Page 1

CONTENTS

i

1

INTRODUCTION/SOFTWARE INSTALLATION 1

The CANNON® Automatic Viscometer (CAV 2000 Series) .............................................. 1

Measuring kinematic viscosity ........................................................................................... 2

Safety cautions.................................................................................................................... 2

Specifications ..................................................................................................................... 4

VISCPRO

Installing VISCPRO

Running the software.......................................................................................................... 6

Checking configuration ...................................................................................................... 8

Manually changing tube calibration constants ................................................................. 11

®

for Windows®.................................................................................................. 5

®

software........................................................................................... 5

Computer requirements .......................................................................................... 5

Windows

Installation actions.................................................................................................. 5

Configuration diskette (First-time installation only!) ............................................ 5

Configuration disk .................................................................................................. 8

Logging in .............................................................................................................. 8

Checking Instrument Settings................................................................................. 9

Viewing/editing setup information ....................................................................... 10

®

XP® installation.................................................................................... 5

2

TESTING SAMPLES

WITH THE CANNON AUTOMATIC VISCOMETER 15

Preparing the CAV............................................................................................................ 15

Preparing sample trays ......................................................................................... 15

Inserting/removing the CAV reference thermometer ........................................... 16

Local mode operation ....................................................................................................... 17

Setting temperature............................................................................................... 17

Preparing the bath................................................................................................. 18

Testing samples..................................................................................................... 18

Aborting a test ...................................................................................................... 18

Concluding a test .................................................................................................. 19

Obtaining kinematic viscosity (KV) readings in Local mode .............................. 19

Other Local mode keypad options........................................................................ 19

Remote operation (computer-controlled) ......................................................................... 20

Setting temperature............................................................................................... 20

Testing samples..................................................................................................... 22

Pausing a test ........................................................................................................ 24

Resuming a test..................................................................................................... 25

Aborting a test ...................................................................................................... 25

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 2

ii

Concluding a test .................................................................................................. 25

Working with Instrument Groups ..................................................................................... 25

Group configuration ............................................................................................. 27

Configuring the Machine Status window to correspond with physical instrument

placement.............................................................................................................. 27

Viewing test results........................................................................................................... 27

Creating an analysis.......................................................................................................... 28

3

4

CALIBRATING THE CAV 29

Calibrating temperature .................................................................................................... 29

Calibration procedure ........................................................................................... 29

Training sensors................................................................................................................30

Standard tube calibration.................................................................................................. 30

Calibration procedure ........................................................................................... 31

Saving a calibration .............................................................................................. 33

CAV calibration equations.................................................................................... 34

USING THE CAV SOFTWARE 35

VISCPRO® generic instrument interface ........................................................................ 35

Main options......................................................................................................... 36

Security options .................................................................................................... 37

Initial security setup ............................................................................................. 37

Adjusting Security Settings .................................................................................. 39

Print/Print setup options ....................................................................................... 39

Analyses options............................................................................................................... 40

Analysis types....................................................................................................... 40

Analyses menu options......................................................................................... 40

Window options................................................................................................................ 42

CAV module menu options............................................................................................... 43

Configure options ................................................................................................. 43

Print Instrument and Tray Settings....................................................................... 43

Instrument Settings ............................................................................................... 45

Tray Settings: Tube and Bath ............................................................................... 46

Tray Settings: Test ................................................................................................ 48

Tray Settings: Wash .............................................................................................. 50

Tray Settings: Advanced....................................................................................... 52

Saving a configuration.......................................................................................... 54

Restoring instrument settings from a saved configuration ................................... 54

Calibration ............................................................................................................ 55

Service menu options ....................................................................................................... 57

Testing samples—software options .................................................................................. 58

Entering sample ID information ........................................................................... 58

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 3

Selecting sample actions....................................................................................... 59

Viscosity Action for viscosity standards .............................................................. 61

Copy & Paste Sample ID data entry options ........................................................ 61

Inserting/deleting a sample ID in the test sequence ............................................. 62

CAV analysis modules.......................................................................................... 62

Configuring the VI Matcher ............................................................................................. 62

Turning off the VI Matcher .................................................................................. 64

Handling errors .................................................................................................................64

Configuring the Energy Saver .......................................................................................... 65

iii

5

OPERATING, MAINTAINING AND SERVICING THE CAV 69

CAV components .............................................................................................................. 69

Bath Unit .............................................................................................................. 69

SDU-200 Solvent Dispensing System.................................................................. 70

CSU-200 Service Unit .......................................................................................... 70

Emptying the waste can.................................................................................................... 70

Viscometer tubes .............................................................................................................. 71

Tube thermistors ................................................................................................... 71

Fast-run viscometer tubes..................................................................................... 72

Temperature bath .............................................................................................................. 72

Expansion vessel (CAV-2100 only)...................................................................... 72

Filling the bath...................................................................................................... 73

Draining the bath .................................................................................................. 74

Bath heaters .......................................................................................................... 74

Heat shield (optional) ........................................................................................... 74

Bath fluid safety features...................................................................................... 75

Temperature probes .............................................................................................. 75

Sample trays/drains .......................................................................................................... 75

Splash guards........................................................................................................ 76

Solvent system..................................................................................................................76

Solvent Dispensing Unit....................................................................................... 77

Checking solvent levels........................................................................................ 77

Solvent/drain lines ................................................................................................ 77

Waste can .............................................................................................................. 78

Drip pan ................................................................................................................ 78

Ventilation......................................................................................................................... 78

Checking bath temperature............................................................................................... 79

Setting bath temperature................................................................................................... 79

Service Unit operational settings...................................................................................... 79

Regulating pneumatic pressure............................................................................. 80

Regulating solvent flow........................................................................................ 80

Regulating vacuum ............................................................................................... 80

Adjusting pneumatic controls........................................................................................... 80

Dual-solvent washing ....................................................................................................... 81

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 4

iv

Solvent wash by computer (Remote mode)...................................................................... 81

Solvent wash by operator (Local mode)........................................................................... 82

Setting wash parameters (Local mode) ................................................................ 82

Wash configuration options (Remote mode) .................................................................... 83

Manually cleaning contaminated viscometer tubes.......................................................... 83

Handling fault conditions ................................................................................................. 84

Preventive maintenance.................................................................................................... 85

Changing the vacuum pump diaphragm............................................................... 86

CAV repair/replacement kits ............................................................................................ 87

6

7

8

ANALYSIS CONFIGURATION OPTIONS 89

Creating an analysis.......................................................................................................... 89

Sorting analysis data......................................................................................................... 90

Using the date filter .......................................................................................................... 90

Using the sample filter...................................................................................................... 91

Using the report/port output filter..................................................................................... 93

Reconfiguring a displayed analysis .................................................................................. 93

Resizing table columns..................................................................................................... 93

Saving a current analysis .................................................................................................. 93

Deleting an analysis configuration ................................................................................... 94

Printing an analysis........................................................................................................... 94

Keystrokes for selecting data for printing ............................................................ 94

Exporting analysis data..................................................................................................... 95

CAV DATA TABLE 97

Configuring the CAV Data Table.......................................................................... 98

STANDARD VI TABLE ANALYSIS 103

9

10

11

Configuring the standard VI table ...................................................................... 103

SAMPLE DATA EXPORT ANALYSIS 107

Configuring the Sample Data Export analysis ................................................... 108

VI DATA EXPORT ANALYSIS 113

Configuring the VI Data Export Analysis .......................................................... 114

ERROR DATA EXPORT ANALYSIS 119

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 5

Configuring the Error Data Export analysis....................................................... 119

v

12

13

14

A

ERROR LOG TABLE ANALYSIS 125

Configuring the Error Log analysis .................................................................... 125

USING THE DATABASE MANAGER 129

Archiving old data .............................................................................................. 130

Changing the database directory ........................................................................ 130

Importing archived data...................................................................................... 131

Repairing/compacting the database.................................................................... 131

Exit ..................................................................................................................... 131

REPLACEMENT PARTS LIST 133

CAV-2100 ....................................................................................................................... 133

CAV-2200 ....................................................................................................................... 134

APPENDIX A–REPLACING THE CAV-2200 THERMOMETER 135

Tools required ................................................................................................................. 135

Procedural overview ....................................................................................................... 135

Disassembly/removal procedure .................................................................................... 135

Assembly procedure ....................................................................................................... 136

I

INDEX 137

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 6

vi

This page intentionally left blank.

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

®

Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 7

CHAPTER

1

1

INTRODUCTION/SOFTWARE

INSTALLATION

The CANNON® Automatic Viscometer (CAV 2000 Series)

The CANNON® Automatic Viscometer (CAV) is a completely automatic

viscometer designed for unattended operation. The operator places

samples in small vials in the sample holders, enters sample identification

information and initiates the testing with software or front panel keypad

commands. Without any further operator involvement, the CAV determines kinematic viscosity , cleans the capillary tube(s) and prepares the

instrument for the next test. All pertinent test data can be saved to a

computer database for future retrieval and reporting.

Manual

This manual is designed to provide the operator with information about:

VISCPRO

®

software installation and operation

Applications

Precision

CAV 2000 Series equipment and operation

Calibration, service and maintenance procedures

For additional information on initial installation and instrument setup,

refer to the Installation & Setup Guide.

Previous CAV models have been used

in laboratories worldwide for over two

decades. CAV instruments can be found

in R&D laboratories, refinery quality

control laboratories, blending plants,

and independent testing laboratories.

The CAV is ideally suited for the

analysis of both transparent and opaque

samples. A variety of materials, such as

used oils, marine fuels, residual fuels,

and crude oils can be tested with ease.

Precision for the kinematic viscosity

determination of the CAV equals or

exceeds that specified in ASTM

Method D 445. This method is required

by the Society of Automotive Engineers

(SAE) Engine Oil Viscosity Classification SAE J300.

The CAV-2200

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 8

2

Measuring kinematic viscosity

Kinematic viscosity is a measure of the internal resistance to flow of a

fluid under gravity with the pressure head being proportional to the

density of the fluid. For any particular viscometer, the time of flow of a

fixed volume of fluid is directly proportional to its kinematic viscosity .

Units of measure

Methodology

Manual viscometers

Automatic viscometers

An accepted unit of kinematic viscosity is one centimeter squared per

second, which is called one stoke. The centistoke (which is equivalent to

2

1 mm

/s) is the unit of measure most frequently used.

ASTM Methods D 445 and D 446, included with this manual, describe

appropriate test methodologies and instruments for glass capillary

viscometry.

Sections 9-11 of ASTM D 445 provide detailed instructions for using

manual viscometers. ASTM D 446 suggests a minimum flow time of 200

seconds for nearly all the glass capillary viscometers (see tables in ASTM

D 446).

For automatic viscometers, ASTM D 445 Section 6.1.2 states, “Automated apparatus may be used as long as they mimic the physical conditions, operations or processes of the manual apparatus they replace ... The

automated apparatus shall be capable of determining kinematic viscosity

of a certified viscosity reference standard within the limits stated ...”

Thus, automated viscometers can be used with flow times less than 200

seconds, as long as the kinetic energy correction and precision requirements are met.

CAV tube characteristics

NOTE

Safety cautions

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Each standard viscometer tube has three bulbs, each of which has its own

calibration. The normal flow times for each bulb are 60-400 seconds.

Each tube has a hundredfold measurement range (for example, range

from 2-200 cSt or 20-2000 cSt for each tube).

CANNON® Instrument Company has not recommended the use of

longer flow times with the CAV, as shorter flow times allow greater

productivity. With longer flow times, the data throughput would be

significantly reduced. However, the viscometer and software design does

permit longer efflux times (up to 600 seconds) as desired by the user.

Please observe the following safety procedures and notices for proper

operation of the CAV:

Make sure that your unit is operated only by qualified personnel.

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 9

Make sure that you read and understand all operating instructions

and safety precautions listed in this manual before installing or

operating your unit. If you have questions regarding instrument

operation or documentation, contact CANNON

®

Instrument Company.

Do not deviate from the installation, operation or maintenance

procedures described in this manual. Improper use of the CAV

instrument may result in a hazardous situation and may void the

manufacturer’s warranty.

Handle and transport the unit with care. Sudden jolts or impacts may

cause damage to components.

Observe all warning labels.

Never remove warning labels.

Never operate damaged or leaking equipment.

Never operate the unit without appropriate levels of approved bath

fluid in the bath.

(CAV-2200 only) Do not fill the expansion vessel higher than the

cold fill level.

Unless procedures specify otherwise, always turn off the unit and

disconnect the mains cable from the power source before performing

service or maintenance procedures, or before moving the unit.

Always empty the bath and disconnect cable and tubing connections

to the Service Unit and Solvent Dispensing System before moving

the unit.

Never operate the equipment with damaged mains power cables.

Refer all service and repairs to qualified personnel.

3

General Caution

Hot Surface Caution

Protective Conductor

WARNING

In addition to the cautionary statements listed previously , additional

cautions may be posted throughout this manual. These cautions, identified by the caution symbol (see left) indicate important operational

procedures. Read and follow these important instructions. Failure to

observe these instructions may void warranties, compromise operator

safety , and/or result in damage to the CAV unit.

Hot surface cautions may be attached on or near hot surfaces of the CAV.

A void touching hot surfaces, particularly when operating the CAV at bath

temperatures exceeding 50°C.

The Protective Conductor Terminal symbol is used to indicate required

ground connections for your instrument electrical supply .

When supplying power to this instrument, ensure that the protective

ground (earth) terminals of the instrument are connected to the protective

conductor of the (supplied) line (MAINS) power cord. Use only the

manufacturer-supplied power cord, which should be inserted in a socket

outlet (receptacle) which is also provided with a protective ground (earth)

contact.

Do not use an extension cord (power cable) without a protective

conductor (grounding).

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 10

4

MAINS

~

AC Power Input Symbol

( O )

Supply OFF Symbol

Hazardous materials

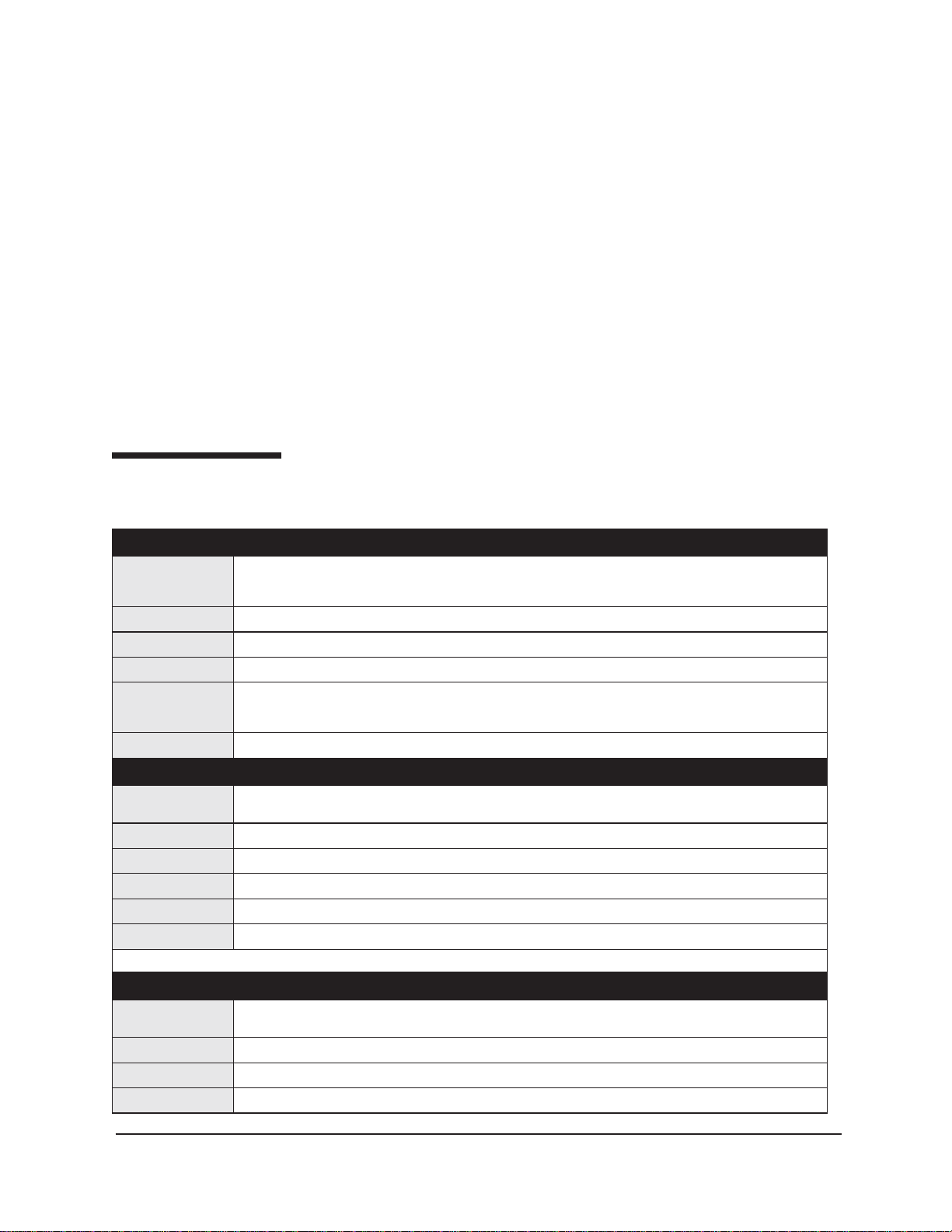

Specifications

lacirtcelE&#traP W0561,zH06/05,CAstlov511:70A-5279#ledoM0022-VAC;W0561,zH06/05,CAstlov511:50A-5279#ledoM0012-VAC

snoisnemiD )"94x53x21(hgihmm5421xpeedmm727xediwmm503

thgieW sredlohelpmasdnadiulfhtabtuohtiw)sbl212(gk69:0002-VACsredlohelpmasdnadiulfhtabtuohtiw)sbl002(gk19:0002-VAC

snoitidnoCgnitarepO 2eergednoitulloP,IIyrogetaCnoitallatsnI,gnisnednoc-nonHR%09-%01,C°03-°51

gnitaResuF "4/1x4/1-1,A51V052M:70A-5279#ledoM0022-VAC;"4/1x4/1-1,A51V052M:50A-5279#ledoM0012-VAC

ecnailpmoC ).ces06,CDV0091(TOP-IH;)CEE/32/37(evitceridegatlovwoL;)CEE/633/98(evitceridCME:kraMEC

12-VAC

The ~MAINS symbol indicates instructions or connections for the AC

power supply . The AC Power input must match the electrical specifications listed on the label on the rear panel of the instrument. The supplied

AC Mains power cord must be attached to the connector labelled

~MAINS. This connection serves as a means of disconnect and should be

readily accessible.

The (O) symbol indicates the OFF position for the electrical switches for

your unit (AC Mains or accessories).

Routine CAV operation may require the use and handling of hazardous

chemicals and solutions. CANNON® Instrument Company strongly

urges the operators and technicians working with the CAV to take proper

safety precautions when working with these materials. These safety

procedures can be found in the Material Safety Data Sheets which

accompany the solutions.

ecnailpmoC/snoitacificepStinUhtaBseireS0002VAC

W0571,zH06/05,CAstlov032:21A-5279#ledoMF0022-VAC;W0571,zH06/05,CAstlov032:01A-5279#ledoMF00

W0571,zH06/05,CAstlov001:71A-5279#ledoM0022-VAC;W0571,zH06/05,CAstlov001:51A-5279#ledoM0012-VAC

"4/1x4

/1-1,A8V052M:21A-5279#ledoMF0022-VAC;"4/1x4/1-1,A7V052M:01A-5279#ledoMF0012-VAC

A-5279#ledoM0022-VAC;"4/1x4/1-1,A51V052M:51A-5279#ledoM0012-VAC

"4/1x4/1-1,A51V052M:71

lacirtcelE&#traP W003,zH06,CAstlov511:7605.16P#traP002-USC

snoisnemiD )"41x02x7(hgihmm653xpeedmm805xediwmm871

thgieW )sbl72(gk3.21

snoitidnoCgnitarepO 2eergednoitulloP,IIyrogetaCnoitallatsnI,gnisnednoc-nonHR%09-%01,C°03-°51

gnitaResuF "4/1x4/1-1,A4V052M:sledoMllA

ecnailpmoC ).ces06,CDV0091(TOP-IH;)CEE/32/37(evitceridegatlovwoL;)CEE/633/98(evitceridCME:kraMEC

#traP 8605.16P#traP001-UDStnevloS-elgniS

snoisnemiD )"41x02x7(hgihmm653xpeedmm805xediwmm871

thgieW )sbl52(gk4.11

noitarepO citamuenP

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

W006,zH05,CAstlov032:8015.16P#traP002-USC

.tinuruoyhtiwdeilppusdrocrewopdevorppaehtylnoesU

6705.16P#traP001-UDStnevloS-lauD

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

ecnailpmoC/snoitacificepStinUecivreSseireS0002VAC

snoitacificepStinUgnisnepsiDtnevloSseireS0002VAC

Page 11

5

VISCPRO® for Windows

®

VISCPRO® is a powerful software product designed to provide a generic

instrument interface for controlling and operating your CANNON

instrument(s) via computer. When the Remote mode setting is selected

with the instrument keypad, all instrument functions necessary for testing

may be computer-controlled. VISCPRO

modules for processing and displaying sample data.

Installing VISCPRO® software

T o install the VISCPRO® software, follow the instructions below in the

sequence presented. Make certain that you complete the sections on

checking instrument settings and initial calibration data. If you encounter

difficulties at any stage in the installation process, call CANNON

service at 814-353-8000.

Computer requirements

Consult CANNON® Instrument Company at 814-353-8000 for current

computer specifications. The computer should be a PC with a working

version of the Windows® operating system (XP® or above) installed.

®

®

also includes reporting/analysis

®

Windows® XP

®

installation

Installation actions

1. Turn on your computer. Wait for the Windows® software to load.

2. Insert the first VISCPRO

®

installation disk or CD-ROM into the disk

drive. If the installation program does not begin automatically, click

Settings/Control Panel from the Windows® Start Bar. Then double-

click the Add/Remove Programs icon and follow the W indows

prompts to complete the installation procedure. The executable file

for VISCPRO® software installation is SETUP.EXE.

The installation program will:

create a directory for your program files. The default directory is

C:\Program Files\Cannon Instrument\VISCPRO).

write SETUP information to the Windows

®

registry.

copy the software executable file and other necessary files to the

directory you specify.

update other files in your Windows

compatible with the current VISCPRO® software.

place a shortcut icon for the VISCPRO

Windows

®

desktop.

®

directories to versions fully

®

executable file on your

Configuration diskette (First-time installation only!)

If you received a Configuration floppy diskette with your VISCPRO II

software, follow the instructions that came with the diskette to copy the

SAMPLES.MDB file to your VISCPRO II installation directory.

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 12

6

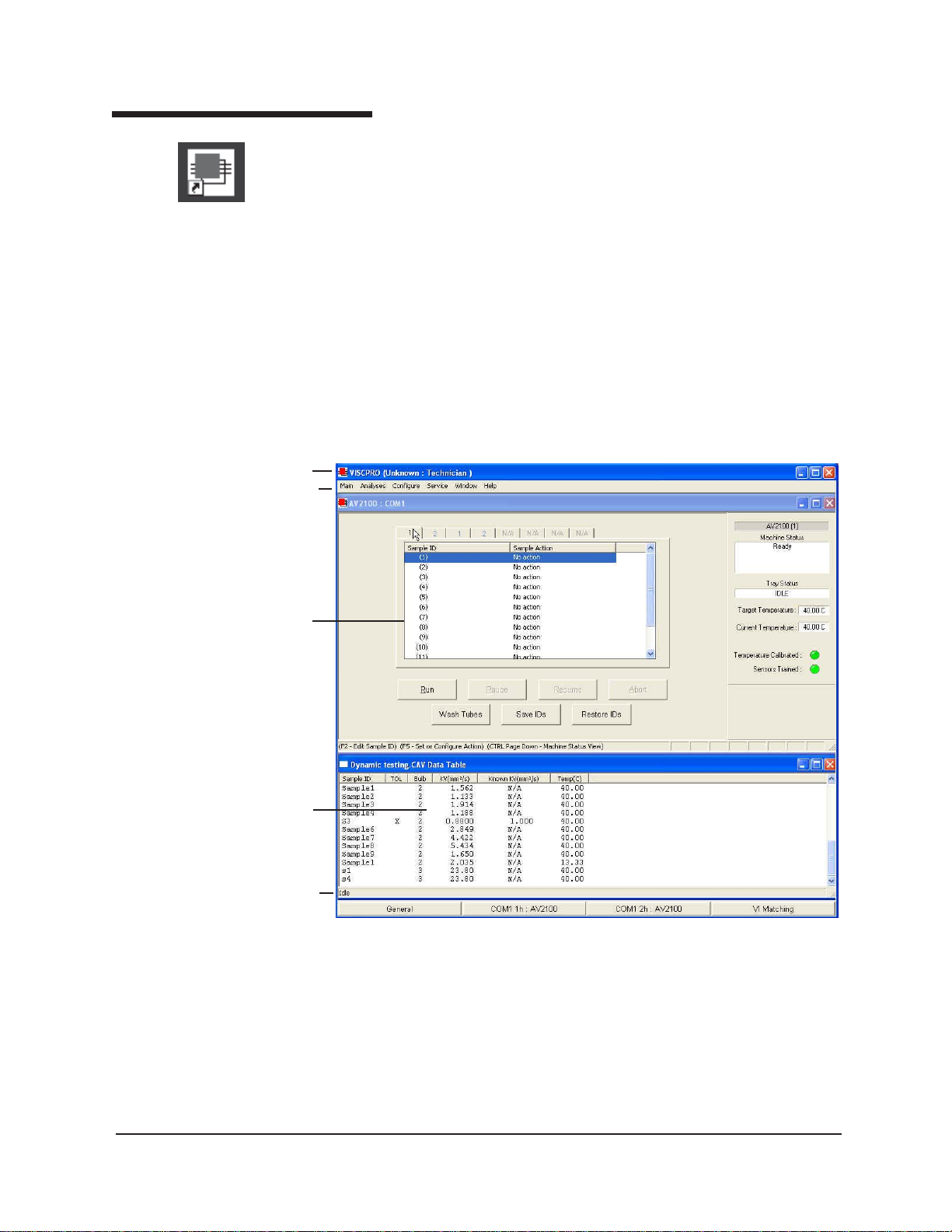

Running the software

the VISCPRO II icon

Title Bar

Menu Bar

Provide power to the CAV instrument, and verify serial connections to

the computer. To load your newly-installed VISCPRO® software, doubleclick on the VISCPRO

®

icon on your Windows® desktop (Windows

®

NT® users can click St art/All Programs/VISCPRO/VISCPRO 2.0).

If this is an initial installation, and you received a configuration disk with

your installation software package, make certain that the samples.mdb

file has been copied to the sample installation directory (see separate

instruction sheet for sample database location on your computer hard

drive). Your software may have already been preconfigured with instrument settings unique to your instrument, including instrument type(s),

tube ranges and serial #s, and calibration constants. In a moment, we will

verify these settings. Right now , your computer monitor should look

something like this.

Sample

Input

window

Analysis

window

Status bar

The VISCPRO® primary display

CANNON

The VISCPRO® primary display window is framed on the top by the

VISCPRO® title bar and menu bar, and on the bottom by the VISCPRO

status bar. The application window may have been preconfigured to include

two child windows which can be opened and closed independently. The first

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

®

Page 13

is a Sample Input window that describes your CANNON® instrument and

provides controls for running tests. The second is an Analysis window

that presents data from CAV tests.

7

The Sample Input window (note networked instrument tubes on tube tabs)

NOTE

If the Sample Input window does not appear when the software loads, click

View Instrument from the Main menu, then click the desired instrument

group (type of instrument, e.g. CAV, CCS, PolyVISC) from the list of

available instruments and click OK. If the Available Instruments list box is

blank, your CAV instrument may not be on-line. Check cable connections

and make certain the control panel red power switch is ON. (Turn the

switch clockwise for ON. Push the switch in when turning the unit OFF.)

The Sample Analysis Table window displays report data based on user-configurable

parameters.

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 14

8

Checking configuration

Configuration disk

For first-time installations, check your software packet for a CONFIGU-

®

RATION floppy disk after installing VISCPRO

. If you have one, insert

the disk in your floppy disk drive and follow the instructions printed on

the disk label to add factory calibration information for your instrument

to your VISCPRO

®

database.

CAUTION

Configuration protection

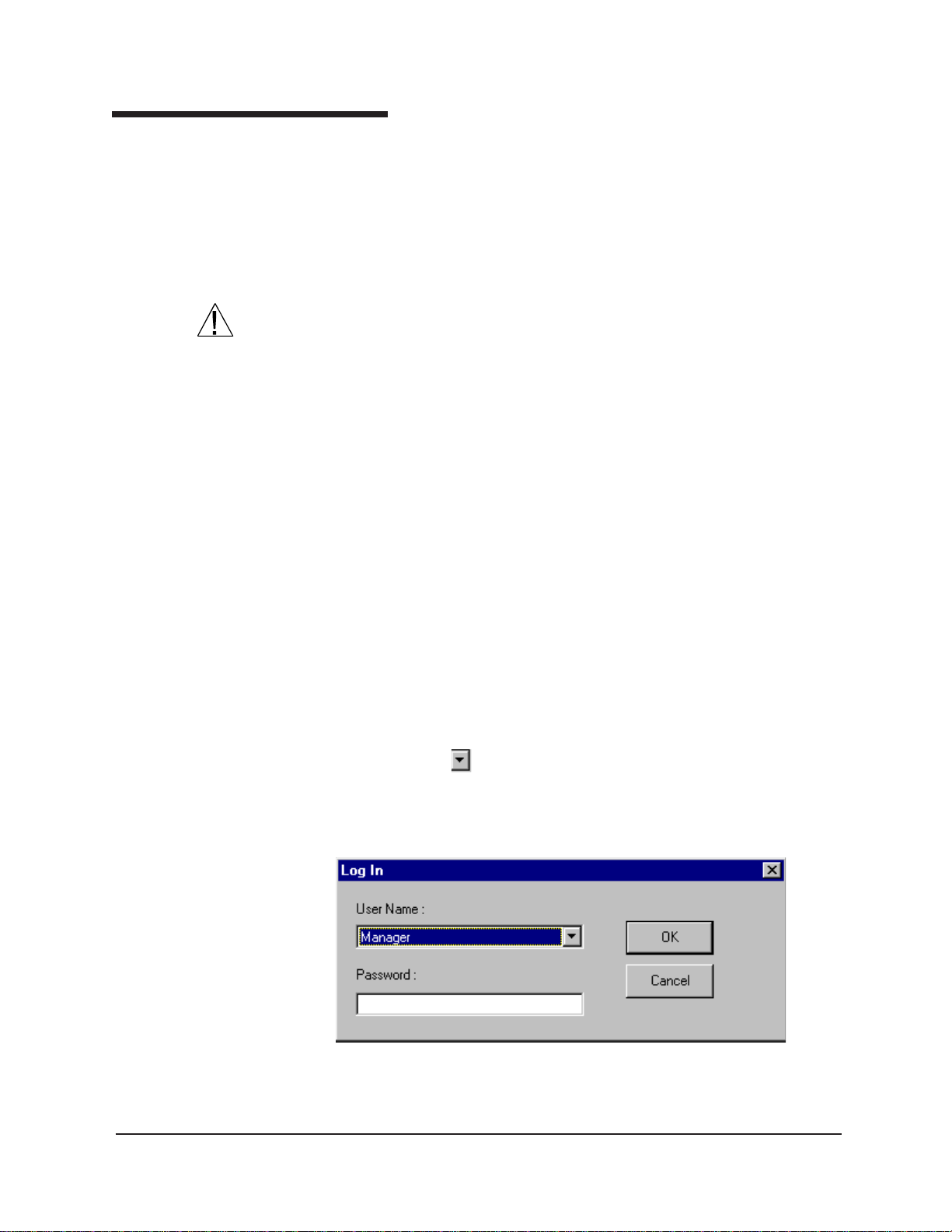

Logging in

Copying floppy disk information to your VISCPRO® directory will overwrite existing sample data. If you wish to restore the original configuration, make certain to archive your sample data before doing so (see

Chapter 13 for information on using the Database Manager software).

Follow the procedures in the next several sections of this chapter to

verify/edit the instrument and calibration settings to ensure that they

conform to the actual characteristics of your CANNON® instrument.

T o check the configuration settings for your instrument(s), you must log

in to the security system as a manager. The software is installed with a

default Manager account. This account has no password, allowing any

operator access to manager-level software functions as long as the

password is not activated/changed. If you would like to engage the fullrelease security options, see Security Options in Chapter 4 for instructions.

1. Use your mouse to click Main from the VISCPRO® menu bar.

2. Click Log In from the Main menu options.

3. Click on the (arrow) on the right side of the User Name: list box

to display the list of registered users.

CANNON

4. Click Manager. Do NOT enter a password!

5. Click OK. The Log In window will close automatically and you will

be logged in as management personnel.

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 15

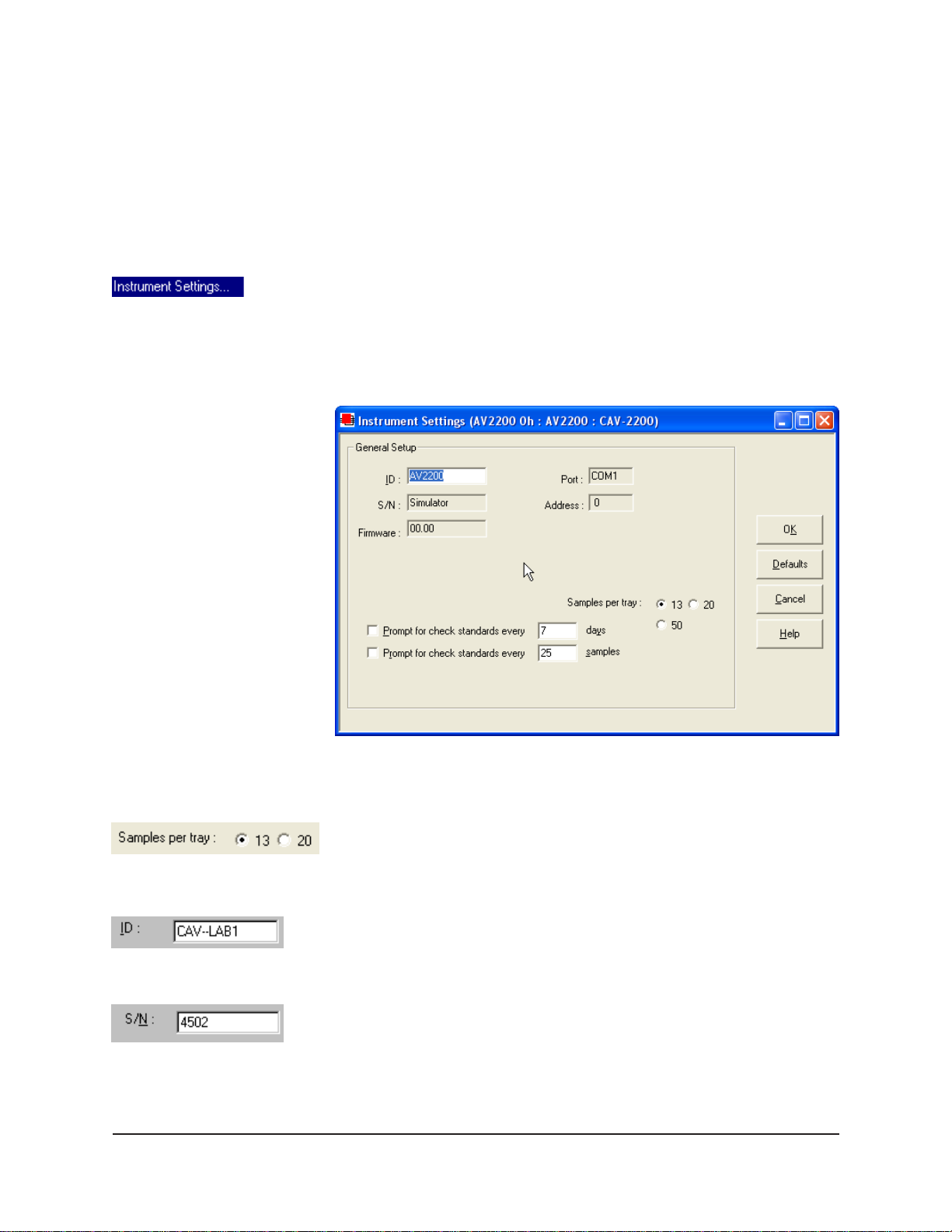

Checking Instrument Settings

1. Use your mouse to click (select) Configure from the VISCPRO

menu bar.

2. Select your instrument from the list of available instruments (there

may be only one instrument in the list).

3. Select Instrument Settings from the list of configuration options.

The Instrument Settings window will appear.

You will use the Instrument Settings window (see below) to describe

and control CAV instrument operational features. These settings affect

the instrument as a whole. Check the instrument settings for your instrument per the instructions below , and make any necessary changes:

9

®

CANNON

The Instrument Settings window

Click the radio button corresponding to the number of sample positions

for your sample trays.

Use the ID field to input instrument identification information using up to

16 alphanumeric characters.

The S/N: field (non-editable) indicates the four-digit serial number from

the label on the CAV rear service panel.

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 16

10

Prompt options

Viewing/editing setup information

The Prompt for Check Standards options permit you to set a computer -

ized “alarm clock” which will pop up a message reminder to run a

calibration standard (using the Verify Known KV viscosity action) based

on the schedule you set with the control. Notice that you can specify a

reminder after “x” number of days and/or “x” number of samples. Click

the check box(es) to enable/disable each reminder.

When you have verified all settings, click OK.

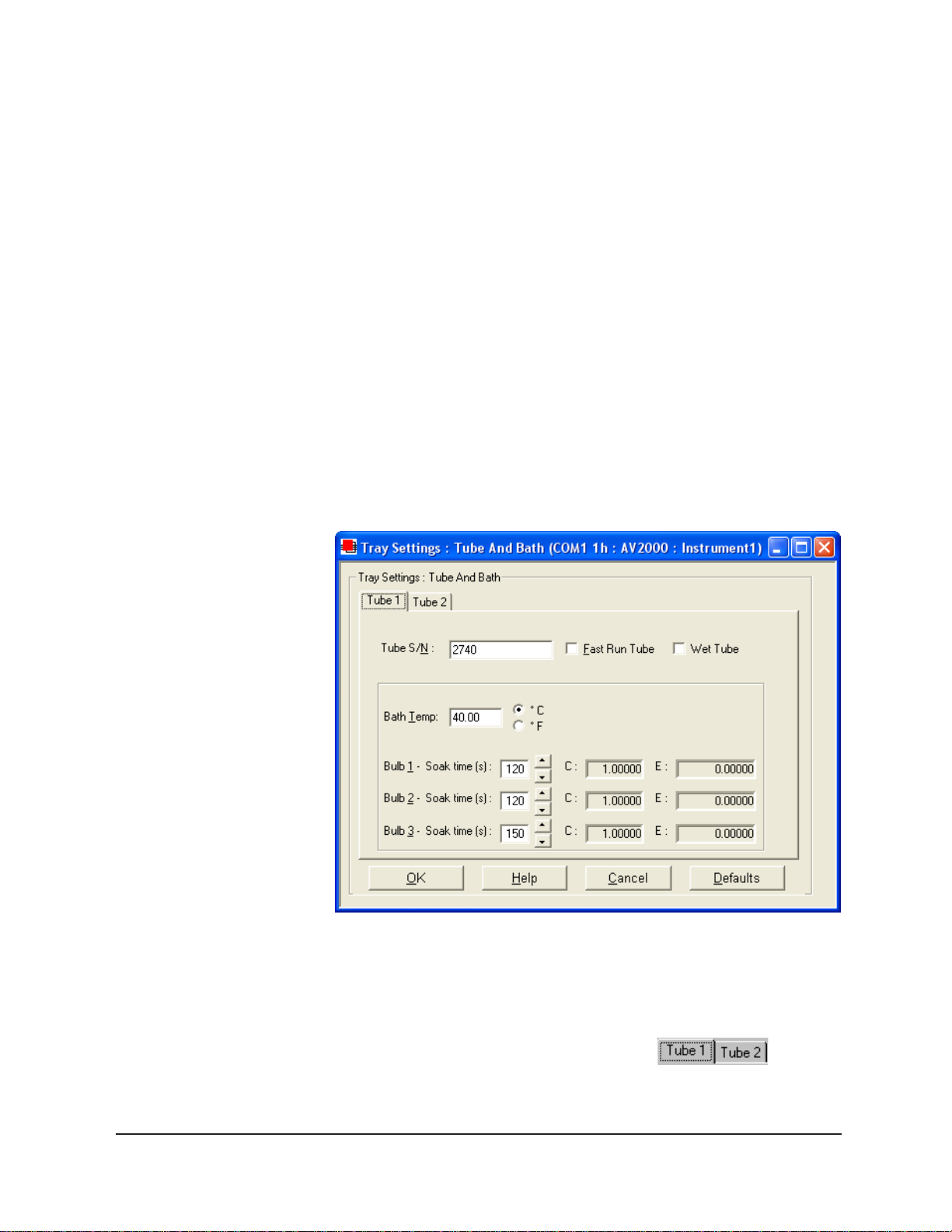

If your instrument has already been set up by a technician, you can use

the instructions in this section of the manual to check or, if necessary,

change the instrument settings.

1. Click Configure from the VISCPRO

®

menu bar .

2. Select your instrument gropu and instrument from the list of avail-

able instruments.

3. Select Tray Settings: Tube and Bath from the list of configuration

options. The Tray Settings: Tube and Bath window will appear.

CANNON

The Tray Settings: Tube and Bath window

The Tray Settings: Tube and Bath window contains setup information

for each tube associated with your instrument. You can click on the tube

tabs to see the setup information for each tube:

4. Click on the tube tab for Tube 1 (the tube on the left).

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 17

5. Verify that the tube serial number (Tube S/N) is correct. If it is not,

input the correct serial number in the text box.

Each tube should have

a unique serial number!

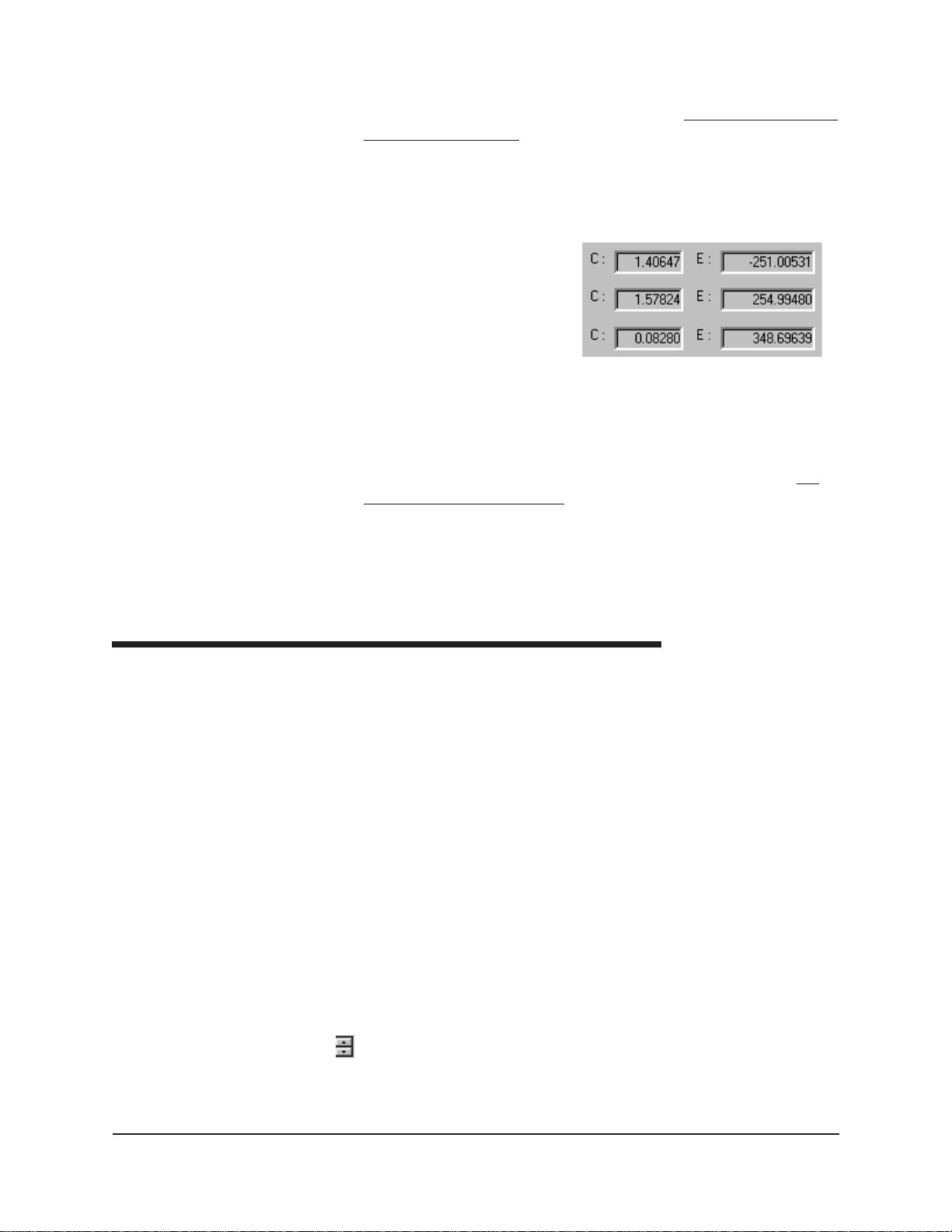

6. Verify that the calibration values (C and E) for each bulb are avail-

able. If calibration data is not available, the default values are C=1

and E=0.

11

NOTE

For first-time installation, make

certain that the factory-prepared

Configuration file has been

copied to the VISCPRO II

directory per instructions.

7. Compare calibration values

to any existing archives of

Sample calibration data

the calibration constants for

each bulb of Tube 1. The values, which cannot be edited from the

Tray Settings: Tube and Bath window , should be identical.

8. Write down the tube and bulb number for any incorrect values.

will change these values later, using the Tube Settings: Calibration

window.

9. Click on the tube tab for Tube 2 and repeat steps 7-8 above. When

you are done, click OK to close the Tray Settings: Tube and Bath

window.

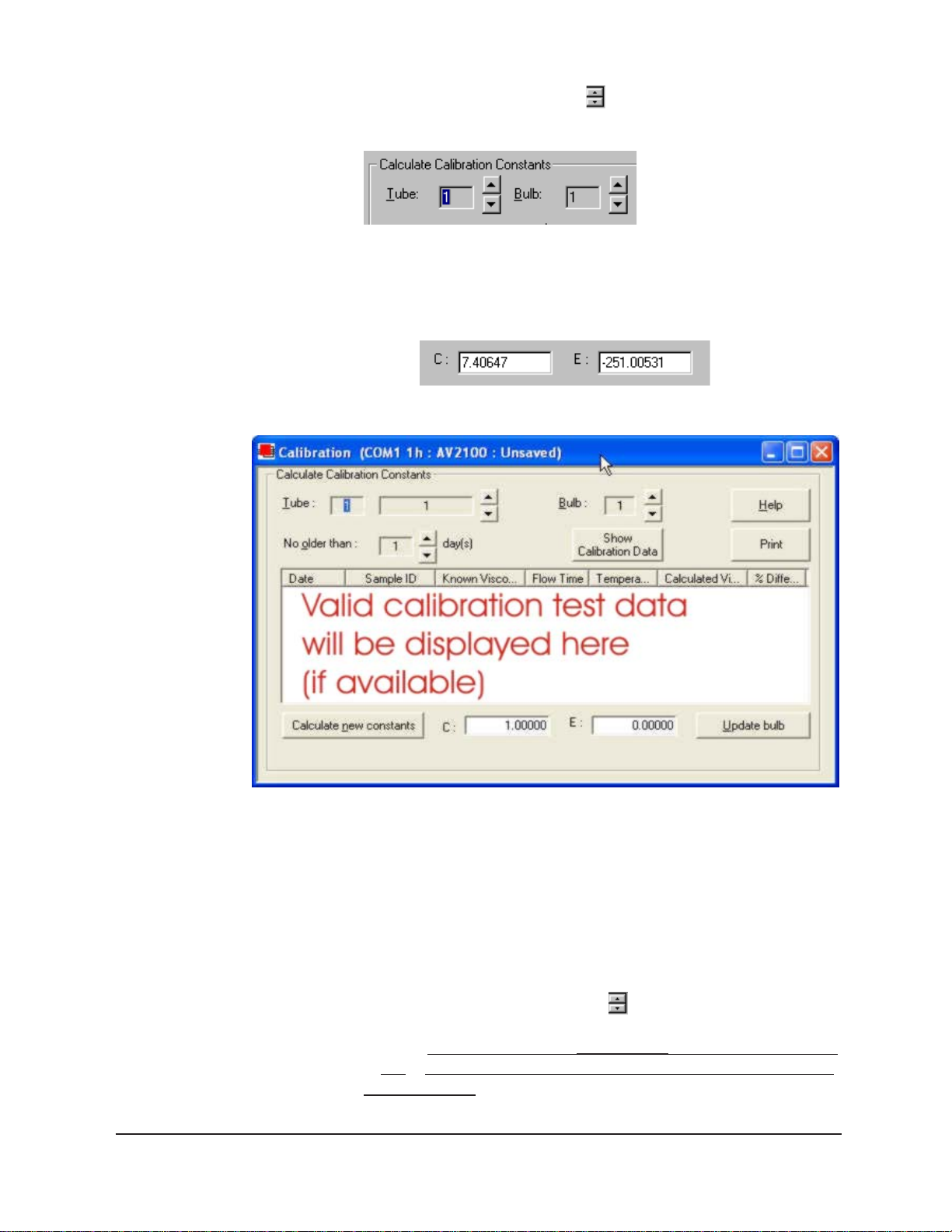

Manually changing tube calibration constants

If you discovered any errors in the values of the calibration constants (see

previous section), follow the directions in this section to manually correct

them using calibration information previously obtained for your unit. If

the calibration values are correct, instrument setup is complete.

We

CANNON

NOTE

This procedure for manually entering/changing calibration constants

bypasses the normal calibration procedure. To ensure the most accurate

viscosity readings, CANNON® Instrument Company recommends that the

instrument be calibrated per the calibration procedure outlined in Chapter

3.

1. Click Configure from the VISCPRO® menu bar .

2. Select your instrument from the list of available instruments.

3. Select Calibration from the list of configuration options. The

Calibration window will appear (see next page).

The Calibration window provides controls for calibrating each tube

associated with your instrument. You can click on the tube spin controls

to display current tube constants and valid check standard data

available for calibration of each tube.

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 18

12

Procedure

1. Make sure that the spin controls for Tube and Bulb are both set

to “1”:

This corresponds to the left-hand tube in the left-hand bath and the

bottom bulb in the tube.

2. Check the values for the calibration constant(s) as they appear at the

bottom of the window:

CANNON

The Calibration window

Compare these values to your archive of the calibration constants (if

available) for tube 1 and bulb 1. The values should be identical.

3. If they are not, place your cursor in the appropriate field, delete the

entry, then type the correct values for the constants in the text boxes.

4. Click Update bulb.

5. Use the tube and bulb spin controls

to select the tubes/bulbs for

which you noted calibration constant errors. Input the correct values

for each.

Make certain to click Update bulb after you have corrected

C and E calibration values for each bulb BEFORE selecting the next

tube and/or bulb.

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 19

6. When you have entered corrected constant values for each bulb on

both tubes, click

You have verified the software configuration of VISCPRO

to exit the Calibration window.

®

. T o test

samples with your instrument, follow the instructions in Chapter 2. For

additional details regarding operating procedures for your instrument or

software, consult the appropriate section of this manual.

13

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 20

14

This page intentionally left blank.

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

®

Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 21

CHAPTER

15

2

CANNON AUTOMATIC VISCOMETER

Preparing the CAV

Turning on the CAV

NOTE

TESTING SAMPLES WITH THE

This chapter of the manual will provide information on testing samples

using the CAV -2100 or CAV-2200 instruments. Observe the safety

cautions noted in the introductory chapter when operating equipment.

The CAV should only be operated by qualified personnel.

1. If CAV power is off, turn on the CAV Bath Unit by rotating the red

power switch on the control panel clockwise. Provide power to the

CSU Service Unit (rear panel On/Off switch) and the Solvent Dispensing Unit (front panel On/Off switch).

If it is necessary to

cut power to the CAV

Bath Unit, press the

power switch IN.

Preparing sample trays

Electrical connections

Using a temperature probe

Sample trays will

slide into place along

the grooved track in

the sample table.

Plated steel vial

adaptors should be

placed in the circular

recesses in the tray .

Glass sample vials slide into the adaptors. To position the first sample

vial under the viscometer tube in preparation for testing, slide the tray

forward until the detente mechanism engages. A heated sample tray

should snap into position against the detent mechanism when the front of

the tray extends approximately 2 centimeters (3/4”) over the edge of the

sample table. The forward edge of an unheated tray will be indented

approximately 2.2 centimeters (7/8”). During sample testing, trays are

automatically advanced by the pneumatic system.

For heated sample trays, verify that the attached three-pin tray cable is

connected to the interior wall connector above the sample table.

A recessed thermometer well at the front of the sample tray permits

insertion of a temperature probe to monitor tray temperature.

CAV-2000 heated sample trays

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 22

16

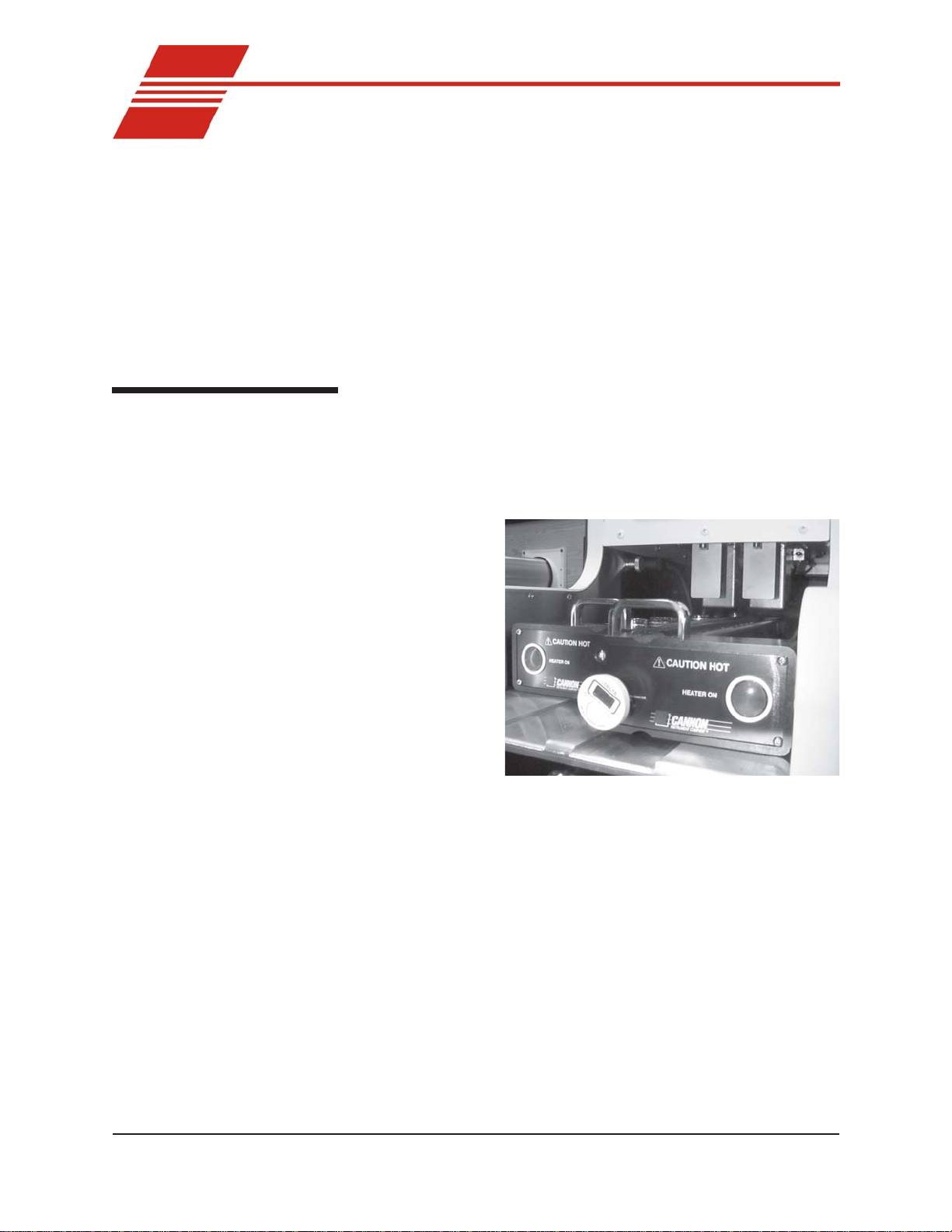

Tray/drain heat operations

CAUTION

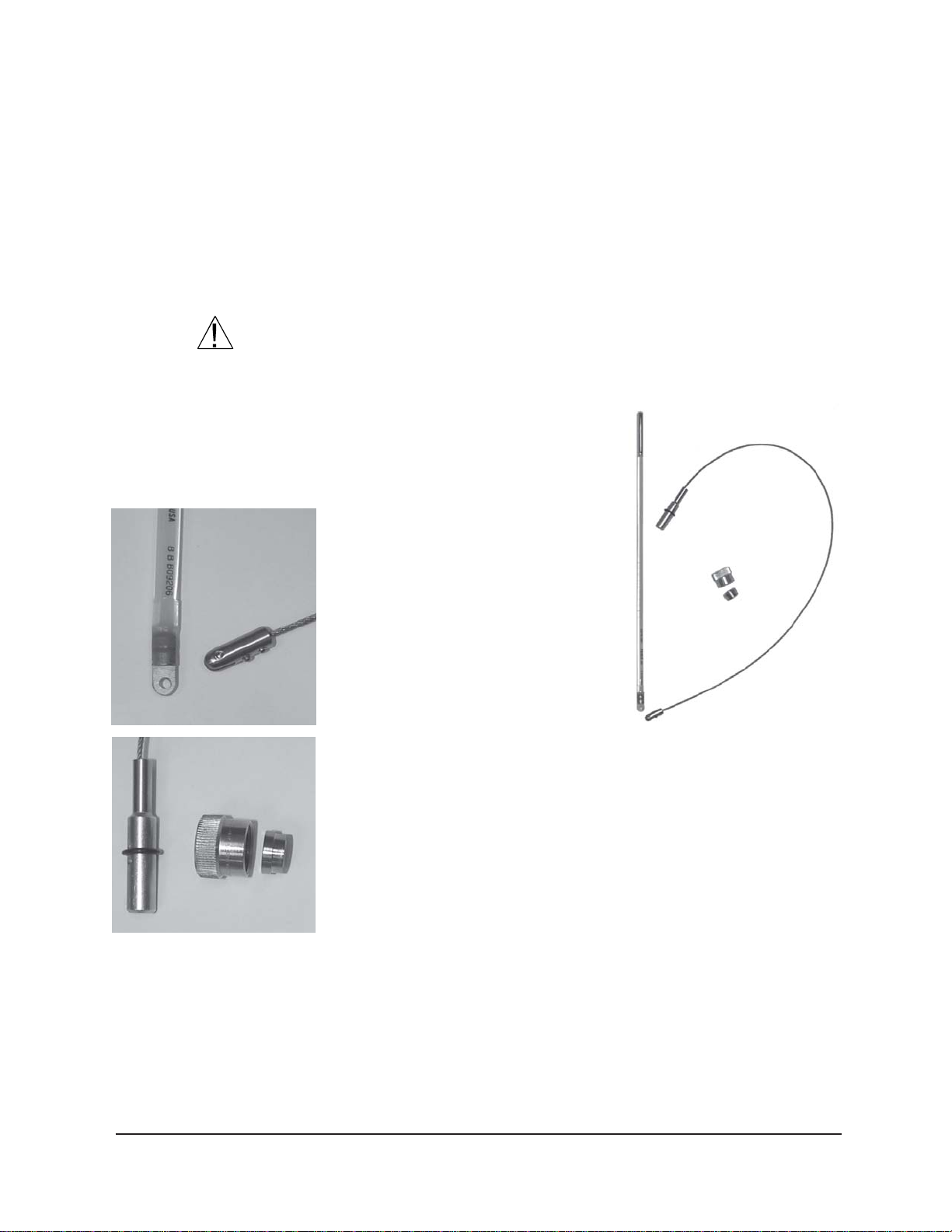

Inserting/removing the CAV reference thermometer

Inserting the thermometer

Thermometer

Cable

Connector

T o provide power to the heated sample trays and/or heated drain lines

which may be installed on your CAV unit, use the heater ON/OFF

switches on the left side of the front panel. These two switches provide

power to left- and right-hand heating elements. To adjust temperature,

use the Adjust knobs on the upper front panel of the Bath Unit. T urn the

knobs clockwise to increase temperature and counterclockwise to lower

it. The knobs regulate the duty cycle of the heaters for the sample trays

and the drain lines. The low-temperature sample heaters will maintain

temperature stability as high as 80°C. The high-temperature sample

heaters will maintain temperature stability as high as 100°C.

Avoid skin contact with heated sample trays, as burns may result. Use

appropriate protection when handling heated samples, vial adaptors, and

sample trays.

ASTM thermometers with speciallyfitting adaptors for the CAV instrument

(see photos) are available from CAN-

NON® Instrument Company . Digital

therometers meeting the ASTM D 445

specifcation are also available.

1. T o install the reference thermometer,

check the current temperature of the

CAV bath and select the calibrated

thermometer appropriate for that

temperature.

Cap

Ferrule

Plug

For additional information

and details for CAV

thermometer installation/

removal, see Appendix A.

Removing the thermometer

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

2. Using the two opposing 0.05” Allen

screws, secure the thermometer

adaptor plate to the connector on the thermometer cable.

3. Using a ladder to access the top of the CAV Bath Unit, remove the

knurled cap, ferrule and O-ring from the thermometer holder.

4. Insert the thermometer assembly into the holder until the plug with

O-ring is seated inside the top of the holder. Rotate the plug until the

thermometer scale is easily visible from the Bath Unit front window .

5. Slide the ferrule over the end of the plug until it seats against the O-

ring.

6. Place the knurled cap over the plug and rotate the cap clockwise to

secure the cap to the top of the thermometer holder. Tighten finger

tight to seal the connection.

T o remove the reference thermometer, permit the bath to cool below

80°C and reverse the above procedure. Use appropriate safety procedures

when handling the thermometer assembly , as it contains mercury.

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 23

Local mode operation

The Local mode option permits manual control of CAV functions via the

control keypad on upper front panel of the Bath Unit. Local mode offers

the advantage of convenient and quick testing for an individual sample.

The single-sample drop time or kinematic viscosity is displayed on the

vacuum fluorescent display (VFD).

17

NOTE

Selecting Local mode

NOTES

Setting temperature

WARNING

The VFD is equipped with a screen saver feature which will reduce the

intensity of the display if the keyboard is not touched for five minutes. To

restore the original intensity of the display, press any key on the keypad.

T o select Local mode operation, toggle the Remote/Local (RMT/LOC)

button on the keypad on the Bath Unit to select Local mode operation.

When the unit is in Remote mode, the front panel display will indicate

REMOTE operation. If the display does not indicate REMOTE operation, then the instrument is in Local mode.

Local mode may be selected at any time during CAV operation. Remote

operations will be suspended. When switching from Remote to Local

mode, it is the user’s responsibility to monitor the instrument tube

state(s) and to properly prepare the instrument before running tests.

Operator intervention is required to test each sample in Local mode.

Additionally, test data is not saved to the VISCPRO® database and

viscosity calculations must be performed manually.

Prior to setting the bath temperature, ensure that the reference thermometer in the bath is suitable for the desired temperature range. If not,

remove thermometer from the bath (see previous page). If the bath

temperature rises above the range of the thermometer, it may be damaged. Mercury thermometers pose particular problems, since mercury

from a damaged thermometer may circulate with bath fluid.

CANNON

T o set the temperature in Local mode, press the Set Temp key on the

front panel keypad, select the desired bath (CAV-2200 only) and input the

target (desired) temperature(s) using the keypad characters. Then press

the Enter key. Acceptable values are any numbers between 20°C and

100°C (150°C for high-temperature CAV models). If necessary, you may

use the decimal point key to input temperature to the nearest 0.01°C.

NOTE

To cancel temperature selection before completing the procedure, press

the Set Temp key a second time.

After the target temperature has been set, the CAV bath temperature will

be adjusted to the target temperature and the bath will equilibrate at the

test temperature. When the instrument has attained a temperature within

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 24

18

0.05°C of the target temperature, the current bath temperature will be

displayed in large type (CAV-2100 only) on the display.

Preparing the bath

When operating in Local mode, visually check the condition of the

viscometer tubes prior to initiating a sample run. If sample or solvent

residue remains in the tube, use the Local mode options to wash and/or

dry the tubes (see Chapter 5, Solvent wash by operator (Local mode)).

Testing samples

1. Pour the test sample into a glass vial and slide the vial into the steel

vial adaptor in the sample tray .

NOTE

Do not fill the vials to the top. Sample overflow may damage the seals of

the LOAD cylinder.

2. Position the vial directly underneath the viscometer tube, using the

detente mechanism as a guide in orienting the sample. A heated

sample tray should snap into position against the detent mechanism

when the front of the tray extends approximately 2 centimeters (3/4”)

over the edge of the sample table. The forward edge of an unheated

tray will be indented approximately 2.2 centimeters (7/8”).

3. Press the Test button.

4. Select the desired tube for testing (Left (1) or Right (2)).

5. Select the desired protocol for the sample drop:

Run (Determine Bulb) will calculate the optimal test bulb.

Run (Use Previous Bulb) will test the sample using the same bulb

as the previous test (this option is desirable when averaging multiple

drop times for the same sample).

The sample will be tested and the drop time and/or kinematic viscosity (see next page) will be indicated on the VFD.

6. After the test has been completed, you may rerun the sample using

the above procedure, or wash the tube using the keypad WASH

option (see pages 18-19 for details on keypad options).

Aborting a test

NOTE

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

T o immediately halt testing for a given tube/tray (left/right), press the

Stop Left and/or Stop Right button on the keypad. On rare occasions

when it is necessary to quickly abort tests on both tubes and remove

power from the unit, press the red power button on the control panel.

Aborting a test using either method clears all sample test information for

that tray. If test actions are aborted, it is the responsibility of the user to

restore the instrument to a safe state before running tests (see Local

mode diagnostics/maintenance in chapter 5 for more information).

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 25

Concluding a test

19

At the conclusion of a test, the drop time for the sample will be displayed

on the display screen. Record the drop time and press the Enter key to

return to the temperature display . Then remove the sample from the tray.

CAUTION

Use appropriate procedures when handling heated sample trays and

heated samples to avoid the possibility of burns.

Empty the oil from the sample vials into the appropriate container(s) for

use/disposal and clean glass vials per approved laboratory procedures.

Wipe any excess oil from the table, sample tray and vial holders (glass

vials only) using an absorbent paper towel. If necessary , clean these items

by wiping with a paper towel wetted with appropriate solvent.

Obtaining kinematic viscosity (KV) readings in Local mode

Local/Remote operation of the CAV is selected via the RMT/LOC button

on the CAV keypad. Local mode operation involves CAV control via the

keypad. Remote operation involves CAV control via the VISCPRO

software interface. Pressing the RMT/LOC button on the CAV keypad

will toggle between the Remote and Local operation modes. To obtain

kinematic viscosity readings in local mode with the CAV 2000 Series

instrument, calibrate each bulb for each bath at the desired bath temperature using VISCPRO II with the instrument set in REMOTE mode.

After calibration, open the Tray Settings: Tube and Bath window for

the desired instrument. Make sure the settings are correct and close the

window by clicking the OK button. This action will transmit the bath

temperature(s), the soak times, and the current bulb calibration constants

to the instrument.

Press the RMT/LOC button on the CAV keypad to change the instrument

mode to LOCAL. Then press the Menu button on the CAV instrument.

On the screen, select option #7: Display KV : YES/NO. Toggle the #7

button to select the desired option. If YES is selected, the KV will be

displayed at the end of a test.

NOTE

If the instrument is set to display KV, it will only display KV if the tube

calibration constants have been loaded as described above; otherwise, it

will display the efflux time. If multiple drops are required for a result, the

customer will need to average the KVs resulting from each drop.

Other Local mode keypad options

The Local mode keypad options described above are the more common

functions available. The Keypad Options table (see next pages) contains

a list of all Local mode keypad options, including entry parameters and

(where applicable) default instrument settings.

Any incomplete keypad command sequence may be cancelled by

pressing the keypad button that initiated the sequence.

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

CANNON

NOTES

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

®

Instrument Company

Page 26

20

Acceptable keypad input is indicated audibly with a short beep. Unacceptable keypad input is indicated audibly with a longer tone.

Remote operation (computer-controlled)

Local/Remote operation of the CAV is selected via the RMT/LOC button

on the control panel. Pressing the button will toggle between the Remote

and Local operation modes. The Remote mode option permits automatic

control of CAV functions via the VISCPRO

Remote mode offers the advantage of multi-drop, multi-sample automatic

testing for up to 100 samples depending on tray type. Sample data is

automatically stored to the VISCPRO® database for future reporting/data

collection. Additionally, several reports (analyses) may be used to

calculate and display kinematic viscosity and viscosity index (VI) values.

See the chapters on VISCPRO

All analyses provide a dynamic operation mode which can immediately

display and transmit test results to your computer screen, printer, and/or

serial port for in-house data collection. See Chapter 6 for more information on configuring analyses.

T o select Remote mode operation, press the Remote/Local (RMT/LOC)

button on the keypad on the Bath Unit until the front panel vacuum

fluorescent display indicates REMOTE operation. If the display does not

indicate REMOTE operation, then the instrument is in Local mode.

®

controlling software.

®

analyses for further information.

NOTE

Setting temperature

NOTE

NOTE

Remote mode may only be selected when the CAV is idle.

T o set the temperature in Remote mode, load the VISCPRO® software

and click Configuration. Select the CAV from the list of available

instruments and click Tray Settings: Tube and Bath. Select the desired

tube and type the desired temperature in the Bath Temp: field. Accept-

able values are any numbers between 20°C and 100°C (150°C for CAV

high-temperature models). If necessary, you may use the decimal point

key to input temperature to the nearest 0.01°C. Press OK to save the

temperature setting.

To cancel temperature selection before completing the procedure, click

Cancel.

After the target temperature has been set, the CAV bath temperature will

be adjusted to the target temperature and the bath will equilibrate at the

test temperature. When the instrument has attained a temperature within

0.05°C of the target temperature, the current bath temperature will be

displayed in large type on the display for CAV-2100 models.

Placing the instrument in Remote mode while the VISCPRO software is

loaded will reset the bath temperature(s) to match the VISCPRO settings.

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 27

COL/TMR

TFELPOTS.ebuttfelrofytivitcaspotS

THGIRPOTS.ebutthgirrofy

PMETTES .retnEsserpnehT.erutarepmetderisedtupnidna)ylno0022-VAC(htabtceleS

UNEMsretemaraPtse

)5

TSET

HSAW

YRD

RETNE .seulavtupnitpeccaotyrtneatadfonoitelpm

,5,4,3,2,1,0

.,9,8,7,6

.edometomeR

tivitcaspotS

T)1ebuttfelesu)1

sretemaraPhsaW)2ebuttfelesu)1

stinUerutarepmeT)3

erutarepmeTetarbilaC)4

srosneSniarT

ecivreS)6

ON

/SEY:VKyalpsiD)7snoitpoON/SEYelggototretnEsserP

ebuttfelesu)1

ebutthgiresu)2

ebuttfelesu)1

ebutthgiresu)2

ebuttfele

su)1

ebutthgiresu)2

sum

F°)1

C°)2

hgiRtsujdA)5

sutat

S)3 scitsongaidtnemurtsnirofsgnittesdnasegatlovsyalpsiD A/N

drowssaP)5

)edoMlacoL(snoitpOdapyeK

noitpircseD/dnammoCdapyeK sretemaraP tluafeD

yalpsiD.edomlacoLotetomeRmorfsegnahC

ebutthgiresu)2

ebutthgiresu)2

.sebutnurtsafrof"0"tateS:3BhsaWA)281-05

lS)4.emitkaostnevlostupnI03-12

eht,ylnotnevloselgnisagnisufI:ETON

."0"ottesebt

meTtnerruCoreZ)2

srosnesllaniarT)3

sserddAtnemurtsnI)1.

lliFebuTlaunaM)4

BsuoiverPesU(nuR)2

ocnopuRETNEsserP.atadciremuntupniotdesU

nopuRETNEsserP.atadciremuntupniotdesU

)BroA(hsaWdesunuehtrofseulav

.sebutnurtsafrof"0"tateS:3BhsaWB)781-02

tesffOerutarepmeTtnerruCteS)1

tesffOerutarep

srosnesebuttfelniarT)1

srosnesebutthgirniarT)2

.stPpirTebuTtfeLtsujdA)4

.stPpirTebuTt

epyTsnoitacinummoC)2

)bluBenimreteD(nuR)1

)blu

.nottub

.snoitpo

.sretemaraphsaWgnisuebutretemocsivsehsaW

.sretemaraphsaWgnisuebutretemocsivseirD

:)s(emiTkaoS]x[bluB552-0021

sretemaraPdecnavdA

)detcirtser(

:1BhsaWA)0

:2BhsaWA)181-09

:)s(lliFvlS)3.emitlliftnevlostupnI03-12

:)s(kaoSv

:1BhsaWB)5

:2BhsaWB)681-05

sulFvlS)8.emithsulftnevlostupnI06-12

:)s(h

:)s(riAlaniF)9.emityrdriatupnI552-5105

.ebutretemocsiveht

584-SR)1

232-SR)2

ebuTtfeLesU)1

ebuTthgiResU)2

xaM)1002-02002

.em

it

.emit

erisedtcelesotsnottubdapyekesUC°/F°C°

utarepmettupniotsnottubdapyekesU

.lecnacotUNEM.tpecca

tinUhtaBhcaerofeulaveuqinutupnI9-00

l

liFlaunaM)1

nwoDpuC)2

.seulavtupnitpeccaotyrtneatadfonoitelpmoc

:)s(emiTlliF1bluB

:)s(emiTtceleS1bluBniM)202-5.35.01

emiTlliF2bluBniM)34-00.1

:)s(emiTytpmEbluBxaM)4006-09004

iTytpmEebuTxaM)5521-551

:)s(em

hsaw"X"bluB/AtnevlostupnI

hsaw"X"bluB/BtnevlostupnI

.stinud

ecnerefermorfer

RETNEsserpnehT.°10.0tseraenehtotretemomreht

otRETNE.deraelceblliwtesffoerutarepmettnerrucehT

.detelpmocsigniniartnehwELDIetacidni

lliwyalpsiD.erudecorpgniniartrosnescitamotuasetaitinI

rednulaivehtnielpmasgnisutnemtsujdarosnessetaitinI

.epytnoitcennoctupnIA/N232-SR

81-011

81-09

A/NA/N

A/NA/N

A/NA/N

serP

detcirtsersseccaotynapmoCtnemurtsnINONNACmorfdrowssaptupnI

nidilavnieraTHGIR/TFELPOTSdnaCOL/TMRtpecxesnoitarepodapyekllA.edometomeRninehwsetacidni

"1"dloH.pucesiarotsserP

otnidiuqilwardotnwodyek

.niardotyekesaeleR.ebut

.pucrewolots

.niardlliwdiuqiL

A/N

21

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

®

Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

Page 28

22

Testing samples

Loading software

NOTES

NOTES

1. Turn on the computer and load the CAV software by double-clicking

the VISCPRO

If the software is already loaded, use your computer mouse to click Main

from the menu bar and click Poll for Instruments from the Main menu

options. This will establish communications between the computer and

the on-line instrument.

Permit the bath(s) to stabilize at test temperature before testing samples.

®

icon on the Desktop.

2. Pour sample material into the glass vial(s). Fill to within 1.3 cm (½”)

of the top of each vial (somewhat less sample may be required for

testing in lower bulbs of the viscometer). Insert the glass vials into

the steel carrier cylinders and place the cylinders into the sample tray .

Do not fill the vials to the top. Sample overflow may damage the seals of

the LOAD cylinder. You should run calibration check standards per your

established laboratory procedures. Recalibrate the CAV (see Chapter 3,

Calibration) if result variance warrants.

3. Place the sample tray into the track underneath the viscometer tube.

Push the sample tray forward until the first vial is under the viscometer tube. A heated sample tray should snap into position against the

detent mechanism when the front of the tray extends approximately 2

centimeters (3/4”) over the edge of the sample table. The forward

edge of an unheated tray will be indented approximately 2.2 centimeters (7/8”).

!

CAUTION

4. Ensure that the splash guard(s) in front of the viscometer tube has

been secured in place with the thumbscrew . If a splash guard has

been removed, replace it.

The splash guard(s) may be removed to allow the user to handle the

sample not yet running (replace with a different sample, etc.). However,

make certain to return the splash guard to its proper position to prevent

sample/solvent contamination and to protect the viscometer tube tip. Do

not allow your hands to contact or obstruct the pneumatic mechanism or

heated sample trays and electrical connections.

5. Check the thermometer in the temperature bath to make sure the bath

is holding the proper temperature. If necessary , calibrate the CAV

temperature control probe using the temperature calibration procedure in Chapter 3.

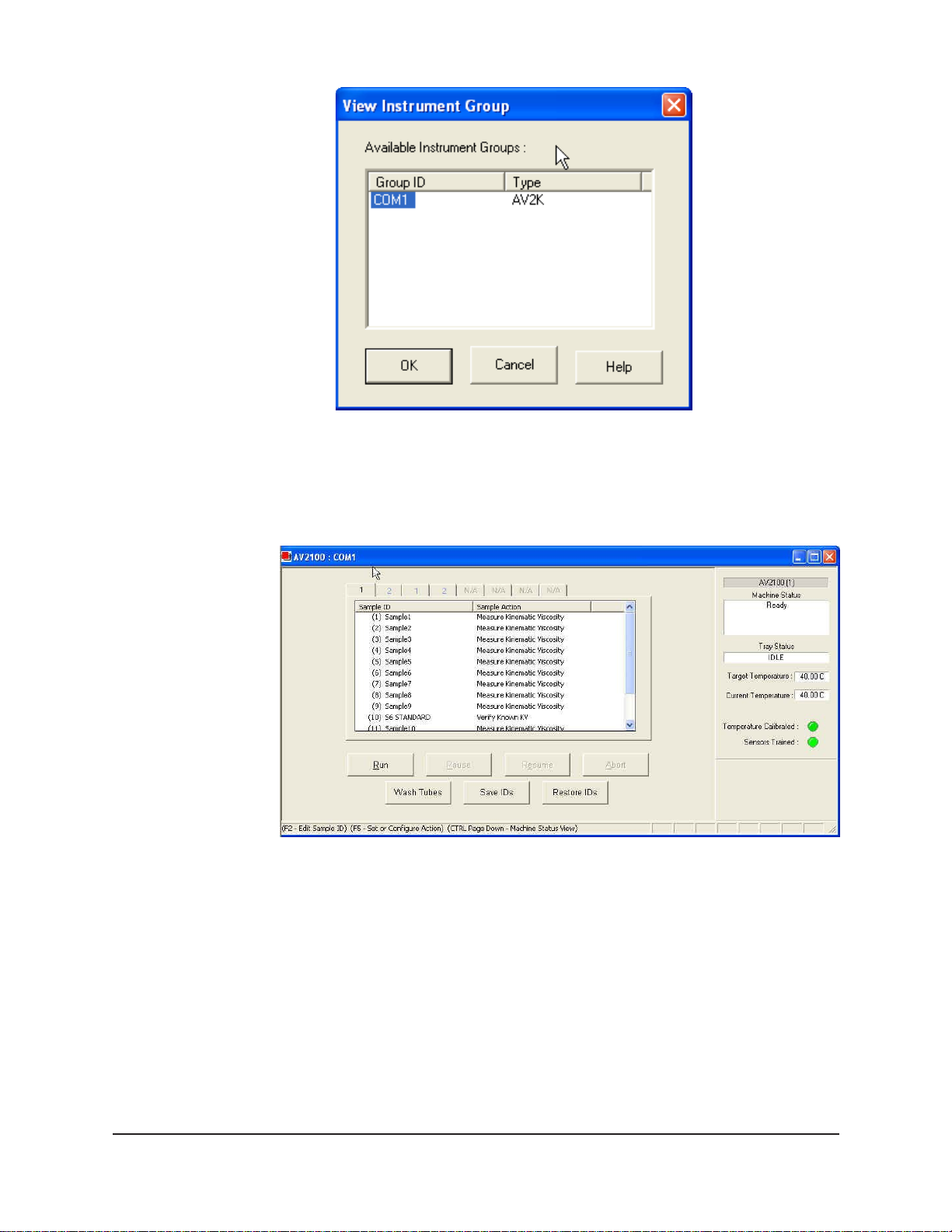

6. Open the View Instrument Group window (if it is not already open)

by clicking View Instrument from the Main menu and selecting the

desired instrument group from the list box (see Chapter 4 for more

information).

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 29

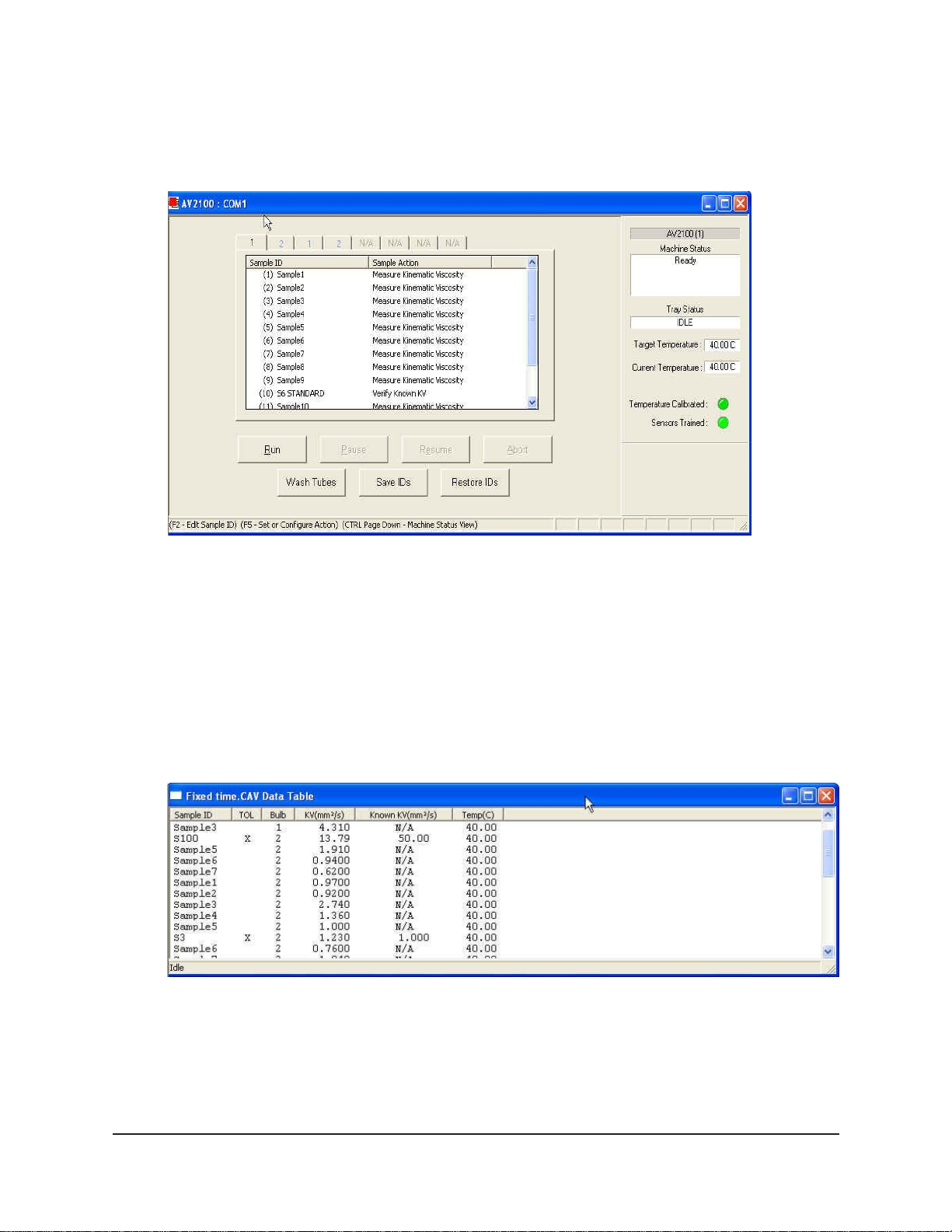

The

View Instrument Group

window

7. Click OK to display the Sample Input View for the desired group:

23

CANNON

The Sample Input window

Then click the Tray tab corresponding with the desired viscometer tube.

8. Double-click on Sample ID (1) with the left mouse button to access

the sample ID data entry field (or press 2).

9. Enter sample ID information in the sample list box using your

computer keyboard. After you have typed the sample ID, press the

T key to save the entry and move the cursor to the next Sample

ID field. Or press R to save the entry .

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 30

24

NOTE

NOTE

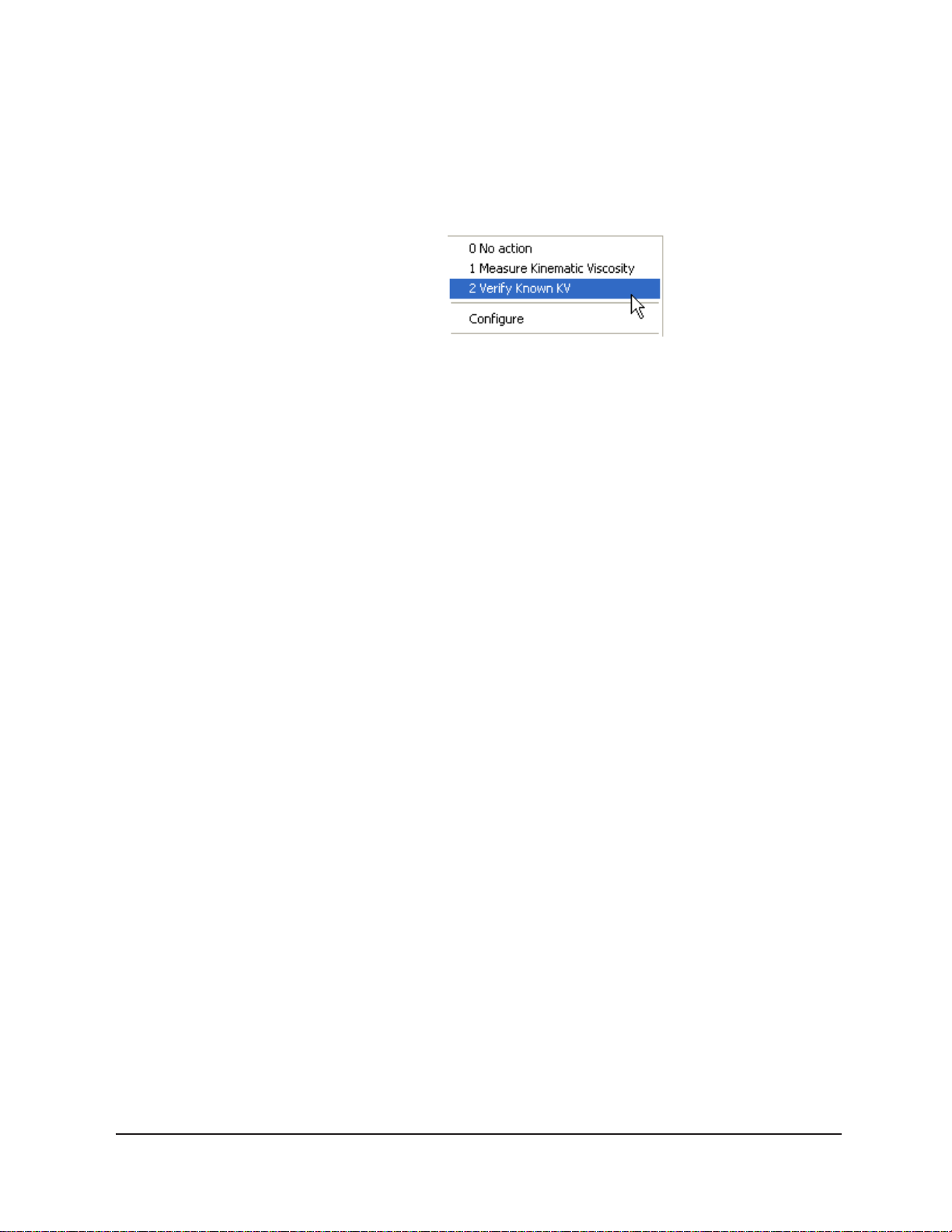

Running check standards

Once sample information is entered, the software automatically assigns

a sample action, Measure Sample Viscosity, for the sample. If you do not

enter a sample ID, the sample is automatically labeled Unknown.

T o select or change a sample action, highlight the appropriate Sample

ID(s) using the mouse or arrow keys, then click the RIGHT mouse

button to access sample action options:

Then you may select the desired action by highlighting it and clicking the left mouse button.

For additional information on software data entry features, including

multiple sample selection and cut & paste options, see Testing

samples—software options in Chapter 4.

If V erify Known KV is selected as the test option for a sample, the

Viscosity Action window will open automatically. Enter the neces-

sary check standard data, including the Check Standard viscosity

from the standard bottle, and click OK to complete data entry . T o

revise or confirm standard data, right-click on the desired sample ID

from the list box and select Configure from the popup menu choices.

NOTE

Pausing a test

NOTE

See Chapter 4 for additional information on the Viscosity Action window.

10. Continue entering sample information for all desired trays. When

sample ID data entry is complete, check the Tray Status window to

verify that all trays are ready for testing.

11. Click on the RUN button at the bottom of the Sample Input win-

dow . The Select T rays window will open.

12. Click on the check box(es) to select the desired prepared tray(s) for

automatic testing. Then click OK to begin the CAV test(s).

T o temporarily halt testing for a given tube/sample, click the Pause

button from the Sample Input window . Then select the desired tray(s)

and pause action(s) from the Select Trays window (Pause Now will

immediately pause test actions; Pause after current sample will pause

testing after the current test is complete). Click OK to pause testing for

the selected tray(s).

If the test was paused prior to the initiation of the Wash cycle, drop time

data for that sample will be discarded.

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 31

Resuming a test

Aborting a test

25

T o resume test actions for paused trays, click the Resume button from

the Sample Input window. Then select the desired trays from the Select

Trays window. Click OK to resume sample testing (see note above).

T o permanently halt testing for a given tube/tray, click the Abort button

from the Sample Input window. Then select the desired trays from the

Select Trays window. Click OK to abort testing for the selected tray.

NOTE

Concluding a test

CAUTION

Aborting a test clears all sample test information for that tray. If test

actions are aborted, it is the responsibility of the user to restore the

instrument to a safe state before running tests (see Service menu

options in chapter 4 for more information on tube washing and drying).

After automatic testing has been completed for a sample tray , make

certain that the final sample has drained and the calculated viscosity for

each sample tested is displayed in the Sample Input window . The tray

status for the tube, as indicated in the VISCPRO® Instrument View Tray

Status window, will be PAUSED. Click the Resume button to clear

sample data from the Sample Input window and return the instrument to

IDLE status. Then remove the sample tray from the tray rack.

Use appropriate procedures when handling heated sample trays and

heated samples to avoid the possibility of burns.

Empty the oil from the sample vials into the appropriate container(s) for

use/disposal and clean glass vials per approved laboratory procedures.

Wipe any excess oil from the table, sample tray and vial holders (glass

vials only) using an absorbent paper towel. If necessary , clean these items

by wiping with a paper towel wetted with appropriate solvent.

Working with Instrument Groups

VISCPRO II provides a new , convenient interface for working with

multiple CANNON instruments simultaneously . Rather than requiring the

user to open individual Instrument Views for each online instrument, the

Sample Input window (formerly the Instrument View window in

VISCPRO) provides individual tabs for each viscometer tube, making it

easy to enter sample information for up to four different instruments

(eight viscometers). The Machine Status window makes it possible to

monitor the performance of all instruments in an Instrument Group

simultaneously.

CANNON

®

Automatic Viscometer Models CAV-2100 and CAV-2200 with VISCPRO® Instruction & Operation Manual

Version 2g — May, 2009; CANNON

2139 High Tech Road • State College, PA 16803 • USA

®

Instrument Company

Page 32

26

Here’s how it works: Just click Main/View Instrument from the

VISCPRO II interface to open the View Instrument Group window,

which displays all CANNON instrument types communicating with your

computer. Then select the desired instrument group (all instruments in a

single group communicate with the computer via the same COM port).

Once you have opened the desired instrument group, the Sample Input

window will appear. Individual viscometer tube tabs now make it possible to enter sample information for each viscometer in the instrument

group.

You can toggle back and forth between the Sample Input window and