic board (EEPROM), reset the EEPROM. Check the above waste ink

absorbers and set the total waste ink amount counter. After resetting the EEPROM,

install the black BJ cartridge and calibrate the auto-alignment sensor. If the

calibration is not performed, an EEPROM error will occur when the printer is turned

on.

BJC-5000

Part 5: 4.3, Logic Board and Waste Ink

(page 5-6). The waste ink counter total can be set to

3) After waste ink absorber replacement

If the waste ink absorbers are replaced when the “waste ink full” error or another

error occurs, reset the total waste ink amount counter of the EEPROM.

Once the memory data of EEPROM is reset, the data cannot be checked by

CAUTION

a test print in the Service Mode. To check the stored data, be sure to

execute a test print in the Service Mode before resetting the EEPROM.

When the EEPROM is reset, all data including the various settings, total

number of sheets printed, and total waste ink amount are reset. The total

number of sheets printed cannot be incremented using the control panel.

1-10

BJC-5000

3.2 Static Electricity Precautions

Part 1: Safety and Precautions

This printer keeps track of the estimated waste ink amount based on the

REF.

Static electricity produced by friction of clothing could damage the electrical parts or

change their electrical characteristics. Before disassembling the printer to perform any

servicing, touch a metallic object that is properly grounded to discharge any built-up

static electricity. For example, a wrist strap can be used to discharge built-up static

electricity.

Before discharging built-up static electricity, do not touch electrical parts such as the

logic board and contacts to the BJ cartridge of the carriage ribbon cable while the

carriage ribbon cable is connected to the logic board (see Figure 1-11).

condition of printer usage immediately after the printer is started. To

prevent ink leakage due to the waste ink absorption capacity being

exceeded, the printer stops printing and displays an error when the waste

ink amount nears the full waste ink absorption capacity. The printer

operation can be restarted by pressing the

used in this condition, the “waste ink full” error is displayed. See “

3.4 Service Mode”

data using a test print or the Service Mode and for resetting procedure.

If the printer operation stops due to “waste ink full” or other errors, follow

the required troubleshooting procedure in “

(page 5-12).

(page 3-18) for information about checking the memory

RESUME button

Part 5: 6, TROUBLESHOOTING”

. If the printer is

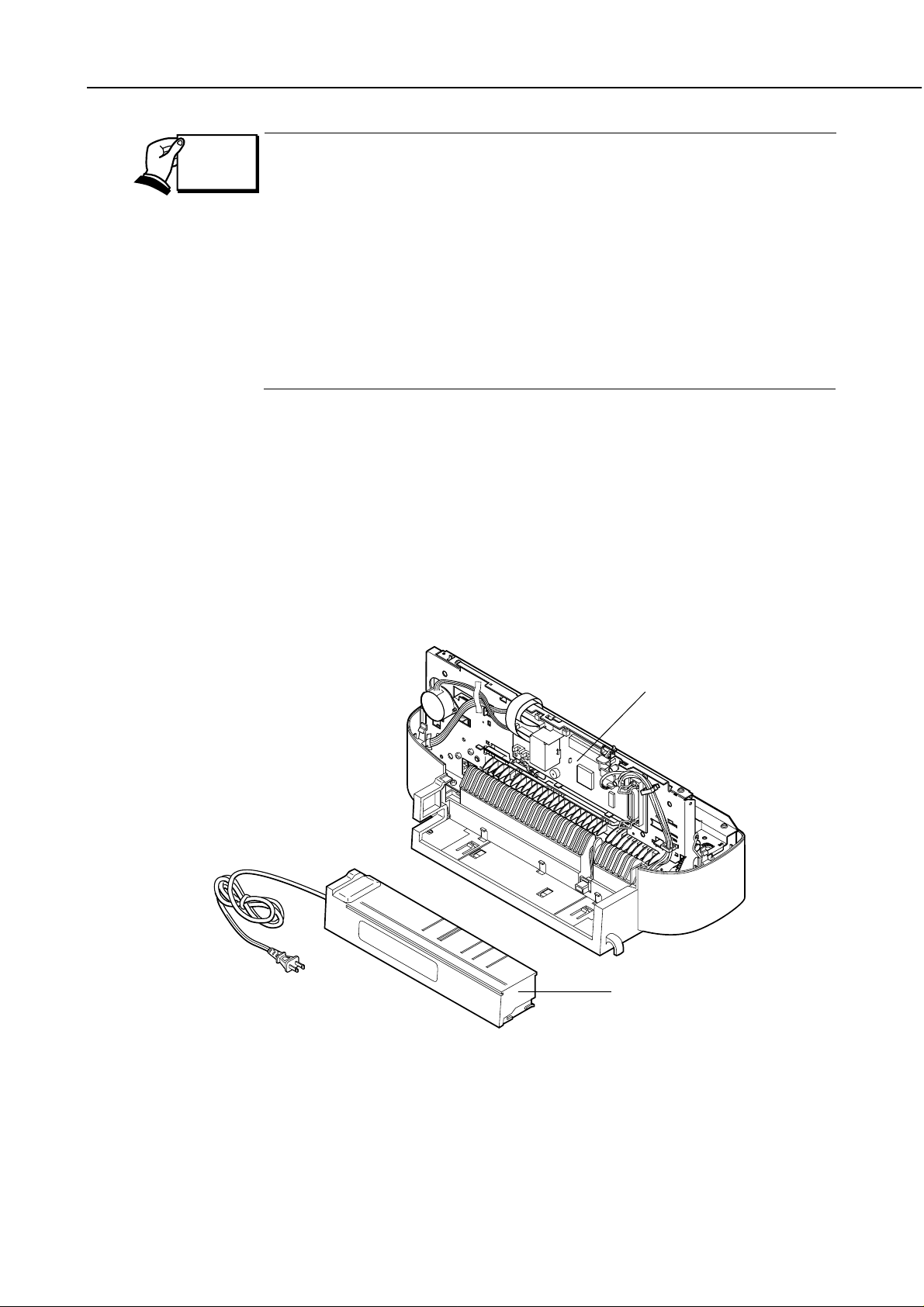

Part 3:

AC Adapter

Figure 1-13 Electrical System of Printer

Logic Board

1-11

Part 1: Safety and Precautions

3.3 Disassembly and Assembly Precautions

The printer has a large number of plastic parts. When you disassemble the printer, be

very careful not to break or bend the plastic hooks.

Some plastic parts are made of highly rigid material containing glass fibers

CAUTION

to improve precision. Such material have low viscosity, however, and the

plastic hooks can break easily. When you disassemble the printer, use a

screwdriver and do not apply excessive force on the plastic hooks.

Hook

BJC-5000

Never apply excessive force

to release a hook.

Figure 1-14 Releasing the Plastic Hooks

3.4 Built-in Self-Diagnosis

The printer is provided with a self-diagnosis feature which analyzes hardware defects.

The results of the self-diagnosis are shown by the indicators and the beeper. See “

3: 3.1, Error Indications”

(page 3-14) for more information.

Part

1-12

Page

Part 2

PRODUCT

SPECIFICATIONS

2 - 1 1. PRODUCT OUTLINE

2 - 1 1.1 Product Outline

2 - 2 1.2 Features

2 - 3 1.3 BJ Cartridge

2 - 5 1.4 Dual Cartridge System

2 - 5 1.5 BJ Cartridge Container

2 - 6 1.6 Consumables

2 - 7 2. SPECIFICATIONS

2 - 7 2.1 Printer Specifications

2 - 9 2.2 Paper Specifications

2 -12 2.3 Interface Specifications

Part 2: Product Specifications

2-1

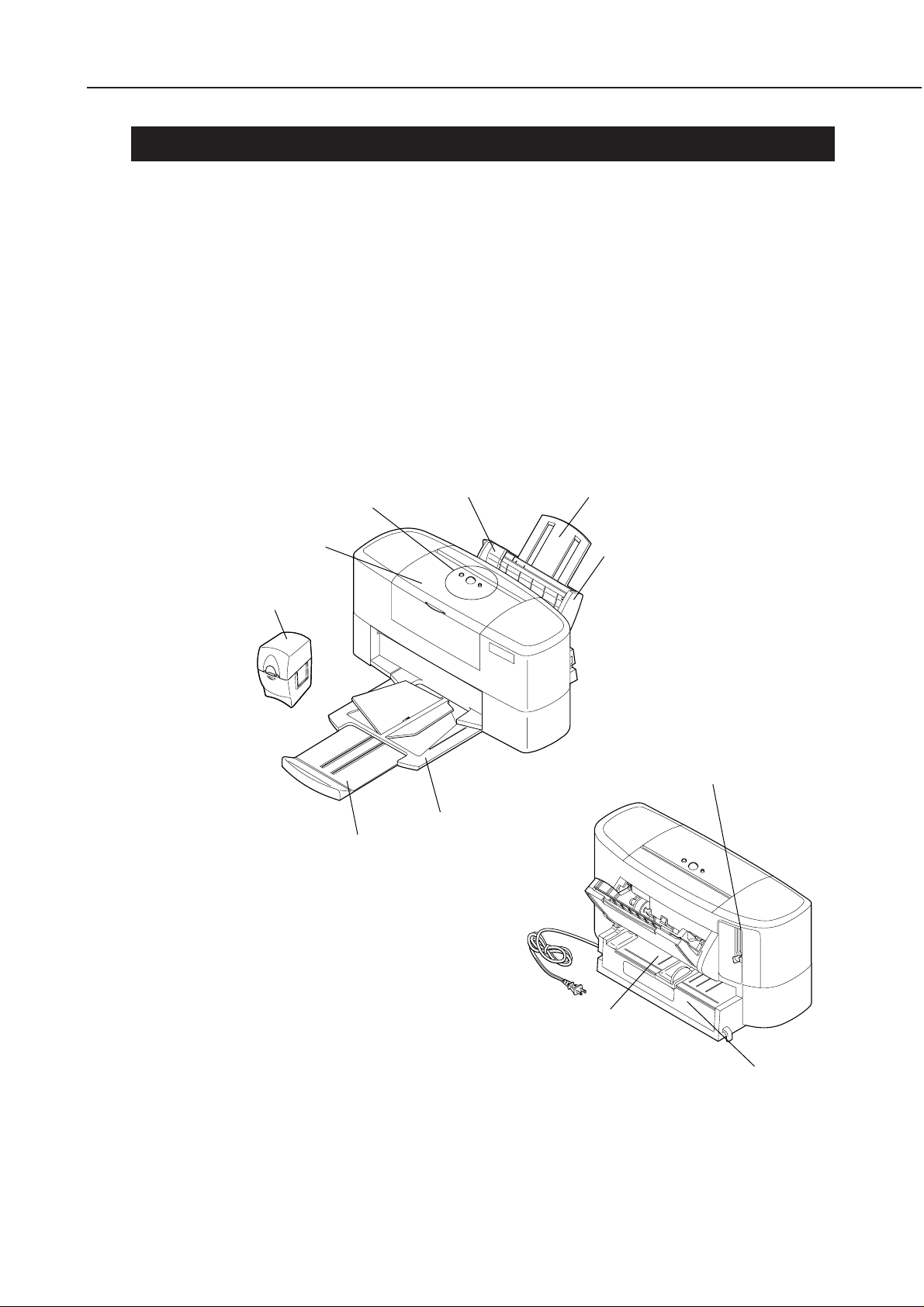

1. PRODUCT OUTLINE

1.1 Product Outline

This desktop color printer achieves high-speed printing by means of a dual cartridge

system. It also realizes maximum 1440 (vertical) x 720 (horizontal) dpi high-resolution

printing by using the printer driver to perform the main data processing.

Moreover, this printer achieves high image printing by adopting a “drop modulation

technology” in the color BJ cartridge and photo BJ cartridge. High-density

monochrome printing is offered with a black BJ cartridge that adopts a newly developed

ink. The reproduction of color graduations has been improved through the combined

use of these cartridges.

In addition, the printing environment is further expanded by the possibilities of printing

on up to A3-size paper and banner (long paper) printing by manual feeding. This is a

high-performance standard machine.

Figure 2-1 Printer Appearance

BJC-5000

Front Cover

BJ Cartridge Container

Operation Panel

Paper Output Tray Extension Guide

Paper Guide

Paper Output Tray

Paper Support

Cut Sheet Feeder

Interface Connector

Manual Feeding Slot

AC Adapter

Part 2: Product Specifications

1.2 Features

1. High-speed printing by dual cartridge system

2. High-resolution printing of maximum 1440 (vertical) x 720 (horizontal) dpi

3. Easy-to-replace, high-speed and high-quality printing-compliant BJ cartridge

Color BJ Cartridge (BC-21e):Adopts a drop modulation technology. Has separate

Black BJ Cartridge (BC-23): 128-nozzle and head single unit type (high-density

Photo BJ Cartridge (BC-22e Photo): Drop modulation technology has been adopted.

Black BJ Cartridge (BC-20 [reference]): 128-nozzle and head single unit type

Ink cartridge:Black ink cartridge and tricolor (Y, M, C) ink cartridge (3-color ink

single unit)

(The previous model Color BJ Cartridge (BC-21) and Photo BJ Cartridge (BC-22

Photo) that are not compliant with the drop modulation technology cannot be

used.)

4. The auto-alignment function which corrects the printing position displacement of

the left and right cartridges and printing direction displacement caused by bidirectional printing has been provided to achieve image maintenance.

5. Exclusive Windows machine using a dedicated driver. Emulation is not supported.

6. A BJ cartridge container is supplied with the printer for storing the removed BJ

cartridge.

7. ECP mode compliant.

8. Banner printing capabilities.

9. Built-in automatic cut sheet feeder without paper lever.

10.Improved operability. Provides an automatic head-to-paper distance adjustment

mechanism (no paper thickness adjustment lever). Also, the cartridge comes to the

replacement position when the cover is opened (no cartridge button).

11.Built-in AC adapter for power supply. (Assembled at the factory before shipment.)

12.Can print on up to A3-size paper by manual feed. (Up to A4/LTR-size full bleed

with ASF.) When printing on A3-size paper, only the left BJ cartridge is used.

(Either monochrome or color printing is enabled and photo printing is disabled

when using A3-size paper.)

13.The printer driver supports an automatic power off feature.

14.The printer can achieve high resolution printing because the main data processing

is performed by the printer driver. Note on the other hand that this printer

requires a more advanced host computer operating environment.

1) Windows95/98

2) CPU: Min. 166MHz

3) RAM: Min. 16MB

4) HDD: Min. 40MB of free space

5) Printer port: ECP/DMA

BJC-5000

ink tanks (Bk) (Y+M+C) and head with 136 nozzles in a

vertical line; 64 nozzles (Bk) + 24 nozzles x 3 (Y, M, C).

type)

136-nozzle and head single unit type

2-2

Loading...

Loading...