Page 1

CONTENTS

i

1

2

3

4

INTRODUCTION 1

Instrument overview.............................................................................................................. 2

Instrument specifications ....................................................................................................... 3

Safety warnings .................................................................................................................... 3

UNPACKING AND ASSEMBLY 5

Unpacking the CMR V -4500................................................................................................. 5

User-Supplied Equipment ..................................................................................................... 6

CMRV-4500 APPARATUS DESCRIPTION 7

CMR V -4500 unit/accessories ............................................................................................... 7

Air/W ater Heat Exchanger .................................................................................................... 9

Front panel operations ........................................................................................................ 10

SETUP 11

Physical placement.............................................................................................................. 11

Tubing connections ............................................................................................................. 12

Filling the Air/W ater Heat Exchanger ................................................................................... 12

Electrical /serial connections ................................................................................................ 13

Pulley-wheel installation ...................................................................................................... 14

Installation notes ................................................................................................................. 15

Setting the CMR V instrument address ................................................................................. 15

Cleaning the instrument housing ........................................................................................... 16

Flushing and draining the Air/W ater Heat Exchanger ............................................................ 16

Flushing fluid from the Exchanger ............................................................................ 16

Draining fluid from the Exchanger ............................................................................ 17

5

VISCPRO® INSTALLATION 19

VISCPRO® for W indows® XP®.......................................................................................... 19

Installing VISCPRO® software............................................................................................ 19

Computer requirements........................................................................................... 19

Windows® XP® installation ...................................................................................... 19

Installation actions................................................................................................... 19

CANNON

®

Mini-Rotary Viscometer

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

CMRV-4500

Instruction & Operation Manual

®

Instrument Company

Page 2

ii

5

6

7

VISCPRO® INSTALLATION (continued)

Running the software........................................................................................................... 20

Loading software .................................................................................................... 20

Displaying the Instrument V iew window................................................................... 20

V iewing report data ................................................................................................ 22

Logging in ............................................................................................................... 23

Checking Instrument Settings .................................................................................. 23

Setting multiple CMR V instrument addresses ....................................................................... 25

Security options .................................................................................................................. 25

Initial security setup................................................................................................. 26

PREPARING FOR CMRV TESTING/CALIBRATION 29

Cleaning cycle .................................................................................................................... 29

Cleaning procedure................................................................................................. 29

Inserting rotors ....................................................................................................... 32

CALIBRATING THE CMRV TEMPERATURE PROBE 33

8

9

Probe calibration procedure .................................................................................... 33

Manual restoration of voltage and offset data ........................................................... 34

CALIBRATING THE CMRV CELLS 35

Calibration theory ............................................................................................................... 35

Cell calibration procedure ................................................................................................... 36

Preparing the cells................................................................................................... 36

Cell calibration test procedure ................................................................................. 38

USING THE CMRV SOFTWARE 41

VISCPRO® generic instrument interface .............................................................................. 41

Main options .......................................................................................................... 42

Security options ...................................................................................................... 44

Initial security setup................................................................................................. 45

Print/Print setup options .......................................................................................... 46

Analyses options................................................................................................................. 46

Analysis types......................................................................................................... 47

Analyses menu options............................................................................................ 47

Window options ................................................................................................................. 48

CANNON

®

Mini-Rotary Viscometer

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

CMRV-4500

Instruction & Operation Manual

®

Instrument Company

Page 3

iii

9

10

USING THE CMRV SOFTWARE (continued)

CMR V module menu options .............................................................................................. 49

Configure options ................................................................................................... 49

Print Instrument and Tray Settings ........................................................................... 49

Instrument Settings.................................................................................................. 49

Profile Designer ...................................................................................................... 50

V iew Cell Constants ............................................................................................... 50

Saving a configuration ............................................................................................. 51

Restoring instrument settings from a saved configuration ........................................... 51

Calibrate Cell Constants ......................................................................................... 52

Service menu options .......................................................................................................... 54

SUMMARY OF TEST PROCEDURE 55

ASTM D 4684 method ...................................................................................................... 55

ASTM D 3829 method ...................................................................................................... 56

ASTM D 6821 method ...................................................................................................... 56

ASTM D 6896 method ...................................................................................................... 57

SAE J300 notes ................................................................................................................. 57

Delayed start option............................................................................................................ 57

11

12

RUNNING PROFILES 59

Starting a profile ................................................................................................................. 61

Profile operation notes ........................................................................................................ 62

Adjusting temperature at the end of a profile ............................................................ 63

Displaying a profile graph .................................................................................................... 63

Printing a profile graph ........................................................................................................ 64

Exporting time/temperature profile data ............................................................................... 64

MEASURING YIELD STRESS AND VISCOSITY 65

Measuring yield stress ......................................................................................................... 65

Notes on yield stress testing ................................................................................................ 67

Measuring apparent viscosity .............................................................................................. 67

Notes on viscosity testing .................................................................................................... 68

Printing yield stress/viscosity test results ............................................................................... 69

Exporting yield stress/viscosity data ..................................................................................... 69

CANNON

®

Mini-Rotary Viscometer

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

CMRV-4500

Instruction & Operation Manual

®

Instrument Company

Page 4

iv

13

14

ANALYSIS CONFIGURATION OPTIONS 71

Creating an analysis ............................................................................................................ 71

Sorting analysis data ........................................................................................................... 73

Using the date filter ............................................................................................................. 73

Using the sample/error filter................................................................................................. 74

Using the report/port output filter......................................................................................... 75

Reconfiguring a displayed analysis ....................................................................................... 75

Resizing table columns ........................................................................................................ 76

Saving a current analysis configuration ................................................................................. 76

Deleting an analysis configuration......................................................................................... 76

Printing an analysis .............................................................................................................. 76

Keystrokes for selecting data for printing ................................................................. 77

DESIGNING CUSTOMIZED PROFILES 79

Cooling Profiles .................................................................................................................. 79

The Profile Designer ........................................................................................................... 79

Opening the Profile Designer ................................................................................... 80

Interface options ..................................................................................................... 81

Managing profiles ................................................................................................... 81

Using the Profile Editor ........................................................................................... 82

Editing points .......................................................................................................... 83

Deleting points ........................................................................................................ 83

Cooling profile limitations .................................................................................................... 84

Profile Designer test parameters .......................................................................................... 84

Changing test parameters ....................................................................................... 85

15

16

17

MRV DATA TABLE ANALYSIS 87

Configuring the MR V Data T able ............................................................................ 88

ERROR LOG TABLE ANALYSIS 91

Configuring the Error Log analysis ........................................................................... 91

EXPORT ANALYSES 95

Configuring the Port Export analyses ....................................................................... 96

CANNON

®

Mini-Rotary Viscometer

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

CMRV-4500

Instruction & Operation Manual

®

Instrument Company

Page 5

v

18

19

A

USING THE DATABASE MANAGER 101

Archiving old data................................................................................................. 102

Changing the database directory............................................................................ 102

Importing archived data ........................................................................................ 103

Repairing/compacting the database........................................................................ 103

Exit ...................................................................................................................... 103

WARRANTY/RETURN INFORMATION 105

Products limited warranty.................................................................................................. 105

Reagent and chemical warranty ......................................................................................... 105

APPENDIX A — TROUBLESHOOTING 107

Instrument status window not updating .................................................................. 107

The CMR V -4 is not heating properly..................................................................... 107

The Y ield and V iscosity lights on the CMR V front panel are blinking rapidly ............ 107

CMR V cooling/temperature control problems........................................................ 107

Yield stress or viscosity test results inconsistent...................................................... 108

T est icons "greyed out"--unable to initiate viscosity tests ......................................... 108

B

C

D

I

APPENDIX B — REPLACEMENT PARTS LIST 109

APPENDIX C — THERMOMETRY 111

Kinematic viscosity and temperature...................................................................................111

ASTM thermometer tables................................................................................................ 112

ASTM D 445 — Checking the ice point ........................................................................... 113

NBS Monograph150: Joining separated mercury columns ................................................. 115

APPENDIX D — MULTI-UNIT CONFIGURATION 117

Introduction ...................................................................................................................... 117

Procedure ........................................................................................................................ 117

INDEX 119

CANNON

®

Mini-Rotary Viscometer

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

CMRV-4500

Instruction & Operation Manual

®

Instrument Company

Page 6

vi

This page intentionally left blank.

CANNON

®

Mini-Rotary Viscometer

Version 1.1e—October, 2011 • CANNON

CMRV-4500

Instruction & Operation Manual

®

Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 7

CHAPTER

1

1

Purpose of the manual

Instrument utility

NOTE

INTRODUCTION

This manual has been written to provide the information necessary for

proper installation, operation, and maintenance of the CANNON

Rotary Viscometer (CMRV-4500).

®

The CANNON

viscosity and yield stress of engine oils and drive line lubricants within

the temperature range of -10

4684, D 3829, D6821 and D 6896. ASTM test method D 4684 is required

by the Society of Automotive Engineers (SAE) Engine Oil Viscosity

Classification SAE J300.

The CMRV-4500 capabilities have been tailored to the requirements of

the current ASTM methods cited above. For this reason, the instrument

may not be suitable for some general-purpose viscometry applications.

Consult with CANNON® Customer Service before testing with materials

and/or methodology at significant variance with ASTM D 4684, ASTM D

3829 or ASTM D 6821.

Mini-Rotary Viscometer is used to measure the apparent

°

C to -40°C using ASTM test methods D

®

Mini-

Improvements

CMRV-4500 with pulley-wheel assembly

The CMRV-4500 is a state-of-the-art system offering many superior

features including:

New Method compatibility

The CMRV-4500 is fully compatible with ASTM D 6821,

the new Drive Line Lubricants test method. The CMRV-4500

is fully compatible with ASTM D 6896, a new method for

testing used diesel oils.

Improved insulation for temperature control

The CMRV-4500 instrument features a redesigned housing

and accessory rotor caps to enhance insulating characteristics

and precision.

Software library of temperature profiles

(cooling profiles)

Predefined cooling profiles that comply with methods ASTM

D 3829, ASTM D 4684, ASTM D 6821 and ASTM D 6896

are supplied with the CMRV software. The user may also

create custom cooling profiles with the Profile Designer.

VISCPRO

®

The VISCPRO

Profile Designer for creating unique cooling profiles.

software for Windows® XP® features a

®

software with Profile Designer

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 8

2

Networking capability for multiple instruments

®

The VISCPRO

software can control/monitor up to four CMRV instruments with one computer via RS-485 serial connections. See APPENDIX

D for more information.

Instrument overview

The CANNON® Mini-Rotary Viscometer is designed for precision

control of temperature over time, enabling accurate yield stress and

viscosity measurement of oil samples in conformance with ASTM D

3829, ASTM D 4684, ASTM D 6821 and ASTM D 6896 test methods.

Test procedure

Oil samples placed in the CMRV-4500 viscometric cells are heated and

cooled at a predetermined rate according to a user-specified cooling

profile. The cooling profile parameters are downloaded to the CMRV4500 onboard memory via a serial interface with the host computer. The

CMRV-4500 then uses this profile to control the rate of temperature

change, independent of the host computer.

All three methods specify that the samples be initially heated to ensure

that all components of the sample are released into solution. The samples

are then slowly cooled to the test temperature using the user-selected

temperature profile and maintained at test temperature for a specified

soak period. Following the soak period, apparent viscosity (and yield

stress if applicable) for each sample is determined by applying a constant

torque to, and measuring the rotational speed of, a cylindrical rotor which

has been immersed in the sample.

The time required for completion of the ASTM D 3829 test cycle is

approximately 19 hours. The time required for completion of the ASTM

D 4684 (TP-1, two-day) test is 45½ to 53½ hours. The time required for

completion of the ASTM D 6821 test cycle is approximately 18 hours.

The time required for completion of the ASTM D 6986 test cycle is

approximately 43½ to 53½ hours.

NOTE

CANNON

See Chapter 10 for additional information on the ASTM procedures.

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 9

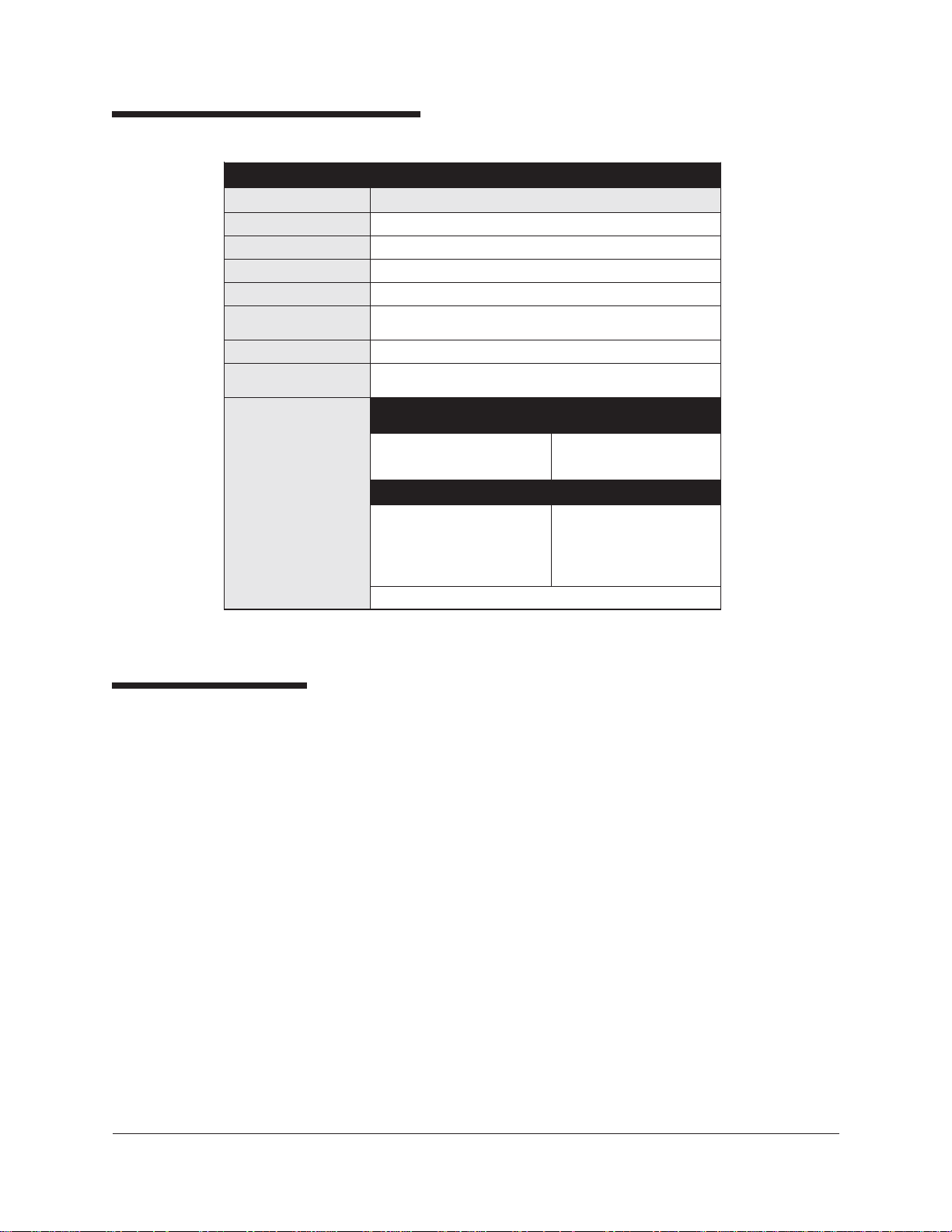

Instrument specifications

ledoMtnemurtsnI

snoisnemiD )"52.91×52.01×5.21(hgihmm984×peedmm062×ediwmm713

thgieW )sbl14(gk6.81

thgieWgnippihS )sbl06(gk72

erutarepmetlanoitarepO C°04-otC°08

snoitidnoCgnitarepO IIyrogetacnoitallatsnI;gnisnednoc-nonHR%09-%01,C°03-C°51

gnitaResuF "¼1;V052A5M×"¼

ecnailpmoC )CEE/32/37(evitceridegatlovwoL;)CEE/633/98(evitceridCME

/rebmuNgolataC

stnemeriuqeRlacirtcelE

3

SNOITACIFICEPSSEIRES0054VRMC

0054ledoM

2eergednoitulloP

).ces06,CDV0091(TOP-IH

)0054ledoM(12R-8279 )0054ledoM(22R-8279

ylbmessAkcolBVRMC

%01±CAV001

sttaw004,zH06/05

)F0054ledoM(32R-8279 )sledoMllA(

ylbmessAkcolBVRMC

%01±CAV032

sttaw004,zH06/05

ylbmessAkcolBVRMC

%01±CAV511

sttaw004,zH06/05

retaW/riAVRMC

regnahcxEtaeH

)1556.25P(%01±CAV001

)2456.25P(%01±CAV511

)3456.25P(%01±CAV032

sttaw0011,zH06/05

.tinuruoyhtiwdeilppusdrocrewopdevorppaehtylnoesU

Safety warnings

Please observe the following safety procedures and notices for proper

operation of your CMRV-4500 unit:

• Make sure that your unit is operated only by qualified personnel

• Make sure that you read and understand all operating instructions

and safety precautions listed in this manual before installing or

operating your unit. If you have questions regarding instrument

operation or documentation, contact CANNON

®

Instrument Company.

• Deviation from the installation, operation or maintenance procedures

described in this manual may result in a hazardous situation and may

void the manufacturer's warranty .

• Transport the unit with care. Sudden jolts or drops may cause dam-

age to components.

• Observe all warning labels.

• Never remove warning labels.

• Never operate damaged or leaking equipment.

• Always turn off the unit and disconnect the mains cable from the

power source before performing service or maintenance procedures,

or before moving the unit.

• Always remove sample from the cells before moving the unit.

• Never operate the equipment with damaged mains power cables.

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

®

Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 10

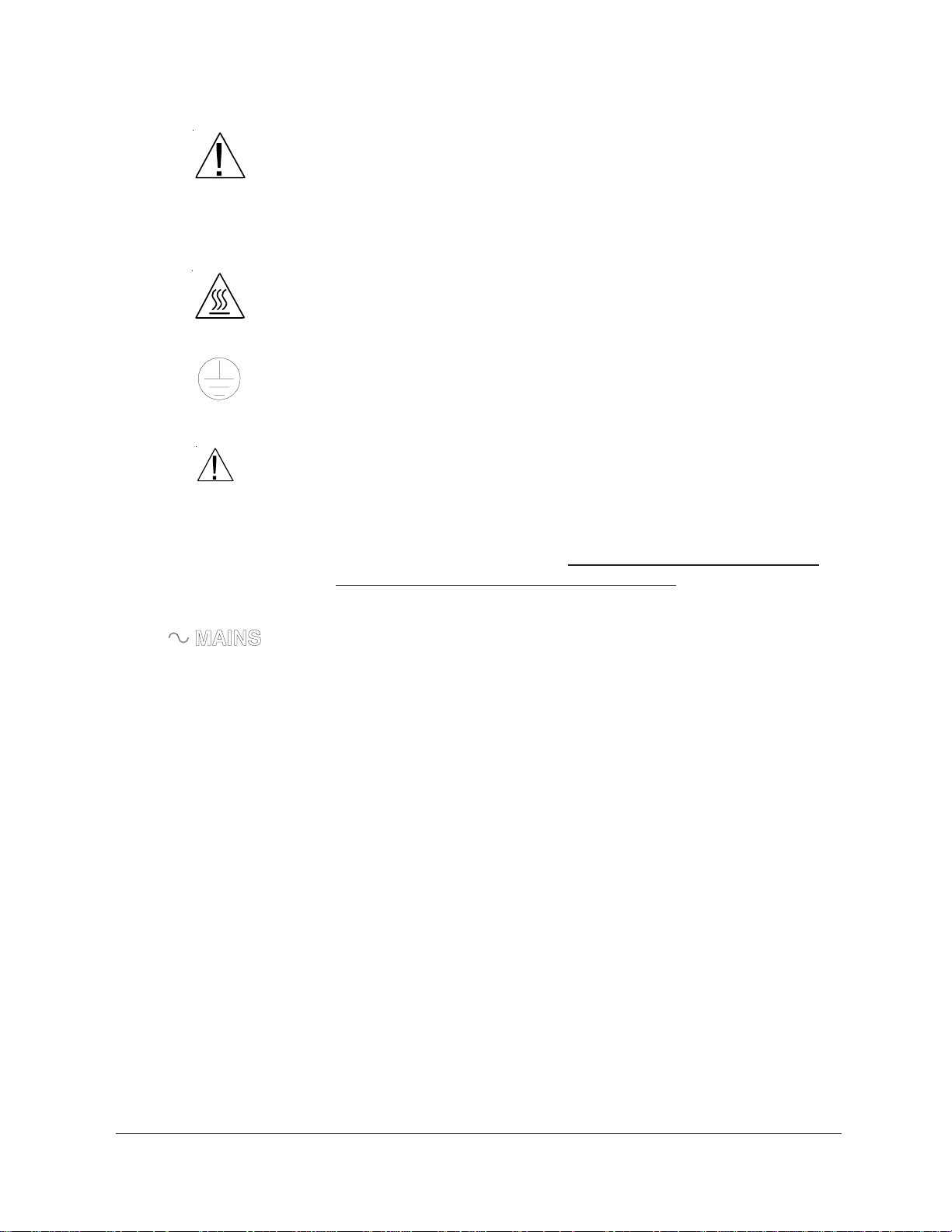

4

• Refer all service and repairs to qualified personnel.

In addition to the warnings previously listed, additional cautions are

posted throughout the manual. These warnings may be designated by an

appropriate symbol inside an equilateral triangle. General cautions are

General Caution

indicated with an exclamation point (see diagram, left). Read and follow

these important instructions. Failure to observe these instructions can

result in permanent damage to the unit, significant property damage, and

personal injury.

Hot surface cautions (see diagram, left) may be attached on or near hot

surfaces of the CMRV-4500. Avoid touching these surfaces when running

Hot Surface Caution

profiles at temperatures above 50°C.

The Protective Conductor Terminal symbol is used to indicate required

ground connections for your instrument electrical supply .

Protective Conductor

WARNING

AC Power Input Symbol

( O )

Supply OFF Symbol

When supplying power to this instrument, connect the protective ground

(earth) terminals of the instrument to the protective conductor of the

(supplied) line (MAINS) power cord. The main plug for the power cord

should only be inserted in a socket outlet (receptacle) provided with a

protective ground (earth) contact.

Do not use an extension cord (power

cable) without a protective conductor (grounding).

The ~MAINS symbol indicates instructions or connections for the AC

power supply . The AC Power input must match the electrical specifications listed on the label on the rear panel of the instrument. The supplied

AC Mains power cord must be attached to the connector labelled

~MAINS. This connection serves as a means of disconnect and should be

readily accessible.

The (O) symbol indicates the OFF position for the electrical switches for

your unit (AC Mains or accessories).

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 11

CHAPTER

5

2

UNPACKING AND ASSEMBLY

Unpacking the CMRV-4500

CAUTION

Some CMRV components, including the Air/Water Heat Exchanger, are

quite heavy. To avoid injury, obtain necessary assistance when lifting

and moving shipping cartons and heavier unpacked components.

Remove all components from the shipping container(s).

Remove any and all packing materials (styrofoam, etc.) from the

components.

V erify reception of shipped materials by comparing equipment items

with packing/parts list(s). Report missing items to CANNON

ment Company immediately.

®

Instru-

Damaged items

System components

Inspect each component for signs for damage. Report damages to the

shipper and to the CANNON

Retain all packing materials until the instrument is connected and functioning properly. If any component(s) must be returned to

CANNON

aged in the original shipping container. Refer to Chapter 19 of this

manual for instructions on returning defective equipment. Customers

outside the United States should contact the local CANNON® agent for

procedures on returning products to CANNON® .

Before beginning assembly , please verify that all components listed on

the packing slip are present, including:

CMRV-4500 chassis/controller

Air/Water Heat Exchanger

®

Instrument Company , the damaged item(s) should be repack-

®

Instrument Company immediately .

Main power cord

Pulley-wheel assembly

9 Matched rotors

9 Rings and threads

RS-232 interface cable

Small uncalibrated thermometer (0°C to +105°C)

Large calibrated ASTM thermometer (-46°C to +30°C)

3k-ohm temperature probe

CD-ROM with VISCPRO

®

software for Windows® XP

®

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 12

6

Set of weights:

One 150-gram weight • One hook-cage • Nine additional weights

1 Bottle of N105B with test sample and data sheet

Tubing and tube clamps

Plexiglas

®

T op Cover

Instruction & Operation Manual

9 Rotor bearing pins

10 Rotor locking pins

User-Supplied Equipment

The user must supply an electrical power source matching the electrical

requirements indicated on the rear panel of the CMRV-4500 model.

Computer

Cleaning supplies

®

An IBM-compatible computer with the W indows

XP® operating system

(see computer specifications sheet included with your instrument) and

printer are also required.

The following items are required for regular cleaning of the viscometer

cells between tests:

oil solvent

acetone

suitable solvent-resistant container for placing/cleaning rotors

vacuum source with trap for solvent and oil

flexible tube, about 150 mm long and 3-5 mm in diameter, connected

to the vacuum trap

two plastic squeeze bottles, each with an extension long enough to

direct oil solvent and acetone directly into the viscometer cells

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 13

CHAPTER

7

3

CMRV-4500 APPARATUS

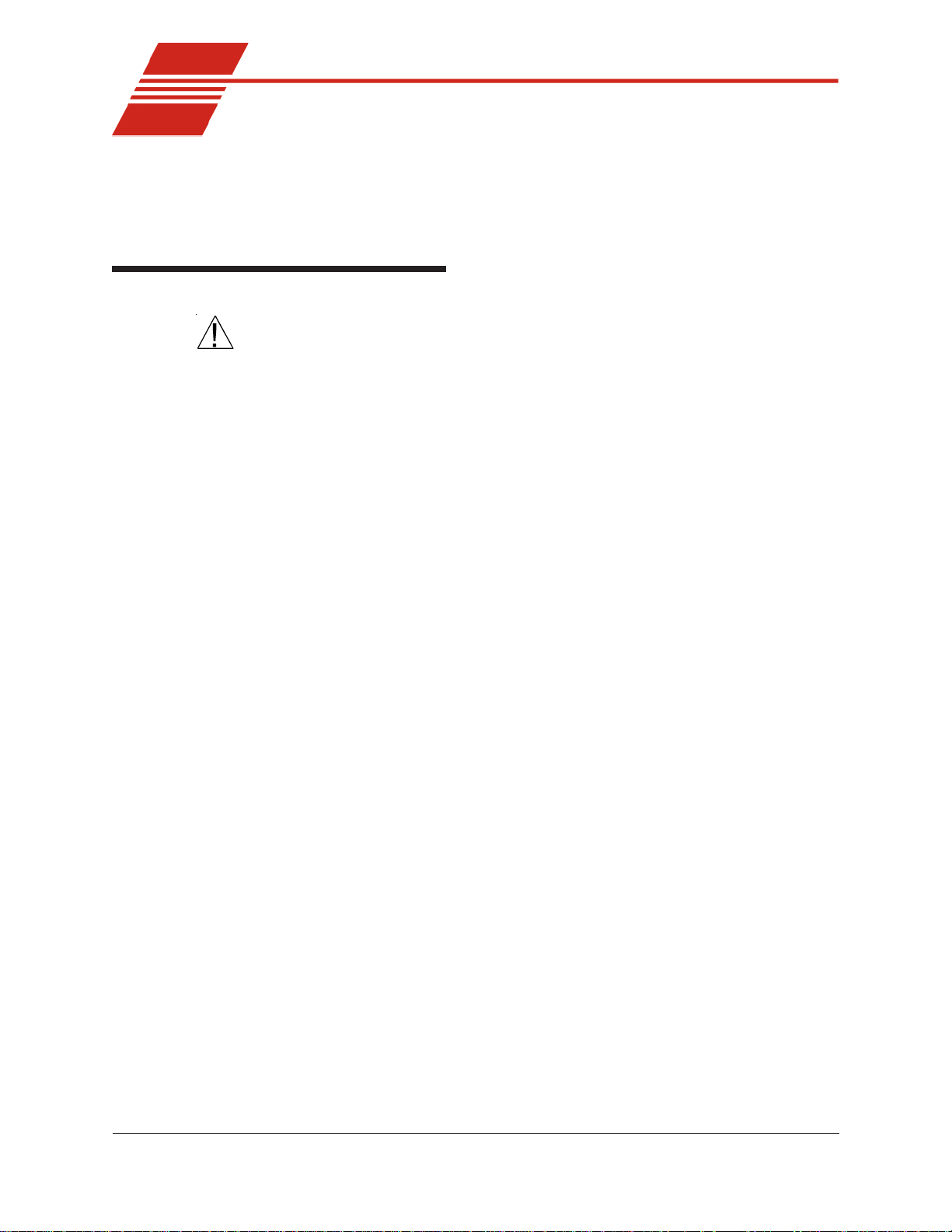

CMRV-4500 unit/accessories

The CMRV-4500 unit contains an aluminum block with

a heater for warming the

block. Nine viscometric cells

are closely fitted into nine

holes in the block (see photo).

There are also two thermometer wells in the block.

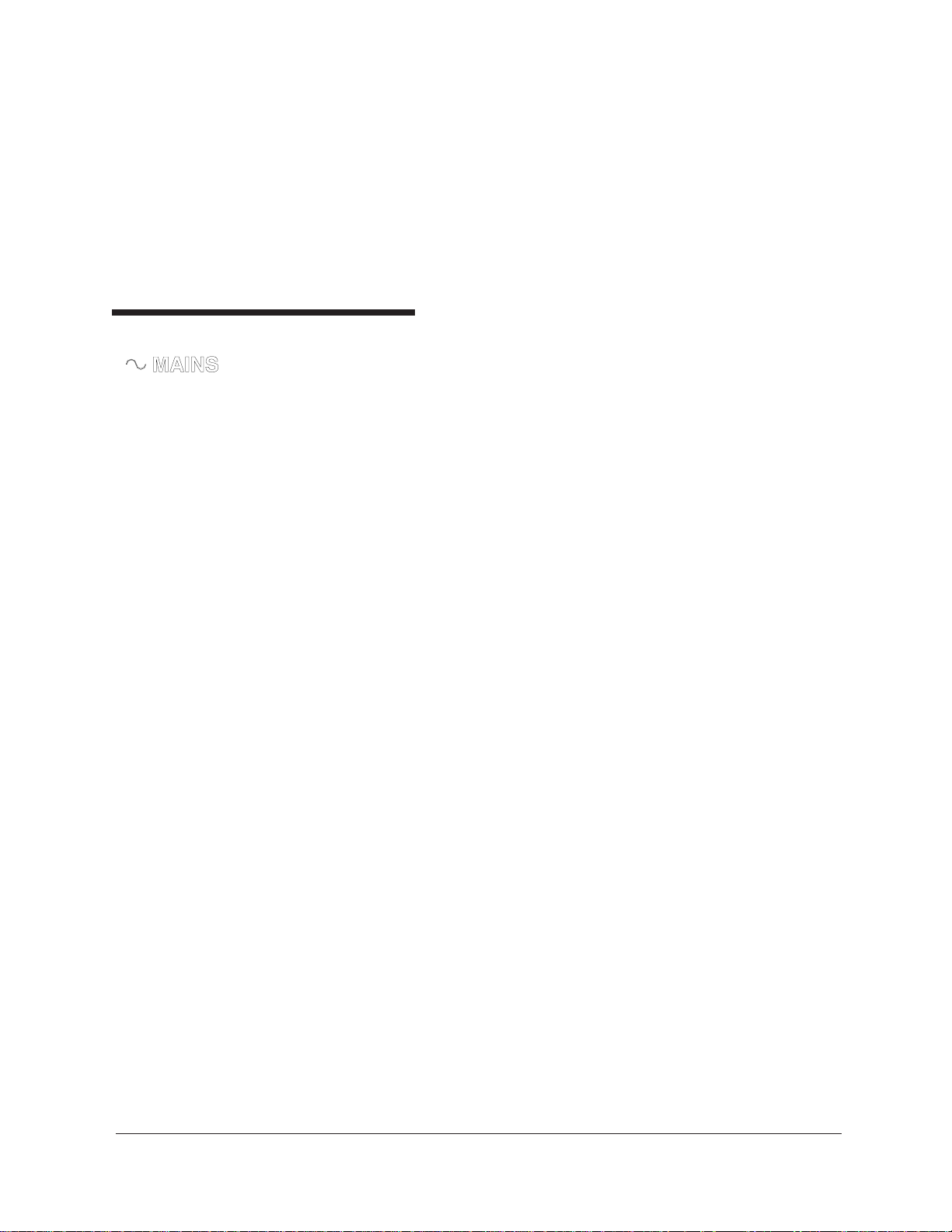

Lower rotor bearing

Each viscometric cell

consists of an aluminum

block aperture with a

rotor resting in a stainless

steel cup at the base. The

rotor is attached to a rotor

shaft with a pivot point at

the bottom. The pivot

point fits a mating

conical depression at the

bottom of the stainless

steel cup; this mechanism

serves as the lower

bearing. The standard rotor composition is hardened stainless steel. The

drive line rotor composition is Delrin

(NOTE: The drive line rotors/pins/

weights must be purchased separately

from CANNON®.)

DESCRIPTION

CMRV-4 unit with rotors inserted

and thread wound on pulley-wheel

Rotor for oil testing (top) and

drive line lubricant testing

®

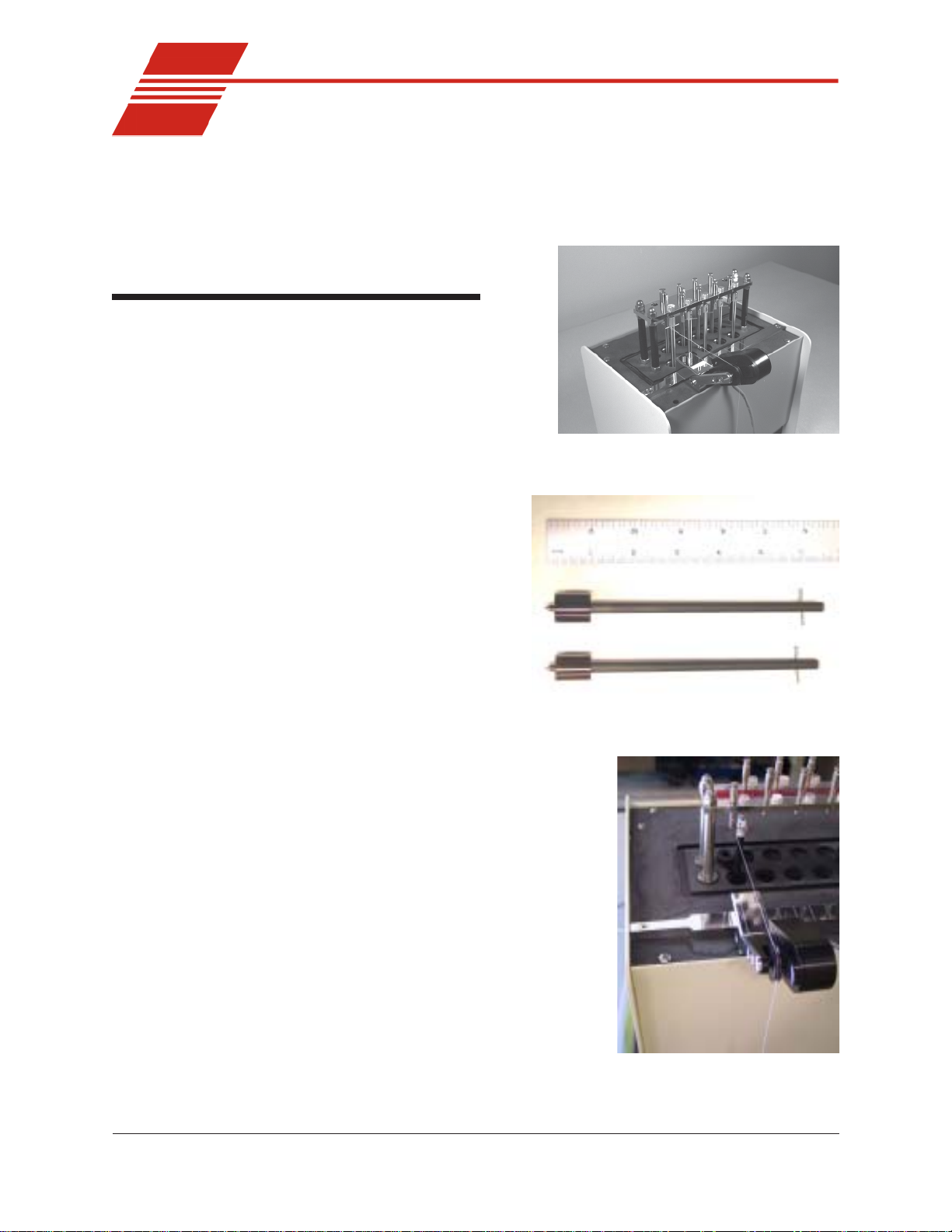

Upper rotor bearing

CANNON

The upper bearing consists of a brass

insert at the top of the rotor shaft with

a 1.2 mm hole on the shaft axis. A

cylindrical rotor pin is inserted

through the upper bearing plate about

one or two millimeters into the hole

on the shaft axis.

Upper bearing assembly with

rotor and rotor locking pin in

place

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 14

8

Rotor crossbar

Rotor locking pins

Pulley-wheel assembly

The rotor crossbar is

used to hold the loop

at the end of the

thread. It also serves

as an indicator for

(optional) manual

timing of rotor

rotation.

The rotor locking pins

String on rotor and pulley-wheel assembly

are used to prevent

unwanted rotor rotation. When the locking pin is lowered over the rotor

crossbar (see photo), rotation is prevented. When the pins are in the

raised (detent) position, the rotors are free to rotate.

The pulley-wheel

assembly consists

of a V-channel

timing wheel with

a digital-optical

sensor permitting

precise measurement of the wheel

rotation. The

pulley-wheel base

is designed to be

fitted to the

CMR V-4500 slide

track adjacent to

the viscometric

cells. The probe

Slide track with pulley-wheel assembly

cable is connected to the jack on the front of the CMRV-4500 housing.

Winding thread

Slide track

CANNON

The thread used for CMRV-4500 testing is a single, nonelastic strand of

70 cm (28") winding thread of silk, cotton, or similar material (Coats

North America or comparable brand, 0.1 mm radius) with a loop on one

end. One end is wound around the CMRV-4500 rotor. The other end of

the thread is tied to a small rigid plastic ring from which the test weight

may be suspended.

The pulley-wheel assembly is designed to interlock with the pulleywheel slide track and move laterally so it can be aligned with the scored

marks on the track opposite each of the nine rotor shafts.

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 15

9

Hook-weights

Temperature probe

Thermometers

Hook-weights are hung on the plastic ring at

the free end of the thread to apply the required

force to the rotor during yield stress and

viscosity measurements. Nine disk weights,

one hook-cage, and one larger hook-weight are

provided. Weights vary depending on the

ASTM Method used for testing.

CMRV-4500 block temperature is detected by

a 3k-ohm temperature probe, which must be

seated securely in the thermistor aperture at the

rear of the CMRV housing and plugged into

the electronic chassis.

Hook-weights

The CMRV-4500 unit is shipped from CAN-

®

with two thermometers to be used to check the temperature of the

NON

block.

The long thermometer used for the probe and cell calibrations is a

PRINCO mercury-thallium calibrated thermometer with a range of

-46°C to +30°C in .2°C increments and an accuracy of ± 0.01°C

below 20°C.

NOTE

If a thermometer is removed from the CMRV-4500 when the unit is

cooling, plug the thermometer aperture in the Plexiglas® cover to prevent

ice formation around the rotors.

The shorter, high-temperature uncalibrated thermometer has a range

of 0°C to 105°C in 1°C increments with an accuracy of ± 1°C.

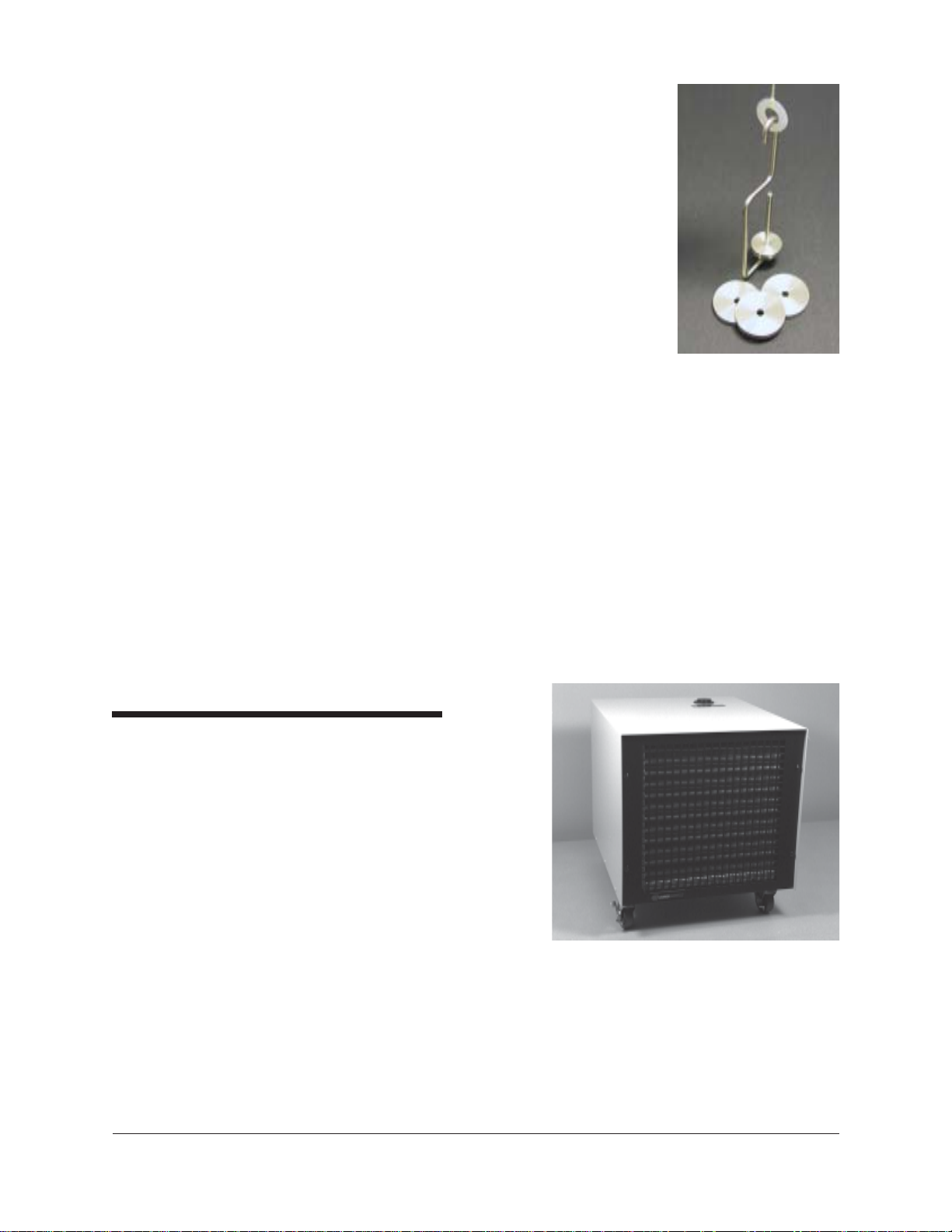

Air/Water Heat Exchanger

CMRV-4500 cooling is

accomplished with internal

thermoelectric cells and an

external Air/W ater Heat

Exchanger circulating a

mixture of water and

antifreeze to remove heat

from the thermoelectric

modules.

The Air/Water Heat Exchanger contains the electronics necessary to monitor

the coolant flow rate and regulate the action of the circulating pump

during the running of ASTM-specified temperature profiles. The Heat

Exchanger also supplies DC power for the operation of the CMRV

thermoelectric modules.

Air/Water Heat Exchanger

(see chapter 4 for Setup diagram)

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 16

10

Front panel operations

CMRV front panel

Control features

CMRV front panel control features are simple and functional. The central

switch on the front panel is the power switch for the unit. The lightemitting diodes (LEDs) above the switch indicate function of the heating

and cooling systems. The Sensor connection on the right side of the

panel mates with the cable from the pulleywheel optical sensor. The Start

Test button on the left side of the panel is used to initiate CMRVcontrolled testing and calibration routines. The Yield and Viscosity

LEDs light during yield stress or viscosity testing.

For additional details on front panel operation, refer to the calibration and

testing chapters of this manual.

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 17

CHAPTER

11

4

CAUTION

Physical placement

CAUTION

Control unit placement

SETUP

The instructions in this chapter are for setting up a single CMRV-4500

with the Air/Water Heat Exchanger. For additional information on multiunit configurations, see APPENDIX D.

Do not apply power to the CMRV-4500 or Heat Exchanger until all

connections are secure.

Some CMRV components, including the Air/Water Heat Exchanger, are

quite heavy. To avoid injury, obtain necessary assistance when lifting

and moving these components.

Place the CMRV-4500 on a stable laboratory bench or table top within 10

mm of the front edge. This will allow the weight suspended from the

pulley-wheel assembly to clear the edge of the table during viscosity and

yield stress tests. Allow 30.5 cm (12") of clearance to the back and sides

of the unit.

A/W Heat Exchanger

CAUTION

Thermometer placement

NOTE

Place the Air/Water Heat Exchanger below the table top on which the

CMRV-4500 is placed. The unit may be located within the parameters

permitted by the length of the hoses and cables shipped with the unit.

Do not obstruct the front or rear cooling vents on the Air/Water Heat

Exchanger.

When in use, the large thermometer (-46°C to +30°C) is placed in the

thermometer well on the left side of the CMR V-4500 unit (seen from the

front).

When in use, the small thermometer (0°C to 105°C) is placed in the thermometer well on the right side of the CMR V-4500 unit (as seen from the

front).

If the mercury column in a thermometer has separated during shipment,

read the instructions included in APPENDIX C. These instructions offer

several methods for joining separated mercury columns.

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 18

12

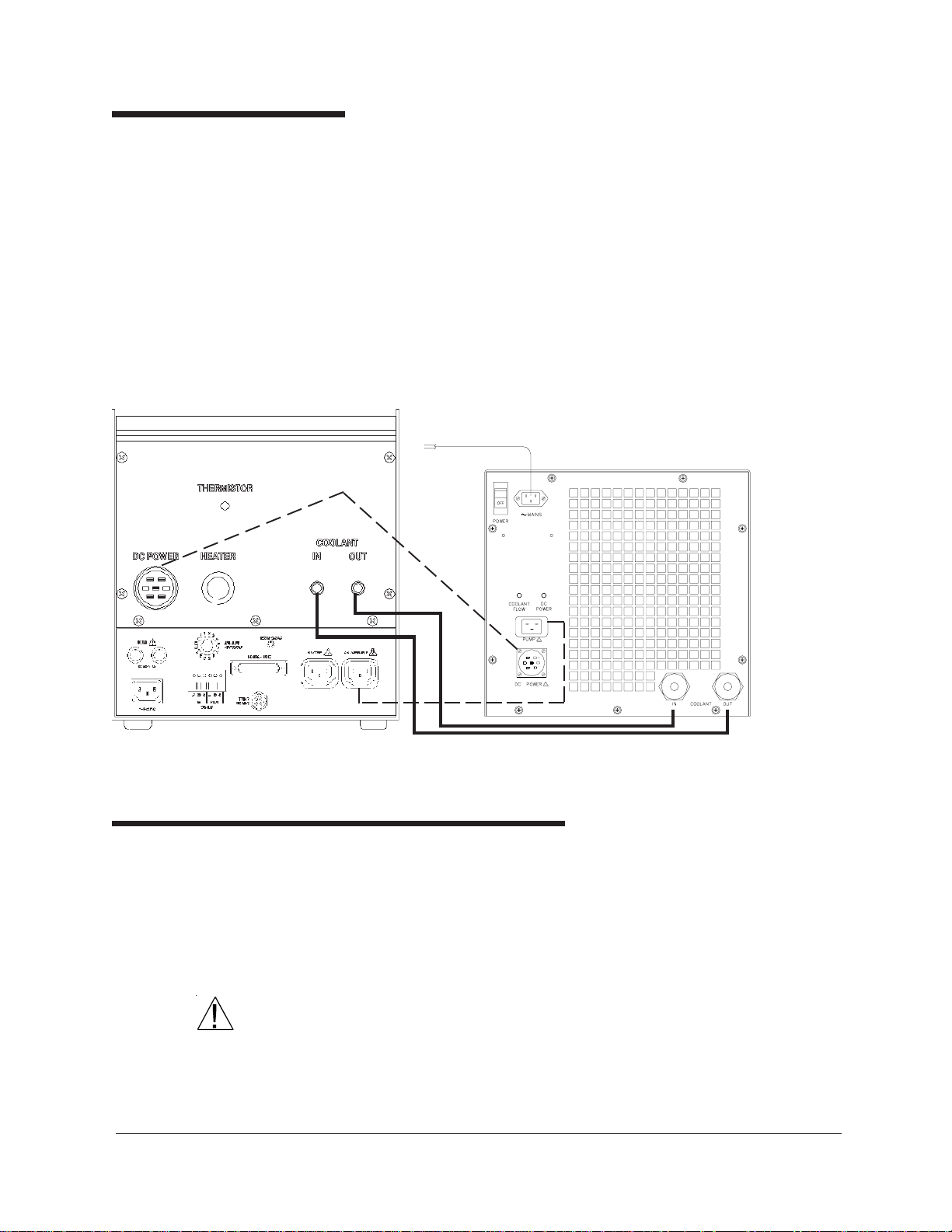

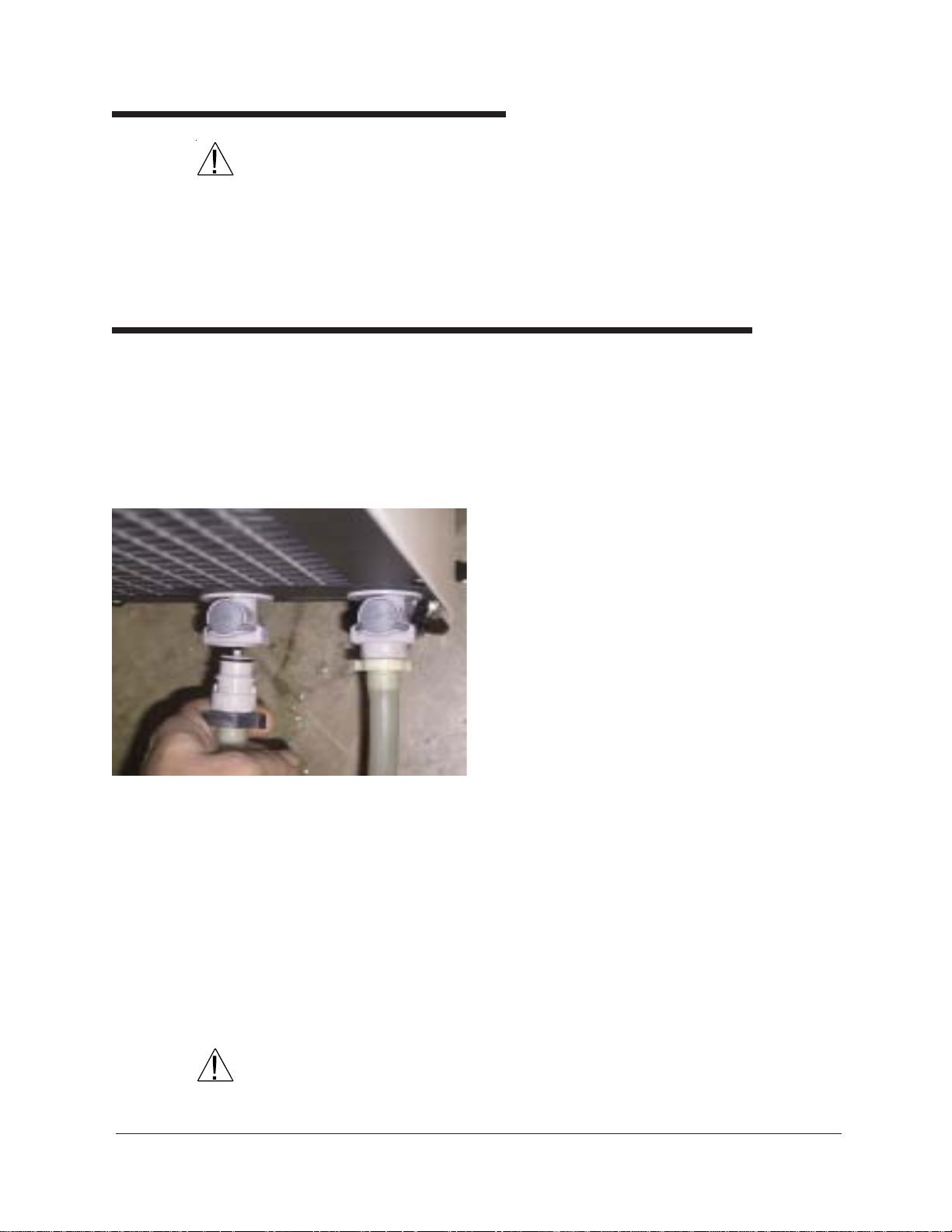

Tubing connections

There are two tubing connections on the rear of the CMRV-4500 housing

(see diagram, next page). The fitting on the left is the coolant INLET (for

introducing coolant to the CMRV-4500) and the fitting on the right of the

rear panel is the coolant OUTLET (for returning coolant to the Ex

changer). Clamp the open ends of both hoses to these fittings, then secure

the hoses to the appropriate bulkhead fittings on the Air/Water Heat

Exchanger using the bulkhead inserts provided with the tubing (see

Figure). The fittings will snap into place. To release and remove the

tubing from the Air/Water Heat Exchanger, push down on the button on

the bulkhead fittings to release the connector locking clips.

CMRV-4500 tubing (solid lines) and electrical (dotted lines) controller/AWHE connections

Filling the Air/Water Heat Exchanger

Obtain a supply of quality automotive antifreeze (ethylene glycol) and

mix it with water in a ratio of 30 percent antifreeze to 70 percent water.

Do not mix antifreeze types in the Air-Water Heat Exchanger.

After you have secured the Exchanger tubing connections (see previous

section) pour this antifreeze/water mixture into the reservoir opening on the

top of the Air/Water Heat Exchanger until it is full (approximately 4 liters).

CAUTION

NOTE

CANNON

Ethylene glycol is a toxic substance. Use proper safety precautions when

handling. Follow appropriate MSDS instructions.

Depending on the amount of fluid displacement in the coolant lines, it

may be necessary to add additional antifreeze/water mixture to the

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 19

Exchanger when the unit commences operation. Y ou will be able to

observe the liquid circulating inside the reservoir from the opening at the

top of the Exchanger during normal operation. If air bubbles are consistently visible in the coolant lines, add additional mixture until the Exchanger is full.

13

CAUTION

The water-antifreeze mix should be replaced annually for reliable performance and to prevent corrosion of internal components (see Flushing

and draining the Air/Water Heat Exchanger, this chapter).

Electrical /serial connections

A/W Heat Exchanger

Plug the male end of the DC power cable into the DC POWER OUT

fitting on the rear panel of the Air/Water Heat Exchanger and turn the

locking clip clockwise to secure the connection. Attach the other end of

the cable to the receptacle labelled DC POWER at the back of the

CMRV-4500 unit (see figure, previous page). This connection provides

power to the thermoelectric cooling modules.

Insert the power cable for the Air/Water Heat Exchanger into the receptacle on the Exchanger rear panel. Secure the power cable in place by

tightening the Phillips screw on the cable clamp.

Make sure the Air/Water Heat Exchanger power switch is in the OFF

position; then insert the power line cord from the Exchanger into an

appropriate power source for your unit.

Before providing mains power to the unit, check the label on the rear

panel of the Exchanger to verify that the electrical specifications for the

unit match those of the power supply.

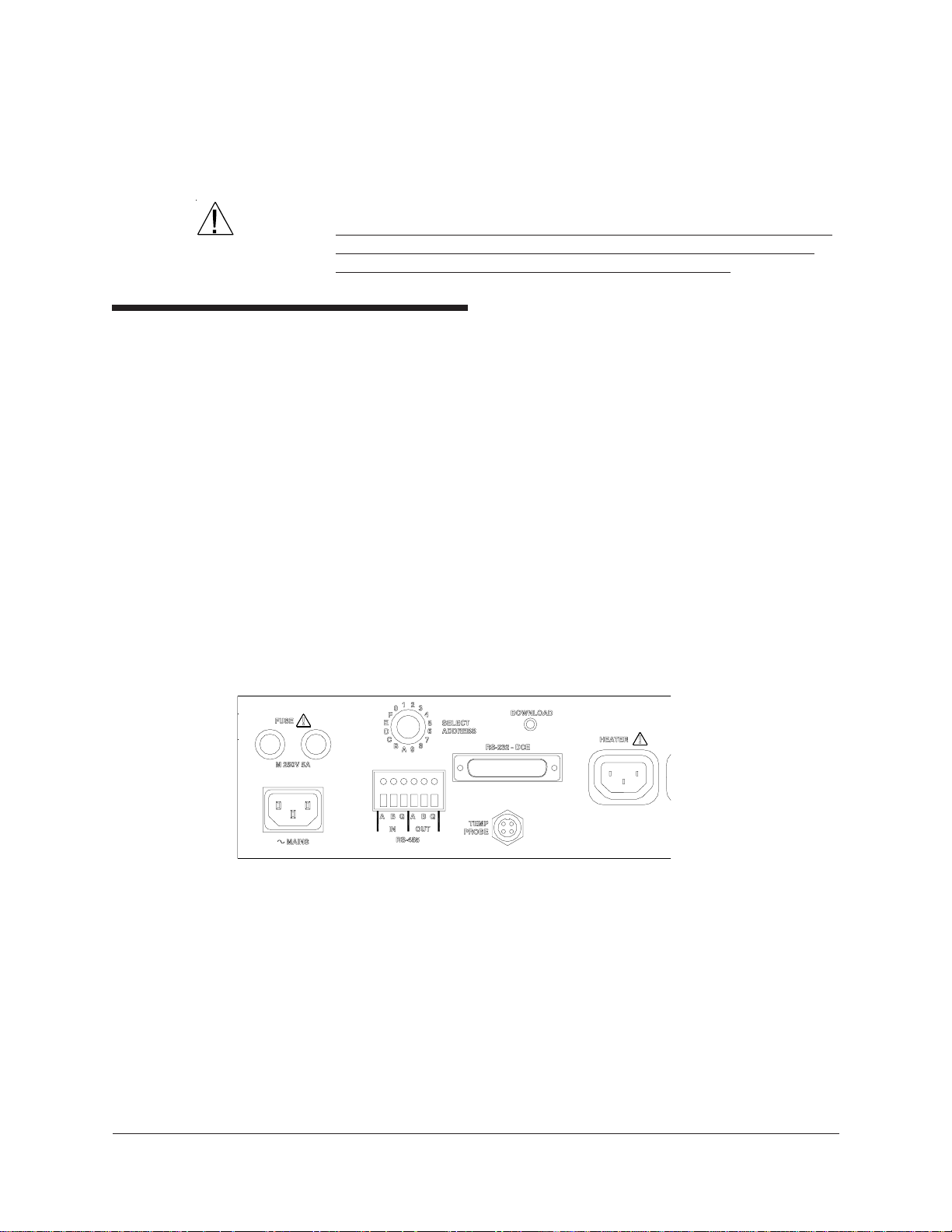

Thermistor

Figure 11: CMRV rear panel

Attach the M-F three-prong connector cable from the Exchanger PUMP

outlet to the PUMP receptacle on the CMRV-4500 controller (see figures on

pages 12-13). This power connection permits CMRV-4500 control of pump

operation.

Insert the Lemo

TEMP PROBE on rear of the CMRV controller (see Figure 11). Insert

the probe tip as far as it will go into the hole marked THERMISTOR on

the rear of the CMRV-4500 chassis.

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

plug from the temperature probe into the jack marked

®

Instrument Company

Page 20

14

Heater

CMRV-4500 power cord

Serial connections

NOTES

Insert the heater plug from the upper section of the CMRV-4500 housing

into the HEATER receptacle on the rear panel of the CMRV controller.

Make sure the CMRV-4500 power switch is in the OFF position. Then

insert the power line cord from the rear panel of the CMRV controller

into an appropriate power source for your unit

Before providing mains power to the unit, check the label on the rear

panel of the Exchanger to verify that the electrical specifications for the

unit match those of the power supply. Use only the supplied, approved

appliance cords for the CMRV.

T o connect a single CMRV -4500 instrument to the host computer,

connect the computer cable to the RS-232, DB-25-pin socket at the rear

of the CMRV-4500 controller and secure the cable connection with the

two small screws on the ears of the plug. Attach the other end of the cable

to the RS-232 port at the rear of your computer.

COM 2 and COM 4 use the same IRQ settings on most computers,

meaning that they cannot be used simultaneously. The COM 1 and

COM 3 ports have the same problem. Do not try to use a device on COM

4 if you are using COM 2 for the CMRV instrument.

Some display adaptors (in particular, S3, 8514A and ATI mach 8) have

an address conflict with COM 4 ports. If this is the case, you may need to

use another COM port or replace your current display adaptor.

RS-485 serial connections

T o install multiple CMRV units using RS-485 serial cable connections,

see the multi-unit configuration instructions in APPENDIX D.

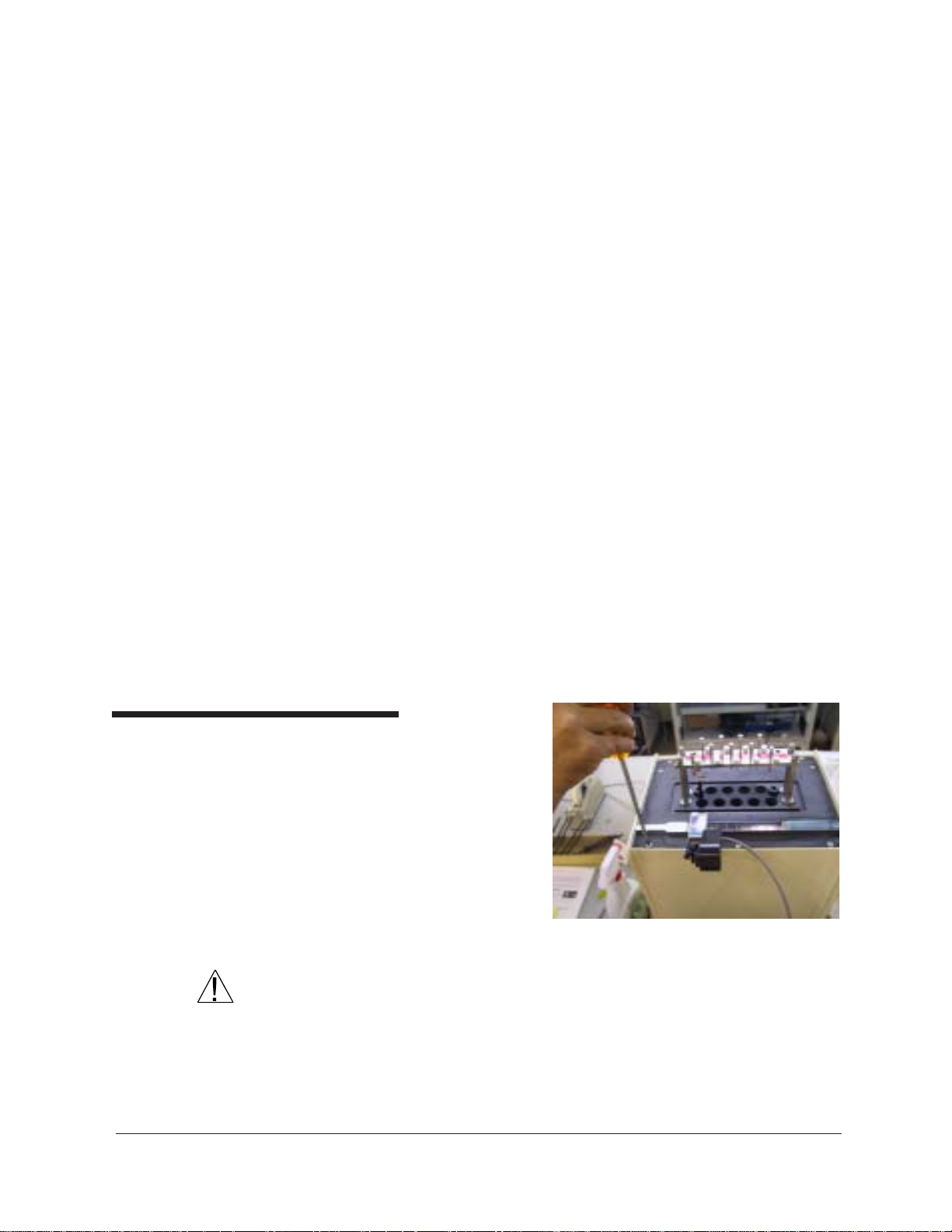

Pulley-wheel installation

T o install the pulley-wheel

assembly atop the CMRV:

1. Remove the left screw

from the front of the

upper panel (see photo).

This will provide

clearance to install the

assembly on the slide

track.

CAUTION

Use care in handling the pulley-wheel assembly to avoid damage to the

wheel or the movement sensor.

Removing screw to install pulley wheel

CANNON

2. Install the pulley-wheel assembly by sliding it onto the left end of the

slide track with the pulley-wheel facing out (see photo).

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 21

15

CAUTION

NOTE

Installation notes

Download button

Make sure that the

assembly is seated

securely on the

track.

3. Replace the

left front

screw . This

Pulley-wheel assembly mounted on slide track

will prevent

the assembly from sliding off the track.

4. Plug the free end of the pulley-wheel sensor wire into the jack

labelled WHEEL on the front of the CMRV-4500 controller.

To disconnect the sensor, pull it out by the knurled portion of the plug.

The CMRV-4500 is capable of receiving firmware updates from the

computer via the DOWNLOAD button on the rear of the electronic

®

chassis. Should such an update be required, CANNON

will provide

detailed instructions regarding the download procedure for updating the

firmware.

NOTE

If the DOWNLOAD button is pressed inadvertently, switch off the CMRV4500 power for at least four seconds, then

restore power to the unit.

Setting the CMRV instrument address

When installing/connecting a new CMR V

instrument, you must set the instrument

address using the SELECT ADDRESS

dial on the rear of the CMRV controller. This dial offers 16 settings (0-9,

A-F).

Procedure

CAUTION

T o set the address, rotate the dial (see photo) to a setting not currently in

use by other CMRV instruments.

The MRVW software will not function correctly unless each networked

CMRV instrument is set to a different address (see APPENDIX D for

multi-unit configuration).

Address selection knob

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 22

16

Cleaning the instrument housing

CAUTION

Before cleaning the CMRV housing, turn off the instrument and unplug

the power cord. Do not clean the instrument unless the cell temperature

is within 10°C of ambient.

Periodically clean the outside of the unit with a damp cloth moistened

with water and/or a mild detergent solution.

Flushing and draining the Air/Water Heat Exchanger

The water-antifreeze mixture should be replaced annually for reliable

performance and to prevent corrosion of internal components. Do not

mix antifreeze types in the Air-Water Heat Exchanger.

T o flush fluid from the Exchanger and CMRV -4500, obtain replacement

antifreeze, a funnel, a drain bucket and a supply of warm water. Then

complete the following procedures:

Flushing fluid from the Exchanger

1. Turn off the Heat Exchanger power switch

to remove power from the Exchanger.

2. Detach the quick-connect fitting securing the

tubing from the CMRV-4500 to the IN

connection on the Exchanger (see photo) by

pushing down on the release button while

pulling the hose connection out. Place the

tube end in the drain bucket and pull the

hose off of the ribbed section of the fitting.

Fluid will begin draining from the CMRV4500 and Exchanger.

Removing the Exchanger tubing connection

4. Turn on the Exchanger power switch to engage the Exchanger

circulating pump. Fluid from the Exchanger and CMRV-4500 will

flow into the drain bucket.

5. Immediately begin adding warm water to the Exchanger reservoir

through the funnel and continue as it is pumped out into the drain

bucket until the water exiting the drain hose into the drain bucket

flows clear.

6. Stop adding water to the reservoir and immediately turn off the Heat

Exchanger power switch.

CAUTION

CANNON

Do NOT permit the Exchanger pump to operate without fluid in the

system. Doing so will damage the pump.

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

3. Open the lid of the Exchanger reservoir and

place the funnel in the opening.

®

Instrument Company

Page 23

7. Replace the connector on the Exchanger hose, and reattach the

connector to the fitting on the Exchanger (see photo).

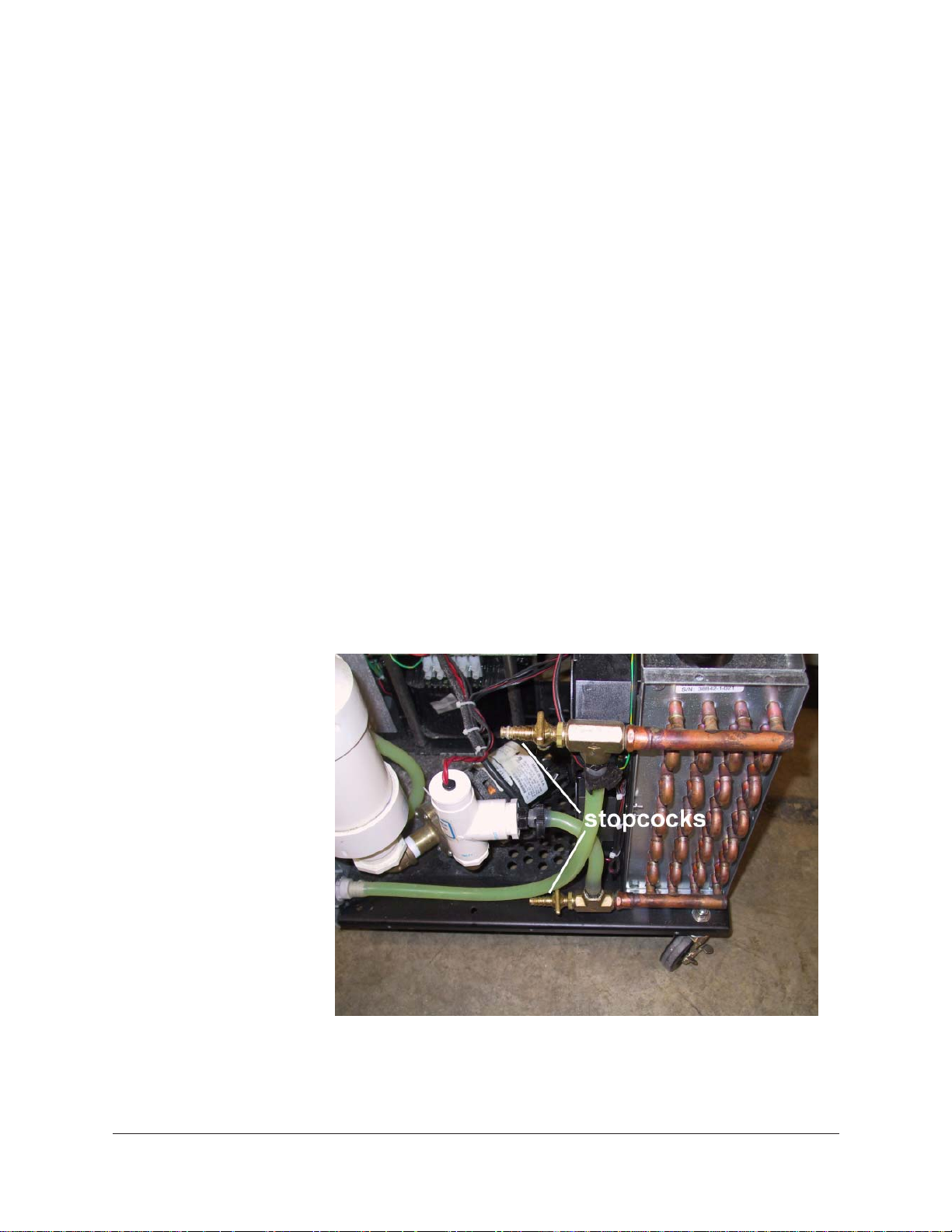

Draining fluid from the Exchanger

After the antifreeze mixture has been flushed from the Air/Water Heat

Exchanger per the preceding procedure, drain the system as follows:

1. Make certain that the Heat Exchanger power is OFF, then remove the

external housing from the Air/Water Heat Exchanger by removing

the six screws securing the housing to the sides of the frame (three

screws on each side of the unit) and the six screws on the top and

sides of the rear panel.

2. Locate the twin stopcocks at the top and bottom of the radiator (see

photo, next page). Attach a drain hose to the bottom stopcock and

place the opposite end of the hose in a drain bucket.

3. Open the top and bottom stopcocks by turning them parallel to the

nozzle and permit water to drain from the radiator. Then close the

stopcocks and remove the drain hose from the bottom stopcock.

17

NOTE

A small amount of water/antifreeze mixture may remain in the tubing

leading from the external connector to the reservoir. If desired, this fluid

may be drained by pulling the hose off of the ribbed section of the quickconnect fitting previously installed. Reattach the tubing before completing

the remainder of this procedure.

CANNON

Heat Exchanger with housing removed and stopcocks highlighted

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 24

18

4. Replace the external housing on the Air/Water Heat Exchanger and

secure it with the six screws previously removed. If necessary, reseat

the gasket around the reservoir opening with a small screwdriver.

5. Add water-antifreeze mixture to the Exchanger per the earlier

instructions in this chapter to complete the water-antifreeze flush and

drain procedure.

FHP MOTOR

NOTES

For rountine maintenance and improved bearing life expectancy , a few

drops of non detergent “twenty weight” oil can be added every 12 months.

Fans should be cleared of dust/other material on a regular basis.

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 25

CHAPTER

19

5

VISCPRO® for Windows® XP

VISCPRO® is a powerful new software product providing a generic

instrument interface for controlling and operating your CANNON

instrument(s) via computer. VISCPRO® also includes reporting/analysis

modules for processing and displaying sample data.

VISCPRO® INSTALLATION

®

Installing VISCPRO® software

T o install the VISCPRO® software, follow the instructions below in the

sequence presented. Make certain that you complete the sections on

checking instrument settings and calibration data. If you encounter

difficulties at any stage in the installation process, call CANNON

service at 814-353-8000.

Computer requirements

IBM-compatible computer with pentium processor and Windows® XP

installed and operating normally • SVGA compatible display •

32 MB RAM • 200 MB hard disk space • CD-ROM drive • serial port

®

®

®

Windows® XP

®

installation

Installation actions

1. Turn on your computer. Wait for the Windows® software to load.

2. From the Windows

the first VISCPRO® installation CD-ROM into the disk drive.

3. Double-click the Add/Remove Programs icon and follow the

Windows prompts to complete the installation procedure. The

executable file for VISCPRO

The installation program will:

®

Start Bar click Settings/Control Panel. Insert

®

software installation is SETUP.EXE.

create a directory for your data files. The default directory is

C:\Program Files\Cannon Instrument\VISCPRO).

write SETUP information to the Windows

®

registry.

copy the software executable file and other necessary files to the

directory you specify.

update other files in your Windows

compatible with the current VISCPRO® software.

place a shortcut icon for the VISCPRO

Windows

®

desktop.

®

directories to versions fully

®

executable file on your

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 26

20

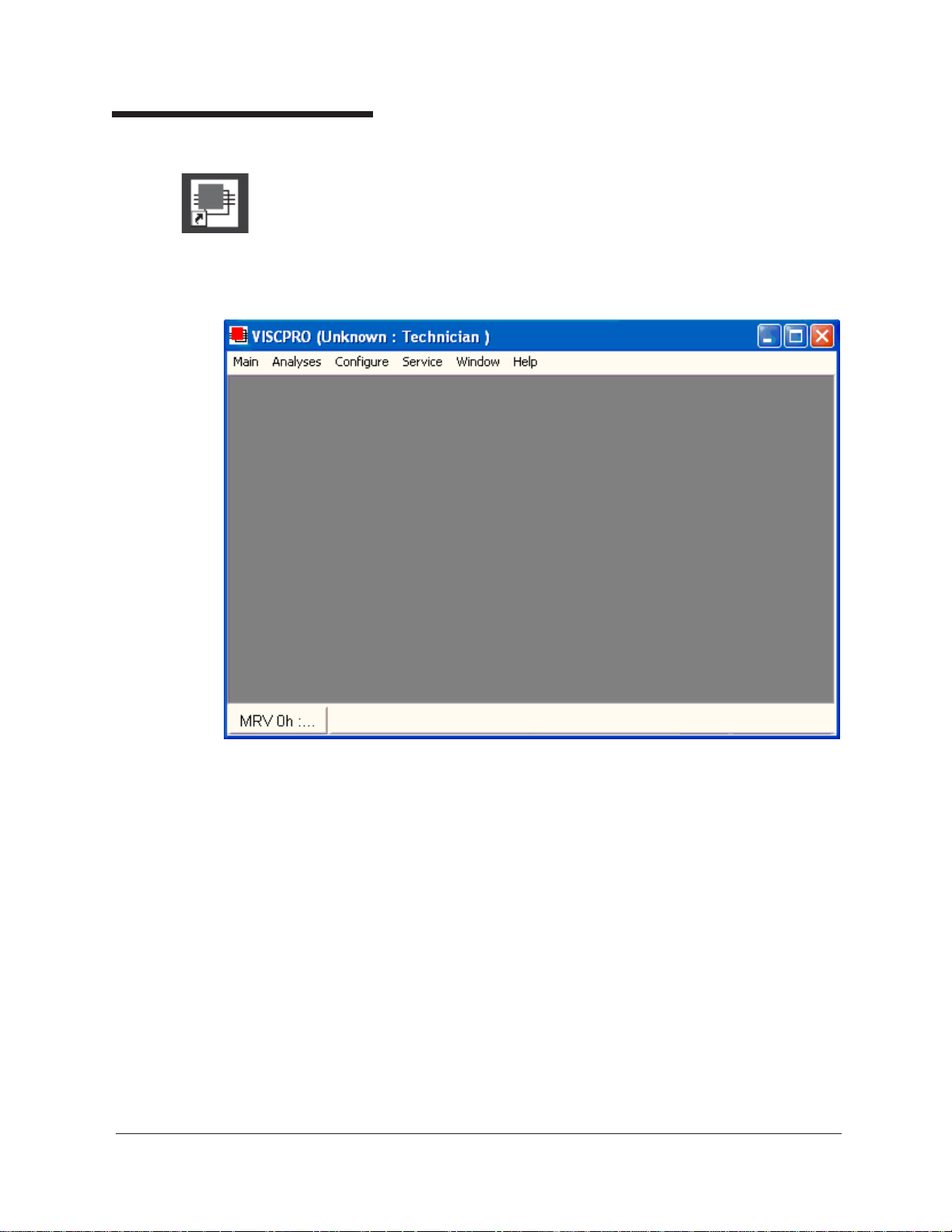

Running the software

Loading software

Make certain that your CMRV instrument is properly connected to your

computer and the CMRV power switch is ON. Then start the VISCPRO

software by double-clicking the VISCPRO® icon on your W indows

desktop. Or click Start/Programs/VISCPRO/VISCPRO.EXE).

Right now , your computer monitor should look like this:

®

®

The VISCPRO® primary display

®

The VISCPRO

primary display window is framed on the top by the

VISCPRO® title bar and menu bar, and on the bottom by the VISCPRO

status bar.

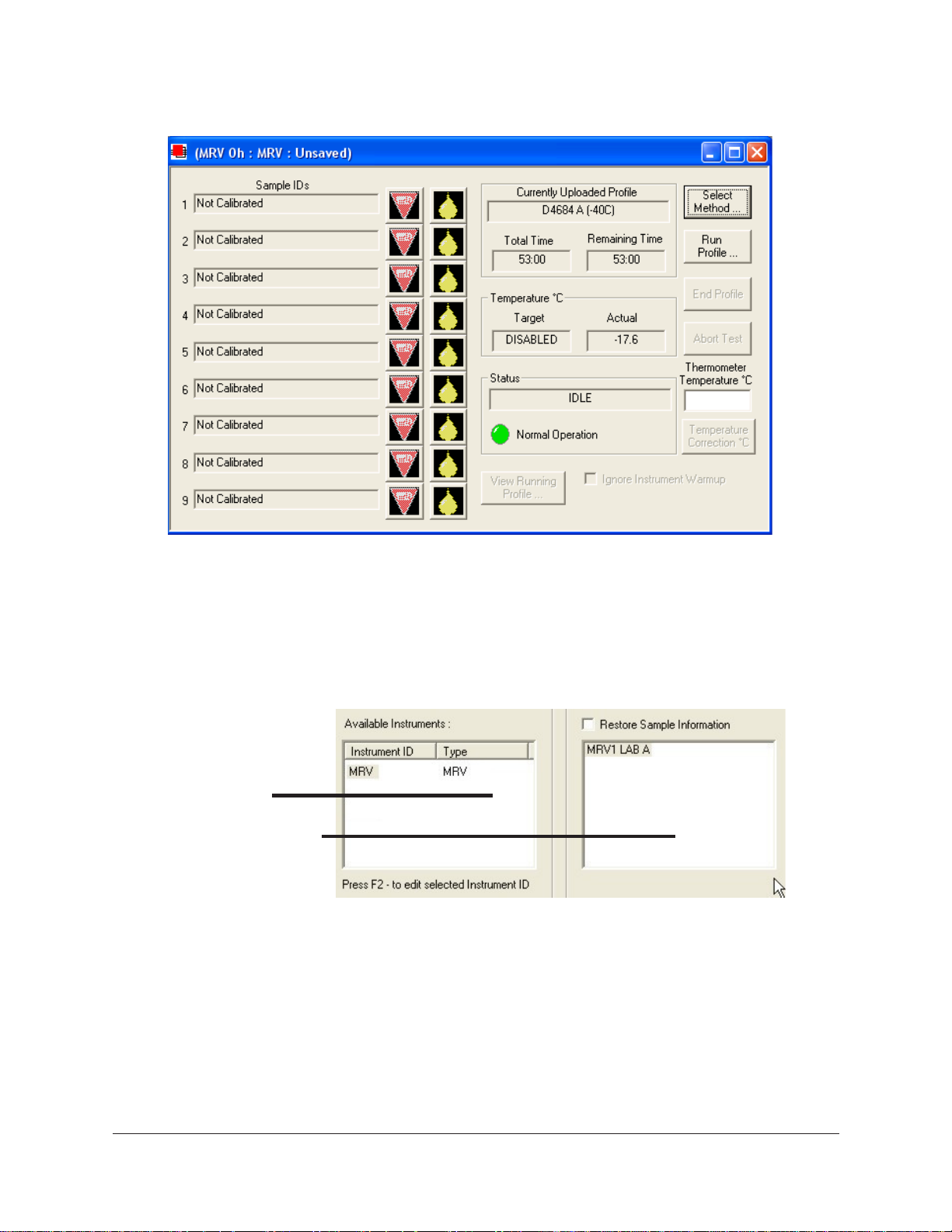

Displaying the Instrument View window

The application window can be configured to display child windows, such as

the Instrument View window, which describes your CANNON® instrument and provides controls for running tests:

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

®

Page 27

21

The Instrument View window

NOTE

Instrument ID/T ype

Instrument Configuration

To display the Instrument View window, click View Instrument from the

Main menu. The View Instrument window will appear. Then click the

MRV instrument ID to display the list of available configurations. For

now, select the default configuration and click OK.

If the Available Instruments list box is blank, your instrument(s) may not

be on-line. Check cable connections and make certain the instrument

power switch is ON.

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 28

22

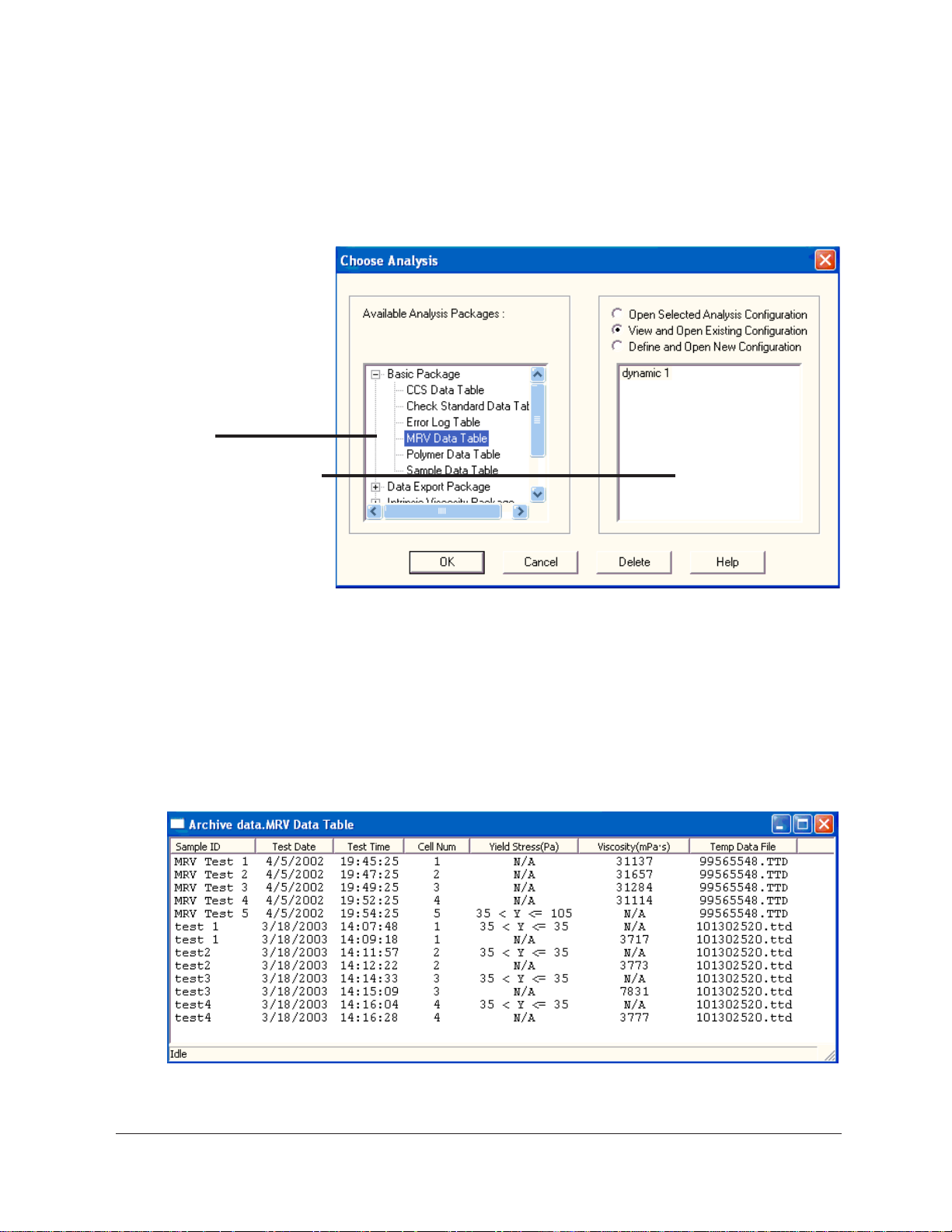

Viewing report data

After you have completed CMRV calibration and testing (see next

chapters), you will be able to display a report window with CMRV-4500

test results. To access the database and display test data, click Analyses/

View Analysis. Then select MRV Data Table from the list of available

analyses:

Report T ype

Report Configuration

The Choose Analysis window

Choose the desired report configuration from the list of available configurations and then click OK to open the Analysis Configuration

window. Then select report configuration options (see Chapter 13 for

more information) and click OK to generate the analysis from existing

sample data. If the report window is blank, you may have to change the

Date Filter options to include the desired range of samples from the

database.

The Sample Analysis Table window

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 29

23

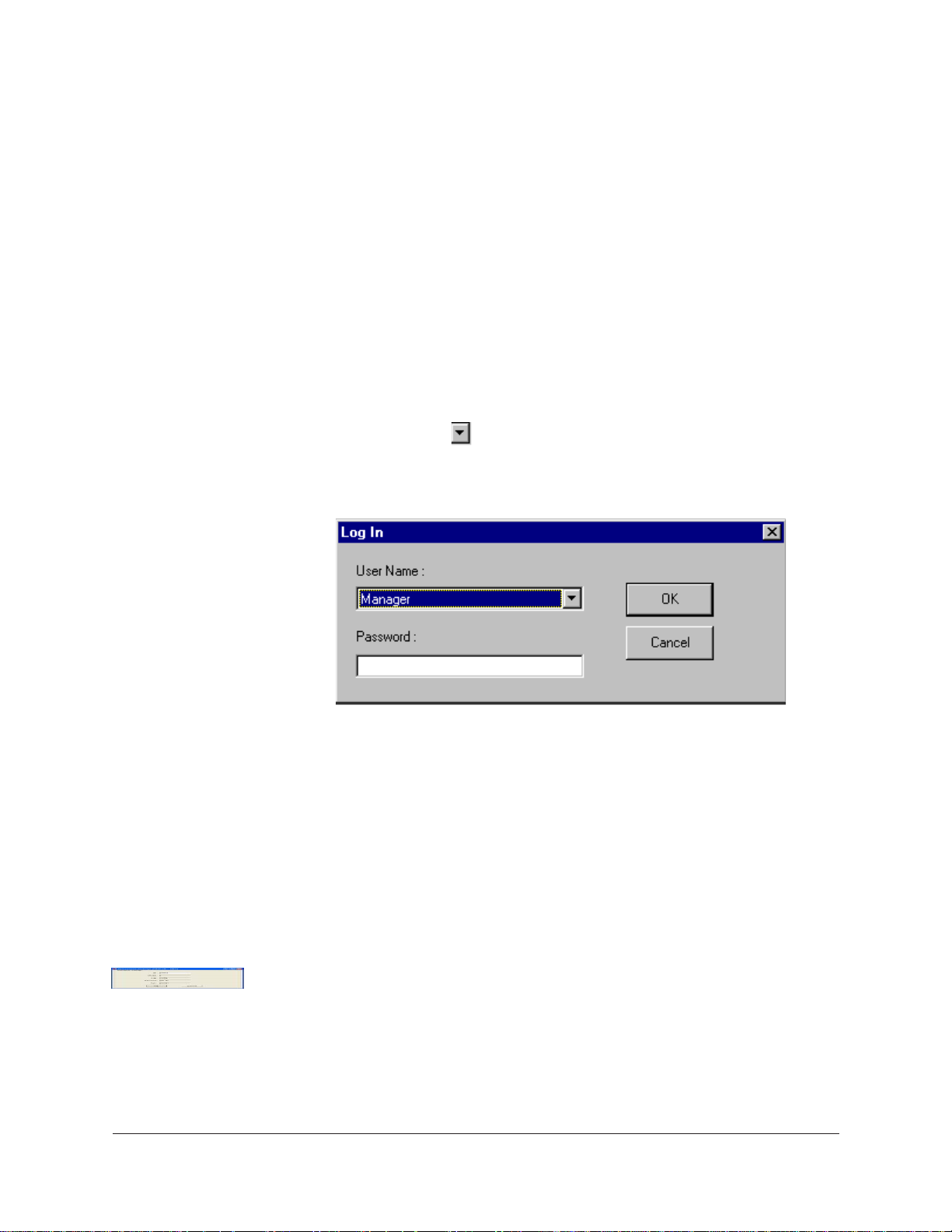

Checking Configuration data

Configuration protection

Logging in

Follow the procedures in the next several sections of this chapter to select

and verify the instrument and calibration settings to ensure that they

®

conform to the actual characteristics of your CANNON

instrument.

T o check the configuration settings for your instrument(s), you must log

in to the security system as a manager. The software is installed with a

default Manager account. This account has no password, allowing any

operator access to manager-level software functions as long as the

password is not activated/changed. If you would like to engage the fullrelease security options, see Security Options, this chapter, for instructions.

1. Use your mouse to click Main from the VISCPRO® menu bar.

2. Click Log In from the Main menu options.

3. Click on the

(arrow) on the right side of the User Name: list box

to display the list of registered users.

4. Click Manager. Do NOT enter a password!

5. Click OK. The Log In window will close automatically and you will

be logged in as management personnel.

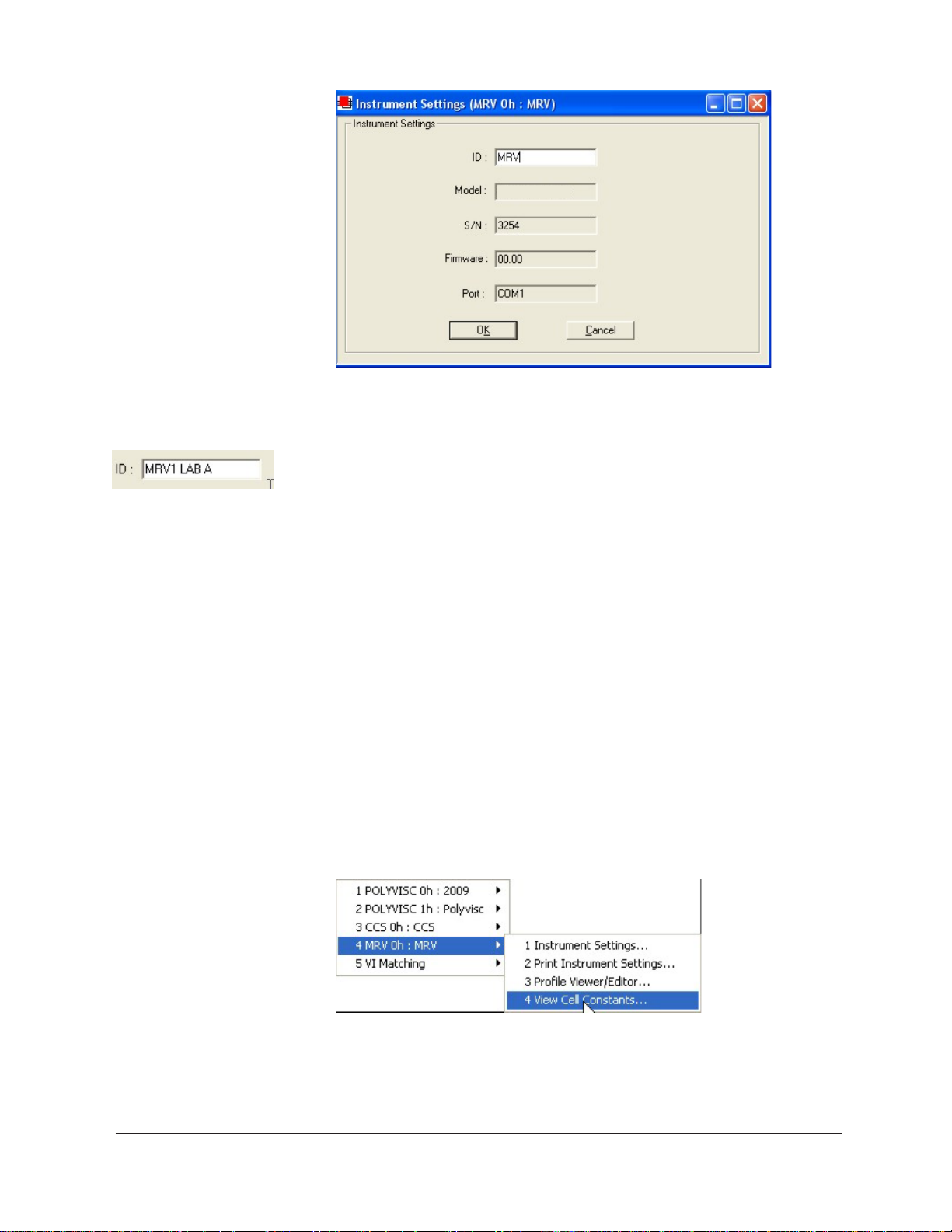

Checking Instrument Settings

1. Use your mouse to click (select) Configure from the VISCPRO

menu bar.

2. Select your instrument from the list of available instruments (there

may be only one instrument in the list).

3. Select Instrument Settings from the list of configuration options.

The Instrument Settings window will appear.

You will use the Instrument Settings window (see graphic following) to

describe and control MRV instrument operational features. These settings

affect the instrument as a whole. Check the instrument settings for your

instrument per the instructions, and make any necessary changes:

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

®

Page 30

24

The Instrument Settings window

4. Use the ID field to input instrument identification information using

up to 30 alphanumeric characters.

Checking initial calibration

The remaining fields in the Instrument Settings window are noneditable (information is obtained via serial communication with the

CMRV instrument). The Model: field will indicate the model of your

instrument. The S/N: field indicates the serial number from the label

on the rear service panel. The Firmware: field indicates the version

for the current instrument firmware. The Port: field indicates the

current communications port for the RS-232 cable connecting your

computer to the CMRV-4500 instrument.

5. When you have entered all settings, click OK.

After you have completed the CMRV instrument calibration for temperature and cell constants (see following chapters), follow the procedure

below to verify the initial calibration settings.

1. From the VISCPRO primary window, click Configure/MRV/View

Cell Constants. The View Cell Constants window will open.

CANNON

2. Ensure that Calibration data, including constants and viscosity, is

available for each cell. Then click OK to close the View Cell Con-

stants window.

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 31

25

NOTE

NOTE

Some fields/options are security-protected, and may not be viewable.

The View Cell Constants window

3. Click Configuration/Print Instrument Settings to open the Win-

®

dows

Print window. Select the desired printer and click OK to print

current calibration settings.

CANNON recommends printing calibration settings each time the

calibration values change.

Setting multiple CMRV instrument addresses

When installing/connecting multiple CMRV instruments, ensure that the

instrument address for each instrument is different. See APPENDIX D

for more information on multi-unit configuration.

Security options

The VISCPRO® application offers a level-based security system with a

log in procedure. This system ensures that available software functions

are appropriate for the user's needs.

Following initial installation of the software, security options may be

accessed and changed from the VISCPRO® Main menu by individuals

who have the manager password (initially blank).

Each user can be assigned a security level, which is used to determine

permitted operations. Three security levels are defined by the software:

Technician (least privileged), Manager (intermediate privilege), and

Service (maximum privilege–reserved for CANNON® Instrument

Company service personnel).

Users log in when using the software by typing their name and (optional)

password in the Log In window . Different security levels offer different

instrument use options. Technicians are permitted to access operational

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 32

26

features required for testing samples and performing other routine

operations. Managers may access advanced configuration and reporting

options. The Service level permits access to all instrument and security

parameters.

Initial security setup

The VISCPRO® software installation creates a security account for one

manager with a blank password. After VISCPRO® installation, a password should be assigned for the manager using the Change Password

menu option from Main. Managers may add or change accounts for

technician status personnel.

Use the Log In feature to identify the CMRV operator and/or access

security functions.

Procedure

Procedure

NOTE

Once an operator is logged in, that operator’s name is associated with

any sample data obtained during that VISCPRO session. The operator

name may be included in analyses.

1. Click Log In from Main.

2. Select the desired name from the drop-down list box.

3. Type the desired password in the Password field for the individual

selected.

4. Click OK.

Use the Change Password feature to change the current user password.

1. Log in to the VISCPRO® software using the Log In command from

Main.

2. Select Change Password from the Main menu options.

3. Type in the new password in the Password field.

4. Retype the password in the Confirm Your New Password field.

5. Click OK to save the new password and close the Change Pass-

word window.

CANNON

Use the Update User Information feature to update the security list of

authorized technicians and managers. User information can only be

updated by an individual logged in with a higher security clearance than

the user for which information is to be altered. Manager status is necessary to change Technician information. Service status is necessary to

change Manager information. T o obtain Service status, it is necessary

to select user CANNON Instrument Company from the Log In window

and to type in the current CANNON® password. For the current password (updated daily), call CANNON® at (814) 353-8000.

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 33

27

Procedure

NOTE

1. Click Log In from Main.

2. Select your Manager or Service level user name from the User

Name list box. Input the correct password in the appropriate field.

3. Click OK.

4. Click Update User Information from Main.

5. Select the desired user from the User Name list box.

To delete a user, just click Remove User after selecting the user name.

The account will be immediately and permanently removed.

6. Enter and verify the desired password, and select user security status

using the appropriate list boxes.

7. Retype the password in the Confirm Password field.

8. Click Add or Update User to save your changes.

9. Click Done to exit the Change User List window.

To use the Log Out feature, click Log Out from Main. The current user

will be logged out of the security list of authorized technicians and

managers. The software will automatically reset to the lowest security

level. Any ongoing test operations will continue.

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 34

28

This page intentionally left blank.

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

®

Instrument Company

2139 High Tech Road • State College, PA • 16803 • USA

Page 35

CHAPTER

29

6

NOTE

A/W Heat Exchanger

Checking thermometers

PREPARING FOR CMRV

TESTING/CALIBRATION

The procedures in this chapter should be followed when preparing for

CMRV-4500 testing or calibration.

In the event that the protocols of your ASTM test method differ from any

of the procedures outlined in this manual, the ASTM method should take

precedence.

T o prepare for operation of the CMRV-4500 unit, turn on the POWER

switch on the upper rear panel of the Air/Water Heat Exchanger.

The ice point of the CMRV-4500 thermometers should be checked

periodically at 76 mm immersion, which corresponds to the depth of

immersion in the CMRV-4500 aluminum block.

Cleaning cycle

CAUTION

CAUTION

Cleaning procedure

Small deviations in the ice point (less than 0.4°C) should be noted and

added to (or subtracted from) calibration readings at all other temperatures (See section on temperature calibration). If corrections larger than

0.4°C are needed, there may be a problem with the thermometer. Examine the thermometer for a bubble of gas in the lower reservoir, a bubble

of mercury in the upper reservoir, or a break in the mercury column. For

information on joining separated mercury columns see APPENDIX C.

Clean the rotors and all nine viscometric cells as described in the following procedure.

When handling the rotors, be careful not to damage the rotor tips.

Damage to the tips will cause erroneous test results and may damage

the cells.

When operating the CMRV, make sure that the rotor and cell numbers

coincide (use the #1 rotor in cell #1, the #2 rotor in cell #2, and so on).

Failure to do so may diminish test accuracy and void the cell calibration

constants.

1. Remove the Plexiglas® cover from the CMRV-4500 and place it away

from the cleaning solvents.

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 36

30

NOTE

CAUTION!

Exposure to acetone liquid or acetone vapor may damage the cover.

2. Turn on the CMRV-4500 (the green power indicator on the switch

will light and the left panel lights will flash once).

The CMRV cleaning procedure may be initiated from a "cold" CMRV;

however, a calibration or profile should not be initiated until the instrument has completed a warmup period of approximately 45 minutes. If the

warm-up period is less than 45 minutes, the instrument may not control

temperature within acceptable tolerance parameters.

3. Assemble the necessary cleaning supplies:

oil solvent

acetone (optional during low humidity)

suitable solvent-resistant container for placing/cleaning rotors

vacuum w/trap for solvent and oil

flexible tube, about 150 mm long and 3-5 mm in diameter, connected

to the vacuum trap

two plastic squeeze bottles, each with an extension long enough to be

able to direct oil solvent and acetone directly into the cup of the

viscometer cells

4. Start the VISCPRO

®

software.

5. Click Service/MRV and select the Cleaning ... option to open the

Cleaning Service window. The window displays the current CMRV

block temperature for the selected instrument, as measured by the

temperature probe. The window also indicates the current instrument

status.

The Cleaning Service window

6. Click Start Cleaning Service. to initiate the cleaning cycle. The

instrument will be heated to 50°C for convenient cleaning.

NOTE

CANNON

7. Remove the threads from the rotors and set the threads aside.

CANNON® recommends hanging the threads on individual hooks during

cleaning. Hanging a paper clip on each loop reduces the chance of curling.

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 37

8. Wait for the CMRV-4500 to reach the cleaning temperature.

31

NOTE

CAUTION

When the CMRV-4500 cleaning cycle is activated, the internal heater

raises the viscometer block temperature 2-3°C per minute to approximately 50°C. Precise temperature control is not necessary for cleaning.

9. When the CMRV-4500 has reached cleaning temperature remove the

rotors and wipe excess oil from them. Gently place the rotors into a

solvent-resistant container, such as a 500-ml glass beaker.

Be careful not to damage the rotor tips when handling the rotors.

10. Use a vacuum to remove oil from the viscometric cells.

11. Thoroughly rinse the

inside surfaces of each

cell at least twice with

oil solvent using a

squeeze bottle with a

length of plastic tubing

attached to the nozzle

(see photo). Direct the

stream from the spray

bottle in such a way that

the liquid swirls around

the inside walls of the

Solvent cleaning of CMRV test cells

cell.

Cleaning rotors

WARNING

WARNING

Your solvent may be a hazardous substance. Use in accordance with

procedures recommended by your Material Safety Data Sheet (MSDS).

Avoid contact with skin and eyes. Avoid inhaling vapors. Use only in a

well-ventilated area.

12. Use vacuum to remove the solvent from the cells after each rinse.

13. Repeat steps 11-12 using acetone in place of solvent.

Acetone is a hazardous substance. Use in accordance with procedures

recommended by your Material Safety Data Sheet (MSDS). Avoid

contact with skin and eyes. Avoid inhaling vapors. Use only in a wellventilated area.

14. After the final rinse, allow the acetone to evaporate from the visco-

metric cell until the surfaces are completely dry .

15. Thoroughly rinse each rotor individually with oil solvent, then with

acetone. Properly dispose of waste liquid after cleaning.

16. After the final acetone rinse, place the rotors in a clean, dry area until

the remaining solvent on rotor surfaces has evaporated.

CANNON

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON

2139 High Tech Road • State College, PA • 16803 • USA

®

Instrument Company

Page 38

32

17. When you have finished cleaning the viscometer cells and rotors,

click Stop Cleaning Cycle. Then click

to exit the Cleaning ...

window.

NOTE

Inserting rotors

CAUTION

Inserting rotor pins

NOTE

After the cleaning cycle, you should permit the cells and rotors to dry for

15 minutes before introducing oil sample into the viscometric cells.

The viscometric cells are numbered from left to right when looking at the

viscometer from the pulley-wheel side, with cells 1, 3, 5, 7, and 9 in the

front row and cells 2, 4, 6, and 8 in the back row. Each rotor is identified

by the number at the top of its shaft.

1. Rotors are normally stored in the integral storage drawer. When you

are ready to begin a temperature profile, inject the sample and gently

place each of the nine numbered rotors into their corresponding

viscometric cells.

Do NOT drop the rotors into position or you may damage the rotor tips.

2. Align the rotor beneath the corresponding hole in the upper bearing

plate.

The upper bearing support should have approximately 1 to 2 mm (1/32

to 1/16 inch) clearance above the top of the rotor shaft. If the rotor tip is

not seated properly, there will not be enough clearance between the top

of the rotor shaft and the upper bearing plate to permit orientation of the

rotor under the bearing plate.

NOTE

Checking rotors

Sensor connection

CANNON

3. Insert the pin through the plate and into the center bearing hole at the

top of the rotor shafts.

The pins, when inserted through the upper bearing plate, should extend

approximately 3 mm (1/8 inch) below the plate.

4. Make sure that the rotor locking pins are in the raised (detent)

position. Rotate each of the rotors to ensure that it spins freely and

without signs of binding at either bearing.

5. Remove the rotors from the viscometric cells.

6. If necessary, install the pulley-wheel assembly on the slide track. See

Chapter 4 for details.

7. Make sure that the free end of the sensor wire from the pulley-wheel

assembly is plugged into the receptacle marked WHEEL on the

CMRV-4500 front panel.

You are now ready to perform the CMRV-4500 calibration procedure or

run a test sample using the applicable test methods or a custom profile.

See the appropriate chapter for further instructions.

®

Mini-Rotary Viscometer CMRV-4500 Instruction & Operation Manual

Version 1.1e—October, 2011 • CANNON