Page 1

TE-3000

Thermo Electric

Temperature

Bath

Instruction

& Operation

Manual

Page 2

Page 3

CONTENTS

i

1

2

3

INTRODUCTION 1

A. Scope ............................................................................................................................. 1

B. Overview ........................................................................................................................ 1

ITEM DESCRIPTIONS 3

A. Lower Control Chassis .................................................................................................. 3

B. Upper Bath Vessel Housing ........................................................................................... 3

C. Cables & hoses, etc. ....................................................................................................... 4

UNPACKING AND INSTALLATION 5

A. Unpacking ...................................................................................................................... 5

B. Checking for damaged/missing items ............................................................................ 5

C. Physical arrangements ................................................................................................... 5

D. Liquid and pneumatic connections ................................................................................ 6

E. Platform/pump assembly ................................................................................................ 6

F. Electrical connections ..................................................................................................... 8

G. Selecting a bath liquid .................................................................................................... 9

4

GENERAL OPERATIONS 11

A. Filling the bath with liquid .......................................................................................... 11

B. Application of power ................................................................................................... 12

1. Cold start .......................................................................................................... 12

2. Warm start ......................................................................................................... 13

C. Self-test sequence ........................................................................................................ 13

D. Normal display and keypad indications....................................................................... 15

E. LED indicators ............................................................................................................. 17

F. Adjusting the liquid level in the bath ............................................................................ 17

G. Setting the target (desired) bath temperature ............................................................... 18

H. Calibration at a given target temperature .................................................................... 19

I. Menu selections ............................................................................................................. 20

1. Celsius or Fahrenheit operation ........................................................................ 20

2. Bath temperature calibrations and offsets ........................................................ 21

3. Communication options.................................................................................... 22

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 4

ii

5

6

7

COMMUNICATIONS 25

A. Downloading firmware updates................................................................................... 25

B. Full duplex (POINT-TO-POINT) operations ............................................................... 25

C. Half duplex and polled (multi-drop) operations .......................................................... 26

D. Commands, queries, responses and reports ................................................................. 26

MAINTENANCE 31

A. Preventative (scheduled) maintenance ........................................................................ 31

Cleaning of painted surfaces and front panel ....................................................... 31

Cleaning the fans and heat sinks .......................................................................... 31

Cleaning the bath window .................................................................................... 32

Draining the bath liquid ........................................................................................ 32

Cleaning the inside of the bath vessel .................................................................. 33

WARRANTY/RETURN INFORMATION 35

Products limited warranty................................................................................................. 35

Reagent and chemical warranty........................................................................................ 35

Returning a product to CANNON®.................................................................................. 36

A

B

APPENDIX A—REPLACEMENT PARTS LIST 37

Accessories ....................................................................................................................... 37

APPENDIX B—TROUBLESHOOTING GUIDE 39

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 5

CHAPTER

11

1

11

A. Scope

1

INTRODUCTION

Manual

Diagnostics/repair

B. Overview

TE-3000 features

The intent of this manual is to assist the user of the TE-3000 in the

general installation, operation, maintenance, and simple field repair of the

unit. This operations manual contains sections dealing with descriptions

of equipments, unpacking and installation, general front panel operations,

remote control/response operations, preventative maintenance, and

simple failure analysis and fault isolation.

Detailed diagnostics and repair should be performed in conjunction with

or solely by CANNON® Instrument Company. Please consult

CANNON® Instrument Company for further assistance beyond the

content of this manual.

The TE-3000 is a state of

the art, microprocessor

controlled and

thermoelectrically

cooled, constant temperature liquid bath. It is

totally self-contained in

two stackable bench-top

units which together

occupy a foot print less

than 15 by 20 inches. The

TE-3000 does not

contain any fluorocarbons or refrigeration

components and the only

moving parts are four

ball-bearing cooling fans

and a long-life vibratory

air pump. It can obtain

any temperature between

+30 degrees to -30

degrees Celsius and

remain stable at that

temperature within .01

degrees under normal

operating conditions.

Figure 1: The TE-3000

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 6

2

Temperature control

Calibration

Networking/communication

The principals of operation for this instrument are the latest in science

and technology. Custom-developed Peltier Cells are arranged on the back

and sides of the bath vessel. Newly designed high density air heat

sinks on the outer surfaces (hot side) of these Peltier Cells are cooled by

muffin fans running at half of their rated voltage. The bath liquid (2.5

liters) is constantly circulated by recycled bath vapors to ensure uniform

temperature distribution and stability. The temperature is controlled (both

heating and cooling) with a custom designed 16 bit digital pulse width

modulator running at a very high frequency.

The TE-3000 can be calibrated to any temperature reference standard for

any desired Celsius or Fahrenheit temperature. The controls for entering

the target (desired) temperature and the calibration at this temperature are

very simple and straight forward. The instrument remembers these

calibration corrections for every possible temperature as well as the latest

desired temperature so that upon power-up, the bath will

adjust to these last known and entered parameters.

The TE-3000 was designed for the future with built in capability for

remote control and networking with a new family of instruments. With

this remote interface capability, it is now possible to obtain quality

assurance data via a computer network. The TE-3000 was also designed

to ensure that its capabilities may be easily changed or updated with new

operating firmware via a remote download over this same network.

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 7

CHAPTER

2 2

2

2 2

A. Lower Control Chassis

The Control Chassis for the TE-3000 is the base unit of the instrument

upon which the Upper Bath Vessel Housing sits.

The Control Chassis contains all of the power conditioning and supplies,

air pump, and electronics needed for the operation of the TE-3000. The

mains power input, two power connectors to the Upper Bath Vessel,

communication (RS-232 and RS-485) connectors, address selection

switch, download demand switch, two air pump connections to the Upper

Bath Vessel, and the bath fluid pump switch reside on the rear panel of

the Lower Control Chassis.

3

ITEM DESCRIPTIONS

Figure 2: TE-3000 Front panel

1

2

3

4

5

The front panel contains:

1 DC power indicator lamp

2 two lighted power switches (bath & lighting)

3 liquid crystal display

4 15-keypad switch array

5 two LED indicators (heating and cooling)

B. Upper Bath Vessel Housing

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

The Bath Vessel Housing for the TE-3000 sits on top of the Lower

Control Chassis. It contains a rectangular aluminum bath vessel with a

four pane, specially designed glass window attached to the elongated

front surface.

Page 8

4

The Bath Vessel Housing also contains the thermoelectric modules,

finned heat sinks, fans, and fluorescent lamps with ballasts. The rear

panel has two power connectors from the Lower Control Chassis, two air

pump connectors from the Control Chassis, and the bath fluid overflow

jar along with integral pump and tubing connections.

C. Cables & hoses, etc.

The TE-3000 system includes several cables, hoses, and accessories

which are necessary for operation of the system.

Power cables

Air hoses

Overflow jar

1.) Two large diameter power cables (AC and DC) with circular connectors on their ends are provided to take power from the lower Control

Chassis up to the upper Bath Vessel Housing. The sex and type of

these connectors constrain their use in only one way - the proper

configuration.

2.) Two small diameter silicon air hoses (tube assemblies) with twist and

lock pneumatic connectors on their ends are provided to supply and

return recirculated bath vapors from/to the upper Bath Vessel to/from

the lower Control Chassis. The sex and type of these connectors

constrain their use in only one way - the proper configuration.

3.) One glass jar with lid is provided to catch the bath overflow liquid

and is to be mounted on the rear overflow jar support along with

three pieces of small diameter silicon tubing and an in-line pump

with connector. For instructions on assembling the overflow jar

support and connecting the Reciprocating Pump, see page 7. The

plastic lid for the jar has a hole into which the 3" tubing is inserted.

The other end of the 3" tubing is connected to the bath overflow

outlet. The 6" tube connects the fitting at the bottom of the jar to the

bottom of the air pump, and the top of the air pump is connected to

the 11" tubing which then rises to the top of the Bath Vessel housing

and mates to the bath fluid return pipe.

RTD sensor

Miscellaneous accessories

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

4.) One Platinum RTD sensor assembly is provided, with the probe and

part of the cable contained under the top plate of the upper Bath

Vessel Housing. This cable has a metal, bayonet style, connector on

one end to be plugged into the back of the lower Control Chassis.

5.) Two hole covers, one 1/4-20 cap nut, and one mercury thermometer

holder are provided.

Page 9

CHAPTER

33

3

33

A. Unpacking

5

UNPACKING AND

INSTALLATION

The TE-3000 should be inspected immediately upon arrival. If the

shipping containers have been damaged externally, the shipping company

should be advised of this condition immediately.

The contents should be carefully removed and placed on a stable bench

or table for further inspection. Retain all original shipping materials and

containers which will be needed if the return of the instrument is necessary for warranty repair/replacement.

B. Checking for damaged/missing items

After all items have been removed from the shipping container and

placed on a bench or table, the items should be compared to the packing

list.

Inspect each component for signs for damage. Report damages to the

shipper and to the CANNON® Instrument Company immediately.

Damaged items

Retain all packing materials until the instrument is connected and functioning properly. If any component(s) must be returned to

CANNON® Instrument Company, the damaged item(s) should be pack-

aged in the original shipping container. Refer to the final chapter of this

manual for instructions on returning defective equipment. Customers

outside the United States should contact the local CANNON® agent for

procedures on returning products to CANNON® .

If an item is missing, please notify CANNON® Instrument Company

immediately.

C. Physical arrangements

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Sections A through C in the previous chapter dealing with item descriptions should be read prior to this section. The final placement for the TE3000 should be a level, strong, and stable bench or table surface.

Occasional access to the rear of the unit should be conveniently permitted. The bath requires adequate ventilation for the integral cooling fans so

a space of at least eight inches should be provided between the rear and

both sides of the TE-3000 and any wall or other obstruction. A clearance

Page 10

6

Figure 3:

TE-3000 rear view with alignment bolt highlighted

area on the right side of the unit is necessary to allow access to the rear

pump switch. An electrical service MAINS power outlet must be located

within nine feet of the TE-3000.

The lower Control Chassis should be placed on the table first followed by

the upper Bath Vessel Housing which is placed on top of the Control

Chassis. The rear mounted alignment bolt on the top rear of the lower

Control Chassis must mate with the hole in the alignment bracket on the

bottom rear of the upper Bath Vessel Housing (see Figure 3). A 1/4-20

hex nut is provided to secure this mating arrangement and should only be

finger-tightened.

D. Liquid and pneumatic connections

The pneumatic connections on the TE-3000 provide the bath agitation

and subsequent stirring by recirculating the bath vapors. Two silicon tube

assemblies are provided which have plastic quick-connect bayonet style

connectors on their ends. These tubes are connected from the air in/out

connections on the bottom Control Chassis to the air out/in connections

on the upper Bath Vessel Housing. There are female connectors on both

ends of one hose and male (black o-ring visible) connectors on both ends

of the other hose. The hose with the female connectors mates with a male

connector on the lower chassis and a male connector on the upper housing.

The hose with the male connectors mates with a female connector on the

lower chassis and a female connector on the upper housing. They all secure

with an insertion and a 1/8 turn lock.

E. Platform/pump assembly

The platform and pump assembly may be completed with the following

items provided by CANNON®:

Overflow Platform & assembly screws (2)

Reciprocating Pump

Pre-cut tubing (approx. 11", 6" & 3" lengths)

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 11

If the rear platform is not yet attached to the bath unit, you should attach

it using the two 6-32 screws provided. The tabs which will hold the

overflow jar in place should be facing upward.

7

Procedure

1. After the platform is securely in place, attach the 11" tubing to the

bath intake at the top rear of the bath unit by pushing the tubing

firmly over the intake nozzle. Then attach the other end of the tube to

the top of the Reciprocating Pump (next to the electric connector

cable) in the same way.

2. Remove the plastic nipple adaptor from the opposite end of the

Reciprocating Pump and insert the pump end into the small hole on

the Overflow Platform so the pump rests on the platform.

3. Reattach the nipple adaptor removed in Step 2 (this holds the unit in

place).

4. Attach the electric connector cable from the Reciprocating Pump to

the receptacle marked PUMP on the Control Unit. To connect the

cable, make sure to align it correctly with the Bath Unit female

connector (tab upwards), then push until the cable connection

“clicks” into place.

5. Attach one end of the 6" tube to the bottom connection on the

Reciprocating Pump.

6. Attach the 3" tube to the bath

unit overflow outlet located

above the Overflow Platform.

Place the Overflow Jar on the

platform, inserting the other

end of the 3" tube through the

lid of the jar.

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

7. Attach the other end of the 6"

tube to the connector on the

underside of the Overflow Jar.

Make sure that all connections

are secure.

Figure 4:

Positioning the overflow jar

Page 12

8

F. Electrical connections

Two large diameter electrical cables

deliver power from the lower Control

Chassis up to the upper Bath Vessel

Housing (see Figure 5). Both of these

cables have circular plastic power connectors on their ends. The cable with

three large rectangular pins carries DC

power to the Bath Vessel Housing from

the Control Chassis and the cable with

nine smaller circular pins carries AC

power to the Bath Vessel Housing. Both

of these cables have a male connector on

one end and its female counterpart on the

AC

Figure 5: AC/DC cable connections

other (see Figure 6). Determining which connector mates is fairly simple

but ensure a good connection by

turning the locking ring on every

plug until a small “click” is felt.

DC

Sensor connections

PUMP connections

POWER connection

The small black cable with a metal

LEMO connector carries the

temperature sensor signal from the

upper Bath Vessel Housing down

to the lower Control Chassis

(labeled PROBE). This connection is keyed and it operates as a

bayonet with a simple push in (no

twisting). The red dot on the plug

must be facing upward or insertion will not be permitted. When this connector is properly inserted, a

small “click” can be felt. Removal is accomplished with a simple pull on

the knurled section of the plug.

The small wire cable from the liquid pump with a gray plastic REDEL

connector mates with the connector on the lower Control Chassis labeled

PUMP. This connection is keyed and it operates as a bayonet with a

simple push in (no twisting). The keyway must be facing upward or

insertion will not be permitted. When this connector is properly inserted,

a small “click” can be felt. Removal is accomplished with a simple pull.

The MAINS power cord provided with the instrument will have an IEC

connector on one end and the appropriate wall outlet connector on the

other.

Figure 6:

Cable locking mechanism

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 13

G. Selecting a bath liquid

9

The “Ideal” Bath Liquid

Temperature Ranges

The “ideal” bath liquid would have a low viscosity, high heat capacity,

and low vapor pressure over a wide range of temperatures. This liquid

would also have a very high flash point and be relatively inexpensive. If

the liquid were to be used in kinematic viscosity measurements where

visual observation is important, it would be clear and colorless.

Unfortunately, there is no one “ideal” liquid to use when a wide temperature range is needed. No single liquid meets all of the above requirements.

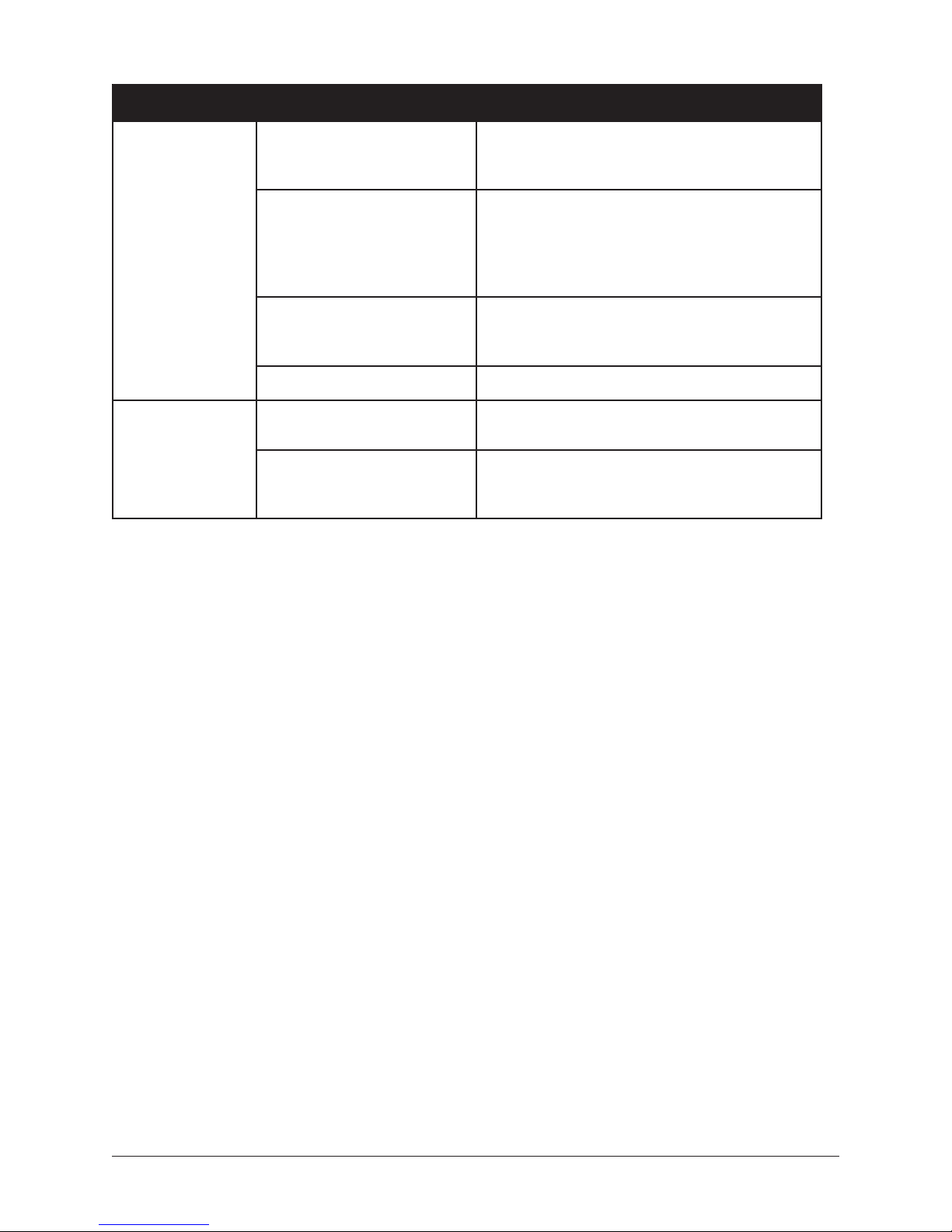

The kind of liquid used in the TE-3000 Temperature Bath depends upon

the desired temperature range of the instrument. The table below lists

several different operating ranges and the liquids suitable for use in those

ranges:

SDIUQILHTAB0003-ET

EGNARERUTAREPMET SDIUQILHTABELBATIUS

C°01+otC°03-lohoclAlyhteM

C°02+otC°01-lohoclAlyporposI

lohoclAlyhtE

CAUTION

CAUTION

CAUTION

Bath Liquid Guidelines

C°03+otC°5+sliOytisocsiVwoL,retaW

Methyl alcohol (methanol) is very close to the “ideal” liquid; it can be

used at all temperatures in the TE-3000 operating range. However,

methanol may not be suitable for some laboratories because of its low

flash point and degree of toxicity.

Isopropyl alcohol is less toxic than methyl alcohol and somewhat less

volatile. However, it becomes very viscous at low temperatures, making

it difficult to maintain good temperature control.

Silicone fluids CANNOT be used in the TE-3000 Constant Temperature

Bath. NEVER place a silicone liquid in the TE-3000.

Do not attempt to use water as a bath fluid for operation at temperatures

of 2°C or lower.

When selecting a liquid for use in the TE-3000, keep the following

guidelines in mind:

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 14

10

YTISOCSIV

tahtoserutarepmetgnitarepohtabtawolyrevebdluohsytisocsiV

.htabehtnistneidargerutarepmetetanimileylevitceffenacgnirritsetaredom

.yticapactaehhgihahtiwdiparsselerahtabehtnisegnahcerutarepmeT

rehtotsoM.sdiulfcinagrotsomfoyticapactaehehteciwttuobasahretaW

YTICAPACTAEH

.retawfoyticapactaehehtfoflahtuobaevahlliwsdiulfhtabrofseciohc

tanoitareporofdiulfhtabasaretawesuottpmettaTONoD(

).rewolroC°2foserutarepmet

.tnemhsinelpertneuqerferiuqerlliwelitalovylevitalersihcihwdiuqilA

YTILITALOV

gniloocasecudorpecafrushtabehttanoitaropavedipar,eromrehtruF

.tluciffideromlortnocerutarepmetgnikam,tceffe

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 15

CHAPTER

GENERAL OPERATIONS

44

4

44

A. Filling the bath with liquid

Prior to filling the TE-3000 with liquid, you should ensure that the bath

overflow liquid reservoir, pump, and hoses are properly in place. For

detailed installation procedure, please see the previous Chapter 3.D

The TE-3000 should be filled through one of the top instrument holes

with a clear, alcohol type, liquid. This alcohol may be either wood or

grain based.

11

CAUTION

Bath volume changes

Do not use silicone fluid!

The dilution of this alcohol should be such to permit adequate stirring at

the lowest operating temperature. Excessive water dilution will cause the

liquid to appear cloudy at cold temperatures and thus impair the visibility

in the bath.

Using room temperature alcohol, carefully pour the liquid into a funnel

sitting in one of the instrument holes at the very top of the Bath Vessel

Housing. As the bath liquid approaches the very top of the bath vessel,

the overflow liquid will spill down the overflow tube into the jar.

The amount of “extra” liquid available in the overflow jar will depend

upon what temperatures you will be operating the bath. Also, some bath

liquid will be displaced by the addition of instruments and thermometers

into the bath - and thus cause the level to rise.

The bath liquid will expand if warmer than room temperatures are

desired. An empty jar at room temperature will fill up with the expanded

liquid as the temperature rises. In this case, you would only install

enough bath liquid to have the level just below the bath top edge and no

liquid in the jar. Do not overfill the bath.

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

The bath liquid will contract if colder than room temperatures are

desired. An almost full jar at room temperature will be depleted with the

compressed liquid as the temperature falls. In this case, you would fill the

bath and about half of the over flow jar with the room temperature liquid

and after the insertion of the instruments, the jar would be almost full.

The purpose of the previous explanations is to illustrate that the steady

state room temperature condition of the bath must be such that you

should never spill any liquid and this level should be maintained with

time after some of the alcohol evaporates.

Page 16

12

Experience will further define the necessary levels to be maintained in

the overflow jar. But in all cases, for proper temperature control the level

of the liquid inside the bath should be about 1/2" above the top edge of

the white baffle.

B. Application of power

Prior to the application of mains power to the TE-3000, ensure that all

tubing and power connectors are properly installed between the upper

Bath Vessel Housing and the lower Control Chassis. The bath liquid

should be in place along with the overflow jar and tubing. Also be certain

that the mains voltage and frequency specified on the rear identification

label matches your mains voltage.

The power cord should have the appropriate power plug to permit

plugging the cord into the mains power outlet on the wall. The other end

contains an IEC connector which plugs into the power inlet receptacle on

the rear of the lower Control Chassis. Be CERTAIN that you are plugging into the correct mains voltage as defined on the rear panel identification label. Both front panel power switches should be OFF while this

power cord is being installed.

Turning on the TE-3000

1. Cold start

Turn on the main BATH power switch. The LIGHTS switch is operable

only if the BATH power is on. You should hear a long "beep” followed

by a short “beep” and the bath electronics will enter one of two possible

start-up procedures.

This is the normal start-up mode for the bath and it occurs when the

power was previously off for a period greater than about two seconds.

The five LEDs in the lower row of keys will turn on and then off, a short

“beep” tone will be heard, and the display on the front panel will initially

and briefly show the following:

TE-3000

Cannon Inst. Co., USA

Ver. X.XX MM/DD/YY

Following this display, the bath will indicate that it is executing a cold

start, thus:

POWER UP

Cold Start

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Initiating Self Test

After this display the bath will automatically enter the self-test sequence

as specified in the following Section 4.C.

Page 17

2. Warm start

This is the abnormal start-up mode for the bath and it occurs only if the

power was previously off for a period less than about two seconds, or if a

fault was detected in the microprocessor. The display will show the

following and the lights on the bottom row of the keyboard should flash

alternating.

POWER UP

Warm Start

Consult User’s Guide

If this condition is ever discovered, the BATH power switch should be

turned off. After waiting several seconds, turn the BATH power switch to

the ON position and wait for the display to indicate either a warm or cold

start again. If the bath comes up in a cold start condition and starts its

normal self-test sequence, it is possible that a momentary power interruption caused the warm start condition and no further action is required. If

the bath continues to enter the warm start condition, the user should

consult CANNON

®

Instrument Company for further assistance.

13

C. Self-test sequence

The self-test sequence is entered immediately after the TE-3000 powers

up in a cold start condition. The tests performed in sequence and the

accompanied displays are as follows:

Testing Display

Testing 32k RAM ...

Test Passed

Testing Pulse Width

Modulator.....

Test Passed

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Testing A/D .....

Calibrating ....OK

Consistency ....OK

Page 18

14

Testing Voltage Levels......

Positive Supply..OK

Negative Supply..OK

Diagnostic Report

All tests PASSED

Entering Normal

Operation

Following this “all tests passed” report, the TE-3000 will enter into the

normal display condition (see the following Section D) provided that the

RTD temperature sensor is in place. If the RTD sensor is unplugged at

any time after the completion of the self-test routine, the following

display will be shown.

The RTD sensor has

been disconnected.

Please reconnect it

to reset the Bath.

If any test fails during this power-up self-test sequence, it will be noted

on the display for that particular test. The displays will resemble the

previous sequence shown above but if any failure is encountered, the OK

will be replaced by BAD and PASSED will be replaced by FAILED!.

All test sequences will be activated, however at the conclusion of the test

sequence, the ENTER key will flash and the final screen will show:

Diagnostic Report

Some tests failed!

SEE OWNER’S MANUAL

Press ENTER to go on

If you wish to continue with the operation of the bath even though the

report issued states that a failure was encountered, you may press the

ENTER switch. The following display will be briefly shown and the bath

will enter the normal display condition (see the following Section D).

Attempting Normal

Operation.

PROCEED WITH CAUTION

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 19

D. Normal display and keypad indications

Figure 7:

TE-3000

Control Chassis

front panel

15

Cooling indication

Heating indication

LIQUID CRYSTAL DISPLAY

The normal or “quiescent” LCD (liquid crystal display) for the TE-3000

bath is shown in the following example:

TEMPERATURE

Actual Target

12.340°C -20.000°C

In the above example, the target temperature is much colder than the

actual temperature of the bath so the display indicates that it is cooling.

The COOLING indicator (green LED) on the right side of the front panel

should be fully illuminated.

In the following example, the target temperature is much warmer than the

actual temperature of the bath so the display indicates that it heating. The

HEATING indicator (red LED) on the right side of the front panel should

be illuminated.

KEYPAD OPTIONS

Cooling

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

TEMPERATURE

Actual Target

-23.450°C -20.000°C

Heating

Page 20

16

Temperature scale

In the following example, the target temperature is within .1 degrees of

the actual temperature of the bath so the display indicates a scale on the

bottom line and the actual temperature is shown on this scale with a dark

marker. For target temperatures colder than +10 degrees Celsius, the

COOLING indicator (green LED) on the right side of the front panel will

indicate various intensities and the HEATING indicator (red LED)

will be extinguished. For target temperatures warmer than +10 degrees

Celsius, the COOLING indicator (green LED) on the right side of the

front panel will indicate various intensities and the HEATING indicator

(red LED) will flash on and off with a one second interval.

TEMPERATURE

Actual Target

-20.003 C -20.000 C

I

-.1 |...|...|...|...|+.1

Keypad

Figure 8: TE-3000 LCD display when controlling at target temperature

(dark marker at midpoint of scale)

The keypad on the front panel of the TE-3000 (see Figure 8) consists of

fifteen keys - white numbers 0 through 9, a white combination “minus

sign” and “decimal point” key (-/.), a yellow SET TEMP[erature] key, a

yellow CAL[ibrate] TEMP[erature] key, a yellow MENU key, and an

orange ENTER key. The bottom row of five keys (non-numerical keys)

have the capability of being illuminated to assist the operator by indicating possible key entry choices.

All keypad lights are off during normal operation of the bath. The only

key entry possibilities at this time are the yellow keys. Depression of any

key other than a yellow key will result in a long “beep” to indicate an

improper entry. If any yellow key is depressed, the appropriate instructions are provided on the LCD and are discussed in later sections of this

manual. If no further action is taken by the operator in any menu or other

screen mode within five minutes, the display will automatically revert

back to the normal (quiescent) display as shown above.

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 21

17

Selecting/canceling options

The

ENTER

key

E. LED indicators

To access any of the primary keypad options, press the appropriate

keypad button once. If you make a data entry error and wish to cancel

your input sequence, press the same keypad option button again.

The ENTER key is the most-used feature on the TE-3000 keypad. You

must confirm each submenu choice and numeric input by pressing this

key.

The two LED indicators on the right side of the front panel signify the

actual control signals commanding the temperature control of the bath.

The COOLING indicator (green LED) may be viewed as a multiple

intensity light with brightness directly proportional to the degree of

cooling power applied to the solid state coolers (thermoelectric modules).

The HEATING indicator (red LED) is more simply on or off and at

warmer temperatures it will blink at one second intervals to signify that

power is applied to the internal heating element in the bath. The

HEATING indicator will be fully illuminated if the bath is commanded

to go to a temperature much warmer than the current temperature.

F. Adjusting the liquid level in the bath

Assuming that the bath has already been filled according to the instructions as provided in Chapter 4-A, the user must adjust the level of the

bath liquid as the bath temperature is decreased. Since the bath liquid

decreases in volume as the temperature decreases, the operator must add

liquid to the bath vessel to maintain proper circulation.

Maintaining bath liquid level

The level of the liquid inside the bath vessel must be maintained at a

level approximately 1/2 inch above the top edge of the rear (white)

baffle. When the liquid is adjusted to the proper level, a large number of

bubbles will be visible rising behind the baffle and causing some turbulence at the surface of the liquid. A push-button switch is provided on the

upper rear right hand side of the lower Control Chassis which when

depressed, activates the small pump next to the overflow jar which

returns the liquid from this jar back into the bath vessel.

Adequate expansion volume is provided in the expansion jar so that you

may operate at -35° Celsius with the bath liquid maintained at approximately 1/2 inch above the top edge of the baffle with the

expansion jar empty. When the bath is powered-off from this condition,

the liquid will expand in the bath vessel and overflow into the jar. The jar

is of sufficient size to accommodate all of this expansion liquid without

overflowing as the temperature slowly rises up toward room temperature.

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 22

18

G. Setting the target (desired) bath temperature

The setting of a new desired temperature for the bath is accomplished by

depressing the yellow SET TEMP key. The display will be changed to

the following:

Enter Target Bath

Temperature:

+_____ °C

SET TEMP to Cancel

With the cursor (dark underline character) in the first position, the user

has the option of setting a negative temperature by depressing the combination -/. key. If any numerical key is depressed in this first position, the

temperature is assumed to be positive. After this first character entry,

there are only two restrictions which apply prior to depression of the

ENTER key and they are:

1. A decimal point MAY be included as an entry. It should be preceded

by at least one number or a "0".

Incorrect settings

High-temp adjustments

2. The entered temperature must be within the operational temperature

range of the bath.

If a temperature is entered which is outside of the operational temperature range of the TE-3000, the following display will be shown on the

LCD and the ENTER key will flash.

*** RANGE ERROR! ***

Range is -43 to 33° C

or -45 to 91° F

ENTER to continue...

If the bath was previously operating at a temperature below +20° Celsius

and a new temperature is entered which is above +20° Celsius, the

operator will be instructed to remove one of the air circulation tubes on

the rear of the instrument. By disconnecting the air input hose on the rear

of the Control Chassis, the alcohol vapors cannot condense inside the air

return hose and subsequently impede the air circulation/stirring of the

bath. For this condition, the display issued to the LCD will be:

DISCONNECT AIR INPUT

HOSE ON BOTTOM OF

CONTROL CHASSIS.

ENTER to continue...

Low-temp adjustments

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

If the bath was previously operating at a temperature above +20° Celsius

and a new temperature is entered which is below +20° Celsius, the

operator will be instructed to replace one of the air circulation tubes on

the rear of the instrument. By reconnecting the air input hose on the rear

Page 23

of the Control Chassis, the alcohol vapors will be contained within the air

return hose and permit the operation at low temperatures. For this condition, the display issued to the LCD will be:

RECONNECT AIR INPUT

HOSE ON BOTTOM OF

CONTROL CHASSIS.

ENTER to continue...

H. Calibration at a given target temperature

The TE-3000 temperature control system permits the calibration of the

bath temperature to agree with any user supplied temperature reference

standard. The bath can be calibrated by the user whenever the bath

temperature is stable for any given TARGET temperature in degrees

Celsius or Fahrenheit.

19

BIN settings

For every whole degree Celsius and Fahrenheit, a calibration “BIN”

exists in nonvolatile memory within the temperature control system. The

“reference actual temperature” is entered by the user as the actual temperature of the bath according to the user’s temperature reference standard and is stored by the bath in this memory and will be used whenever

that particular target temperature is entered. Fractional degrees will use

the closest whole number bin. In the following example, the target

temperature is -20 degrees Celsius and the bath temperature is stable and

controlling well within +/- .01 degrees. When the CAL TEMP key is

depressed, the display will show:

Enter Actual Bath

Temp. for Bin Offset

at -20 C: +_____ °C

CAL TEMP to Cancel

With the cursor (dark underline character) in the first position, the user

has the option of entering a negative temperature by depressing the

combination -/. key. If any numerical key is depressed in this first

position, the temperature entered is assumed to be positive. After this first

character entry, there are three restrictions which apply prior to depression of the ENTER key and they are:

Multiple corrections

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

1. A decimal point MAY be included as an entry. It should be preceded

by at least one number or a "0".

2. The entered temperature must be within the operational temperature

range of the bath.

3. The entered actual temperature must not cause a correction in temperature greater than +/- 2.5 degrees.

Multiple or successive entries of correction for any temperature are

permissible. A newly entered corrected temperature is mathematically

Page 24

20

compensated with the previously entered correction and is stored as the

latest correction.

Data entry errors

I. Menu selections

If a temperature is entered which is outside of the operational temperature range of the TE-3000 plus or minus the allowable correction factor,

the following display will be shown on the LCD:

*CALIBRATION ERROR!*

Range is -45 to 35°C

or -49 to 95°F.

ENTER to continue...

If an actual reference temperature is entered which is within the operational temperature range of the TE-3000 BUT the amount of the correction (delta to displayed temperature) is too large, the following display

will be shown. The user should check his reference thermometer to verify

the actual temperature. If the user cannot correct the error, contact

CANNON® Instrument Company for further assistance.

*CALIBRATION ERROR!*

Calib amount is too

large. Can’t store.

ENTER to continue...

Whenever the bath is in the normal or quiescent mode, the MENU key

may be depressed. The MAIN MENU will be entered and the following

display will be shown:

From this MAIN MENU, the user may enter any number from 1 to 3

followed by the ENTER key or the MENU key will return back to the

normal display. The following sections describe any subsequent menus or

action taken by the TE-3000 control system.

1. Celsius or Fahrenheit operation

The TE-3000 is capable of being operated in either degrees Celsius or

Fahrenheit. If the user is presently operating in Celsius degrees, depressing a 1 in the MAIN MENU followed by the ENTER key will cause the

bath to operate in degrees Fahrenheit. If the user is presently operating in

Fahrenheit degrees, depressing a 1 in the MAIN MENU followed by the

ENTER key will cause the bath to operate in degrees Celsius. The

normal display will then return after this entry.

MAIN MENU

1. Change to °F

2. Bath Temp Offsets

3. Comm Setup :_

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 25

2. Bath temperature calibrations and offsets

The previous Section H dealt with the setting of individual temperature

correction bins for temperature calibrations at any given set temperature.

When the user enters a 2 in the MAIN MENU, the following display is

shown. It is possible to clear (or zero) ALL bin calibration data or enter

the GENERAL BATH OFFSET menu.

BATH TEMP OFFSETS

1. Clear Bin Offsets

2. Set Gen Bath Ofs.

(Protected) :_

a. Clearing all temperature calibrations/offsets

Whenever a 1 is entered in the BATH TEMP OFFSET menu, the following screen is shown. This command will clear ALL of the temperature

correction “bins” for degrees Celsius AND Fahrenheit which may have

previously been set. This command is usually used prior to adjustment of

the “general bath offset”. This command may also be used if significant

differences become apparent between the user supplied reference temperature and the displayed temperature of the bath or if CAL TEMP

entries were made when the bath was not stable. Once this "clear"

command is issued, new calibration entries may be made in the CAL

TEMP menu.

21

ABOUT TO CLEAR ALL

CALIB. CONSTANTS!

ARE YOU SURE?

ENTER-Yes MENU-No

b. Setting the bath general offset

Whenever a 2 is entered in the BATH TEMP OFFSET menu, the following screen is shown. The setting of the BATH GENERAL OFFSET

mathematically compensates all temperature readings displayed as

“Actual Temperature”. This function is normally performed at the factory

prior to shipment of the instrument and is accomplished at a temperature

near the midpoint of operation of the TE-3000. This function is password-protected so the user must contact CANNON

®

Instrument Com-

pany if access to this capability is required.

This is a protected

function. Enter the

passkey to continue.

Press MENU to Cancel

Once the correct password is entered, the user will be presented with the

following display. The current “general bath offset” is displayed as a

delta in degrees and two choices are permissible.

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 26

22

GEN. OFFSET CORRECT

Offset: 0.000 °C

1. Set Gen. Offset

2. Clear Offset :_

If a 1 is entered in the GEN. OFFSET CORRECT menu, the following

display is shown. The user is prompted to enter the correct “reference”

actual temperature of the bath. At this point the temperature of the bath

should be stable or no entry should be made.

Enter Actual Bath

Temperature for Gen.

Offset: +_____ °C

MENU to Cancel

With the cursor (dark underline character) in the first position, the user

has the option of entering a negative temperature by depressing the

combination -/. key. If any numerical key is depressed in this first

position, the temperature entered is assumed to be positive. After this first

character entry, there are three restrictions which apply prior to depression of the ENTER key and they are:

1. A decimal point MAY be included as an entry. It should be preceded

by at least one number or a "0".

2. The entered temperature must be within the operational temperature

range of the bath.

3. The entered actual temperature must not cause a correction in temperature greater than +/- 2.5 degrees.

If a 1 is entered in the GEN. OFFSET CORRECT menu, the general

offset will be zeroed in value and the normal display will then be shown.

3. Communication options

The “Communication Setup” menu is entered from the Main Menu by

selecting item 3 and the following is presented on the display. The user

may enter a 1 or a 2 followed by enter or else the MENU key may be

depressed to return to the normal display.

COMMUNICATION SETUP

1. Change Port Speed

2. Change Mode

:_

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

a. Changing the port speed

Page 27

If the user selects to enter a 1 from the COMMUNICATION SETUP

menu, the COMM PORT SPEED menu will display five baud rate

options: 1200, 2400, 9600, 19.2K, and 38.4K BAUD. The baud rate

selected will be effective on both the RS-485 interface (polled) and the

RS-232 interface (point-to-point). The user may enter a number from 1

through 5 followed by ENTER or else the MENU key may be depressed

to return to the normal display.

COMM PORT SPEED

1. 1200 4. 19.2K

2. 2400 5. 38.4K

3. 9600 :3

23

NOTE

The number shown after the colon denotes the present baud rate.

b. Configuring the mode of operation

If the user selects to enter a 2 from the COMMUNICATION SETUP

menu, one of the two following submenu screens will be shown. If the

TE-3000 was previously configured to operate in a polled (RS-485)

environment, the first display will be provided - showing that timed

reports are disabled and the present mode is polled (:1). If the user wishes

to operate in a point-to-point environment with or without timed interval

reports, a 2 should be entered now.

COMMUNICATION MODE

1. Polled

2. Point to Point

(Reports Disabled):1

If the TE-3000 was previously configured to operate in a point-to-point

(RS-232) environment, the following display will be provided - showing

that timed reports may be utilized and the present mode is point-to-point

(:2). An entry of 1 at this time will place the bath in a polled environment. For an entry of 3, please see the next section (5.D.) for the response to a TR command.

Selecting a report interval

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

COMMUNICATION MODE

1. Polled

2. Point to Point

3. Config Reports :2

c. Configuring reporting periods

If a 3 is entered in the COMMUNICATION MODE menu, the system

was previously configured for point-to-point operation and therefore the

following display is shown. The user may select any reporting interval in

“seconds” or NO reporting interval which is OFF. The :1 in the bottom

right hand corner indicates the presently selected period. A number entry

from 1 to 8 is acceptable.

Page 28

24

SELECT REPORT PERIOD

1. OFF 4. 5 7. 60

2. 1 5. 10 8.120

3. 2 6. 30 :1

NOTE

These reports are only issued if the mode of communications is configured as POINT-TO-POINT.

If the bath is configured in the point-to-point mode of communication

operations, then the controller has a full-duplex communication link (RS-

232) and can therefore issue these unrestricted timed reports. If the bath

is re-configured in the polled mode of communication operations, the

controller has a half-duplex communication link (RS-485) and cannot

issue timed reports. The report option will be automatically disabled and

a message indicating the report status will be displayed on the LCD

screen. Press the blinking ENTER key to return to the normal screen

display.

See Section D of Chapter 5 for more information on the structure of these

reports, which are identical to the response to a TR query.

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 29

CHAPTER

COMMUNICATIONS

55

5

55

The TE-3000 is equipped with a full-duplex RS-232C point-to-point

interface as well as a half-duplex RS-485 network interface. Commands

and Queries may be sent to the TE-3000 via either interface and Responses and Reports received by a master controlling computer. This

interface is configured as 8 data bits with no parity and one stop bit. The

Baud rate of the interface is configured only via the front panel menu

system and can be set at 1200, 2400, 9600, 19.2k, or 38.4k Baud. The

mode of operation, point-to-point or polled (multi-drop), can only be

configured via the front panel menu system. Time interval reports of the

actual and desired bath temperature can only be enabled if the TE-3000 is

configured in the point-to-point mode of operation.

A. Downloading firmware updates

25

The TE-3000 is capable of receiving new operational software via either

the RS-232 or RS-485 interface. If this software is updated and a new

release is issued by CANNON® Instrument Company, a diskette will be

sent to the users along with instructions on how to perform this upgrade.

Download button

A “download” push-button is provided on the rear panel of the TE-3000

which places the instrument into the download mode. When this mode is

entered, the front panel display will show the version number of both the

resident download hardware code and the version of the present operational firmware. A computer will then be required to send the new

firmware to the TE-3000.

B. Full duplex (POINT-TO-POINT) operations

The RS-232 interface is furnished for a direct connection from one TE3000 to one computer. A DB-25 connector, configured as Data Communication Equipment (DCE), is provided on the rear panel of the TE-3000.

This configuration permits a direct connection (straight through cable pins 1 through 8, & 20) from the TE-3000 to virtually any computer.

Most present day computers have a DB-9 connector which requires the

use of an adaptor or a cable with a DB-25 male connector on one end and

a DB-9 female connector on the other end. For a complete description of

the Commands, Queries, Responses and Reports on this interface, please

refer to the section D which follows.

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 30

26

C. Half duplex and polled (multi-drop) operations

The RS-485 interface is provided to permit a network connection from

one computer to multiple instruments. A three-wire (with feed-through)

screw terminal connector is furnished on the rear panel of the TE-3000

which allows the use of any three conductor cable (two wire shielded,

preferred) to be connected into and out of the instrument. The computer

must have an RS-232 to RS-485 adaptor plugged into the computer serial

port.

Network capability

The network is capable of supporting up to 16 instruments at distances of

up to 4000 feet. If the network is configured for more than three occupants and/or if the network spans a long distance (>100 feet) then it may

be required that termination resistors be added to the first and last occupant on the network. Contact CANNON® Instrument Company for

further assistance about the configuration of your particular network

needs.

For a complete description of the Commands, Queries, Responses, and

Reports on this interface, please refer to section D which follows.

D. Commands, queries, responses and reports

The protocol on the serial interfaces includes commands and queries

which are sent by a master controlling computer, and responses which are

sent by the TE-3000 in reply to every command or query it receives. The

TE-3000 may also issue timed interval reports automatically if it is

configured to operate in the point-to-point mode. If the TE-3000 is

configured to operate in the multi-drop mode, reports will only be issued

in response to a specific query.

Protocol

All Commands and Queries sent to the TE-3000, regardless of which

interface, must be preceded by a / and a #. The # is the selected address

(rear address switch) of the TE-3000 and must be 0-9 or A-F while the /

is a simple slash character denoting the beginning of an addressed

command or query.

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

All Commands must then be identified with the letter C and all Queries

must be identified with the letter Q. Commands and Queries have various

types which are always defined with two letters - $$. Some command

and query types have arguments which may be associated with it to

further define the action which must be taken - &..&.

And finally, all Commands and Queries must end with a carriage return

(R).

Page 31

27

Format examples

Therefore, the format for a typical COMMAND line is:

/#C$$&..&

And the format for a typical QUERY line is:

/#Q$$&

On the following pages is a table of Command types with possible

arguments along with a description of the action taken by the TE-3000

and its subsequent response.

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 32

28

dnammoC

epyT

"$$"

DA enon siesnopserehtenodnehW.retrevnocDotAtib61ehtsetarbilaC ON_DA ehtfi

TR enon denrutersiesnopserA.purewopnonursitahtenoehtekiltseT-flesetelpmocasnuR

CD enon dnammocsihT.stroperllanidnaDCLehtnosuisleCseergednierutarepmetllayalpsiD

elbissoP

0003-ETybnekaTnoitcAfonoitpircseD

tnemugrA

”&..&“

na,elbazingocer RRE .denrutersi

DAC5/

sihtekilkoolthgimesnopserehT

SEYDAC5-

dnammocfotpiecergnitacidniyletaidemmi SEYTR tonsidnammocehteslero

adnaelbazingocer RRE .esnopserehtsi

TRC6/

:sihtekilkoolthgimesnopserehT

SEYTRC6-

dnammocfotpiecergnitacidniyletaidemmi SEYCD tonsidnammocehteslero

adnaelbazingocer RRE .esnopserehtsi

CDC1/

:sihtekilkoolthgimesnopserehT

SEYCDC1-

tonsidnammocehtfI.lufsseccussawnoitarbilacehtfi”SEYDA“ro,deliafnoitarbilac

:5fosserddanahtiw0003-ETaottnessawdnammocsihtfi,elpmaxenasA

:6fosserddanahtiw0003-ETaottnessawdnammocsihtfi,elpmaxenasA

denrutersiesnopserA.secnerefererutarepmetllarofedomsuisleCehtnihtabehtsecalp

:1fosserddanahtiw0003-ETaottnessawdnammocsihtfi,elpmaxenasA

FD enon sihT.stroperllanidnaDCLehtnotiehnerhaFseergednierutarepmetllayalpsiD

RS &&& retcarahceerhtehtybdenifedsasdnoces-flahfoeulavehtotlavretnignitropeRehtsteS

A.secnerefererutarepmetllarofedomtiehnerhaFehtnihtabehtsecalpdnammoc

dnammocfotpiecergnitacidniyletaidemmidenrutersiesnopser SEYFD ehteslero

adnaelbazingocertonsidnammoc RRE .esnopserehtsi

:2fosserddanahtiw0003-ETaottnessawdnammocsihtfi,elpmaxenasA

FDC2/

:sihtekilkoolthgimesnopserehT

SEYFDC2-

eblliwFFFot000morfstnemugraylnO.LAMICEDAXEHnisihcihw&&&tnemugra

deussiebotstropertimrepsrebmunrehtoynadnaffostroperllasnrut000erehwdetpecca

-ETEHTFIYLNO(sdnoces5.740,2otpusdnoces5.morflavretnidnoces-flahynano

sidnammocehtfI.)NOITAREPOFOEDOMTNIOP-OT-TNIOPEHTNISI0003

ahtiwnruterlliwtnemurtsnieht,detpecca SEYRS lliwlavretnitroperwenehtdnaesnopser

eblliwesnopsereht,neessidleifxehdilavninafI.tceffeekat ON_RS eslegnihtynadna,

anitluserlliw RRE .esnopserehtsa

aottnessaw,slavretnidnoces-eviftastropergnitseuqer,dnammocsihtfi,elpmaxenasA

:3fosserddanahtiw0003-ET

A00RSC3/

:sihtekilkoolthgimesnopserehT

SEYRSC3-

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 33

29

dnammoC

epyT

"$$"

TS &&&.&&&+

BC F|C suisleCnitnemugraehtybdenifedsasniBtesffonoitarbilacehtfollasraelC

elbissoP

tnemugrA

”&..&“

ro

&&&.&&&-

0003-ETybnekaTnoitcAfonoitpircseD

tnemugraehtybdenifedsahtabehtfoerutarepmeT)derised(tegratehtsteS

.tesylsuoiverpsatiehnerhaFrosuisleCseergednisihcihw&&&.&&&±

ehtnihtiwebtsumyehtdnadetpeccaeblliwsrebmuntniopdexifylnO

a,detpeccasidnammocehtfI.htabehtfoegnargnitarepo SEYTS eblliw

aesiwrehto,esnopsereht RRE .denrutereblliw

fosserddanahtiw0003-ETaottnessawdnammocsihtfi,elpmaxenasA

:4 000.020-TSC4/

:sihtekilkoolthgimesnopserehT

SEYTSC4-

onsierehtdnayletaidemmidemrofrepsidnammocsihT.tiehnerhaFro

epytBSehtgnidnesotroirpdesuyllaususidnammocsihT.esnopser

,sesacllanituB.sdnammoc

.dnammocepytEEnahtiwdedneebyllautnevedluohsti

fosserddanahtiw0003-ETaottnessawdnammocsihtfi,elpmaxenasA

:9 CBCC9/

)esnopseronsierehT(

BS &&&.&±@@±C

ro

&&&.&±@@±F

EE enon sihT.yromemmorpEEelitalov-nonotMARelitalovfostnetnocehtseipoC

erutarepmeteergedelohwdeificepsehtrofniBtesffonoitarbilacehtsteS

.&&&.&seergednidenifedsatesffoehthtiwFroCrofdenifedsa@@

rofsunimrosulpahtiwgnoladenifedebtsumnibtiehnerhaFrosuisleCehT

sunimrosulpsadenifedebtsumtesffoehtfoeulavehT.eergedelohwsiht

ehtfI.&&&.&htiwseergedfoshtdnasuohtehtotdenifedebnacdna

a,detpeccasidnammoc SEYBS aesiwrehto,esnopserehteblliw RRE lliw

epytEEeht,deussierasepytdnammocesehtfoseiresaretfA.denrutereb

.wollofdluohsdnammoc

fosserddanahtiw0003-ETaottnessawdnammocsihtfi,elpmaxenasA

:3 321.0-02-CBSC3/

:sihtekilkoolthgimesnopserehT

SEYBSC3-

epytBSdnaBCfoecneuqesynadneotdesuebdluohsdnammoc

refsnartyromemehtretfA.snibehtfostnetnocehtetadpuhcihwsdnammoc

a,yllufsseccusdetelpmocsah SEYEE a,sliafrefsnartehtfI.tneseblliw

ON_EE aesiwrehto;esnopserehteblliw RRE .deussieblliw

fosserddanahtiw0003-ETaottnessawdnammocsihtfi,elpmaxenasA

:8 EEC8/

:sihtekilkoolthgimesnopserehT

SEYEEC8-

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 34

30

The following is a table of Query types with possible arguments along with a description of the response given by the TE-3000.

yreuQ

epyT

"$$"

BTF|C rosuisleCrehtierofsniBerutarepmeteergedelohwehtfollastimsnarT

elbissoP

tnemugrA

&..&""

0003-ETybnevigesnopseRfonoitpircseD

eslerotiehnerhaF RRE ehtnirebmunnibehtsahesnopsersihT.dettimsnartsi

fiecapsroynafi(ngisehtnehtdna,secapsowtybdewollofsnmuloceviftsrif

.tesffoehtdna)enon

:9sserddata0003ETaottnessiyreuqgniwollofehtfi,elpmaxenasA

CBTQ9/

:deviecereblliwtropergniwollofehT.snibsuisleCehtseireuqsihT

000.0C340-

321.0+C240-

------

redroniseunitnoc( )...htiw

654.0-C230+

987.0-C330+

SEYBTQ9-

)reifitneditroperfodne(

:9sserddata0003ETaottnessiyreuqgniwollofehtfi,elpmaxerehtonasA

FBTQ9/

:deviecereblliwtropergniwollofehT.snibtiehnerhaFehtseireuqsihT

000.0F540-

321.0+F440-

------

)...htiwredroniseunitnoc(

654.0-F090+

987.0-F190+

SEYBTQ9-

)reifitneditroperfodne(

RTenon ehthtiwtroperenilelgnisasisihT.sretemaraphtabyekfotropeRastimsnarT

TMenon sitroperenilelgnisA.noisreverawmrifdnaepyTenihcaMehtseireuqsihT

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

roCanehtdnaecapsenoybdewollofnmuloctsrifehtnigniebsserddakrowten

dnaecapsenotsaeltaybdewollofsielacserutarepmetehttahwetacidniotF

rofstigidowt,nolocaybdewollof,sruohetacidniotstigidowtroenoneht

ehtecnisdespaleemitehtsihcihwsdnocesrofstigidowtdna,lamiceda,setunim

elbissopa,ecapsenotsaeltaybdewollofsisihT.yrtneerutarepmetdetceffatsal

sihT.eergedafohtdnasuohtehtoterutarepmetderisedehtnehtdna,ngissunim

lautcaehtnehtdna,ngissunimelbissopa,ecapsenotsaeltaybdewollofsi

.eergedafohtdnasuohtehtothtabehtfoerutarepmet

suisleCnignitarepo0003ETaottnessiyreuqgniwollofehtfi,elpmaxenasA

sserddatakrowtenehtnognidiserdnaseerged02-foerutarepmettegratahtiw

:3

RTQ3/

:deviecereblliwtropergniwollofehT.tropererutarepmetehtseireuqsihT

200.02-000.02-65.43:21C3

SEYRTQ3-

)reifitneditroperfodne(

sihttatnemurtsniehtfonoitangisedrebmundnaledomehtgnitacidnideussi

gniwollofehtfi,elpmaxenasA.levelnoisivererawmrifehthtiwgnolasserdda

:7sserddakrowtenta0003ETaottnessiyreuq

TMQ7/

:deviecereblliwtropergniwollofehT.epytenihcamehtseireuqsihT

10.10VF0003ETTMTMQ7-

)yravyam#esaelererawmrif(

Page 35

CHAPTER

MAINTENANCE

66

6

66

The TE-3000 was designed for minimal care and maximum reliability.

By following a few basic rules of preventative maintenance, the TE-3000

should provide years of trouble free operation.

Additionally, the TE-3000 provides an automatic built-in self test which

examines the operation and performance of the instrument. These diagnostic routines assist the user by presenting the results of all tests and a

determination of what is wrong if any test fails. This gives the user a high

level of confidence that the instrument is functioning properly or if not,

exactly where the problem is located.

A. Preventative (scheduled) maintenance

The TE-3000 requires a minimum amount of maintenance at intervals

that are entirely dependent upon the environment and the degree of

usage. In the typical situation of an average modern laboratory performing a dozen tests daily, the following items should be performed every six

months. If the bath is located in a dirty environment and/or is heavily

used, the preventative maintenance listed below should be scheduled on a

monthly basis.

31

Cleaning of painted surfaces and front panel

Cleaning the fans and heat sinks

Cleaning fans

The finish of the TE-3000 is a baked-on epoxy enamel in colors of

almond and black. This paint is virtually immune to most solvents,

however, if acetone is rubbed on the painted surfaces, the paint will be

removed. A good quality household cleaner may be used on all painted

surfaces and the front panel. Do not spray the cleaning fluid directly on

any surface, especially the area where the fans and heat sinks are located.

The liquid will harden dust particles and cause an accumulation of dust to

be imbedded into the heat sinks and make removal very difficult. Instead,

a soft cloth should be sprayed with the cleaning solution and the cloth

should be used to transfer the solution to the surface of the instrument.

Dust and dirt will accumulate with time in the small gaps of the air heat

sinks and around the blades of the fans. These deposits will affect the

cooling effectiveness of the thermoelectric cells and will ultimately affect

the ability of the bath to go to cold temperatures. The easiest and most

effective way to clean these heat sinks and fans is by using a compressed

air source and blowing the dust away. This should be accomplished by

moving the upper Bath Vessel Assembly outside or away from any clean

environment, apply the blasts of clean air through the fans on the sides

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 36

32

and the rear, and alternately apply blasts of air directly into the heat

sinks. This can be accomplished without removal of any panels surrounding this upper Bath Vessel Housing.

Cleaning heat sinks

Removing side panels

Compressed air cleaning

If the bath is operating in a high humidity environment, the dirt may

become very hard and encrusted on the fins of the heat sinks. When this

condition is noticed while attempting to blow out the dust, remove the

left and right side panels to gain access to the heat sinks.

Each side panel is attached with four screws and should be removed by

moving the detached side panel outward for a small distance and then

upward to avoid striking the fluorescent lamp.

Using a soft, long bristled brush (available in automotive departments for

cleaning wire wheels) loosen the encrusted dust and then blow it away

with the compressed air source. Care should be taken to not bend or

crush the fins of the heat sinks.

Assemble the side panels back onto the Bath Vessel Housing by reversing

the removal procedure.

If a central or self-contained air compressor line with a blow gun is not

available, compressed air (aerosol) cans may be obtained from most

computer supply dealers. These cans may be used in conjunction with a

long nozzle to facilitate directing most of the air into a confined area.

Cleaning the bath window

The viewing window on the TE-3000 is constructed with four panes of low

emissivity glass with all panes tempered for safety. The space between these

panes are filled with a gas and sealed to provide a frost-free viewing window. The outside (front) surface of this window may become smudged and

dirty and should be cleaned with common household window cleaner. Apply

window cleaner to a soft cloth and wipe on the front window of bath.

NOTE

Do not spray cleaner directly

on front face of glass.

Draining the bath liquid

Remove all power from the TE3000 and remove all instruments from the bath prior to the

draining operation.

The bath liquid in the TE-3000

must be removed by siphoning

action (see Figure 9). A general

purpose siphon is available

wherever kerosene heaters are

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Figure 9: Siphoning bath liquid

Page 37

sold. This simple plastic device has an integral squeeze pump to start the

siphoning with a long, straight input hose and a flexible output hose.

A more effective method is a vacuum system with a container trap for

containment of the bath fluid. The continuous vacuum in such a system

provides an easy means to remove any solid dirt particles and completely

empty the bath.

Using a siphon or vacuum hose placed into one of the two instrument

holes at the top, transfer all of the bath liquid into another container.

Briefly turn on bath power and energize the fluid return pump by depressing the push button on the rear of the Control Housing.

33

CAUTION

Do NOT leave TE-3000 power on without liquid in the bath!

Once it is apparent that most of the liquid has been removed from the

overflow jar and hoses and transferred back into the bath, remove the

power from the TE-3000 again and continue to siphon or vacuum the

bath liquid.

After the bath has been drained as much as possible, remove the overflow

jar and associated hoses from the rear of the Bath Vessel Housing and

empty their contents into this container.

Cleaning the inside of the bath vessel

Depending on the grade of alcohol being used as a bath liquid, the

frequency of replacing the bath liquid may vary greatly. The contaminants contained in solution with the alcohol will remain as sediment in

the bath after the alcohol evaporates. If the bath temperature is always

maintained at a cold temperature and the holes at the top are always

covered, the rate of evaporation of the alcohol will be at a minimum.

Conversely, if the bath is maintained in the power off condition and the

top holes are uncovered, the room temperature alcohol will evaporate

quickly.

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

After all of the bath liquid has been removed and the bath vessel is at

room temperature, the cleaning procedure can begin. The actual process

of cleaning is difficult at best without the proper cleaning implements. A

long handled brush, such as one available from Thomas Scientific (cat.

No. 1929-M80), permits scrubbing the baffle, side walls, and the inside

of the bath window. Again, a good quality household cleaning agent may

be used. Spray the liquid cleaning agent through one of the top holes in

the bath vessel and use the brush to scrub off the residue on the baffle,

side walls, and bath window. Water should be used to rinse the vessel and

a siphon or vacuum system for removing the remaining mixture from the

vessel. Ensure that the vessel is clean and dry before refilling with clean

alcohol. Use lint-free towels to wipe the vessel dry if a vacuum system is

not available.

Page 38

34

This page intentionally left blank.

CANNON® TE-3000 Thermoelectric Constant Temperature Bath

Version 1.1c — May, 2005; CANNON® Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 39

CHAPTER

77

7

77

Products limited warranty

In addition to other manufacturers’ warranties, CANNON® Instrument

Company (“the Company”) warrants all products (other than reagents

and chemicals) delivered to and retained by their original purchasers to

be free from defect in material and workmanship for one year from the

date of the Company’s invoice to the purchaser. For a period of one year

from the date of such invoice, the Company will correct, either by repair

or replacement at the Company’s sole election, any defect in material or

workmanship (not including defects due to misuse, abuse, abnormal

conditions or operation, accident or acts of God, or to service or modification of the product without prior authorization of the Company)

without charge for parts and labor. The determination of whether any

product has been subject to misuse or abuse will be made solely by the

Company.

35

WARRANTY/RETURN

INFORMATION