Page 1

CANNON® CAV® 4.2

Automated Dual-Bath Kinematic Viscometer

CAV® 4.2

P/N 68.0505

Operator’s Manual

Revision 2.0, February 5, 2016

ASTM D445

Page 2

Page 3

CAV® 4.2

CANNON Instrument Company®

Operator’s Manual

Revision 2.0, February 5, 2016

2139 High Tech Road

State College, PA 16803

Page 4

CANNON®

CAV® 4.2 Operator's Manual, Rev. 2.0

Revision

Date

Details

Revision 1.0

June 12, 2015

Initial release

Revision 2.0

February 5, 2016

Add VISCPRO II operating instructions

Copyright

Copyright © 2016 CANNON Instrument Company®. All rights reserved.

Trademarks

CANNON® and the CANNON® logo are registered trademarks of CANNON Instrument

Company®.

Brookfield® is a registered trademark of Brookfield® Engineering Laboratories, Inc.

Watlow® is a registered trademark of Watlow® Electric Manufacturing Company.

Revision History

Contact

Address: CANNON Instrument Company®

2139 High Tech Road

State College PA 16803, USA

Phone: 1-814-353-8000; 1-800-676-6232

Fax: 1-814-353-8007

Website: http://www.cannoninstrument.com

Email:

Sales: sales@cannoninstrument.com

Service: service@cannoninstrument.com

ii

Page 5

CANNON®

CAV® 4.2 Operator's Manual, Rev. 2.0

Contents

Overview........................................................................................................................... 1

Related documents ....................................................................................................................... 1

Specifications / Compliances ........................................................................................................ 2

Notes/Cautions/Warnings ............................................................................................................. 3

Safety precautions ........................................................................................................................ 3

Getting Started ................................................................................................................. 5

Unpack and inspect ...................................................................................................................... 5

Setup the CAV® 4.2 ...................................................................................................................... 8

Connect hoses ........................................................................................................................ 10

Fill baths .................................................................................................................................. 13

Connect cables ........................................................................................................................ 15

Set bath temperature (CAV 4.2 GUI) ........................................................................................... 16

Calibrate temperature (CAV 4.2 GUI) ........................................................................................... 17

Set vacuum and pressure (CAV 4.2 GUI) ..................................................................................... 19

Adjust the default wash settings (CAV 4.2 GUI) .......................................................................... 20

Run a wash (CAV 4.2 GUI) ........................................................................................................... 21

Train sensors (CAV 4.2 GUI) ........................................................................................................ 22

Run a sample test (CAV 4.2 GUI) ............................................................................................. 23

Review and export data (CAV 4.2 GUI) ........................................................................................ 24

Connecting with VISCPRO II ............................................................................................. 25

Connect equipment .................................................................................................................... 26

Install VISCPRO II ........................................................................................................................ 26

Set up network adapter .............................................................................................................. 28

Configure firewall rules ............................................................................................................... 30

Configure USB Power Settings ................................................................................................... 32

CAV Registry settings .................................................................................................................. 33

Operation ....................................................................................................................... 35

CAV 4.2 GUI .................................................................................................................................35

VISCPRO® II software interface .................................................................................................. 39

iii

Page 6

CANNON®

CAV® 4.2 Operator's Manual, Rev. 2.0

Manage user accounts (VISCPRO II / CAV 4.2 GUI) ...................................................................... 41

Log in ...................................................................................................................................... 41

Change password .................................................................................................................... 42

Setup and edit user accounts .................................................................................................. 42

Logout .................................................................................................................................... 42

Connect VISCPRO II to the CAV® 4.2 .......................................................................................... 43

Set bath temperature (VISCPRO II) ............................................................................................. 43

Calibrate temperature (VISCPRO II) ............................................................................................ 44

Set vacuum and pressure (VISCPRO II) ........................................................................................ 44

Train sensors (VISCPRO II) .......................................................................................................... 45

Run a wash (VISCPRO II) ............................................................................................................. 45

Run a sample test (VISCPRO II) ................................................................................................... 46

View test results (VISCPRO II) ..................................................................................................... 49

Control preheaters ...................................................................................................................... 49

Control sample cup heaters ........................................................................................................ 50

Advanced Setup .............................................................................................................. 51

Calibrate viscometer tube (VISCPRO II) ...................................................................................... 51

Method/Test settings .................................................................................................................. 52

Print method settings ............................................................................................................. 52

Edit method settings ............................................................................................................... 53

Adjust Default Wash Settings ..................................................................................................... 56

Create a standard CAV Data Table analysis ................................................................................. 57

Maintenance and Service ................................................................................................. 59

Update CAV 4.2 software and firmware ...................................................................................... 59

Tools and materials required ................................................................................................... 59

To prepare the USB flash drive ................................................................................................ 59

To replace the UI updater ........................................................................................................ 60

To update the UI software....................................................................................................... 60

To update the controller firmware .......................................................................................... 60

To update the VISCPRO II software......................................................................................... 61

Change viscometer tube ............................................................................................................. 62

Replace power supply ................................................................................................................. 63

djust solvent dosing chamber sensors ...................................................................................... 64

A

Specifications.................................................................................................................. 65

iv

Page 7

CANNON®

CAV® 4.2 Operator's Manual, Rev. 2.0

Warranty......................................................................................................................... 67

Products limited warranty .......................................................................................................... 67

Reagent and chemical warranty ................................................................................................. 67

Returning a product to CANNON® ............................................................................................. 68

Required information.............................................................................................................. 68

Hazardous materials ............................................................................................................... 68

Shipping notification .............................................................................................................. 68

Replacement Parts List..................................................................................................... 69

List of Figures

Figure 1 — Complete CAV® 4.2 System ............................................................................................ 8

Figure 2 — Tubing connections ....................................................................................................... 10

Figure 3 — Solvent inlets ................................................................................................................. 11

Figure 4 — Temperature baths ........................................................................................................ 13

Figure 5 — Temperature bath details .............................................................................................. 14

Figure 6 — Bath top (fill hole) .......................................................................................................... 15

Figure 7 — Main screen ................................................................................................................... 16

Figure 8 — Temperature settings screen ........................................................................................ 16

Figure 9 — Field entry screen .......................................................................................................... 16

Figure 10 — Thermometer access holes ........................................................................................... 17

Figure 11 — Temperature calibration screen ................................................................................... 18

Figure 12 — Bath screen .................................................................................................................. 19

Figure 13 — Services menu ............................................................................................................. 19

Figure 14 — Pressure/vacuum adjustment screen ........................................................................... 19

Figure 15 — Settings menu ............................................................................................................. 20

Figure 16 — Wash screen ................................................................................................................ 20

Figure 17 — Main screen (wash button)........................................................................................... 21

Figure 18 — Train screen ................................................................................................................. 22

Figure 19 — Methods screen ........................................................................................................... 23

Figure 20 — Field entry screen ........................................................................................................ 23

F

igure 21 — Closed network settings .............................................................................................. 25

Figure 22 — Network connections .................................................................................................. 28

v

Page 8

CANNON®

CAV® 4.2 Operator's Manual, Rev. 2.0

Figure 23 — Connection properties ................................................................................................. 28

Figure 24 — TCP/IP properties ........................................................................................................ 29

Figure 25 — Advanced settings ....................................................................................................... 29

Figure 26 — Main screen menu ....................................................................................................... 35

Figure 27 — Main screen ................................................................................................................. 37

Figure 28 — Bath screen ................................................................................................................. 38

Figure 29 – VISCPRO interface window .......................................................................................... 40

Figure 30 — Solvent dosing chamber .............................................................................................. 64

List of Tables

Table 1 — Related documents ........................................................................................................... 1

Table 2 — Specifications and compliances ........................................................................................ 2

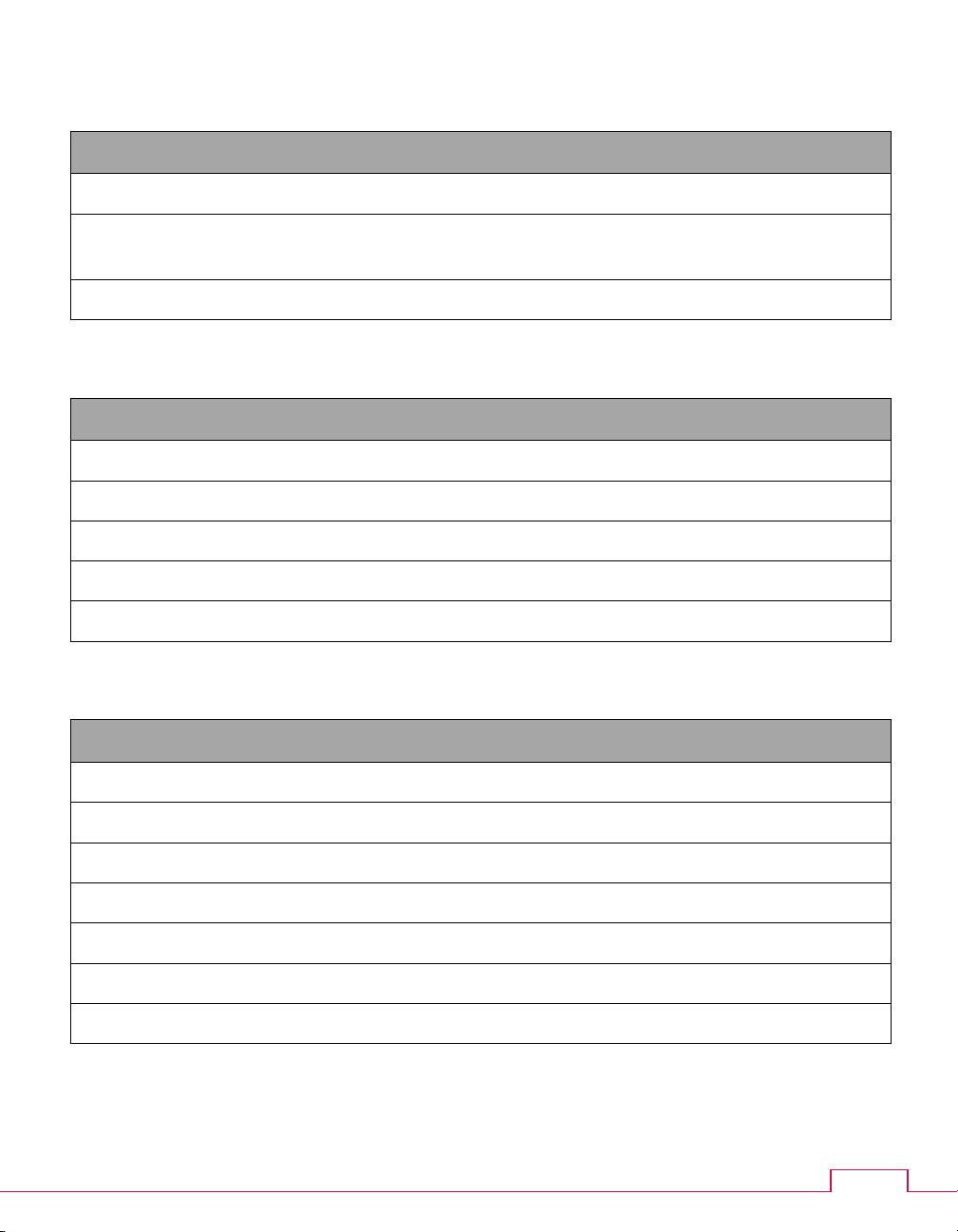

Table 3 — Packing list (main components) ........................................................................................ 5

Table 4 — Packing list (installation) .................................................................................................. 6

Table 5 — Packing list (tools) ............................................................................................................ 6

Table 6 — Packing list (consumables) ............................................................................................... 7

Table 7 — Packing list (networking) .................................................................................................. 7

Table 8 — Packing list (spares) .......................................................................................................... 7

Table 9 — Tools and materials required ............................................................................................ 9

Table 10 — Silicone bath fluid selection .......................................................................................... 13

Table 11 — Tools and materials required ..........................................................................................17

Table 12 — Tools and materials required ........................................................................................ 19

Table 13 — Tools and materials required ......................................................................................... 21

Table 14 — Tools and materials required ........................................................................................ 22

Table 15 — Tools and materials required ......................................................................................... 23

Table 16 — Tools and materials required ........................................................................................ 26

Table 17 — VISCPRO II registry entries ............................................................................................ 27

Table 18 — CAV® 4.2 registry entries .............................................................................................. 33

able 19 — GUI screen details ......................................................................................................... 36

T

Table 20 — VISCPRO window details .............................................................................................. 39

Table 21 — Default user accounts ................................................................................................... 41

Table 22 — Preheater settings ........................................................................................................ 49

vi

Page 9

CANNON®

CAV® 4.2 Operator's Manual, Rev. 2.0

Table 23 — Sample cup heater settings (may vary between instruments, this is a starting point) ... 50

Table 24 — Method Settings: Test ...................................................................................................53

Table 25 — Method Settings: Wash ................................................................................................ 54

Table 26 — Method Settings: Advanced ......................................................................................... 55

Table 27 — Method Settings: Drop Criteria ..................................................................................... 56

Table 28 — CAV data table fields ..................................................................................................... 57

Table 29 — Specifications ............................................................................................................... 65

Table 30 — CAV 4.2 replacement parts ........................................................................................... 69

vii

Page 10

CANNON®

CAV® 4.2 Operator's Manual, Rev. 2.0

viii

Page 11

CANNON®

CAV® 4.2 Operator's Manual, Rev. 2.0

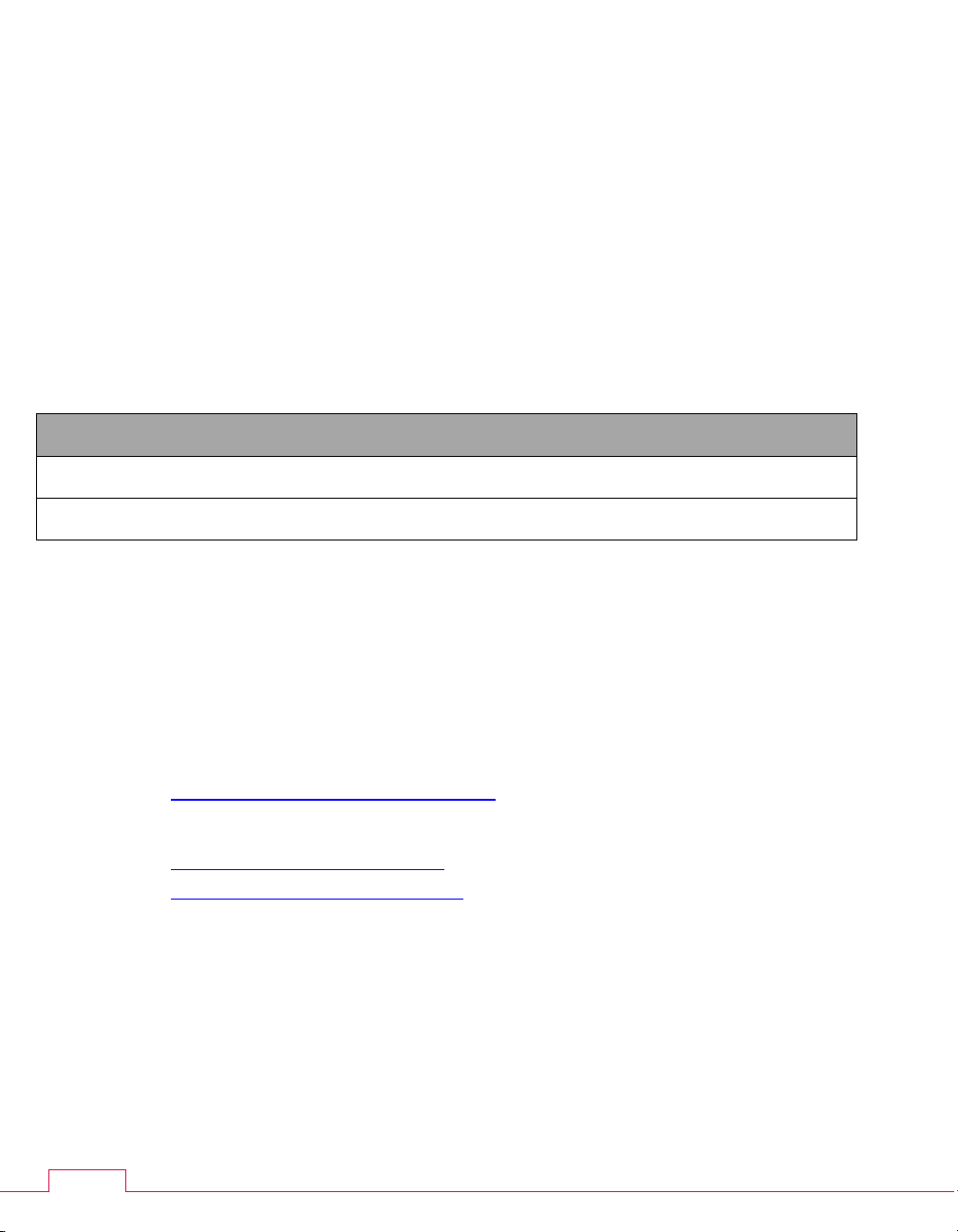

Title

Reference Number

Standard Test Method for Kinematic Viscosity of Transparent and

ASTM D445

Standard Specifications and Operating Instructions for Glass

ASTM D446

Petroleum products -- Transparent and opaque liquids --

ISO 3104

Glass capillary kinematic viscometers -- Specifications and

operating instructions

ISO 3105

Petroleum products -Transparent and opaque liquids -

viscosity

IP 71

Overview

The CANNON® CAV® 4.2 is an automated, high throughput, dual-bath kinematic viscometer

for ASTM D445. The CAV® 4.2 combines CANNON® quality and reliability with modern

design and unique features to enhance lab productivity, reduce costs, and improve data

quality.

Related documents

Table 1 — Related documents

Opaque Liquids (and Calculation of Dynamic Viscosity)

Capillary Kinematic Viscometers

Determination of kinematic viscosity and calculation of dynamic

viscosity

Determination of kinematic viscosity and calculation of dynamic

1

Page 12

Overview CANNON®

CAV® 4.2 Operator's Manual, Rev. 2.0

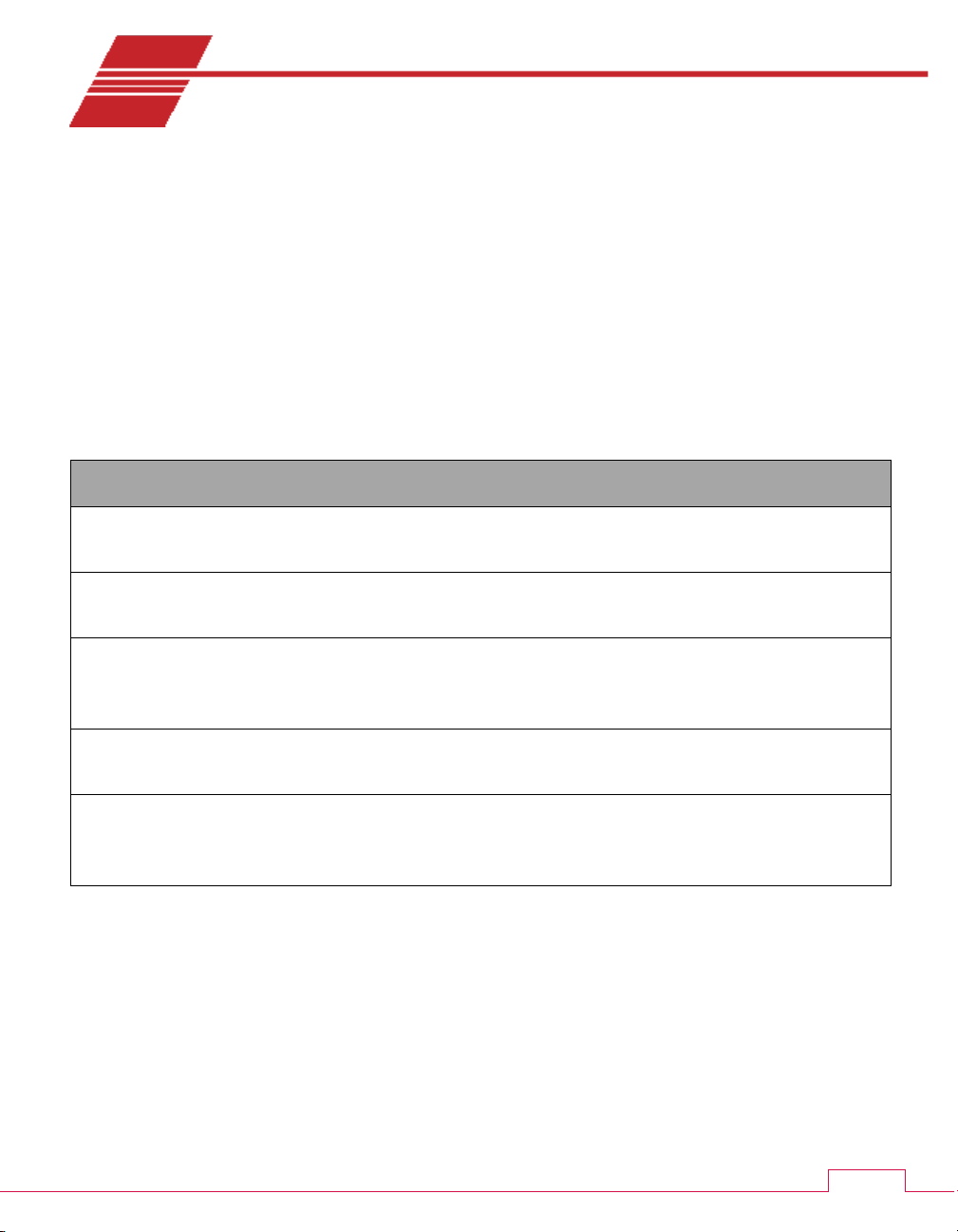

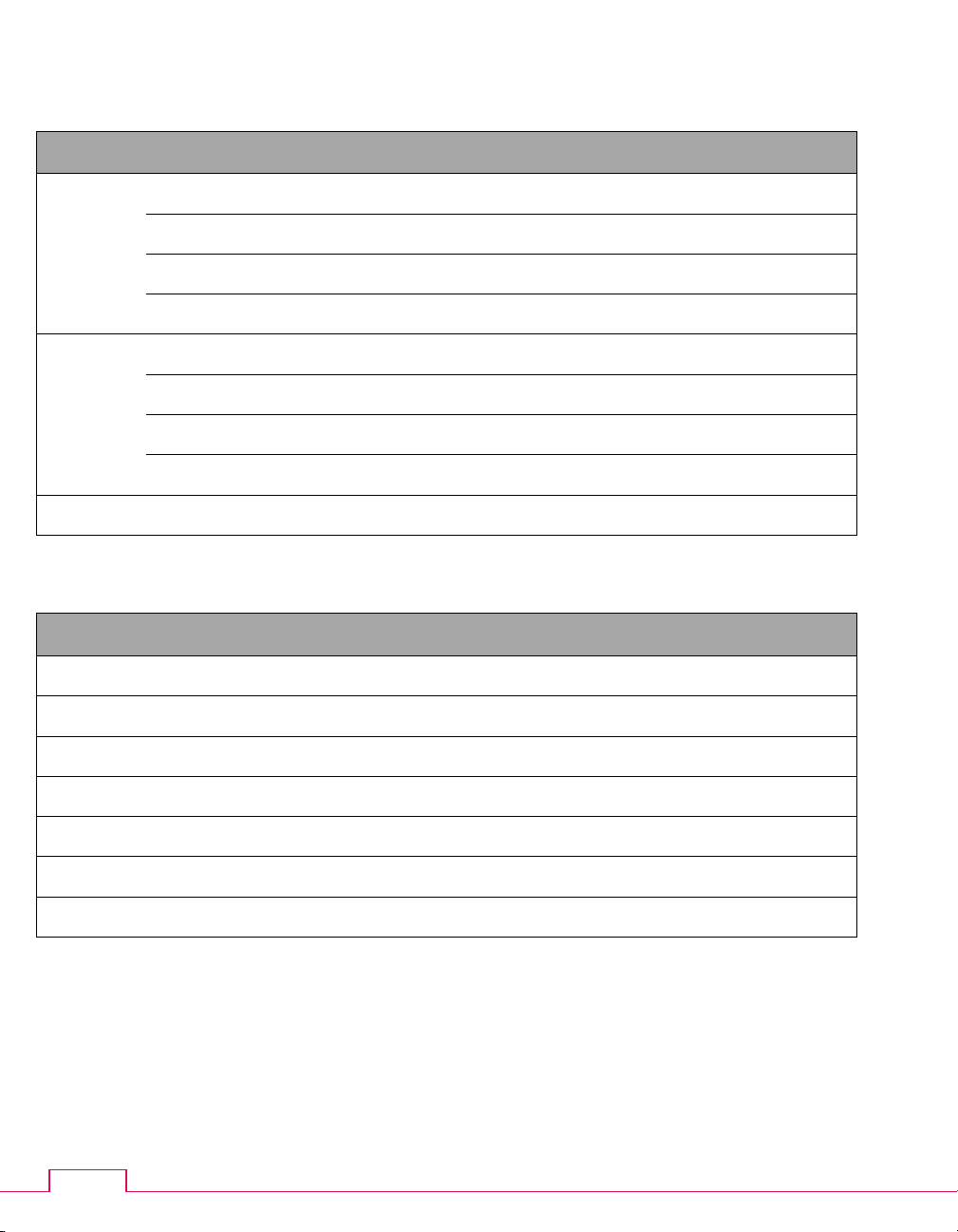

Specifications / Compliances

Specifications

Details

Model

CAV® 4.2

Methodology

ASTM D445/D446, ISO 3104/3105, IP 71

Applications

Formulated oil analysis, hydraulic oil analysis, additive

heavy fuel testing, waxes/paraffin, crude oil testing, glycols

Dimensions (W × D × H)

36 cm × 66 cm × 72 cm (14.25 in × 26 in × 28.5 in)

Weight

63 kg (140 lb)

Operational temperature

20 °C to +100 °C (± 0.01 °C); without a TE bath cooler, the

Down to 15 °C (± 0.03 °C) with integrated TE bath cooler

Maximum throughput

24 tests per hour

Automated sample capacity

28 positions (2 × 14 positions)

Minimum sample/solvent

volume required

8 mL sample/15 mL solvent per test

Viscosity range

0.5 mm²/s to 10,000 mm2/s in 100-fold increments

are also available.

Timing resolution

0.01 seconds (timing accuracy to ± 0.001 seconds)

Power requirements

100 VAC, 50/60 Hz, 1200 W

230 VAC, 50/60 Hz, 1200 W

Operating conditions

15 °C to 30 °C, 10% to 75% relative humidity (non-

Compliance

CE Mark: EMC Directive (2004/108/EC); Low Voltage

Directive (2006/95/EC); ROHS

Table 2 — Specifications and compliances

analysis, marine fuel testing, base stock analysis, light and

range

minimum temperature is +5 °C above ambient temperature

Up to 150 °C (± 0.03 °C) with integrated high temperature

bath

(depending on viscometer tubes selected). Fast run tubes

115 VAC, 50/60 Hz, 1200 W

condensing), Installation Category II, Pollution Degree 2

2

Page 13

CANNON® Overview

CAV® 4.2 Operator's Manual, Rev. 2.0

Notes/Cautions/Warnings

Notes, caution, and warnings are used in the manual to call an operator’s attention to

important details prior to performing a procedure or step. Read and follow these important

instructions. Failure to observe these instructions may void warranties, compromise operator

safety, and/or result in damage to the CAV® 4.2.

Notes provide more information about the content that follows.

Cautions alert the operator to conditions that may damage equipment.

Warnings alert the operator to conditions that may cause injury.

Safety precautions

Please observe the following general safety precautions for proper and safe operation of the

CAV® 4.2.

• Only qualified personnel should operate the CAV® 4.2.

• Make sure that you read and understand all operating instructions and safety

precautions listed in this manual before installing or operating your unit. If you have

questions regarding instrument operation or documentation, contact CANNON

Instrument Company.

• Do not deviate from the installation, operation, or maintenance procedures described in

this manual. Improper use of the CAV® 4.2 may result in a hazardous situation and may

void the manufacturer’s warranty.

• Handle and transport the unit with care. Sudden jolts or impacts may cause damage to

components.

• Observe all warning labels. Never remove warning labels.

3

Page 14

Overview CANNON®

CAV® 4.2 Operator's Manual, Rev. 2.0

~MAINS

• Never operate damaged or leaking equipment.

• Unless procedures specify otherwise, always turn off the unit and disconnect the mains

cable from the power source before performing service or maintenance procedures, or

before moving the unit.

• Refer all service and repairs to qualified personnel.

~MAINS

(O)

The

supply. The AC power input must match the electrical specifications of

the instrument.

Never operate the equipment with a damaged MAINS AC power cable.

Use only the manufacturer-supplied MAINS AC power cable. This cable

must be inserted into a receptacle with a protective earth ground.

The (O) symbol indicates the OFF position for the electrical switches for

your unit.

symbol indicates the connections for the AC power

4

Page 15

CANNON®

CAV® 4.2 Operator's Manual, Rev. 2.0

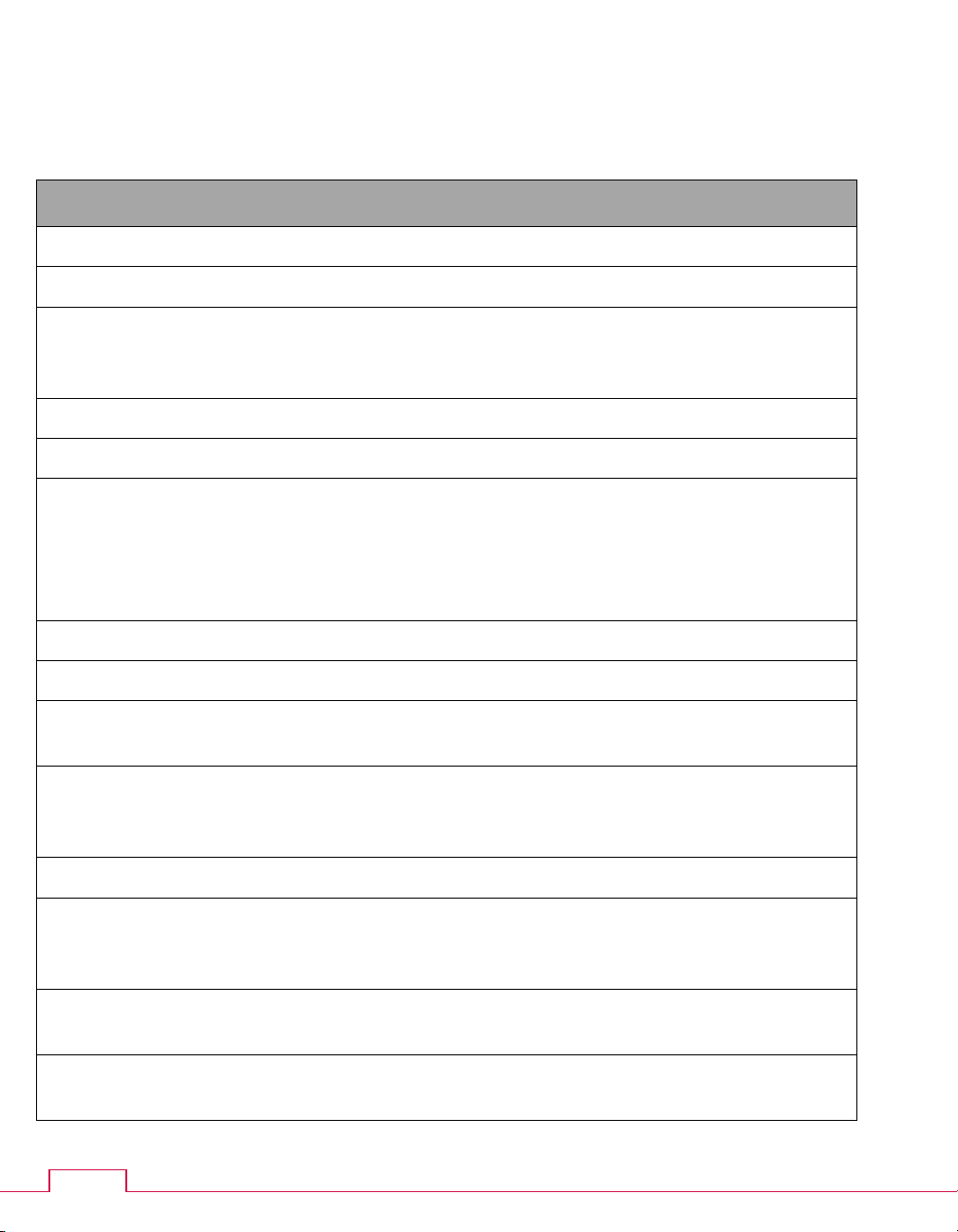

Description

Part Number

CAV® 4.2

68.0229

Sample carousel (2)

68.0049 for use with glass vials

68.0092 for use with metal vials

MAINS AC power cable

Varies by locale

Dostmann digital thermometer

61.5600

Thermometer probes (2)

61.5601

CAV® 4.2 Operator’s Manual

68.0505

Getting Started

This chapter covers all steps necessary to set up, calibrate, and run a sample on the CAV® 4.2.

Procedures are intended to be performed in the order written. These are basic, simplified

procedures that will familiarize an operator with the instrument. More detailed instructions

are provided in other chapters.

Unpack and inspect

Unpack and inspect the complete CANNON® CAV® 4.2 and all accessories as soon as they are

received.

Caution: Many components are fragile. Use caution when moving and

handling the CAV® 4.2 and accessories.

1. Carefully unpack the entire contents of the shipment.

2. Referring to the packaging list, verify that all materials were received.

3. Inspect materials for defects and shipping damage. Contact your CANNON

representative to resolve any issues.

Table 3 — Packing list (main components)

5

Page 16

CAV® 4.2 Operator's Manual, Rev. 2.0

Getting Started CANNON®

Description

Part Number

Solvent

1

⁄8" blue FEP tubing (25 ft)

81.2185

Brass tee fittings (2)

81.0007

Bottle caps for GL-38 bottles (4)

65.3201

20 micron filters (4)

65.0047

1

⁄2" white nylon tubing (15 ft)

62.1500.3

Brass elbow

68.0309

1

⁄2" white nylon elbows (2)

62.1500.2

1

⁄2" white nylon tees (2)

62.1500.4

Exhaust

6 mm blue FEP tubing (15 ft)

81.2102

Description

Part Number

1

⁄8" Allen wrench

27.1340

3

⁄16" Allen wrench

68.0464

T-wrench

81.2222

Glass funnel

81.3112

Rubber stoppers (3)

11.3115

Tubing cutter

81.1074

Yellow Tygon tubing (2 ft)

71.4.16

Table 4 — Packing list (installation)

Waste

Table 5 — Packing list (tools)

6

Page 17

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Getting Started

Description

Part Number

Sample test oils

varies

Glass vials (144 vials)

9717-V01: glass vials

Silicone bath fluid (2 L)

Varies by application

Description

Part Number

CAT cables, red (2)

61.3378

USB to Ethernet adapter

68.0496

8-port network switch

68.0495

USB cable

68.0508

USB flash drive

17.5121

Description

Part Number

6 A fuses (4)

28.0851

12 A fuses (4)

25.2455

Thermal fuse

68.0439

Hose fittings (2)

81.2101

Compression connectors (4)

81.2096

Brass 3⁄8" to 1⁄4" reducer fittings (2)

61.3566

O-rings (4)

61.3567

Table 6 — Packing list (consumables)

(optional) Metal sleeves (14)

68.0455: metal sleeves

Table 7 — Packing list (networking)

Table 8 — Packing list (spares)

7

Page 18

CAV® 4.2 Operator's Manual, Rev. 2.0

Getting Started CANNON®

Setup the CAV® 4.2

Initial setup of the CAV® 4.2 involves connecting the hoses and cables and filling the baths

with silicone bath fluid.

Figure 1 — Complete CAV® 4.2 System

8

Page 19

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Getting Started

Description

Hose connections

Complete CAV® 4.2

1⁄8" blue FEP tubing (25 ft)

MAINS AC power cable

1⁄2" white nylon tubing (15 ft)

Waste receiver

Bottle caps for GL-38 bottles (4)

Solvent

20 micron filters (4)

7

⁄8" wrench

3⁄16" Allen wrench

Glass funnel

Rubber stopper

Silicone bath fluid (2 L)

Tubing cutter

Glass or metal vials

Optional

Networking

Brass tee fittings (2)

CAT cables, red (2)

Brass elbow

USB to ethernet adapter

1⁄2" white elbows (2)

8-port network switch

1⁄2" white tees (2)

6 mm blue FEP tubing (15 ft)

Table 9 — Tools and materials required

9

Page 20

CAV® 4.2 Operator's Manual, Rev. 2.0

Getting Started CANNON®

Solvent inlets

Waste outlets

Exhaust ports

Connect hoses

Assemble the CAV® 4.2 on a secure, level surface with sufficient room behind the instrument

to maintain a clear airflow and allow for unimpeded connection of the solvent inlet and waste

outlet tubing.

Figure 2 — Tubing connections

10

Page 21

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Getting Started

Solvent inlet well

Solvent tubing

Inlet pipes with

connectors

B A A B

1. Place the CAV® 4.2 on a solid, level workbench. The workbench must be located near a

MAINS AC power connection capable of providing sufficient current (10 A at 115 V

AC) to

the CAV® 4.2. Depending on the materials tested, solvent used, and laboratory

regulations, the work area may also need to be equipped with a ventilation system.

2. Place the waste receiver beneath the CAV® 4.2. In order to promote proper drainage, the

top of the waste receiver must be lower than the waste outlets on the back of the

instrument.

3. Place the solvent bottles alongside or beneath the CAV® 4.2.

4. Measure and cut the

1

⁄8" blue FEP tubing to use as the solvent tubing. Each piece of

tubing must run from the solvent inlet well to the bottom of a solvent bottle.

5. Connect the solvent tubing to the CAV® 4.2:

a. Remove the cover plate from the solvent inlet well.

b. Thread the tubing through the solvent inlets on the back of the lid.

c. Unscrew the appropriate compression connector and slide it onto the tubing.

d. Slide the tubing onto the flared inlet pipe and hand tighten the compression

connector.

Figure 3 — Solvent inlets

compression

11

Page 22

CAV® 4.2 Operator's Manual, Rev. 2.0

Getting Started CANNON®

Note: Each piece of tubing must run from the middle of the CAV® 4.2

6. Insert the solvent tubing into the solvent bottle:

a. Thread the tubing through the bottle cap.

b. Screw a 20 micron filter onto the end of the tubing.

c. Screw the bottle cap onto the solvent bottle.

7. Repeat steps 4 through 6 for each piece of solvent tubing.

into the waste receiver. 1⁄2" white nylon elbows and tees are provided to

enable combining both waste tubes into one tube before entering the

waste receiver. A brass elbow is also provided to connect the waste

tubing to the waste receiver.

8. Measure and cut the

1

⁄2" white nylon tubing to use as the waste tubing.

Caution: Do not overtighten the waste outlet compression nut.

9. For each bath, connect the waste tubing to the CAV® 4.2:

a. Unscrew the brass compression nut from the waste outlet fitting.

b. Thread the tubing through the compression nut.

1

c. Slide the ferrule onto the tubing. Position it

⁄2" from the end of the tubing.

d. Insert the tubing into the outlet fitting until the ferrule is seated.

e. Tighten the compression nut by hand.

7

f. Using a

⁄8" wrench, tighten the compression nut to create a good seal.

10. Connect the waste tubing to the waste receiver.

11. Measure, cut, and install the 6 mm blue FEP tubing as exhaust tubing.

12

Page 23

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Getting Started

Bath operating range

Recommended bath fluid viscosity

20 °C to 100 °C

10 cSt

101 °C to 150 °C

20 cSt

Left bath

Right bath

Display hood

Plumbing lid

Fill baths

Each temperature bath must be filled with Dow Corning 200 silicone fluid prior to operation.

The viscosity of the fluid depends upon the temperature of the bath during most operations:

Table 10 — Silicone bath fluid selection

Figure 4 — Temperature baths

13

Page 24

CAV® 4.2 Operator's Manual, Rev. 2.0

Getting Started CANNON®

Drain plug

Warning: Follow all lab policies regarding the safe handling and

disposal of all hazardous materials.

1. Open the plumbing lid.

2. Raise the display hood by pulling it forward, up, and then back in an arcing motion until

the hood rests on top of the frame. Once raised, the latches will keep the hood in

position.

3

3. Insert the

/16" Allen wrench into each drain plug access hole and verify that the drain

plug is closed (clockwise to close).

Cold fill level

access holes

Figure 5 — Temperature bath details

4. Insert the funnel into the thermometer hole in the top of the bath to be filled.

5. Slowly pour a small amount of silicone fluid into the bath. Check for leaks. Continue

filling until the bath fluid reaches the cold fill level (marked with a thin black/red line on

the glass), approximately 0.9 L.

6. Repeat steps 3 through 5 for the second bath.

14

Page 25

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Getting Started

Fill hole

Figure 6 — Bath top (fill hole)

Connect cables

1. Connect the MAINS AC power cord to the CAV® 4.2.

2. Plug the power cord into the MAINS AC outlet at the work station.

3. (optional) Connect the CAV® 4.2 to the network switch with one CAT cable.

4. (optional) Connect the network switch to the PC with a CAT cable and USB adapter.

15

Page 26

CAV® 4.2 Operator's Manual, Rev. 2.0

Getting Started CANNON®

Target

temperature

Current

temperature

Target

Current

temperature

Set bath temperature (CAV 4.2 GUI)

Set the temperature of the baths before calibrating the instrument.

1. From the main screen, click the target temperature button ( ) for the appropriate

bath. The temperature settings screen opens.

temperature

Figure 7 — Main screen

2. Click the Target Temperature field. A field entry screen opens.

Figure 8 — Temperature settings screen Figure 9 — Field entry screen

16

Page 27

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Getting Started

Description

Assembled CAV® 4.2

Dostmann digital thermometer

Thermometer probe

Thermometer

3. Enter the target temperature, then click the green checkmark to submit it and return to

the temperature settings screen.

4. Click Save and then Back to return to the main screen.

5. Wait for the current temperature to match the target temperature.

6. Repeat steps 1 through 5 for the second bath.

Calibrate temperature (CAV 4.2 GUI)

The temperature calibration of the CAV® 4.2 should be verified whenever the instrument is

moved, bath fluid is refilled, or a new temperature is to be used. The instrument is calibrated

by inserting a thermometer through an access hole in the display hood, measuring the actual

temperature of the bath fluid, and entering that temperature into the CAV® 4.2 software.

Table 11 — Tools and materials required

1. If it is raised, lower the display hood and plumbing lid.

2. Carefully insert a thermometer through the access hole in the display hood and into the

bath until the tip of the thermometer is in the middle of the capillary portion of the

viscometer tube. The thermometer passes through the same hole in the top of the bath

unit that was used to fill the unit with fluid.

access holes

Figure 10 — Thermometer access holes

17

Page 28

CAV® 4.2 Operator's Manual, Rev. 2.0

Getting Started CANNON®

screen

3. Wait for the thermometer to adjust to the temperature of the bath fluid. Read the

reference temperature.

4. From the main screen, click the current bath temperature button ( ) for the

appropriate bath. The temperature

calibration screen opens.

5. Click the Reference Temperature field.

A field entry screen opens.

6. Enter the reference temperature

measured in step 3, then click the

green checkmark to submit it and

return to the temperature calibration

screen.

7. Click Calibrate, wait for the system to

save the adjustment, and then click

Back to return to the main screen.

8. Remove and clean the thermometer.

9. Repeat steps 2 through 8 for the second bath.

Figure 11 — Temperature calibration

18

Page 29

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Getting Started

Description

Assembled CAV® 4.2

Rubber stoppers

Set vacuum and pressure (CAV 4.2 GUI)

Set the vacuum and pressure of the CAV® 4.2 before running the instrument.

Table 12 — Tools and materials required

1. From the main screen, swipe the screen with left or right to move to the appropriate

bath screen.

Figure 12 — Bath screen Figure 13 — Services menu

2. On the bath screen, click on the

Service button. The services menu

opens.

3. Click Adjust Pressure/Vacuum. Follow

the instructions on the screen.

4. Click Back to return to the bath

screen.

5. Repeat steps 1 through 4 for the

second bath.

Figure 14 — Pressure/vacuum adjustment

screen

19

Page 30

CAV® 4.2 Operator's Manual, Rev. 2.0

Getting Started CANNON®

Note: The CAV® 4.2 wash settings are defined in the method settings of

Adjust the default wash settings (CAV 4.2 GUI)

Verify and adjust the default wash settings before running a wash for the first time.

the last run test. When you start the CAV® 4.2 from a complete

1. From the main screen, swipe the screen with left or right to move to the appropriate

bath screen.

2. On the bath screen, click the Settings button. The settings menu opens.

shutdown, it has no knowledge of the last run test and uses the default

wash settings.

Figure 15 — Settings menu Figure 16 — Wash screen

3. Click Default Wash. The Wash screen opens.

4. Verify and adjust the wash values as necessary. To change the wash value, you must be

logged onto the CAV® 4.2 with appropriate privileges.

5. Click Save when you are done adjusting the settings.

6. Click Back to return to the bath screen.

7. Repeat steps 1 through 6 for the second bath.

20

Page 31

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Getting Started

Description

Assembled CAV® 4.2

Sample vials

Wash button

Wash button

Run a wash (CAV 4.2 GUI)

Wash solvent through the CAV® 4.2 prior to training sensors or running a test.

Table 13 — Tools and materials required

1. Insert an empty vial into position 1 of the carousel for the bath to be washed.

2. From the main screen, click the wash button ( ) for the appropriate bath. The

instrument immediately starts the wash cycle.

Figure 17 — Main screen (wash button)

3. When the wash cycle is complete, repeat steps 1 and 2 for the second bath.

21

Page 32

CAV® 4.2 Operator's Manual, Rev. 2.0

Getting Started CANNON®

Description

Description

Assembled CAV® 4.2

Sample test oil

Sample vials

Sample preparation materials

Notes: The ubbelohde tubes in each bath may have different viscosity

Note: Do not check the

Train sensors (CAV 4.2 GUI)

Train the sensors whenever a CAV® 4.2 bath is to operate at a new temperature. Once trained,

the calibration values for a particular temperature are saved and will be recalled if the CAV®

4.2 is set to run at that temperature again. Retraining for a particular temperature is only

necessary when the viscometer tube is changed or if sensor performance changes over time.

Table 14 — Tools and materials required

limits.

1. Insert an empty vial into position 1 of the carousel for the bath to be trained.

2. Fill a vial with a test solution that has a viscosity approximately 3 times higher than the

lower viscosity limit of the ubbelohde tube. Insert the vial into position 2.

Temperature calibration must be performed first.

3. From the main screen, click the tube button ( ) for the appropriate bath. The train

screen opens.

Prewash or Trip Points

4. Click Start Training.

5. When training is complete, repeat

steps 1 through 4 for the second bath.

22

Only boxes.

Figure 18 — Train screen

Page 33

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Getting Started

Description

Description

Assembled CAV® 4.2

Sample test oil

Sample vials

Sample preparation materials

Run a sample test (CAV 4.2 GUI)

This test verifies system calibration and provides a technician with basic training in operating

the CANNON® CAV® 4.2.

Table 15 — Tools and materials required

1. Following your laboratory practices, prepare a 10 mL sample of test oil in the provided

sample vials, and then insert the sample vial into position 1 of the appropriate carousel.

2. From the main screen, click the circle representing position 1 on the appropriate bath.

The methods screen opens.

Figure 19 — Methods screen Figure 20 — Field entry screen

3. Click Verify Known KV. The field entry screen open.

4. Enter the sample ID, then click the green checkmark to submit it. Another field entry

screen opens.

5. Enter the viscosity value (in cSt) of the test oil, then click the green checkmark to submit

it and return to the main screen.

6. Click the run button ( ).

7. When the test is complete, click the Results button to review the test results.

23

Page 34

CAV® 4.2 Operator's Manual, Rev. 2.0

Getting Started CANNON®

Review and export data (CAV 4.2 GUI)

Once a test completes, the results can be exported to a USB drive in CSV format.

1. From the main screen, click the Results button.

2. Review the results.

3. Click the Export button. A field entry screen opens.

4. Enter the sample filename, then click the green checkmark to submit it. A Save As

window opens.

5. Select the location to which to save the data file, then click Save.

24

Page 35

CANNON®

CAV® 4.2 Operator's Manual, Rev. 2.0

Connecting with VISCPRO II

The CAV® 4.2 ships from CANNON® ready for deployment on a dedicated, closed network.1

The following graphic displays the default settings for the closed network.

Figure 21 — Closed network settings

1

For other network configurations, please contact the CANNON service department.

25

Page 36

CAV® 4.2 Operator's Manual, Rev. 2.0

Connecting with VISCPRO II CANNON®

Description

Description

Assembled CAV® 4.2

CAT cables, red (1 + 1 per CAV® 4.2)

USB flash drive with VISCPRO II

installation software and drivers

USB to Ethernet adapter

PC with Windows® 8/7/Vista/XP

8-port network switch

Connect equipment

All CAV® systems and the PC (with USB 2.0 to Ethernet adapter) connect to the network

switch using standard CAT 5e/6 cables.

Table 16 — Tools and materials required

1. Start and log onto the PC.

2. Plug the USB to Ethernet adapter into a USB 2.0 port on the PC. Windows® will attempt

to automatically install the required drivers. If necessary, a copy of the driver is provided

on the USB flash drive.

3. Connect a CAT cable from the Ethernet adapter to the network switch.

4. Connect CAT cables from each CAV® 4.2 to the network switch.

Install VISCPRO II

There are no configurable options in the VISCPRO installation routine.

1. Uninstall any previous version of VISCPRO software.

2. Insert the USB drive into an open USB port on the PC.

3. Run USB Flash Drive > VISCPRO > setup.exe.

26

Page 37

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Connecting with VISCPRO II

Registry Key

Default value

Description

EthernetPortNumber

1982

TCP port on which VISCPRO listens

EthernetServerIPAddress

10.0.1.2

IP address of the Ethernet connection

MaxAllowedInstruments

4

Maximum number of instrument to

has been reached, it stops polling.

MaxPollResponseWaitTime

2000

Maximum time in milliseconds that

MaxResponseWaitTime

20000

Maximum time in milliseconds that

The following registry keys are set to default values during installation of VISCPRO. You

cannot edit them from within the VISCPRO software. The only way to change these values is

by directly editing the registry.

Caution: Editing registry entries may be hazardous to the health of

your Windows® installation.

Table 17 — VISCPRO II registry entries

that VISCPRO uses

which VISCPRO will connect. VISCPRO

polls for instruments in sequential order

of the InstrumentAddress. Once the

maximum number of allowed instrument

(2 seconds)

(20 seconds)

VISCPRO waits for an instrument

response when polling.

VISCPRO waits for an instrument

response.

27

Page 38

CAV® 4.2 Operator's Manual, Rev. 2.0

Connecting with VISCPRO II CANNON®

Set up network adapter

1. Open Network and Sharing Center on the PC.

2. Click Change adapter settings. The Network Connections window opens. Right-click the

device associated with the USB adapter, and rename the connection USB To Ethernet

Connection.

Figure 22 — Network connections

3. Right-click the connection and select Properties. The Connection Properties window

opens.

Figure 23 — Connection properties

4. Click Configure. The Controller Properties window opens.

5. Select the Power Management tab. Uncheck Allow the computer to turn off this device to

save power. Click OK.

28

Page 39

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Connecting with VISCPRO II

6. Right-click the connection and select Properties. The Connection Properties window

opens.

7. Uncheck Internet Protocol Version 6 (TCP/IPv6).

8. Double-click Internet Protocol Version 4 (TCP/IPv4). The Internet Protocol (TCP/IP)

Properties window opens.

Figure 24 — TCP/IP properties Figure 25 — Advanced settings

9. Set the IP address to 10.0.1.2, the subnet mask to 255.255.255.0, and the default gateway

to 10.0.1.1, then click OK to close the Internet Protocol (TCP/IP) Properties window.

10. Click OK to close the Properties window.

11. In the top Network Connections menu bar, click Advanced > Advanced Settings.

12. Move the USB to Ethernet Connection to the last connection position. Click OK.

29

Page 40

CAV® 4.2 Operator's Manual, Rev. 2.0

Connecting with VISCPRO II CANNON®

Configure firewall rules

The Windows® Firewall on the PC on which VISCPRO is installed must be configured to

permit inbound, outbound, and ping communications on port 1982 (default).

1. If necessary, close VISCPRO.

2. Open Control Panel > Windows Firewall > Advanced Settings. This opens the Windows

Firewall with Advanced Security window.

3. Configure an inbound rule:

• In the upper left corner, click Inbound Rules.

• In the upper right corner under Actions, click New Rule.

• Select Port. Click Next.

• Select TCP and Specific local ports. Enter 1982 in the port field.

• Select Allow the connection. Click Next.

• Check all boxes: Domain, Private, and Public. Click Next.

• In the Name field, enter Viscpro_IN. Click Finish.

4. Configure an outbound rule:

• In the upper left corner, click Outbound Rules.

• In the upper right corner under Actions, click New Rule.

• Select Port and click Next.

• Select TCP and Specific local ports. Enter 1982 in the port field.

• Select Allow the connection. Click Next.

• Check all boxes: Domain, Private, and Public. Click Next.

• In the Name field, enter Viscpro_Out. Click Finish.

5. Configure on inbound rule to respond to ping requests:

• In the upper left corner, click Inbound Rules.

• In the upper right corner, under Actions, click New Rule.

• Select Custom. Click Next.

30

Page 41

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Connecting with VISCPRO II

• Select All programs and click Next.

• Change Protocol Type to ICMPv4.

• Click Customize.

• Select Specific ICMP types.

• Check Echo Request and click OK. Click Next.

• Select both Any IP address boxes. Click Next.

• Select Allow the connection. Click Next.

• Check all boxes: Domain, Private, and Public. Click Next.

• In the Name field, enter Ping In. Click Finish.

6. Configure on outbound rule to send ping requests:

• In the upper left corner, click Outbound Rules.

• In the upper right corner, under Actions, click New Rule.

• Select Custom. Click Next.

• Select All programs and click Next.

• Change Protocol Type to ICMPv4.

• Click Customize.

• Select Specific ICMP types.

• Check Echo Request and click OK. Click Next.

• Select both Any IP address boxes. Click Next.

• Select Allow the connection. Click Next.

• Check all boxes: Domain, Private, and Public. Click Next.

• In the Name field, enter Ping Out. Click Finish.

7. Close the Windows Firewall with Advanced Security window.

31

Page 42

CAV® 4.2 Operator's Manual, Rev. 2.0

Connecting with VISCPRO II CANNON®

Configure USB Power Settings

The Windows® Firewall on the PC on which VISCPRO is installed must be configured to

constantly provide power to the USB port for the USB to Ethernet adapter.

Hints:

• Under Control Panel > Power Options, select Change plan settings for your power plan.

Select Change advanced power settings:

• Under the Hard Disk >Turn off hard disk after, change the setting to Never.

• Under the USB settings > USB selective suspend setting, change the setting to

Disabled.

• Under Device Manager > Universal Serial Bus controllers, double-click on the appropriate

USB hub, select the Power Management tab, and uncheck Allow the computer to turn off

this device to save power.

32

Page 43

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Connecting with VISCPRO II

Registry Key

CAV 4.2

Default

Description

EthernetPortName

Remote

10.0.1.2

IP address of the Ethernet

InstrumentAddress

Instrument

Address2

1-4

Numeric address for the

instrument

Instrument ID

Instrument

4

Instrument name

Serial Number

Serial

Number3

Text string

Instrument serial number

EthernetPortNumber

Not

1982

TCP port on which VISCPRO

CAV Registry settings

The following registry keys are set up at CANNON® prior to shipping and should not need to

be adjusted for the initial installation. However, when reconfiguring a network or adding an

additional CAV® 4.2 to your setup, you may need to change the Instrument Address and

Instrument ID to avoid device collision. These values and the Remote Client Name can be

editing from within the CAV 4.2 GUI. Other values can only be changed by directly editing the

registry.

Caution: Editing registry entries may be hazardous to the health of

your Windows® installation.

Table 18 — CAV® 4.2 registry entries

GUI

Client

Name

2

value

connection to which the

instrument connects

ID2

available

listens

2

On either bath screen, click Settings > Instrument Settings to access these entries.

3

On either bath screen, click Settings > Setup to access this entry.

33

Page 44

CAV® 4.2 Operator's Manual, Rev. 2.0

Connecting with VISCPRO II CANNON®

34

Page 45

CANNON®

CAV® 4.2 Operator's Manual, Rev. 2.0

Operation

The CAV 4.2 can be operated in either local or remote mode through a pair of software

programs. In Local Mode, the CAV 4.2 GUI software program controls the instrument, while in

Remote Mode a separate computer with the VISCPRO II software program installed controls it.

Each of these programs is independent of the other and maintains its own data set, where a

data set consists of a run of tests, test results and error logs. Common instrument settings,

method templates, and equipment status are shared between the programs.

The operating status of the CAV 4.2 is shown on the left-most button of the main screen menu

of the CAV 4.2 GUI. This button toggles between Local Mode and Remote Mode. A green icon

indicates that the instrument is connected to VISCPRO II. In Remote Mode, the Users, Results,

and Errors action buttons are grayed to indicate that instrument operation cannot be

managed from the CAV 4.2 GUI.

Figure 26 — Main screen menu

CAV 4.2 GUI

The CAV 4.2 GUI is the software program shown on the touch-screen embedded in the display

hood of the CAV 4.2. The Getting Started chapter of this manual introduces the operator to

the basic usage of the CAV 4.2 GUI. This chapter provides more in-depth instructions.

35

Page 46

CAV® 4.2 Operator's Manual, Rev. 2.0

Operating the CAV 4.2 CANNON®

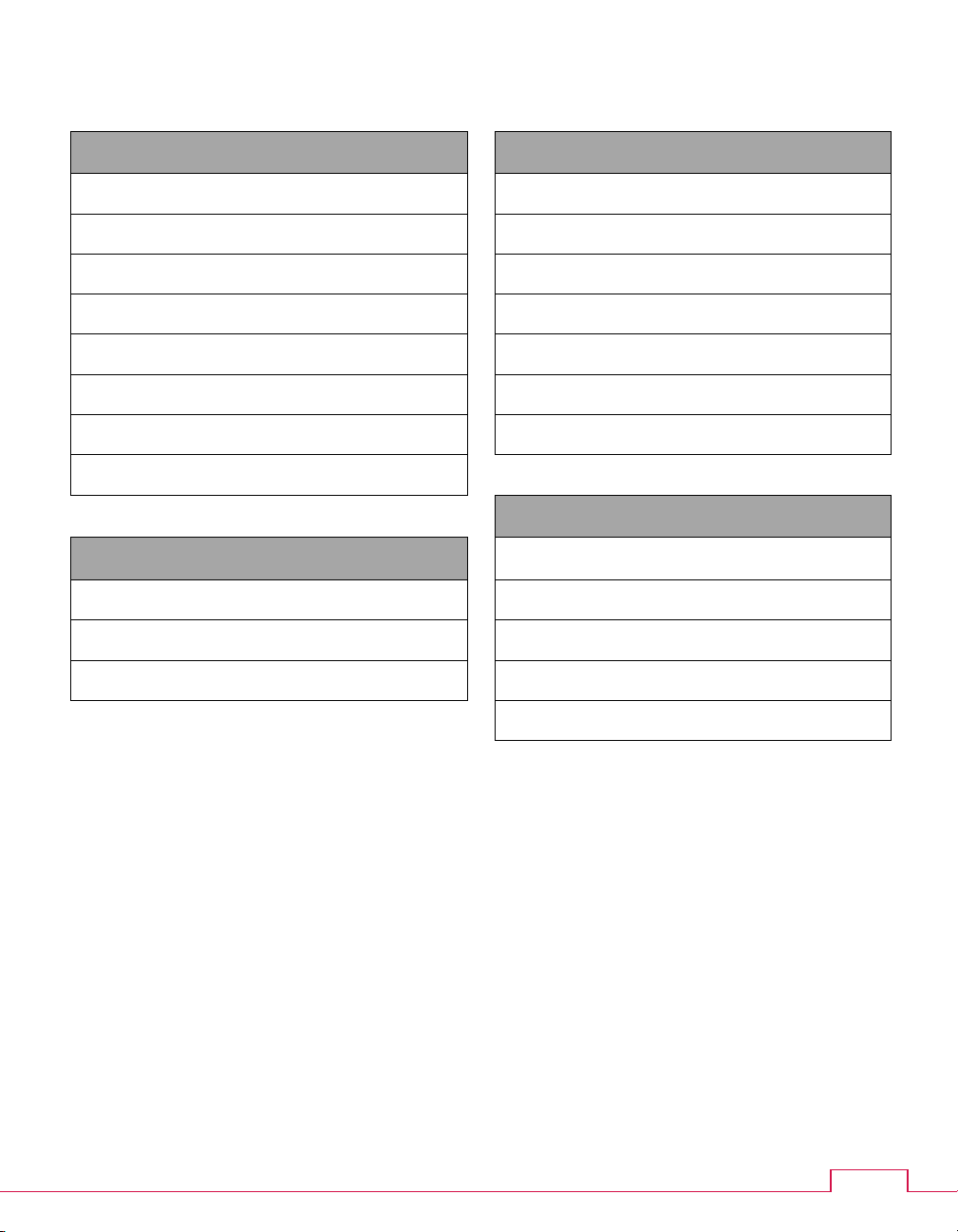

Area

Button

Action

Main screen

Local / Remote Mode

Toggles between control modes.

Users

Opens login menu.

Results

Opens local results log.

Errors

Opens local errors log.

Help

Opens help menu.

Settings

Opens settings menu.

Tube Calibration

Opens tube calibration menu.

Methods

Opens methods menu.

Services

Opens services.

Each position displays the title of the sample.

Click center of carousel for bath options.

Screen sliders

Left / right arrows

Slides between screens.

Displays the status of the bath sensors.

Displays the status of the TE cooler.

Click to turn on/off the TE cooler.

Current

Displays the current bath temperature.

Target

temperature

Displays the target temperature.

Click to set target temperature.

Activity message

Displays current activity.

Preheater temperature

Displays current preheater temperature.

menu

Bath screen

menu

Table 19 — GUI screen details

Carousel Positions 1 – 14

Sensors

TE Cooler

Status

temperature

Click to configure a sample.

Red – unavailable

Green – covered; Gray – uncovered

Click to train sensors.

Click to calibrate temperature.

36

Page 47

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Operating the CAV 4.2

Area

Button

Action

Actions

Run / Stop

Click to start or stop a run.

Wash

Click to run a wash.

Pause

Click to pause a run or wash.

Main screen menu

Carousel Carousel

Slider

Actions

Status Status

Actions

Bath 1

Figure 27 — Main screen

Bath 2

Slider

37

Page 48

CAV® 4.2 Operator's Manual, Rev. 2.0

Operating the CAV 4.2 CANNON®

Bath screen menu

Carousel

Slider

Figure 28 — Bath screen

38

Page 49

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Operating the CAV 4.2

Area

Detail

Click to open a window for …

Main

… managing the VISCPRO application.

… displaying, configuring, and managing

analysis logs.

… configuring the settings of attached

Service

… servicing an attached instrument.

Window

… managing the open windows.

Help

… managing VISCPRO help.

CAV 4.2 Instrument

Use this window to view the status of the instrument and

Analysis Log

Displays a specific analysis report.

Click to open the general information

status window.

Click to open the VI Matching information

Click to open a status window for a

VISCPRO® II software interface

VISCPRO® II is a Windows® software program comprising the general interface application

and instrument/analysis-specific modules. Figure 29 shows a typical VISCPRO II interface with

an open instrument window, analysis log, application specific status window, and general

information status windows.

Table 20 — VISCPRO window details

Analyses

VISCPRO II Menu

Window

Information Status Bar

Configure

manage sample test runs.

General

VI Matching

<instrument>

instruments.

status window.

particular instrument.

39

Page 50

CAV® 4.2 Operator's Manual, Rev. 2.0

Operating the CAV 4.2 CANNON®

Figure 29 – VISCPRO interface window

40

Page 51

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Operating the CAV 4.2

Username

Privilege level

Privileges

CANNON Instrument Company Inc

Service

Access to all instrument and

Manager

Manager

Access to advanced configuration

and reporting options

Unknown

Technician

Access to operational features

routine operations

Manage user accounts (VISCPRO II / CAV 4.2 GUI)

VISCPRO II and CAV 4.2 GUI user accounts are independent of each another. The VISCPRO II

accounts are associated with the entire software installation and are not instrument specific.

Both VISCPRO II and the CAV 4.2 GUI start with three default accounts:

Table 21 — Default user accounts

security parameters. Call

CANNON® for the current

password for the CANNON

Instrument Company Inc login.

required for testing samples and

VISCPRO II displays the username and privilege level of the active user in the title bar of the

main window. If no user is logged in, VISCPRO II displays the default account (Unknown:

Technician). The CAV 4.2 GUI does not display login status.

Log in

Log in as soon as possible to avoid problems. You can log in as another user even if you are

already logged in.

Note: The initial password for the Manager account is blank.

1. For VISCPRO II: click Main > Log In… The Log In window opens.

For CAV 4.2 GUI: click Users. The Login Menu window opens.

2. Select the appropriate user. Type the corresponding password.

3. Click OK.

41

Page 52

CAV® 4.2 Operator's Manual, Rev. 2.0

Operating the CAV 4.2 CANNON®

Change password

In order to change a password, you must be logged in as the user whose password you are

changing. However, in VISCPRO II a user with a higher privilege level may assign a new

password by editing a user account.

1. For VISCPRO II: click Main > Change Password … The Change Password window opens.

For CAV 4.2 GUI: click Users > Change Manager Password. Because new accounts cannot

be created using the CAV 4.2 GUI, this is the only option.

2. Type your new password into the appropriate fields.

3. Click OK or the green checkmark.

Setup and edit user accounts

(VISCPRO II only) Service level users can setup and edit manager and technician accounts.

Manager level users can setup and edit only technicians. The default account may not be

edited.

1. Click Main > Update User Information … The Change User List window opens.

2. Select the appropriate user. To create a new user, type a unique user name.

3. To assign a password to a user, type the password into the appropriate fields.

4. To assign a privilege level, select the appropriate level in the drop-down box.

5. To save changes click Add or Update User.

6. To close the Change User List window, click Done.

7. To delete the user record from the database, click Remove User.

Logout

It is not necessary to logout in order to change user accounts. Logout does not close

VISCPRO II. It changes the login to the default (Unknown: Technician) account.

1. For VISCPRO II: click Main > Logout.

For CAV 4.2 GUI: click Users > Logout.

42

Page 53

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Operating the CAV 4.2

Note: CAV 4.2 are grouped according to the Ethernet port number on

Caution: When multiple instruments (CAV 2100/2200, miniAV, CAV

Connect VISCPRO II to the CAV® 4.2

VISCPRO II and the CAV® 4.2 must be set up and communicating prior to attempting to

establish a connection. Refer to Connecting with VISCPRO II for instructions.

1. Start VISCPRO II on the PC.

2. On the CAV 4.2 GUI, touch the Local Mode/Remote Mode button to toggle the

instrument state. The icon will turn green to indicate that the CAV 4.2 has found

VISCPRO II.

3. In the VISCPRO II Menu, click Main > Poll for Instruments. If an instrument is located, an

associated message box will be added to the status bar on the bottom of the VISCPRO II

window.

which they communicate. Since VISCPRO II can only communicate on

4. Click Main > View Instrument and select the CAV 4.2 instrument group. The CAV 4.2

Instrument Window opens.

one Ethernet port at a time, there will be only one group of CAV 4.2

instruments.

4.2) are connected to the same instance of VISCPRO II, verify that all

instruments have completed their current operations before closing

VISCPRO II.

Set bath temperature (VISCPRO II)

1. In the VISCPRO II Menu, select Configure > [instrument group] > [instrument] > Tray

Settings: Temperature.

2. Adjust the Temperature Units, Target Temperature, and Temperature Tolerance as

necessary.

3. Click Save; wait for the system to save the changes, and then click Close.

4. Wait for the bath to adjust to the new temperature.

43

Page 54

CAV® 4.2 Operator's Manual, Rev. 2.0

Operating the CAV 4.2 CANNON®

Note: Temperature calibration, vacuum and pressure adjustment, and

sensor training can easily be performed directly from the CAV 4.2 GUI.

Refer to Getting Started for more information.

Calibrate temperature (VISCPRO II)

Calibrate the temperature of the CAV® 4.2 whenever the instrument is moved, a new bath

temperature is to be used, or the bath fluid is refilled. The instrument is calibrated by

inserting a thermometer through an access hole in the display hood, measuring the actual

temperature of the bath fluid, and entering that temperature into the CAV® 4.2 software.

1. If it is raised, lower the display hood and plumbing lid.

2. Carefully insert a thermometer through the access hole in the display hood and into the

bath until the top of the thermometer is in the middle of the capillary portion of the

viscometer tube. The thermometer passes through the same hole in the top of the bath

unit that was used to fill the unit with fluid.

3. Wait for the thermometer to adjust to the temperature of the bath fluid. Read the

reference temperature.

4. In the VISCPRO II Menu, select Service > [instrument group] > [instrument] > Temperature

Calibration. The Temperature Calibration window opens.

5. Enter the reference temperature measured in step 3 in the Reference Temperature field.

6. Click Calibrate; wait for the system to save the adjustment, and then click Done to close

the window.

7. Remove and clean the thermometer.

8. Repeat steps 2 through 7 for the second bath if necessary.

Set vacuum and pressure (VISCPRO II)

Set the vacuum and pressure of the CAV® 4.2 before running the instrument.

1. In the VISCPRO II Menu, select Service > [instrument group] > [instrument] > Adjust

Vacuum/Pressure.

2. Follow the instructions on the screen to set the vacuum, then the pressure for each bath.

44

Page 55

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Operating the CAV 4.2

Train sensors (VISCPRO II)

Train the sensors whenever the CAV® 4.2 bath is to operate at a new temperature. Once

trained, the calibration values for a particular temperature are saved and will be recalled if the

CAV® 4.2 is set to run at that temperature again. Retraining for a particular temperature is

only necessary when the viscometer tube is changed or if sensor performance changes over

time.

Note: Sensor training uses Test and Advanced settings from the default

method, but Default Wash settings.

1. Insert an empty vial into position 1 of the carousel for the bath to be trained.

2. Fill a vial with a test solution that has a viscosity approximately 3 times higher than the

lower viscosity limit of the ubbelohde tube. Insert the vial into position 2.

3. In the VISCPRO II Menu, select Service > [instrument group] > [instrument] > Train

viscometer tube sensors. The Train viscometer tube sensors window opens.

4. (Optional) Check Prewash to run a wash cycle prior to training sensors.

5. (Optional) Check Trip Points Only to skip adjusting the power levels of the sensors.

6. Click Start.

7. When training is complete, repeat this procedure for the second bath if necessary.

Run a wash (VISCPRO II)

When necessary, washes may be run independent of a sample test.

1. In the VISCPRO II Menu, select Service > [instrument group] > [instrument] > Wash

viscometer tube.

2. Select the tube to wash.

3. Select whether to use wash parameters from the last sample run or use default wash

parameters.

4. The initial cup evacuation can be bypassed by checking the appropriate box.

5. Click Begin Wash.

45

Page 56

CAV® 4.2 Operator's Manual, Rev. 2.0

Operating the CAV 4.2 CANNON®

Note: Do not overfill the vials or your sample may overflow when the

Run a sample test (VISCPRO II)

This procedure details how to run and configure various kinematic viscosity tests on the

CAV® 4.2 using VISCPRO II software.

1. Verify that the CAV® 4.2 is running and has achieved steady-state temperature in each

bath to be used.

• The status window displays IDLE. During warmup, SEEKING TEMPERATURE will be

displayed.

• The current temperature and target temperature icons are green, indicating that the

bath has been temperature calibrated at that temperature. If any other condition is

indicated, refer to Calibrate temperature.

• The tube sensor icons are all grey, indicating that the sensors are trained and

uncovered. If any other condition is indicated, refer to Train sensors.

2. Connect VISCPRO II to the CAV® 4.2:

a. Start VISCPRO II on the PC.

b. On the CAV 4.2 GUI, touch the Local Mode/Remote Mode button to toggle the

instrument state. The icon will turn green to indicate that the CAV 4.2 has found

VISCPRO II.

c. In the VISCPRO II Menu, click Main > Poll for Instruments. If an instrument is

located, an associated message box will be added to the status bar on the bottom of

the VISCPRO II window.

d. Click Main > View Instrument and select the CAV® 4.2 instrument group. The CAV

4.2 Instrument window opens.

vial is raised into position and the viscometer tube displaces some

3. Follow your laboratory practices to prepare 10 mL samples and load the vials into the

carousel. 10 mL is half a vial.

46

sample.

Page 57

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Operating the CAV 4.2

4. Populate the sample run in VISCPRO II:

a. In the CAV 4.2 Instrument window, click on the tab corresponding to the desired

CAV 4.2 tray.

b. Left-click on the first tray position that is populated with a sample. The entire entry

highlights blue.

c. Left-click the Sample ID field and enter a short description for the sample. Press

Enter. The Sample Action field is populated with the default action ("Method")

associated with the viscometer tube.

If the default action is Verify Known KV, the Sample Configuration window opens

automatically. Enter the kinematic viscosity value (cSt) of the sample as the

Parameter Value of Check Standard KV. When finished, click Save, and then Close.

d. Continue entering data in the remaining positions. Press ESC to stop entering data.

5. To edit or customize the sample action for a particular tray position, right-click

anywhere on the row to open the editing menu.

• Shift-left-click—to select a contiguous range of entries.

• Ctrl-left-click—to select multiple entries.

• Configure—enables editing of all values for the selected entry. These localized

changes do not affect the default values of the sample action ("Method").

• Sample Actions—selecting a new action (method template) will replace the existing

action. All localized changes will be lost.

• Delete—deletes the selected entry. All following positions are decreased one place.

• Insert At—inserts a new entry into the carousel at the active position. All following

positions are advanced one place.

• Copy All Selected Samples—copies selected entries to the clipboard.

• Paste Into Selected Samples—pastes all entries that were copied to the clipboard

into the carousel, only at the highlighted positions. This is not an "insert" action.

Existing entries are overwritten, not moved.

47

Page 58

CAV® 4.2 Operator's Manual, Rev. 2.0

Operating the CAV 4.2 CANNON®

Note: Other actions—several additional actions are available from the

right-click editing menu:

• Sequential Sample IDs—use this action to populate sequential

Sample ID fields.

• Clear All Trays—clears all entries from all trays

• Save Tray to Archive—saves the current tray (carousel) to an

archive file. Each saved tray is associated with a specific bath.

6. Click Run. The Select Trays window opens.

7. Select the trays to run. Click OK. The CAV 4.2 begins running the selected trays.

Additional samples may be added to the trays until the run completes.

You cannot save a tray for bath 1 and load it into bath 2.

However, you can copy the complete set of entries from one tray

to another.

• Restore Tray from Archive—restores a previously saved tray.

• Delete Tray from Archive—opens the archive to allow deleting

saved trays.

• Pause—opens a selection window. Pausing a tray "Now" immediately halts all

actions for that tray. If a test is halted prior to the start of the wash cycle, the data for

that sample is discarded.

• Resume—opens a selection window to resume operation for selected trays.

• Abort—opens a selection window to abort all activity for selected trays.

8. When each test completes, the measured KV is shown in the Sample Action field. Once

the entire test run finishes, the tray pauses. No additional samples may be added to the

run. Click Resume to clear all data for the active tray.

48

Page 59

CAV® 4.2 Operator's Manual, Rev. 2.0

CANNON® Operating the CAV 4.2

Parameter name

Description

Preheat Type

No preheat

preheat time.

Minimum Preheat Time

This is the time that the preheater is applied to the

sample.

Preheat Temperature Units

Select either Fahrenheit or Celsius.

Preheat Temperature

Fahrenheit: 0 °F to 437 °F; Celsius: 0 °C to 225 °C

View test results (VISCPRO II)

Data obtained during sample testing is temporarily displayed in the Sample Action field and

permanently stored in the data base, which may be viewed by opening an analysis package.

Tests must finish running before they can be viewed. The entire tray does not need to have

finished, but individual results are only available in the database after they have completely

finished running.

1. In the VISCPRO II Menu, select Analyses > View Analysis. The Choose Analysis window

opens.

2. Open Basic Package and select CAV Data Table.

3. Select the Open Select Analysis Configuration radio button.

4. Select an analysis and click OK.

Control preheaters

The preheaters are associated with the sample test. Preheater settings can be modified by

editing the configuration of a specific sample test or editing the test method template.

Table 22 — Preheater settings

Minimum preheat starts the preheat cycle as soon as the

previous sample begins running and runs for at least the

set preheat time.

Serialized preheat starts the preheat cycle after the

previous sample finishes and runs for exactly the set

The heater temperature is determined by the Preheat

Temperature setting of the sample that is in the preheat

position, even if that sample is set to No preheat. Set the

temperature to 0 (zero) to turn off the heater.

49

Page 60

CAV® 4.2 Operator's Manual, Rev. 2.0

Operating the CAV 4.2 CANNON®

Bath

temperature

Sample cup

heater duty cycle

Bath

temperature

Sample cup

heater duty cycle

< 40 °C

0 80 °C to 90 °C

60%

40 °C to 50 °C

20%

90 °C to 100 °C

70%

50 °C to 60 °C

30%

100 °C to 110 °C

80%

60 °C to 70 °C

40%

110 °C to 120 °C

90%

70 °C to 80 °C

50%

> 120 °C

100%

Control sample cup heaters

Note: You must be logged onto the GUI or into VISCPRO as a manager

in order to change tray/tube settings.

The sample cup heaters assist in maintaining sample temperature during a run and in

improving the efficiency of the wash cycle. They are associated with the tray/tube settings.

• For VISCPRO II: select Configure > [instrument group] > [instrument] > Tray Settings:

Tube. The Tray Settings window opens.

Select the correct tube, and enter the appropriate number of duty cycle into the Sample

Cup Heater Duty Cycle, Parameter Value field. Click Save and then Close.

• For CAV 4.2 GUI: navigate to the appropriate Bath Screen, click Settings > Tube.

Enter the appropriate number of duty cycle into the Sample Cup Heater Duty Cycle field.

Click Save and then Close.

Table 23 — Sample cup heater settings

(may vary between instruments, this is a starting point)

50

Page 61

CANNON®

CAV® 4.2 Operator's Manual, Rev. 2.0

Advanced Setup

Note: You must be logged into the CAV4.2 GUI or VISCPRO as a

manager in order to perform advanced procedures.

Calibrate viscometer tube (VISCPRO II)

Viscometer tube calibration values are associated with specific temperatures, so calibration

must be performed when operating a CAV® 4.2 bath at a new temperature. Once a tube is

calibrated at a particular temperature, the C and E constants are saved by the instrument and

will be recalled if that tube is set to run at that temperature again.

1. Assemble a set of standard oils with known kinematic viscosities. Use at least different

two standards for each bulb to be calibrated. The CAV 4.2 is designed to run "thin"

standards (those with viscosities less than 10X the lower limit of the viscometer tube) in

two bulbs, while "thick" standards (those with viscosities greater than 10x the lower limit

of the viscometer tube) run in only the lower bulb.

2. Follow the procedures in Run a sample test to prepare, load, and run all of the

calibration standards as method Verify Known KV.

3. When all tests have completed, from the VISCPRO II Menu, select Configure >