Page 1

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 2

This page left intentionally blank

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 3

Table of contents Page

1. Introduction ............................................................................................................................................................... 2

1-1. Overview of the instrument ........................................................................................................................... 2

1-2. About the manual .......................................................................................................................................... 3

1-3. Safety symbols ..................................................................................................................................... 4

2. Preparations for measurement ................................................................................................................................... 7

2-1. Supplied parts with D155 .............................................................................................................................. 7

2-2. Installation and start-up ................................................................................................................................. 9

2-2-1. Power cable ........................................................................................................................................ 9

2-2-2. Connecting the tube lines – D155 with Peristaltic Pump ................................................................. 10

2-2-3. Connecting the tube lines – D155 without Pump ............................................................................ 10

2-3. Parts name and functions ............................................................................................................................. 11

2-3-1. Outward appearance and configuration ........................................................................................... 11

2-3-2. Key functions (General description) ................................................................................................ 13

2-3-3. LCD Display Layout ........................................................................................................................ 14

2-4. Display during initialization ........................................................................................................................ 14

2-4-1. The initial display upon power up ................................................................................................... 14

2-4-2. Display during warm up period ....................................................................................................... 14

2-4-3. Display after warm-up ..................................................................................................................... 14

2-5. Preparation before measurements ................................................................................................................ 15

3. Basic procedure ....................................................................................................................................................... 16

3-1. Flow chart for the basic measuring procedure ............................................................................................. 16

3-2. Factor calibration with pure water ............................................................................................................... 17

3-3. Measuring procedure ................................................................................................................................... 20

3-4. Clean measuring cell after measurements ................................................................................................... 22

3-5. Procedure after a day’s measurements ........................................................................................................ 23

4. Menu Navigation ..................................................................................................................................................... 24

4-1. Menu:1 View Stored Results ....................................................................................................................... 24

4-2. Menu 2: Set Sampling Time ........................................................................................................................ 25

4-3. Menu 3: Select Oil Table ............................................................................................................................. 25

4-4. Menu 4: Set Test Temperature .................................................................................................................... 26

4-5. Menu 5: Set Date and Time ......................................................................................................................... 26

4-6. Menu 6: Set LCD Contrast .......................................................................................................................... 27

4-7. Menu 7: Reset Test Number ........................................................................................................................ 27

4-8. Menu 8: Clear Stored Results ...................................................................................................................... 27

4-9. Menu 9: Export Stored Data to USB Drive ................................................................................................. 28

4-10. Menu 10: View Serial No. & Firmware Ver. ............................................................................................ 29

4-11. Parameters and default .............................................................................................................................. 30

4-12. How to connect the optional printer or a personal computer (PC) ............................................................ 31

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 4

5. Maintenance ............................................................................................................................................................ 32

5-1. Daily check .................................................................................................................................................. 32

5-1-1. Cleaning the measuring cell ............................................................................................................. 32

5-2. Other maintenance ....................................................................................................................................... 33

5-2-1. Replacement of the power fuse ........................................................................................................ 33

5-2-2. Adjustment of Injection Adapter (and tightening of tube nozzles) .................................................. 33

5-2-3. Replacement of optional peristaltic pump tubing ............................................................................. 35

6. Troubleshooting ....................................................................................................................................................... 37

6-1. Error messages and remedies ....................................................................................................................... 37

6-2. Symptoms for error numbers and associated remedies ................................................................................ 37

6-3. Troubleshooting ........................................................................................................................................... 38

6-3-1. Cannot turn on the main unit with the power switch ........................................................................ 38

6-3-2. “Ready to Test” message does not appear and/or cell temperature is unstable. ............................... 39

6-3-3. The unit does not work even though power is on. ............................................................................ 39

6-3-4. LCD does not function ..................................................................................................................... 39

6-3-5. Key entry does not work .................................................................................................................. 40

6-3-6. Air bubbles are easily trapped in the sample and visible in the measurement cell ........................... 40

6-3-7. There is poor repeatability on measured values ............................................................................... 41

6-3-8. Sampling time is too long (optional peristaltic pump) ..................................................................... 42

6-3-9. Measuring time is too long ............................................................................................................... 43

6-3-10. Data cannot be stored in the memory ............................................................................................. 43

7. Others ...................................................................................................................................................................... 44

7-1. Basic specifications ...................................................................................................................................... 44

7-2. Principle of measurement ............................................................................................................................ 45

7-2-1. Oscillating U-tube Cell .................................................................................................................... 45

7-2-2. Density Tables .................................................................................................................................. 46

7-3. Warranty/Return Information ...................................................................................................................... 48

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 5

1. Introduction

1-1. Overview of the instrument

Please read this manual thoroughly in advance for the best performance of the equipment.

Thank you for your patronage of CANNON products. The D155 Density Meter you have purchased is

an oscillation-type density/specific gravity meter which can measure density, specific gravity and API

degrees. This meter is equipped with thermal control, which enables you to set a measurement

temperature. Also an optional peristaltic pump is available (factory installed) for sampling, thus

measurement is made easier by just pressing a button.

Key Features

1) Density, specific gravity and API degrees can be easily measured.

2) Measurement can be started simply by pressing a button.

3) The built-in thermal control enables you to set a measurement temperature in the range between

15°C to 25°C.

4) Measurement results on the display can be selected from density, specific gravity or API degrees.

5) The meter can be calibrated on one-point with pure water.

6) An optional printer can be connected, or data can be exported as an MS-Excel file and saved to an

external USB storage device for analysis on a personal computer.

2

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 6

There exists the danger of physical injury or even possible death if the

There exists the danger of property damage if the instruction is

1-2. About the manual

Please keep this manual near your system so that you can easily access to the necessary information

you are looking for while operating or preparing for measurement.

The examples below represent the three types of messages (warning, caution, and note) encountered

throughout the manual.

1. Where there exists a danger of physical injury or even possible death:

Warning!

instruction is disregarded.

2. Where there exists a danger of property damage:

3

Caution!

ignored.

3. When there exists a possibility of failure of instrument performance:

Note:

There exists the possibility of failure of instrument performance.

If ignored, warranty may not be covered.

* It is prohibited to copy or reproduce in part or in whole this manual without authorization by copyright.

* If you should find any part in this manual not clear to understand or missing article, contact your local

dealer or sales representative.

* Manufacturer will not be liable for any loss or damage directly or indirectly caused by use of the

instrument or its consequences.

* This manual pertains directly to the D155. For details relating to other accessories or equipment

please refer to the appropriate manufacturers supplied documentation..

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 7

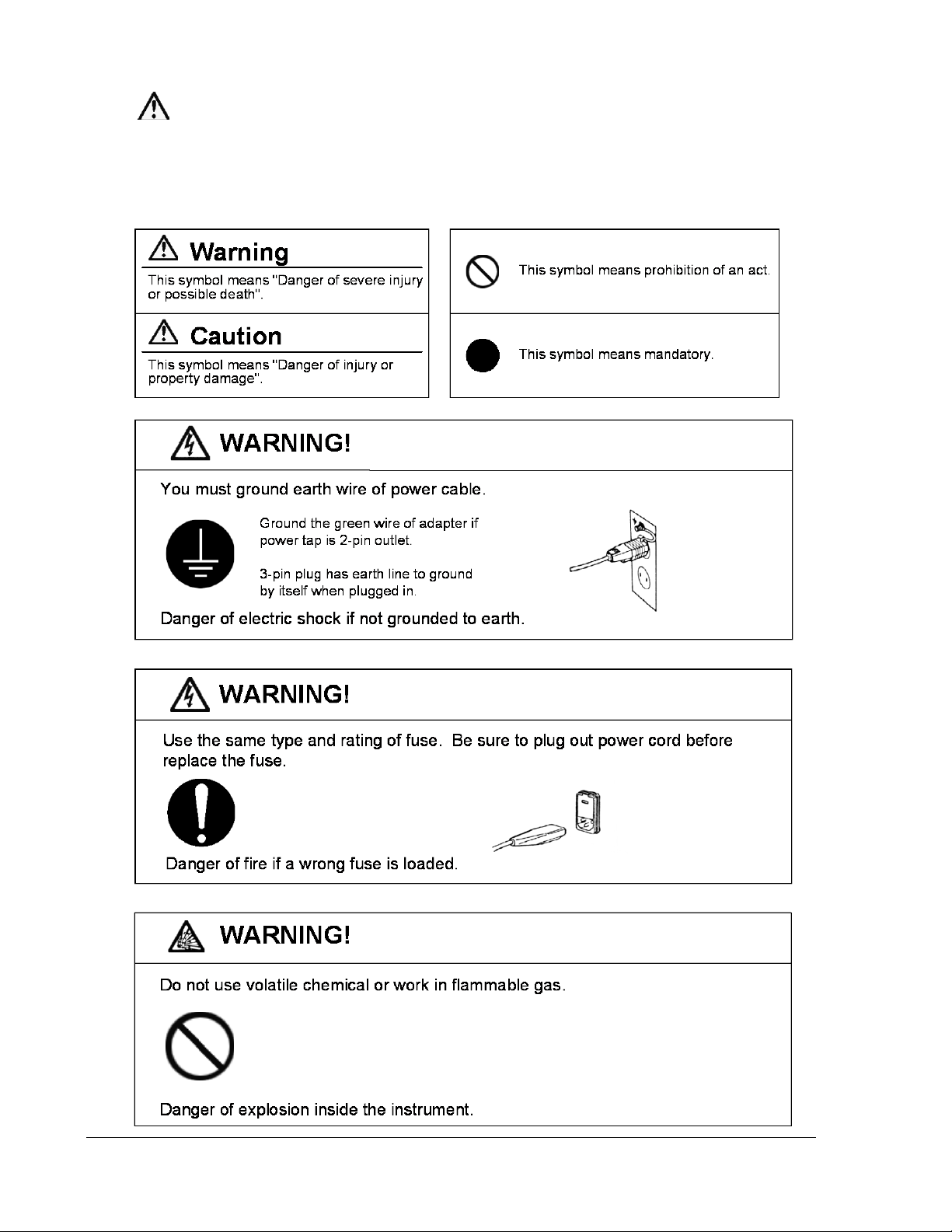

1-3. Safety symbols

Always observe these signs and instructions.

You must observe cautionary messages and warnings in order to protect yourself as well as prevent

others from physical injury or property damages.

4

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 8

5

WARNING!

Wear safety glasses, gloves or protective mask if necessary,and well

ventilate the room.

Danger of injury on your skin or in the eyes by splashing chemical.

Also your windpipe may get hurt if toxic gas is breathed in.

Danger of fire, electric shock or damage to the instrument.

Do not operate in a way other than specified in the manual.

CAUTION!

CAUTION!

Do not open housing case or overhaul the unit for repair except by an

authorized service person.

Danger of fire, shock or malfunctioning of the unit.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 9

About place for installation

Avoid the use of this instrument under the environment described below.

(Failure can lead to the degradation of performance and reliability of the system.)

• Operation of devices with strong electric motors using common power source

• Near strong magnetic/electric field

• Use of power source with too variable load

• Location of strong vibration

• Exposure to direct sunlight

• Location with large temperature difference

• Exposure to corrosive gas

• Exposure to extreme heat (Operation temperature: 5 to 35°C (41 to 95°F))

• Exposure to high humidity (Over 85%RH)

About power source

• Power for this instrument is 100-240V AC ±10%and 50/60Hz.

• Supply power direct from the outlet, and do not share power from a tap,

extension cord, or power outlet strip.

About place for storage

6

• If the instrument is not operated for a long period of time (more than several

• For storage, avoid a place with temperature extremes, high humidities and

Other caution

• Do not use such a solvent as alcohol, acetone, thinner or the like for cleaning the

external parts or surfaces of this instrument. Doing so may adversely affect the

instrument, e.g. deformation, discoloration or cracks. When cleaning this instrument,

wipe it with a soft cloth or tissue paper, after applying mild detergent diluted with water to

the soft cloth or tissue paper and adequately wringing out excess water in order not to

allow water to enter the instrument.

• Prior to the actual sample measurement, check the meter calibration with pure distilled

water. Additionally, certified density reference oils are available from Cannon Instrument

Company and can be used to verify the performance of the D155.

weeks), rinse the measurement cell with a suitable solvent followed by pure

water and a drying solvent, and then pack the whole unit into the carton box

which contained the instrument when first delivered.

dust.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 10

Part name

CANNON Part Number

Qty

Sketch

w/ ground

Operation

manual

2. Preparations for measurement

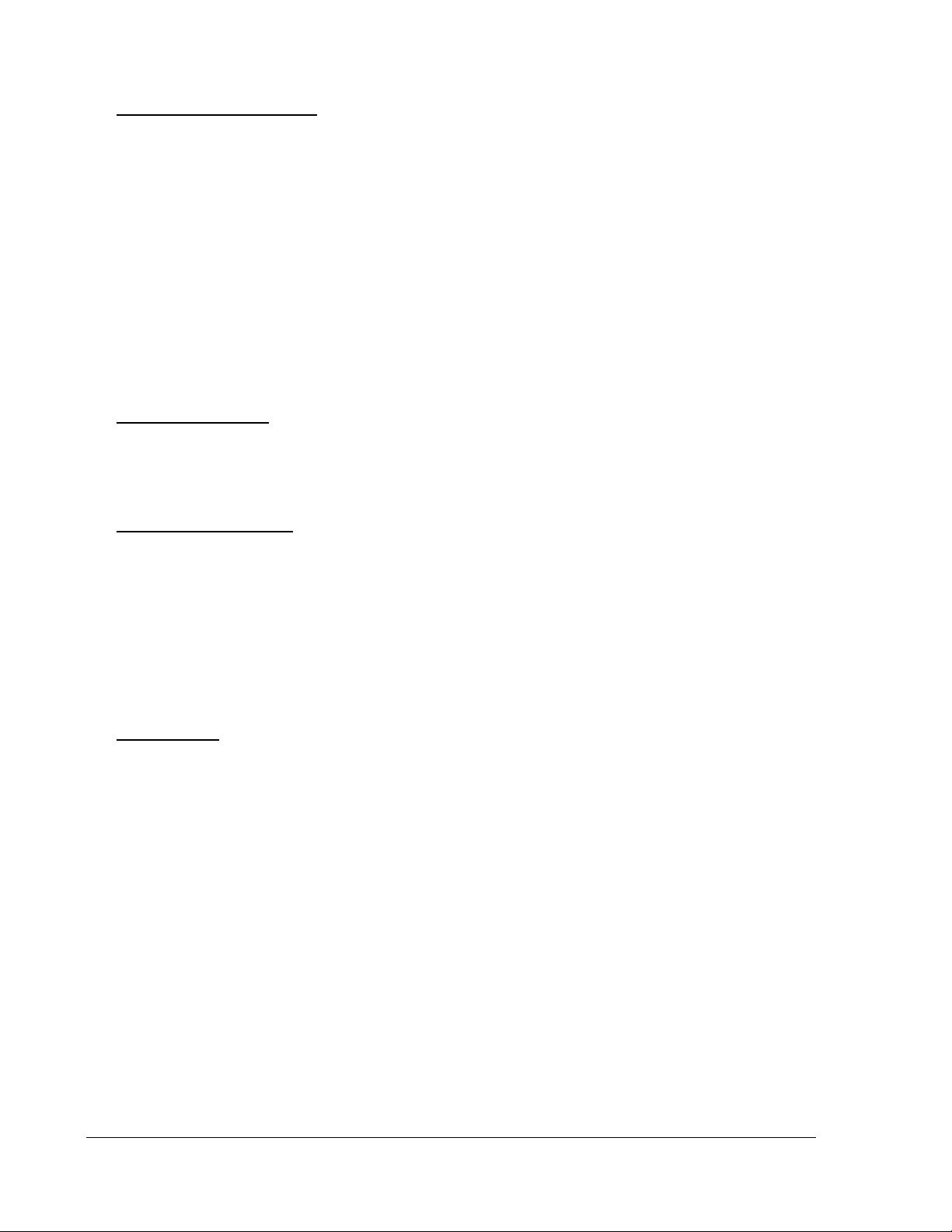

2-1. Supplied parts with D155

Check the supplied parts referring to the following parts list. If any missing or broken parts including

main unit, accessories or manual are found, contact your sales representative or local dealer.

9726-P10

D155 unit

(with peristaltic pump)

115V AC

Power cord

Connection

Tube with

Union

1 unit

9726-P15

74.2110

1 pc.

95.0254 1 pc.

7

Red Tubing,

1.5 mm OD,

95.0297 1 pc.

PTFE

Wrench,

open-ended

95.0298 1 pc.

95.0238

Syringe 2mL

Operation

(re-order in pack of 100)

95.0250

manual

5 pc.

1

copy

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 11

Part name

CANNON Part Number

Qty

Sketch

(L=2000mm)

Part name

CANNON Part Number

Qty

Sketch

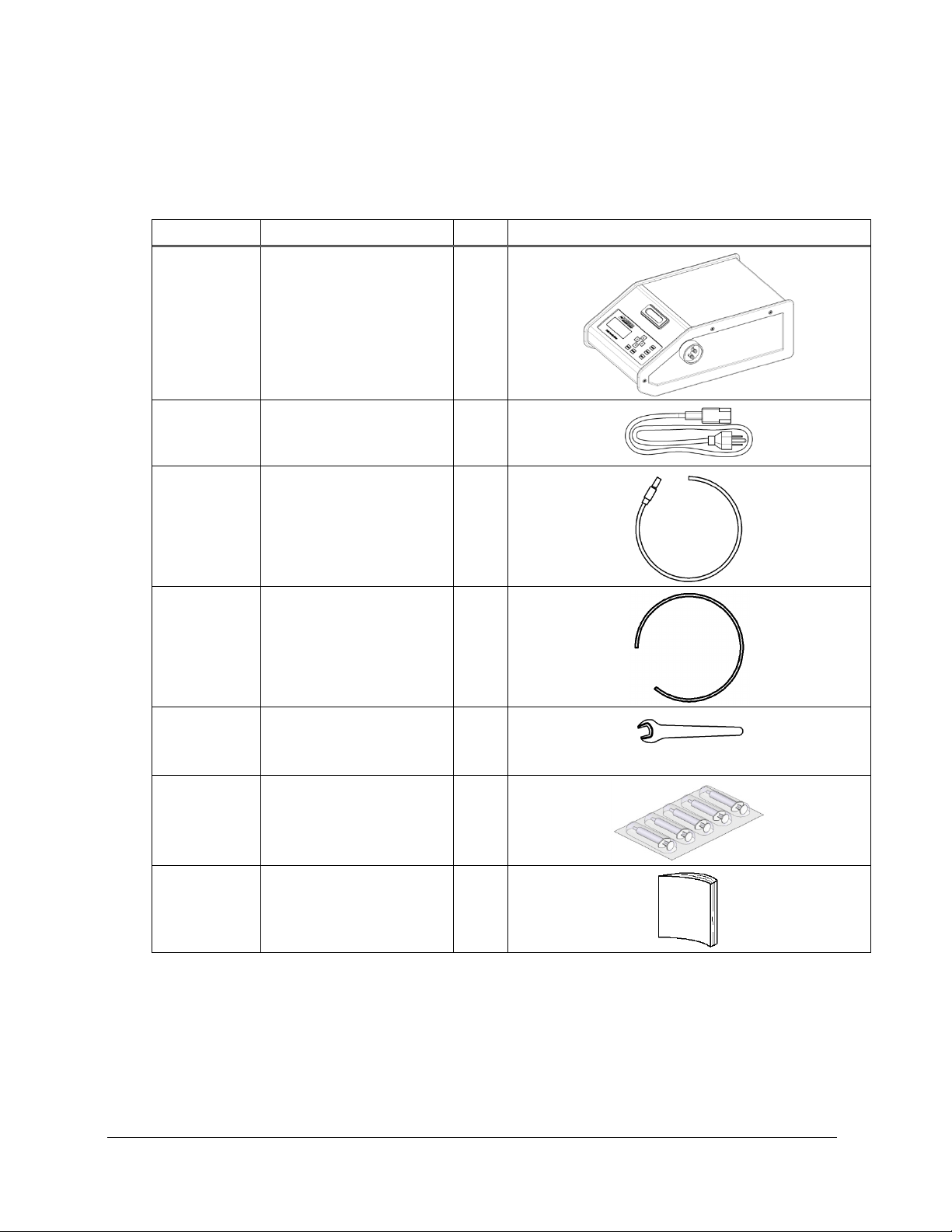

Additional Parts supplied with optional peristaltic pump

Peristaltic

Pump

(includes all

tubing below)

Peristaltic

Pump Tube

Gore400

Connection

Tube with

Union

95.0255 1 pc.

95.0256 1 pc.

95.0254 1 pc.

8

Drain Tube 95.0253 1 pc.

Additional Parts supplied with optional printer

Dot Matrix

Printer Kit

(includes

cable and

spare ribbon)

Null-Modem

RS-232

Cable

DB9F-DB25M

95.0239 1 pc.

95.0240 1 pc.

Ribbon, Black

Theramark

P5570

82.0059 1 pc.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 12

grounds to the AC Mains earth.

2-2. Installation and start-up

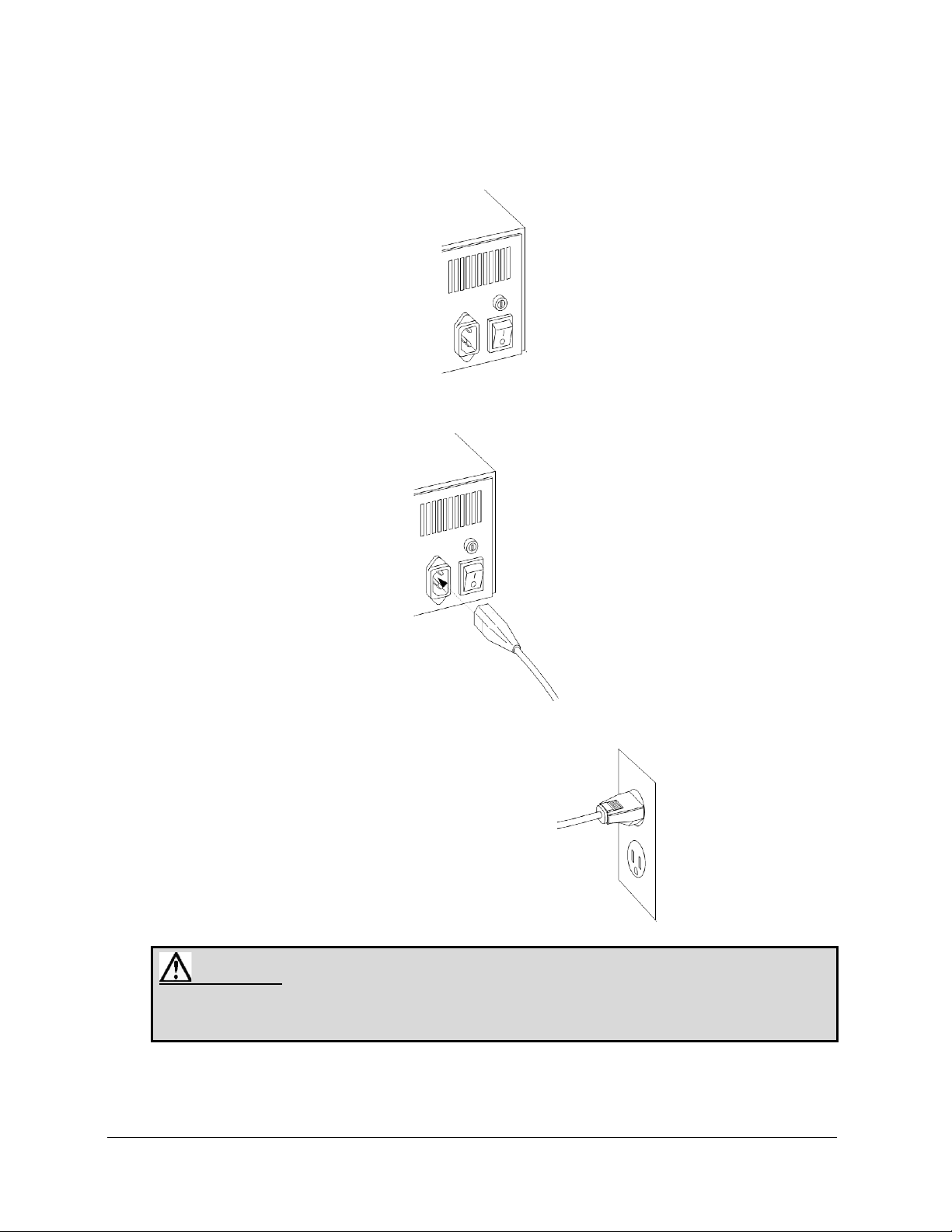

2-2-1. Power cable

1) Make sure the power switch is in the OFF position.

2) Plug in the supplied power cable on the back of unit.

9

3) Connect the power cable to the power outlet.

< 3-pin plug >

The 3 pins plug has an earth terminal and

Warning!

The earth wire must be grounded. If not, there exists a danger of electric

shock.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 13

OUT

IN

2

1

2

Syringe

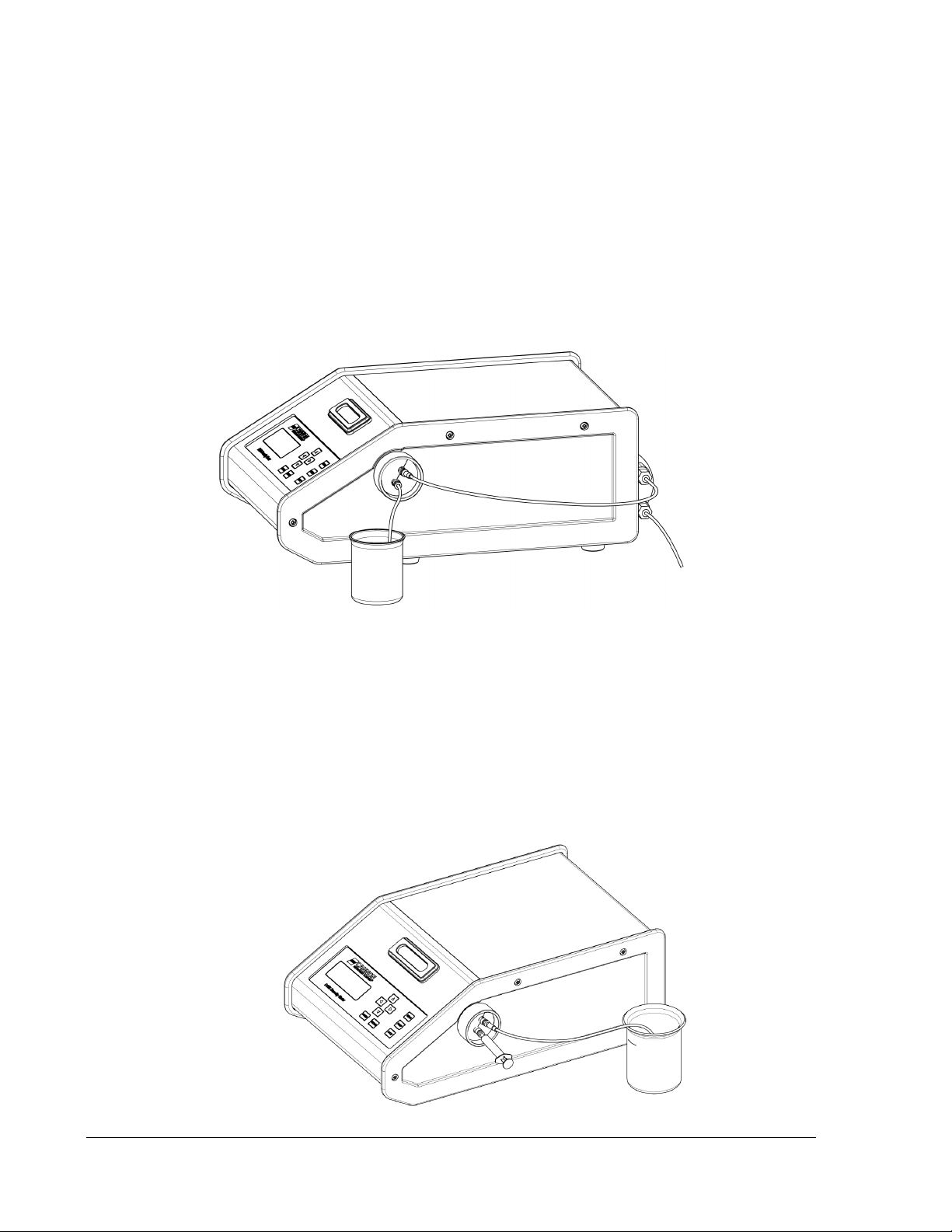

2-2-2. Connecting the tube lines – D155 with Peristaltic Pump

1) The sampling inlet and outlet ports (1) and (2) are Luer friction-type fittings. See image below for

connecting the tubing.

2) Insert and press the first Connection Tube with Union into the sample inlet Port (1) of the D155 as

shown below. The free end of this tube will later be inserted into the sample container.

3) Connect the second Connection Tube with Union to the sample outlet Port (2). The free end of

this tubing is then connected to the peristaltic pump IN (upper port) fitting as shown below. Connect

the Drain Tube to the peristaltic pump OUT fitting. The free end of the Drain Tube should then be

placed in a suitable waste container such as a beaker or bottle.

10

2-2-3. Connecting the tube lines – D155 without Pump

1) The sampling inlet and outlet ports (1) and (2) are Luer friction-type fittings. See image below for

connecting the tubing.

2) Use a syringe with friction Luer fitting to inject sample into the sample inlet Port (1) noted as “syringe”

of the D155 as shown below.

3) Insert and press the Connection Tube with Union into the sample outlet Port (2) on the D155 and

place the other end of the tube in a suitable waste container such as a beaker or bottle.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 14

2

3 4 5

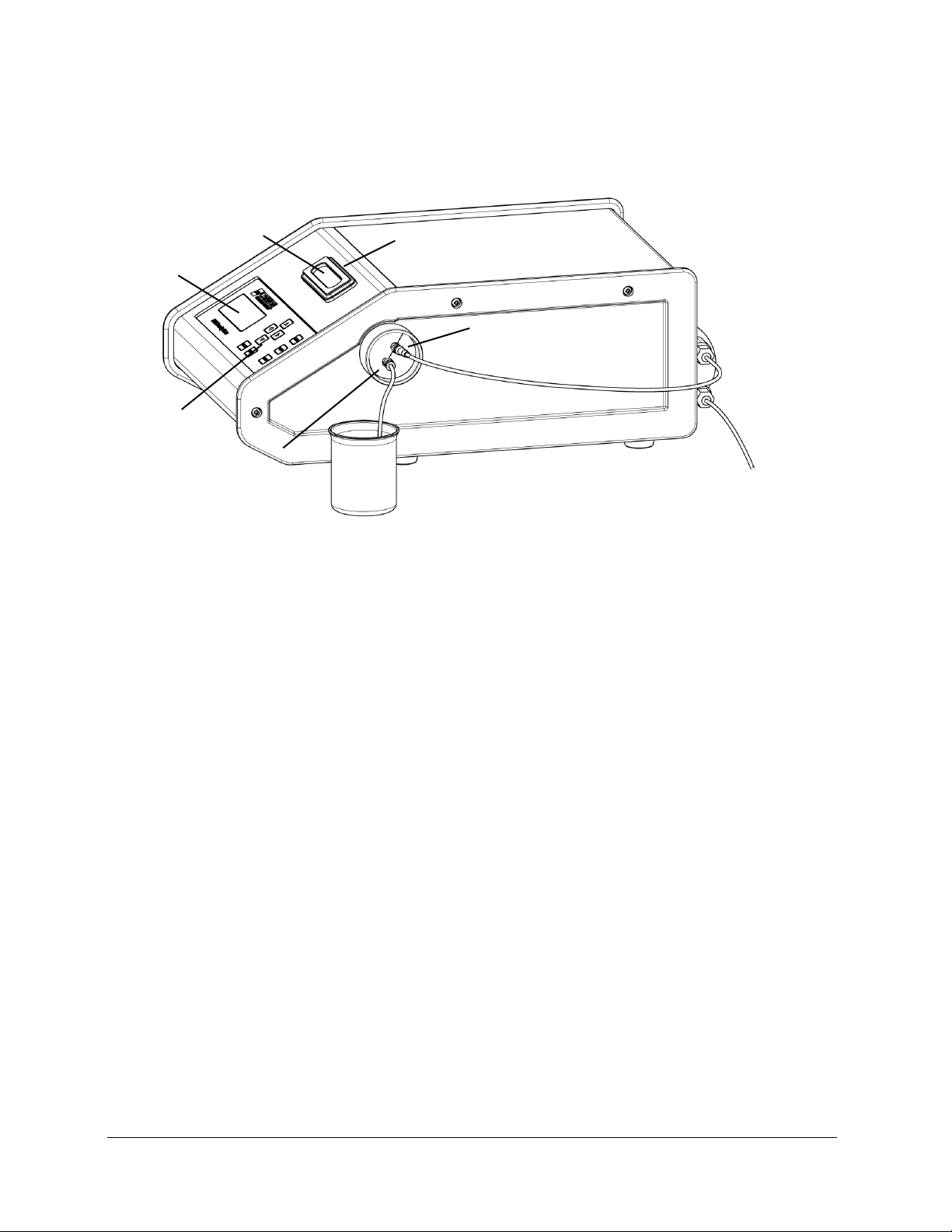

2-3. Parts name and functions

2-3-1. Outward appearance and configuration

< Front and Right side panel >

1

11

6

1) Measuring cell unit

Internal to the instrument, this unit contains the oscillating U-tube measuring cell for sample

measurement.

2) Cell viewport

The sample can be seen through this window to check if the liquid contains air. The cell is

illuminated for easy viewing of the sample in the glass U-tube.

3) LCD display

The display of 20 digits by 4 lines shows measurement results, measured temperature, peristaltic

pumping condition (if installed) and instrument prompts.

4) Operating panel

This keypad contains 9 soft-touch buttons for controlling the density meter for setup, measurement

start, and function selection.

5) Sample inlet

Here is where the sample or cleaning solvent is injected either by syringe or the sampling tube is

connected for units which have the peristaltic pump installed.

6) Sample outlet

This port is connected to either a suitable waste container or the peristaltic pump “IN” port for units

with the peristaltic pump.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 15

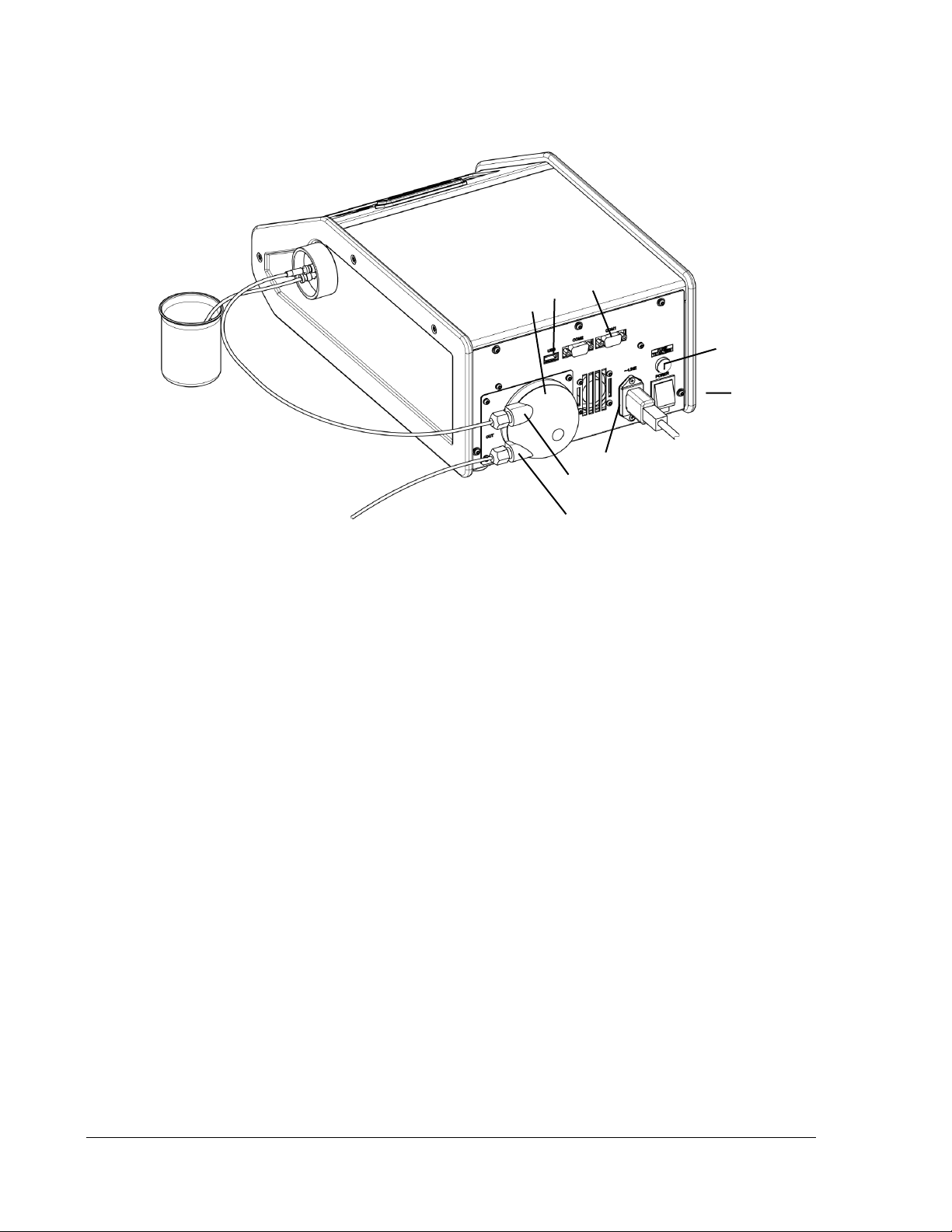

12

10

9

8

7

11

13

14

< Rear panel >

12

7) Peristaltic pump “IN” (if equipped)

The sample outlet is connected here.

8) Peristaltic pump “OUT” (if equipped)

The tube for draining out the sample or solvent can be connected here.

9) Peristaltic pump (if equipped)

This pump transfers sample liquid by peristaltic movement.

10) RS-232C port

An optional printer or a personal computer (PC) can be connected here.

11) ∼ LINE

The AC Mains power cord is connected with this receptacle.

12) Power switch

Turn on or off the unit with this switch.

13) Fuse holder

A miniature 5x20mm cartridge fuse is housed in here. Only replace the fuse with like rating fuses

(T3.15A 250V) as noted on the rear label of the instrument

14) USB port

Use for connecting an external USB storage device for exporting stored data from the density meter.

This port is also used to uploaded firmware to the density meter.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 16

2-3-2. Key functions (General description)

Here is a brief description of function of each key:

[][][][] key : Key to select menu options, settings, or enter numeric values.

[MEAS] key : Key to start density measurement.

[PUMP] key : Key to turn or off the optional peristaltic sampling pump. This key can be

used during both calibration and measurement.

[STOP] key : Key to abort density measurement or calibration and also escape or return

back to standby mode (the main display screen) or previous menu selection.

[ENTER] key : Key to confirm the menu selection or numeric data entry.

[MENU] key : Key to select the menu selection screen. Pressing this key and then the

Up/Down arrow keys will cycle through the following menu options:

13

Menu:0 Calibrate Cell

Calibrate with pure water standard

Menu:1 View Stored Results Display measurement results

Menu:2 Set Sampling time Select sampling time (amount of time the peristaltic pump runs)

Menu:3 Select Oil-Table Select API temperature compensation table for oil

Menu:4 Set Test Temperature Set measurement temperature

Menu:5 Set Date & Time Select date and time for measurements

Menu:6 Set LCD Contrast Adjust brightness of display screen

Menu:7 Reset Test Number Reset Sample test number to “01”

Menu:8 Clear Stored Results Clear the memory of stored measurement results

Menu:9 Export Stored Data to USB Drive Export data to external USB storage device (MS-Excel format)

Menu:10 View Serial No. & Firmware Ver. Check instrument serial number and firmware version

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 17

Highlighted Text Denotes Blinking Cursor or Characters

1 0 / 3 0 / 1 2 0 9 : 5 0

D e n s i t y 0 . 9 9 8 5 g / c m ³

T e m p 2 0 . 0 0 ° C T e s t 0 1

P r e s s E N T E R t o P r i n t

C A N N O N

D 1 5 5 D e n s i t y M e t e r

V e r 2 . 0 0

1 0 / 3 0 / 1 2 0 9 : 2 9

1 0 / 3 0 / 1 2 0 9 : 3 0

E Q U I L I B R A T I N G

T a r g e t 2 0 . 0 ° C

< < P l e a s e W a i t > >

1 0 / 3 0 / 1 2 0 9 : 4 0

R e a d y t o T e s t 2 0 . 0 ° C

P l e a s e L o a d S a m p l e

P r e s s M E A S t o S t a r t

2-3-3. LCD Display Layout

2-4. Display during initialization

2-4-1. The initial display upon power up

The following display appears during power up.

14

2-4-2. Display during warm up period

The instrument requires a warm up period to ensure an accurate measurement. Normally, the

warm-up period is complete within 30 minutes this will vary room temperature and test temperature.

The following display occurs during warm up period.

2-4-3. Display after warm-up

The following display occurs after the instrument has stabilized. The instrument is now ready to

measure a sample.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 18

2-5. Preparation before measurements

1) Tools required for sampling

2 to 5 mL Syringe (for manual injection) and a beaker or bottle to hold the sample

2) Solvent for cleaning the cell

Solvent (e.g. water for aqueous solution or heptane for oil) is necessary to clean the cell. Note,

user is responsible for determining the appropriate solvent for the sample type being measured.

3) Lint-free towels or tissues

Used for wiping the outside of the sampling tube or cell ports.

15

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 19

Set sample and press

[Meas.] button

Drain out the sample and

clean the measuring cell

Measurement

Turn off the unit

Measurement completed?

No

Yes

Fill the measuring cell with

pure water

No

Yes

Perform factor calibration with

pure water

Power on

Ready mode?

Calibration

Calibrated properly?

Yes

No

[MEAS]

3. Basic procedure

3-1. Flow chart for the basic measuring procedure

16

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 20

must be taken to avoid air bubbles or other foreign

3-2. Factor calibration with pure water

For correct measurement, the meter needs to be checked and adjusted to the reference using the

density standard of water.

Prior to each day’s work, measure the water by pressing [MEAS] key to make sure the result of specific

gravity (SG) shows a value within ± 0.0005 of the nominal value of pure water at the test temperature. If

the measuring cell and tube lines were filled with ethanol (for short-term storage), wash out the ethanol

with as much pure water before measurement is started. If the result shows a SG (t/t) value outside of

the ± 0.0005 range, repeat the cell cleaning and re-measure the water standard. If the measurement

results for pure water continue to fall outside of this range, the meter should be factor calibrated as

follows:

Note:

The measuring cell must be cleaned with water before calibration. Care

materials/contaminates in the water in the cell during measurement to

avoid measurement error.

17

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 21

18

set temperature and that

the cell well. For effective

thanol with as much pure water before

↓ [MENU]

3) Press [MENU] key

↓ [ENTER]

5) Press [ENTER] key.

If using a syringe, inject 2 mL taking care not to introduce any air

standard.

1 0 / 3 0 / 1 2

0 9 : 4 0

R e a d y t o T e s

t 2 0 . 0 ° C

P l e a s e L o

a d S a m p l e

P r e s s

M E A S t o S t a r t

M

e n u : 0

C a l

i b r a t e C e l l

P r e s s E N T E R o r U p / D n

M

e n u : 0

C a l i b r a t e

C e l l

P l e a s e L o a d

W a t e r

P r e

s s E N T E R t o S t a r

t

1) Make sure that the cell temperature is stable at the

“Ready to Test” appears on the main display as shown below.

D155 with pump

D155 with syringe

2) Clean the cell with pure water

a. Put the tube into water as shown on the left or inject the water with a

10 mL syringe. If using a syringe, inject two full syringes so that a

total of 20 mL is flushed through the cell.

b. If the optional peristaltic pump is installed, press [PUMP] key to flow

in more than 20 mL water, to flush

cleaning, lift up the tip of tube from the water a few times to allow

some air to be pulled in.

Note:

When the measuring cell and tube lines were filled with

ethanol, rinse out e

measurement is started.

4) Move the cursor with [] or [] key to “Menu:0 Calibrate Cell”

6) Inject the cell with a pure water standard

a.

bubbles in the measurement cell. Visually inspect the cell through

the cell window to ensure that no bubbles are present in the cell.

b. If the optional peristaltic pump is installed, place the tube in the water

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 22

19

the Menu:2 Sampling Time.

present in the cell.

↓

M e n u

: 0

C a l i b r a t e C e l l

S A M P L I N G :

1 0 s

< < P l e a s e

W a i t > >

M e n u : 0

C a l i b r a t e C e l l

C A L I B

R A

T I N G

< <

P l e a s e W a i t > >

M

e n u : 0

C a l i b r a

t e C e l l

O K

P r e s s S T O P o r M E N

U

↓ [ENTER]

Press [ENTER] key.

If the peristaltic pump is installed, the pump will run for the amount of seconds set in

8) When calibration is normally completed, the display shows:

The above screen will only appear when using the optional peristaltic pump and

the Sampling Time (Menu:2 Sampling Time) is set to a value greater than zero.

7) When sampling is complete, the display shows:

Visually inspect the cell through the cell window to ensure that no bubbles are

When “NG” (No Good) appears instead of “OK”, press [STOP] and then repeat

the calibration starting with step 3 above.

9) If the optional peristaltic pump is installed, press [PUMP] key to drain out water.

Otherwise use an empty syringe to push out the water with air.

10) Blot the sample drops on the sampling tube with tissue paper.

Note:

If calibration fails, previously calibrated values will be printed out.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 23

measure the water

standard. If the measurement results for pure water continue to fall

be factor calibrated as per

that “Ready to Test” appears on the main display as shown above.

2 to 5 mL of the sample to be

measured.

will be

↓

are present in the cell

↓

1 0

/ 3 0 / 1 2

0 9

: 4 0

R e a d y t o T e

s

t

2 0 . 0 ° C

P l e a s e

L

o a d

S a m p l e

P r e s s M E A S t o

S t

a r t

1 0 / 3 0

/ 1 2 0 9 : 4 5

S A M P L I N G : 1 0 s

< < P l e a s e W a

i t > >

1 0 /

3 0 / 1 2 0 9 : 4 6

M E A S U R I N G

< < P l e a s e W a i t > >

3-3. Measuring procedure

Note:

Prior to each day’s work, measure pure water by pressing [MEAS] key to

make sure the result of specific gravity (SG) shows a value within

± 0.0005 of the nominal value of pure water at the test temperature. If the

measuring cell and tube lines were filled with ethanol (for short-term

storage), wash out the ethanol with as much pure water before

measurement is started. If the result shows a SG (t/t) value outside of the

± 0.0005 range, repeat the cell cleaning and re-

outside of this range, the meter should

Section “3-2 Factor calibration with pure water.”

20

D155 with pump

D155 with syringe

1) Make sure that the cell temperature is stable at the set temperature and

2) Inject the sample to be measured into a clean cell:

a. If using the optional peristaltic pump, put the tube into the

sample liquid as shown on the left.

b. If using a syringe, inject

3) Press [MEAS] key. If using the peristaltic pump, the sample

automatically injected for the Sampling Time (set in Menu:2.) as shown

below:

4) When measurement starts, the display will show:

Visually inspect the cell through the cell window to ensure that no bubbles

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 24

re are four results display windows. To change between these

displays.

push out the sample with air.

after measurements”.

When you have changed the measurement temperature, make sure to

The D155

1 0 / 3 0 / 1 2

0 9 : 5 0

D e n s

i t y 0 . 9 9 8 5 g / c m

³

T e m

p 2 0 . 0 0 ° C T e s t

0 1

P r e s s U p / D n U

n i t s

1 0 /

3

0 /

1 2

0 9

: 5

0

A

P I D e g r e e 5 D :

2 4 . 1

T e m p 2 0 . 0 0 ° C

T

e s t 0 1

P r

e s

s U p / D n U n i t s

1 0 / 3 0 / 1 2

0 9 : 5 0

1 5 ° C D e n

5 3 D : 0 . 9 9 9 5

T e m p 2

0 . 0 0 ° C T e s t 0 1

P r e s s U p / D n

U n i t s

1 0 / 3 0 /

1 2 0 9 : 5 0

S G ( t / t ) :

0 . 9 9 9 0

T e m p 2 0 . 0

0 ° C T e s t 0 1

P r e s s U p / D n U n i t s

21

5) After measurements are completed, the results will appear on the screen

display.

If a printer is connected, the results will automatically print.

The

windows, press the [] [] keys. Below are the three additional results

7) Clean the measuring cell according to Section “3-4. Clean measuring cell

6) When continuing measurement on the same sample, return to Step 1).

When the intended number of measurements is completed, remove the

sample from the cell. If the optional peristaltic pump is installed, press

[PUMP] key to drain out the sample. Otherwise use an empty syringe to

Note:

perform calibration before measuring at the new temperature.

will not allow a measurement to be made at a temperature which has not

been calibrated.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 25

measurement cell

3-4. Clean measuring cell after measurements

The measuring cell must be cleaned when a different type of sample is to be measured or when a series

of measurement is complete. Follow the following steps:

Instrument with optional peristaltic pump

1) Remove the sampling tube from the sample and wipe with tissue paper.

2) Put the sampling tube into the cleaning solution/solvent and draw the solution/solvent with [PUMP]

key. For more effective cleaning, we suggest that you pull out the tube from the solution/solvent

momentarily (while the pump is running) - several times to draw in some air. Continue pulling

solution/solvent until roughly 10 mL have been pulled through the cell. Some samples may require

more than 10 mL of cleaning solution/solvent to effectively remove the sample from the cell (see

note below).

3) Take the sampling tube out of the cleaning solution/solvent. When the solution/solvent is clear from

the sample tube, press [PUMP] key to stop the pump.

4) Remove the sampling tube from the cleaning solution/solvent and wipe with tissue paper.

Instrument without pump

1) Remove the sample syringe from the sample inlet and wipe the inlet with tissue paper.

2) Ensure the sampling tube (outlet) on the D155 (upper port) is placed in a suitable waste container

such as a beaker or bottle.

3) Fill a 10 mL syringe with cleaning solution/solvent and inject the solution into the cell. Periodically

remove the syringe and re-insert to allow air to be introduced into the cell for more effective cleaning.

Repeat this step if necessary. Some samples may require more than 10 mL of cleaning

solution/solvent to effectively remove the sample from the cell (see note below).

Note:

When viscous samples are measured, rinse the

thoroughly with the cleaning solvent/solution to remove the sample.

Correct measurement results cannot be expected if any residue of the

previous sample remains in the measuring cell.

22

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 26

ibration or

3-5. Procedure after a day’s measurements

When the day’s work of measurement is completed, the measuring cell needs to be cleaned with the

cleaning solution/solvent and be filled with pure water in order to avoid contamination on the glass

measurement cell walls:

1) Clean the measuring cell according to the steps in Section 3-4.

2) When certain oily substances or deposits are adhered to the cell, follow the steps in Section 5-1-1.

3) Fill the measuring cell with pure water:

a. If using the optional peristaltic pump, put the sampling tube into pure water and press [PUMP]

key to draw water into the cell. When the cell is filled with pure water, press [PUMP] key to

stop the pump.

a. If using a syringe, inject two full 10mL syringes so that a total of 20 mL is flushed through the

cell.

When the unit is not used longer than one week, the cell should be filled with 99% or higher

concentration of Ethanol instead of pure water in order to avoid the growth of mold inside the cell.

23

Note:

When the cell is filled with Ethanol for storage, flush the inside cell with

at least 20mL pure water using either a syringe or the [PUMP] key if using

the optional peristaltic pump before starting next cal

measurement. If the residue of Ethanol remains in the cell or tube lines,

correct calibration or measurement cannot be performed.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 27

M e n u : 1

V i e w S t o r e d R e s u l t s

P r e s s E N T E R o r U p / D n

1 0 / 3 0 / 1 2 0 9 : 5 0

D e n s i t y 0 . 9 9 8 5 g / c m ³

T e m p 2 0 . 0 0 ° C T e s t 0 1

P r e s s E N T E R t o P r i n t

1 0 / 3 0 / 1 2 0 9 : 5 0

A P I D e g r e e 5 D : 2 4 . 1

T e m p 2 0 . 0 0 ° C T e s t 0 1

P r e s s E N T E R t o P r i n t

1 0 / 3 0 / 1 2 0 9 : 5 0

1 5 ° C D e n 5 3 D : 0 . 9 9 9 5

T e m p 2 0 . 0 0 ° C T e s t 0 1

P r e s s E N T E R t o P r i n t

1 0 / 3 0 / 1 2 0 9 : 5 0

S G ( t / t ) : 0 . 9 9 9 0

T e m p 2 0 . 0 0 ° C T e s t 0 1

P r e s s E N T E R t o P r i n t

4. Menu Navigation

4-1. Menu:1 View Stored Results

1) Press [MENU] then press [] or [] to select Menu 1 as shown below

2) Press [ENTER]

3) Press [] or [] key to select the test result (numbered)

4) Press [] or [] to select the preferred data result screen. There are four results display windows.

To change between these windows, press the [] [] keys.

24

5) Press [ENTER] to print test result (if optional printer is connected to the D155)

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 28

23A

Crude Oils 60/60°F

23B

Refined Products 60/60°F

23D

Lube Oils 60/60°F

53A

Crude Oils 15°C

53B

Refined Products 15°C

M e n u : 2

S e t S a m p l i n g T i m e

P r e s s E N T E R o r U p / D n

M e n u : 2

S a m p l i n g T i m e : 1 0 s

A r r o w K e y s t o C h a n g e

E N T E R t o A c c e p t

M e n u : 3

S e l e c t O i l T a b l e

P r e s s E N T E R o r U p / D n

M e n u : 3

O i l T a b l e : 5 3 A

A r r o w K e y s t o C h a n g e

E N T E R t o A c c e p t

4-2. Menu 2: Set Sampling Time

Select sampling time adequate for the sample to be injected. The default is ‘10’ (seconds).

1) Press [MENU] then press [] or [] to select Menu 2 as shown below

2) Press [ENTER]

3) Press [] or [] key to select the digit to change

4) Press [] or [] to increase or decrease the number. The D155 allows any value from 00 (pump

off or disabled) to 99 seconds. The default setting for instruments with the pump installed is 10.

5) Press [ENTER] to accept the value entered

4-3. Menu 3: Select Oil Table

25

The API temperature compensation table for oil can be selected as follows. It depends on the samples

you wish to measure.

1) Press [MENU] then press [] or [] to select Menu 3 as shown below

2) Press [ENTER]

3) Press [] or [] to select the appropriate API temperature compensation table. The available

tables are:

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 29

53D

Lube Oils 15°C

59A

Crude Oils 20°C

59B

Refined Products 20°C

59D

Lube Oils 20°C

M e n u : 4

S e t T e s t T e m p e r a t u r e

P r e s s E N T E R o r U p / D n

M e n u : 4

T e s t T e m p . : 2 0 . 0 ° C

A r r o w K e y s t o C h a n g e

E N T E R t o A c c e p t

M e n u : 5

S e t D a t e & T i m e

P r e s s E N T E R o r U p / D n

M e n u : 5

1 0 / 3 0 / 1 2 0 9 : 5 0

A r r o w K e y s t o C h a n g e

E N T E R t o A c c e p t

4) Press [ENTER] to accept the selected table.

4-4. Menu 4: Set Test Temperature

Measurement temperature can be set as follows:

1) Press [MENU] then press [] or [] to select Menu 4 as shown below

2) Press [ENTER]

26

3) Press [] or [] key to select the digit to change

4) Press [] or [] to increase or decrease the number. The D155 allows any temperature between

15.0 and 25.0 °C

5) Press [ENTER] to accept the value entered

4-5. Menu 5: Set Date and Time

Enter the present date and time so that they are stored/printed with each measurement result.

1) Press [MENU] then press [] or [] to select Menu 5 as shown below

2) Press [ENTER]

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 30

M e n u : 6

S e t L C D C o n t r a s t

P r e s s E N T E R o r U p / D n

M e n u : 6

L C D C o n t r a s t : 7 5 ↑

A r r o w K e y s t o C h a n g e

E N T E R t o A c c e p t

M e n u : 7

R e s e t T e s t N u m b e r

P r e s s E N T E R o r U p / D n

M e n u : 7

R e s e t T e s t N u m b e r ?

E N T E R t o A c c e p t

S T O P o r M E N U t o Q u i t

3) Press [] or [] key to select the digit to change

4) Press [] or [] to increase or decrease the number.

5) Press [ENTER] to accept the date and time entered

4-6. Menu 6: Set LCD Contrast

The contrast of the LCD display can be selected as follows:

1) Press [MENU] then press [] or [] to select Menu 6 as shown below

2) Press [ENTER]

27

3) Press [] or [] to increase or decrease the LCD display contrast.

4) Press [ENTER] to accept the setting

4-7. Menu 7: Reset Test Number

The sample number will be output together with measurement results. The number is incremented each

time a new measurement is made up to 99. This resets the numbering to start again at “01”.

1) Press [MENU] then press [] or [] to select Menu 7 as shown below

2) Press [ENTER]

3) Press [ENTER] to accept the reset, or [STOP] or [MENU] to quit.

4-8. Menu 8: Clear Stored Results

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 31

M e n u : 8

C l e a r S t o r e d R e s u l t s

P r e s s E N T E R o r U p / D n

M e n u : 8

C l e a r A L L R e s u l t s ?

E N T E R t o A c c e p t

S T O P o r M E N U t o Q u i t

Date & Ti me

'07/13/ 13 04:31 Sample No. 2

Meas. Temp. 20.000000

Density 0. 1035 SG(t/t) 0.1037

Oil-Table 53A

15C De n 0. 1035 API Degre e

**.*

Date & Ti me

'07/13/ 13 04:31 Sample No.

3 Meas. Temp. 20.000000 Density 0.1035 SG(t/t)

0.1037 Oil-Table

53A 15C De n 0. 1035 API Degre e **.*

Date & Ti me '07/13/ 13 04:32 Sample No. 4 Meas. Temp.

20.000000 Density 0.1035

SG(t/t) 0.1037 Oil-Table 53A 15C Den 0. 1035

API Degre e **.*

Date & Ti me '07/13/ 13 04:33 Sample No.

5 Meas. Temp. 20.000000 Density

0.1035 SG(t/t) 0.1037 Oil-Table 53A 15C Den

0.1035 API Degree **.*

Date & Ti me

'07/13/ 13 04:34 Sample No. 6 Meas. Temp. 20.000000

Density 0. 1035

SG(t/t) 0.1037 Oil-Table 53A 15C Den

0.1035 API Degree **.*

Date & Ti me '07/13/ 13 04:35 Sample No. 7 Meas. Temp.

20.000000 Density 0.1035 SG(t/t) 0.1037 Oil-Table

53A 15C De n

0.1035 API Degree **.*

Date & Ti me '07/13/ 13 04:36 Sample No.

8 Meas. Temp. 20.000000

Density 0. 1035 SG(t/t) 0.1037 Oil-Table 53A 15C Den

0.1035 API Degree **.*

Date & Ti me '07/13/ 13 04:37 Sample No. 9 Meas. Temp. 20.000000 Density

0.1035 SG(t/t) 0.1037 Oil-Table 53A 15C Den

0.1035 API Degree **.*

Date & Ti me '07/13/ 13 04:38 Sample No. 10

Meas. Temp. 20.000000 Densi ty 0.1035 SG(t/t)

0.1037 Oil-Table 53A 15C De n 0. 1035 API Degre e **.*

Date & Ti me '07/13/ 13 04:44 Sample No. 11 Meas. Temp.

20.000000 Density 0.1035 SG(t/t)

0.1037 Oil-Table 53A 15C De n 0. 1035 API Degre e

**.*

M e n u : 9

E x p o r t S t o r e d D a t a

t o U S B D r i v e

P r e s s E N T E R o r U p / D n

The last 10 measurement results are stored in memory. Subsequent data measurements will cause the

D155 to delete the oldest stored result first. These data can be cleared using this function. Caution,

data cannot be restored once it is cleared.

1) Press [MENU] then press [] or [] to select Menu 8 as shown below

2) Press [ENTER]

3) Press [ENTER] to clear all 10 stored results, or [STOP] or [MENU] to quit.

4-9. Menu 9: Export Stored Data to USB Drive

28

The D155 memory only stores the last 10 measurement results. Subsequent data measurements will

cause the D155 to delete the oldest stored result first. This function allows the data to be exported to

an external USB storage device in an MS-Excel file format. The D155 will create a folder on the USB

drive named X:/D155/Parameter, where ‘X:’ is the USB drive designation. If this folder already exists,

then it will continue to use this folder. The D155 will create a new file each time data is exported. The

filename will be created using the date and time of the export. Below is an example of the MS-Excel

file format for exported data:

2) Press [MENU] then press [] or [] to select Menu 9 as shown below

4) Press [ENTER]

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 32

M e n u : 9

E x p o r t A L L D a t a ?

E N T E R t o A c c e p t

S T O P o r M E N U t o Q u i t

M e n u : 1 0

V i e w S e r i a l N o . &

F i r m w a r e V e r .

P r e s s E N T E R o r U p / D n

M e n u : 1 0

S / N : J J A 0 8 B 4 3

V e r : 2 . 0 0 A 2

E N T E R t o C o n t i n u e

Press [ENTER] to export stored results to USB device, or [STOP] or [MENU] to quit.

4-10. Menu 10: View Serial No. & Firmware Ver.

You can check the serial number and firmware version of the unit. Such information will be necessary

to identify your density meter when calling for help.

1) Press [MENU] then press [] or [] to select Menu 10 as shown below

2) Press [ENTER]

29

3) Press [ENTER] to continue back to the menu selection screen.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 33

Menu/Parameter

Description

Setting range

Default

0: Calibrate Cell

Calibration with pure water

—

—

Results

Time

59D: Lube Oils 20°C

Temperature

Time

Time format: HH:MM (24 hour format)

12/31/99 23:59

Contrast

Number

Results

stores the last 10 measurement results.

Drive

Firmware

4-11. Parameters and default

30

1: View Stored

2: Set Sampling

3: Select Oil

Table

4: Set Test

5: Set Date &

Display measurement results — —

Select sampling time 00 to 99s 10s

Select temperature compensation table for oil

23A: Crude Oils 60/60°F

23B: Refined Products 60/60°F

23D: Lube Oils 60/60°F

53A : Crude Oils 15°C

53B : Refined Products 15°C

23A/23B/23D/

53A/53B/53D/

59A/59B/59D

53A

53D : Lube Oils 15°C

59A: Crude Oils 20°C

59B: Refined Products 20°C

Set measurement temperature 15.0 to 25.0°C 20.0°C

Enter date and time. Date format: MM/DD/YY

01/01/00 00:00 to

—

6: Set LCD

7: Reset Test

8: Clear Stored

9: Export Stored

Data to USB

10: Serial No. &

Adjust LCD brightness 0/25/50/75/100 50

Reset Sample Test No. to ‘01’ — 01

Erase the memory of stored results. The D155 only

— —

Export Stored Data from Memory to an MS-Excel

formatted file.

— —

View D155 Serial Number and Firmware Version — —

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 34

line voltage. Make

the outlet.

Do not place the printer on the top of the main unit in order to avoid the

is configured

as shown below. When you have changed this switch configuration,

1 2 3 4 5 6 7 8

Dip SW-1

OFF

OFF

ON

OFF

OFF

OFF

OFF

OFF

4-12. How to connect the optional printer or a personal computer (PC)

The optional printer can be connected to the D155 unit so that the measurement and calibration results

together with the date and time of measurement can be printed out. Connect the supplied printer cable

to the RS-232C port (DB-9M) on the back of D155 unit as shown.

A personal computer (PC) can be connected instead of the printer so that data can be exported. A

data collection software package – SOFT-CAP Data Capture Software is available as an option with the

D155. Please consult the separate SOFT-CAP Operation Manual for more details on installation and

use.

31

Warning!

Use correct AC power adapter suitable for the AC

sure to use the proper rated voltage before plugging it into

Failure may damage the printer or even cause the adapter itself to catch

fire.

Note:

influence magnetic field of the printer on the measuring cell.

The DIP switch on the Dot Matrix printer kit (P/N: 95.0239)

refer to the Instruction manual for the printer and set it as shown below:

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 35

5. Maintenance

5-1. Daily check

5-1-1. Cleaning the measuring cell

When the repeatability of measurements has degraded or measuring time is prolonged, the measuring

cell is considered to be contaminated. Also, when the cell is apparently contaminated with a sample of

such nature, the measuring cell must be cleaned with an appropriate solvent like household chlorine

bleach, acid or alkali. When particular samples containing fatty acids or protein (such as biodiesel) are

measured, the cell must be cleaned once a week as described below.

The following example describes how to rinse out fats and oils with Sodium hydroxide:

1) For units with the optional peristaltic pump installed

a. Insert the sampling tube into 0.1∼0.5mol/L Sodium hydroxide and press [PUMP] key to inject.

b. When the cell becomes filled with Sodium hydroxide, press [PUMP] key to stop filling.

c. Leave the sodium hydroxide in the cell for about 15 minutes.

d. Drain out Sodium hydroxide solution with [PUMP] key.

2) For units without the pump

a. Inject 0.1∼0.5mol/L Sodium hydroxide using a suitable 2-5 mL syringe.

b. Leave the sodium hydroxide in the cell for about 15 minutes.

c. Push out the sodium hydroxide from the cell using an empty syringe filled with air.

3) Clean the measuring cell with pure water according to the Step “3-4”.

32

Warning!

The alkali may etch the glass of the measuring cell. Avoid rinsing the

cell with strong alkali for hours. Always rinse the cell with plenty of pure

water after cleaning the cell with alkali cleaners.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 36

5-2. Other maintenance

5-2-1. Replacement of the power fuse

If the power fuse should blow, replace it with a like size and power rating. Note the fuse size and rating

is listed on the rear of the instrument immediately above the fuse holder. As shown below, turn the

fuse holder cover by 90 degrees counterclockwise using a flat screw driver. After the fuse is replaced,

turn the fuse holder cover back 90 degrees clockwise.

33

Warning!

Be aware of the danger of electric shock. Turn off the main switch and

remove the AC mains power cord before replacing the power fuse.

5-2-2. Adjustment of Injection Adapter (and tightening of tube nozzles)

If leakage from the Injection Adapter (Sample inlet and outlet port nozzles) is observed, they need to be

re-tightened

1) Twist to remove the Connection Tubes with Unions from the Injection Adapter Nozzles.

2) Remove the black protective foam insert

3) Insert the red PTFE tubing into the tube nozzles as shown

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 37

4) Loosen the screw with the provided wrench

5) Tighten the tube nozzles clockwise – hand-tighten only

34

6) Follow steps 1 thru 4 in reverse to tighten the Injection Adapter nut and remove the red PTFE tubing

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 38

5-2-3. Replacement of optional peristaltic pump tubing

If the pump tube is deteriorated, the tubing may fail causing sample liquid to leak. This may eventually

lead to pump failure. Replace pump tubing as follows:

1) Disconnect the tubes connected to the pump tube cassette.

2) Turn the cassette counterclockwise to

remove it.

3) Remove the tube joint from the cassette by

pulling one of the ends, and then pull out the

tube.

35

4) Apply grease (such as petroleum jelly) over

the tube and the axle of pump cassette as

illustrated.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 39

Rotor

Tube joint

Pump tube

Pull out

Axle

Match

Pump tube

Fix the cassette by

turning clockwise

until it stops.

Replace the

5) Fit in the new pump tube around the rotor as

shown by pulling it out a little bit.

Fix the tube joint securely to the groove as

illustrated.

6) Match the axle and rotor, and fix the

cassette by turning clockwise until it stops.

36

Caution!

Some samples may shorten the life of the pump tubing.

pump tubing when appropriate.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 40

Error message

Description

Remedy

or your local dealer.

message

2, 3, 4

The thermistor is defective (broken).

• Contact CANNON or your local dealer.

wiring to the cell is damaged.

local dealer.

stored data/calibrations cleared.

6. Troubleshooting

6-1. Error messages and remedies

When the main unit is operated improperly, the following error messages will appear with a

corresponding beep sound.

Check the window to see if air

bubbles are trapped in the measuring

Time Over Measuring time exceeds 10 minutes.

6-2. Symptoms for error numbers and associated remedies

When a fault occurs within the D155 unit, the following warning number will appear with a beep sound.

cell.

If this message persists while nothing

wrong is observed, Contact CANNON

37

Error

5 The measuring cell is defective or the

6 Temperature is not stabilized in an

hour.

7 The voltage level of the back-up

battery becomes low. This will

cause memory to be initialized and all

Description Remedies

• Contact CANNON or your local dealer.

After the following two steps are confirmed,

turn on the power again.

• The ambient temperature for D155 is

5∼35°C. Check to see if the ambient

temperature does not exceed this range

during operations.

• Make sure that the air vents at the front,

rear, and bottom of unit are not clogged

with dust or blocked in any way. If the

error persists, Contact CANNON or your

• Contact CANNON or your local dealer.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 41

START

Is the line voltage

conforming?

Repairing by the

manufacturer

Is everything O.K.?

END

U

se the correct line voltage

Yes

Yes

No

No

Voltage

100-240V

30 Watts

T3.15A/250V

50/60Hz

6-3. Troubleshooting

6-3-1. Cannot turn on the main unit with the power switch

38

(Note 1) Specifications on power source

AC Mains

Wattage Fuse Frequency

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 42

START

Check the air-intake at the

bottom to see if clogged

Check ambient

temperature (5

°C~+35

°

C)

Operate the unit within the range

of the specified temperature

No

Yes

Check the air-intake at the bottom

to see if clogged

No

Yes

END

Repairing by manufacturer

Is everything O.K.?

No

Yes

6-3-2. “Ready to Test” message does not appear and/or cell temperature is unstable.

Follow the following steps if “Ready to Test” message does not appear after more than 1 hour or the cell

temperature appears unstable after having reached the preset measurement temperature.

39

6-3-3. The unit does not work even though power is on.

If the “Ready to Test” message does not appear after the D155 has been powered on for more than 30

minutes, check on the line voltage. If correct power voltage is supplied, Contact CANNON or your local

dealer.

6-3-4. LCD does not function

If the LCD display is found to be defective (no message appears on screen) or the brightness of display

cannot be adjusted, Contact CANNON or your local dealer.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 43

START

Is the system leaking?

Check tube lines on any loosened

joint. Also ensure the cross section

of tube is upright.

Yes

No

Contact our local dealer.

Is everything O.K.?

END

Yes

No

Yes

Degas the sample (boil, stir or else)

No

Can the sample be

degassed?

6-3-5. Key entry does not work

If beep sound is not heard each time any keys are pressed or key entry itself does not function, Contact

CANNON or your local dealer.

6-3-6. Air bubbles are easily trapped in the sample and visible in the measurement cell

40

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 44

Contact our local dealer to

check the cell.

START

Is the sample homogeneous?

Is there

any repeatability for the

measurement with

pure water?

Is the work bench vibrating?

Any sample residue

in joint portions (tube nozzle A,

joint B or the like)?

Are air bubbles found

in the sample?

Is the measuring cell dirty?

Is the temperature of

measuring cell stable?

Repeat sampling. (When air bubbles

appear again, refer to Section 6-3-6.)

Stir to make it homogeneous. (No

repeatability when the sample is

unevenly mixed.)

Overhaul the joints and clean

them.

Rinse the cell thoroughly

.

Measure after temperature

becomes stabilized.

Yes

No

Contact our local dealer.

Is everything O.K.?

END

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

Measure the sample on a

stable bench.

No

6-3-7. There is poor repeatability on measured values

41

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 45

START

Is the tube peristaltic

pump deteriorated?

Replace the tube.

Contact our local dealer.

Is everything O.K.?

END

Yes

No

Yes

No

6-3-8. Sampling time is too long (optional peristaltic pump)

42

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 46

START

Are air bubbles

found in the sample?

Is cell temperature stable?

Measure after the cell temperature

becomes stabilized.

Yes

No

Contact our local dealer.

Is everything O.K.?

END

Yes

No

Yes

No

Yes

Repeat sampling and measure again.

(If air bubbles appear again, refer to

Section 6-3-6.)

6-3-9. Measuring time is too long

43

6-3-10. Data cannot be stored in the memory

The back-up battery needs to be replaced when the clock function does not work or preset parameters

cannot be saved. Contact CANNON or your local dealer.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 47

Type and Model

D155 Density Meter

Discipline

Oscillating Glass U-tube

Measuring Range

0 to 2g/cm3

Measuring Temperature Range

15 to 25℃

Density

±0.001g/cm

3

Temperature

±0.1℃

Repeatability

Density

SD 0.0005g/cm3

Resolution

Density

0.0001g/cm3 step

Temperature

0.05℃ step (Setting Resolution: 0.1℃ step)

Specific Gravity

0.0001 step

Temperature

Parameter

API Degree

0.1 step

Measurement Time

2 to 4 min

Viscosity Correction

None

20℃Density)/ API Degree/ Other messages

(optional peristaltic pump for automatic sampling)

Min. required Sample Amount

Syringe: Approx. 1mL, Pump: 8mL

Maximum Sample Viscosity

Approximately 1000 mPa⋅s when using optional peristaltic pump

Calibration

Pure Water (factory/service calibration of air)

Storage of Measurement Result

Last 10 measurement results stored in internal memory

Temperature Compensation

Table for Petroleum Products

ASTM D1250 Table 23(A,B,D), 53(A,B,D), 59(A,B,D)

Interface

RS-232C×1ch, USB×1ch

2) Humidity: Below 85%RH (No condensation)

Power Source

AC100~240V 50/60Hz

Power Consumption

Approx. 30W

Dimension

251mm (W) × 408mm (D) × 165mm (H) [10” x 16” x 6.5”)

Weight

11.6kg (25.64 lbs)

- Tube 0.5x1.5 L=400 PTFE: Qty 1

- Soft-Cap Data Capture Software

7. Others

7-1. Basic specifications

Precision

44

Compensated

Display 1) Screen: 4×20 LCD backlight

Sampling Method Manual sampling by syringe

Ambient Conditions for unit 1) Temperature: 5 to 35℃

0.0001 step

2) Displayed Parameter:

Temperature (℃)/ Density/ Specific Gravity

Number of temperature compensation tables for petroleum products

Temperature Compensated Parameter (60℉Specific Gravity/ 15℃

Density/

Standard Supplied Accessory

- Connection Tube: Qty 1

- Syringe 2ml: Qty 5

- AC Power Cord: Qty 1

- Wrench: Qty 1

Optional Accessories

- Dot matrix printer

- Peristaltic pump

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 48

T

dVc Mc

K

=+2π

d

K

Vc

T

Mc

Vc

= −

4

2

2

π

F

K

Vc

d d

T T

a

w

a w

= =

−

−

4

2 2 2

π

d

d F T T

a a

=

− −( )

2

2

7-2. Principle of measurement

7-2-1. Oscillating U-tube Cell

When a measurement cell filled with liquid or gas is oscillated spontaneously, resultant oscillating cycle

varies with the density of the sample in the measurement cell. The oscillating cycle T is expressed

follows.

where,

d = Density of sample in measurement cell

Vc = Volume of sample in measurement cell, or measurement cell internal volume

Mc = Mass of measurement cell

K = Constant

45

Supposing that the oscillating cycles Ta and Tw are obtained through measurement of reference

materials of known density (density da and dw), the facto value F is calculated as follows.

Accordingly, the density “d” of unknown sample can be calculated according to the following formula by

measuring its oscillating cycle T.

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 49

25.1013

)(

)(00367.01

0012932.0

)/(

3

hPaP

Ct

cmgd ×

×+

=

Temp.

(°C)

Density

(g/cm3)

Temp.

(°C)

Density

(g/cm3)

Temp.

(°C)

Density

(g/cm3)

Temp.

(°C)

Density

(g/cm3)

0

0.00129

25

0.00118

50

0.00109

75

0.00101

1

0.00129

26

0.00118

51

0.00109

76

0.00101

2

0.00128

27

0.00118

52

0.00109

77

0.00101

3

0.00128

28

0.00117

53

0.00108

78

0.00101

4

0.00127

29

0.00117

54

0.00108

79

0.00100

5

0.00127

30

0.00116

55

0.00108

80

0.00100

6

0.00127

31

0.00116

56

0.00107

81

0.00100

7

0.00126

32

0.00116

57

0.00107

82

0.00099

8

0.00126

33

0.00115

58

0.00107

83

0.00099

9

0.00125

34

0.00115

59

0.00106

84

0.00099

10

0.00125

35

0.00115

60

0.00106

85

0.00099

11

0.00124

36

0.00114

61

0.00106

86

0.00098

12

0.00124

37

0.00114

62

0.00105

87

0.00098

13

0.00123

38

0.00113

63

0.00105

88

0.00098

14

0.00123

39

0.00113

64

0.00105

89

0.00097

15

0.00123

40

0.00113

65

0.00104

90

0.00097

16

0.00122

41

0.00112

66

0.00104

17

0.00122

42

0.00112

67

0.00104

18

0.00121

43

0.00112

68

0.00103

19

0.00121

44

0.00111

69

0.00103

20

0.00120

45

0.00111

70

0.00103

21

0.00120

46

0.00111

71

0.00103

22

0.00120

47

0.00110

72

0.00102

23

0.00119

48

0.00110

73

0.00102

24

0.00119

49

0.00110

74

0.00102

7-2-2. Density Tables

Dried air density

Density of dried air at t°C and 1013.25hPa is calculated according to the following formula.

Density of air at 1013.25hPa of air pressure;

46

Chemical Handbook Fundamental Version, Rev. 3, Table 5・1

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 50

(°C)

(g/cm3)

(°C)

(g/cm3)

(°C)

(g/cm3)

0

0.99984

25

0.99705

50

0.98805

1

0.99990

26

0.99679

55

0.98570

2

0.99994

27

0.99652

60

0.98321

3

0.99996

28

0.99624

65

0.98057

4

0.99997

29

0.99595

70

0.97779

5

0.99996

30

0.99565

75

0.97486

6

0.99994

31

0.99534

80

0.97183

7

0.99990

32

0.99503

85

0.96862

8

0.99985

33

0.99471

90

0.96532

9

0.99978

34

0.99438

10

0.99970

35

0.99404

11

0.99961

36

0.99369

12

0.99950

37

0.99333

13

0.99938

38

0.99297

14

0.99925

39

0.99260

15

0.99910

40

0.99222

16

0.99894

41

0.99183

17

0.99878

42

0.99144

18

0.99860

43

0.99104

19

0.99841

44

0.99033

20

0.99821

45

0.99022

21

0.99799

46

0.98980

22

0.99777

47

0.98937

23

0.99754

48

0.98894

24

0.99730

49

0.98849

Water density

Temp.

Density

Temp.

Density

Temp.

47

Density

Chemical Handbook Fundamental Version, Rev. 3, Table 5・2

CANNON® D155 Density Meter Instruction & Operation Manual

Version 1.1b – August 2014; CANNON® Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 51

7-3. Warranty/Return Information

1. Products limited warranty

In addition to other manufacturers’ warrantees, CANNON® Instrument Company (“the Company”)

warrants all products (other than reagents and chemicals) delivered to and retained by their original

purchasers to be free from defect in material and workmanship for one year from the date of the

Company’s invoice to the purchaser. For a period of one year from the date of such invoice, the

Company will correct, either by repair or replacement at the Company’s sole election, any defect in

material or workmanship (not including defects due to misuse, abuse, abnormal conditions or

operation, accident or acts of God, or to service or modification of the product without prior

authorization of the Company) without charge for parts and labor. The determination of whether any