Page 1

CAUTION:

READ THIS MANUAL CAREFULLY

BEFORE OPERATING YOUR NEW

CANNON

RETAIN FOR FUTURE REFERENCE.

®

DOWNRIGGER.

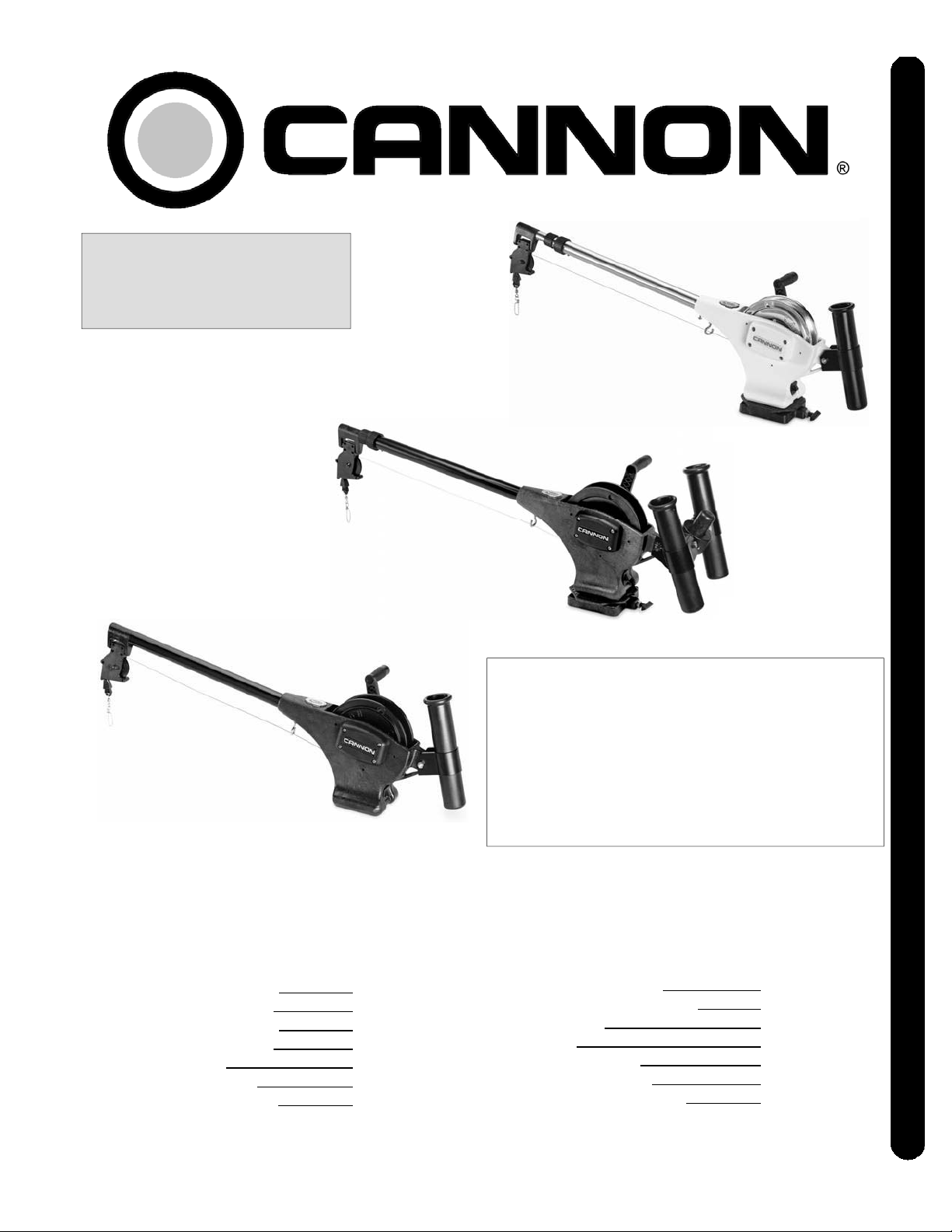

Uni-troll 10ts

Uni-troll 10

NOTE: Do not return your CANNON® Downrigger to your

retailer. Your retailer is not authorized to repair or replace this

unit. You may obtain service by:

• calling CANNON® at 1-800-227-6433;

• returning your downrigger to the Factory Service Center;

• sending or taking your downrigger to any CANNON®

Authorized Service Center on enclosed list.

Please include proof of purchase, serial number and purchase

date for warranty service with any of the above options.

Uni-troll 5

OWNER’S MANUAL

Introduction to Downriggers pg. 2

Mounting Your Downrigger

Attaching the Crank Handle

Terminator & Line Release

Cannon Uni-Release

Attaching the Rod Holder

Operating Your Downrigger

pg. 2-7

pg. 8

pg. 9

pg. 9

pg. 10

pg. 11

The Effects of Blowback

Maintaining Your Downrigger

Troubleshooting

Trolling Tips

Warranty Information

Cannon Service Policy

Authorized Service Centers pg. 16

pg. 12

pg. 13

pg. 13

pg. 14

pg. 15

pg. 15

Page 2

Introduction to downriggers

Introduction to Controlled Depth Fishing

Undoubtedly there are many fishermen

familiar with the methods and use of controlled

depth fishing. During the mid 1960's the state of

Michigan introduced Pacific salmon into the Great

lakes in an attempt to revitalize its sport fishing

industry. From this successful transplant, new

fishing techniques and equipment were

developed. One such method was controlled

depth fishing which enabled fishermen to place a

lure at a desired depth by utilizing downriggers.

Because of the varying factors (water

temperature, thermocline, weather, tides, time of

day, or time of year) it is necessary for successful

fishing to maintain specific water depths that

coincide with fish movements and feeding

patterns.

One essential feature of the downrigger is

the depth meter or gauge that indicates lure

depth. This allows the angler to control as well

as return to specific depths where fish have

been caught.

Due to the success of controlled depth

fishing, downriggers are now being used

throughout the world to catch a wide variety of

species in both fresh and salt water. Whether

fishing for blues off Rhode Island, walleyes in

Lake Erie, sailfish off the coast of Florida, or

stripers in Tennessee, the use of downriggers

will make your fishing more successful and more

enjoyable.

Attach Line Release

to Rear Hook on

Weight

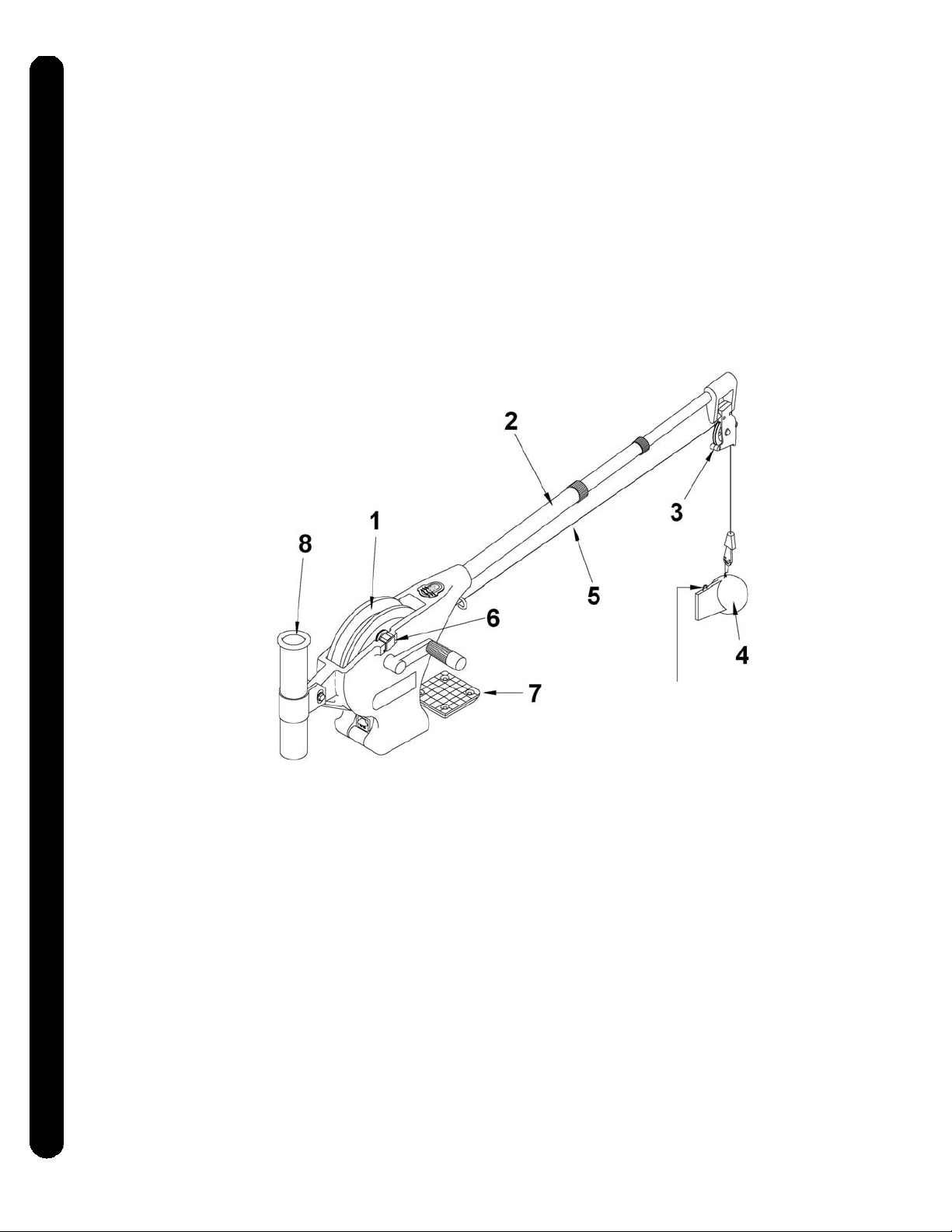

Parts Description

1. Reel This is used to spool the cable, available in lengths ranging from 150 to 400 feet.

2. Boom This is used to extend the weight out from the body of the downrigger and has a pulley fixed

to its end. Boom lengths range from 24 to 53 inches.

3. Swivel Head This relays the cable at the end of the boom to lower the weight.

4. Weight This is used to maintain the depth at which you want to fish. Sizes of weights range from 4 to

20 lbs.

5. Cable This connects to the weight. Cable material is 150 lb. test stainless steel cable.

6. Depth Meter This determines how much cable you have run out, enabling you to choose your trolling

depth.

7. Mounting Base This attaches to the boat, enabling you to place the downrigger where you choose.

8. Rod Holder This holds your fishing rods while trolling and may also be used for storing rods.

2

Page 3

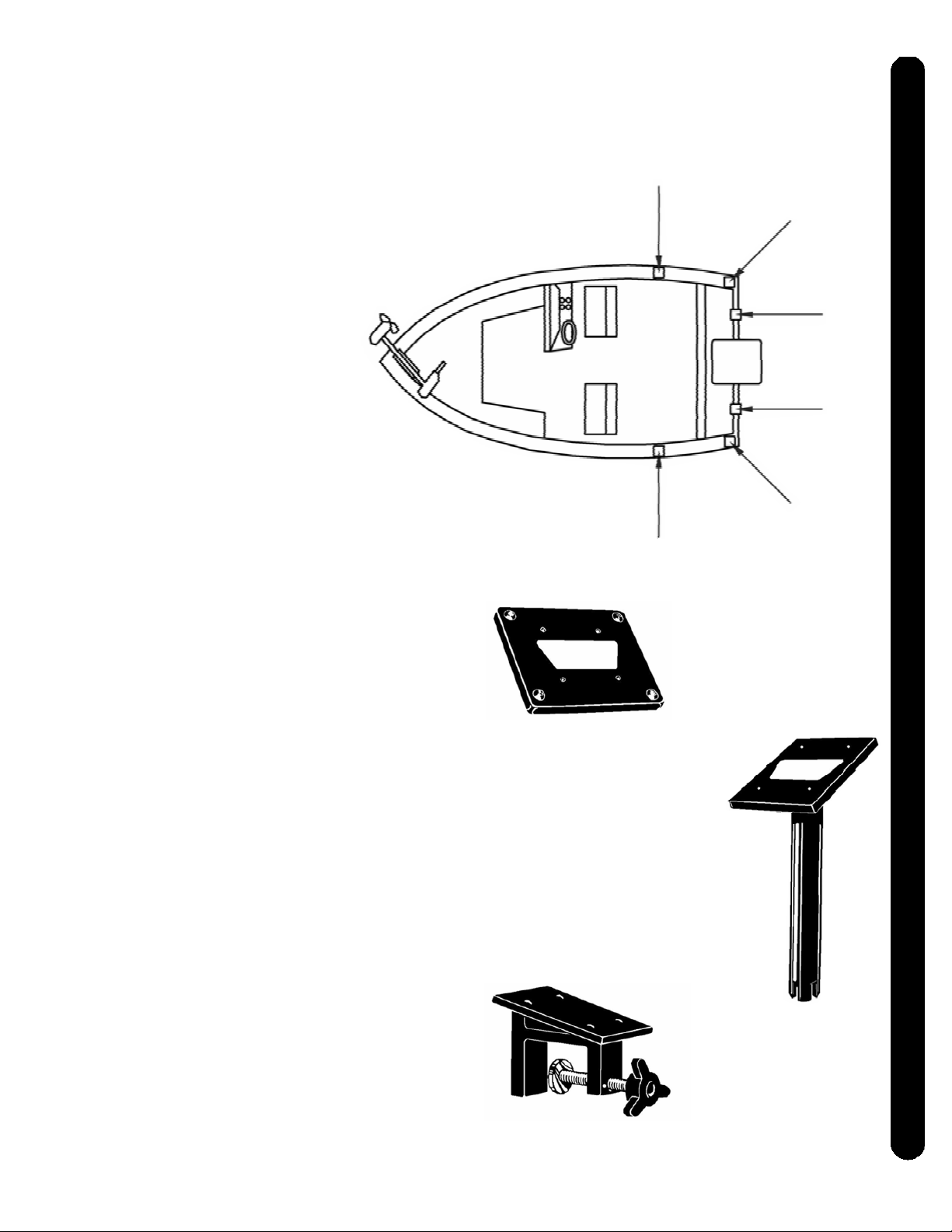

Downrigger Mounting on Boats

A downrigger should be mounted where ever it

is easy to operate and observe. You want to be

able to see your fishing rod and to react quickly.

So, choosing a good spot to mount your

downrigger on your boat is 99% of the job.

Due to the great variety of boats available,

mounting your downrigger can be a dilemma.

Having proper mounting accessories is essential.

Cannon has a complete line of mounting

accessories to conveniently mount your

downriggers on any boat.

MOUNTING & SETUP

Arrows

Indicate

Mounting

Locations

Mounting Accessories

Deck Plates are necessary when extra

strength must be added to the base material of

the boat and for attaching the downrigger to other

mounting accessories.

Gimbal Mounts are designed to fit mediumsized flush mounted rod holders built into the

gunwale of many larger fishing boats and

cruisers. Only sturdy, high quality rod holders

should be used for this temporary mounting

system. Gimbal mounts are available in 9” or 12”

post lengths.

Clamp Mounts can be mounted at the

junction of two rail sections with the aid of two ¼"

pieces of plywood. They will protect your rail from

any marks from the clamp and provide a non-slip

surface.

Deck Plate

Gimbal Mount

Clamp Mount

3

Page 4

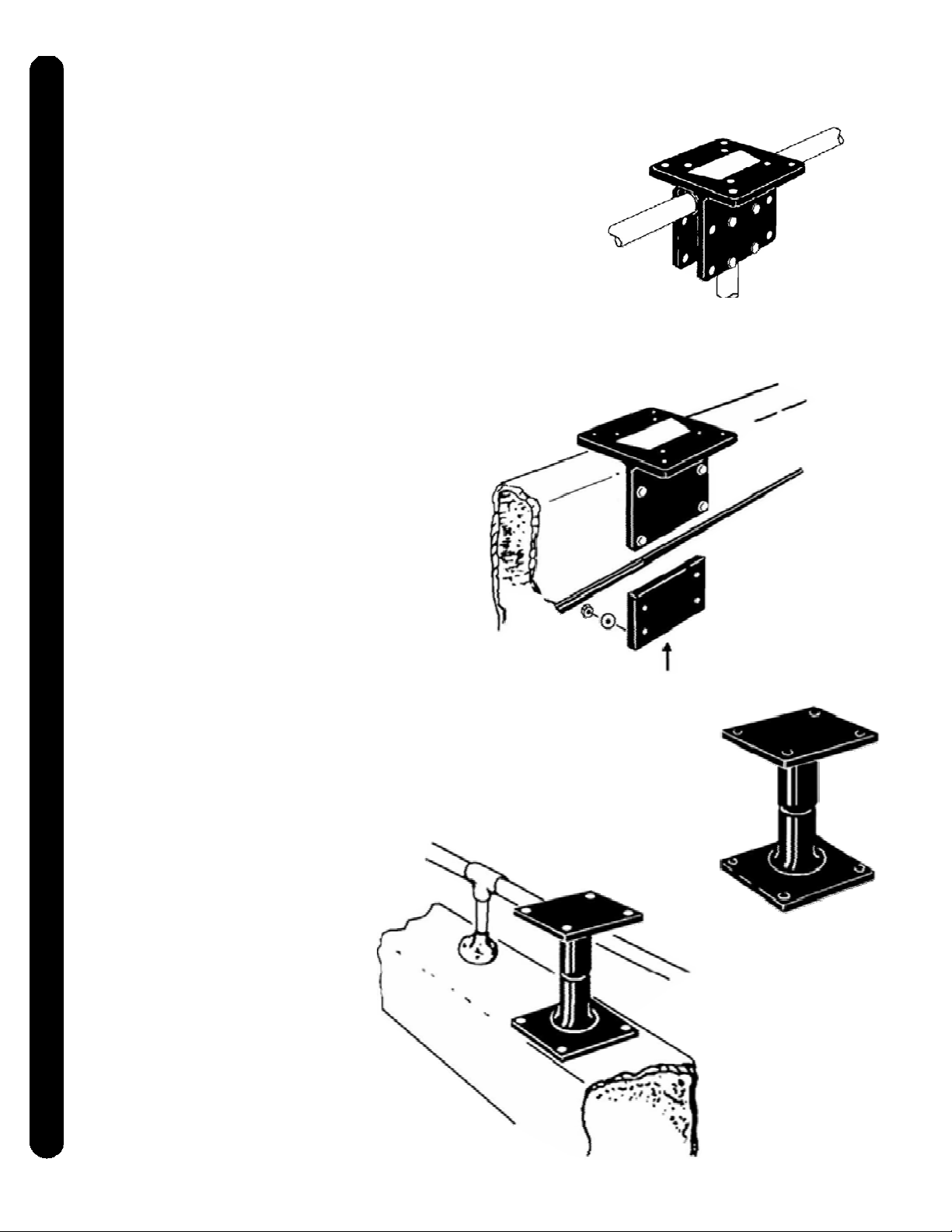

MOUNTING & SETUP

Side Rail Mounting

Side/Rail mounts can be mounted to a

welded T-section. It can also be used at the two

rail section butt joint. In both installations it is

recommended to use a non-slip material, such

as rubber or a thin wood sheet, between metal

surfaces.

You can also use these for mounting to a very

narrow side gunwale. There is a plate provided

for back-up with bolts and washers. If the

gunwale compartment is foamed in, then

wellnuts should be used. It is also recommended

to install two additional flat head screws through

the top plate for stabilization (you will need to

drill and countersink).

Side/Rail on T-Section

Side/Rail on Gunwale

NOTE: In no case should this mount be used

on fiberglass ¼" thick or less unless it is

foamed in.

Pedestal Mounting

Pedestals are used wherever additional height is

needed for ease of operation or to clear

obstructions, such as handrails.

Caution: When using a pedestal mount or side/

rail mount, do not extend the

telescopic boom on your Uni-Troll.

The increased leverage will cause

excessive strain and possible failure

of the mount.

Pedestal for Additional Height

4

Page 5

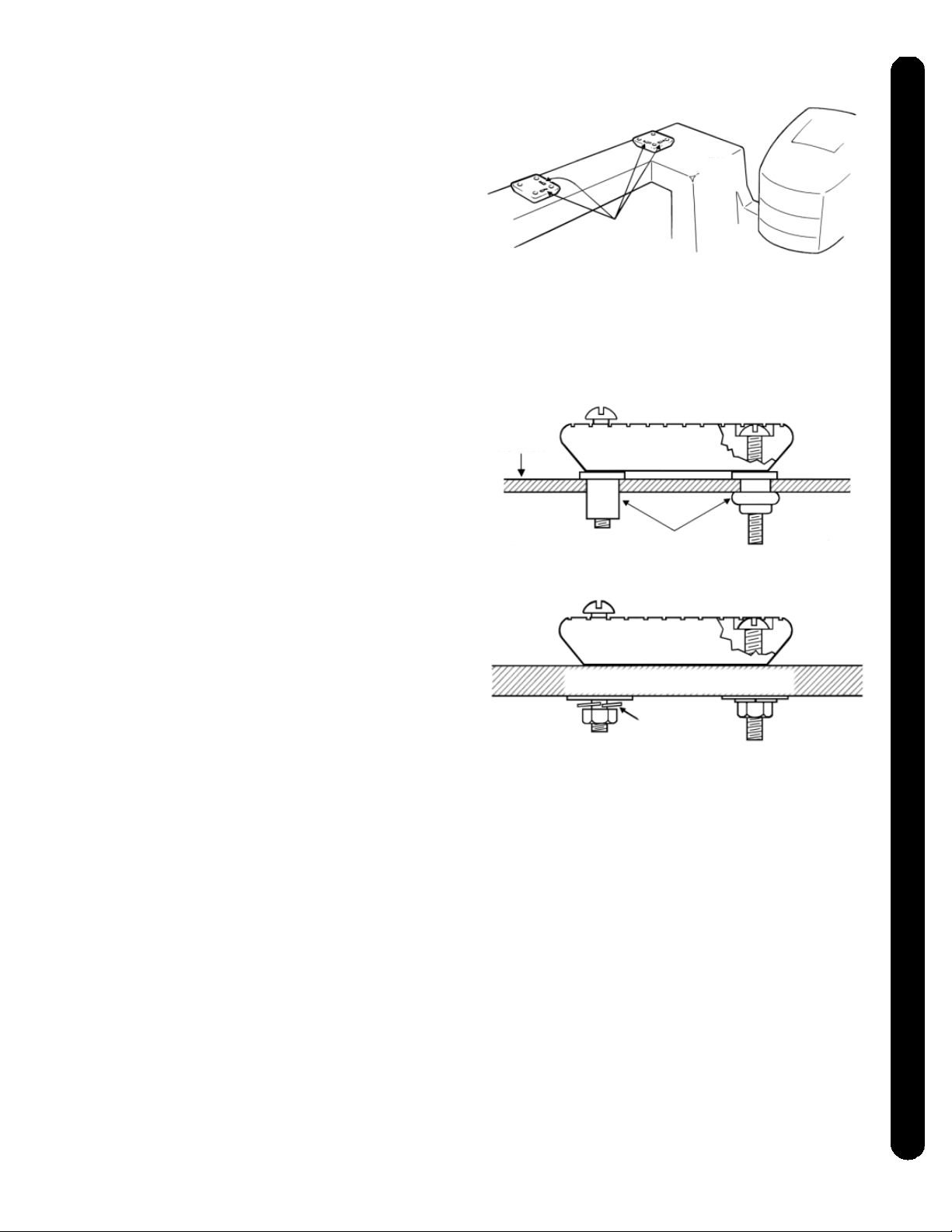

Installing the Base on Your Boat

Decks up to 7/16" thick

Where access to the underside of the deck is

not available, the mounting base can be mounted

using wellnuts. Use the base as a template to mark

locations and drill four 1/2" holes. Mount the base

using four 1/4"-20 x 1 1/2" truss head screws and

four wellnuts. Tighten the screws so the wellnuts are

firmly compressed as pictured.

Decks thicker than 7/16"

For decks thicker than 7/16", or where the

underside of the deck is accessible, mount the base

with screws, nuts, and washers. Use the base as a

template to mark the locations and drill four 9/32"

holes. Use four 1/4" -20 x 2 1/2" truss head screws

and four each flat washers, lock washers, and nuts.

Fasten the base to the deck as pictured.

NOTE: Wellnuts cannot be used on decks thicker

than 7/16".

Outboard Facing

Side

or

Gunwale

Note Locking

Slots in Base

Decks

up to

7/16"

Thick

MOUNTING & SETUP

Stern Facing

Rear

or

Stern

Base

Wellnuts

Base

Decks Thicker Than 7/16"

Washer, Lock Washer,

and 1/4-20 Hex Nut

5

Page 6

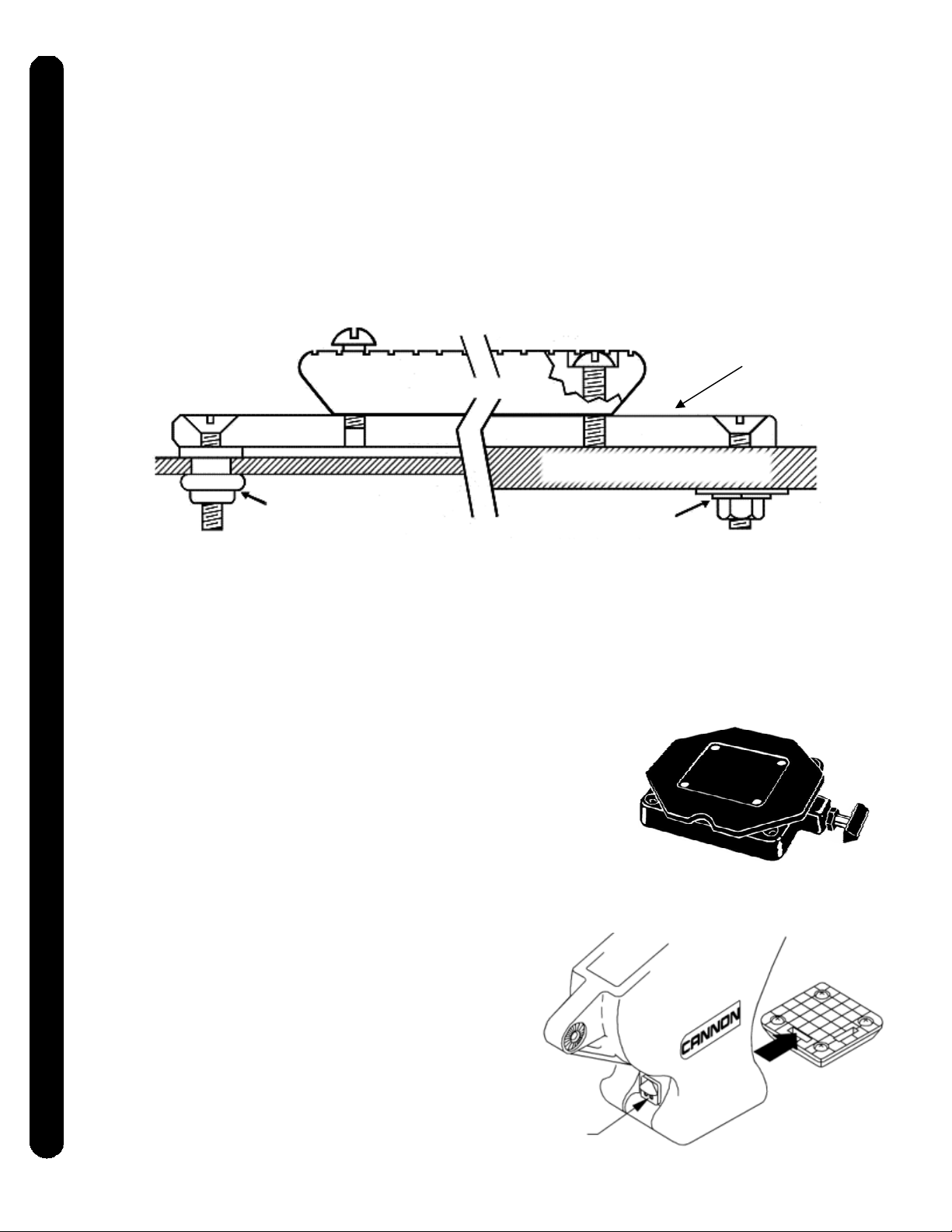

MOUNTING & SETUP

Decks thinner than 1/4"

Use a Cannon Deck Plate to prevent

deflection and add stability to decks thinner than

1/4". Use the deck plate as a template to mark the

hole locations.

If access to the underside of the deck is not

available, the deck plate can be mounted using

screws and wellnuts. Drill 1/2" holes. Use four

1/4”-20 x 2" flat head screws and four wellnuts to

mount deck plate as pictured. Tighten the screws

so the wellnuts are firmly compressed.

Where the underside is accessible, mount the

deck plate using screws, nuts, and washers. Drill

9/32" holes. Use four 1/4”-20 x 2" flat head

screws, nuts and washers (flat and lock). Fasten

plate to deck as pictured. To secure the low-profile

base to the deckplate use four 1/4”-20 x 1 1/2"

truss head screws.

Cannon Deck Plate

Deck Up to 7/16" Thick

Wellnut

Base

Deck Thicker Than 7/16"

Washers, Screws,

& Nuts

NOTE: When using the telescopic boom, we strongly recommend the use of a deck plate on all

boats to provide adequate stability for the downrigger.

FOR Uni-Troll 10 and Uni-Troll 10 TS:

The Low-Profile Swivel Base mounting follows

Low-Profile Swivel Base

the same procedure as for the deck plate except

that four 1/4"-20 x 1 1/2" truss head screws are

used to fasten the mounting base and four

additional 1/4"-20 x 2 1/2" truss head screws fix the

swivel base to the boat deck.

Mounting the Downrigger on the Base

Slide the bottom of the frame over the lip of the

base, with the boom outboard or facing the stern.

Move the frame over the base until the latch clicks

into place. If properly seated, the frame should

completely cover the base.

CAUTION: If not fully seated, your downrigger can

be dislodged from the base.

Tip: Periodically check base to ensure integrity. The

base should be replaced at least every 5 years.

6

Latch

Page 7

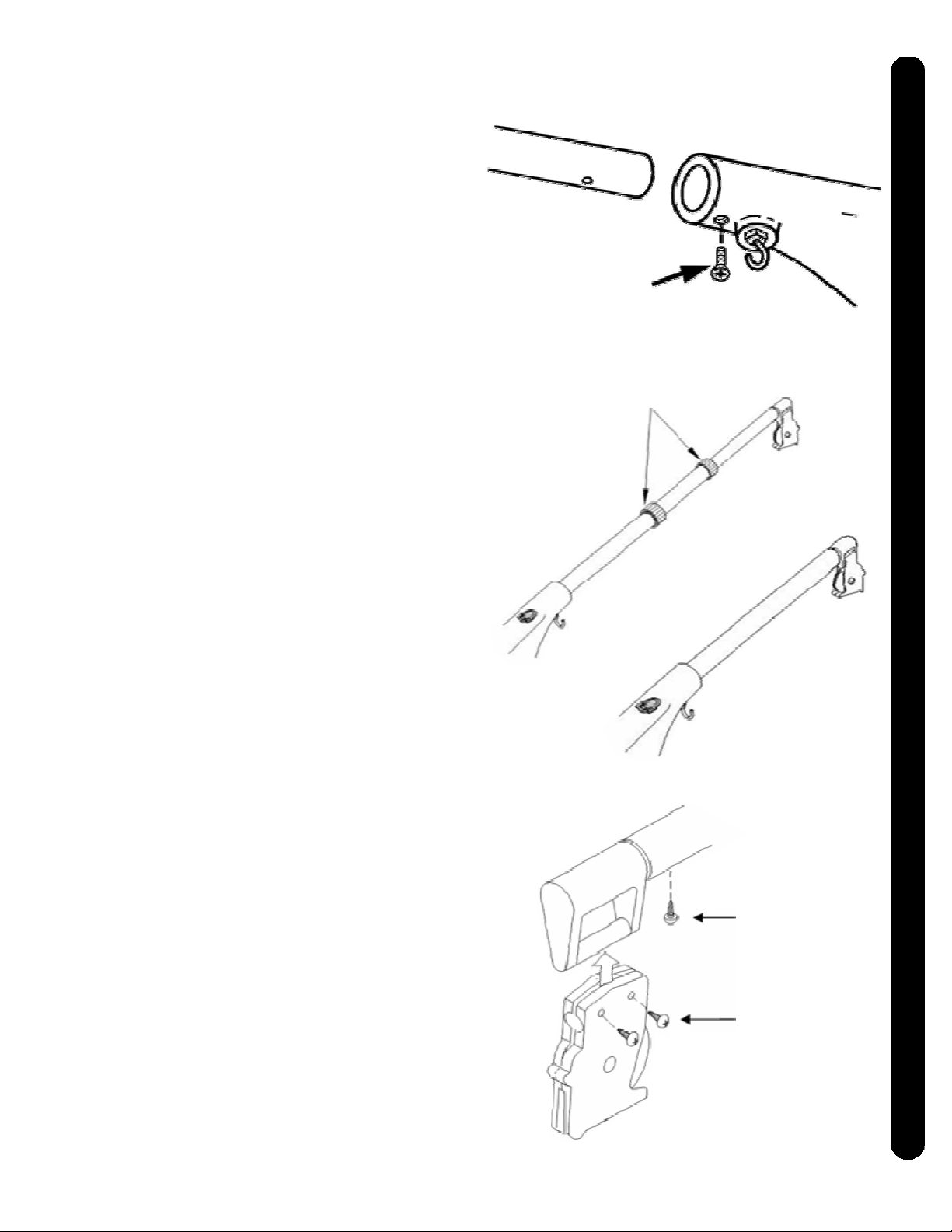

Setting Up Your Downrigger

Attaching the Boom

Telescopic Boom

The intermediate section of the telescopic

boom must be extended approximately 5" before

the boom locking screw can engage the hole in

the boom. Slip the boom end into the frame and

align the holes. Secure with boom locking screw.

To adjust boom length, with the boom

extending away from you, rotate clamps

approximately 1/4 turn counter - clockwise to

unlock, and slide boom section to desired position.

To lock, rotate clamp clock-wise until tight.

TIP: Whenever downriggers with boom lengths

beyond 24" are used, Cannon's Retro-Ease

Weight Retriever will make bringing in the weight

safe and easy. It attaches to the cable below the

boom end allowing you to pull the weight to

yourself without having to lean way out or collapse

the boom to reach the weight.

The Standard 24 Inch Boom inserts into the

downrigger frame (see bottom diagram on page

7). Be sure that the boom is held securely by

seating it firmly against the shoulder inside the

fame and fastening the boom locking screw such

that it engages the hole in the boom.

Assemble Swivel Head To Boom

Insert the telescopic boom-end into the boomalign holes and fasten in place with a #8 x 5/8

screw. Spread the swivel head side plates and slip

the assembly over the boom end axle. Snap the

assembly together and install two #4 x 1/2" screws

into the swivel head.

TIP: Adjusting the angle of the boom head can

help control cable wrap on the reel.

MOUNTING & SETUP

The 3/4"-Long Phillips

Screw Must Engage

Hole in Boom

Clamps

Standard 24"

Boom

#8 x 5/8"

Screw (1)

#4 x 1/2"

Screws (2)

7

Page 8

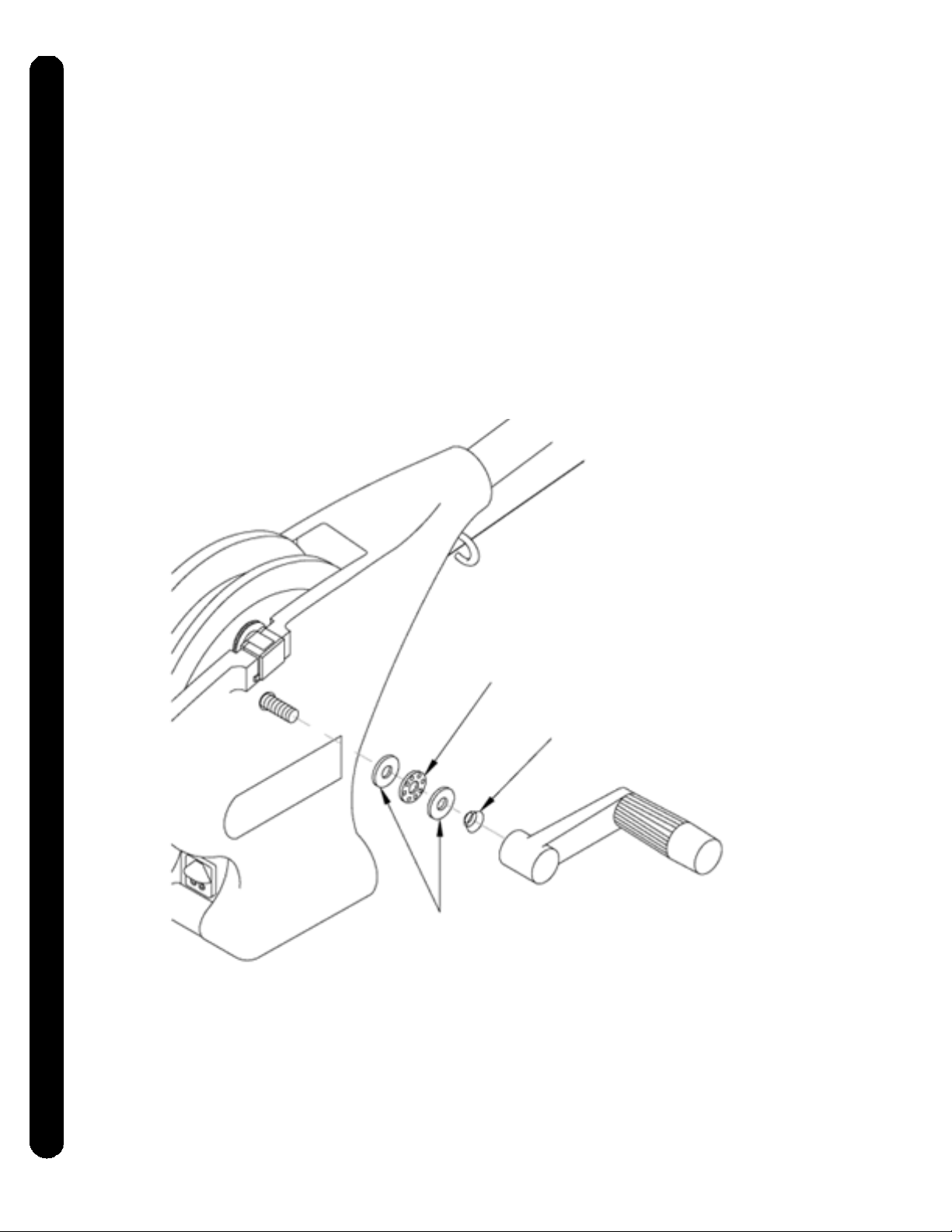

Attaching the crank handle

Attaching the Crank Handle

Assembly

Make sure the thrust bearing is sandwiched

between its two races. The thrust bearing spring

should be oriented where the narrow end is

toward the bearing. Slide the bearing with races

and spring over the ratchet shaft. Then, carefully

thread the crank handle onto the shaft and

continue turning the handle clockwise until the

clutch is fully tightened

NOTE: Place your fingertip on the edge of the

bearing and races. This allows the crank to be

threaded more easily until the spring puts

resistance on the clutch pad.

Races

Thrust

Bearing

Spring

Crank

Handle

8

Page 9

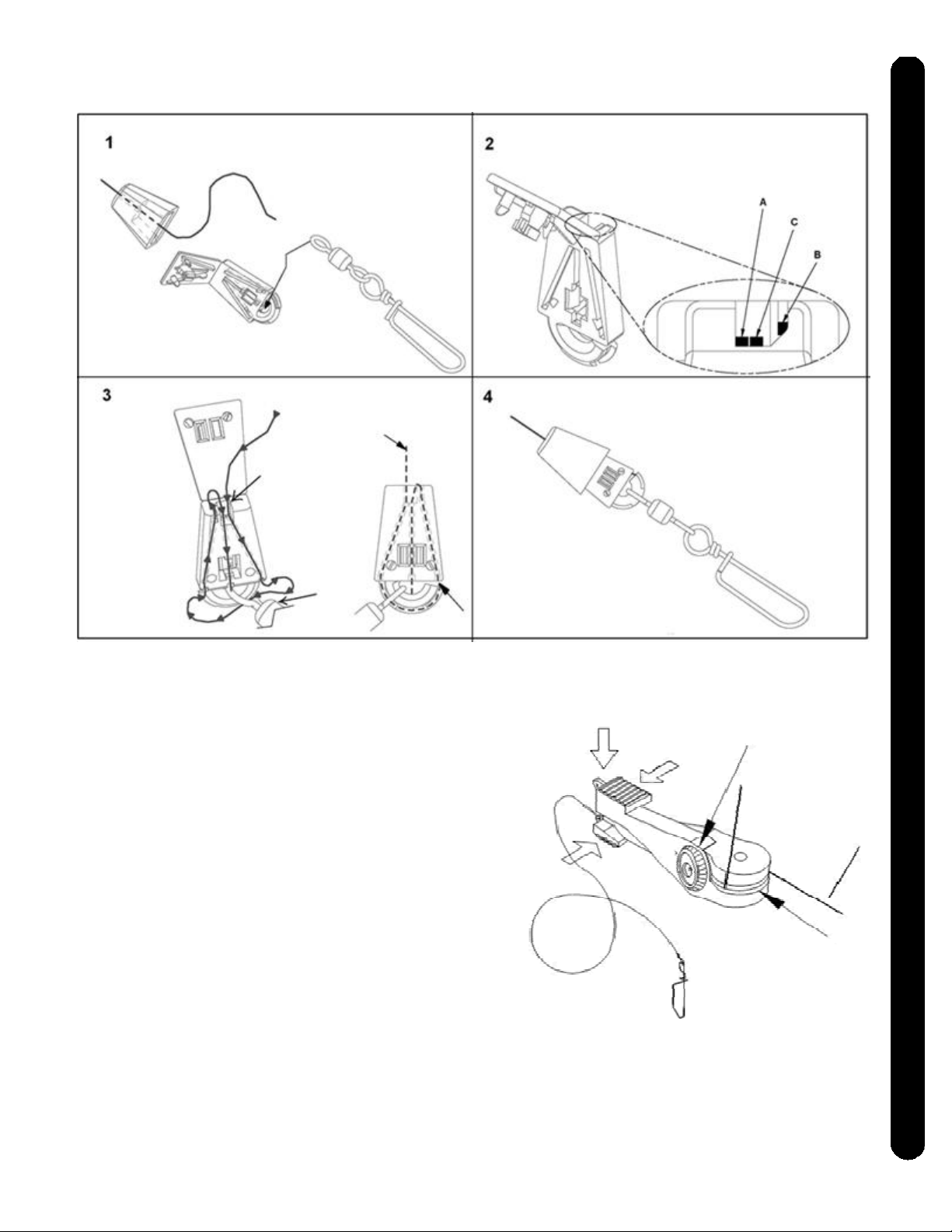

Terminating the Downrigger Cable

Rubber Cushion

Cable

Unwind about 2 feet of cable

and thread the cable through

the rubber cushion.

TERMINATOR & LINE RELEASE

Examine the top of the terminator and note the

order shown in the detail to run cable.

CABLE IN

CABLE IN

Tip: A set of pliers with wire cutters is

recommended for this part of setup.

TIP: Use only straight cable, not kinked.

Lead cable into

HOLE A.

Pull six inches of

cable through.

Thread cable

through swivel,

then up into

bottom of the

terminator.

Lead cable out of

HOLE B and into

HOLE C. Push

the cable until its

end touches the

inside of the

terminator hook.

HOLE A

Attach to terminator.

Tighten cable

by squeezing

terminator until

it snaps shut.

Then pull at top

and bottom

until drawn

tight. Make

sure that the

cable threads

in groove of

the hook.

Swivel

CABLE

OUT

Snap &

Swivel

Slide the cushion over the top of the

terminator and give it a test pull.

The cable is set to attach a Cannon

Trolling Weight.

Cannon Uni-Release

The Cannon Uni-Release attaches directly to

the downrigger weight. Attach fishing line to the

clip at the end of the release, and then click

through a series of increasing tension settings.

The release can be used with any test line on salt

or fresh water and may be adjusted from 2 to 22

pounds of grip tension on the line.

To change line release tension, turn tension knob

to (+) to increase or (-) to decrease. Tension also

may vary according to where the line is placed in

the grips. Higher tension is on the line if it is set

back toward the hinge, and lower if set closer to

the opening. To open the release, spread the

release arms with thumb and forefinger applying

pressure to the sides.

Open

Close

Open

Tension

Adjust

Fishing Line

Gripper

Pads

9

Page 10

ATTACHING THE ROD HOLDER

Attaching the Rod Holder

The positive lock rod holder incorporates a

locking disk that allows the rod holder to be

aligned in 15 degree increments. Slide the rod

holder tube into the clamp to the desired position

within the recommended area (see below).

Be sure the angled shoulders are facing up.

Place the locking disk into the mating recess of

the frame.

Slip the clamp arms in place where the

obround tab on the disk fits into the slot on the

clamp. Slide the star washer between the arm of

the clamp and the frame. Place the flat washer

onto the bolt. Then insert the bolt with washer

through the clamp by entering the disk, going

through the frame, the star washer, and out the

other side of the clamp. Tighten the nut to secure

the rod holder. Reposition the rod holder by

loosening the nut and adjusting the tilt.

CAUTION: This rod holder is intended for use

of up to 30 lb. test line only, and is not

recommended for use with any tackle IGFA

rated higher than 30 lb. A safety strap (not

included) is recommended for all

applications.

The rod holder assembly is not warranted

when used with tackle above 30 lbs.

Equipment placed in the rod holders and the

loss thereof is the responsibility of the user

and is in no way warranted by JOHNSON

OUTDOORS, INC. Mounting must be in

accordance with the above instructions and

diagram to be warranted.

Single Rod Holder Assembly

Recommended

Area to Clamp

Rod Holder

Angled

Shoulder

Dual Rod Holder Assembly

Star Washer

Placement

10

Page 11

Operating Your Downrigger

After mounting the Cannon downrigger to your

boat, release some line from your rod and reel so

that the lure is anywhere from 5 to 100 feet behind

the boat. This is called drop back.

Attach the fishing line firmly into the line

release. Lower the weight to the desired depth as

indicated on the depth meter. Place the fishing rod

in the rod holder and reel up the slack so that your

rod has a slight bend in it. When a fish strikes the

lure, the line will separate from the release. Then

you will be free to fight the fish and bring it in on

your rod and reel.

Lowering the Weight

You can lower the trolling weight at a controlled

rate by turning the crank handle gently counterclockwise (away from the boom). Depending on

how far you turn, you can let your trolling weight

descend as fast or as slowly as you wish. Turn the

crank handle clockwise (toward the boom) until it

you hear a click to stop the weight. This gives you

control to let it plunge rapidly or sink slowly to a

predetermined trolling depth. With multiple

downriggers, you could start all your weights

creeping down, one at a time, and then stop them

each in turn.

Raising the Weight

Turn the crank handle clockwise (toward the

boom) as rapidly as you desire to retrieve the

trolling weight.

Adjusting the Clutch Tension

The clutch is built into the crank mechanism.

Turn crank handle clockwise to increase the drag

and counterclockwise to reduce it.

NOTE: In case your reel continues to slip no

matter how hard you tighten the crank see the

Troubleshooting section of this booklet.

CAUTION: Remove weight from downrigger

before traveling either by water or transporting on

trailer.

OPERATING YOUR DOWNRIGGER

To Lower

Weight

To Raise

Weight

11

Page 12

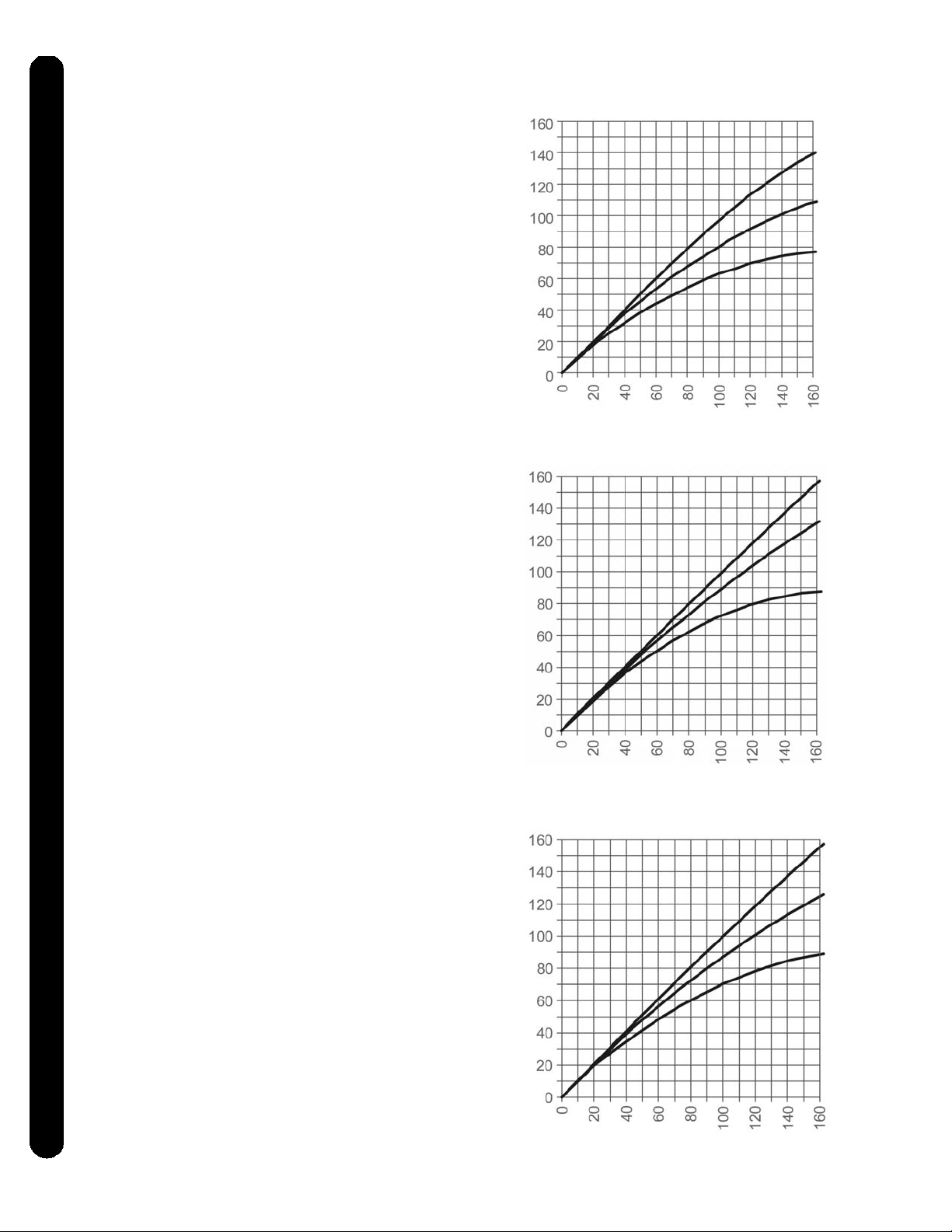

Blowback

Blowback

Simply stated, blowback is what happens to

the downrigger weight when you pull it through the

water behind your boat. As your speed increases,

so does the horizontal distance between the

weight and your downrigger. The faster you go,

the farther the weight is behind you. The farther

the weight is behind you, the shallower the weight

is.

The following charts provide you with

blowback information for three sizes of Cannon

downrigger weights pulled at three different

speeds with no lures attached and with no current.

Current drag, water salinity and the use of nonCannon products will affect your actual trolling

depth.

As an example, the first chart shows that if you

are trolling at 4 MPH with an 8 pound weight and

you have 100 FT. of cable in the water with no

current; the downrigger ball is actually at a depth

of about 80 FT.

Actual Depth of Weight (ft.)

ActualDepth of Weight (ft.)

Blowback Charts

8-Lb. Weight at 2, 4, and 6 MPH

2 MPH

4 MPH

6 MPH

Amount of Cable in Water (ft.)

10-Lb. Weight at 2, 4, and 6 MPH

2 MPH

4 MPH

Actual Depth of Weight (ft.)

6 MPH

Amount of Cable in Water (ft.)

12-Lb. Weight at 2, 4, and 6 MPH

2 MPH

4 MPH

6 MPH

12

Amount of Cable in Water (ft.)

Page 13

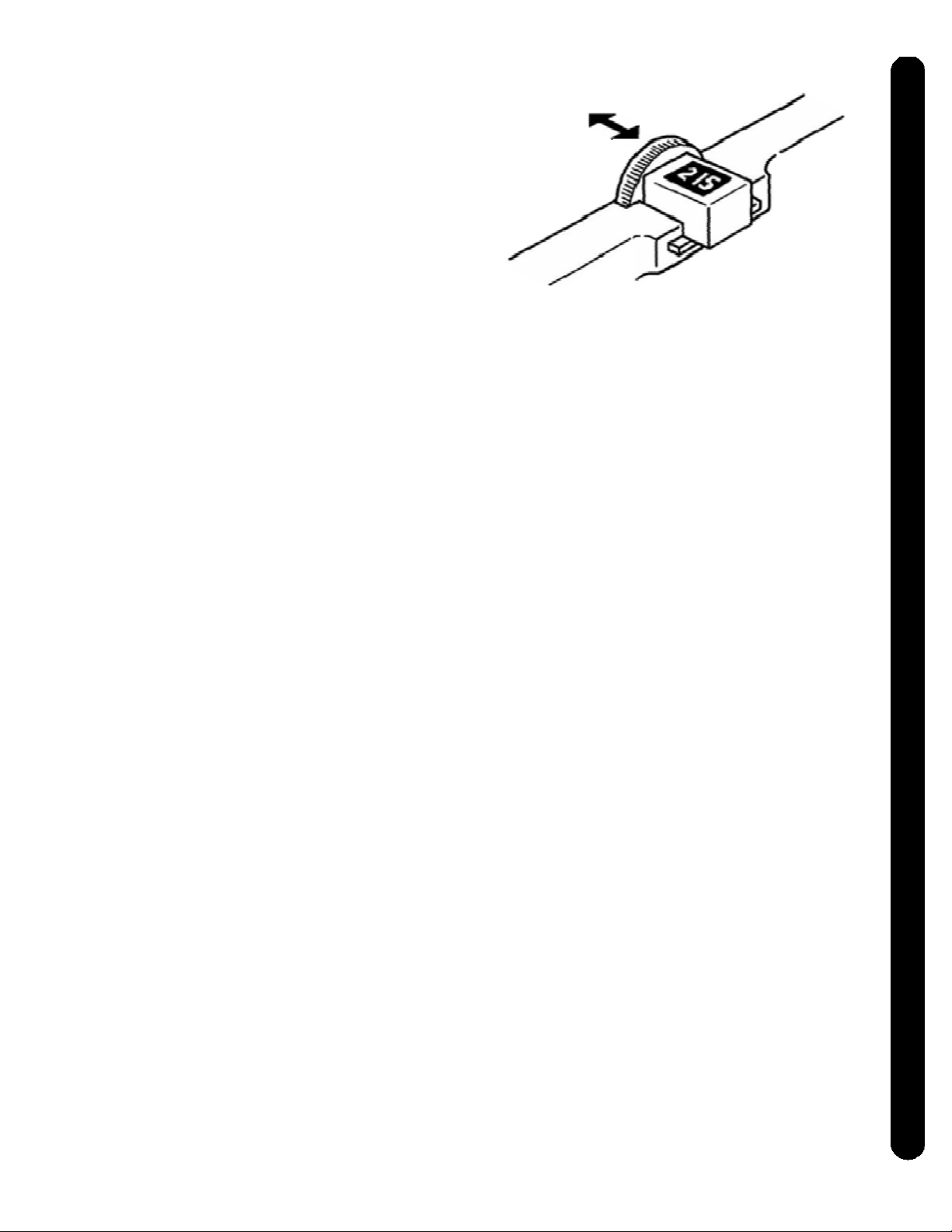

Adjusting the Depth Meter

The Cannon Depth Meter provides non-slip

accuracy, plus easy resetting. To reset, just slide

the meter away from the reel until the gears are

disengaged. Spin meter gear to change setting.

NOTE: Actual fishing depth may vary from

depth shown on meter due to trolling speed

and weight of cannon ball. (See "Blowback")

Maintaining Your Downrigger

At the beginning of each fishing season and

more often during periods of heavy usage, lightly

grease the thrust bearing, reel shaft bearings,

swivel head pulley, ratchet brake face, and

ratchet dog. When using for saltwater fishing,

thoroughly rinse the entire downrigger with fresh

water after each trip and lubricate on a frequent

basis. Replace the cable at least every two years.

For repairs or servicing your downrigger refer

to the Warranty Information section of this

booklet.

Trouble Shooting

PROBLEM:

Clutch slips

SOLUTION:

The set screw in the reel may have come

loose off the shaft. Follow the instructions

below:

1) Unwind the cable from the reel.

2) Remove the set screw.

3) Align the set screw hole in the reel with the

hole in the reel shaft by inserting a 3/16" or

smaller rod and rotating the reel until you feel

it drop into the shaft hole.

4) Replace the set screw and tighten until you

feel resistance.

5) By gently rocking the reel back and forth while

tightening the set screw, you can feel it

engage in the shaft hole. The half dog point

on the set screw must enter the hole in the

shaft; not just be tightened against the reel

shaft.

maintaining & TROUBLE SHOOTING

13

Page 14

TROLLING TIPS

Ten Good Trolling Tips

1) Test your lures over the boat side before

sending them down and back. Do this to make

sure the lure wiggles and wobbles properly without

going belly up or wandering off. Some lures can be

adjusted, fine tuned actually, to impart maximum

action. For example, a slight bend in the tail of a

spoon or twist of the hook eye in the nose of a plug

can make a noticeable difference in how the lure

performs.

Also, when running two or more lures, make sure

the offerings are compatible. Lures that run out of

harmony with each other are bound to tangle and

that means wasted time to straighten out the mess.

Testing them first will avoid the problem.

2) Consider different sizes, shapes, and colors

of lures. No one has ever figured out with precision

what makes a fish strike or snub a lure. There is no

doubt, that matching the forage (minnows, crayfish,

etc.) in color, shape, action, and size can help

trigger those strikes from hungry fish. On the other

hand, if fish such as bluegills, small mouth bass or

Coho salmon are protecting spawning beds, they

may attack whatever is threatening. So, bright

colors in lures may out produce bland colors.

3) Vary trolling speeds. Goosing the engine now

and then or slowing to a crawl every so often will

change the action of the lures and may get fish to

strike them.

4) Vary trolling patterns and lead lengths. The

amount of line you let out often determines how

deep the lure will run and, to some extent, what

degree of action it will impart. For starters, consider

running lures about ten feet behind downrigger

weights. If flat line trolling, put them back about fifty

feet, then experiment depending on what the fish

do.

Trolling patterns affect lure action too, that is

why some anglers like to wheel a lazy S course.

On turns, outside lures will speed up momentarily

while inside lures hang for a moment or two. Fish

may nail lures that change speeds. Also, zigzag

patterns allow for more water coverage, plus it

keeps lures out of propeller boil, an important

consideration for browns and other wary species.

5) Locate fish on a vertical plane. Place lures in

areas where fish might be. Skilled fishermen call

these areas the “strike zones”. They include the

edges of the week beds, structure along bottom,

drop-offs, preferred temperature of the target

species, and the thermocline. Remember that fish

occupy certain areas for certain reasons (sources

of food, protective cover, preferred temperatures,

etc.).

6) Consider special knots and swivels. A good

ball bearing swivel will all but eliminate line twist

and will aid in getting maximum performance from

a lure. Many anglers add the tiny swivels to split

rings already on the lure itself. On the other hand,

a swivel may dampen the action of a sensitive lure,

such as a Rapala. Some fisherman tie tiny

improved cinch or loop knots. Loop knots in

particular may enhance up and down and side to

side action of lures. Any good fishing manual will

explain how to tie these and other knots.

7) Consider releases for flatline trolling. A

good tip is to secure a piece of downrigger cable or

heavy monofilament to the water ski hook or

handle below the transom of most boats. To the

other end of the mono or cable, add a pinch-rrelease. After letting out your lure to the desire

distance, put the rod in its holder, then bend the tip

and secure the fishing line in the release.

8) Add a weed guard. Having trouble with weeds

hanging up lures? Consider tying a three-inch

piece of monofilament a foot above the lure.

Leaves, smaller weeds and other debris may catch

here momentarily then fall off to the side of the lure

without tangling. Weedless lures are another smart

consideration. Downrigger cables are effective

weed catchers when trolling for pike, muskies, or

bass in weed-infested lakes.

9) Add a stinger hook. When fish short strike,

slap at lures without becoming hooked, adding a

stinger hook can solve the problem. Simply tie a

treble hook to one end of a four inch piece of

monofilament and then tie the extra hook to the

last gang of hooks on your lure. The stinger hook,

which trails the lure, provides extra insurance.

10) Keep hooks sharp. Some of the best

fishermen sharpen all hooks after every fish

caught. Hooks get dull through both use and

misuse, and probably more fish are lost to dull

points than anything else.

14

Page 15

CANNON® LIMITED WARRANTY

Johnson Outdoors Inc. warrants to the original purchaser that if

the accompanying product (see exclusions below) proves to be

defective in material or workmanship within the following warranty

periods, Johnson Outdoors Inc. will, at its option, either repair or

replace same without charge (but no cash refunds will be made):

1) The boom, motor, and reels, plus all Lexan®* parts, including

but not limited to frames and bases, will be free from defects

in materials and workmanship, subject to normal wear and

tear, for the original purchaser's lifetime.

2) All other items will have 1-year limited warranties from the

date of original retail purchase, except THE FOLLOWING

ITEMS THAT HAVE NO WARRANTY WHATSOEVER: boot

covers, clothing, Dacron line, rubber bands, swivel lock pin,

weights, and wire cable.

This limited warranty may be enforced only by the original

purchaser; all subsequent purchasers acquire the product "as

is" without any benefit of this limited warranty. Repair or

replacement of the product as set forth in this limited warranty

shall be the original purchaser’s sole and exclusive remedy

and Johnson Outdoors Inc.’s sole and exclusive liability for

breach of this warranty.

EXCLUSIONS

This warranty does not apply in the following circumstances:

• When the product has been connected, installed, combined,

altered, adjusted, serviced, repaired, or handled in a manner

other than according to the instructions furnished with the

product

• When a serial number has been effaced, altered, or removed

• When any defect, problem, loss, or damage has resulted from

any accident, misuse, negligence, carelessness, or abnormal

use, or from any failure to provide reasonable and necessary

maintenance in accordance with the instructions of the

owner's manual

LIMITATION AND EXCLUSION OF IMPLIED WARRANTIES AND

CERTAIN DAMAGES

THERE ARE NO EXPRESS WARRANTIES OTHER THAN

THESE LIMITED WARRANTIES. JOHNSON OUTDOORS INC.

DISCLAIMS LIABILITY FOR INCIDENTAL AND CONSEQUENTIAL

DAMAGES, AND IN NO EVENT SHALL ANY IMPLIED

WARRANTIES (EXCEPT ON THE BOOM, MOTOR, REELS, AND

ALL LEXAN®* PARTS), INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE,

EXTEND BEYOND ONE YEAR FROM THE DATE OF PURCHASE

(AND IN THE CASE OF THE BOOT COVERS, CLOTHING,

DACRON LINE, RUBBER BANDS, SWIVEL LOCK PIN, WEIGHTS,

AND WIRE CABLE, JOHNSON OUTDOORS INC. DISCLAIMS ALL

IMPLIED WARRANTIES). THIS WRITING CONSTITUTES THE

ENTIRE AGREEMENT OF THE PARTIES WITH RESPECT TO THE

SUBJECT MATTER HEREOF; NO WAIVER OR AMENDMENT

SHALL BE VALID UNLESS IN WRITING SIGNED BY JOHNSON

OUTDOORS INC.

Some states do not allow limitations on how long an implied warranty

lasts or the exclusion or limitation of consequential damages, so the

above limitation or exclusion may not apply to you. This warranty

gives you specific legal rights, and you may also have other rights

that vary from state to state.

* Lexan is a registered trademark of General Electric.

CANNON® SERVICE POLICY

LIMITED WARRANTY & SERVICE POLICY

AFTER THE APPLICABLE WARRANTY PERIOD

After the applicable warranty period, or, if one of the above

exclusions applies, Cannon® products will be repaired for a charge of

parts plus labor. All factory repairs, after the applicable warranty

period, carry a 90-Day Limited Warranty, subject to the exclusions

and limitations stated above.

TO ENFORCE WARRANTY OR TO

OBTAIN REPAIRS AFTER WARRANTY

To obtain warranty service in the U.S., the downrigger or part

believed to be defective and the proof of original purchase (including

the date of purchase) must be presented to a Cannon® Authorized

Service Center or to Cannon®’s factory service center in Mankato,

MN. Except as noted below, any charges incurred for service calls,

transportation or shipping/freight to/from the Cannon® Authorized

Service Center or Cannon®’s factory, labor to haul out, remove, reinstall or re-rig products for warranty service, or any similar items are

the sole and exclusive responsibility of the purchaser. Downriggers

purchased outside of the U.S. (or parts of such downriggers) must be

returned prepaid with proof of purchase (including the date of

purchase and serial number) to any Authorized Cannon® Service

Center in the country of purchase. Warranty service can be arranged

by contacting a Cannon® Authorized Service Center listed on the

enclosed sheet, or by contacting the factory at 1-800-227-6433 or

Fax 1-800-527-4464. If the necessary repairs are covered by the

warranty, we will pay the return shipping charges to any destination

within the United States.

DO NOT return your Cannon

Your retailer is not authorized to repair or replace them.

Major parts, such as the motor and main frame, must be returned

to Johnson Outdoors Inc. in Mankato, Minnesota, or a Cannon

Authorized Service Center, for repair or replacement. To reduce

shipping costs, we suggest removal of loose parts such as the boom

and rod holders. Small parts that can be easily removed such as the

handle and/or the counter, may be removed from the downrigger and

returned for repair or replacement.

Retain your sales receipt! Proof of purchase must accompany

product when returned.

Return Address: Johnson Outdoors Inc.

Cannon Division

121 Power Drive

Mankato, MN 56001

FOR YOUR INFORMATION:

Serial No.

Date Purchased

Store Where Purchased

RETAIN THIS SECTION FOR YOUR RECORDS

®

downrigger or parts to your retailer.

®

15

Page 16

Service Centers

Authorized Service Centers

Your new Cannon® Downrigger was built to exacting specifications under rigid quality control to provide you years of trouble-free

operation. If it should ever need adjustment or service, you may send it to any Cannon® Authorized Service Center near you.

ALASKA

Alaska Performance

6820 Arctic Blvd

Anchorage 99518

907-522-8965

North Repair

172 Chandler Rd

Ketchikan 99902

907-225-3690

CALIFORNIA

Fisherman’s Warehouse

9035 Folsom Blvd

Sacramento 95826

916-362-1259

B & F Rod & Reel

1028 W. 4th St.

Ontario 91762

909-988-9229

FLORIDA

Master Repair, Inc.

4446 SE Commerce Ave

Stuart 34997

772-220-7777

Pace’s Minn Kota Service Center

3618-B Fowler St

Ft Myers 33901

239-939-9851

Trolling Motor Service

4125 Blanding Blvd

Jax 32210

904-573-0480

KENTUCKY

Wayne Co. Marine

Rt 1 Box 290-A

Monticello 42633

606-348-5483

MICHIGAN

Cannon Service Center

2080 Lakeshore Dr.

Muskegon 49441

231-731-8352

MICHIGAN (continued)

Trolling Motor Repair

119 E Main St Box 77

Kingsley 49649

231-263-5998

Coastline Power & Lighting, LLC

8338 Anchor Bay Dr

Algonac 48001

810-794-5951

MINNESOTA

Electrotech

1332 E. 4th St.

Duluth 55805

218-727-8919

Lake of the Woods Marine

3208 Bur Oak Rd

Baudette 56623

213-634-2289

NEVADA

Pyramid Lake Store

29555 Pyramid Hwy

Sutcliff 89510

775-476-0555

NEW HAMPSHIRE

Paugus Bay Sporting Goods

135 Weirs Blvd

Laconia 03246

603-524-4319

NEW JERSEY

Sportsman Center

Rt. 130

Bordentown 08505

609-298-5300

NEW YORK

A & P Custom Tackle

155 Hidley Rd

Wynantskill 12198

518-283-5920

Bill’s Hooks

5139 W Lake Rd

Dunkirk 14048

716-366-0268

NEW YORK (continued)

Fish307.Com

1571 State Rt. 9

Lake George 12845

518-798-9203

Screwy Louie’s

596 Main St. PO Box 37

Fairhaven 13064

315-947-6348

Tony’s Reel Repair

7686 Michael Rd

Orchard Park 14127

716-662-5692

NORTH CAROLINA

Fisherman’s Friend

1401 S Ridge Ave

Kannapolis 28083

704-934-2122

OREGON

Ollie Damon’s

236 SE. Grand Ave.

Portland 97214

503-232-3193

PENNSYLVANIA

Dave’s Sport Center

1127 N. Easton Rd.

Doylestown 18902

215-766-8000

SOUTH CAROLINA

Port-Tronics

1904 Piedmont Hwy.

Greenville 29605

864-299-1432

SOUTH DAKOTA

Pierre Sports Center

1440 N. Garfield

Pierre 57501

605-224-5546

TEXAS

Bob Ridgway Repair

605 W. Mockingbird

Dallas 75247

214-630-8161

UTAH

Swede R’s at Croft Power Equipment

596 W. 1500 St.

Woods Cross 84087

801-397-1675

VERMONT

Vermont Home & Marine

323 Industrial Ave.

Williston 05487

802-658-5427

VIRGINIA

Queen’s Creek Reel & Downrigger

Intersection of Routes 3 & 198

PO Box 900

Cobbs Creek 23035

804-725-3889

WASHINGTON

Pacific NW Downrigger Repair

45795 Geo Star Rd.

PO Box 238

Grand Coulee 99133

509-633-0708

Northern Sales

510 E. College Way

Mount Vernon 98273

360-424-8522

DROP OFF LOCATIONS

The Duffle Bag

8207 S. Tacoma Way

Lakewood, WA 98499

Jerry’s Surplus

2031 Broadway

Everett, WA 98201

WISCONSIN

Howie’s Tackle

223 Greenbay Rd.

Sturgeon Bay 54235

920-746-9916

16

For a current list of authorized Cannon Service Centers, including those outside of the US and Canada, please see our web page at

www.cannondownriggers.com.

All CANNON Downriggers are covered by US Pat.D-269, 992. Copyright 2006 Johnson Outdoors, Inc. All rights reserved. Conforms to 89/336/

EEC (EMC) under standards EN 55022A, EN 50082-2 since 1996 LN V9677264

WARNING: This product contains chemical(s) known to the state of California to cause cancer and/or reproductive toxicity.

Form No. 339-7103 Rev 07/07

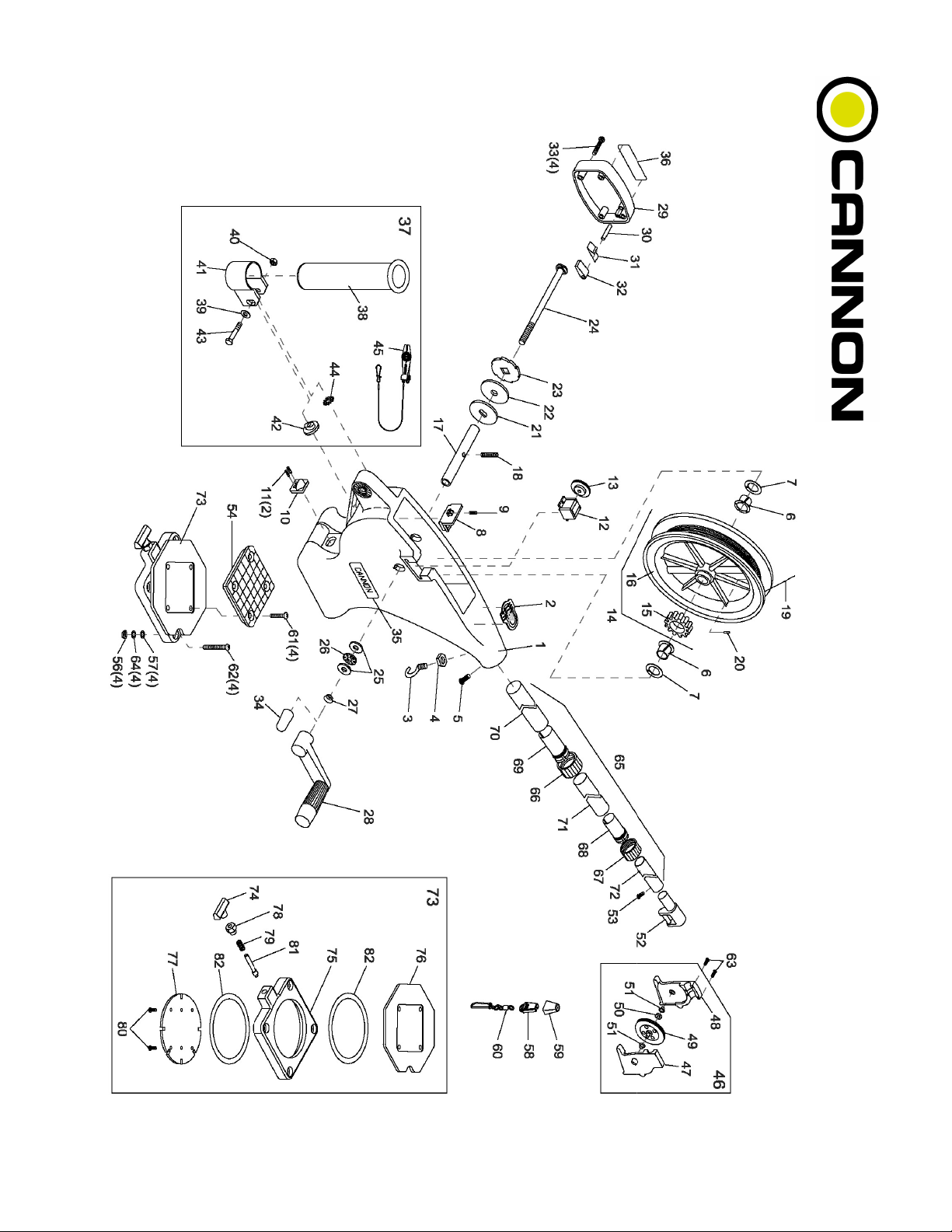

Page 17

Form No. 3394905 Rev 12/06

UNI-TROLL 10

1901100

TM

Page 18

Form No. 3394905 Rev 12/06

21 0467695 BRAKE PLATE - REEL 49 0269726 ►PULLY - SWIVEL HEAD 77 2267006 >INDEXING PLATE (TAPPED)

22 1264670 CLUTCH PAD 50 3397300 ►WASHER - .735 OD X .36 ID 78 2277001 >NUT - RETAINER RELEASE

23 0467694 BRAKE PLATE - RATCHET 51 9010070 ►HDW BEARING BRASS[2.EA] 79 2287002 >SPRING - RELEASE PIN

24 1000904 SHAFT - RATCHET - UNI-TROLL 52 2227820 BOOM END - TELESCOPIC (LEXAN) 80 2372100 >SCREW - #8 x 5/8" PPHMS [2.EA]

25 9010310 WASHER - THRUST [2.EA] 53 2372100 SCREW - #8 x 5/8" PPHMS 81 3392600 >RELEASE PIN

26 9010280 BEARING - THRUST 54 3307002 LOW PROFILE MOUNTING BASE (LEXAN) 82 9010004 >BEARING - SWIVEL BASE [2.EA]

27 9400040 SPRING - HAND CRANK 55 2994894 *BAG ASSEMBLY, MOUNTING (KIT #4)

28 0902000 CRANK HANDLE - UNI-TROLL 56 2263102 NUT - HEX 1/4"-20 [4.EA]

> PART OF ASSEMBLY ►ITEM CANNOT BE SOLD SEPARATELY * PARTS USED BUT NOT SHOWN

20 9100070 CABLE LEADER SLEEVE 48 0267002 ►SIDE PLATE (LH) 76 2267002 >SWIVEL PLATE (LEXAN)

16 3397904 ►REEL - ROUGH 5.75" 44 9430160 >WASHER - STAR 5/16" 72 2290830 ►BOOM END TUBE (BLACK)

13 3333003 GEAR - COUNTER, UNI-TROLL 41 3319005 >CLAMP - ROD HOLDER w/ SLOT 69 2222826 >BASE TUBE COLLET

14 3397913 REEL ASSEMBLY - UNI-TROLL HIGH SPEED 42 3325002 >DISK - ROD HOLDER 70 2290828 ►BOOM BASE TUBE (BLACK)

15 3333004 >GEAR - REEL, UNI-TROLL 43 9040310 >BOLT - HEX 5/16"-18 x 2" 71 2290829 ►BOOM MID TUBE (BLACK)

17 1080001 SHAFT - REEL, UNI-TROLL 45 2277002 >UNIVERSAL LINE RELEASE 73 2998905 SWIVEL BASE

18 3393412 SCREW - SET 5/16"-18 x 1" (REEL) 46 3992300 SWIVEL HEAD ASSEMBLY 74 2249001 >KNOB - RELEASE PIN (LEXAN)

19 3775396 SPOOL CABLE SS [200.FT] 47 0267001 ►SIDE PLATE (RH) 75 2267001 >BASE PLATE (LEXAN)

10 3356052 BASE LATCH TAB 38 0290796 >TUBE - ROD HOLDER 66 2219822 >BASE TUBE CLAMP

11 9370010 SCREW - #4 x 1/2" PPH [2.EA] 39 2151726 >WASHER - 5/16" FLAT 67 2219823 >MID TUBE CLAMP

12 0220477 DEPTH COUNTER - 3 DIGIT 40 2383106 >NUT - 5/16"-18 SS 68 2222825 >MID TUBE COLLET

7 9430003 WASHER - 5/8" ID (NYLON) [2.EA] 35 3395631 DECAL - CANNON SMALL 63 9370010 SCREW - #4 x 1/2" PPH [3.EA]

8 3356050 BASE LATCH 36 3395630 DECAL - CANNON LARGE 64 9950357 WASHER - LOCK 1/4" SPLIT [4.EA]

9 9400050 SPRING - BASE LATCH 37 2477001 BAG ASSY - SINGLE ROD HOLDER 65 2210821 TELESCOPIC BOOM

In the U.S.A., replacement parts may be ordered directly from CANNON Parts Dept., 121 Power Drive, Mankato, Minnesota 56001. In Canada, parts may be ordered from any of the Canadian Authorized Service Centers shown on the enclosed list. Be

sure to provide the MODEL and SERIAL numbers of your downrigger when ordering parts. Please use the correct part numbers from the parts list. Payment for any parts ordered from the CANNON parts department, may be by cash, personal check,

Discover Card, MasterCard or VISA. To order, call 1-800-227-6433 or FAX 1-800-527-4464.

1 3330002 FRAME - UNI-TROLL 29 3321001 COVER - CLUTCH, ROUND (LEXAN) 57 2371712 WASHER - 9/32" FLAT [4.EA]

2 3327004 DECAL - NOSE, UNI-TROLL 30 9250003 PIN - DOWEL 3/16" x 7/8" - RATCHET 58 9100100 TERMINATOR

3 9040040 HOOK - 1/4" - 20 ROLLED 31 9400070 SPRING - DOG RATCHET 59 9100101 TERMINATOR CUSHION

4 2263102 NUT - HEX 1/4"-20 32 9100160 DOG - RATCHET 60 9100620 TERMINATOR SNAP & SWIVEL

5 9280750 SCREW - 1/4" - 20 (RH) x 3/4" PPH 33 9370001 SCREW - #10 x 1-1/4" PPHSMS [4.EA] 61 9280713 BOLT - TRUSS 1/4" - 20 x 1-1/2" [4.EA]

6 9010001 BEARING - REEL SHAFT NYLINER [2.EA] 34 9100721 RED THREAD CAP 62 9280725 BOLT - TRUSS 1/4" - 20 x 2-1/2" [4.EA]

Page 19

Form No. 3394913 Rev 12/06

UNI-TROLL 10 METRIC

1901101

TM

Page 20

28 9400040 SPRING - HAND CRANK 56 2994894 *BAG ASSEMBLY, MOUNTING (KIT #4)

24 0467694 BRAKE PLATE - RATCHET 52 9010070 ►HDW BEARING BRASS[2.EA] 80 2287002 >SPRING - RELEASE PIN

23 1264670 CLUTCH PAD 51 3397300 ►WASHER - .735 OD X .36 ID 79 2277001 >NUT - RETAINER RELEASE

22 0467695 BRAKE PLATE - REEL 50 0269726 ►PULLY - SWIVEL HEAD 78 2267006 >INDEXING PLATE (TAPPED)

21 9100070 CABLE LEADER SLEEVE 49 0267002 ►SIDE PLATE (LH) 77 2267002 >SWIVEL PLATE (LEXAN)

25 1000904 SHAFT - RATCHET - UNI-TROLL 53 2227820 BOOM END - TELESCOPIC (LEXAN) 81 2372100 >SCREW - #8 x 5/8" PPHMS [2.EA]

26 9010310 WASHER - THRUST [2.EA] 54 2372100 SCREW - #8 x 5/8" PPHMS 82 3392600 >RELEASE PIN

27 9010280 BEARING - THRUST 55 3307002 LOW PROFILE MOUNTING BASE (LEXAN) 83 9010004 >BEARING - SWIVEL BASE [2.EA]

> PART OF ASSEMBLY ►ITEM CANNOT BE SOLD SEPARATELY * PARTS USED BUT NOT SHOWN

20 3775396 SPOOL CABLE SS [200.FT] 48 0267001 ►SIDE PLATE (RH) 76 2267001 >BASE PLATE (LEXAN)

15 3374010 REEL ASSY - HS ELECTRIC (METRIC) 43 3325002 >DISK - ROD HOLDER 71 2290828 ►BOOM BASE TUBE (BLACK)

16 0274732 ►REEL - ROUGH 3.75" 44 9040310 >BOLT - HEX 5/16"-18 x 2" 72 2290829 ►BOOM MID TUBE (BLACK)

12 3320011 DEPTH COUNTER - 3 DIGIT (METRIC) 40 2151726 >WASHER - 5/16" FLAT 68 2219823 >MID TUBE CLAMP

13 3333010 COUNTER GEAR (METRIC) 41 2383106 >NUT - 5/16"-18 SS 69 2222825 >MID TUBE COLLET

14 0854654 COUNTER CUSHION/STOPPER [2.EA] 42 3319005 >CLAMP - ROD HOLDER w/ SLOT 70 2222826 >BASE TUBE COLLET

17 3333011 >GEAR - REEL (METRIC) 45 9430160 >WASHER - STAR 5/16" 73 2290830 ►BOOM END TUBE (BLACK)

18 1080001 SHAFT - REEL, UNI-TROLL 46 2277002 >UNIVERSAL LINE RELEASE 74 2998905 SWIVEL BASE

19 3393412 SCREW - SET 5/16"-18 x 1" (REEL) 47 3992300 SWIVEL HEAD ASSEMBLY 75 2249001 >KNOB - RELEASE PIN (LEXAN)

10 3356052 BASE LATCH TAB 38 2477001 BAG ASSY - SINGLE ROD HOLDER 66 2210821 TELESCOPIC BOOM

11 9370010 SCREW - #4 x 1/2" PPH [2.EA] 39 0290796 >TUBE - ROD HOLDER 67 2219822 >BASE TUBE CLAMP

7 9430003 WASHER - 5/8" ID (NYLON) [2.EA] 35 9100721 RED THREAD CAP 63 9280725 BOLT - TRUSS 1/4" - 20 x 2-1/2" [4.EA]

8 3356050 BASE LATCH 36 3395631 DECAL - CANNON SMALL 64 9370010 SCREW - #4 x 1/2" PPH [3.EA]

9 9400050 SPRING - BASE LATCH 37 3395630 DECAL - CANNON LARGE 65 9950357 WASHER - LOCK 1/4" SPLIT [4.EA]

4 2263102 NUT - HEX 1/4"-20 32 9400070 SPRING - DOG RATCHET 60 9100101 TERMINATOR CUSHION

5 9280750 SCREW - 1/4" - 20 (RH) x 3/4" PPH 33 9100160 DOG - RATCHET 61 9100620 TERMINATOR SNAP & SWIVEL

6 9010001 BEARING - REEL SHAFT NYLINER [2.EA] 34 9370001 SCREW - #10 x 1-1/4" PPHSMS [4.EA] 62 9280713 BOLT - TRUSS 1/4" - 20 x 1-1/2" [4.EA]

In the U.S.A., replacement parts may be ordered directly from CANNON Parts Dept., 121 Power Drive, Mankato, Minnesota 56001. In Canada, parts may be ordered from any of the Canadian Authorized Service Centers shown on the enclosed list. Be sure to

provide the MODEL and SERIAL numbers of your downrigger when ordering parts. Please use the correct part numbers from the parts list. Payment for any parts ordered from the CANNON parts department, may be by cash, personal check, Discover Card,

MasterCard or VISA. To order, call 1-800-227-6433 or FAX 1-800-527-4464.

1 3330002 FRAME - UNI-TROLL 29 0902000 CRANK HANDLE - UNI-TROLL 57 2263102 NUT - HEX 1/4"-20 [4.EA]

2 3327004 DECAL - NOSE, UNI-TROLL 30 3321001 COVER - CLUTCH, ROUND (LEXAN) 58 2371712 WASHER - 9/32" FLAT [4.EA]

3 9040040 HOOK - 1/4" - 20 ROLLED 31 9250003 PIN - DOWEL 3/16" x 7/8" - RATCHET 59 9100100 TERMINATOR

Form No. 3394913 Rev 12/06

Page 21

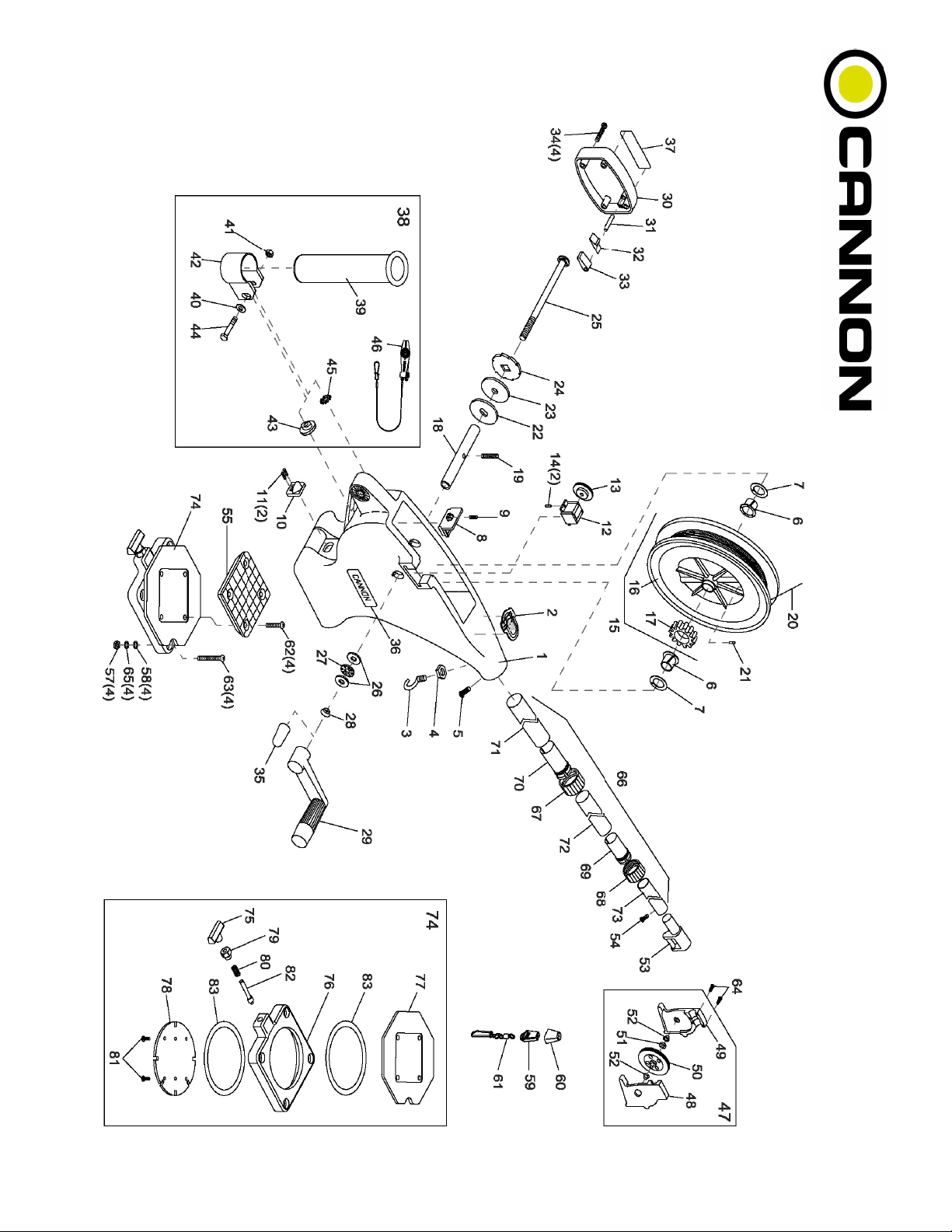

Form No. 3394914 Rev 12/06

UNI-TROLL 10 TS

1901110

TM

Page 22

Form No. 3394914 Rev 12/06

21 0467695 BRAKE PLATE - REEL 49 0269726 ►PULLY - SWIVEL HEAD 77 2267006 >INDEXING PLATE (TAPPED)

22 1264670 CLUTCH PAD 50 3397300 ►WASHER - .735 OD X .36 ID 78 2277001 >NUT - RETAINER RELEASE

23 0467694 BRAKE PLATE - RATCHET 51 9010070 ►HDW BEARING BRASS[2.EA] 79 2287002 >SPRING - RELEASE PIN

24 1000904 SHAFT - RATCHET - UNI-TROLL 52 2227820 BOOM END - TELESCOPIC (LEXAN) 80 2372100 >SCREW - #8 x 5/8" PPHMS [2.EA]

25 9010310 WASHER - THRUST [2.EA] 53 2372100 SCREW - #8 x 5/8" PPHMS 81 3392600 >RELEASE PIN

26 9010280 BEARING - THRUST 54 3307002 LOW PROFILE MOUNTING BASE (LEXAN) 82 9010004 >BEARING - SWIVEL BASE [2.EA]

27 9400040 SPRING - HAND CRANK 55 2994894 *BAG ASSEMBLY, MOUNTING (KIT #4)

28 0902000 CRANK HANDLE - UNI-TROLL 56 2263102 NUT - HEX 1/4"-20 [4.EA]

> PART OF ASSEMBLY ►ITEM CANNOT BE SOLD SEPARATELY * PARTS USED BUT NOT SHOWN

20 9100070 CABLE LEADER SLEEVE 48 0267002 ►SIDE PLATE (LH) 76 2267002 >SWIVEL PLATE (LEXAN)

16 3397901 ►REEL - ROUGH 5.75" SS 44 9430160 >WASHER - STAR 5/16" 72 3392003 ►BOOM END TUBE (SS)

13 3333003 GEAR - COUNTER, UNI-TROLL 41 3319005 >CLAMP - ROD HOLDER w/ SLOT 69 2222826 >BASE TUBE COLLET

14 3397914 REEL ASSEMBLY - HIGH SPEED SS 42 3325002 >DISK - ROD HOLDER 70 3392001 ►BOOM BASE TUBE (SS)

15 3333004 >GEAR - REEL, UNI-TROLL 43 9040310 >BOLT - HEX 5/16"-18 x 2" 71 3392002 ►BOOM MID TUBE (SS)

17 1080001 SHAFT - REEL, UNI-TROLL 45 2200109 >OFFSHORE SALTWATER RELEASE 73 2998905 SWIVEL BASE

18 3393412 SCREW - SET 5/16"-18 x 1" (REEL) 46 3992300 SWIVEL HEAD ASSEMBLY 74 2249001 >KNOB - RELEASE PIN (LEXAN)

19 3775396 SPOOL CABLE SS [200.FT] 47 0267001 ►SIDE PLATE (RH) 75 2267001 >BASE PLATE (LEXAN)

10 3356052 BASE LATCH TAB 38 0290796 >TUBE - ROD HOLDER 66 2219822 >BASE TUBE CLAMP

11 9370010 SCREW - #4 x 1/2" PPH [2.EA] 39 2151726 >WASHER - 5/16" FLAT 67 2219823 >MID TUBE CLAMP

12 0220477 DEPTH COUNTER - 3 DIGIT 40 2383106 >NUT - 5/16"-18 SS 68 2222825 >MID TUBE COLLET

7 9430003 WASHER - 5/8" ID (NYLON) [2.EA] 35 3395633 DECAL - CANNON SMALL TS 63 9370010 SCREW - #4 x 1/2" PPH [3.EA]

8 3356050 BASE LATCH 36 3395632 DECAL - CANNON LARGE TS 64 9950357 WASHER - LOCK 1/4" SPLIT [4.EA]

9 9400050 SPRING - BASE LATCH 37 3991903 BAG ASSY - REAR ROD HOLDER TS 65 3392010 TELESCOPIC BOOM SS

In the U.S.A., replacement parts may be ordered directly from CANNON Parts Dept., 121 Power Drive, Mankato, Minnesota 56001. In Canada, parts may be ordered from any of the Canadian Authorized Service Centers shown on the enclosed list. Be

sure to provide the MODEL and SERIAL numbers of your downrigger when ordering parts. Please use the correct part numbers from the parts list. Payment for any parts ordered from the CANNON parts department, may be by cash, personal check,

Discover Card, MasterCard or VISA. To order, call 1-800-227-6433 or FAX 1-800-527-4464.

1 3392506 FRAME - UNI-TROLL, WHITE 29 3390202 COVER - CLUTCH, ROUND, WHITE (LEXAN) 57 2371712 WASHER - 9/32" FLAT [4.EA]

2 3327004 DECAL - NOSE, UNI-TROLL 30 9250003 PIN - DOWEL 3/16" x 7/8" - RATCHET 58 9100100 TERMINATOR

3 9040040 HOOK - 1/4" - 20 ROLLED 31 9400070 SPRING - DOG RATCHET 59 9100101 TERMINATOR CUSHION

4 2263102 NUT - HEX 1/4"-20 32 9100160 DOG - RATCHET 60 9100620 TERMINATOR SNAP & SWIVEL

5 9280750 SCREW - 1/4" - 20 (RH) x 3/4" PPH 33 9370001 SCREW - #10 x 1-1/4" PPHSMS [4.EA] 61 9280713 BOLT - TRUSS 1/4" - 20 x 1-1/2" [4.EA]

6 9010001 BEARING - REEL SHAFT NYLINER [2.EA] 34 9100721 RED THREAD CAP 62 9280725 BOLT - TRUSS 1/4" - 20 x 2-1/2" [4.EA]

Page 23

Form No. 3394919 Rev 12/06

UNI-TROLL 10 TS/E

1901111

TM

Page 24

28 9400040 SPRING - HAND CRANK 56 2994894 *BAG ASSEMBLY, MOUNTING (KIT #4)

24 0467694 BRAKE PLATE - RATCHET 52 9010070 ►HDW BEARING BRASS[2.EA] 80 2287002 >SPRING - RELEASE PIN

23 1264670 CLUTCH PAD 51 3397300 ►WASHER - .735 OD X .36 ID 79 2277001 >NUT - RETAINER RELEASE

22 0467695 BRAKE PLATE - REEL 50 0269726 ►PULLY - SWIVEL HEAD 78 2267006 >INDEXING PLATE (TAPPED)

21 9100070 CABLE LEADER SLEEVE 49 0267002 ►SIDE PLATE (LH) 77 2267002 >SWIVEL PLATE (LEXAN)

25 1000904 SHAFT - RATCHET - UNI-TROLL 53 2227820 BOOM END - TELESCOPIC (LEXAN) 81 2372100 >SCREW - #8 x 5/8" PPHMS [2.EA]

26 9010310 WASHER - THRUST [2.EA] 54 2372100 SCREW - #8 x 5/8" PPHMS 82 3392600 >RELEASE PIN

27 9010280 BEARING - THRUST 55 3307002 LOW PROFILE MOUNTING BASE (LEXAN) 83 9010004 >BEARING - SWIVEL BASE [2.EA]

> PART OF ASSEMBLY ►ITEM CANNOT BE SOLD SEPARATELY * PARTS USED BUT NOT SHOWN

12 3320011 DEPTH COUNTER - 3 DIGIT (METRIC) 40 2151726 >WASHER - 5/16" FLAT 68 2219823 >MID TUBE CLAMP

13 3333010 GEAR - COUNTER, (METRIC) 41 2383106 >NUT - 5/16"-18 SS 69 2222825 >MID TUBE COLLET

14 0854654 COUNTER CUSHION/STOPPER [2.EA] 42 3319005 >CLAMP - ROD HOLDER w/ SLOT 70 2222826 >BASE TUBE COLLET

15 3397916 REEL ASSY - HIGH SPEED SS (METRIC) 43 3325002 >DISK - ROD HOLDER 71 3392001 ►BOOM BASE TUBE (SS)

16 3333011 >GEAR - REEL, UNI-TROLL (METRIC) 44 9040310 >BOLT - HEX 5/16"-18 x 2" 72 3392002 ►BOOM MID TUBE (SS)

17 3397902 ►REEL - ROUGH 3.75" SS 45 9430160 >WASHER - STAR 5/16" 73 3392003 ►BOOM END TUBE (SS)

18 1080001 SHAFT - REEL, UNI-TROLL 46 2200109 >OFFSHORE SALTWATER RELEASE 74 2998905 SWIVEL BASE

19 3393412 SCREW - SET 5/16"-18 x 1" (REEL) 47 3992300 SWIVEL HEAD ASSEMBLY 75 2249001 >KNOB - RELEASE PIN (LEXAN)

20 3775396 SPOOL CABLE SS [200.FT] 48 0267001 ►SIDE PLATE (RH) 76 2267001 >BASE PLATE (LEXAN)

10 3356052 BASE LATCH TAB 38 3991903 BAG ASSY - REAR ROD HOLDER TS 66 3392010 TELESCOPIC BOOM SS

11 9370010 SCREW - #4 x 1/2" PPH [2.EA] 39 0290796 >TUBE - ROD HOLDER 67 2219822 >BASE TUBE CLAMP

7 9430003 WASHER - 5/8" ID (NYLON) [2.EA] 35 9100721 RED THREAD CAP 63 9280725 BOLT - TRUSS 1/4" - 20 x 2-1/2" [4.EA]

8 3356050 BASE LATCH 36 3395633 DECAL - CANNON SMALL TS 64 9370010 SCREW - #4 x 1/2" PPH [3.EA]

9 9400050 SPRING - BASE LATCH 37 3395632 DECAL - CANNON LARGE TS 65 9950357 WASHER - LOCK 1/4" SPLIT [4.EA]

4 2263102 NUT - HEX 1/4"-20 32 9400070 SPRING - DOG RATCHET 60 9100101 TERMINATOR CUSHION

5 9280750 SCREW - 1/4" - 20 (RH) x 3/4" PPH 33 9100160 DOG - RATCHET 61 9100620 TERMINATOR SNAP & SWIVEL

6 9010001 BEARING - REEL SHAFT NYLINER [2.EA] 34 9370001 SCREW - #10 x 1-1/4" PPHSMS [4.EA] 62 9280713 BOLT - TRUSS 1/4" - 20 x 1-1/2" [4.EA]

In the U.S.A., replacement parts may be ordered directly from CANNON Parts Dept., 121 Power Drive, Mankato, Minnesota 56001. In Canada, parts may be ordered from any of the Canadian Authorized Service Centers shown on the enclosed list. Be sure to

provide the MODEL and SERIAL numbers of your downrigger when ordering parts. Please use the correct part numbers from the parts list. Payment for any parts ordered from the CANNON parts department, may be by cash, personal check, Discover Card,

MasterCard or VISA. To order, call 1-800-227-6433 or FAX 1-800-527-4464.

1 3392506 FRAME - UNI-TROLL, WHITE 29 0902000 CRANK HANDLE - UNI-TROLL 57 2263102 NUT - HEX 1/4"-20 [4.EA]

2 3327004 DECAL - NOSE, UNI-TROLL 30 3390202 COVER - CLUTCH, ROUND, WHITE (LEXAN) 58 2371712 WASHER - 9/32" FLAT [4.EA]

3 9040040 HOOK - 1/4" - 20 ROLLED 31 9250003 PIN - DOWEL 3/16" x 7/8" - RATCHET 59 9100100 TERMINATOR

Form No. 3394919 Rev 12/06

Page 25

Form No. 3394915 Rev 12/06

UNI-TROLL 5

1901105

TM

Page 26

Form No. 3394915 Rev 12/06

14 3397913 REEL ASSEMBLY - UNI-TROLL HIGH SPEED 36 3395630 DECAL - CANNON LARGE 58 9100100 TERMINATOR

15 3333004 >GEAR - REEL, UNI-TROLL 37 2477001 BAG ASSY - SINGLE ROD HOLDER 59 9100101 TERMINATOR CUSHION

16 3397904 ►REEL - ROUGH 5.75" 38 0290796 >TUBE - ROD HOLDER 60 9100620 TERMINATOR SNAP & SWIVEL

17 1080001 SHAFT - REEL, UNI-TROLL 39 2151726 >WASHER - 5/16" FLAT 61 9280713 BOLT - TRUSS 1/4" - 20 x 1-1/2" [4.EA]

18 3393412 SCREW - SET 5/16"-18 x 1" (REEL) 40 2383106 >NUT - 5/16"-18 SS 62 9280725 BOLT - TRUSS 1/4" - 20 x 2-1/2" [4.EA]

19 3775396 SPOOL CABLE SS [200.FT] 41 3319005 >CLAMP - ROD HOLDER w/ SLOT 63 9370010 SCREW - #4 x 1/2" PPH [3.EA]

20 9100070 CABLE LEADER SLEEVE 42 3325002 >DISK - ROD HOLDER 64 9950357 WASHER - LOCK 1/4" SPLIT [4.EA]

21 0467695 BRAKE PLATE - REEL 43 9040310 >BOLT - HEX 5/16"-18 x 2" 65 2290828 24" BOOM - HEAVY DUTY

22 1264670 CLUTCH PAD 44 9430160 >WASHER - STAR 5/16"

> PART OF ASSEMBLY ►ITEM CANNOT BE SOLD SEPARATELY

13 3333003 GEAR - COUNTER, UNI-TROLL 35 3395631 DECAL - CANNON SMALL 57 2371712 WASHER - 9/32" FLAT [4.EA]

8 3356050 BASE LATCH 30 9250003 PIN - DOWEL 3/16" x 7/8" - RATCHET 52 2216403 BOOM END

9 9400050 SPRING - BASE LATCH 31 9400070 SPRING - DOG RATCHET 53 2372100 SCREW - #8 x 5/8" PPHMS

5 9280750 SCREW - 1/4" - 20 (RH) x 3/4" PPH 27 9400040 SPRING - HAND CRANK 49 0269726 ►PULLY - SWIVEL HEAD

6 9010001 BEARING - REEL SHAFT NYLINER [2.EA] 28 0902000 CRANK HANDLE - UNI-TROLL 50 3397300 ►WASHER - .735 OD X .36 ID

7 9430003 WASHER - 5/8" ID (NYLON) [2.EA] 29 3321001 COVER - CLUTCH, ROUND (LEXAN) 51 9010070 ►HDW BEARING BRASS[2.EA]

10 3356052 BASE LATCH TAB 32 9100160 DOG - RATCHET 54 3307002 LOW PROFILE MOUNTING BASE (LEXAN)

11 9370010 SCREW - #4 x 1/2" PPH [2.EA] 33 9370001 SCREW - #10 x 1-1/4" PPHSMS [4.EA] 55 2994894 *BAG ASSEMBLY, MOUNTING (KIT #4)

12 0220477 DEPTH COUNTER - 3 DIGIT 34 9100721 RED THREAD CAP 56 2263102 NUT - HEX 1/4"-20 [4.EA]

1 3330002 FRAME - UNI-TROLL 23 0467694 BRAKE PLATE - RATCHET 45 2277002 >UNIVERSAL LINE RELEASE

2 3327004 DECAL - NOSE, UNI-TROLL 24 1000904 SHAFT - RATCHET - UNI-TROLL 46 3992300 SWIVEL HEAD ASSEMBLY

3 9040040 HOOK - 1/4" - 20 ROLLED 25 9010310 WASHER - THRUST [2.EA] 47 0267001 ►SIDE PLATE (RH)

4 2263102 NUT - HEX 1/4"-20 26 9010280 BEARING - THRUST 48 0267002 ►SIDE PLATE (LH)

In the U.S.A., replacement parts may be ordered directly from CANNON Parts Dept., 121 Power Drive, Mankato, Minnesota 56001. In Canada, parts may be ordered from any of the Canadian Authorized Service Centers shown on the enclosed list. Be sure to

provide the MODEL and SERIAL numbers of your downrigger when ordering parts. Please use the correct part numbers from the parts list. Payment for any parts ordered from the CANNON parts department, may be by cash, personal check, Discover Card,

MasterCard or VISA. To order, call 1-800-227-6433 or FAX 1-800-527-4464.

* PARTS USED BUT NOT SHOWN

Page 27

Form No. 3394916 Rev 12/16

UNI-TROLL 5 METRIC

1901106

TM

Page 28

Form No. 3394916 Rev 12/16

22 0467695 BRAKE PLATE - REEL 44 9040310 >BOLT - HEX 5/16"-18 x 2" 66 2290828 24" BOOM - HEAVY DUTY

14 0854654 COUNTER CUSHION/STOPPER [2.EA] 36 3395631 DECAL - CANNON SMALL 58 2371712 WASHER - 9/32" FLAT [4.EA]

15 3374010 REEL ASSY - HS ELECTRIC (METRIC) 37 3395630 DECAL - CANNON LARGE 59 9100100 TERMINATOR

16 0274732 ►REEL - ROUGH 3.75" 38 2477001 BAG ASSY - SINGLE ROD HOLDER 60 9100101 TERMINATOR CUSHION

17 3333011 GEAR - REEL (METRIC) 39 0290796 >TUBE - ROD HOLDER 61 9100620 TERMINATOR SNAP & SWIVEL

18 1080001 SHAFT - REEL, UNI-TROLL 40 2151726 >WASHER - 5/16" FLAT 62 9280713 BOLT - TRUSS 1/4" - 20 x 1-1/2" [4.EA]

19 3393412 SCREW - SET 5/16"-18 x 1" (REEL) 41 2383106 >NUT - 5/16"-18 SS 63 9280725 BOLT - TRUSS 1/4" - 20 x 2-1/2" [4.EA]

20 3775396 SPOOL CABLE SS [200.FT] 42 3319005 >CLAMP - ROD HOLDER w/ SLOT 64 9370010 SCREW - #4 x 1/2" PPH [3.EA]

21 9100070 CABLE LEADER SLEEVE 43 3325002 >DISK - ROD HOLDER 65 9950357 WASHER - LOCK 1/4" SPLIT [4.EA]

> PART OF ASSEMBLY ►ITEM CANNOT BE SOLD SEPARATELY

13 3333010 COUNTER GEAR (METRIC) 35 9100721 RED THREAD CAP 57 2263102 NUT - HEX 1/4"-20 [4.EA]

7 9430003 WASHER - 5/8" ID (NYLON) [2.EA] 29 0902000 CRANK HANDLE - UNI-TROLL 51 3397300 ►WASHER - .735 OD X .36 ID

8 3356050 BASE LATCH 30 3321001 COVER - CLUTCH, ROUND (LEXAN) 52 9010070 ►HDW BEARING BRASS[2.EA]

9 9400050 SPRING - BASE LATCH 31 9250003 PIN - DOWEL 3/16" x 7/8" - RATCHET 53 2216403 BOOM END

4 2263102 NUT - HEX 1/4"-20 26 9010310 WASHER - THRUST [2.EA] 48 0267001 ►SIDE PLATE (RH)

5 9280750 SCREW - 1/4" - 20 (RH) x 3/4" PPH 27 9010280 BEARING - THRUST 49 0267002 ►SIDE PLATE (LH)

6 9010001 BEARING - REEL SHAFT NYLINER [2.EA] 28 9400040 SPRING - HAND CRANK 50 0269726 ►PULLY - SWIVEL HEAD

10 3356052 BASE LATCH TAB 32 9400070 SPRING - DOG RATCHET 54 2372100 SCREW - #8 x 5/8" PPHMS

11 9370010 SCREW - #4 x 1/2" PPH [2.EA] 33 9100160 DOG - RATCHET 55 3307002 LOW PROFILE MOUNTING BASE (LEXAN)

12 3320011 DEPTH COUNTER - 3 DIGIT (METRIC) 34 9370001 SCREW - #10 x 1-1/4" PPHSMS [4.EA] 56 2994894 *BAG ASSEMBLY, MOUNTING (KIT #4)

In the U.S.A., replacement parts may be ordered directly from CANNON Parts Dept., 121 Power Drive, Mankato, Minnesota 56001. In Canada, parts may be ordered from any of the Canadian Authorized Service Centers shown on the enclosed list. Be

sure to provide the MODEL and SERIAL numbers of your downrigger when ordering parts. Please use the correct part numbers from the parts list. Payment for any parts ordered from the CANNON parts department, may be by cash, personal check,

Discover Card, MasterCard or VISA. To order, call 1-800-227-6433 or FAX 1-800-527-4464.

1 3330002 FRAME - UNI-TROLL 23 1264670 CLUTCH PAD 45 9430160 >WASHER - STAR 5/16"

2 3327004 DECAL - NOSE, UNI-TROLL 24 0467694 BRAKE PLATE - RATCHET 46 2277002 >UNIVERSAL LINE RELEASE

3 9040040 HOOK - 1/4" - 20 ROLLED 25 1000904 SHAFT - RATCHET - UNI-TROLL 47 3992300 SWIVEL HEAD ASSEMBLY

* PARTS USED BUT NOT SHOWN

Loading...

Loading...