Page 1

CCS-2100/

2100LT

Automatic

Cold-Cranking

Simulator

Instruction

& Operation

Manual

Page 2

CONTENTS

i

1

INTRODUCTION/INSTALLATION 1

Overview ............................................................................................................................ 1

Equipment........................................................................................................................... 2

Required accessories .......................................................................................................... 3

Utilities ............................................................................................................................... 4

Safety cautions.................................................................................................................... 4

Unpacking........................................................................................................................... 5

Positioning CCS components ............................................................................................. 6

Computer connections ........................................................................................................ 6

Controller power distribution ............................................................................................. 7

Optional connections for non-thermoelectric operation......................................... 8

Simulator Mechanism/Controller cable connections.......................................................... 9

Tubing connections............................................................................................................. 9

Waste system connections ...................................................................................... 9

Coolant connections ............................................................................................. 10

Filling the refrigerated chiller........................................................................................... 11

Installing VISCPRO® software......................................................................................... 12

Windows® installation .......................................................................................... 12

Installation actions................................................................................................ 12

Specifications ................................................................................................................... 13

2

Configuring the CCS 15

Checking/editing configuration settings in VISCPRO..................................................... 15

Running the software............................................................................................ 15

Logging in ............................................................................................................ 15

Checking/editing Instrument Settings .................................................................. 16

Viewing/editing other setup information .............................................................. 17

VISCPRO software interface elements ............................................................................ 18

Initial Stepper Motor Service (CCS-2100 only)............................................................... 20

Setting the CCS Set Motor Current .................................................................................. 21

CANNON

Version 2.0a — November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 3

ii

3

4

CALIBRATING THE CCS 23

Calibration procedure ....................................................................................................... 23

Preparing/updating the list of calibration standards ............................................. 23

Testing calibration standards ................................................................................ 25

Performing the calibration .................................................................................... 27

Checking calibration accuracy ......................................................................................... 28

Viewing current calibration constants .................................................................. 30

Saving a calibration .............................................................................................. 30

TESTING SAMPLES WITH THE CCS 31

Preparing the CCS and samples ....................................................................................... 31

Test options....................................................................................................................... 35

Running a test ....................................................................................................... 35

Pausing a test ........................................................................................................ 35

Resuming a test..................................................................................................... 35

Aborting a test ...................................................................................................... 35

Concluding a test .................................................................................................. 35

Viewing results .................................................................................................................36

Creating an analysis.......................................................................................................... 36

5

USING THE CCS SOFTWARE 39

VISCPRO® generic instrument interface.......................................................................... 39

Main options......................................................................................................... 39

Security options .................................................................................................... 42

Initial security setup ............................................................................................. 43

Print/Print setup options ....................................................................................... 44

Analyses options............................................................................................................... 44

Analysis types....................................................................................................... 45

Analyses menu options......................................................................................... 45

Window options................................................................................................................ 46

CCS module menu options ............................................................................................... 47

Configure options ................................................................................................. 47

Print Instrument and Tray (Test) Settings............................................................. 48

Instrument Settings ............................................................................................... 48

Probe constants..................................................................................................... 48

Tray (Test) Settings............................................................................................... 49

Saving a configuration.......................................................................................... 50

Restoring instrument settings from a saved configuration ................................... 51

Calibration ............................................................................................................ 51

CCS Calibration Standards................................................................................... 53

CANNON

Version 2.0a — November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 4

CCS Choose Calibration Standards...................................................................... 54

Current Cell Calibration Standards ...................................................................... 55

CCS Setup ............................................................................................................ 56

Service menu options ....................................................................................................... 56

Testing samples—software options .................................................................................. 57

Entering sample ID information ........................................................................... 57

Selecting sample actions....................................................................................... 58

Copy & Paste Sample ID data entry options ........................................................ 61

Inserting/deleting a sample ID in the test sequence ............................................. 61

Analysis modules.................................................................................................. 62

Status bar CCS error tracking........................................................................................... 62

iii

6

7

MAINTAINING AND SERVICING THE CCS 63

CCS components .............................................................................................................. 63

CCS Unit .............................................................................................................. 63

Waste system ........................................................................................................ 64

Emptying the waste container .......................................................................................... 64

Repairs/diagnostics........................................................................................................... 64

Rotor/stator assembly ........................................................................................... 65

Checking/reseating the thermistor probe.............................................................. 65

Replacing the vacuum pump diaphragm .............................................................. 66

Gapping the rotor in the stator well...................................................................... 67

Preventive maintenance................................................................................................... 68

Biannual maintenance .......................................................................................... 68

Cleaning the instrument housing ...................................................................................... 68

ANALYSIS CONFIGURATION OPTIONS 69

Creating an analysis.......................................................................................................... 69

Sorting analysis data......................................................................................................... 71

Using the date filter .......................................................................................................... 71

Using the sample/error filter............................................................................................. 72

Using the report/port output filter..................................................................................... 73

Reconfiguring a displayed analysis .................................................................................. 73

Resizing table columns..................................................................................................... 74

Saving a current analysis .................................................................................................. 74

Deleting an analysis configuration ................................................................................... 75

Printing an analysis........................................................................................................... 75

Keystrokes for selecting data for printing ............................................................ 75

Exporting analysis data..................................................................................................... 76

8

CCS DATA TABLE 77

Configuring the CCS Data Table.......................................................................... 78

CANNON

Version 2.0a — November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 5

iv

9

10

11

12

ERROR LOG TABLE ANALYSIS 81

Configuring the Error Log analysis ...................................................................... 81

EXPORT ANALYSES 85

Configuring the Port Export analyses................................................................... 86

USING THE DATABASE MANAGER 91

Archiving old data ................................................................................................ 91

Changing the database directory .......................................................................... 92

Importing archived data........................................................................................ 92

Repairing/compacting the database...................................................................... 93

Exit ....................................................................................................................... 93

REPLACEMENT PARTS LIST 95

13

A

B

I

WARRANTY/RETURN INFORMATION 97

Products limited warranty................................................................................................. 97

Reagent and chemical warranty........................................................................................ 97

Returning a product to CANNON®.................................................................................. 98

APPENDIX A—WEISSENBERG EFFECT 99

APPENDIX B—SAE VISCOSITY CLASSIFICATIONS

FROM -10°C to -35°C101

INDEX 103

CANNON

Version 2.0a — November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 6

CHAPTER

1

Overview

1

INTRODUCTION/INSTALLATION

Manual

The CCS instruments

This manual is intended for use with both the CCS-2100 and the CCS2100L T Cold-Cranking Simulator (CCS) models from CANNON

Instrument Company . It provides information about:

®

Installation and operation of the CCS-2100 instruments

Standard ASTM testing and methods related to the CCS

Calibration of the CCS for the customer’s specific needs

Use of the CCS computer software

Maintenance and repair of the CCS

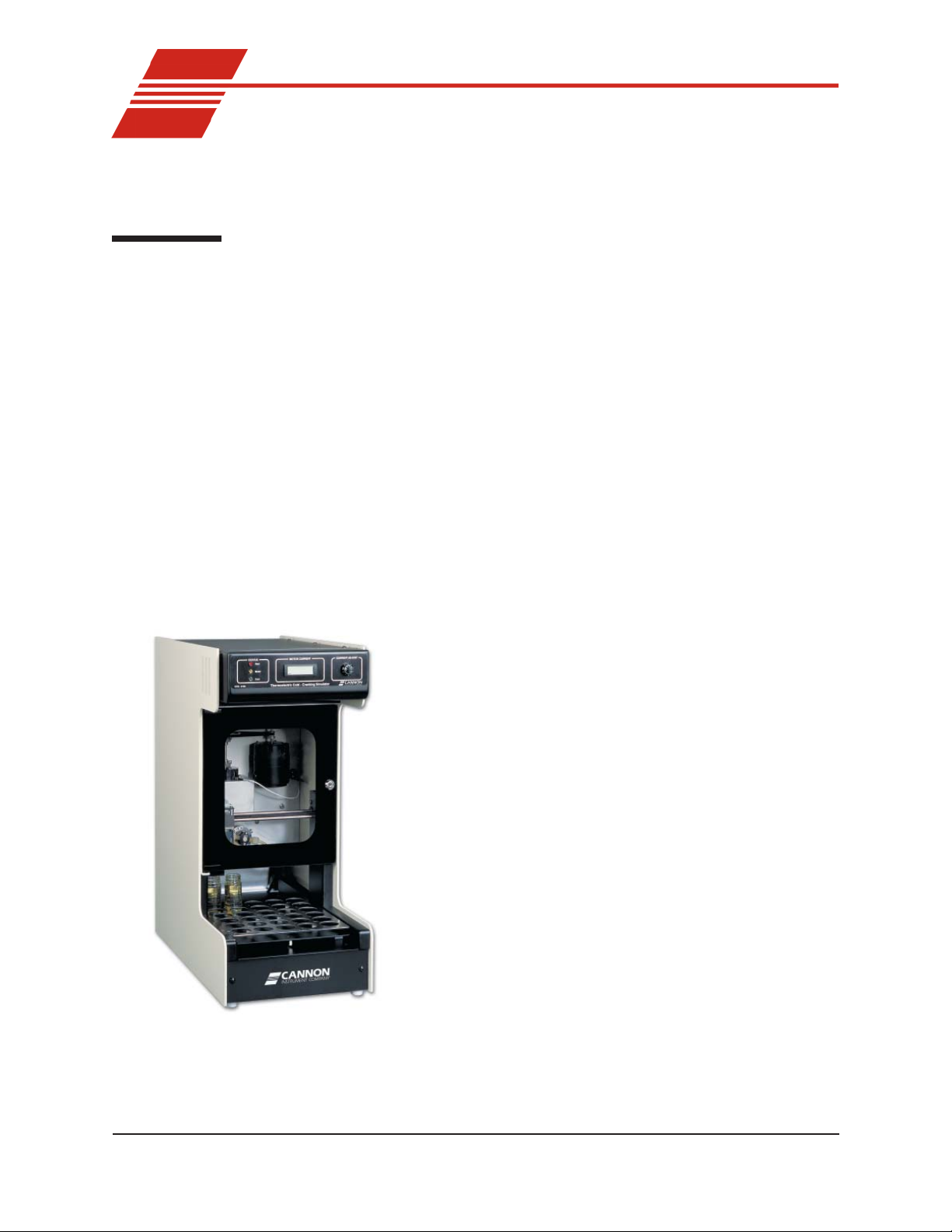

The CANNON® Cold-Cranking Simulator (CCS-2100) is a solid-state,

thermoelectrically-cooled, fully-automatic test instrument for the determination of cold-cranking viscosity of engine lubricants. The CCS-2100

operator initially loads oil samples into the Sample Tray and enters sample

identification via the computer keyboard or with a simple software

procedure restores a previously saved test configuration.

Without further operator intervention, the CCS-2100 tests and

determines the apparent viscosity for up to 30 test samples at

specified sub-ambient test temperatures, and records the

results.

New features

The CCS 2000 Series instruments offer several advantages

over previous CCS models, including improved temperature

management and elimination of the required warm-up sample

at the beginning of the test cycle. The thermoelectric system

also enhances cell cleaning with a warming cycle, improving

measurement precision. An attractive cabinet combines the

simulator mechanism and the modular CCS Series II Controller.

Applications

The CCS-2100 is used to determine the apparent viscosity of

engine oils at low temperatures at shear rates similar to those

at starting conditions of cold engines. CCS instruments are

found in quality control oil testing laboratories, major oil

corporation laboratories, independent test facilities, blending

facilities, and automotive corporation laboratories.

CANNON

Version 2.0a— November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 7

2

Precision

Temperature range

Viscosity range

Calibration constants

Equipment

The CCS-2100 is designed to produce measurements that meet or exceed

the accuracy and precision dictated in ASTM test method D 5293.

The CCS-2100/2100LT is capable of measuring the apparent viscosity of

oils at test temperatures ranging from -5°C to -40°C in increments of

5°C. The refrigerated water chiller must be set to +5°C to facilitate

operation of the thermoelectric cooling system.

The CCS-2100 is capable of calculating viscosity values ranging from 900

to 25,000 cP at test temperatures. Alternative ranges are possible.

Contact CANNON® technical services for more information.

The CCS-2100 will automatically calculate the appropriate calibration

constants (refer to Chapter 3 for more information). After calibration, the

CCS-2100 will use those constants for future tests without the necessity

of operator intervention.

The CCS instrument includes a Simulator Mechanism and the integral

CCS Series II Controller. The peripheral waste system includes a vacuum

pump (for evacuation of the sample) and a waste container.

Simulator Mechanism

CCS Series II Controller

Waste system

The Simulator Mechanism contains a temperature-controlled rotor/stator

test mechanism and a constant metering, positive displacement piston

pump which transfers the oil samples from the sample bottles to the rotor/

stator assembly via an injection tube. The Simulator Mechanism also

includes a 30-position automatic X-Y Sample Table. The Sample Table

can process up to 30 sequential samples. The CCS-2100 automatically

accesses a new sample when the previous test is complete.

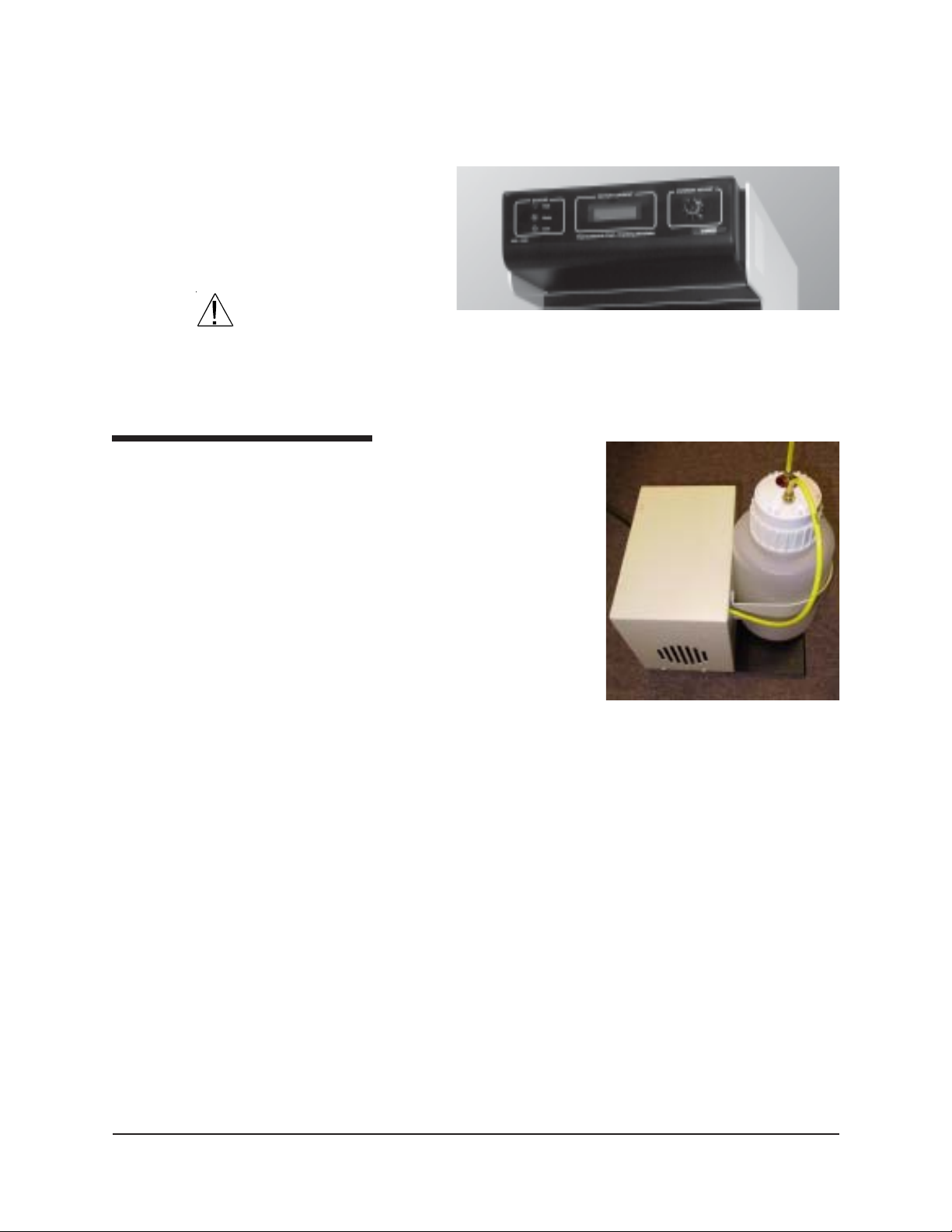

The CCS Series II

Controller translates

input from the CCS

sensors and transfers

the data to the computer for analysis. The

CCS Series II Controller also provides

power and relays

computer commands

to the Simulator

Mechanism.

The waste system is

designed to eliminate

the need for solvent

cleaning. Used sample

is flushed from the

CCS rotor/stator assembly

rotor/stator with a

CANNON

Version 2.0a — November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 8

portion of the sample to be tested. The waste system includes the tubing

and connections from the CCS to the waste container and vacuum pump.

The pump is encased in a protective housing that includes a mounting

bracket for the large polypropylene waste container. The container is

capable of

holding waste

from approximately 45

sample tests.

3

CAUTION

The liquid level

in the waste

container should be checked frequently and the container should be

emptied prior to multi-sample tests.

Required accessories

The CCS requires a refrigerated

chiller capable of circulating a

distilled water mixture with 10

percent antifreeze to the CCS

thermoelectric system at a controlled

temperature of +5°C at a rate of at

least 1-2 liters/minute (see refrigerated chiller specifications, this

chapter). CANNON® recommends

and supplies a Julabo chiller for this

purpose. The CCS also requires an

IBM or IBM-compatible computer

and printer (request current specifications from CANNON) to run the

CCS software and produce printouts of the data collected by the CCS.

The CCS-2100 Series II Controller

The CCS waste system

CANNON

Version 2.0a — November 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 9

4

Utilities

The customer must be able to provide the appropriate power and grounding for the CCS.

AC power input

CAUTION

Grounding

Safety cautions

Specifications of the voltage and frequency of the AC power source for

the CCS are provided by the customer when placing an order. If you have

any questions regarding the correct voltage for your CCS model, call

®

CANNON

Only attach the power cord from the rear of the CCS Series II Controller

to an AC mains with the power requirements specified on the label on

the rear of the Controller.

for assistance.

It is very important that the power source for the CCS has an electrical

ground. The CCS is equipped with an IEC 320 socket which must be

plugged into a grounded outlet.

Please observe the following safety procedures and notices for proper

operation of the CCS:

Make sure that your unit is operated only by qualified personnel.

Make sure that you read and understand all operating instructions

and safety precautions listed in this manual before installing or

operating your unit. If you have questions regarding instrument

operation or documentation, contact CANNON

®

Instrument Company .

Do not deviate from the installation, operation or maintenance

procedures described in this manual. Improper use of the CCS

instrument may result in a hazardous situation and may void the

manufacturer’s warranty.

Handle and transport the unit with care. Sudden jolts or impacts may

cause damage to components.

Observe all warning labels.

Never remove warning labels.

Never operate damaged or leaking equipment.

Unless procedures specify otherwise, always turn off the unit and

disconnect the mains cable from the power source before performing

service or maintenance procedures, or before moving the unit.

Never operate the equipment with damaged mains power cables.

Refer all service and repairs to qualified personnel.

General Caution

In addition to the cautionary statements listed previously , additional

cautions may be posted throughout this manual. These cautions, identified by the caution symbol (see left) indicate important operational

procedures. Read and follow these important instructions. Failure to

observe these instructions may void warranties, compromise operator

safety , and/or result in damage to the CCS unit.

CANNON

Version 2.0a — November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 10

Protective Conductor

5

The Protective Conductor T erminal symbol is used to indicate required

ground connections for your instrument electrical supply .

WARNING

MAINS

~

AC Power Input Symbol

( O )

Supply OFF Symbol

Hazardous materials

When supplying power to this instrument, ensure that the protective

ground (earth) terminals of the instrument are connected to the protective

conductor of the (supplied) line (MAINS) power cord. Use only the

manufacturer-supplied power cord, which should be inserted in a socket

outlet (receptacle) which is also provided with a protective ground (earth)

contact.

Do not use an extension cord (power cable) without a protective

conductor (grounding).

The ~MAINS symbol indicates instructions or connections for the AC

power supply . The AC Power input must match the electrical specifications listed on the label on the rear panel of the instrument. The supplied

AC Mains power cord must be attached to the connector labelled

~MAINS. This connection serves as a means of disconnect and should be

readily accessible.

The (O) symbol indicates the OFF position for the electrical switches for

your unit (AC Mains or accessories).

Routine CCS operation may require the use and handling of hazardous

chemicals and solutions. CANNON® Instrument Company strongly

urges the operators and technicians working with the CCS to take proper

safety precautions when working with these materials. These safety

procedures can be found in the Material Safety Data Sheets which

accompany the solutions.

Unpacking

NOTE

CAUTION

CANNON

Version 2.0a — November 2010; CANNON

Some CCS components are quite heavy. To avoid injury, obtain necessary assistance when lifting and moving shipping cartons and heavier

unpacked components.

1. Carefully remove all components from their shipping cartons.

2. Consult the packing list to ensure that all items listed have been

received. The CCS is usually shipped in three packing crates (including the refrigerated chiller unit, if it is ordered from CANNON

3. Notify CANNON

®

Instrument Company if any items are missing.

4. Inspect all components for damage. Report any damage to the

shipping company and to CANNON

®

Instrument Company immediately . Remove any visible packing materials (packing foam, etc.)

from the components.

You should retain all packing materials until the CCS is connected and

functioning properly. If any component is returned to CANNON® Instru-

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

®

).

Page 11

6

ment Company , it should be packed in it s original shipping container . You

must call CANNON® prior to returning any products (see warranty and

return information at the conclusion of this manual).

Positioning CCS components

1. Place the CCS on a stable laboratory bench or table.

2. Place the computer adjacent to the CCS.

3. Use the key provided to open the hinged door protecting the Simulator Mechanism.

4. Remove any pieces of foam packing that may have been included to

prevent shipping damage

to internal moveable

components.

5. Close the hinged door.

Sample Tray

6. Place the CCS-2100

Sample Tray on the

Simulator Mechanism

Sample Table so that the

arrow on the tray is

aligned with the arrow on

the left guide of the

Sample T able (see

photo). The gear on the underside of the Sample T ray must engage

the gear in the center of the base of the instrument. When the alignment is correct, the CCS sampler mechanism at its default position

(farthest left) will be centered over sample #1 on the Sample Tray.

Computer connections

Ensure that the computer specifications meet the minimum requirements

for your CCS instrument. These requirements are listed on the Computer

Specifications sheet provided with your Instruction & Operation Manual.

RS-232 serial connections

Locate the RS-232 (25-pin) CCS Control Cable. Connect one end to the

COM port on the rear of the computer . Connect the other end of this

cable to the socket on the rear of the CCS Series II Controller (note that

the connectors are “D” shaped, and fit only one way).

Sample Tray (top view) correctly

aligned on Sample Table (guides

CANNON

Version 2.0a — November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 12

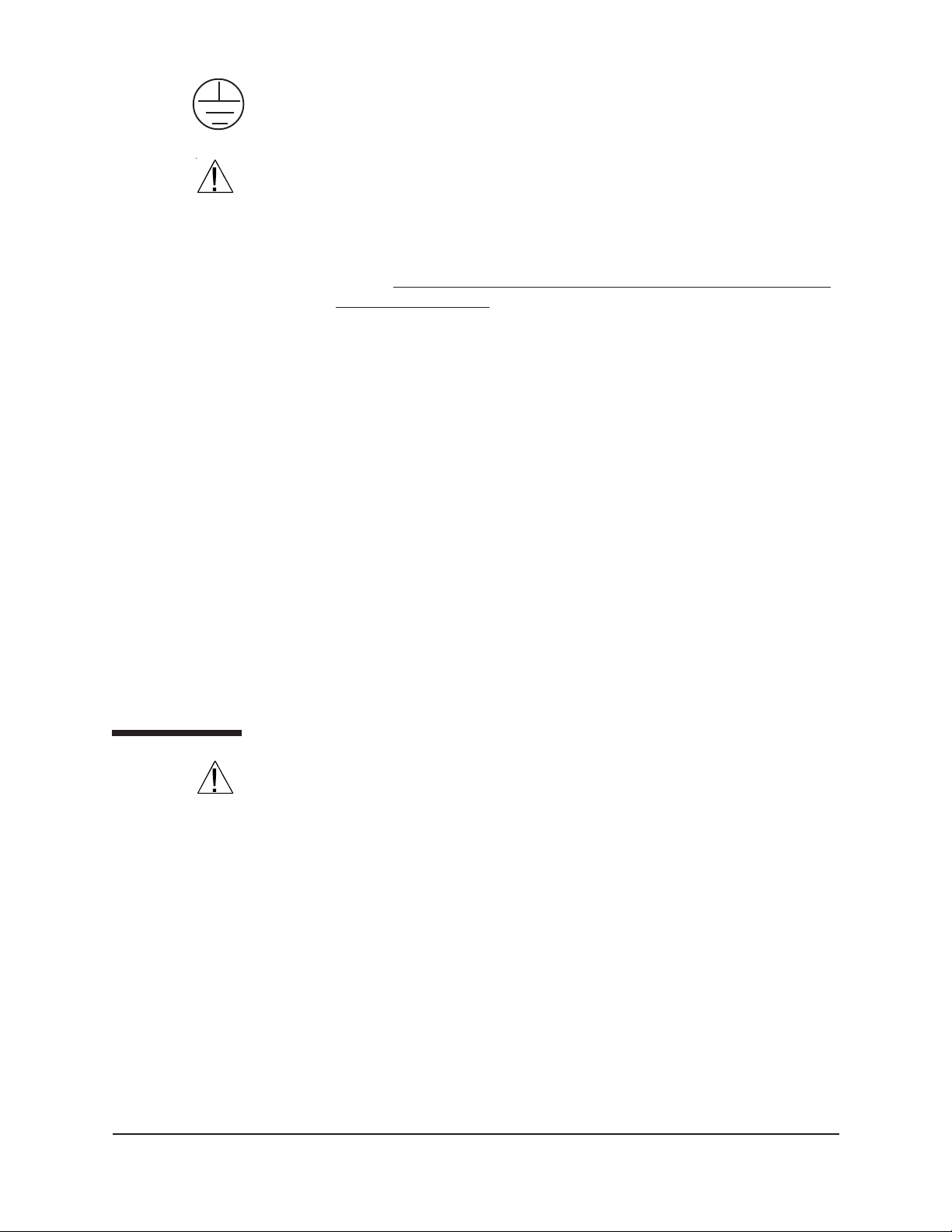

Controller power distribution

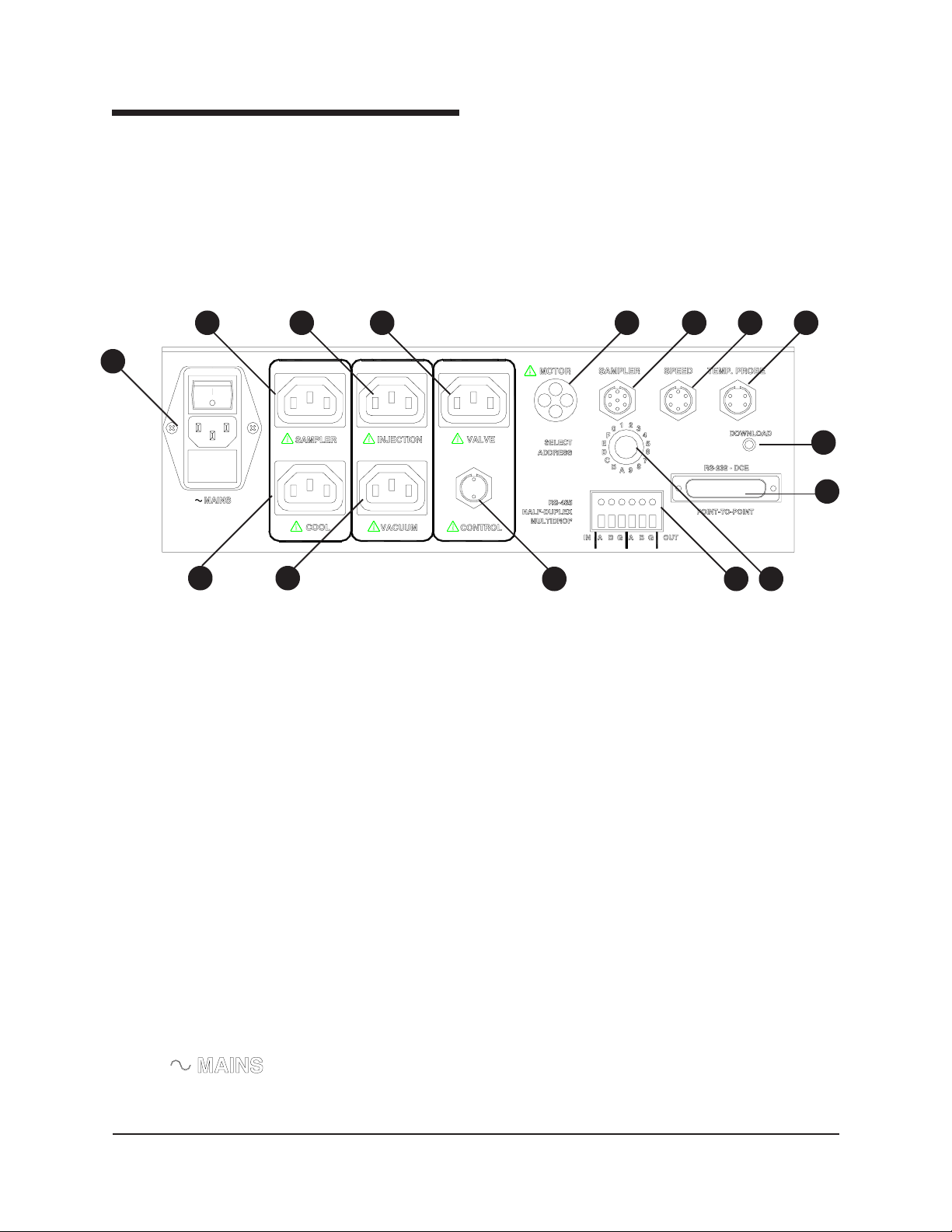

7

Receptacle connections

2 3 4 6 7 8

1

9 10

There are five AC power receptacles and one DC receptacle on the rear

of the CCS Series II Controller. The AC receptacles provide AC power

matching the AC mains input for the various CCS AC devices. The

Motor receptacle supplies regulated DC voltage for the rotor motor .

Power for the CCS Simulator Mechanism is supplied via the CCS Series

II Controller. AC Power cords from the CCS are labelled to match their

receptacles. Connect the power cords as follows:

5

15

14

1211 13

CCS Series II Controller rear panel with connections marked (see list below)

1. Mains power (to AC power source), ON/OFF switch and fuses

2. CCS sampler mechanism power connection

3. Injection pump power connection

4. Coolant valve power connection (unused)

5. CCS rotor motor power connection

6. CCS sampler control

7. Rotor speed sensor connection

8. CCS temperature probe connection

9. Thermoelectric cooling power connection to internal power

supply

10. Vacuum pump power connection

11. Thermoelectric cooling control (from stator assembly)

12. RS-485 connection (for multiple CCS instruments)

13. Address select (unused)

14. RS-232 serial connection (to computer COM port]

15. Download button (for future firmware upgrades—not used for

installation)

Mains

Make certain that the instrument power switch on the Controller rear

panel above the Mains power cord connection is turned off. Then attach

the Mains power cord from the Mains receptacle to the power supply

matching the label on the rear of the CCS unit.

CANNON

Version 2.0a — November 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 13

8

NOTES

Sampler

Injection pump

Cool

Vacuum pump

NOTE

Motor

Use only the CANNON®-approved supplied power cables for the CCS unit.

Do not use serial or power cables exceeding 3 meters in length. Do not

turn on the CCS power switch unless the chiller is attached and operating.

Connect the Sampler power cord from the Simulator Mechanism to the

SAMPLER receptacle on the CCS Series II Controller.

Connect the power cord from the INJECTION pump receptacle to the

Simulator Mechanism, at the receptacle labeled INJECTION.

Connect the power cord from the thermoelectric power supply to the

receptacle labelled COOL on the rear panel of the CCS Series II Control-

ler. This receptacle is energized whenever the controller power is ON.

Connect the power cord from the waste container vacuum pump to the

VACUUM pump receptacle on the Controller.

If an in-house vacuum is to be used to remove oil from the CCS, you

may omit the use of the waste container vacuum pump connection.

Connect the Simulator rotor motor power cord to the MOTOR recep-

tacle.

Control

RS-232

Valve

CAUTION

Do not connect any other cable to the MOTOR receptacle. The power

draw will damage the motor control circuit.

If it is not already attached, connect the control cable from the stator

thermoelectric cooling assembly to the CONTROL receptacle.

Connect the RS-232 serial cable from the computer COM port to the RS232 connector.

Optional connections for non-thermoelectric operation

The Valve connection (see photo image, page 7) is for optional nonthermoelectric cooling only—it is not used for normal thermoelectric

operation. The non-thermoelectric version CCS (earlier version) required

a custom-built rotor/stator assembly. If using a non-thermoelectric (older)

instrument, connect the power cord from the optional external solenoid

valve to the VALVE receptacle on the CCS Series II Controller. The

solenoid valve regulates coolant flow from the optional non-thermoelectric cooling device through the CCS cooling system.

CAUTION

Valve (or pump) voltage must match the CCS mains input voltage and

frequency. Use only CANNON®-approved supplied accessories in the

VALVE outlet. Do not circulate methanol refrigerants in thermoelectric

instruments!

CANNON

Version 2.0a — November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 14

9

NOTES

The solenoid valve may be obtained from CANNON® and must be

installed to the coolant return line by the customer. (In some cases, a

solenoid valve may already be included in the customer-supplied chiller.)

If the refrigerated chiller has a constant-running internal pump, it may not

be necessary to connect the pump to the CCS Controller.

Simulator Mechanism/Controller cable connections

Three cables from the Simulator Mechanism must be connected to the

matching receptacle on the rear panel of the CCS Series II Controller:

1. Connect the grey cable from the Simulator Mechanism speed sensor

to the SPEED jack on the CCS Series II Controller.

2. Connect the white temperature probe cable with the metal LEMO

plug to the matching TEMP PROBE jack on the Controller.

3. Attach the seven-pin connector cable to the seven-pin SAMPLER

jack on the Controller (see diagram, page 10). Connect the other end

of this seven-pin cable to the corresponding jack in the lower left

corner of the Simulator Mechanism rear panel.

4. Attach the four-pin connector cable from the thermoelectric cooling

unit to the CONTROL jack on the Controller (see diagram).

5. Set the Instrument Address on the rear panel of the CCS instru-

Tubing connections

Waste system connections

A short 1/4" yellow plastic tube links the sample/solvent waste container

with the waste container vacuum pump. This tube is taped to the vacuum

pump housing for shipping. Remove the tape and make certain that there

are no kinks in the vacuum hose. The longer tube should be attached

from the waste container to the CCS (see instructions below).

CAUTION

NOTE

The

severely damage the vacuum pump.

If an in-house vacuum is to be used to remove oil from the CCS, you

may omit the use of the waste container vacuum pump.

ment. Ordinarily the address should be set to "0". If other CANNON

instruments are to be controlled from the same computer, each

instrument must have a unique address. Each CCS requires a dedicated COM port.

waste container

must be connected properly or waste liquid may

Connection procedure

1. If the shorter length of yellow tubing is not already attached to the

vacuum pump, it will be necessary to access the pump to attach it to

the Waste Vacuum connector by removing the six screws securing the

pump housing to the waste system assembly . After the housing has

CANNON

Version 2.0a — November 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 15

10

been removed,

connect one end of

the yellow tubing to

the fitting on the

vacuum pump.

Attach the other

end to the remaining fitting on the

waste container

(see photo, above).

2. Connect the longer

length of 1/4"

yellow plastic

tubing to the other fitting on the lid (this fitting includes a hose

extension which projects into the bottle).

3. Connect the other end of this longer tube to the vacuum fitting

mounted on the right rear panel of the Simulator Mechanism. This

"T" connection from viscometric cell to rear

panel waste container fitting

to

vacuum

pump

to

CCS unit

Waste container lid

fitting completes the vacuum connection to the CCS

viscometric cell (see photo).

Coolant connections

There are two tubing connections on the rear of the

CCS housing. The fitting on the left is the coolant

INLET (for introducing the water/antifreeze mixture from the refrigerated chiller to the CCS) and

the fitting on the right of the rear panel is the

coolant OUTLET (for returning coolant to the

refrigerated chiller). Secure the ends of both hoses

to these fittings, then secure both hoses to the

appropriate bulkhead fittings on the refrigerated

chiller (see photo) using any connection hardware

provided with the tubing (if applicable). Route the

hose from the CCS OUTLET to the refrigerated

chiller INLET, and the hose from the CCS INLET

to the refrigerated chiller OUTLET.

Refrigerated chiller coolant connections

CANNON

Version 2.0a — November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 16

Filling the refrigerated chiller

Check the operations manual for the refrigerated chiller to determine its

capacity . Then obtain the necessary volume of water and high-quality

automotive antifreeze (ethylene glycol) necessary to provide a mix with a

ratio of 10 percent antifreeze to 90 percent water. After you have secured

the refrigerated chiller tubing connections to the CCS instrument (see

previous section) add the necessary quantity of water/antifreeze mixture

to the refrigerated chiller. The modified Julabo refrigerated chiller

includes a sight glass for monitoring the liquid level.

the temperature for the circulating coolant should be set at +5°C.

11

For CCS operation,

CAUTION

NOTE

Ethylene glycol is a toxic substance. Use proper safety precautions

when handling. Follow appropriate MSDS procedures.

Ensure that the chiller is connected to the CCS and functioning properly

before providing power to the CCS.

The water-antifreeze mix should be replaced annually for reliable performance and to prevent corrosion of internal components.

Do not set the chiller temperature below the freezing point of water (0°C).

Depending on the amount of fluid displacement in the coolant lines, it

may be necessary to add additional antifreeze/water mixture to the

refrigerated chiller when the unit commences operation. Monitor the

liquid level in the refrigerated chiller during normal operation. If air

bubbles are consistently visible in the coolant lines, add additional

mixture until the refrigerated chiller is full.

EPYT obaluJA.erusserpcirehpsomtaotnepo,)delaestontub(riovreserdesolC

SNOITACIFICEPSRELLIHCDETAREGIRFERDERIUQER

sirellihcdeifidom

.NONNACmorfelbaliavadnadednemmocer

MUIDEMGNILOOC ezeerfitnatnecrep01htiwretawdellitsidfoerutxiM

YTICAPAC

ETARWOLFPMUP 1ta.nim/)strauq1.2-1(sretil2-1tsaeltAdaehfo)sehcni93(retem

SENILGNILOOC ni)sehcni5.-52.0(mm21-6,htgnelni)sehcni93(retem1yletamixorppA

YTICAPACLAVOMERTAEH C°5+tasttaw002tsaeltA

ERUTAREPMETWOL

C°5+taniatniamdnalortnoC

retemaid

CANNON

Version 2.0a — November 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 17

12

Installing VISCPRO® software

VISCPRO® is a powerful new software product providing a generic

instrument interface for controlling and operating your CANNON

instrument via computer. VISCPRO® also includes reporting/analysis

modules for processing and displaying sample data.

T o install the VISCPRO

sequence presented. Make certain that you complete the sections on

checking instrument settings and calibration data. If you encounter

difficulties at any stage in the installation process, call CANNON

T echnical Services at 814-353-8000.

Windows® installation

1. Turn on your computer. Wait for the Windows® software to load.

2. From the Windows

3. Double-click the Add/Remove Programs icon and follow the

Installation actions

The installation program will:

create a directory for your data files. The default directory is

write SETUP information to the Windows

copy the software executable file and other necessary files to the

update other files in your Windows

place a shortcut icon for the VISCPRO

®

®

software, follow the instructions below in the

®

®

Start Bar click Settings/Control Panel. Insert

the first VISCPRO® installation disk or CD-ROM into the disk drive.

Windows prompts to complete the installation procedure. The

executable file for VISCPRO

®

software installation is SETUP.EXE.

C:\Program Files\Cannon Instrument\VISCPRO).

®

registry.

directory you specify.

®

directories to versions fully

compatible with the current VISCPRO® software.

®

executable file on your

Windows

®

desktop.

CANNON

Version 2.0a — November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 18

Specifications

SNOISNEMID mm001tsaeltadda(peed)"62(mm066×ediw)"8/1-31(mm333×hgih)"82(mm117

THGIEW fi(tinugniloocobaluJrof).sbl09(gk14/tinuyramirp0012-SCCrof).sbl531(gk16

THGIEWGNIPPIHS 521(gk75;seirosseccadnatinuyramirp0012-SCCrof).sbl462(gk021yletamixorppA

morfdesahcrup NONNAC

)noitallatsnirofhtpedot)"4(

®

(tinugniloocobaluJrof).sbl NONNAC

morfdesahcrupfi

13

SNOITACIFICEPS0012-SCC

seirosseccarof).sbl56(gk03;)

®

)

LACIRTCELE W0001,zH06/05,%01±CAstlov511/001:0012-SCC#ledoM

GNITAREPO

SNOITIDNOC

GNITARESUF mm02x5,A4V052M:tinutlov032;mm02x5,A8V052M:tinutlov511/001:rellortnoC

ECNAILPMOC ,CDV0091(TOP-IH,)CEE/32/37(evitceridegatlovwoL;)CEE/633/98(evitceridCME

W0001,zH06/05,%01±CAstlov032:F0012-SCC#ledoM

2eergednoitulloP,IIyrogetaCnoitallatsnI,gnisnednoc-nonHR%09-%01,C°03-°51

).ces06

.tinuruoyhtiwdeilppusdrocrewopdevorppaehtylnoesU

CANNON

Version 2.0a — November 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 19

14

This page intentionally left blank.

CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

Version 2.0a — November, 2010; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 20

CHAPTER

Configuring the CCS

2

This chapter contains information on configuring the CCS instrument for

successful operation. Additional configuration information may be found

in a separate document, CCS Installation Notes, provided with your CCS

instrument or software upgrade.

Checking/editing configuration settings in VISCPRO

15

Original installation

CAUTION

Configuration protection

Your original software installation package may have included preset

instrument configuration data on an accompanying floppy disk. This

information should be copied to the VISCPRO® directory on your

computer immediately following initial installation of the VISCPRO

software. Consult the CCS Installation Notes for further information.

Copying or recopying floppy disk information to your VISCPRO® directory will overwrite existing sample data. If you wish to retain a record of

previously-saved configurations, make certain to archive your existing

sample data before doing so (see Chapter 11 for information on using

the Database Manager software).

Follow the procedures in this chapter and the chapter on CCS calibration

to verify/edit the instrument and calibration settings to ensure that they

conform to the actual characteristics of your CANNON® instrument.

T o check the configuration settings for your instrument(s), you must log

in to the security system as a manager. The software is installed with a

default Manager account. This account has no password, allowing any

operator access to manager-level software functions as long as the

password is not activated/changed. If you would like to engage the fullrelease security options, see Security Options in Chapter 5 for instructions.

®

Running the software

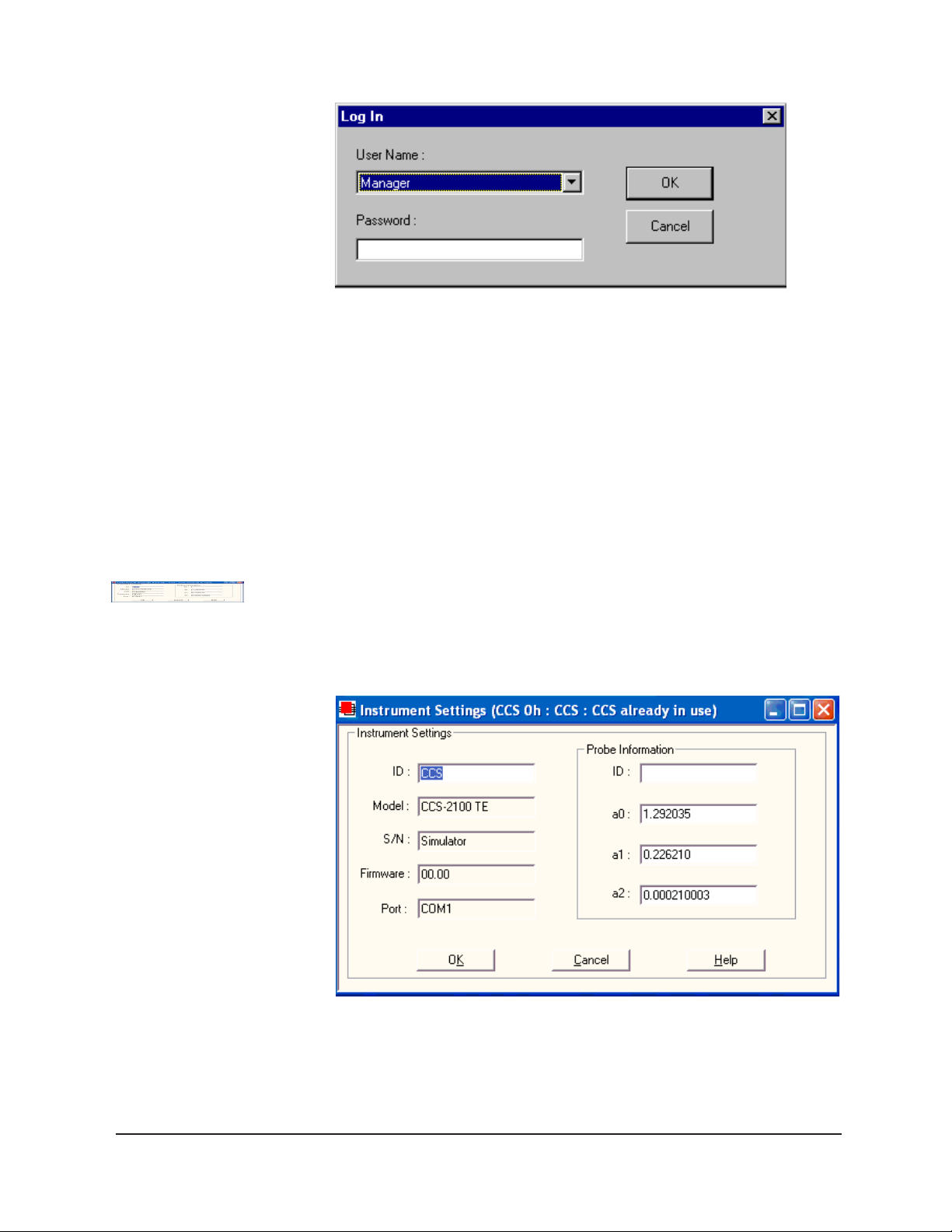

Logging in

CANNON

Version 2.0a— November, 2010; CANNON

2139 High Tech Road • State College, PA 16803 • USA

T o start the VISCPRO® software program, double-click the VISCPRO

icon on your Windows® desktop (Windows® NT® users can click Start/

Programs/VISCPRO/VISCPRO.EXE).

1. Use your mouse to click Main from the VISCPRO® menu bar.

2. Click Log In from the Main menu options.

3. Click on the

to display the list of registered users.

4. Click Manager. It is not necessary to enter a password.

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

(arrow) on the right side of the User Name: list box

®

Instrument Company

®

Page 21

16

5. Click OK to complete the Log In procedure.

NOTE

For more information on VISCPRO security options, see page 40.

Checking/editing Instrument Settings

1. Use your mouse to click (select) Configure from the VISCPRO

menu bar (see graphic, next section).

2. Select your instrument from the list of available instruments (there

may be only one instrument in the list).

3. Select option 2, Instrument Settings, from the list of configuration

options. The Instrument Settings window will appear.

You will use the Instrument Settings window (see below) to describe

and control CCS instrument operational features. These settings affect the

instrument as a whole. Check the instrument settings for your CCS per

the instructions below , and make any necessary changes:

®

The Instrument Settings window

CANNON

Version 2.0a — November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 22

Use the ID field to input instrument identification information using up to

30 alphanumeric characters.

The S/N: field should correspond to the four-digit serial number from the

label on the CCS rear service panel.

The probe constant values (a0, a1, and a2) must be identical to the values

on the calibration certificate provided with your temperature probe.

Verify that the values correspond.

Note that firmware and communication port settings are automatically

determined. These values cannot be altered from this window.

When you have verified all settings for all editable fields, click OK.

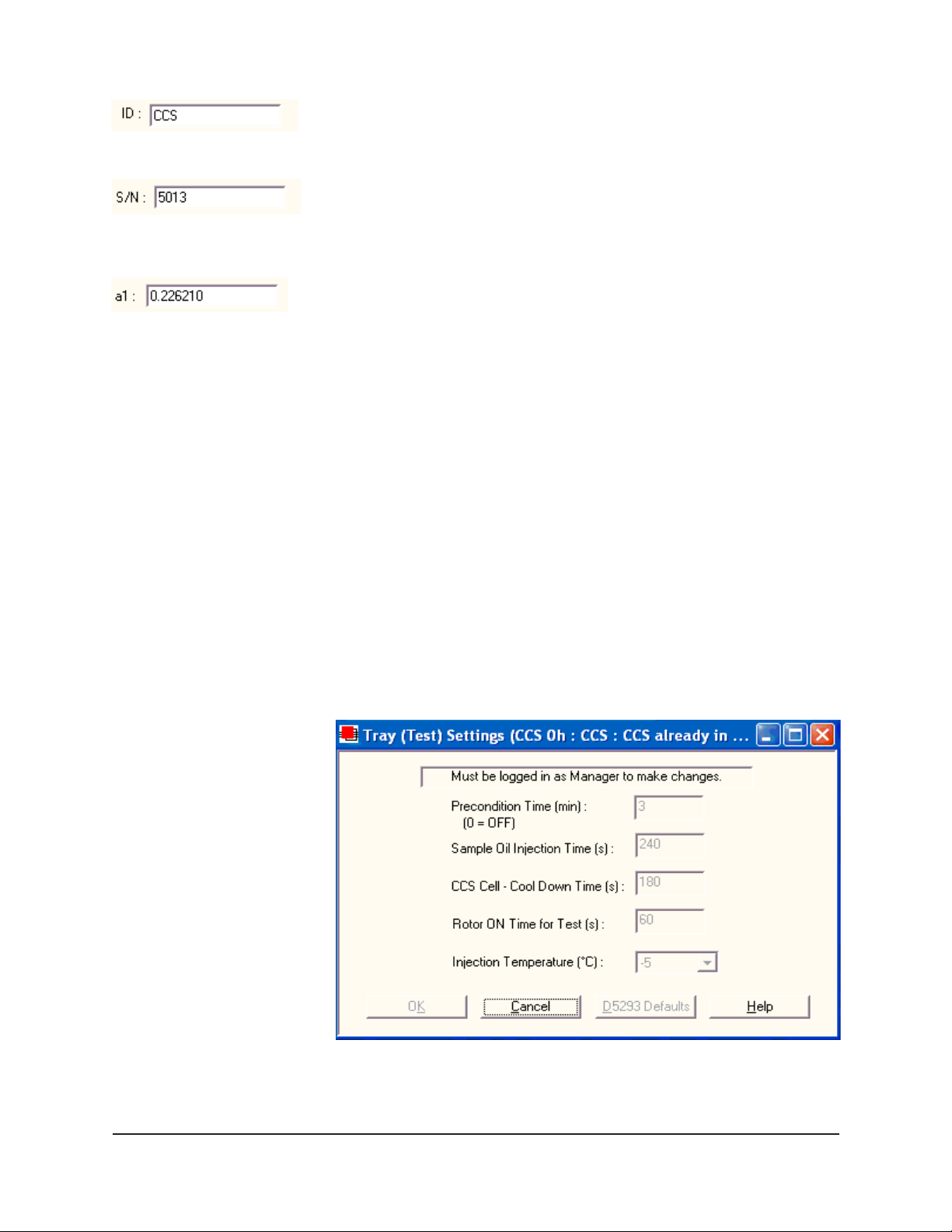

Viewing/editing other setup information

If your instrument has already been set up by a technician, you can use

the instructions in this section of the manual to check or, if necessary,

change the instrument settings.

17

1. Click Configure from the VISCPRO® menu bar .

2. Select your instrument from the list of available instruments.

3. Select Tray (Test) Settings from the list of configuration options.

The Tray (Test) Settings window will appear.

The Tray (Test) Settings window

CANNON

Version 2.0a — November 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 23

18

The T ray (Test) Settings window contains setup information for your

instrument. Default test settings (which may be restored at any time by

clicking the Defaults button) are specified in ASTM D 5293. In certain

circumstances, the user may wish to alter these settings. For more information, see Tray (Test) Settings in Chapter 5.

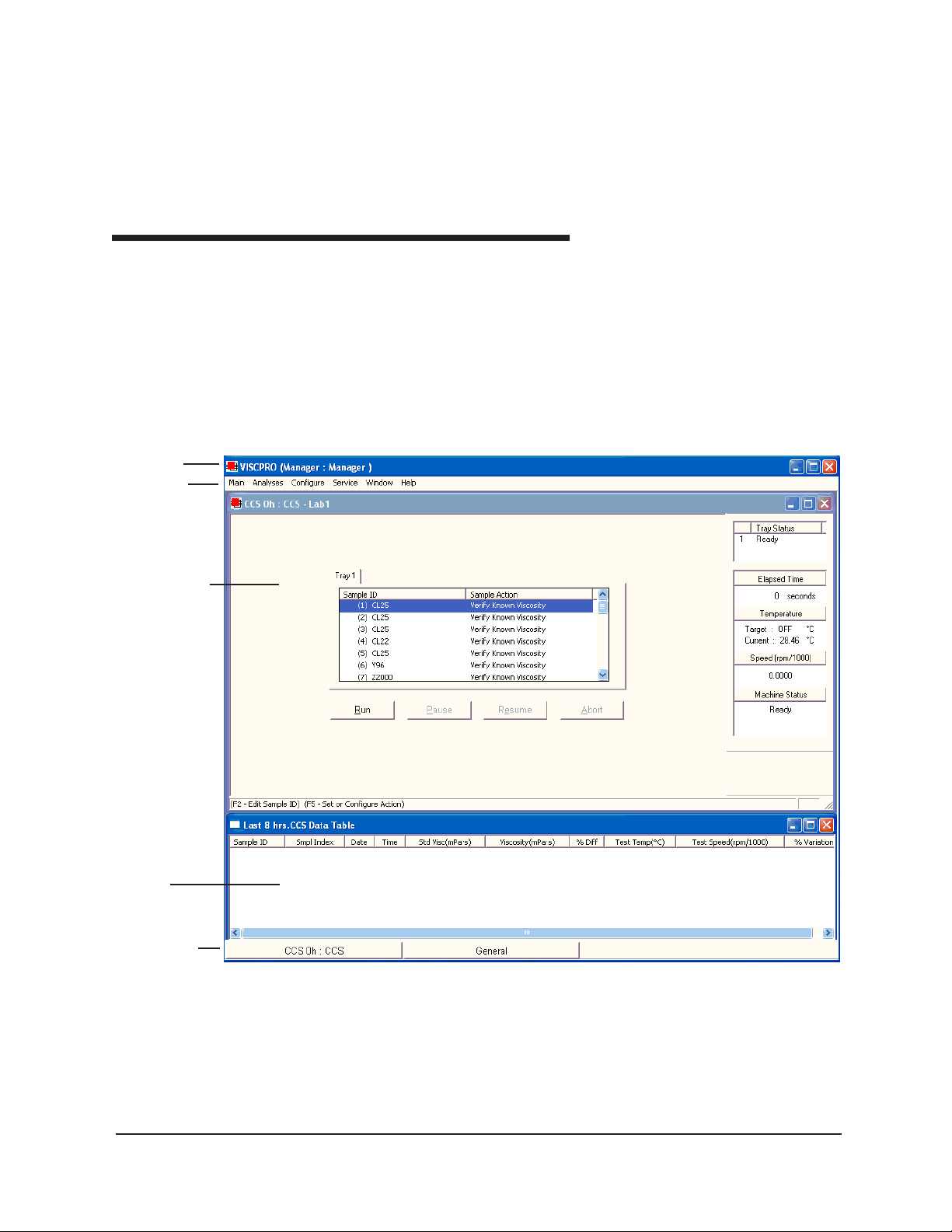

VISCPRO software interface elements

Title Bar

Menu Bar

Instrument

View window

The VISCPRO® primary display window is framed on the top by the

VISCPRO

®

title bar and menu bar, and on the bottom by the VISCPRO

status bar. The application window is usually preconfigured to include

two child windows. The first is an Instrument View window, which

®

describes your CANNON

instrument and provides controls for CCS

testing, and the second is an analysis window that displays data from

CCS tests.

®

Analysis

window

Status bar

The VISCPRO® primary display

CANNON

Version 2.0a — November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 24

19

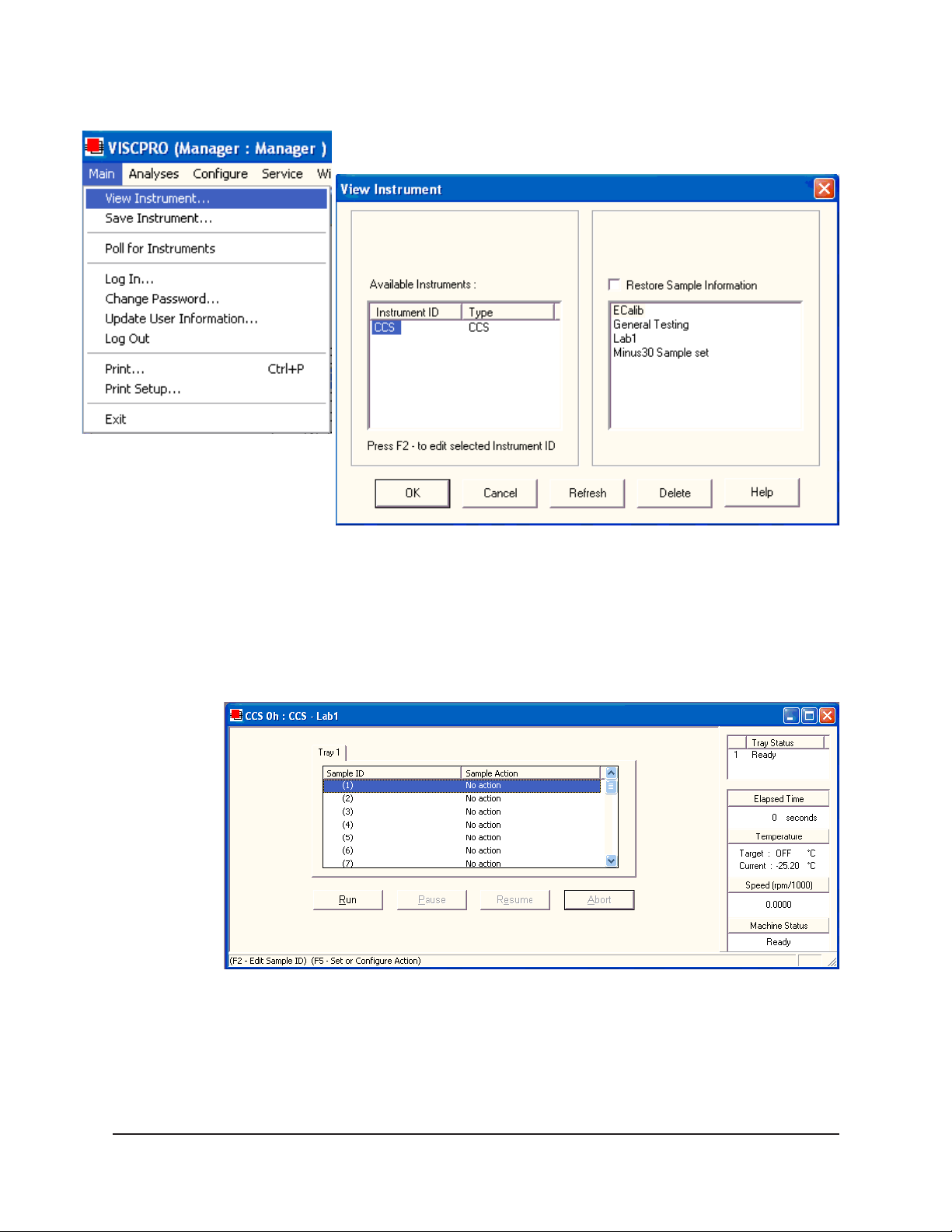

NOTE

If the Instrument View window does not appear, click View Instrument

from the Main menu:

The View Instrument window

Then click the desired instrument from the list of available instruments

and click OK. If the Available Instruments list box is blank, your CCS

instrument may not be on-line. Check cable connections and make

certain the instrument is ON.

The Instrument View window

CANNON

Version 2.0a — November 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 25

20

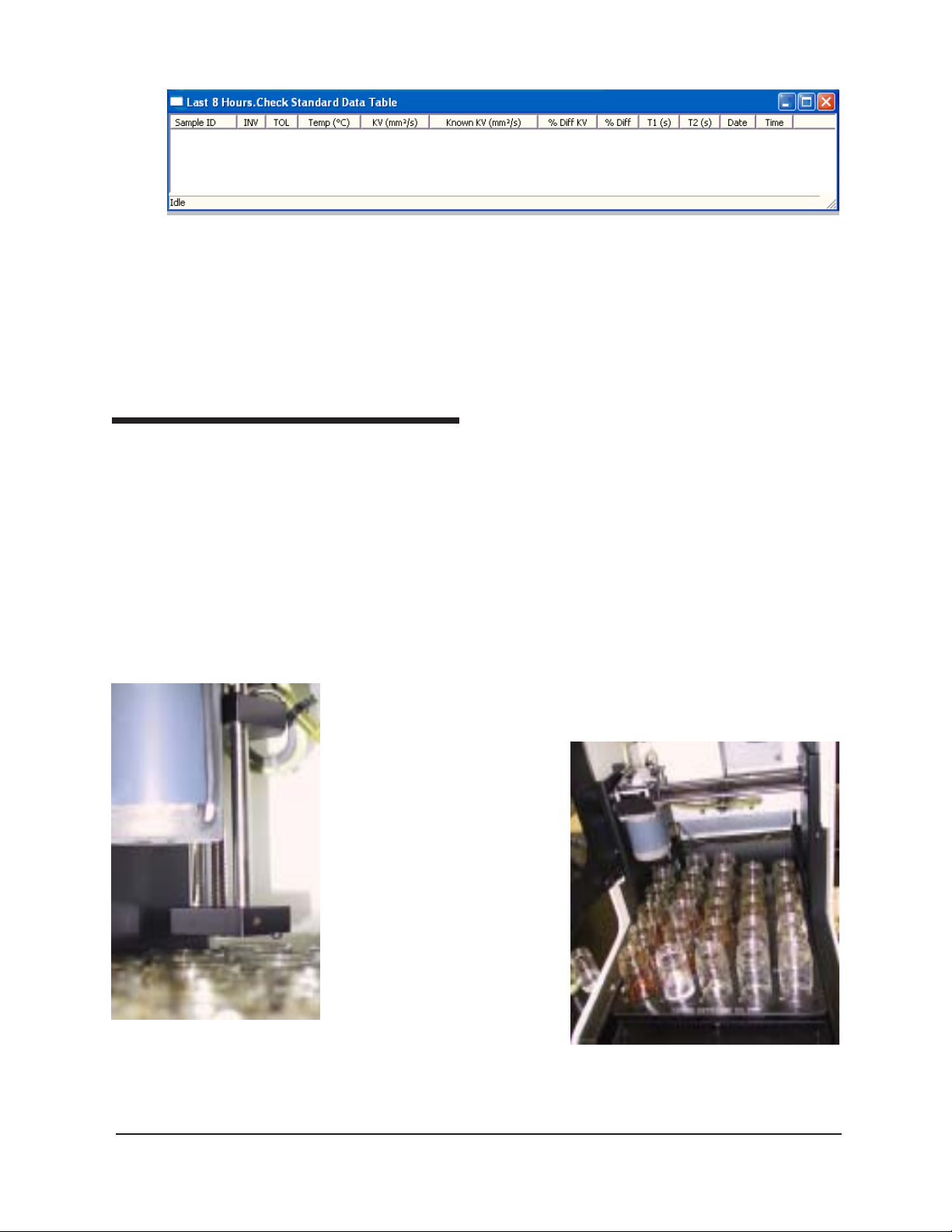

The CCS Data Table window

NOTE

To change the Tray (Test) Settings for your instrument(s), you must log in

to the security system as a manager.

4. Edit the values for Tray (Test) Settings as necessary. When done,

click OK to save current values and exit the Tray (Test) Settings

window.

Initial Stepper Motor Service

Prior to performing instrument actions with the CCS-2100 Automatic

Cold-Cranking Simulator, you must first home the Sample Tray mechanism as follows:

1. Make certain that the chiller is connected and operating properly .

Then turn the CCS instrument is ON.

2. Load the VISCPRO software by double-clicking the VISCPRO

on your W indows® desktop (Windows® NT® users can click Start/

Programs/VISCPRO/VISCPRO.EXE).

3. Click Service from the menu bar and select your CCS instrument

from the list.

4. Select Stepper Motor Service from the Service options.

®

icon

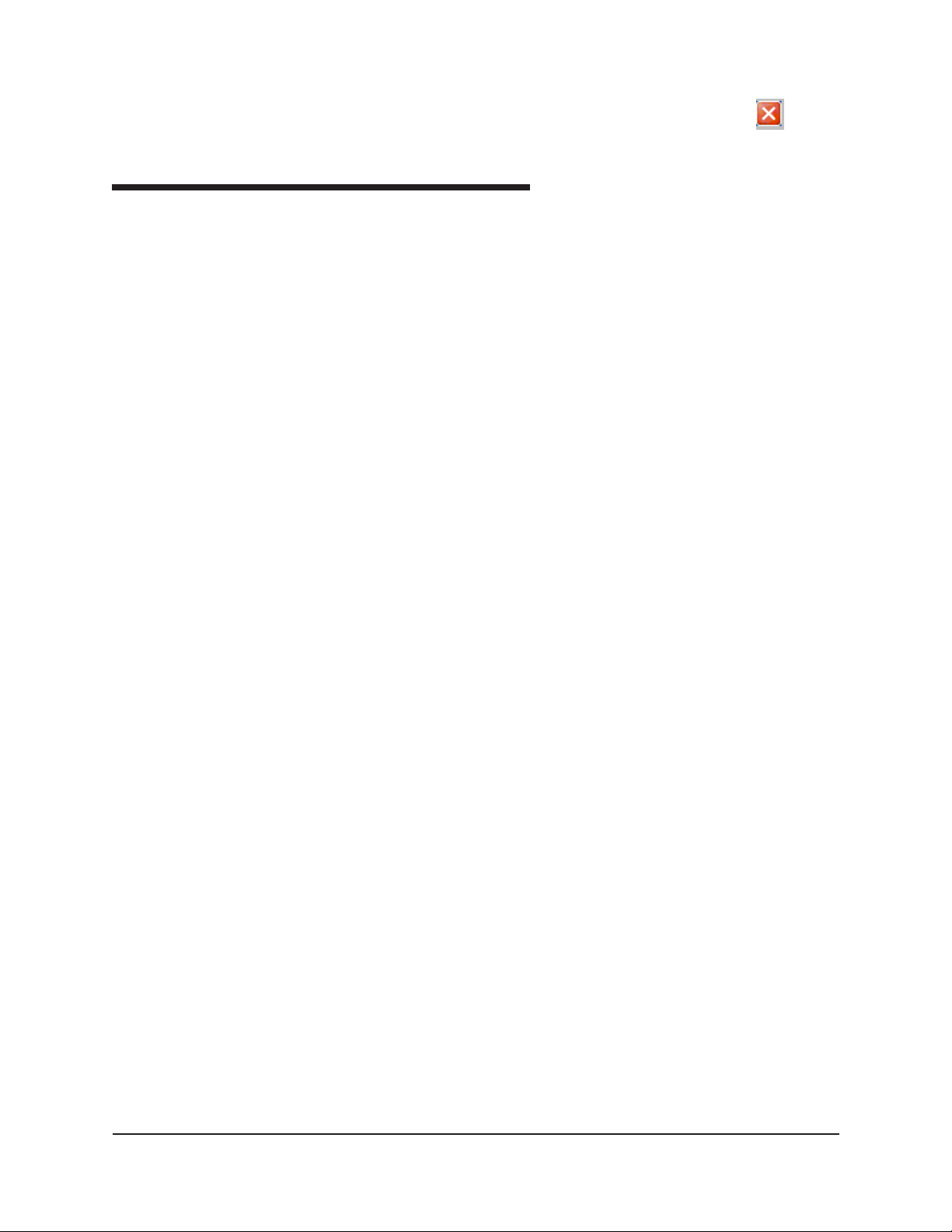

CCS sampler mechanism

with tube in home position

(raised)

CANNON

Version 2.0a — November, 2010; CANNON

5. Click on the Tube Up

button until the tube has

reached the top of its

travel.

6. Ensure that the arrow on

the Sample Tray is aligned

with the arrow on the

Sample T able (Table

Forward/Table Back

buttons).

7. Click on the Trolley Left

button until the sampler

has reached the limit of its

travel. If the Sample Tray

has been aligned properly ,

the sampler should now be

CCS-2100 with tray in home posi-

centered over the #1

sample position.

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 26

8. Click the Set Home Flag button. Note that the button will disappear

when the home flag has been set successfully . Then click

close the window .

Setting the CCS Set Motor Current

The CCS Motor Current window in VISCPRO® provides the software

interface for adjustment of the CCS motor current. To set the CCS motor

current:

1. Select the Set Motor Current option from the Service menu. The

Set Motor Current Service window will appear.

2. Prepare a 60 ml bottle of CANNON

place it in position 1 of the Sample Table. Then press the Start

button. The CCS will begin the current adjustment procedure.

3. When the rotor/stator has reached the correct temperature, the

software will prompt you to adjust the CCS motor current using the

dial on the front panel of the Control Unit. Adjust the current until

the value in the Speed: field of the Motor Current Service window

indicates a rotor speed of 240 rpm.

to

®

CL25 viscosity standard and

21

The Set Motor Current Service window will continue to display cell

temperature and cell motor speed. When you have completed the rotor

speed adjustment procedure, press the Close button to exit the Set

Motor Current Service window. To terminate the Set Motor Current

Service process at any time, click Finished.

CANNON

Version 2.0a — November 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 27

22

This page intentionally left blank.

CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

Version 2.0a — November, 2010; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 28

CHAPTER

3

Calibration is essential for the proper operation of the CCS. The CCS is

calibrated before it is shipped to the customer; however, the CCS should

be recalibrated after installation. Frequency of recalibration is at the

discretion of the user.

The CCS calibration procedure ensures that the mathematical constants

used in calculation of viscosity from CCS measurements accurately

reflect the unique properties of the CCS rotor/stator mechanism.

Calibration procedure

During calibration, the software uses calibration standard data from CCS

tests of viscosity standards to perform the mathematical calculations

necessary to derive three calibration constants– b0, b1 and b2. Then the

program displays the new constants and recomputes a viscosity (in cSt)

for each of the calibration standards. The resulting viscosity calculation is

compared with the known viscosity of the standard and displayed on the

computer screen.

23

CALIBRATING THE CCS

NOTES

The software allows the operator to manually change the constants if

necessary to more closely match actual and calculated viscosities.

A calibration must be performed for each temperature at which samples

will be tested.

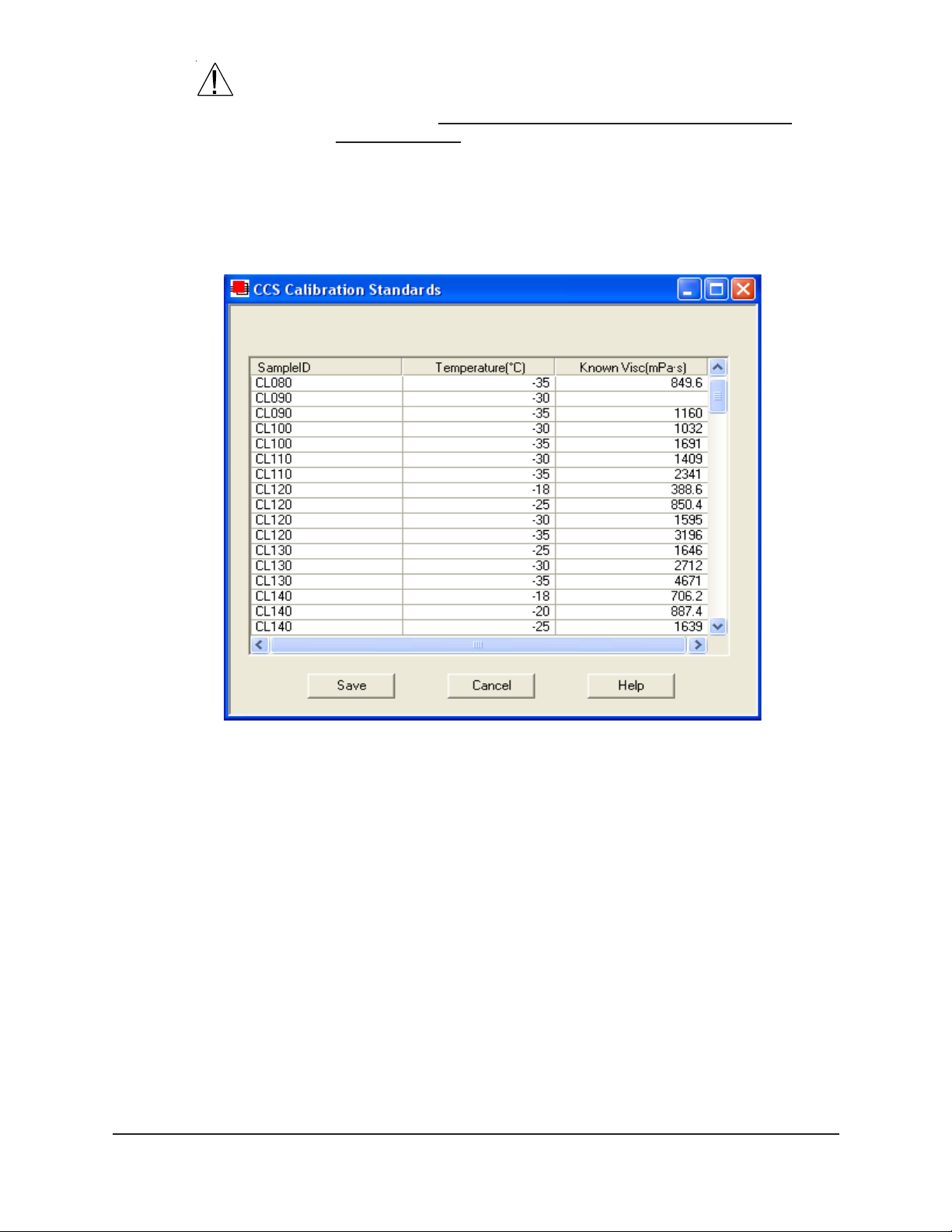

Preparing/updating the list of calibration standards

During installation of your VISCPRO® software package, a list of current

CANNON CL standards (see table, next page) is automatically loaded

into the VISCPRO® database. Before testing calibration standards, it will

be necessary for you to enter the viscosity data from the standard bottles

into the VISCPRO® program using the following procedure:

1. Click Configure from the VISCPRO® primary display and select

your CCS instrument.

2. Click CCS Calibration Standards from the Configure menu

options. The CCS Calibration Standards window will appear (see

graphic, following).

3. Assemble your calibration standards and input the viscosity data (in

mPa·s) from the standard bottles for each CL standard and temperature in the appropriate fields. If you have additional standards,

including user-defined standards, you can enter these by right-

CANNON

Version 2.0a— November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 29

24

clicking your mouse in the Sample ID field and selecting the Insert

New option . To delete an unused standard, right-click your mouse in

the Sample ID field and select Delete.

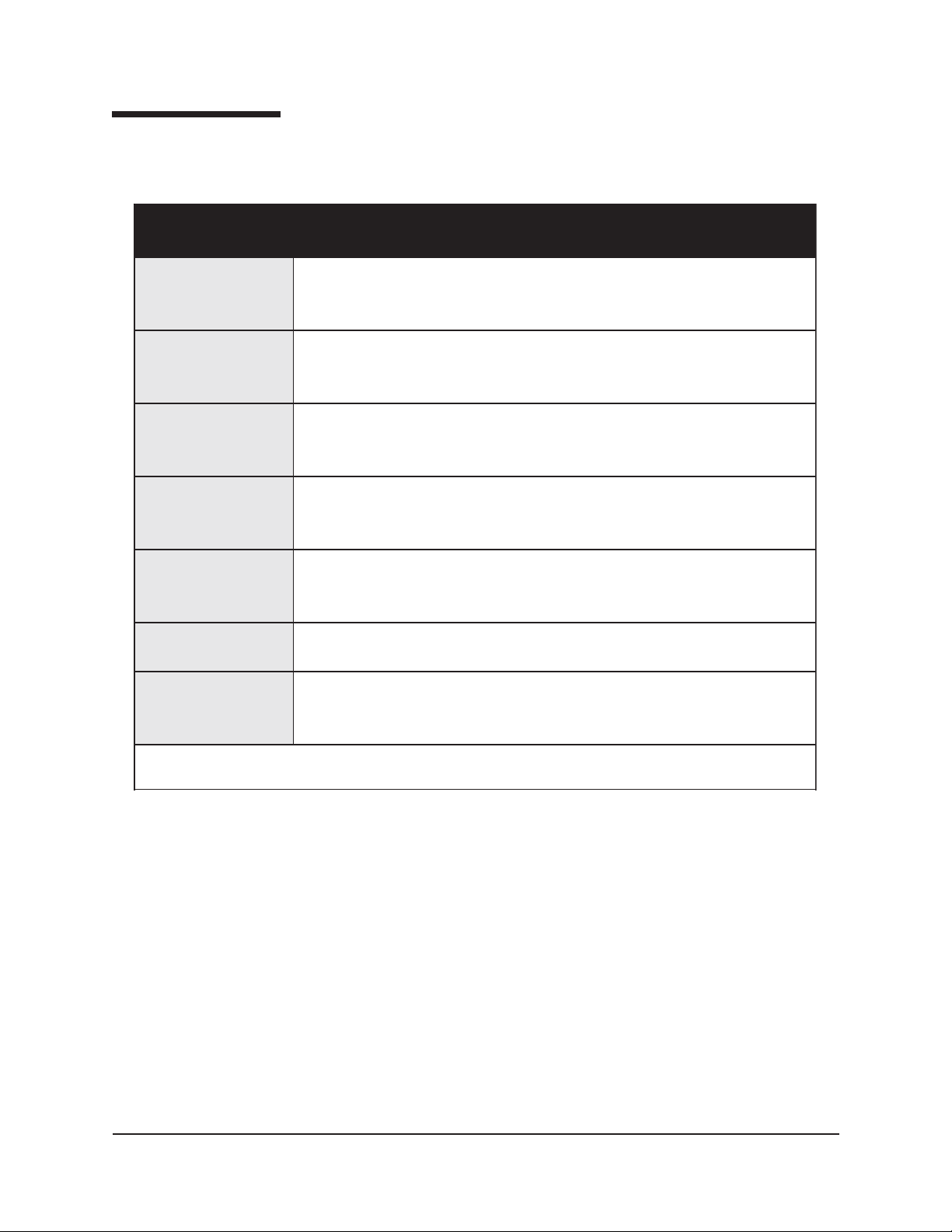

®

NONNAC

-itarbilaC

liOno

C°5- C°01- C°51- C°02- C°52- C°03- C°53-

080LC 009

090LC 0021

001LC 0090071

011LC 05510052

021LC 00800610023

031LC 005100920584

041LC 008006105230007

051LC 0071007200640508

061LC 0052005500011

071LC 054105220073003600311

091LC 00810053004700071

002LC 776105620034055700731

022LC 00310052001500111

042LC 0522006300060070100891

052LC 00810053004700271

062LC 057100720044005700431

082LC 0031005200050039

003LC 0042057300160050100391

023LC 00810053003700951

043LC 00720024000749121

083LC 0092008500031

024LC 0025005850441

084LC 00320054005900012

035LC 0006348918861

006LC 0073003700651

086LC 0559

047LC 000600021

erutarepmeT

SDRADNATSNOITARBILAC

detacidnItaytisocsiVlanimoNetamixorppA

NOTE

A minimum of five oils are required for calibration at each temperature in

accordance with ASTM D 5293- 08.

CANNON

Version 2.0a — November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 30

25

CAUTION

Make certain to verify the Known Viscosity (calibration standard viscosity

in mPa·s) in the calibration list BEFORE testing selected standards (see

next sections). Incorrect or outdated viscosity data may skew future

calibration results.

4. After you have entered all ID, temperature and viscosity information

into the CCS Calibration Standards list (see graphic), click the

SAVE button to save the data and exit the window.

Testing calibration standards

Selecting standards

The CCS Calibration Standards list window

T o calibrate the CCS instrument, it is first necessary to test samples of

known viscosity at the desired calibration temperatures.

1. Assemble a group of CANNON® standard oils with known viscosi-

ties for calibration. Refer to the table on the previous page when

choosing the appropriate CL standards.

2. Click Configure from the VISCPRO

your CCS instrument.

3. Click CCS Choose Calibration Standards from the Configure

menu options. The CCS Choose Calibration Standards window

(see graphic, next page) will appear.

4. Click the desired standards to select them for calibration. A check

mark indicates that the standard has been selected.

CANNON

Version 2.0a — November 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

®

primary display and select

Instrument Company

Page 31

26

NOTE

NOTE

The Choose Calibration Standards window

5. After the desired standards have been selected, click the desired

temperatures for calibration. Then click Generate List. The

VISCPRO software will automatically create a calibration test

sequence using the standards you selected and display the test

sequence in the Instrument View window .

To open a window displaying the complete list of samples to be tested,

along with the test temperatures for each sample, click CCS Sample List

Service from the Service menu.

6. Prepare the instrument and calibration standards in the same manner

as you would prepare samples for viscosity testing (see next chapter).

CCS-2100 users should place the standards in the sample table in the

test sequence indicated, and (if necessary) execute the Stepper Motor

Service (see page 19) to home the sampler mechanism.

7. T o initiate the calibration test sequence, click Run from the Instru-

ment View window. The instrument will begin testing with the first

sample in the test sequence. At the conclusion of testing, the sampler

mechanism for the CCS-2100 will return to the home position.

CANNON

Version 2.0a — November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 32

Performing the calibration

After valid calibration data has been obtained by testing calibration

standards, the CCS instrument may be calibrated using the following

procedure:

1. Use the VISCPRO

in order to access the calibration menu.

2. Click Configure from the VISCPRO

your CCS instrument.

3. Click Calibration. The Calibration window will appear.

®

software to log on as a Manager (Main/Log In)

®

primary display and select

27

CCS Calibration window

4. Select the desired calibration Test T emperature. If calibration

constants are known, they may be input manually in the appropriate

fields and saved by clicking Save New Constants. If test data from

calibration standards is to be used, select the desired date range for

CANNON

Version 2.0a — November 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 33

28

acceptable calibration data by using the No older than [x] hours spin

controls to set the date search parameters. Any calibration

standards successfully tested during the time frame you specified will

appear in the window list box.

NOTE

Selecting samples

NOTE

Saving new constants

Standards which were not within 0.05°C of the desired test temperature

during the test, according to temperature probe readings, will not be

displayed in the calibration window.

5. Select (or deselect) the specific sample entries you desire to use for

calibration from the displayed list by clicking on them to highlight

them. To select a range of samples, click on the first sample, then

press and hold the S key while clicking the last sample. To

select several individual samples for calculation, hold down the C

key while clicking the desired samples to select (or deselect) them.

You must select at least four sample entries or the software will not

recalculate the constants.

6. When the desired samples have been selected, click on Calculate

New Constants. The new constant(s) b0, b1 and b2 will be dis-

played in their respective fields in the window .

7. If the new calibration constants are acceptable (see next section),

click on Save New Constants to save the constants for the current

instrument. If the difference is not within acceptable limits, review

the calibration information more closely and select a different range

of standards for inclusion in the calibration routine.

8. Repeat steps 4-7 until a satisfactory calibration result is obtained for

each calibration temperature. If you are unable to calibrate successfully , refer to Chapter 6 for CCS maintenance/service information.

9. Click Close to exit the Calibration window. Test several standards

to verify a successful calibration.

Checking calibration accuracy

It is very important to check the accuracy of the calibration procedures

since any small errors in calibration could result in faulty viscosity

readings and erroneous data. The calibration window (see previous page)

provides vital calibration data including:

Test Visc[osity]: The viscosity of the standard (from the bottle label)

Calc Visc[osity]: The CCS-calculated viscosity for the standard

using the current calibration constants.

ReCalc Visc[osity]: The CCS-calculated viscosity for the standard

as calculated using the calibration constants derived from currentlyselected calibration data in the calibration window.

CANNON

Version 2.0a — November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 34

% Diff[erence]: The percentage difference between the Known

Visc[osity] and the Recalc[ulated] Visc[osity] as determined by the

formula:

%Diff =

Recalc Viscosity

(

[

Test Viscosity

) - 1

100

*

]

%Var: An indicator of rotor speed variation during the last 5 seconds

of each sample/standard run. This value is determined by the equation:

22

x5x

−∑

29

*100Var%

=

5

x

Where: x = { set of the last 5 seconds of speed readings}

You may evaluate the accuracy of the new calibration constants by

comparing the Known Visc[osity] for the standard with the

Recalc[ulated] Visc[osity] for each standard selected for the new

calibration. This difference is displayed as a percentage in the last

column (% Diff) of the updated sample list box.

_

x = mean of x

2

Σx

= sum of x

2

R: The displayed value is an indicator of how well the raw data fits

the calibration equation using the newest calibration constants. A

“perfect fit” value is 1.0000. CANNON recommends an “R” value in

excess of 0.9. Acceptable values will vary depending on the user’s

application.

Std. Dev (visc. * speed): The displayed value indicates viscosity

times rotor speed in the quadratic equation:

N * n = b0 + (b1*N) + (b2*N

Where N = rotor speed and n = viscosity

2

)

Recalc with constants

Saving new constants

NOTES

The Recalc with constants option will recalculate the %Diff[erence]

value using constants input manually by the user. To use this option,

input the desired constants in the appropriate fields and then press the

Recalc with constants button.

When you are satisfied with the calibration, click the Save New Con-

stants button. Then click Close to exit the Calibration window.

Once the Save New Constants button is pressed, the updated calibration

constants are associated with the selected instrument, and will remain

the same regardless of the instrument configuration defined for that

instrument.

You must click Save New Constants if you wish to save the new calibra-

tion constants.

T est several standards to verify a successful calibration.

CANNON

Version 2.0a — November 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 35

30

Viewing current calibration constants

T o view current calibration constants for your instrument, click Current

Cell Calibration Constants from the Configure menu.

The Current Cell Calibration Constants window will be displayed.

The Current Cell Calibration Constants window

Saving a calibration

When calibration is complete, the calibration information is only saved to

the current instrument configuration. This calibration information will

remain in effect until the instrument is recalibrated at that same temperature, or until instrument and tray settings from a previously-saved

instrument configuration are restored.

T o avoid losing valid calibration data, CANNON® recommends saving

the instrument configuration settings immediately after completing a new

calibration (see Saving a configuration). The name for the instrument

configuration should identify the specific instrument, the calibration

time, and the temperature(s):

EXAMPLE:

1-10-02 at -20 for CCS

After the instrument configuration has been saved, calibration data may

be restored at any time using the View Instrument option from the Main

menu. Note that the Restore Instrument Settings must be selected to

restore calibration data.

NOTE

The Restore Instrument Settings option is security-protected at the

Manager level (see manual instructions regarding security).

CANNON

Version 2.0a — November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 36

CHAPTER

4

31

TESTING SAMPLES WITH THE

CCS

This chapter of the manual will provide information on testing samples

using the CCS instrument.

®

controlling software offers the advantage of multi-

NOTE

The VISCPRO

sample testing for up to 30 samples. Sample data is automatically stored

to the VISCPRO® database for reporting and data collection. Additionally, several reports (analyses) may be used to calculate and display

viscosity values. All analyses provide a dynamic operation mode which

can immediately display and transmit test results to your computer

screen, printer, and/or serial port for in-house (LIMS) data collection.

Observe the safety cautions noted in the introductory chapter when

operating equipment. The CCS should only be operated by qualified

personnel.

The CCS instrument must be calibrated before it will be possible to test

samples and achieve accurate results. Complete all calibration procedures in Chapter 3 prior to testing samples with the CCS instrument.

Frequency of recalibration is at the discretion of the user.

Preparing the CCS and samples

Turning on the CCS

1. Verify that the water chiller is on and is operating at +5°C. If CCS

power is off, turn on the CCS by pressing the power switch on the

rear panel of the instrument. The (O) symbol indicates the OFF

position for the electrical switch for your unit (AC Mains).

CAUTION

CAUTION

CANNON

Version 2.0a— November, 2010; CANNON

2. Pour approximately 60 ml of each oil to be tested into clean 60 ml

sample jars.

NEVER test used oil samples in the CCS unless the samples are filtered

with a 5-micron filter. Particulate from unfiltered samples will severely

damage the copper stator, requiring the replacement of both the rotor

and the stator.

Oils with an anticipated test viscosity of less than 1200

mPa·s (cP) or greater than 30,000 mPa·s (cP) should NOT be tested in

the CCS. Damage to the motor or rotor/stator mechanism may result.

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 37

32

3. Prepare samples for

testing by pouring

approximately 55 ml of

sample material into the

60-ml sample jars. CCS2100 users should

position up to 30 sample

jars in the Sample Tray

(see photo) in the desired

order for testing.

Placing sample jars on the Sample

Sample Tray

NOTES

NOTES

You may wish to test calibration standards per your established laboratory procedures prior to sample testing. Recalibrate the CCS (see

Chapter 3, Calibration) if result variance warrants.

4. Turn on the computer and start the CCS software by double-clicking

the VISCPRO® icon on the Desktop. CCS-2100 users must execute

the Stepper Motor Service (see page 19) to home the sampler mechanism.

If you start the VISCPRO software before turning on your CCS instrument, use your computer mouse to click Main from the menu bar and

click Poll for Instruments from the Main menu options. This will establish

communications between the computer and the on-line instrument.

5. Orient the Sample Tray on the Simulator Mechanism Sample Table so

that the arrow on the tray is aligned with the arrow on the left guide

of the Sample Table (see photo). The gear on the underside of the

Sample Tray must engage

the gear in the center of

the base of the instrument.

When the alignment is

correct, the CCS sampler

mechanism at its default

position (farthest back and

left) will be centered over

sample #1 on the Sample

Tray.

CCS-2100 Sample Tray (top view)

correctly aligned on Sample Table

6. Ensure that the current

instrument is displayed in the VISCPRO

®

Instrument View window.

If it is not, click View Instrument from the Main menu and select the

desired instrument configuration from the list box on the left. Then

further define/select the desired instrument characteristics using the

check box option(s)

(see Chapter 5 for more information).

CANNON

Version 2.0a — November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 38

33

The

View Instrument

window

7. Click OK to display the Instrument View for the desired instrument:

The Instrument View window

8. T o enter sample information, double-click on Sample ID (1) with the

left mouse button to access the sample ID data entry field (or press

2).

9. Enter sample ID information in the sample list box using your

computer keyboard. After you have typed the sample ID, press the

T key to save the entry and move the cursor to the next Sample

ID field. Or press R to save the entry .

CANNON

Version 2.0a — November 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 39

34

NOTES

Once sample information is entered, the software automatically assigns

a sample action, Measure Sample Viscosity, for the sample. If the

Measure Sample Viscosity action is unavailable, the CCS has not been

calibrated for testing at that temperature.

If you do not enter a sample ID, the sample is automatically labeled

Unknown.

For information on saving and restoring sample ID information, see

Chapter 5.

T o select or change a sample action, highlight the appropriate Sample

ID(s) using the mouse or arrow keys, then click the RIGHT mouse

button (or press 5) to access sample action options:

NOTE

Testing calibration standards

NOTE

Sample action options

Then select the desired action by highlighting it with your mouse

cursor and clicking the left mouse button.

For additional information on software data entry features, including

multiple sample selection and cut & paste options, see Testing

samples—software options in Chapter 5.

If Verify Known V iscosity is selected as the test option for a sample,

the Select a Calibration S tandard window will open automatically.

Click on the desired standard and test temperature from the list of

available standards. Then click OK to close the window and complete data entry . To change your selection, right-click on the desired

sample ID from the list box and select Configure from the popup

menu choices.

For additional information on Calibration Standard Options, refer to

Chapter 3.

10. Continue entering sample information. When sample ID data entry is

complete, check the Tray Status window to verify that the instru-

ment is ready for testing.

CANNON

Version 2.0a — November, 2010; CANNON

®

CCS-2100 with VISCPRO® Instruction & Operation Manual

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 40

Test options

Running a test

35

Click on the RUN button in the Instrument View window to begin the

CCS test(s).

Introducing sample

CAUTION

Test details

Calculating viscosity

During testing the oil sample is introduced to the viscometric cell, which

contains a rotor/stator assembly . There is a very small clearance (gap)

between the rotor and the sides of the stator. The sample oil fills the

space below the rotor, the small gap between the rotor and the stator, and

the remaining space above the rotor and below the top of the stator.