Page 1

CONTENTS

i

1

2

3

INTRODUCTION 1

Overview ............................................................................................................................. 1

Safety features ...................................................................................................................... 3

Operator Safety .................................................................................................................. 3

UNPACKING AND ASSEMBLY 5

Unpacking the CT -1000 ....................................................................................................... 5

Assembly procedure ............................................................................................................. 5

Glass jar installation .............................................................................................................. 6

Motor-stirrer ............................................................................................................ 8

Inserting viscometer tubes/thermometers................................................................................ 9

Filling the bath .................................................................................................................... 10

Draining the Bath ................................................................................................................ 11

BATH OPERATION 13

Turning on the CT -1000...................................................................................................... 13

Setting the bath temperature ................................................................................................ 14

Fixed temperature adjustments ................................................................................ 14

V ariable temperature adjustments ............................................................................ 14

Setting the Limit Control ..................................................................................................... 15

A

B

C

D

APPENDIX A — CT-1000 PROBLEM ANALYSIS 17

APPENDIX B — CORRECTING SHAFT & IMPELLER MISALIGNMENT 19

Shaft run-out correction ...................................................................................................... 19

APPENDIX C — CHOOSING A TEMPERATURE BATH LIQUID 21

APPENDIX D — ADJUSTING TRIMPOTS (POTENTIOMETERS) 23

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 2

ii

E

F

APPENDIX E — CT-1000 SPARE PARTS LIST 25

WARRANTY/RETURN INFORMATION 27

Products limited warranty.................................................................................................... 27

Reagent and chemical warranty ........................................................................................... 27

Returning a product to CANNON®.................................................................................... 28

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 3

1

1

Overview

CT-1000 function

Temperature range

Manual/video

INTRODUCTION

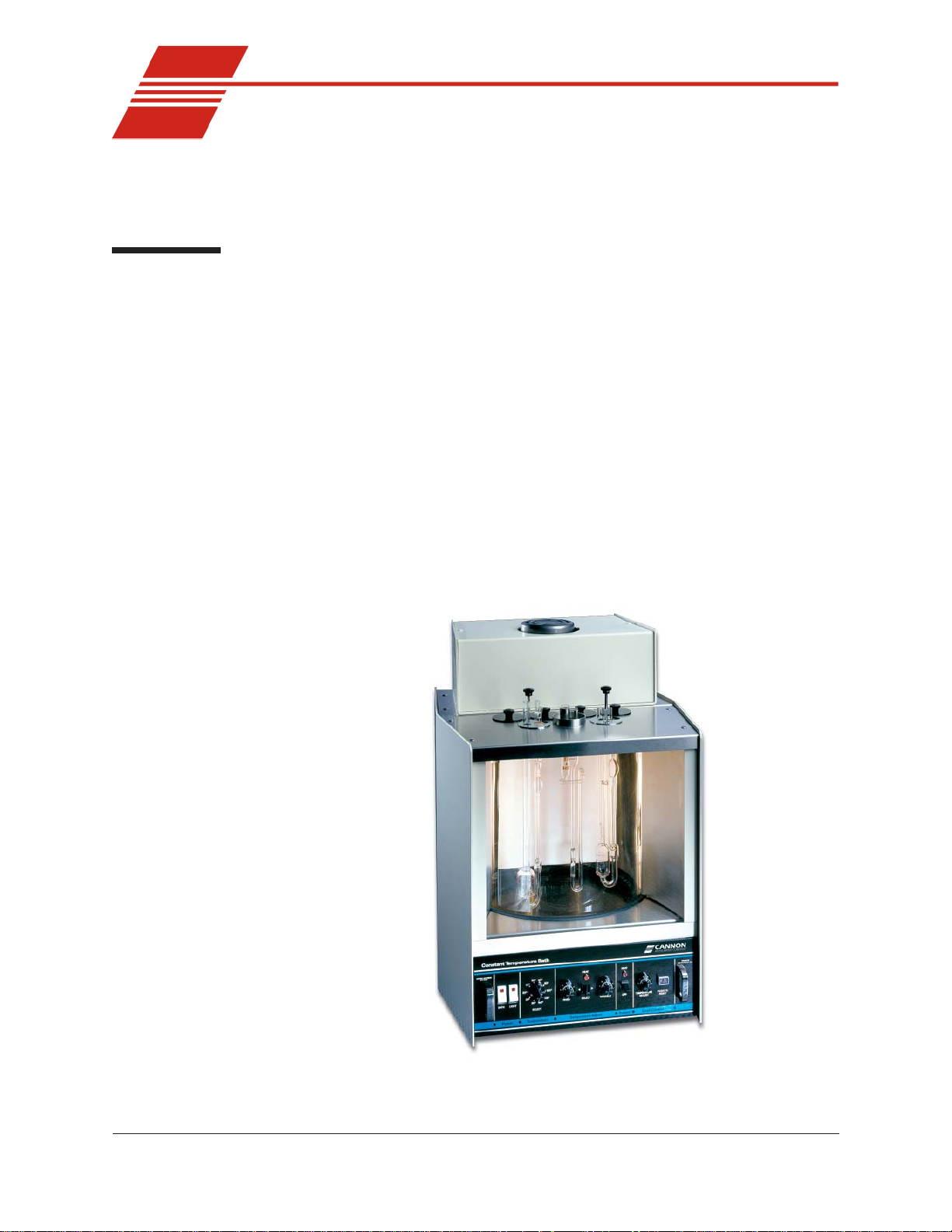

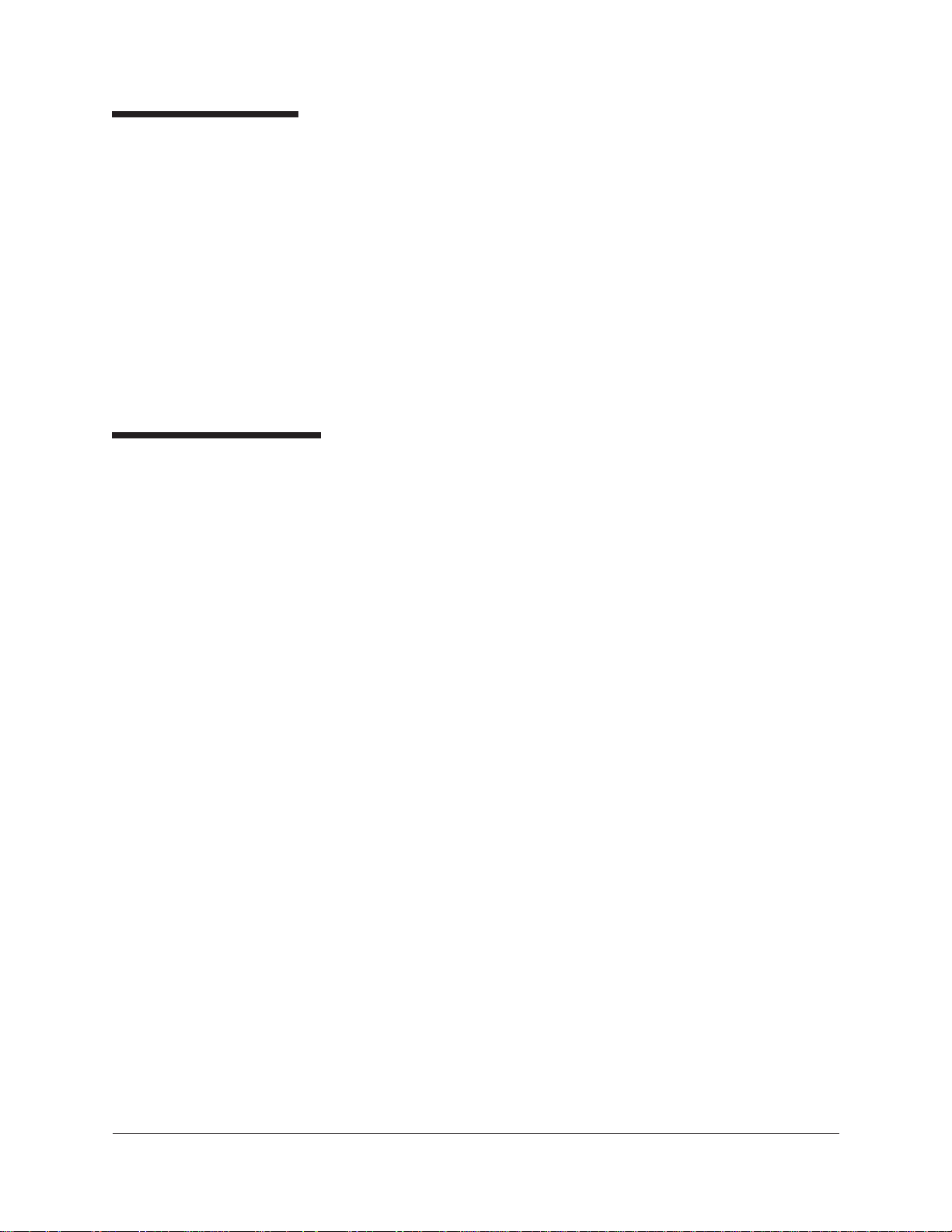

The CANNON® CT-1000 Constant Temperature Bath is designed to

maintain precise temperatures at a wide range of settings for accurate

viscosity measurements. Because of its temperature stability and ease of

use, it is also suitable for any other application where temperatures must

be maintained within close tolerances.

The CANNON® CT-1000 will maintain temperatures of 20°C to 100°C

within 0.01°C and temperatures of 101°C to 150°C within 0.03°C.

This manual is intended to provide information on the installation,

characteristics and operation of the CANNON® CT-1000 Constant

T emperature Bath. The manual materials are supplemented and enhanced

CANNON

Figure 1: The CT-1000

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 4

2

by an instructional video shipped with the bath.

Temperature selection

Bath description

T en of the most commonly-used temperatures for kinematic viscosity

measurement can be set by using a switch on the bath front panel. The

bath will equilibrate within a fraction of one degree of the desired

temperature. A fine-tuning control permits further temperature adjustments. By switching to the variable setting on the front panel, the operator can set any temperature within the operating range of the instrument.

The bath chamber is a cylindrical clear Pyrex® vessel 300 mm (12 inches)

in diameter and 300 mm (12 inches) high. A stainless steel baf fle is

located in the center of the bath and provides a convenient backdrop for

viewing viscometers placed in the bath. The top cover contains seven

round holes 51 mm (two inches) in diameter for insertion of viscometer

holders. T wo additional holes are provided for thermometers. Twin

fluorescent lamps provide glare-free illumination of the bath.

A solid-state control circuit equipped with a stainless steel-encased

thermistor provides proportional temperature control. A motor-driven

stirrer ensures that a uniform temperature is maintained throughout the

bath.

The bath housing is fabricated from heavy aluminum and coated with a

corrosion-resistant epoxy . The top cover consists of three layers; a

stainless steel top surface, an insulating layer, and a bottom stainless steel

heat reflector.

Temperature stability

The temperature control of ± 0.01°C below 100°C, and ± 0.03°C from

100 to 150°C, provides the sensitivity required by ASTM D 445 for

kinematic viscosity measurements. A built-in cooling coil, when connected to tap water or a cooling system, permits operation below or

slightly above ambient temperature.

snoitacificepS0001-TC

snoisnemiD

)sehcni32x52.81x52.71(

hgihmm485xpeedmm464xediwmm834

yticapaC )lag5.4(L71

thgieW )bl59(gk34

thgieWgnippihS )bl321(gk8.55

sttaw0041,zH06/05,CA)ledomtlov-021(02A-6279

rebmuNgolataC

sttaw0041,zH06/05,CA)ledomtlov-042(52A-6279

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 5

Safety features

3

Overheat thermistor

Thermistor detection/cutoff

Liquid-level control float

Operator Safety

A thermistor in the bath senses any over-temperature fault condition. If

such a condition occurs, all power is removed from the bath until an

operator resets the over-temperature limit circuit.

If the control thermistor is disconnected, all power to the bath heaters is

cut off.

Operation of the bath is not possible unless it is filled with liquid to a safe

operating level. A liquid-level control float prevents the control circuit

from heating the bath until the safe operating level is attained. The bath

heaters are automatically turned off if the bath liquid drops below the

minimum safe level.

All technicians who use the CT-1000 should follow these basic safety

procedures:

Do not place the CT-1000 system on an unstable cart or stand. The

CT-1000 should be placed on a stable laboratory table or bench.

If any liquids are spilled into the electronic components of the CT-

1000, contact CANNON

®

Instrument Company immediately .

Do not position power cords so that they are likely to be walked on

or pinched by items placed on or against them. Keep all connections

as neat as possible.

If the CT-1000 will not be used for an extended period of time,

unplug the power cord from the wall outlet. To disconnect the power

cord, pull it out by the plug. Never pull the cord itself.

CAUTION

Do not attempt to service the CT-1000 system by removing panels and

trying to effect repairs. Contact CANNON® Instrument Company regarding service and repair needs.

CAUTION The bath fluid used with the CT-1000 may be dangerous. Use the proper

safety precautions when handling the bath fluid in use (refer to the

Material Safety Data Sheet included with the bath fluid for more detail.)

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 6

4

This page intentionally left blank.

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 7

5

2

UNPACKING AND ASSEMBLY

This chapter of the manual provides assistance in unpacking and assembling the CT-1000 Constant Temperature Bath. For additional assistance,

consult the instructional video.

Unpacking the CT-1000

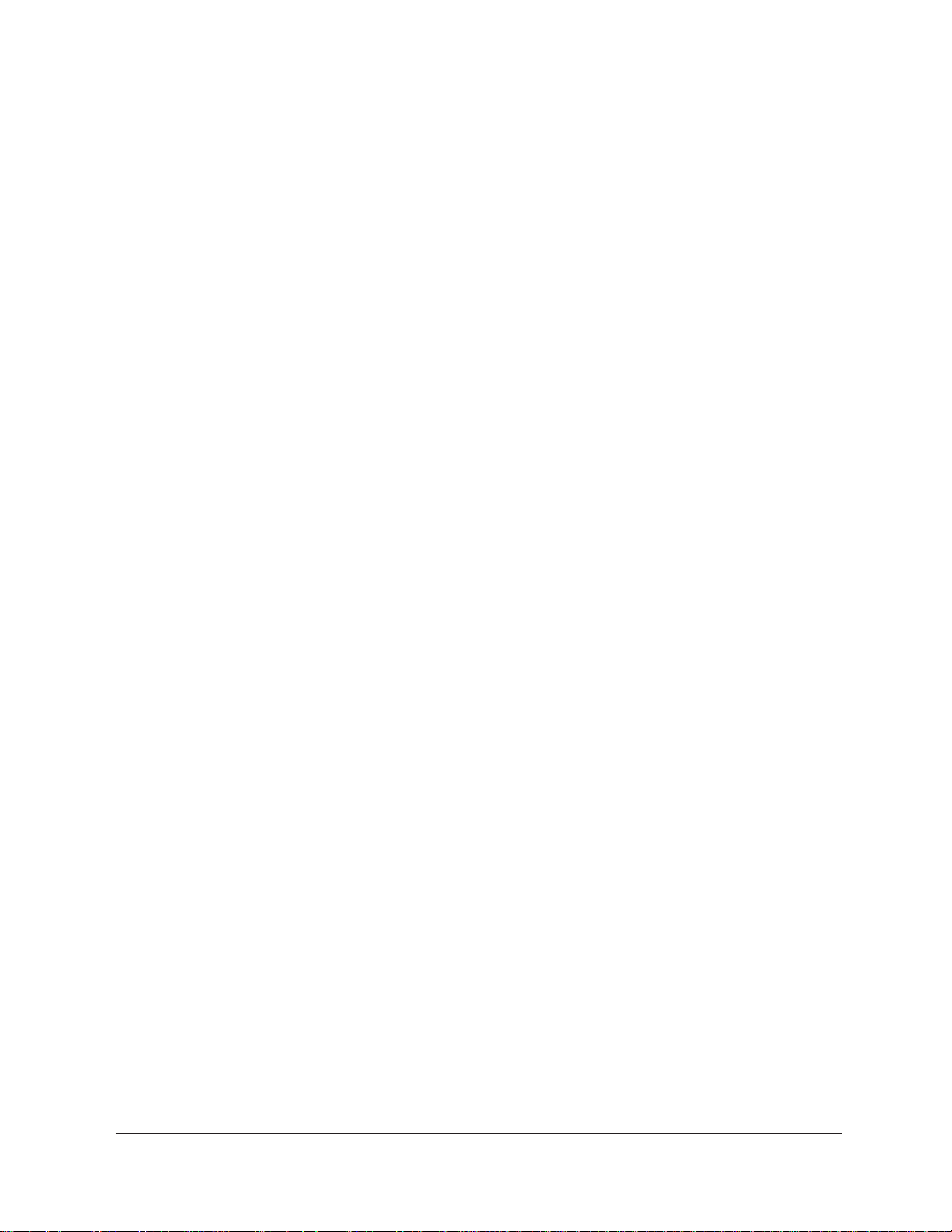

The CANNON® CT-1000 Constant Temperature Bath is shipped in two

boxes:

Box 1 contains the glass jar, front glass panel pieces, jar gasket top,

trimpot adjust screwdriver, Allen wrench, seven hole covers, rubber

thermometer holder and instruction manual.

Box 2 contains the bath housing, including the electronics drawer.

Box 2 also contains a smaller box with the motor and stirrer, including the impeller and mounting plate.

The bath unit housing is shipped completely assembled. However, the

glass jar, the glass panels, and the motor and stirrer must be installed in it.

T o allow this, some disassembly of the bath unit housing is required. The

tools required are a utility knife, phillips screwdriver, and a 1/8" Allen

wrench. The Allen wrench is included with the bath.

Assembly procedure

1. Unpack the bath unit housing.

CANNON

Figure 2: Primary bath components after unpacking

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 8

6

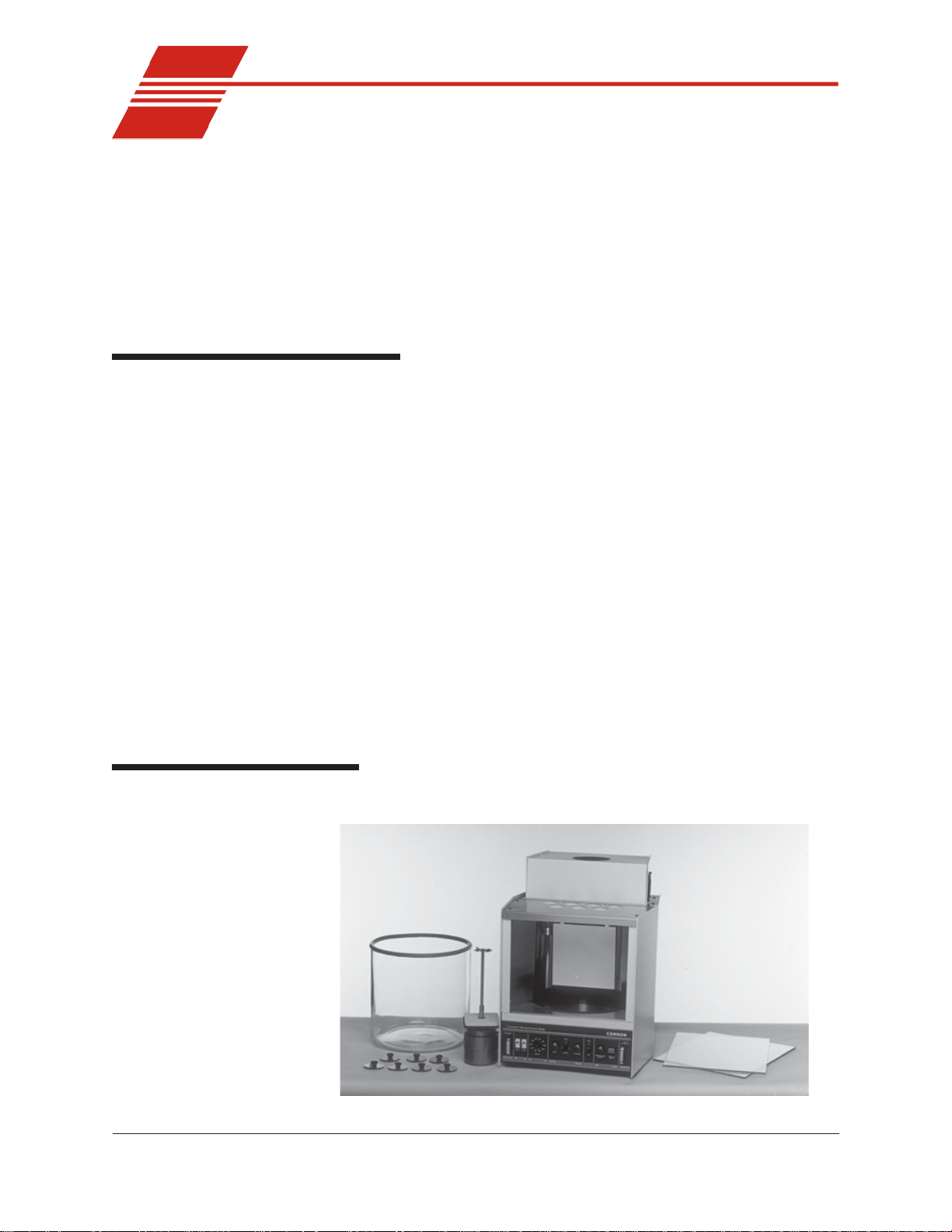

2. Move the bath

unit housing to its

permanent location on the

laboratory bench.

3. Remove all eight

screws from the

stainless steel top

covers (see Figure

3).

4. Disconnect all

probes, heaters,

and float switch

from the rear

panel.

5. Remove the front top cover and rear top cover (see Figure 4 and 5).

Use caution when removing the rear top cover because the temperature control probes and heating elements are attached to it.

Figure 3: Removing screws from top cover

Figure 4:

Removing front top cover

Glass jar installation

1. Remove the glass jar from its

WARNING

CANNON

The glass jar is heavy. Use

caution when lifting it.

2. Make sure the rubber support

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

box.

ring is seated properly around

the bottom jar opening in the

bath unit (see Figure 6).

Figure 5:

Removing rear top cover

Figure 6: Checking support ring

Page 9

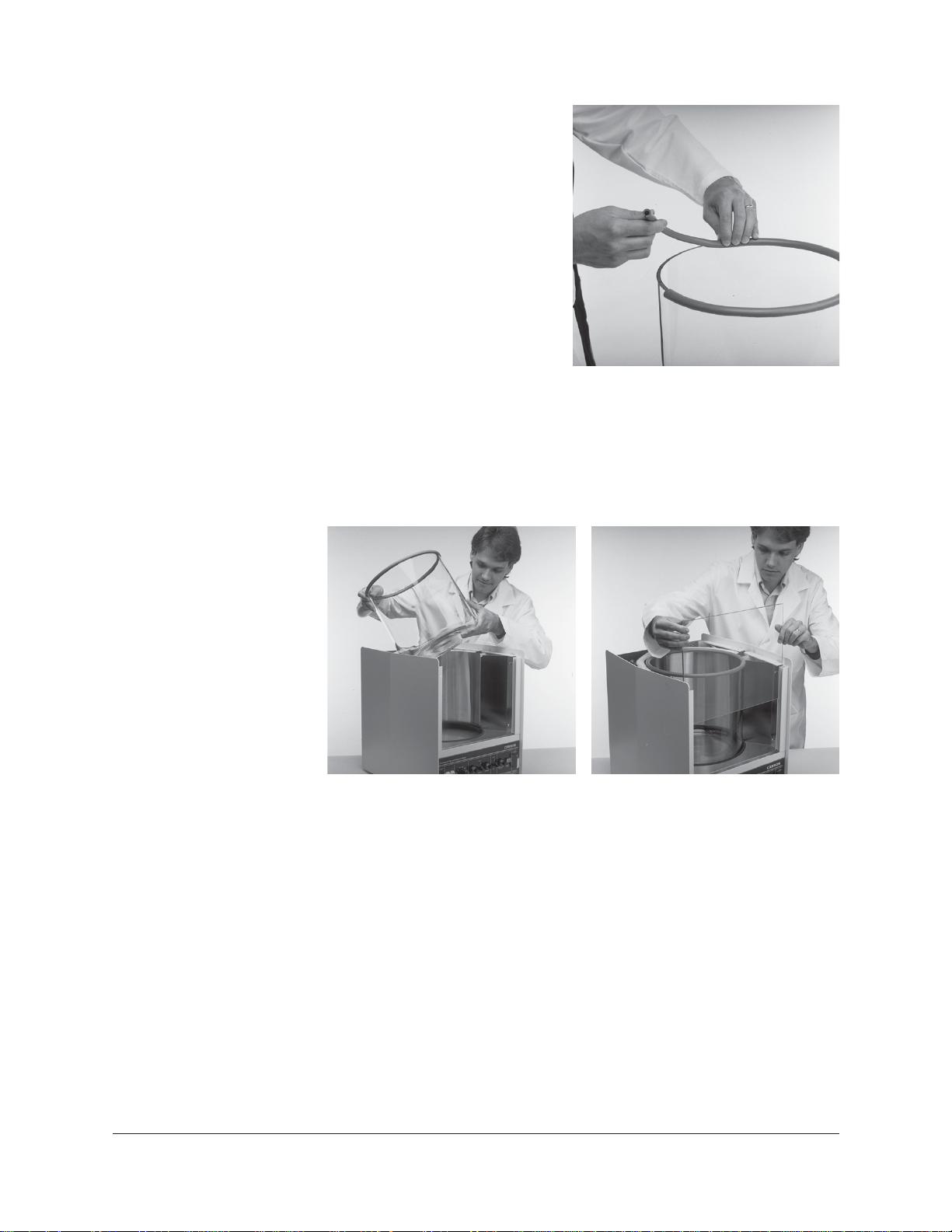

3. Place the rubber gasket

around the top rim of the

jar (see Figure 7). The

rubber may have to be

trimmed slightly to allow

the ends of the rubber

gasket to meet with no gap

when placed around the

rim.

4. Remove the large piece of

foam packing from the

inside of the cabinet. Also

remove the small piece of

foam from the float level,

Figure 7: Placing gasket

located on the upper lefthand corner of the inside of the cabinet.

5. Lower the glass jar into the cabinet so it seats evenly on the rubber

support ring (see Figure 8).

7

CANNON

Figure 8: Installing bath jar Figure 9: Placing inner glass plate

6. Unwrap the two glass panels. Place the thinner of the two piece of

glass in the slot closest to the jar (see Figure 9).

7. Place the wider (tempered) piece of glass in the front slot furthest

away from the jar. The middle slot is left empty as a vapor barrier.

8. Replace the rear top cover. Align the four holes, then insert and

tighten the screws.

9. Replace the front top cover. Line up the four holes, then insert and

tighten the screws.

10. T o ensure that the gasket forms a tight seal with the top covers of the

bath, proceed as follows:

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 10

8

11. Pull out the drawer using the handles provided, disconnecting the

two connection cables as you do so.

CAUTION

You will need to pull the AC line (power) cord through the rear panel

opening as you remove the drawer—you should not try to remove the

cord until you loosen the screw securing the power cord to its connection

on the back of the drawer).

12. Press down or pull up on the plastic release bars on either side of the

drawer track to release the drawer, then pull the drawer completely

free of the unit and set it aside.

13. When the drawer is removed, locate the four 1/4-20 set screws

visible at the top of the drawer opening underneath the bath.

14. Turn the set screws

clockwise with the

Allen wrench (included with the bath)

until the top of the jar

forms a tight seal

with the covers (see

Figure 10). Make

sure you tighten the

set screws uniformly

so the jar remains

level.

FIgure 10: Adjusting seal with set screws

Motor-stirrer

NOTE

15. Run the AC cord through the rear panel opening

16. Replace the drawer in the slide tracks and push the drawer back into

its opening. Insert the two plugs into the rear of the drawer assembly .

Complete the assembly of the bath, including the motor-stirrer installation, per the instructions below:

1. T ake the motor/stirrer from its

box. Remove the two screws on

the top heater housing and lift off

the housing (see Figure 11).

2. After checking the impeller blades

to make sure that the flat sections

all lie in the same plane (see

Appendix B), insert the motor

stirrer in the opening provided (see

Figure 12, next page).

To keep from accidentally bending the motor shaft, do not hold the motor

assembly by the shaft. Use care when inserting the motor shaft and

impeller to prevent damage to delicate components.

Figure 11: Removing housing

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 11

9

NOTE

Two screws located on either side

of the opening for the motor stirrer

serve as locating pins for the

motor support pad. Do not

remove these screws; the holes in

the pad fit loosely over their

heads. The motor line cord should

point toward the rear of the bath

(offset slightly to the right or left).

The motor stirrer should now lie flat

on the top of the bath.

3. Reattach the top heater

Figure 12: Installing the motor

housing , making sure that the heater, motor, and fan cords pass

through the left-hand opening (as viewed from the rear) and that the

control probe, over-temperature probe, and level switch cords exit

from the right opening (as viewed from the rear). The back lip on the

rear top cover fits into the slot on the top heater housing. Line up the

holes, insert screws, and tighten.

4. Connect all plugs and probes to the correspondingly labeled sockets

at the rear of the CT-1000 bath unit.

5. Adjust the four feet on the bottom of the bath housing to level the

bath. This should be done before filling the bath with fluid.

Inserting viscometer tubes/thermometers

The top cover of the CT-1000 contains seven apertures, 51 mm (2”)

in diameter, for the insertion of viscometer tube holders. Two additional

holes are provided for insertion of thermometers.

Inserting viscometer tubes

NOTE

Thermometer immersion

If necessary , remove the viscometer tube hole cover(s) from the top of

the bath and carefully place the viscometer tube(s), with the proper

holder attached, into the bath through the aperture(s) in the top cover .

After filling the bath with fluid, adjust the height of the viscometer tube(s)

to ensure that the liquid under test and/or any timing marks on the tube

are a minimum of 6 mm (¼") below the top level of the liquid.

Proper thermometer immersion is critical for viscosity measurements.

Even a calibrated thermometer will read incorrectly if is it improperly

immersed in the bath. “T otal immersion” kinematic viscosity thermometers should be used with the bulb and only the mercury column beneath

the surface of the liquid, but with the emergent stem above the surface at

ambient temperatures.

NOTE

CANNON

Different thermometers have different immersion requirements. Refer to

the information included with the thermometer in use for specific instructions.

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 12

10

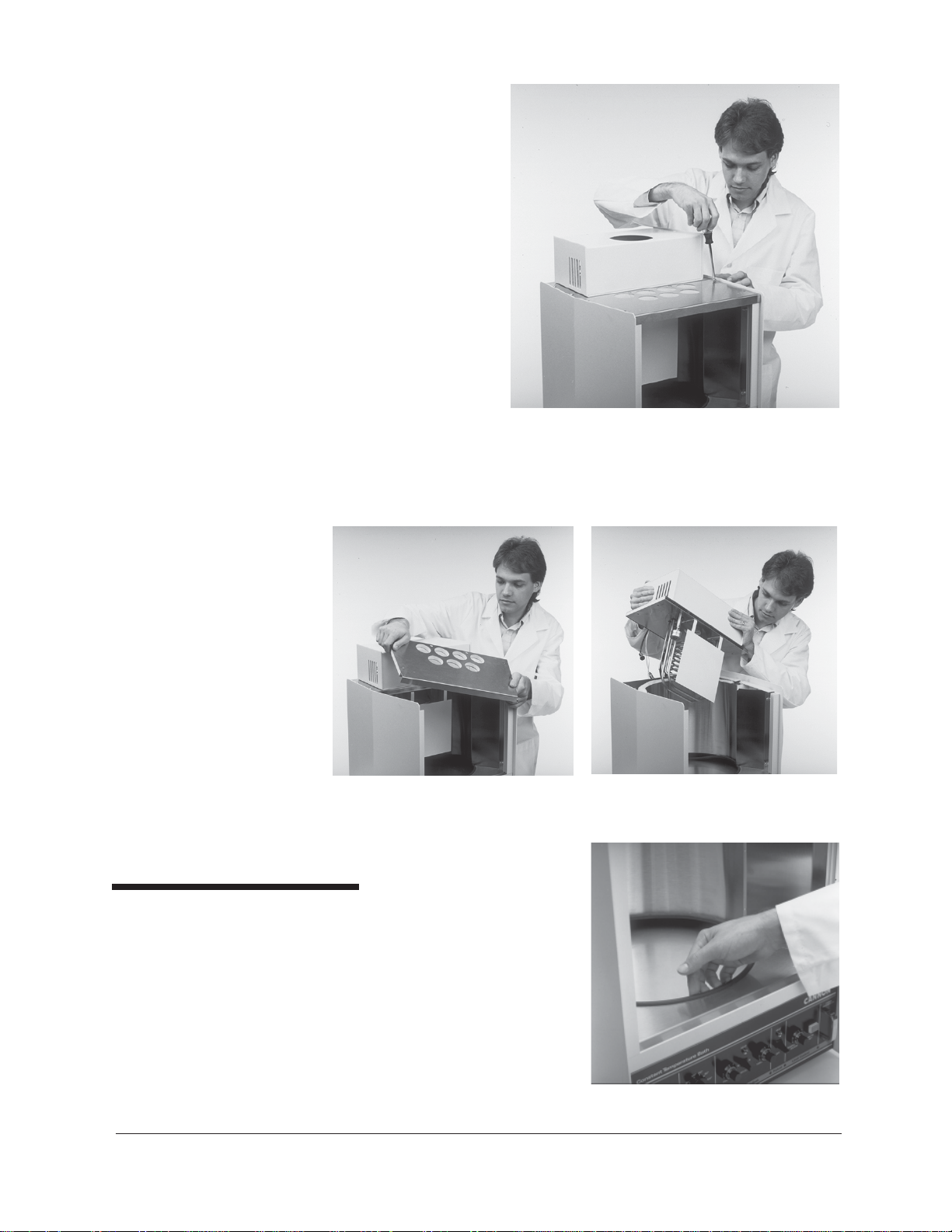

Filling the bath

After CT-1000 assembly

is complete, you are

ready to fill the bath.

CAUTION

Make sure that the bath

is placed in its intended

final position before

adding bath fluid. The

CT-1000 should not be

moved with bath fluid in

the bath jar. NEVER USE

FLAMMABLE BATH

LIQUIDS.

1. Make sure that the

instrument power is

OFF and select a

bath liquid appropri-

Figure 13: Filling the CT-1000 bath

ate to your operating

temperature range (see APPENDIX C).

2. Fill the jar with bath liquid at ambient temperature to a level sufficient to engage the float switch. This float permits bath operation

when the minimum amount of fluid has been added to the bath jar.

3. Continue to add fluid until the bath liquid level has risen to approximately 40 mm (1.5") of the top of the jar.

4. Turn the instrument power ON and incrementally heat the bath to

desired control temperature while monitoring the bath liquid level

carefully . The bath level must be 15-20 mm (approximately ½" to

¾") from the top of the jar at the control temperature. If it becomes

apparent that this liquid level will not be achieved, return the bath to

within 10°C of ambient, turn the instrument power OFF and add or

remove liquid as necessary .

5. Repeat step four until you have attained the proper bath liquid level

at the desired control temperature.

CAUTION

Different bath fluids expand at different rates. Do not overfill the bath!

WARNING Monitor the level of bath liquid closely when operating the CT-1000 at

higher temperatures (100-150°C). The bath liquid will expand as the

temperature increases. The CT-1000 bath jar is not designed to contain

liquid under pressure. If the bath is overfilled, liquid may overflow.

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 13

Draining the Bath

11

If it becomes necessary to drain the liquid from the bath:

Obtain a suitable container to hold all of the liquid drained from the bath

(approximately 20-22 liters or 4.5 - 5 gallons). Make sure that the bath

liquid is within 10°C of ambient temperature. Then insert a tube into the

bath chamber from the top opening and siphon the liquid from the bath

into a container positioned lower than the bath.

WARNING

Always use a rubber bulb or similar device to apply suction to a tube

containing bath liquids.

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 14

12

This page intentionally left blank.

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 15

13

3

NOTE

Turning on the CT-1000

The various functions controlling the bath are printed at the bottom of the

front panel of the CT-1000. These functions, reading from left to right,

are: 1) Power, 2) Temperature, 3) Temperature Adjust, 4) Preheat,

and 5) Limit Control. In this manual the five functions are printed in

boldface upper- and lowercase letters (to match their typeface on the

panel). The switches and dials controlling each function are also printed

in boldface type, but in capital letters (to match their typeface on the

panel).

1. Turn the Power BATH switch on.

BATH OPERATION

NOTE

The bath heaters will not be activated if there is no liquid in the bath.

2. Set the Limit Control TEMPERATURE ADJUST turn the dial

clockwise to its furthest setting to enable the bath to heat properly .

Proper technique for resetting the dial after the bath reaches operating temperature is described in the instructional video and in the

following section of the manual

3. Turn on the Power LIGHT switch to illuminate the interior of the

bath.

4. Move the Temperature Adjust SELECT switch to the left.

5. After releasing its lock, move the T emperatur e Adjust FIXED dial

to 50. Relock the dial.

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 16

14

NOTE

All the dials except Temperature SELECT are equipped with a dial lock

to prevent accidental changing of dial settings. Push the lock upward to

release the dial. When the dial has been set to the proper position, push

the lock downward to relock the dial.

Setting the bath temperature

There are two ways to set the bath temperature, depending on whether or

not the desired temperature is on the Temperature SELECT dial.

Fixed temperature adjustments

T o set the bath to a temperature on the Temperature SELECT switch:

1. Choose a temperature using the Temperature SELECT switch.

NOTE

The Preheat switch activates an auxiliary heater for the CT-1000. You

may turn it ON to heat up the bath more rapidly. You should turn the

Preheat switch OFF when the desired temperature is reached if the

operational temperature is under 120°C. For bath temperatures in

excess of 120°C, the Preheat switch must remain ON to maintain

temperature control. After the Preheat switch has been turned ON, the

Preheat HEAT light will glow continuously until the bath temperature is

approximately that selected with the Temperature SELECT switch,

when the light will begin to blink.

The light above the T emperature Adjust control will glow steadily when

the bath is heating. The light will start to blink when the bath temperature

is approximately that selected with the Temperature SELECT switch.

2. T o adjust the bath to the exact temperature, read from the kinematic

viscosity thermometer (see Appendix F), then release the dial lock on

the T emperature Adjust FIXED dial and turn the dial to incrementally adjust the temperature. To decrease the temperature, turn the

dial counterclockwise; to increase the temperature, turn the dial

clockwise. Relock the T emperature Adjust FIXED dial after each

adjustment and allow several minutes for the bath to equilibrate.

NOTE

If the desired temperature cannot be obtained by turning the Temperature Adjust FIXED dial, it may be necessary to adjust the small trimpots

on the circuit board in the electronics drawer (see Appendix D).

Variable temperature adjustments

T o set the bath to a temperature that is not on the Temperature SELECT

switch you should use the following procedure:

1. Turn the Temperature SELECT switch to the temperature closest to

that desired.

CANNON

2. Move the Temperature Adjust SELECT switch to the right.

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 17

15

NOTE

NOTE

The Preheat switch activates an auxiliary heater for the CT-1000. You

may turn it ON to heat up the bath more rapidly. You should turn the

Preheat switch OFF when the desired temperature is reached if the

operational temperature is under 120°C. For bath temperatures in

excess of 120°C, the Preheat switch must remain ON to maintain

temperature control. After the Preheat switch has been turned ON, the

Preheat HEAT light will glow continuously until the bath temperature is

approximately that selected with the Temperature SELECT switch,

when the light will begin to blink.

The light above the T emperature Adjust control will start to blink when

the bath temperature has approximated the setting on the Temperature

SELECT switch.

3. T o adjust the bath to the exact temperature, read from the kinematic

viscosity thermometer (see Appendix F), then release the dial lock on

the T emperatur e Adjust V ARIABLE dial and turn it. To incrementally decrease the temperature, turn the dial counterclockwise; to

increase the temperature, turn the dial clockwise. Relock the Tem-

perature Adjust V ARIABLE dial after each adjustment and allow

several minutes for the bath to equilibrate.

If a desired bath temperature is within two or three degrees of one on the

Temperature SELECT dial, it is sometimes possible to attain the temperature by using the Temperature Adjust FIXED dial. Because this dial

has a finer adjustment than the Temperature Adjust VARIABLE dial,

the final temperature may be reached more quickly. If you wish to try this

alternate method, follow the procedure for fixed temperature adjustments

given on the previous page.

NOTE

To attain temperatures below ambient temperature (20-25°C), a coolant

must be pumped through the bath’s cooling coil. The coil is accessed

through the rear of the bath. Coolant temperature should be approximately 3°C below the desired bath temperature. Temperature stability

below ambient temperature may be limited by the flow rate of the coolant.

Adjusting the High Temperature Limit Control

Using a screwdriver, slowly turn the LC- TEMPERA TURE ADJUST

control counterclockwise until the OVERTEMP message lights up on the

LC PUSH TO RESET button.

Turn the control clockwise approximately 1/4 to 1/2 turn.

Push the LC- PUSH TO RESET button. If the bath doesn’t recover,

repeat step 2 and try again.

NOTE

The temperature may change slightly when you set the Limit Control, but

the bath temperature will quickly stabilize.

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 18

16

This page intentionally left blank.

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 19

17

A

Problem

Bath does not appear to

have power.

Bath illumination not

functioning.

Bath liquid not agitated.

APPENDIX A — CT-1000

PROBLEM ANALYSIS

Probable Cause

• Power cable not connected to outlet or rear of electrical drawer.

• Over-temperature control set too low.

• Power out on mains.

• Separate switch for LIGHT must be on.

• fluorescent lamps may be defective.

• Lamps may be out of sockets.

• Lamp ballast may be defective.

• Power supply to ballast may not be working properly.

• Check connection of stirring motor on rear panel.

• Check for working motor by connecting to outlet with the proper

voltage (see motor label for correct voltage).

Bath does not heat.

Bath control outside of

specific limits.

Bath top surface

temperature too high.

Air bubbles in bath fluid.

• Check connections for sensors on rear panel.

• Check temperature setting — it must be above existing bath

temperature for heat to go on.

• Bath fluid level may be too low.

• Limit Control Temperature Adjust dial may be set too low (turn

completely clockwise to 999, then press PUSH TO RESET

button).

• Bath fluid viscosity may be too high (if the fluid is too viscous at the

desired temperature the stirring will be inadequate, resulting in

poor control).

• Check for normal function of stirring motor and motor impeller.

• Remove control thermistor probe plug and check resistance with an

ohmmeter (call CANNON

temperature).

• Check cooling fan on rear panel.

• Check cooling fan in top assembly.

• Level of fluid may be too low.

• Stirring impeller may be on shaft with the wrong orientation.

• Bath fluid may be too viscous for operation at this temperature.

®

for proper resistance at bath

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 20

18

This page intentionally left blank.

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 21

19

B

NOTE

Set Screw Alignment

APPENDIX B — CORRECTING

SHAFT & IMPELLER

MISALIGNMENT

Motor-stirrer units supplied by CANNON® Instrument Company are

checked after assembly to ensure minimum run-out (deviation from

concentric rotation) at the impeller end of the shaft. The following

instructions are intended to assist those who may be experiencing excessive vibration in the motor-stirrer because of shaft run-out or misalignment of the impeller blades.

See the instructional video on the CT-1000 for a detailed description of

the procedure described below.

The motor shaft contains a flat area. The coupling should be oriented in

such a way that the set screw is aligned with the flat. The stirrer shaft and

motor shaft should be inserted to approximately the same length in the

coupling.

You can test for shaft run-out and impeller blade alignment by placing

the motor on a soft surface with impeller facing up. Connect the motor to

the appropriate AC power source and observe the impeller and shaft. If

run-out is severe, the motor will vibrate and the shaft will flutter noticeably . The impeller will appear blurred if the impeller blades are not in the

same plane.

If necessary you can adjust the impeller blades by bending the large

horizontal sections of each of the four segments so that they lie in the

same plane. Since these segments are easily bent, check alignment

whenever the impeller is bumped, or if there is any suspicion that the

blade segments may have become misaligned.

Shaft run-out correction

The following procedure is suggested to correct shaft run-out:

Grasp the motor firmly with the left hand and touch the tip of a soft

crayon (a glass marking pencil, for example) momentarily to the side of

the shaft near the impeller end while the motor is running. It is advisable

to remove the impeller while carrying out this procedure. The mark

produced by the crayon will be evident as a line part way around the

shaft.

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 22

20

Disconnect the motor, hold the motor tightly against the body, and grasp

the shaft in the right hand. Bend the shaft away from the line segment on

the shaft.

Repeat the test procedure, marking the shaft at a location slightly removed from the first crayon mark.

If the mark appears at the same side of a shaft as the first mark and is

about the same length, the bending was not great enough to alter the

condition and should be repeated with more force applied. If the mark

has shifted to the opposite side, the force was too great and the shaft must

be bent back with less force to correct the situation.

This is a trial-and-error process which usually must be repeated several

times. When the crayon makes a line at least two-thirds of the way

around the shaft, the run-out has diminished to an acceptable level. A

uniform line completely around the shaft would indicate no run-out

detectable by this procedure.

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 23

21

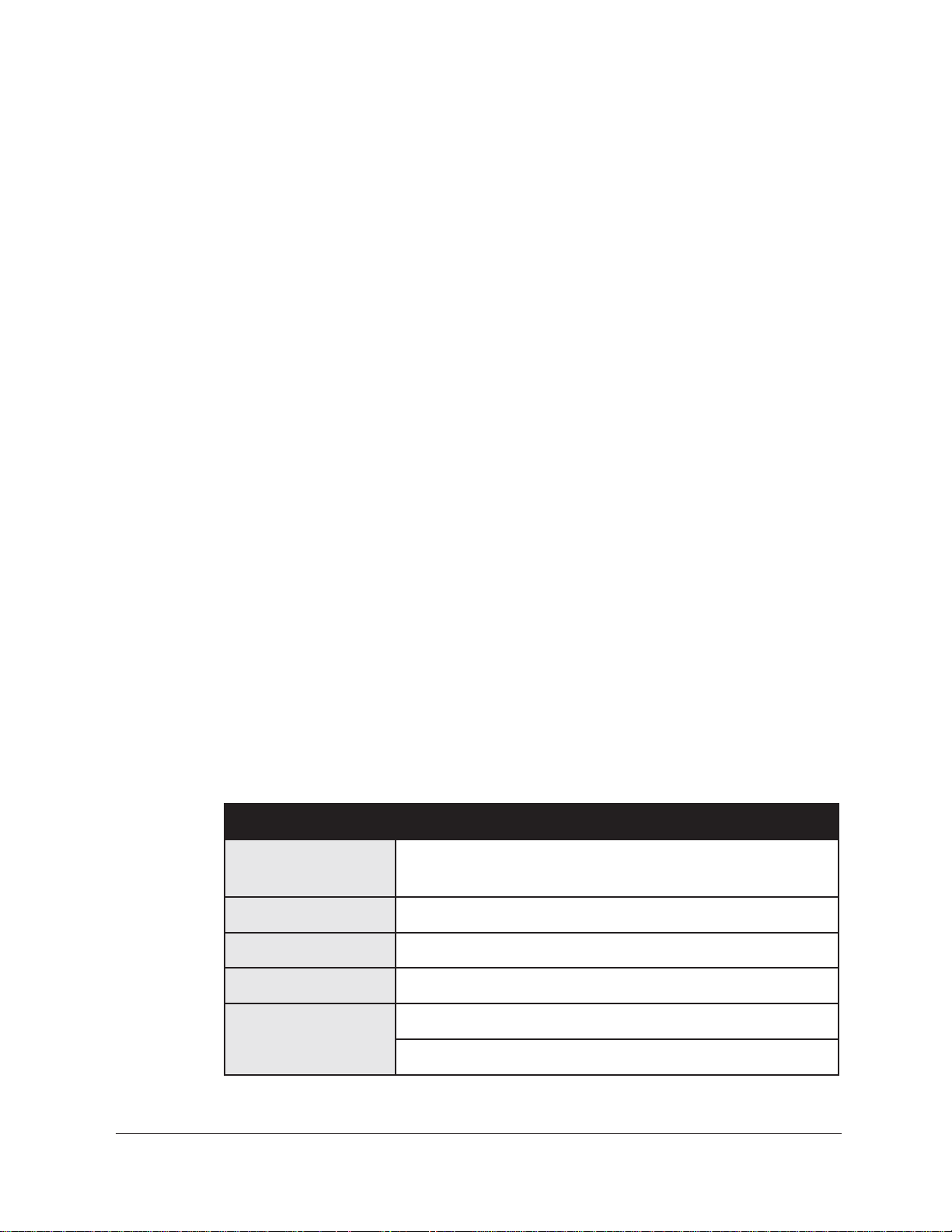

C

APPENDIX C — CHOOSING A

TEMPERATURE BATH LIQUID

The ideal bath liquid would possess low viscosity , high heat capacity, and

low vapor pressure over a wide range of temperatures. In addition, the

liquid should have a very high flash point and be relatively low in cost. If

the fluid is to be used in a kinematic viscosity bath where it is necessary

to view the instruments through the bath liquid, then it is important for

the liquid to be clear and without color. Unfortunately, no single fluid

meets all these requirements.

Because no single fluid can be used at all possible bath temperatures, the

choice of a suitable fluid must begin by establishing the temperature

range over which the bath will be operated. The following table provides

a list of operating temperature ranges and some liquids suitable for use in

these ranges:

Methyl alcohol

)C°002+otC°001-(SNOITPODIULFHTAB

erutarepmeT

)C°(egnaR

C°01+otC°001-lohoclAlyhteM

C°02+otC°01-senociliSytisocsiV-woL,lohoclAlyporposI

C°5+

Methyl alcohol is relatively volatile, has a low flash point, and has a

degree of toxicity . The only reason for using it is that there seems to be

no reasonable substitute. There are some very expensive halogen-based

fluids which might be considered, but these also have a high volatility

and may be somewhat toxic.

C°06+ot

C°001+otC°06+

C°531+otC°001+)tSc02,diulf002woD(senociliS

C°002+otC°531+)tSc05,diulf002woD(se

)tSc1,diulf002woD(

)tSc01,diulf002woD(

nociliS

sdiuqiLhtaBelbatiuS

senociliS,sliOytisocsiVwoL,retaW

senociliS,rotibihnInoitadixOhtiwsliOetihW

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 24

22

Isopropyl alcohol

Silicone fluids

Water

Refined white oils

Isopropyl alcohol is less toxic than methyl alcohol and somewhat less

volatile. However, it becomes very viscous at low temperatures and is

therefore unsuitable for use at very low temperatures.

Silicone fluids are available in a wide range of viscosities and can be

used over a wide range of temperatures if the proper selection of viscosity is made for the temperature range of interest. Silicones are also

relatively expensive liquids. However, a bath containing silicones

requires extra care when used for capillary viscometry . If silicones are

introduced into a viscometer capillary , its calibration factor will be

altered by a significant amount.

Water is almost the ideal fluid in the temperature range in which it can be

used. Because in some cases there is a tendency for algae formation,

some degree of water treatment may be necessary . Water can be used at

temperatures close to the boiling point, but water replenishment to offset

evaporation becomes a nuisance and the hot vapor can make working

above the bath uncomfortable. Also, it may be dif ficult to establish

optimum control at elevated temperatures because of the rapid cooling

resulting from surface evaporation.

Refined white oils (paraffin oils) of relatively low viscosity can be used

at temperatures above the level at which water becomes unsatisfactory .

Because these oils will turn faintly yellow and continue to darken with

prolonged exposure to heat, we recommend adding an oxidation inhibitor

to retard discoloration. The addition of an inhibitor will prolong the

useful life of the oil, but it will eventually become as dark as untreated

oil.

The search for more suitable bath oils is unending. Hydrogenated vegetable oils, coconut oil, synthetic oils, and certain chemical compounds

have been used with some success at various temperatures.

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 25

23

D

APPENDIX D — ADJUSTING

TRIMPOTS (POTENTIOMETERS)

The ten trimpots located immediately behind the front control panel can

be accessed by pulling the drawer forward a few inches. An opening in

the drawer cover allows direct

access without the necessity of

removing the cover. The

trimpots are adjusted with a

small screwdriver (see Figure

15).

There is one trimpot corresponding to each of the set

temperatures on the dial. These

are normally set so that the

T emperature Adjust FIXED

dial will be at the midpoint

(500 on the ten-turn dial) of

range when at the control

temperature. Setting the

T emperature Adjust FIXED dial at the midpoint ensures maximum

adjustment in either direction to establish the desired temperature if

additional adjustment is necessary .

Figure 15: Adjusting potentiometers

CANNON

If a temperature other than one that is available on the T emperatur e SELECT switch is to be accessed frequently , it may be possible to obtain this

temperature by adjusting the trimpot that coincides with the Temperature

SELECT temperature that is close to the desired temperature.

For example, if 100°F is a temperature that is often needed, and 40°C is

not used, set the Temperature SELECT switch to 40°C and adjust the

trimpot until the kinematic viscosity thermometer indicates the bath is

controlling at 100°F. It is necessary to note for future reference that the

40°C position on the select dial is now 100°F. In some cases it may also

be necessary to set the T emperature Adjust FIXED dial to a position

other than the midpoint in order to obtain the desired temperature.

While the method described above will permit the Temperature SE-

LECT setting to be altered, it may not be possible to obtain settings for

temperatures that are widely different from those on the Temperature

SELECT dial. In this case, use the T emperature Adjust V ARIABLE

dial to obtain the desired temperature.

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 26

24

This page intentionally left blank.

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 27

25

E

APPENDIX E — CT-1000 SPARE

PARTS LIST

Following is a list of parts for the CT-1000 which may be reordered from

CANNON® Instrument Company .

Part Number Description

P20.1 PYREX JAR 12 X 12

P20.22 THERMOMETER HOLDER (RUBBER)

P22.26 JAR TOP GASKET

P22.39 HOLE COVERS & THERM HOLDER SET

P22.40 JAR SUPPORT GASKET

P27.1260 SOCKET LAMP

P27.1300 FLOURESCENT LAMP

P27.1310 LAMINA TED SAFETY GLASS

P27.1320 PLATE GLASS

P27.2190 LIGHTED SWITCH ROCKER 120V

P27.2220 P ANEL MOUNT LED

P27.2230 TEMPERA TURE RESET SWITCH

P27.2230.11 LAMP RESET SWITCH

P27.2250 SOLID ST A TE RELA Y 25A

P27.2280 BALLAST SOILD ST A TE

P27.2330 15 AMP CIRCUIT BREAKER 120V

P27.2331 8 AMP CIRCUIT BREAKER 240V

P27.3700 SCREWDRIVER TRIMPOT ADJ

P27.5110 FRONT BA TH COVER W/ROUND HOLES

P27.5250 BAFFLE, WHITE

P27.5260 COOLING COIL (SS)

P27.5270 HEATER 700W 120V

P27.5290 HEATER 400W 120V

P27.5291 HEATER 400W 240V

P27.5320 TEMPERA TURE CONTROL PROBE

P27.5330 TEMPERA TURE PROBE OVER

P27.5410.1 LEVEL SWITCH

P27.6100 CT1000 MOTOR STIRRER 120V

P27.6101 CT1000 MOTOR STIRRER 240V

P27.6121 SPONGE SUPPORT PA D

P50.82 10 TURN DIAL

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Page 28

This page intentionally left blank.

Page 29

F

Products limited warranty

In addition to other manufacturers’ warranties, CANNON® Instrument

Company (“the Company”) warrants all products (other than reagents

and chemicals) delivered to and retained by their original purchasers to be

free from defect in material and workmanship for one year from the date

of the Company’s invoice to the purchaser. For a period of one year from

the date of such invoice, the Company will correct, either by repair or

replacement at the Company’s sole election, any defect in material or

workmanship (not including defects due to misuse, abuse, abnormal

conditions or operation, accident or acts of God, or to service or modification of the product without prior authorization of the Company) without

charge for parts and labor. The determination of whether any product has

been subject to misuse or abuse will be made solely by the Company .

WARRANTY/RETURN

INFORMATION

The Company shall not be liable for any special, incidental, or consequential damages, or any damage to plant, personnel, equipment or products,

directly or indirectly resulting from the use or misuse of any product sold

by the Company except as set forth in and limited by the foregoing

warranties. Representations and warranties made by any person, including dealers and representatives of the Company , which are inconsistent, in

conflict with, or in excess of the terms of this warranty shall not be

binding upon the Company unless placed in writing and approved by an

officer of the Company.

Reagent and chemical warranty

CANNON® Instrument Company (“the Company”) warrants all reagents and chemicals sold by the Company and delivered to and retained

by their original purchasers to conform to the weight, specifications and

standards stated on the package. The Company will, at its sole option,

either replace or refund the price (net of freight, handling charges and

taxes), of any reagent or chemical sold by the Company which does not

conform to such weight, specifications and standards upon the prompt

return of the unused portion. Except for replacement or refund of the net

price, the Company shall not be liable for any damages occurring as a

consequence of the failure of any reagent or chemical sold by the Company to conform to the weight, specifications and standards stated on the

package.

Page 30

28

Returning a product to

Procedure

Before returning a CANNON® product for repair or service, make every

attempt to identify the problem. If, after careful checking, the problem

remains unidentified or unsolved, telephone CANNON® Instrument

Company (or the local service agent) to consult with a product specialist.

If the specialist cannot recommend a simple solution or repair, CAN-

NON® will authorize the return of the product through the issuance of a

Return Authorization number (RA).

Products returned to CANNON

to the following address:

Please include the following:

CANNON

CANNON

®

®

Telephone Number 814-353-8000

CANNON® Fax Number 814-353-8007

®

must be carefully packed. Ship prepaid

CANNON Instrument Company

A TTN: Return Authorization # __________

2139 High Tech Road

State College, P A 16803 USA

Required information

Hazardous materials

Shipping notification

• The Return Authorization number (RA).

• The name and telephone number of the person at your company to

contact regarding the product.

• Shipping and billing instructions for the return of the product to your

location.

• A detailed explanation of the reason for the return.

If the product is not covered by warranty, the customer will be provided

with an estimate of the repair costs and asked for approval before any

repairs are made. The customer will be required to issue a purchase

order for the cost of the repairs.

Stringent government regulations restrict the shipment of mercury. Please

contact CANNON® before returning a product that could possibly

contain mercury.

Products returned without prior notification (by either telephone or fax),

or without Cannon’s authorization, will not be accepted.

The customer may be billed a testing fee if a product is returned to

CANNON® and found to be working properly.

CANNON

®

CT-1000 Constant Temperature Bath Instruction & Operation Manual

Revision 3.1e—June, 2011; CANNON® Instrument Company

2139 High Tech Road • State College, PA • USA 16803

Loading...

Loading...